service CHEVROLET CORVETTE 2009 6.G Manual PDF

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2009, Model line: CORVETTE, Model: CHEVROLET CORVETTE 2009 6.GPages: 434, PDF Size: 2.53 MB

Page 318 of 434

Brake Wear (Except ZR1)

This vehicle has disc brakes. Disc brake pads have

built-in wear indicators that make a high-pitched warning

sound when the brake pads are worn and new pads

are needed. The sound can come and go or be heard

all the time the vehicle is moving, except when applying

the brake pedal �rmly.

{CAUTION:

The brake wear warning sound means that soon

the brakes will not work well. That could lead to an

accident. When the brake wear warning sound is

heard, have the vehicle serviced.

Notice:Continuing to drive with worn-out brake

pads could result in costly brake repair.

Some driving conditions or climates can cause a brake

squeal when the brakes are �rst applied or lightly applied.

This does not mean something is wrong with the brakes.

Brake linings should always be replaced as complete

axle sets.

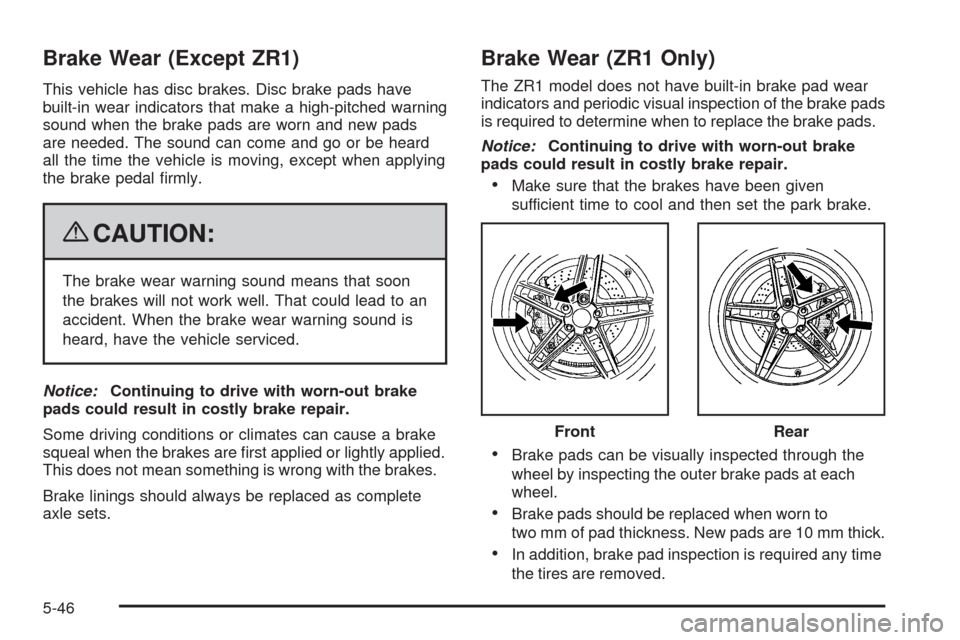

Brake Wear (ZR1 Only)

The ZR1 model does not have built-in brake pad wear

indicators and periodic visual inspection of the brake pads

is required to determine when to replace the brake pads.

Notice:Continuing to drive with worn-out brake

pads could result in costly brake repair.

Make sure that the brakes have been given

sufficient time to cool and then set the park brake.

Brake pads can be visually inspected through the

wheel by inspecting the outer brake pads at each

wheel.

Brake pads should be replaced when worn to

two mm of pad thickness. New pads are 10 mm thick.

