throttle linkage CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 174 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 174

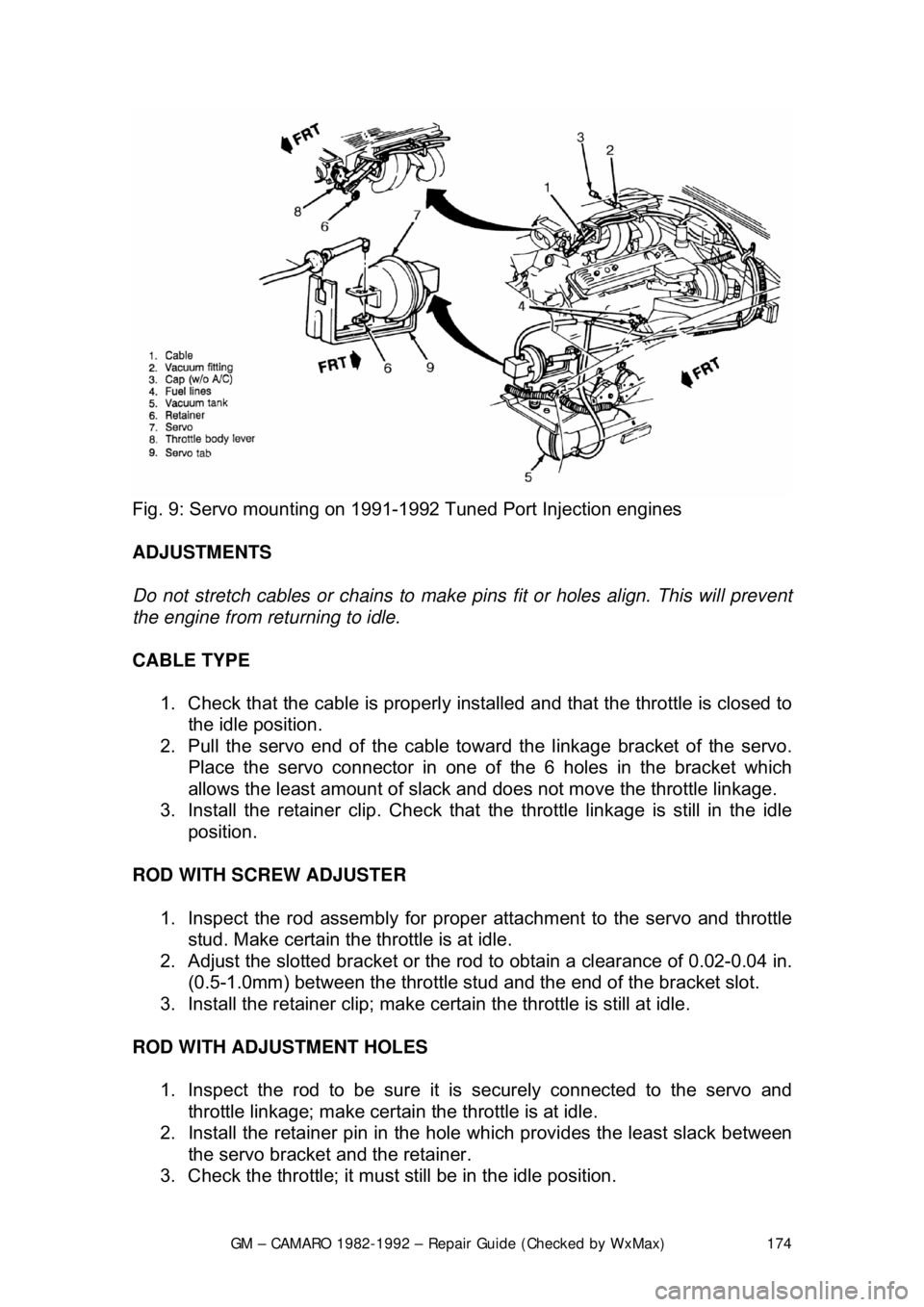

Fig. 9: Servo mounting on 1991-1992 Tuned Port Injection engines

ADJUSTMENTS

Do not stretch cables or chains to make pins fit or holes align. This will prevent

the engine from returning to idle.

CABLE TYPE 1. Check that the cable is properly installed and that the throttle is closed to

the idle position.

2. Pull the servo end of the cable towa rd the linkage bracket of the servo.

Place the servo connector in one of the 6 holes in the bracket which

allows the least amount of slack and does not move the throttle linkage.

3. Install the retainer clip. Check that the throttle linkage is still in the idle

position.

ROD WITH SCREW ADJUSTER 1. Inspect the rod assembly for proper attachment to the servo and throttle\

stud. Make certain the throttle is at idle.

2. Adjust the slotted bra cket or the rod to obtain a clearance of 0.02-0.04 in.

(0.5-1.0mm) between the throttle stud and the end of the bracket slot.

3. Install the retainer clip; make certain the throttle is still at idle.

ROD WITH ADJUSTMENT HOLES 1. Inspect the rod to be sure it is securely connected to the servo and

throttle linkage; make certain the throttle is at idle.

2. Install the retainer pin in the hole which provides the least slack between

the servo bracket and the retainer.

3. Check the throttle; it must still be in the idle position.

Page 310 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 310

modulator pressure rises as the thro

ttle is opened wider. By responding to these

two pressures, the shift valves caus e the upshift points to be delayed with

increased throttle opening to make the bes t use of the engine's power output.

Most transmissions also make use of an auxiliary circuit for downshifting. This

circuit may be actuated by the throttle linkage the vacuum line which actuates

the modulator, by a cable or by a solenoid. It applies pressure to a special

downshift surface on the shift valve or valves.

