CHEVROLET CORVAIR 1986 2.G Service Manual

Manufacturer: CHEVROLET, Model Year: 1986, Model line: CORVAIR, Model: CHEVROLET CORVAIR 1986 2.GPages: 56, PDF Size: 22.23 MB

Page 41 of 56

Downloaded from www.Manualslib.com manuals search engine Also, all hoses, fittings and the inlet air filter should be

inspected, cleaned and replciced if necessary.

NOTE: If the positive crankcase ventilator valve should

become

dogged, the engine idle will be adversely

affect~d. Therefore, if the engine idle becomes too slow

or rough, the ventilator valve should be checked before

any carburetor ad;ustments are made to compensate for

the trouble.

AIR INJECTION REACTOR (A.I.R.l

The Air

Injection Reactor system is designed to re

duce .air pollution caused by exhaust emissions. It is entirely separate from the Positive Crankcase Ventilating

system. The Air

Injection Reactor system operates by

oxidizing (or burning) the

hydrocarbons and carbon

monoxide as they are expelled from the combustion

chamber into the exhaust. A positive displacement air

pump, driven by the engine, compresses clean frltered

air, which

is distributed and injected at the exhaust part

of each cylinder. This fresh air mixes with the hot exhaust

gases and promotes further oxidation (or burning) of

both hydrocarbons and carbon monoxide by converting

some

of them to carbon dioxide and water. This does not

reduce the danger of inhaling carbon monoxide in con

frned areas. See page 7 for carbon monoxide warning.

Supplementing

the air pump a special carburetor and

distributor plus related components are required.

The Air

Injection Reactor system should have the A.I.R. pump filter serviced and the drive belt inspected

for

wear and tension every 12 months or 12,000 miles,

38

whichever occurs frrst. In addition, complete effectiveness

of the system, as well as full power and performance,

depends upon idle speed, ignition timing, and idle fuel

mixture being

set according to specifrcation. A quality

tune-up which includes

these adjustments should be per

formed periodically to assure normal engine efficiency,

operation and performance.

STEERING GEAR

Every 36,000 miles -Re

move frller plug and

check lubricant level. If

necessary, add water

resistant EP chassis lu

bricant which meets

General Motors Specifr

cation GM 6031 M to

bring to level

of frller

plug hole.

FAN BELT

Every 6000 miles-check condition of belt. Check belt

guide to belt clearance. Belt guide ciearance should

be approximately 1/16" after belt is tensioned.

(See page 49). Retensioning a belt unnecessarily

may result

in premature belt fciilure.

ENGINE OIL CHANGE INTERVAL

Change engine oil each 4 months. If more than

6000 miles are driven in a 4-month period, change oil

Page 42 of 56

Downloaded from www.Manualslib.com manuals search engine every 6000 miles. This interval applies to the initial

change as well as subsequent oil changes. The oil

change interval for your Corvair engine is based on the

use

of oils that meet the requirements indicated in the

section on

"Engine Oil Recommendations". Oil change

intervals longer than 4 months or 6,000 miles will result

in serious reductions in engine life and may effect Chev

rolet's

obligation under the provisions of the New Vehicle Warranty.

Certain atmospheric and/or driving conditions includ

ing

prolonged operations at sub-zero temperatures or

under extremely dusty conditions, frequent trailer haul

ing, and extensive idling necessitate more frequent oil

and filter changes. * Operation in dust storms may require

an immediate change of both oil and filter. See your

Chevrolet dealer for advice on frequency of oil and

filter changes because of unusual driving conditions.

A high

quality MS oil meeting General Motors

Standard GM 6041-M was installed in your engine at

the factory. It is not necessary to change this factory

installed oil

prior to the recommended normal change

period. However, the oil level should be checked more

frequently during

the break-in period since somewhat

higher oil consumption is normal until the piston rings

become seated.

*In many such situations, oil change intervals should not exceed 2

months, or 3000 miles, whichever occurs first, and similarly, filter changes should not exceed 4 months or 6000 miles, whichever comes

first.

39

OIL FILTER

Replace filter of first oil change and at every second

oil change thereafter. This recommendation is based on

the use of engine oil which meets the requirements indi

cated in the section on "Engine Oil Recommendations,"

and the use of the applicable AC. or equivalent quality replacement oil filter.

TRANSMISSION-3 AND 4-SPEED

The manual transmission and the rear axle have' a

common

oil sump. Provisions for checking and main

taining lubricant level are provided on each unit.

Follow recommendations given

under "Rear Axle"

on page 41 for inspection intervals and type of trans

mission lubricant.