In addition, brake pad inspection is required any time

the tires are removed.Front

Rear

5-46

Page 319 of 434

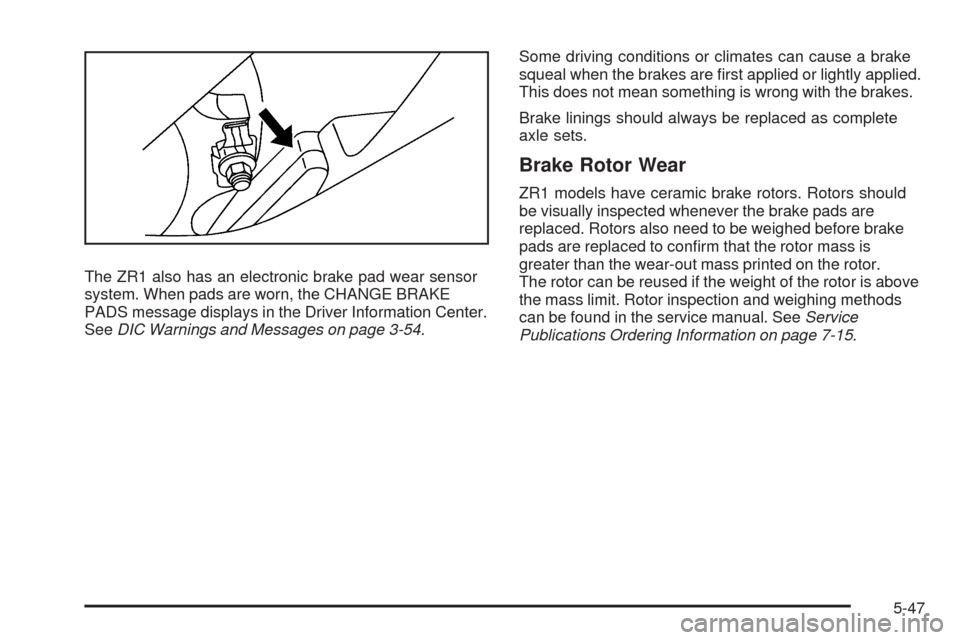

The ZR1 also has an electronic brake pad wear sensor

system. When pads are worn, the CHANGE BRAKE

PADS message displays in the Driver Information Center.

SeeDIC Warnings and Messages on page 3-54.Some driving conditions or climates can cause a brake

squeal when the brakes are �rst applied or lightly applied.

This does not mean something is wrong with the brakes.

Brake linings should always be replaced as complete

axle sets.

Brake Rotor Wear

ZR1 models have ceramic brake rotors. Rotors should

be visually inspected whenever the brake pads are

replaced. Rotors also need to be weighed before brake

pads are replaced to con�rm that the rotor mass is

greater than the wear-out mass printed on the rotor.

The rotor can be reused if the weight of the rotor is above

the mass limit. Rotor inspection and weighing methods

can be found in the service manual. SeeService

Publications Ordering Information on page 7-15.

5-47

Page 321 of 434

A rotor protector should always be installed before any

wheel removal. The protector can be installed by feeding

it through the wheel spokes and slipping it over the outer

edge of the rotor. Leave the protector in place, over the

rotor edge, until the wheel is re-installed. Rotor protectors

are available through your dealer/retailer.

Brake Pedal Travel

See your dealer/retailer if the brake pedal does not

return to normal height, or if there is a rapid increase

in pedal travel. This could be a sign that brake service

might be required.

Brake Adjustment

Every brake stop, the disc brakes automatically adjust

for wear.

Replacing Brake System Parts

The braking system on a vehicle is complex. Its many

parts have to be of top quality and work well together if

the vehicle is to have really good braking. The vehicle

was designed and tested with top-quality brake parts.

When parts of the braking system are replaced — for

example, when the brake linings wear down and new

ones are installed — be sure to get new approved

replacement parts. If this is not done, the brakes might

not work properly. For example, if someone puts in

brake linings that are wrong for the vehicle, the balance

between the front and rear brakes can change — for the

worse. The braking performance expected can change in

many other ways if the wrong replacement brake parts

are installed.

5-49

Page 322 of 434

Battery

This vehicle has a maintenance free battery. When it is

time for a new battery, see your dealer/retailer for one

that has the replacement number shown on the original

battery’s label.

For battery replacement, see your dealer/retailer or the

service manual. To purchase a service manual, see

Service Publications Ordering Information on page 7-15.

Warning:Battery posts, terminals, and related

accessories contain lead and lead compounds,

chemicals known to the State of California to cause

cancer and reproductive harm. Wash hands after

handling.

Vehicle Storage

{CAUTION:

Batteries have acid that can burn you and gas that

can explode. You can be badly hurt if you are not

careful. SeeJump Starting on page 5-51for tips

on working around a battery without getting hurt.

Infrequent Usage: If the vehicle is driven infrequently,

remove the black, negative (−) cable from the battery.

This helps keep the battery from running down.

See “Power Window Initialization” inPower Windows on

page 2-17.

Extended Storage: For extended storage of the vehicle,

remove the black, negative (−) cable from the battery or

use a battery trickle charger. This helps maintain the

charge of the battery over an extended period of time.