The transmission modulator also governs the line pressure, used to actuate the

servos. In this way, the clutches and bands will be actuated with a force

matching the torque output of the engine.

IDENTIFICATION

Two types of transmissions are used on th e vehicles; Turbo Hydra-Matic 200C

3-speed and Turbo Hydra-Matic 700-R4 4-speed. Beginning in 1991, the 700-

R4 was redesignated the 4L60.

FLUID PAN

REMOVAL, FLUID/FILTER CH ANGE, & INSTALLATION

Refer to General Information & Ma intenance for fluid pan procedures.

ADJUSTMENTS

BANDS

There are no band adjustments possible or required.

Page 312 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 312

4. Rotate the shift lever clockwis

e to the park detent and then back to

neutral.

5. Tighten cable attachment to 11 ft. lbs. (15 Nm).

The lever must be held out of P when tightening the nut.

SHIFT LINKAGE 1. Place the manual shaft of the transmission in N. Place the console shift

lever in N.

2. Install the cable in the slot of the shift lever. Adjust the cable so that the

pin has free movement.

3. Install and tighten t he nut to the pin.

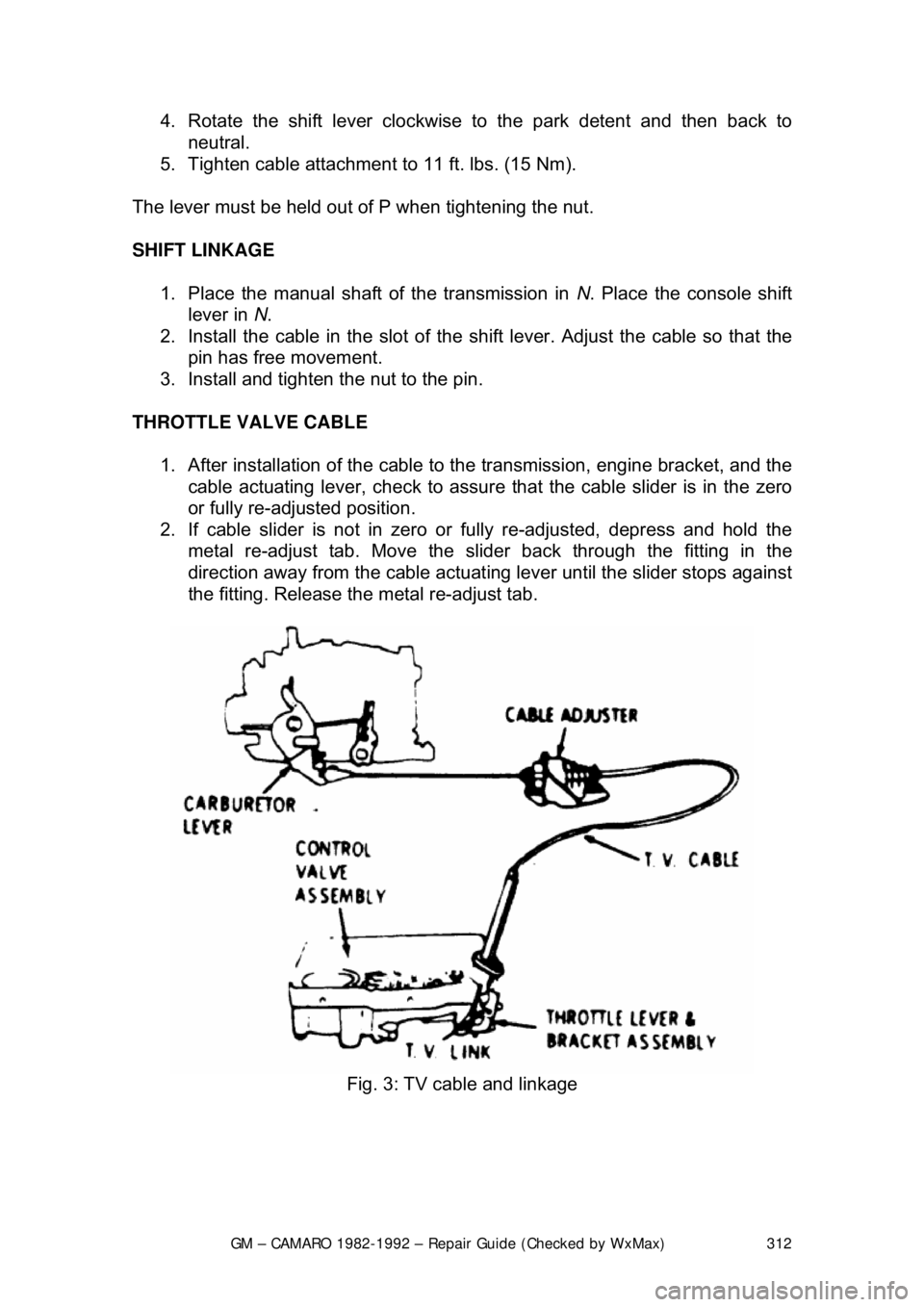

THROTTLE VALVE CABLE 1. After installation of the cable to the transmission, engine bracket, and the

cable actuating lever, check to assure that the cable slider is in the zero

or fully re-adjusted position.

2. If cable slider is not in zero or fully re-adjusted, depress and hold the

metal re-adjust tab. Move the sli der back through the fitting in the

direction away from the cable actuat ing lever until the slider stops against

the fitting. Release the metal re-adjust tab.

Fig. 3: TV cable and linkage

Page 364 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 364

5. Drain the radiator and remove t

he radiator hoses. Disconnect the heater

hoses and the transmission cooler lines.

6. Remove the upper half of the radi ator shroud, if equipped with a manual

transmission. Remove the radiator and fan shroud assembly, if equipped

with an automatic transmission.