Page 43 of 56

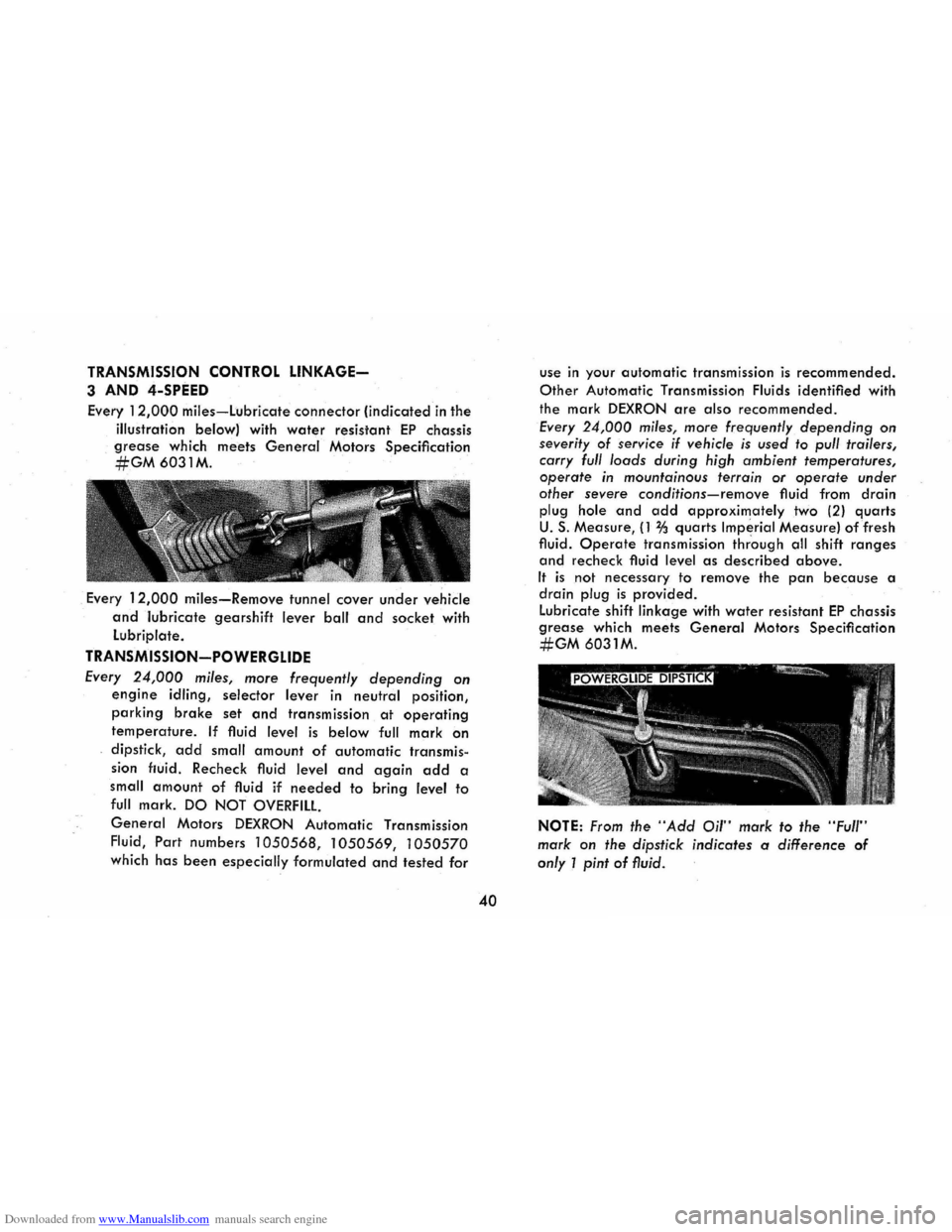

Downloaded from www.Manualslib.com manuals search engine TRANSMISSION CONTROL LlNKAGE-

3 AND 4-SPEED

Every 12,000 miles-Lubricate connector (indicated in the

illustration below) with

water resistant EP chassis

grease which meets General Motors Specification

#GM6031M.

. Every 12,000 miles-Remove tunnel cover under vehicle

and lubricate gearshift lever ball and socket with

Lubriplate.

TRANSMISSION-POWERGLIDE

Every 24,000 miles, more frequently depending on

engine idling, selector lever in neutral position,

parking brake set and transmission at operating

temperature. If fluid level is below full mark on

dipstick, add small amount of automatic transmis

sion fluid. Recheck fluid level and again add a

small

amount of fluid if needed to bring level to

full mark. DO NOT OVERFILL

General Motors DEXRON Automatic Transmission

Fluid,

Part numbers 1050568, 1050569, 1050570

which has been especially formulated and tested for

40

use in your automatic transmission is recommended.

Other Automatic Transmission Fluids identified with

the mark

DEXRON are also recommended.

Every 24,000 miles, more frequently depending on

severity of service if vehicle is used to pull trailers,

carry full loads during high ambient temperatures,

operate in mountainous terrain or operate under

other severe

conditions-remove fluid from drain

plug hole and add approximately two (2) quarts

U. S. Measure, (1 % quarts Imperial Measure) of fresh

fluid.

Operate transmission thr'ough all shift ranges

and recheck fluid level as described above.

It is not necessary to remove the pan because a

drain plug is provided .

Lubricate shift linkage with

water resistant EP chassis

grease which meets General Motors Specification

#GM 6031M.

