CHEVROLET CORVETTE 2003 5.G Owners Manual

Manufacturer: CHEVROLET, Model Year: 2003, Model line: CORVETTE, Model: CHEVROLET CORVETTE 2003 5.GPages: 368, PDF Size: 2.55 MB

Page 331 of 368

75,000 Miles (125 000 km)

qInspect engine air cleaner ®lter. If necessary, replace

the ®lter. If vehicle is driven in dusty/dirty conditions,

inspect ®lter at every engine oil change. See

Engine Air Cleaner/Filter on page 5-18for more

information.An Emission Control Service. (See

footnote ².)

90,000 Miles (150 000 km)

qReplace engine air cleaner ®lter. SeeEngine Air

Cleaner/Filter on page 5-18for more information.An Emission Control Service.

100,000 Miles (166 000 km)

qReplace spark plugs.An Emission Control Service.

qInspect spark plug wires.An Emission Control

Service.

qChange automatic transmission ¯uid and ®lter.

Manual transmission ¯uid doesn't required change.

150,000 Miles (240 000 km)

qDrain, ¯ush and re®ll the cooling system (or every

60 months since last service, whichever occurs

®rst). See

Engine Coolant on page 5-23for what to

use.An Emission Control Service.

qInspect engine accessory drive belt.An Emission

Control Service.

6-7

Page 332 of 368

Part B: Owner Checks and Services

Listed in this part are owner checks and services

which should be performed at the intervals speci®ed to

help ensure the safety, dependability and emission

control performance of your vehicle.

Be sure any necessary repairs are completed at once.

Whenever any ¯uids or lubricants are added to your

vehicle, make sure they are the proper ones, as shown

in Part D.

At Each Fuel Fill

It is important for you or a service station attendant to

perform these underhood checks at each fuel ®ll.

Engine Oil Level Check

Check the engine oil level and add the proper oil if

necessary. SeeEngine Oil on page 5-13for further

details.

Engine Coolant Level Check

Check the engine coolant level and add DEX-COOLž

coolant mixture if necessary. SeeEngine Coolant

on page 5-23for further details.

Windshield Washer Fluid Level Check

Check the windshield washer ¯uid level in the windshield

washer tank and add the proper ¯uid if necessary.

See

Windshield Washer Fluid on page 5-36for further

details.

At Least Once a Month

Tire In¯ation Check

Make sure tires are in¯ated to the correct pressures.

SeeTires on page 5-54for further details.

Cassette Tape Player Service

Clean cassette tape player. Cleaning should be done

every 50 hours of tape play. SeeAudio System(s)

on page 3-62for further details.

Power Antenna Service

Clean power antenna mast. SeeAudio System(s) on

page 3-62for further details.

6-8

Page 333 of 368

At Least Twice a Year

Restraint System Check

Make sure the safety belt reminder light and all your

belts, buckles, latch plates, retractors and anchorages

are working properly. Look for any other loose or

damaged safety belt system parts. If you see anything

that might keep a safety belt system from doing its

job, have it repaired. Have any torn or frayed safety belts

replaced.

Also look for any opened or broken air bag coverings,

and have them repaired or replaced. (The air bag

system does not need regular maintenance.)

Wiper Blade Check

Inspect wiper blades for wear or cracking. Replace

blade inserts that appear worn or damaged or that

streak or miss areas of the windshield. Also see

Cleaning the Outside of Your Vehicle on page 5-78.

Weatherstrip Lubrication

Silicone grease on weatherstrips will make them last

longer, seal better, and not stick or squeak. Apply

silicone grease with a clean cloth. During very cold,

damp weather more frequent application may be

required. See

Part D: Recommended Fluids and

Lubricants on page 6-14.

Manual Transmission Check

Check the transmission ¯uid level; add if needed. SeeManual Transmission Fluid on page 5-20. Check

for leaks. A ¯uid leak is the only reason for ¯uid loss.

Have the system inspected and repaired if needed.

Automatic Transmission Check

It is not necessary to check the transmission ¯uid level.