7. Disconnect the throttle linkage, includi ng the cruise control detent cable.

8. Remove the air conditioning compressor and lay aside.

Do not disconnect the air conditioning lines.

9. Disconnect the power steering pump and drain the fluid into a suitable

container. Remove the vacuum brake booster line.

10. Remove the distributor cap and spark plug wires.

11. Disconnect the engine electrical connection at the bulkhead connection

and disconnect any necessary vacuum hoses.

12. Working inside the vehicle, re move the right-hand hush panel and

disconnect the ECM harness at the EC M. Raise and safely support the

vehicle. Remove the right fenderwell splash shield and feed the harness

through the fenderwell.

13. Disconnect the exhaust pipes at the exhaust manifolds and remove

exhaust system from the vehicle.

14. Remove the flywheel cover and remo ve the converter bolts, if equipped

with automatic transmission.

15. Disconnect the transmission an d starter wire connections.

16. Remove the bellhousing and t he motor mount through-bolts.

17. Disconnect the clutch fork return spring, if equipped with a manual

transmission. Lower the vehicle.

18. Relieve the fuel system pressu re. Disconnect the fuel lines.

19. Support the transmission with a suit able jack. Attach an engine lifting

device.

20. Remove the engine assembly.

To install: 21. Position the engine assembly in the vehicle.

22. Attach the motor mount to engine br ackets and lower the engine in place.

Remove the engine lifting device and the transmission jack.

23. Raise and support the vehicle safely.

24. Install the motor mount through-bolts and tighten the nuts to specification. Install t he bellhousing bolts and tight en to 35 ft. lbs. (47

Nm).

25. On vehicles with automatic transmissi on, install the converter to flywheel

attaching bolts to 46 ft. lbs. (63 Nm).

26. Install the flywheel splash shield and tighten to 89 inch lbs. (10 Nm).

Install the clutch return spring, if equipped with manual transmission.

27. Connect the starter wires and the fuel lines.

28. Install the exhaust system.

29. Lower the vehicle.

30. Install the power steering pump and the air conditioning compressor.

Page 365 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 365

31. Connect the bulkhead harness connec

tor, wires and hoses. Reroute the

ECM harness in its original location. Install the hush panel and fenderwell

splash panel.

32. Install the radiator, fan and fan sh roud. Connect the radiator and heater

hoses, along with the transmission cooler lines.

33. Connect the vacuum brake booster li ne, the throttle linkage and cruise

control cable. Install the distributor cap.

34. Fill the cooling system with the proper type and amount of coolant and

the crankcase with the proper type of oil to the correct level.