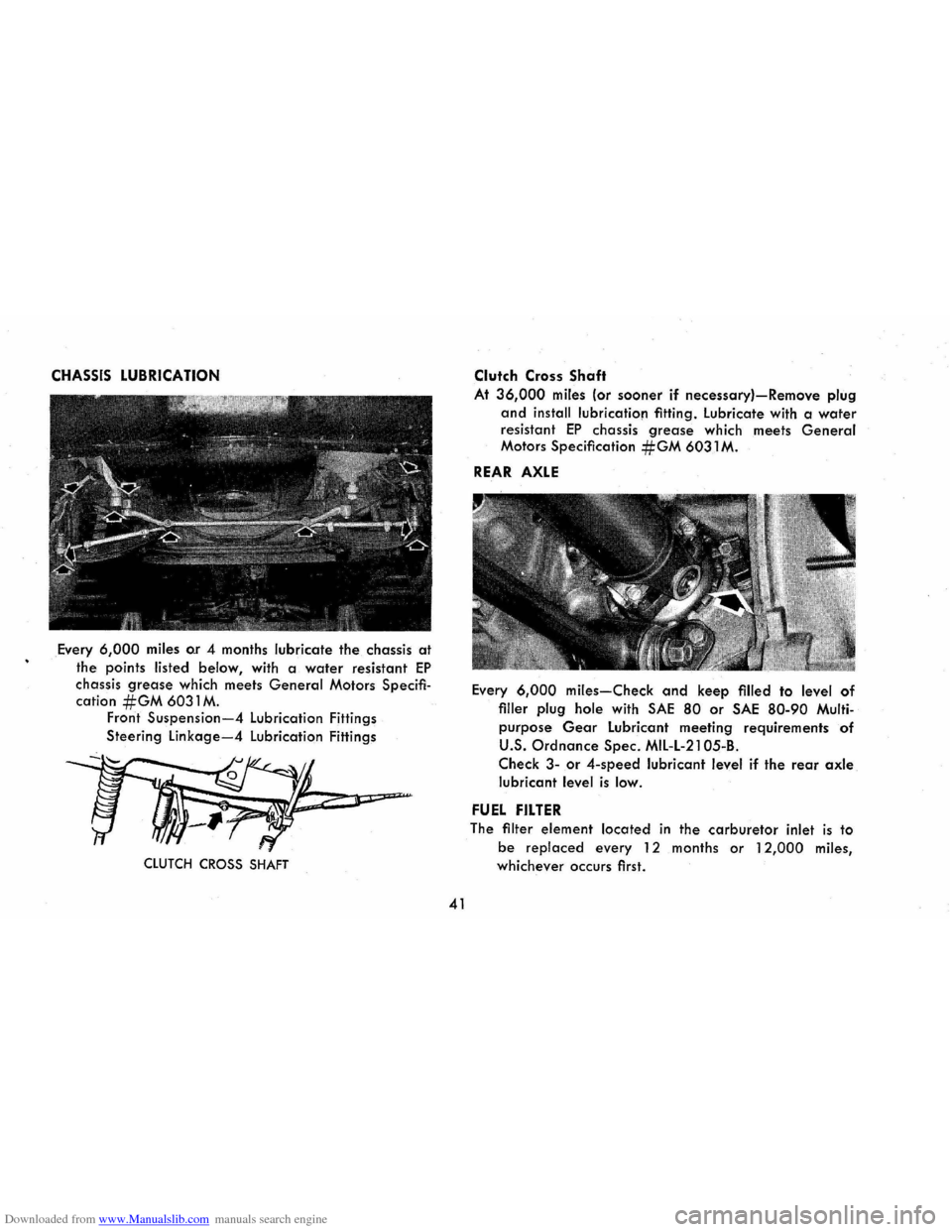

NOTE: From the "Add Oil" mark to the "Full"

mark on the dipstick indicates a difference of

only 1 pint of fluid.

Page 44 of 56

Downloaded from www.Manualslib.com manuals search engine CHASSIS LUBRICATION

Every 6,000 miles o.r 4 months lubricate the chassis at

the points listed below, with a water resistant EP

chassis grease which meets General Motors Specifi

cation #GM 6031 M. Front Suspension-4 Lubrication Fittings

Steering

Linkage-4 Lubrication Fittings

, WJ~P;=-

CLUTCH CROSS SHAFT

41

Clutch Cross Shaft

At 36,000 miles (or sooner if necessary)-Remove plug

and install lubrication fitting. Lubricate with a water

resistant EP chassis grease which meets General

Motors Specification #GM 6031 M.

REAR AXLE

Every 6,000 miles-Check and keep filled to level of

filler plug hole with SAE 80 or SAE 80-90 Multi

purpose Gear Lubricant meeting requirements of

U.S. Ordnance Spec. MIL-L-21 05-B.

Check 3-or 4-speed lubricant level if the rear axle

lubricant level is low.

FUEL FILTER

The filter element located in the carburetor inlet is to

be replaced every 12 months or 12,000 miles,

whichever occurs first.

Page 45 of 56

Downloaded from www.Manualslib.com manuals search engine AIR CLEANER

CAUTION: In addition to its function of filtering air

drawn into

the engine through the carburetor, the air

cleaner also acts as

a flame arrester in the event the

engine backfires. Because backfiring

may cause fire in

the engine compartment, the air cleaner should be in

stalled at all times unless its removal is necessary for

repair or maintenance services.

Paper Element Type

The oil-wetted paper element is a long-life efficient air

cleaner and should not require replacement before

24,000 miles except under extreme adverse condi

tions .

Inspect air cleaner at 12,000 miles for dust leaks,

holes

or other damage, replace if necessary . If

condition is satisfactory, rotate element 1800 from

originally installed position. Replace

at 24,000 miles.

Under extreme

adverse conditions inspect every 6,000 miles.

Oil Bath Type

Every 12,000 miles-Inspect and clean if necessary.

Refill with SAE 50 engine oil when lowest anticipated

temperature is above freezing; use SAE 20 if below

freezing.

BATTERY (ENERGIZER)

Every 6,000 miles-Clean and oil battery terminals and

oil felt washer. Check fluid level frequently. Keep

filled with distilled water to level of split ring in

42

vent tube. The electrolyte level indicator in the cap

of one cell will glow if the fluid level is low. In this

case each cell should be checked.

CAUTION: Since normal battery or Energizer

chemical action generates hydrogen gas which

is highly explosive when mixed with air, never

expose the battery to an open flame or electric

spark. Also, avoid getting battery fluid, which

is a sulfuric acid solution, on skin, on clothing

or other fabrics, or on painted surfaces . Eye

protection should

be worn while working on the

battery for

any reason.