A transmission ¯uid leak is the only reason for ¯uid

loss. Check for leaks. If a leak occurs, take the vehicle

to your dealer and have it repaired as soon as

possible.

At Least Once a Year

Key Lock Cylinders Service

Lubricate the key lock cylinders with the lubricant

speci®ed in Part D.

Body Lubrication Service

Lubricate all body door hinges. Also lubricate all hinges

and latches, including those for the hood, rear

compartment, console door and any folding seat

hardware. Part D tells you what to use. More frequent

lubrication may be required when exposed to a corrosive

environment.

6-9

Page 334 of 368

Starter Switch Check

{CAUTION:

When you are doing this check, the vehicle

could move suddenly. If it does, you or others

could be injured. Follow the steps below.

1. Before you start, be sure you have enough room

around the vehicle.

2. Firmly apply both the parking brake and the regular

brake. See

Parking Brake on page 2-30if

necessary.

Do not use the accelerator pedal, and be ready to

turn off the engine immediately if it starts.

3. On automatic transmission vehicles, try to start the

engine in each gear. The starter should work only

in PARK (P) or NEUTRAL (N). If the starter works in

any other position, your vehicle needs service.

On manual transmission vehicles, put the shift lever

in NEUTRAL (N), push the clutch down halfway

and try to start the engine. The starter should work

only when the clutch is pushed down all the way

to the ¯oor. If the starter works when the clutch isn't

pushed all the way down, your vehicle needs

service.

Automatic Transmission Shift Lock

Control System Check

{CAUTION:

When you are doing this check, the vehicle

could move suddenly. If it does, you or others

could be injured. Follow the steps below.

1. Before you start, be sure you have enough room

around the vehicle. It should be parked on a level

surface.

2. Firmly apply the parking brake. See

Parking Brake

on page 2-30if necessary.

Be ready to apply the regular brake immediately if

the vehicle begins to move.

3. With the engine off, turn the key to the ON position,

but don't start the engine. Without applying the

regular brake, try to move the shift lever out

of PARK (P) with normal effort. If the shift lever

moves out of PARK (P), your vehicle needs service.

6-10

Page 335 of 368

Ignition Automatic Transmission

Lock Check

While parked, and with the parking brake set, try to turn

the ignition key to OFF in each shift lever position.

The key should turn to OFF only when the shift lever is

in PARK (P).

On all vehicles, the key should come out only in OFF.

Parking Brake and Automatic

Transmission Park (P)

Mechanism Check

{CAUTION:

When you are doing this check, your vehicle

could begin to move. You or others could be

injured and property could be damaged. Make

sure there is room in front of your vehicle in

case it begins to roll. Be ready to apply the

regular brake at once should the vehicle begin

to move.Park on a fairly steep hill, with the vehicle facing

downhill. Keeping your foot on the regular brake, set the

parking brake.

·To check the parking brake's holding ability:

With the engine running and transmission in

NEUTRAL (N), slowly remove foot pressure from

the regular brake pedal. Do this until the vehicle is

held by the parking brake only.

·To check the PARK (P) mechanism's holding

ability: With the engine running, shift to PARK (P).

Then release the parking brake followed by the

regular brake.

Underbody Flushing Service

At least every spring, use plain water to ¯ush any

corrosive materials from the underbody. Take care to

clean thoroughly any areas where mud and other debris

can collect.

6-11

Page 336 of 368

Part C: Periodic

MaintenanceInspections

Listed in this part are inspections and services which

should be performed at least twice a year (for instance,

each spring and fall).

You should let your dealer's

service department do these jobs. Make sure any

necessary repairs are completed at once.

Proper procedures to perform these services may be

found in a service manual. SeeService Publications

Ordering Information on page 7-10.

Steering and Suspension Inspection

Inspect the front and rear suspension and steering

system for damaged, loose or missing parts, signs of

wear or lack of lubrication. Inspect the power steering

lines and hoses for proper hook-up, binding, leaks,

cracks, cha®ng, etc.

Tire and Wheel Inspection

Inspect the tires for uneven wear or damage. If there is

irregular or premature wear, check the wheel

alignment. Inspect for damaged wheels.