35. Install the water pump drive bel t, the air cleaner duct and the hood.

36. Connect the negative battery cable, st art the engine and check for leaks.

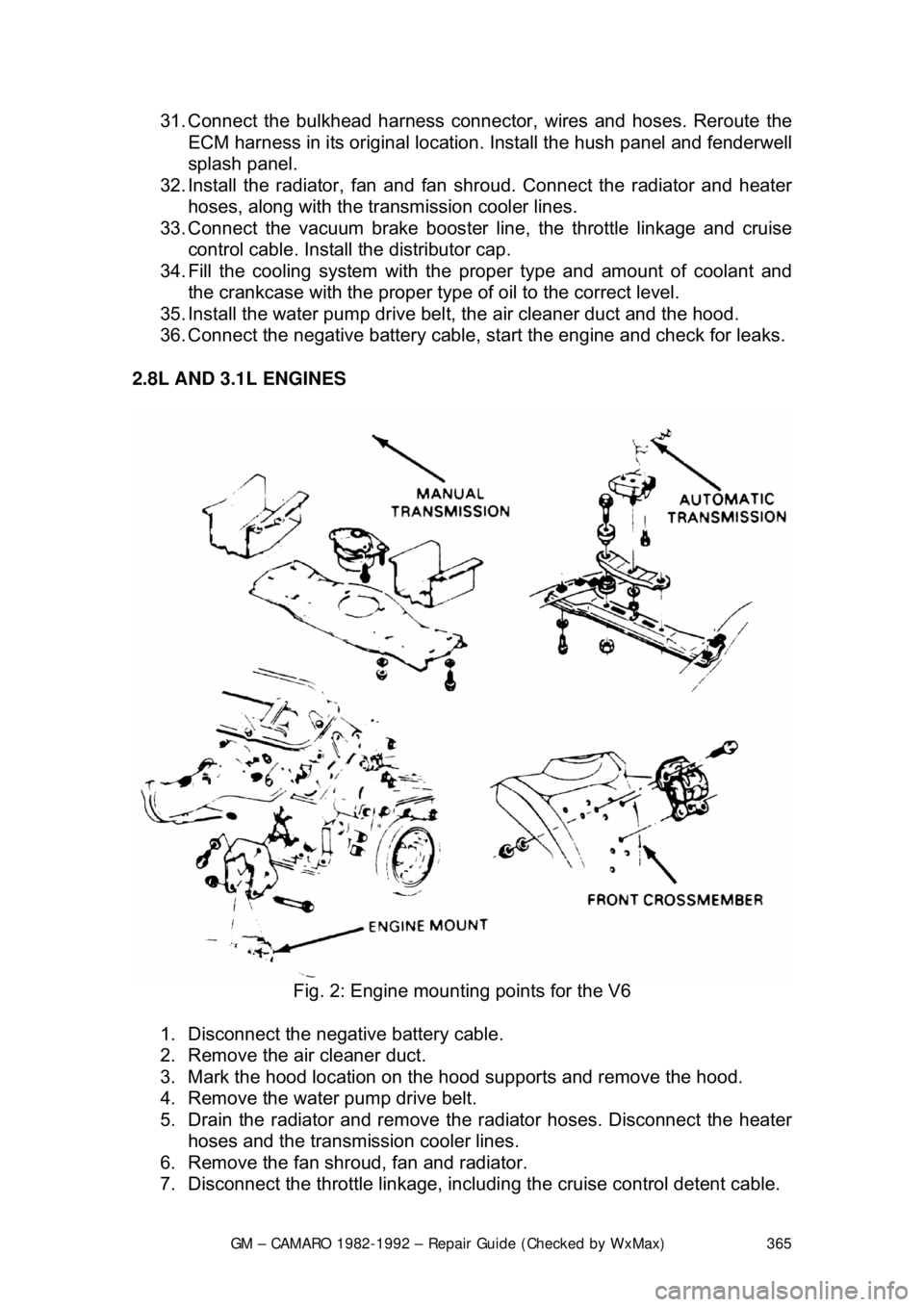

2.8L AND 3.1L ENGINES

Fig. 2: Engine mountin g points for the V6

1. Disconnect the negative battery cable.

2. Remove the air cleaner duct.

3. Mark the hood location on the hood supports and remove the hood.

4. Remove the water pump drive belt.

5. Drain the radiator and remove t he radiator hoses. Disconnect the heater

hoses and the transmission cooler lines.

6. Remove the fan shroud, fan and radiator.

7. Disconnect the throttle linkage, includi ng the cruise control detent cable.

Page 366 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 366

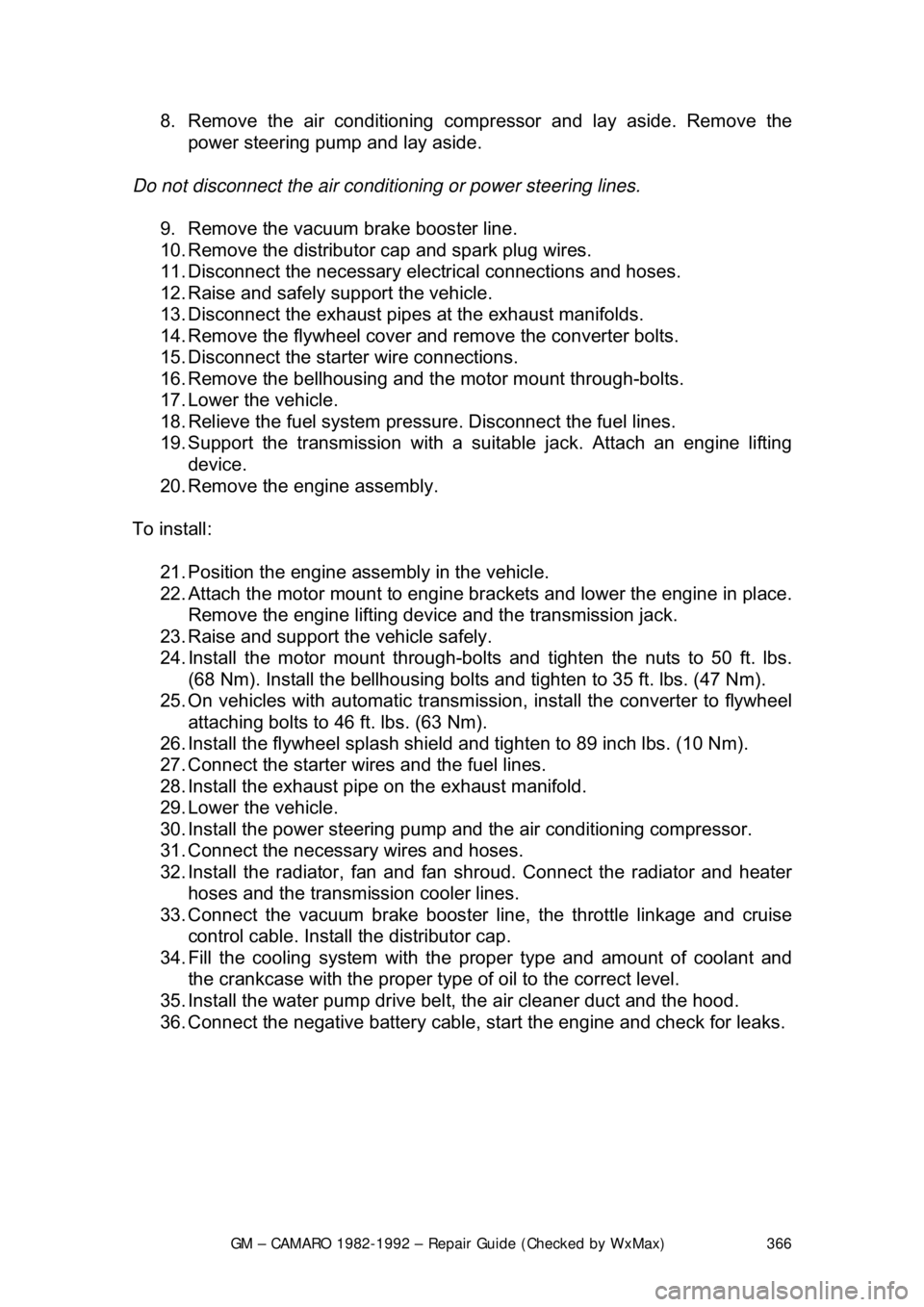

8. Remove the air conditioning co

mpressor and lay aside. Remove the

power steering pump and lay aside.

Do not disconnect the air conditioning or power steering lines.