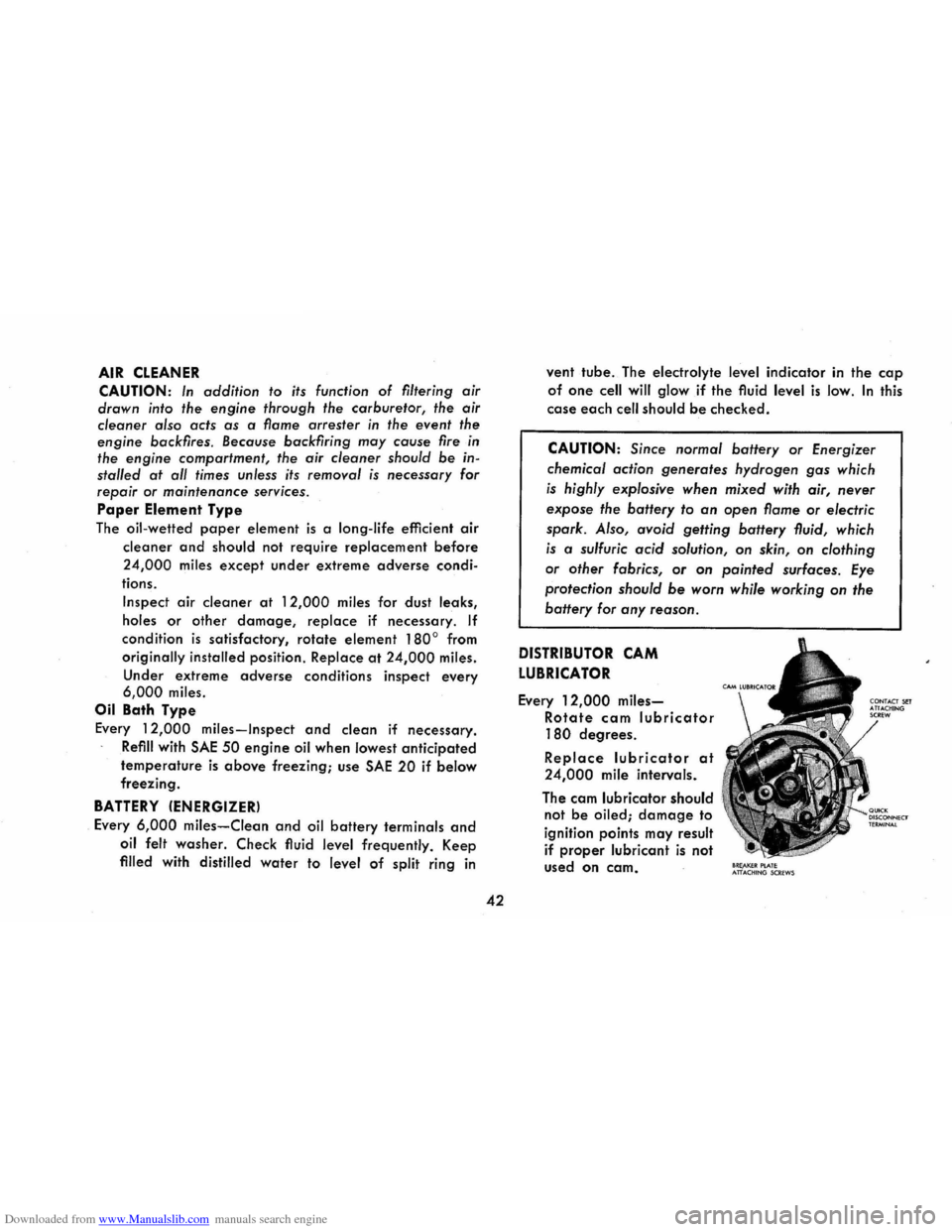

DISTRIBUTOR CAM

LUBRICATOR

Every 12,000 miles

Rotate cam lubricator

180 degrees.

Replace lubricator at

24,000 mile intervals.

The cam lubricator should

not

be oiled; damage to

ignition points may result

if

proper lubricant is not

used

on cam. 8RE,AKEIt PlATE ATTACHtNG SCREWS

Page 46 of 56

Downloaded from www.Manualslib.com manuals search engine AIR CONDITIONING

Have your Chevrolet Dealer check your air conditioning

system

at some time during the winter months to be

sure there has been no loss in cooling output. Dur

ing

the summer, see your Chevrolet Dealer immedi

ately if you suspect the system is not performing as

it should.

BRAKE LININGS

Brake linings should be periodically inspected for wear.

The frequency of this inspection depends upon driv

ing conditions such

as traffic or terrain, and also

the driving techniques of individual owners. Your

Chevrolet Dealer is best qualified to advise you as

to how often this inspection should be performed.

When brakes require relining use genuine General

Motors Parts or equivalent.

BRAKE MASTER CYLINDER

Every 6,000 miles-Check fluid level in each reservoir

and maintain % II below lowest edge of each open

ing with G.M. Hydraulic Brake Fluid Supreme No. 11

PARKING BRAKE AND CLUTCH PULLEYS

AND CABLES

Every 12,000 miles-lubricate pulleys under dash. Re

move. the tunnel cover under vehicle and lubricate

pulleys

and cable bearing points with a water resist

ant EP chassis grease which meets General Motors

43

Specification #GM 6031 M. Lubricate gearshift lever

ball and socket (see page 38) at the same time.

FRONT WHEEL BEARINGS

Clean, repack with high melting point wheel bearing

lubricant, and adjust whenever the wheels and hub

are removed. Replace grease seals at the same time.

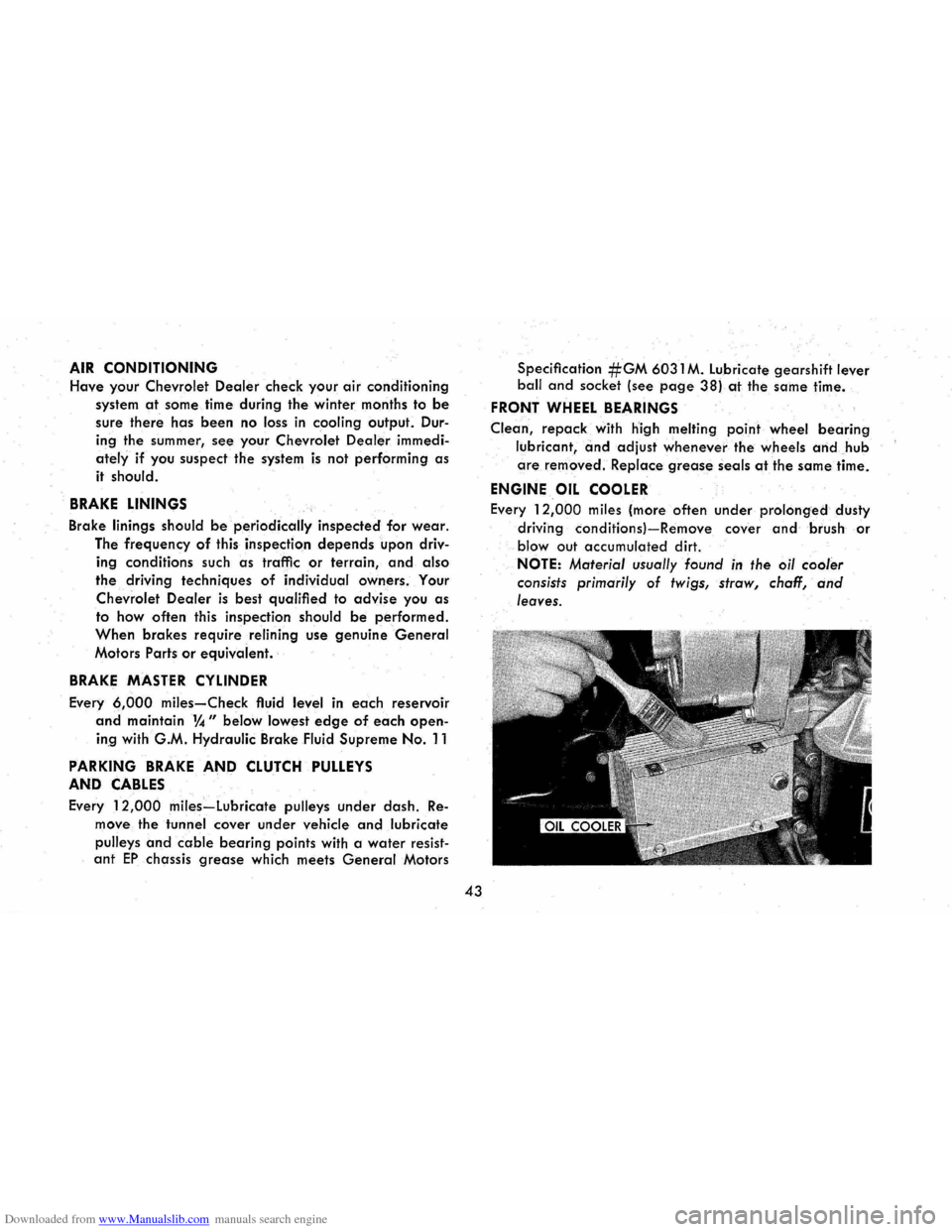

ENGINE OIL COOLER

Every 12,000 miles (more often under prolonged dusty

driving

conditionsl-Remove cover and brush or

blowout accumulated dirt.