Exhaust System Inspection

Inspect the complete exhaust system. Inspect the body

near the exhaust system. Look for broken, damaged,

missing or out-of-position parts as well as open seams,

holes, loose connections or other conditions which

could cause a heat build-up in the ¯oor pan or could let

exhaust fumes into the vehicle. See

Engine Exhaust

on page 2-35.

6-12

Page 337 of 368

Fuel System Inspection

Inspect the complete fuel system for damage or leaks.

Engine Cooling System Inspection

Inspect the hoses and have them replaced if they

are cracked, swollen or deteriorated. Inspect all pipes,

®ttings and clamps; replace as needed. Clean the

outside of the radiator and air conditioning condenser.

To help ensure proper operation, a pressure test of

the cooling system and pressure cap is recommended

at least once a year.

Rear Axle Service

Check the gear lubricant level in the rear axle and add if

needed. SeeRear Axle on page 5-46. A ¯uid loss

may indicate a problem. Check the axle and repair it if

needed.

Brake System Inspection

Inspect the complete system. Inspect brake lines and

hoses for proper hook-up, binding, leaks, cracks,

cha®ng, etc. Inspect disc brake pads for wear and rotors

for surface condition. Inspect other brake parts,

including calipers, parking brake, etc. You may need to

have your brakes inspected more often if your driving

habits or conditions result in frequent braking.