9. Remove the vacuum brake booster line.

10. Remove the distributor cap and spark plug wires.

11. Disconnect the necessary elec trical connections and hoses.

12. Raise and safely support the vehicle.

13. Disconnect the exhaust pipes at the exhaust manifolds.

14. Remove the flywheel cover and remove the converter bolts.

15. Disconnect the star ter wire connections.

16. Remove the bellhousing and t he motor mount through-bolts.

17. Lower the vehicle.

18. Relieve the fuel system pressu re. Disconnect the fuel lines.

19. Support the transmission with a suit able jack. Attach an engine lifting

device.

20. Remove the engine assembly.

To install: 21. Position the engine assembly in the vehicle.

22. Attach the motor mount to engine br ackets and lower the engine in place.

Remove the engine lifting device and the transmission jack.

23. Raise and support the vehicle safely.

24. Install the motor mount through-bolts and tighten the nuts to 50 ft. lbs. (68 Nm). Install the bellhousing bolts and tighten to 35 ft. lbs. (47 Nm).

25. On vehicles with automatic transmissi on, install the converter to flywheel

attaching bolts to 46 ft. lbs. (63 Nm).

26. Install the flywheel splash shield and tighten to 89 inch lbs. (10 Nm).

27. Connect the starter wires and the fuel lines.

28. Install the exhaust pipe on the exhaust manifold.

29. Lower the vehicle.

30. Install the power steering pump and the air conditioning compressor.

31. Connect the necessary wires and hoses.

32. Install the radiator, fan and fan sh roud. Connect the radiator and heater

hoses and the transmission cooler lines.

33. Connect the vacuum brake booster li ne, the throttle linkage and cruise

control cable. Install the distributor cap.

34. Fill the cooling system with the proper type and amount of coolant and

the crankcase with the proper type of oil to the correct level.

35. Install the water pump drive bel t, the air cleaner duct and the hood.

36. Connect the negative battery cable, st art the engine and check for leaks.

Page 381 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 381

It is not necessary to remove the radi

ator hose from the thermostat housing.

4. Remove the two retaining bolts from the thermostat housing and remove

the thermostat.

To install: 5. Using a new gasket, install the thermostat and housing.

6. Tighten the bolts to 21 ft lbs. (28 Nm).

7. Fill and bleed t he cooling system.

INTAKE MANIFOLD

REMOVAL & INSTALLATION

When servicing all vehicles, be absolutel y sure to mark vacuum hoses and

wiring so that these items may be properly reconnected during installation. Also,

when disconnecting fitting lines (fuel lines, power brake vacuum lines,

transmission and engine cooler lines, etc.), always use two flare nut (or line)

wrenches. Hold the wrench on the large fitti ng with pressure on the wrench as if

you were tightening the fitting (clockw ise), THEN loosen and disconnect the

smaller fitting from the larger fitting. If this is not done, damage to the line will

result. Always relieve fuel system pressure before disconnecting lines.

CAUTION - When draining the coolant, keep in mind that cats and dogs are

attracted by the ethylene gl ycol antifreeze, and are quite likely to drink any that

is left in an uncovered container or in puddles on the ground. This will prove

fatal in sufficient quantity. Always drai n the coolant into a sealable container.

Coolant should be reused unless it is contaminated or several years old.