NOTE: Material usually found in the oil cooler

consists primarily

of twigs, straw, chaff, and

leaves.

Page 47 of 56

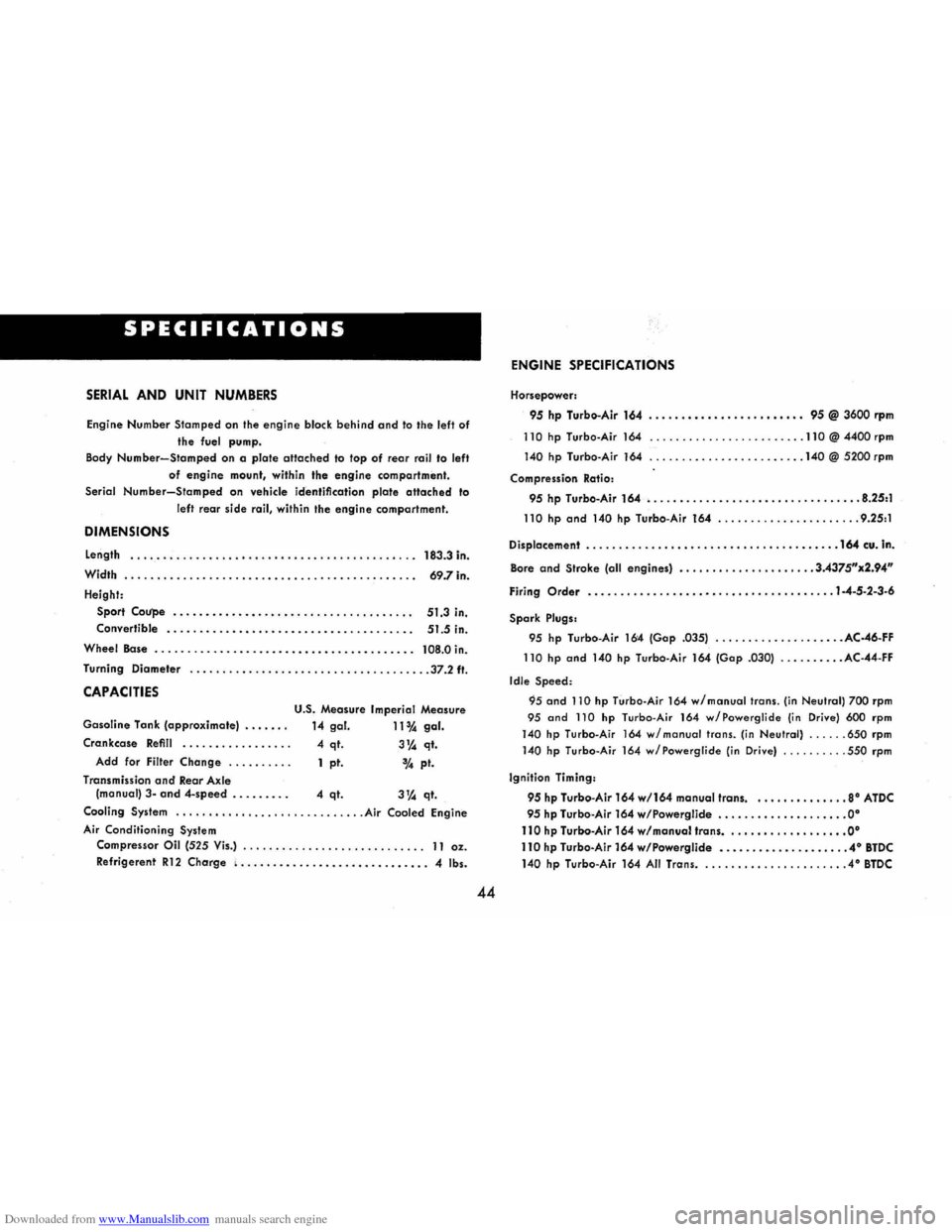

Downloaded from www.Manualslib.com manuals search engine SPECIFICATIONS

SERIAL AND UNIT NUMBERS

Engine Number Stamped on the engine block behind and to the left of

the fuel pump.

Body

Number-Stamped on a plate attached to top of rear rail to left

of engine mount, within the engine compartment .

Serial

Number-Stamped on vehicle identification plate attached to

left

rear side rail, within the engine compartment.

DIMENSIONS

Length .•...............•.•.•..................•... 183.3 in.

Width

.......•....•. . ....•..••......•.............• 69.7 in.

Height: Sport

Coupe ......•...••• ..•..••............•..•• 51.3 in.

Convertible

..........•.....••..•...•............. 51.5 in.

Wheel Base

...................•..•...•.... , ........ 108.0 in.

Turning Diameter .

.•..........•............... ........ 37.2 ft.

CAPACITIES

U.S. Measure Imperial Measure

Gasoline Tank (approximate) ...... .

14 gal. 11 % gal.

Crankcase Refill •....•..... ...... 4 qt. 3~ qt.

Add for Filter Change ......... . 1 pt. 3,4 pt.

Transmission

and Rear Axle

(manual) 3-and 4-speed ........ . 4 qt. 3~ qt.

Cooling System .....••...................... Air Cooled Engine

Air Conditioning System

Compressor Oil (525 Vis.) ...•............. ......... " 11 oz.

Refrigerent

R12 Charge ( •......•................•.... 4 Ibs.