6-13

Page 338 of 368

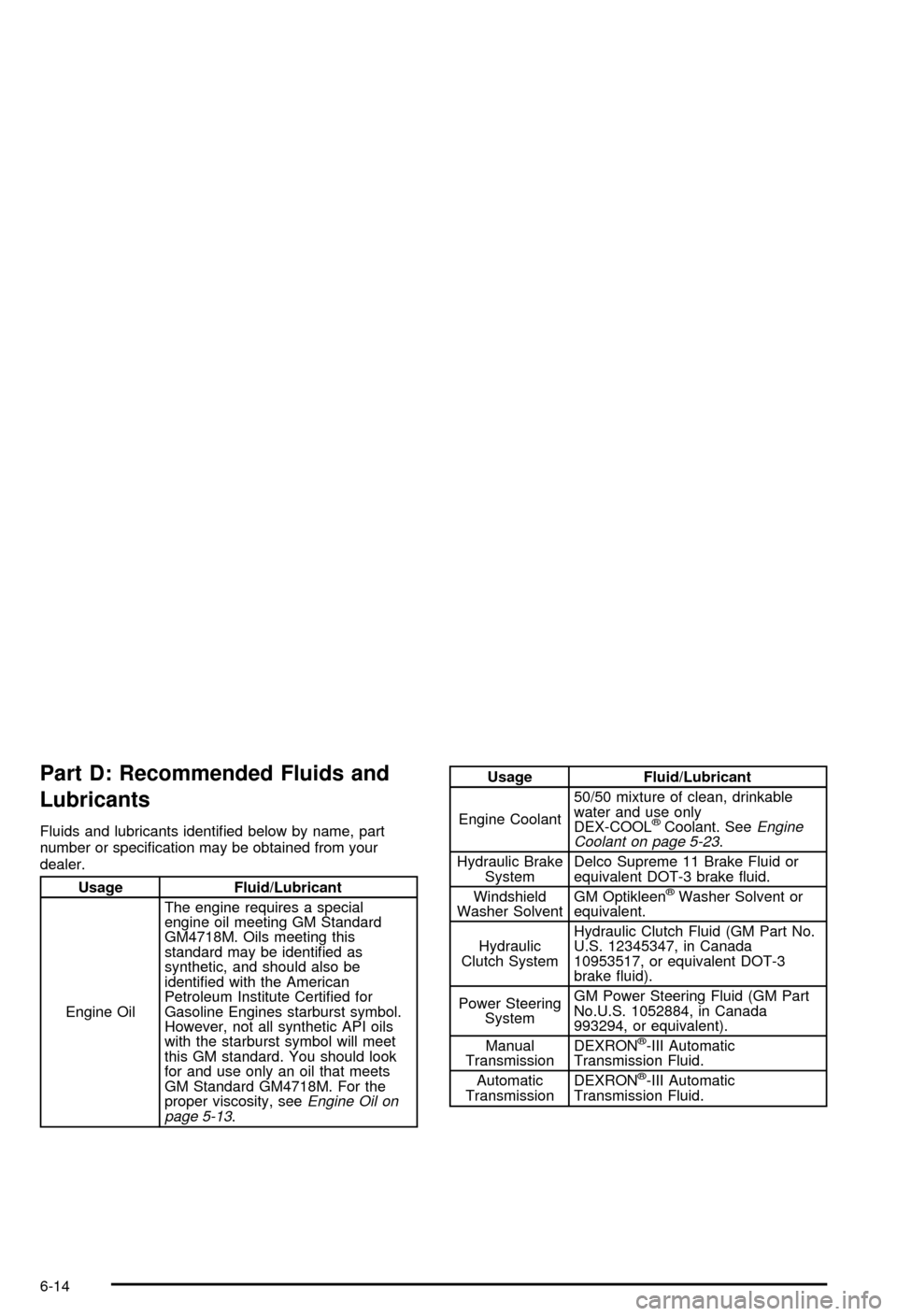

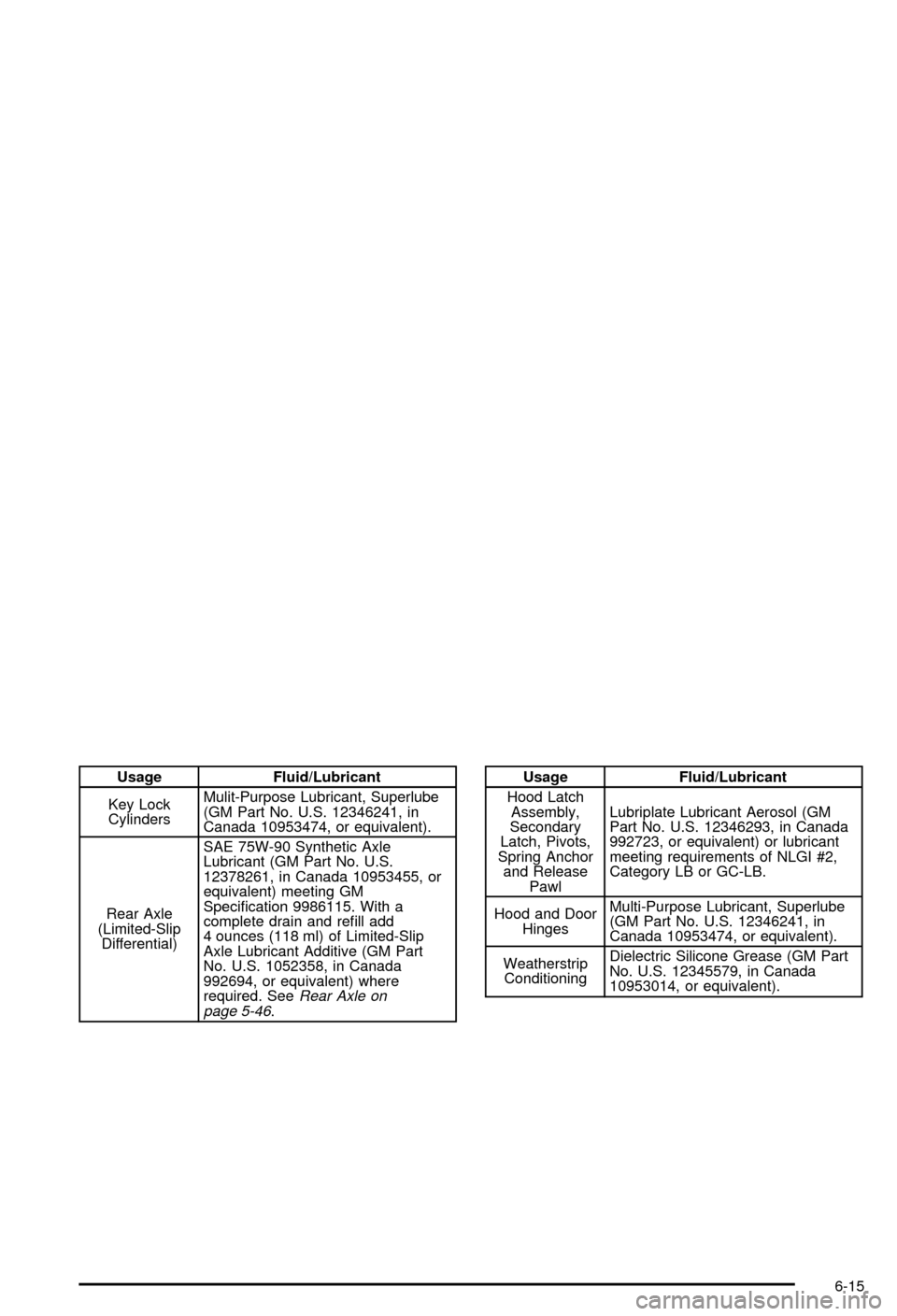

Part D: Recommended Fluids and

Lubricants

Fluids and lubricants identi®ed below by name, part

number or speci®cation may be obtained from your

dealer.

Usage Fluid/Lubricant

Engine OilThe engine requires a special

engine oil meeting GM Standard

GM4718M. Oils meeting this

standard may be identi®ed as

synthetic, and should also be

identi®ed with the American

Petroleum Institute Certi®ed for

Gasoline Engines starburst symbol.

However, not all synthetic API oils

with the starburst symbol will meet

this GM standard. You should look

for and use only an oil that meets

GM Standard GM4718M. For the

proper viscosity, see

Engine Oil on

page 5-13.

Usage Fluid/Lubricant

Engine Coolant50/50 mixture of clean, drinkable

water and use only

DEX-COOL

žCoolant. SeeEngine

Coolant on page 5-23.

Hydraulic Brake

SystemDelco Supreme 11 Brake Fluid or

equivalent DOT-3 brake ¯uid.

Windshield

Washer SolventGM Optikleen

žWasher Solvent or

equivalent.

Hydraulic

Clutch SystemHydraulic Clutch Fluid (GM Part No.

U.S. 12345347, in Canada

10953517, or equivalent DOT-3

brake ¯uid).

Power Steering

SystemGM Power Steering Fluid (GM Part