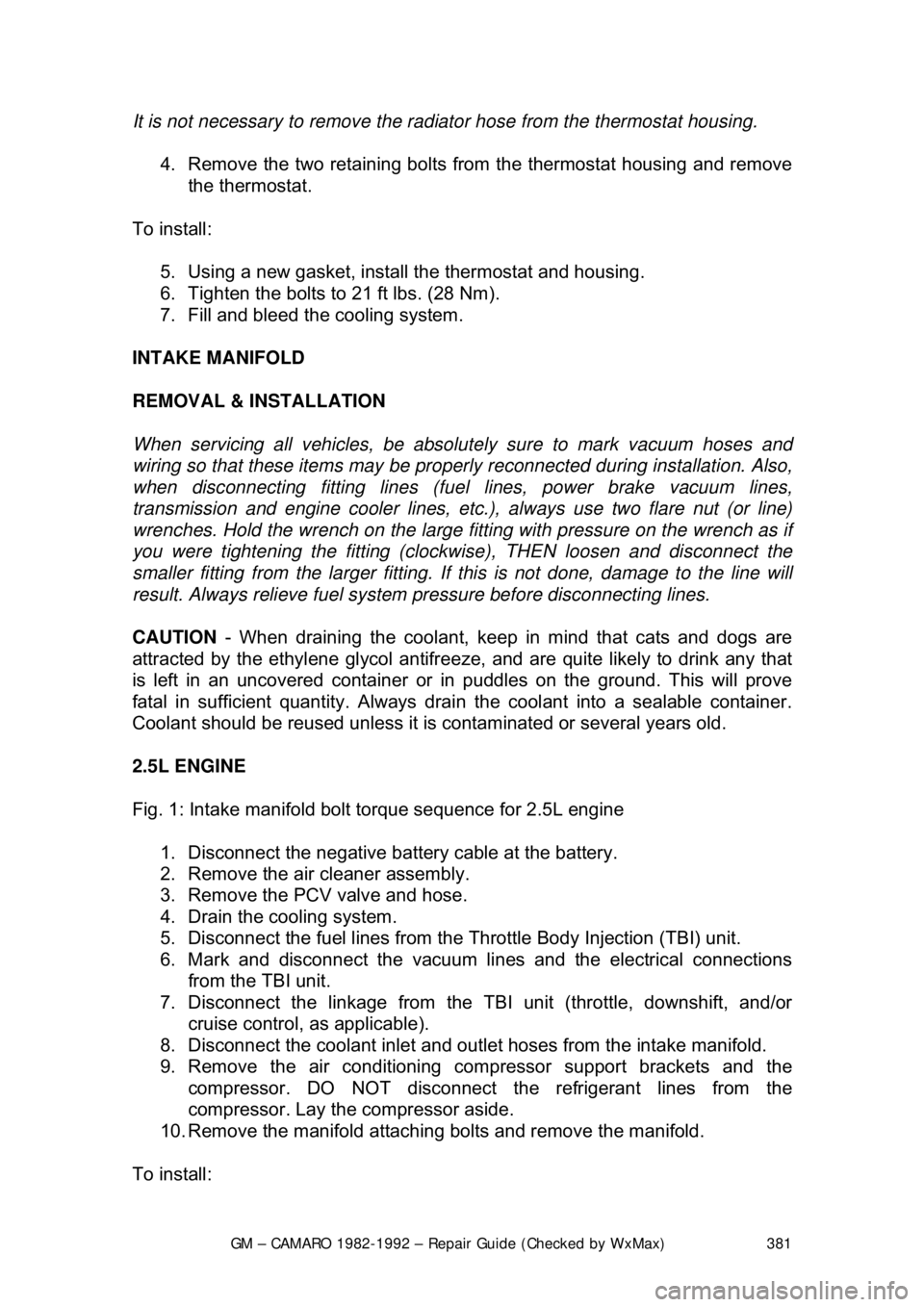

2.5L ENGINE

Fig. 1: Intake manifold bol t torque sequence for 2.5L engine

1. Disconnect the negative batte ry cable at the battery.

2. Remove the air cleaner assembly.

3. Remove the PCV valve and hose.

4. Drain the cooling system.

5. Disconnect the fuel lines from the Throttle Body Injection (TBI) unit.

6. Mark and disconnect the vacuum li nes and the electrical connections

from the TBI unit.

7. Disconnect the linkage from the TBI unit (throttle, downshift, and/or

cruise control, as applicable).

8. Disconnect the coolant inlet and outlet hoses from the intake manifold.

9. Remove the air conditioning co mpressor support brackets and the

compressor. DO NOT disconnect the refrigerant lines from the

compressor. Lay the compressor aside.

10. Remove the manifold attachi ng bolts and remove the manifold.

To install:

Page 382 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 382

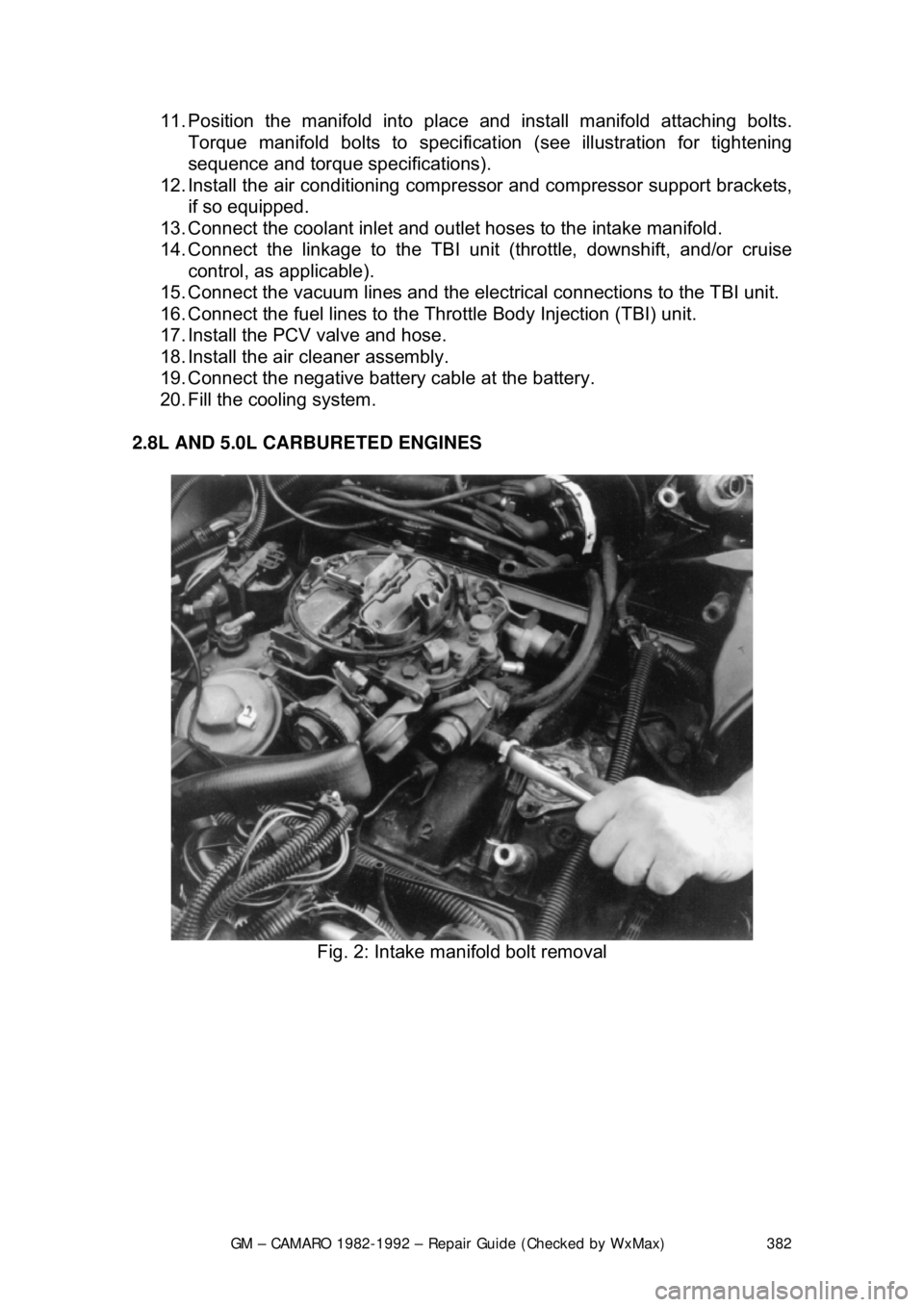

11. Position the manifold into place and install manifold attaching bolts.

Torque manifold bolts to specificat ion (see illustration for tightening

sequence and torque specifications).