44

ENGINE SPECIFICATIONS

Horsepower:

95 hp Turbo-Air 164 ......••.•.•........•.•• 95 @ 3600 rpm

110 hp Turbo-Air 164 ........................ 110 @ 4400 rpm

140 hp Turbo -Air 164 ........................ 140 @ 5200 rpm

Compression Ratio:

95 hp Turbo-Air 164 •...•........•.•.••••.•...••.•••. 8.25:1

110 hp and 140 hp Turbo-Air 164 ...................... 9.25:1

Displacement

......•....••••••..••••••...•..•.••\

•.•• 164 cu. In.

Bore and Stroke (all engines) ................. .... 3.4375"x2.94"

Firing Order •.........•..•••••••..•.•.••.•\

..••..•. 1-4-5-2-3·6

Spark Plugs.

95 hp Turbo-Air 164 (Gop .035)

.................... AC-46-FF

110

hp and 140 hp Turbo-Air 164 (Gop .030) .......... AC- 44-FF

Idle

Speed:

95 and 110 hp Turbo-Air 164 wi manual trans. (in Neutral) 700 rpm

95

and 110 hp Turbo-Air 164 w/Powerglide (in Drive) 600 rpm

140 hp Turbo-Air 164 wi manual trans. (in Neutral) ...... 650 rpm

140 hp Turbo-Air 164 w/Powerglide (in Drive) .......... 550 rpm

Ignition Timing:

95 hp Turbo-Air 164 wl164 manual trans •..•...•.•••.•. 8· ATDC

95 hp Turbo-Air 164 w/Powerglide ••.•..•••.••••..•••• 0·

110 hp Turbo-Air 164 wi manual Irons •....•..•..••....•. 0·

110 hp Turbo-Air 164 w/Powerglide •.••..•••.•..•••••.. 4· BTDC

140 hp Turbo-Air 164 All Trans ....................... 4° BTDC

Page 48 of 56

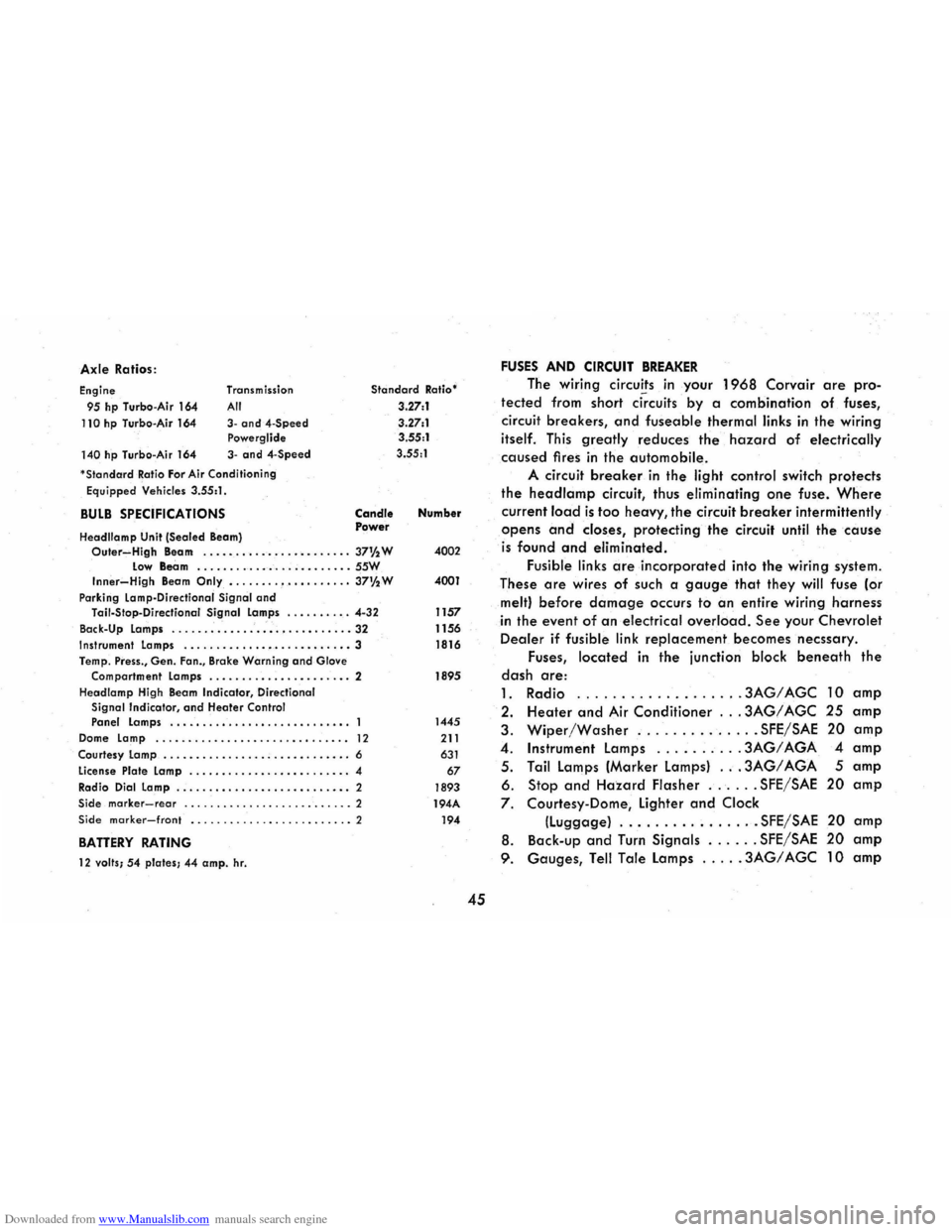

Downloaded from www.Manualslib.com manuals search engine Axle Ratios :

Engine

95 hp Turbo -Air 164

110 hp Turbo-Air 164

140 hp Turbo -Air 164 Transm

ission

All

3-and4-Speed Powerglide

3-and 4-Speed

'

StandardRatio For Air Cond itioning

Equipped Vehicles 3.55:1 .