No.U.S. 1052884, in Canada

993294, or equivalent).

Manual

TransmissionDEXRON

ž-III Automatic

Transmission Fluid.

Automatic

TransmissionDEXRON

ž-III Automatic

Transmission Fluid.

6-14

Page 339 of 368

Usage Fluid/Lubricant

Key Lock

CylindersMulit-Purpose Lubricant, Superlube

(GM Part No. U.S. 12346241, in

Canada 10953474, or equivalent).

Rear Axle

(Limited-Slip

Differential)SAE 75W-90 Synthetic Axle

Lubricant (GM Part No. U.S.

12378261, in Canada 10953455, or

equivalent) meeting GM

Speci®cation 9986115. With a

complete drain and re®ll add

4 ounces (118 ml) of Limited-Slip

Axle Lubricant Additive (GM Part

No. U.S. 1052358, in Canada

992694, or equivalent) where

required. See

Rear Axle on

page 5-46.

Usage Fluid/Lubricant

Hood Latch

Assembly,

Secondary

Latch, Pivots,

Spring Anchor

and Release

PawlLubriplate Lubricant Aerosol (GM

Part No. U.S. 12346293, in Canada

992723, or equivalent) or lubricant

meeting requirements of NLGI #2,

Category LB or GC-LB.

Hood and Door

HingesMulti-Purpose Lubricant, Superlube

(GM Part No. U.S. 12346241, in

Canada 10953474, or equivalent).

Weatherstrip

ConditioningDielectric Silicone Grease (GM Part

No. U.S. 12345579, in Canada

10953014, or equivalent).