12. Install the air conditioning comp ressor and compressor support brackets,

if so equipped.

13. Connect the coolant inlet and outlet hoses to the intake manifold.

14. Connect the linkage to the TBI unit (throttle, downshift, and/or cruise

control, as applicable).

15. Connect the vacuum lines and the elec trical connections to the TBI unit.

16. Connect the fuel lines to the Th rottle Body Injection (TBI) unit.

17. Install the PCV valve and hose.

18. Install the air cleaner assembly.

19. Connect the negative battery cable at the battery.

20. Fill the cooling system.

2.8L AND 5.0L CARBURETED ENGINES

Fig. 2: Intake manifold bolt removal

Page 466 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 466

wear. Worn piston rings, scored or wo

rn cylinder bores, blown head gaskets,

sticking or burnt valves, and worn valve seats are all possible culprits. A check

of each cylinder's compression will help locate the problem.

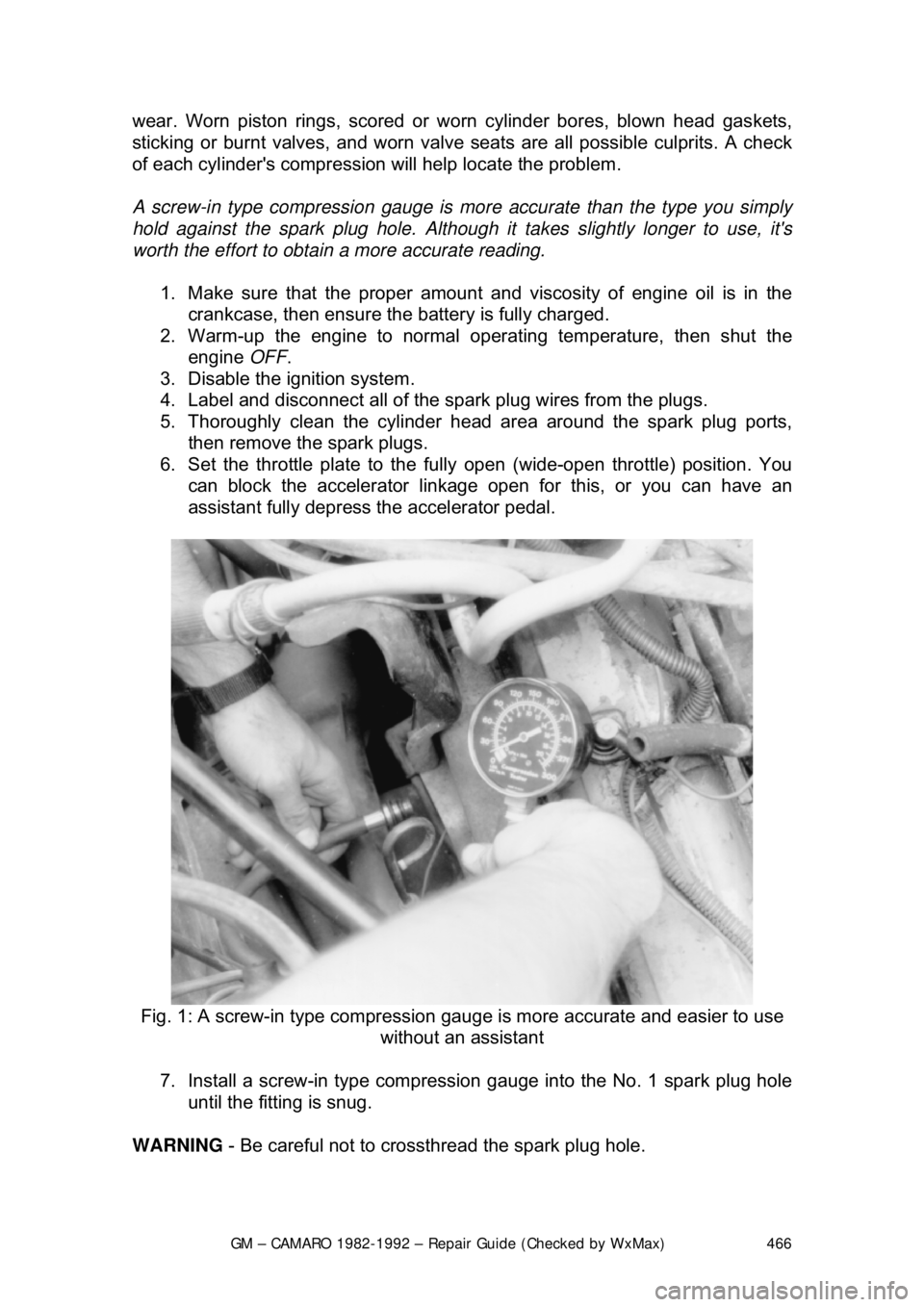

A screw-in type compression gauge is more accurate than the type you simply

hold against the spark plug hole. Although it takes slightly longer to use, it's

worth the effort to obtain a more accurate reading.

1. Make sure that the proper amount and viscosity of engine oil is in the

crankcase, then ensure the battery is fully charged.