BULB SPECIFICATIONS

Headllamp Unit (Sealed Beam)

Standard Ratio'

3.27:1

3 .27:1

3.55:1

3.55 :1

Candle Power Number

Outer~High Beam . .....•...•...•........ 37% W 4002 Low Beam .......... _ ....... _ .. _ .. SSW Inner-High Beam Only •....... , •.•. •.•... 37%W 4001

Park ing Lamp-Directional Signal and Tail-Stop -Directianal Signal Lamps ........ . . 4-32 1157

Back-Up Lamps

............................ 32 1156 Instrument Lamps ........ _ ...•••.....•....• 3 1816

Temp . Press., Gen. Fan., Brake Warning and Glove

Compartment Lamps ...........•... ..•..• . 2 1895

Headlamp High Beam

Indicator , Directional Signal Indicator, and Heater Control Panel Lamps ................•......•.•.. 1445

Dome Lamp ........................... ..• 12 211

Courtesy Lamp ............... . ; ....•..••... 6 631

License Plate Lamp ..............• •......... 4 67

Radio Dial Lamp .....................•..• " 2 1893 Side marker-rear .......................... 2 194A Side marker-front ......................... 2 194

BATTERY RATING

12 valls; 54 plates; 44 amp. hr.

45

FUSES AND CIRCUIT BREAKER

The wiring circuits in your 1968 Corvair are pro

tected from short ci~cuits by a combination of fuses,

circuit

breakers, and fuseable thermal links in the wiring

itself. This greatly reduces the hazard of electrically

caused fires in the automobile.

A circuit breaker in the light control switch protects

the headlamp circuit, thus eliminating one fuse. Where

current lo.ad is too heavy, the circuit breaker intermittently

opens and closes, protecting the circuit until the cause

is found and eliminated.

Fusible links are incorporated into the wiring system.

These

are wires of such a gauge that they will fuse (or

melt) before damage occurs to an entire wiring harness

in the event of an electrical overload. See your Chevrolet

Dealer if fusible link replacement becomes necssary.

Fuses,

located in the junction block beneath the

dash are:

1. Radio .

........ ...... .. , .3AG/AGC 10 amp

2. Heater and Air Conditioner ... 3AG/ AGC 25 amp

3. Wiper/Washer .............. SFE/SAE 20 amp

4 . Instrument lamps ......... . 3AG/ AGA 4 amp

5 . Tail lamps (Marker lamps) ... 3AG/ AGA 5 amp

6. Stop and Hazard Flasher ...... SFE/SAE 20 amp

7. Courtesy-Dome, lighter and Clock

(luggage) ................ SFE/SAE 20 amp

8. Back -up and Turn Signals ...... SFE/SAE 20 amp

9. Gauges, Tell Tale lamps ..... 3AG/ AGC 10 amp

Page 49 of 56

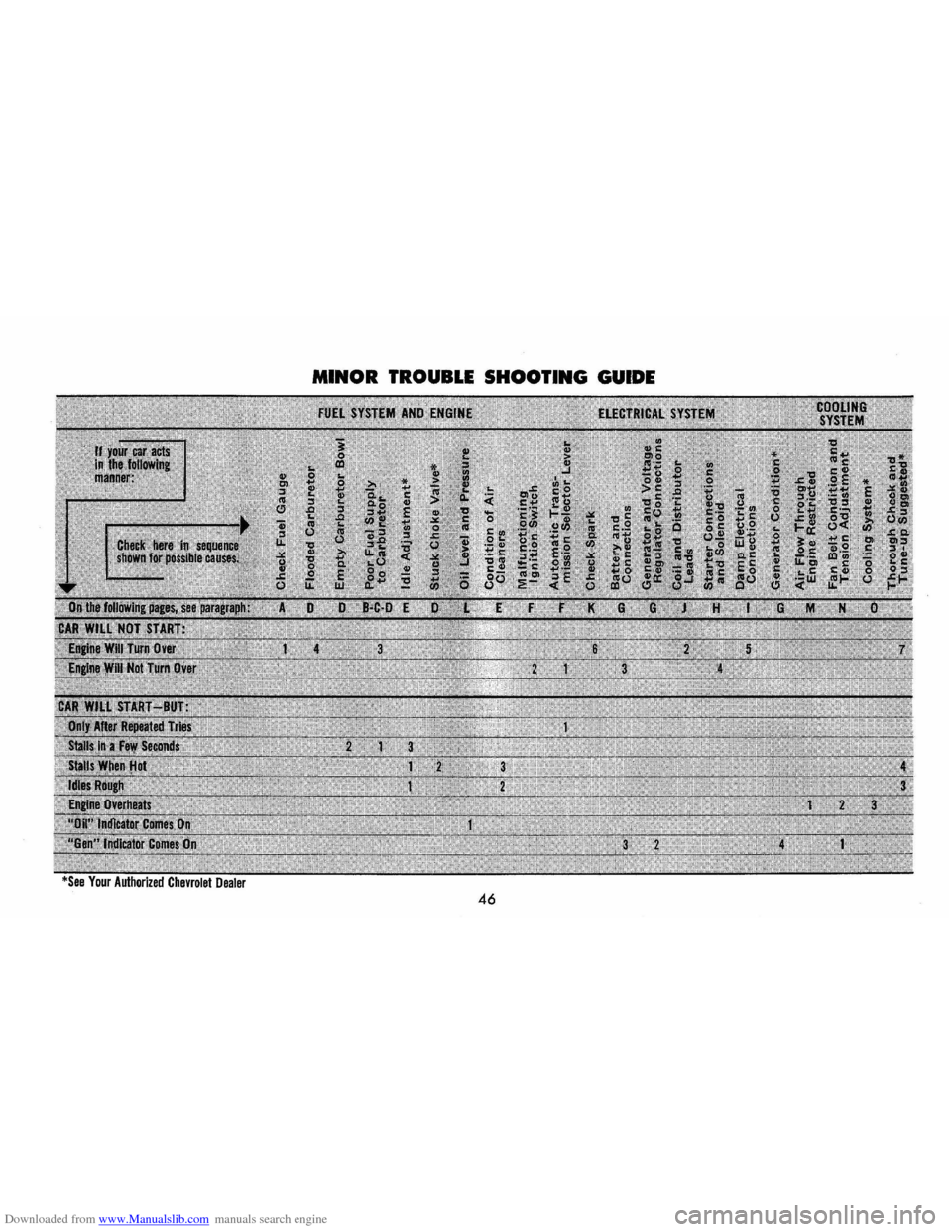

Downloaded from www.Manualslib.com manuals search engine MINOR TROUBLE SHOOTING GUIDE

46

Page 50 of 56

Downloaded from www.Manualslib.com manuals search engine MINOR TROUBLE SHOOTING PROCEDURES

The chart on the previous page, and the information on the pages

which follow, contains information designed to aid the average

driver to discover, and possibly correct, conditions resulting in minor

mechanical

difficulties in his car. The chart, designed to point out

possible solutions to

several of the most common automotive mal

functions

and point out a logical checking sequence, will lead step

by step to the most likely causes and corrective procedures. If, after

making the checks and adjustments suggested, the source of the

trouble

has not been found and corrected, it is strongly recom

mended

that an Authorized Chevrolet Dealer inspect the vehicle and

make whatever repairs or adjustments are necessary.