6-15

Page 340 of 368

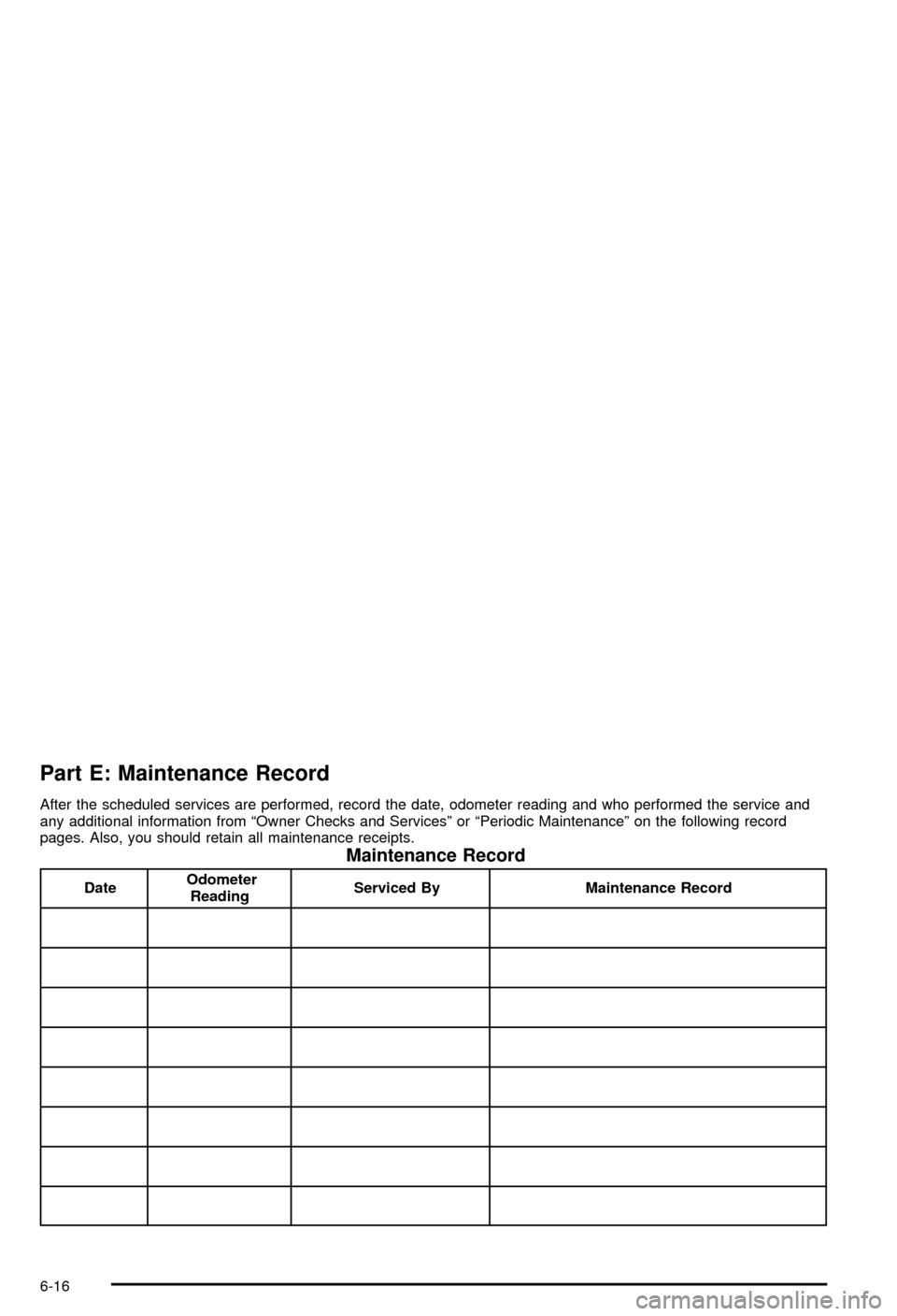

Part E: Maintenance Record

After the scheduled services are performed, record the date, odometer reading and who performed the service and

any additional information from ªOwner Checks and Servicesº or ªPeriodic Maintenanceº on the following record

pages. Also, you should retain all maintenance receipts.

Maintenance Record

DateOdometer

ReadingServiced By Maintenance Record

6-16