2. Warm-up the engine to normal operat ing temperature, then shut the

engine OFF.

3. Disable the ignition system.

4. Label and disconnect all of the spark plug wires from the plugs.

5. Thoroughly clean the cylinder h ead area around the spark plug ports,

then remove the spark plugs.

6. Set the throttle plate to the fully open (wide-open throttle) position. You

can block the accelerator linkage open for this, or you can have an

assistant fully depress the accelerator pedal.

Fig. 1: A screw-in type compression gauge is more accurate and easier to use

without an assistant

7. Install a screw-in type compression gauge into the No. 1 spark plug hole

until the fitting is snug.

WARNING - Be careful not to crossthread the spark plug hole.

Page 673 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 673

3. Turn the screw counterclockwise and

remove it. Lift the solenoid and the

connector from the float bowl.

4. Remove the float and bend the arm up to adjust. The float must be

correctly aligned after adjustment.

5. To install the components, reverse the order of removal. Back out the

solenoid mixture screw t he number of turns that wa s recorded earlier.

THROTTLE LINKAGE

ROCHESTER E2SE

No adjustment of the thro ttle cable can be made.

ROCHESTER E4ME AND E4MC

Due to the design of the throttle cable, no adjustments of the throttle linkage can

be made.

CHOKE UNLOADER (PRIMARY)

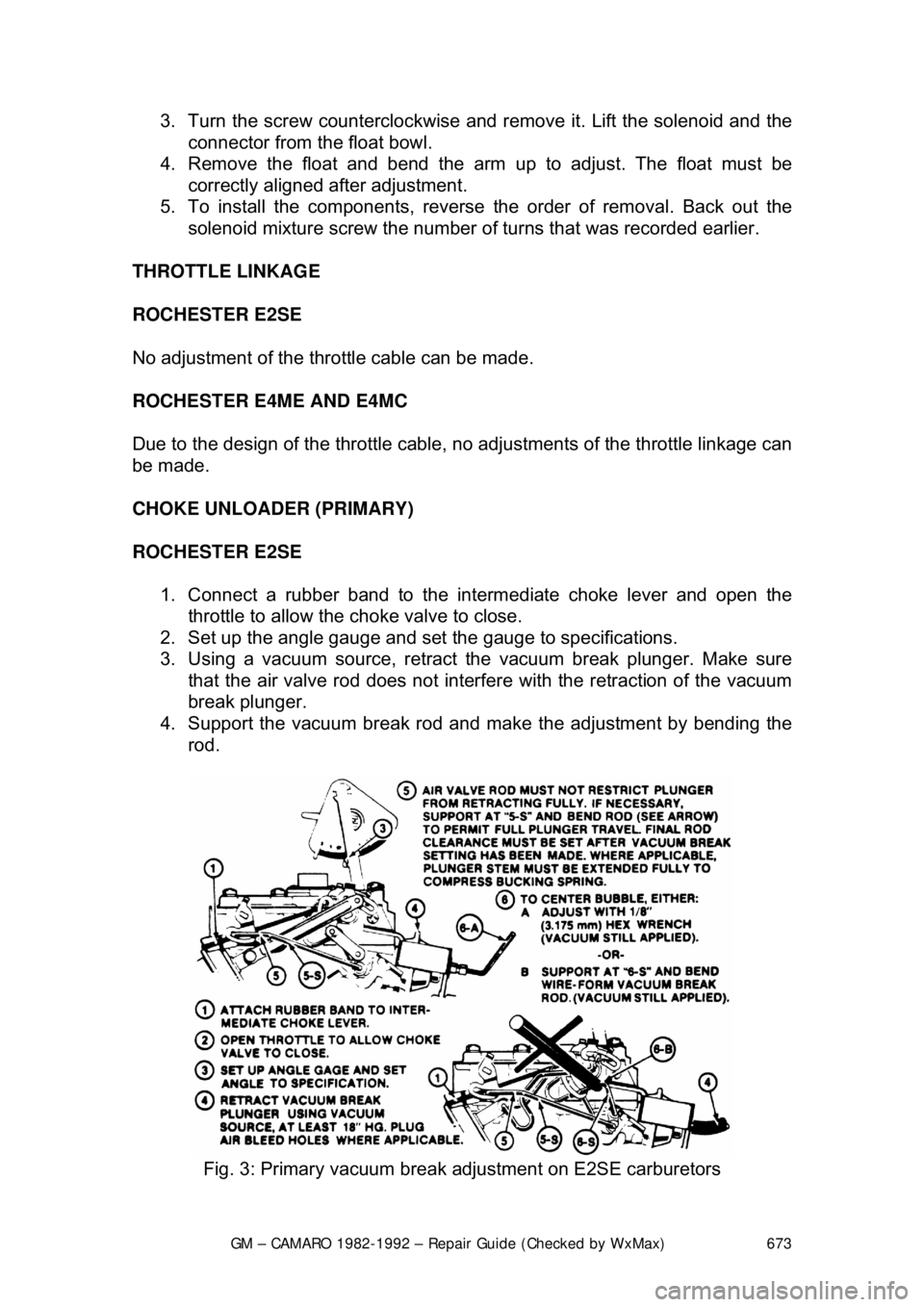

ROCHESTER E2SE

1. Connect a rubber band to the in termediate choke lever and open the

throttle to allow the choke valve to close.

2. Set up the angle gauge and set the gauge to specifications.

3. Using a vacuum source, retract the vacuum break plunger. Make sure

that the air valve rod does not interf ere with the retraction of the vacuum

break plunger.

4. Support the vacuum br eak rod and make the adjustment by bending the

rod.

Fig. 3: Primary vacuum break adjustment on E2SE carburetors