FUEL SYSTEM AND ENGINE

If the ignition switch will cause the engine to "turn over" or

"crank" but the car will not start, check Steps A through D below.

NOTE:

If continual "flooding" of the carburetor is evidenced by a

carburetor wet with fuel or black exhaust smoke, perform the

operation

suggested in paragraph 0 only .

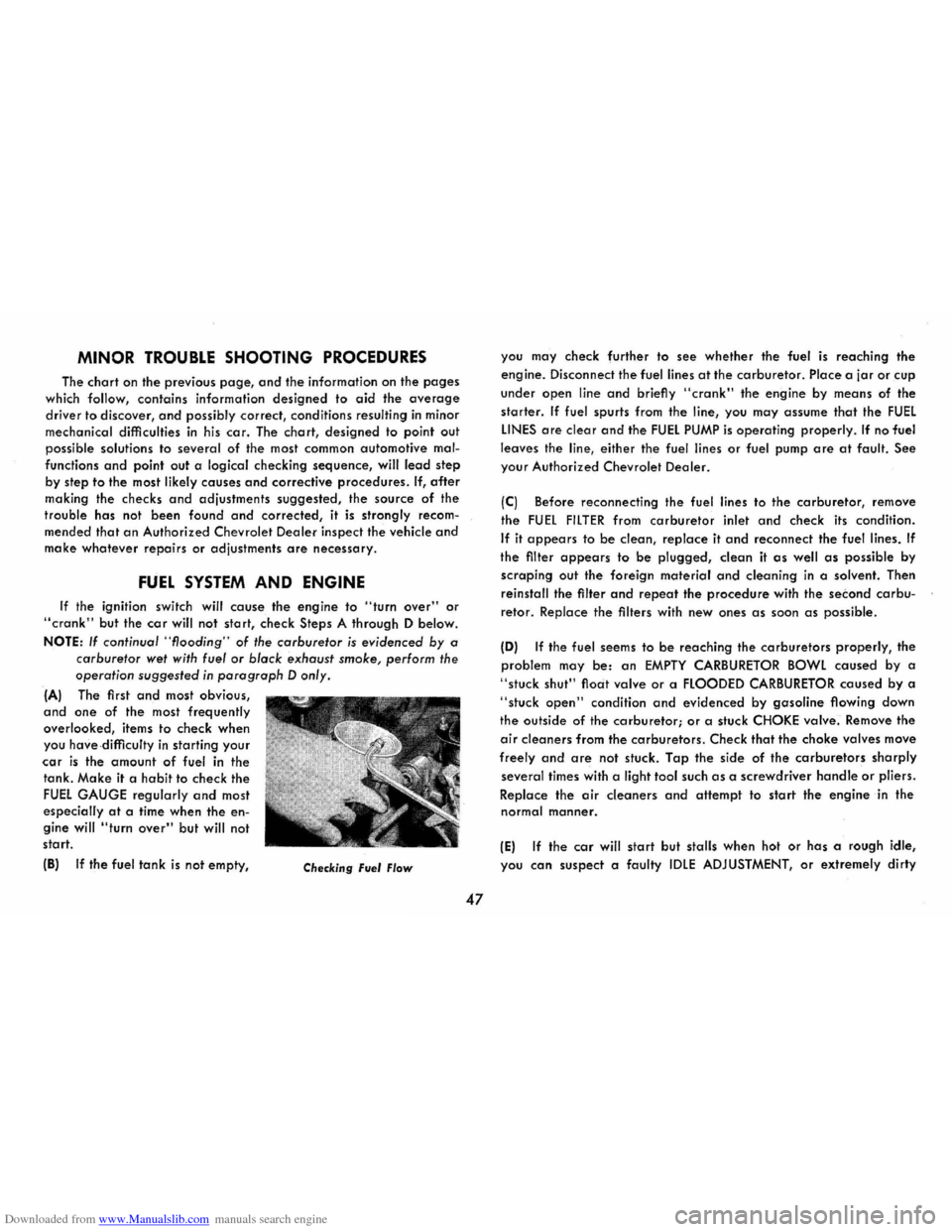

(A) The first and most obvious,

and one of the most frequently

overlooked, items to check when

you

have- difficulty in starting your

car is the amount of fuel in the

tank.

Make it a habit to check the

FUEL GAUGE regularly and most

especially

at a time when the en

gine will "turn over" but will not

start.

(8)

If the fuel tank is not empty, Checking Fuel Flow

47

you may check further to see whether the fuel is reaching the

engine. Disconnect the fuel lines

at the carburetor. Place a jar or cup

under open line and briefly "crank" the engine by means of the

starter. If fuel spurts from the line, you may assume that the FUEL

LINES are clear and the FUEL PUMP is operating properly. If no fuel

leaves the line, either the fuel lines

or fuel pump are at fault. See

your Authorized Chevrolet Dealer.

(C) Before reconnecting the fuel lines to the carburetor, remove

the

FUel FilTER from carburetor inlet and check its condition.

If it appears to be clean, replace it and reconnect the fuel lines. If

the filter appears to be plugged, clean it as well as possible by

scraping out the foreign material and cleaning in a solvent. Then

reinstall the filter

and repeat the procedure with the second carbu

retor. Replace the filters with new ones as soon as possible .

(0) If the fuel seems to be reaching the carburetors properly, the

problem may

be: an EMPTY CARBURETOR BOWL caused by a

"stuck shut" float valve or a flOODED CARBURETOR caused by a

"stuck open" condition and evidenced by gasoline flowing down

the outside

of the carburetor; or a stuck CHOKE valve. Remove the

air cleaners from the carburetors. Check that the choke valves move

freely and are not stuck. Tap the side of the carburetors sharply

several times with a light tool such as a screwdriver handle or pliers.

Replace the

air deaners and attempt to start the engine in the

normal manner.

(E) If the car will start but stalls when hot or has a rough idle,

you

can suspect a faulty IDLE ADJUSTMENT, or extremely dirty