5-50

Page 326 of 434

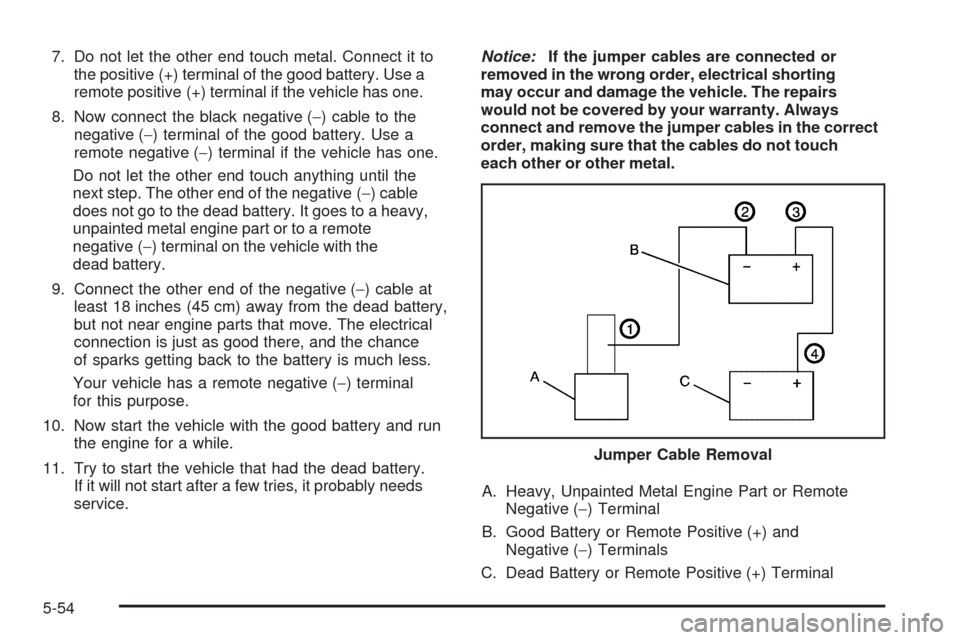

7. Do not let the other end touch metal. Connect it to

the positive (+) terminal of the good battery. Use a

remote positive (+) terminal if the vehicle has one.

8. Now connect the black negative (−) cable to the

negative (−) terminal of the good battery. Use a

remote negative (−) terminal if the vehicle has one.

Do not let the other end touch anything until the

next step. The other end of the negative (−) cable

does not go to the dead battery. It goes to a heavy,

unpainted metal engine part or to a remote

negative (−) terminal on the vehicle with the

dead battery.

9. Connect the other end of the negative (−) cable at

least 18 inches (45 cm) away from the dead battery,

but not near engine parts that move. The electrical

connection is just as good there, and the chance

of sparks getting back to the battery is much less.

Your vehicle has a remote negative (−) terminal

for this purpose.

10. Now start the vehicle with the good battery and run

the engine for a while.

11. Try to start the vehicle that had the dead battery.

If it will not start after a few tries, it probably needs

service.Notice:If the jumper cables are connected or

removed in the wrong order, electrical shorting

may occur and damage the vehicle. The repairs

would not be covered by your warranty. Always

connect and remove the jumper cables in the correct

order, making sure that the cables do not touch

each other or other metal.

A. Heavy, Unpainted Metal Engine Part or Remote

Negative (−) Terminal

B. Good Battery or Remote Positive (+) and

Negative (−) Terminals

C. Dead Battery or Remote Positive (+) TerminalJumper Cable Removal

5-54

Page 328 of 434

What to Use

To add lubricant when the level is low, use Dexron

LS Gear Oil 75W-90 (GM Part No. US. 88862624, in

Canada 88862625) meeting GM Speci�cation 9986290.

To completely re�ll after draining, seeRecommended

Fluids and Lubricants on page 6-12. Then �ll to the

bottom of the �ller plug hole with the Synthetic Gear

Lubricant.

Headlamp Aiming

Headlamp aim has been preset at the factory and

should need no further adjustment.

However, if your vehicle is damaged in a crash, the

headlamp aim may be affected. Aim adjustment to the

low-beam headlamps may be necessary if oncoming

drivers �ash their high-beam headlamps at you

(for vertical aim).

If the headlamps need to be re-aimed, it is

recommended that you take the vehicle to your

dealer/retailer for service.

Bulb Replacement

For the proper type of replacement bulbs,

seeReplacement Bulbs on page 5-59.

For any bulb changing procedure not listed in

this section, contact your dealer/retailer.

High Intensity Discharge (HID)

Lighting

{CAUTION:

The low beam high intensity discharge lighting

system operates at a very high voltage. If you try to

service any of the system components, you could

be seriously injured. Have your dealer/retailer or a

quali�ed technician service them.

The vehicle may have HID headlamps. After an

HID headlamp bulb has been replaced, you may

notice that the beam is a slightly different shade

than it was originally. This is normal.

5-56

Page 334 of 434

Tires

Your new vehicle comes with high-quality tires

made by a leading tire manufacturer. If you ever

have questions about your tire warranty and where

to obtain service, see your vehicle Warranty booklet

for details. For additional information refer to the tire

manufacturer.

{CAUTION:

Poorly maintained and improperly used

tires are dangerous.

Overloading your tires can cause

overheating as a result of too much

�exing. You could have an air-out and

a serious accident. SeeLoading the

Vehicle on page 4-22.

CAUTION: (Continued)

CAUTION: (Continued)

Underin�ated tires pose the same danger

as overloaded tires. The resulting accident

could cause serious injury. Check all tires

frequently to maintain the recommended

pressure. Tire pressure should be

checked when your tires are cold. See

Inflation - Tire Pressure on page 5-70.

Overin�ated tires are more likely to

be cut, punctured, or broken by a sudden

impact — such as when you hit a pothole.

Keep tires at the recommended pressure.

Worn, old tires can cause accidents.

If your tread is badly worn, or if your tires

have been damaged, replace them.

SeeHigh-Speed Operation on page 5-72for

in�ation pressure adjustment for high speed

driving.

5-62

Page 336 of 434

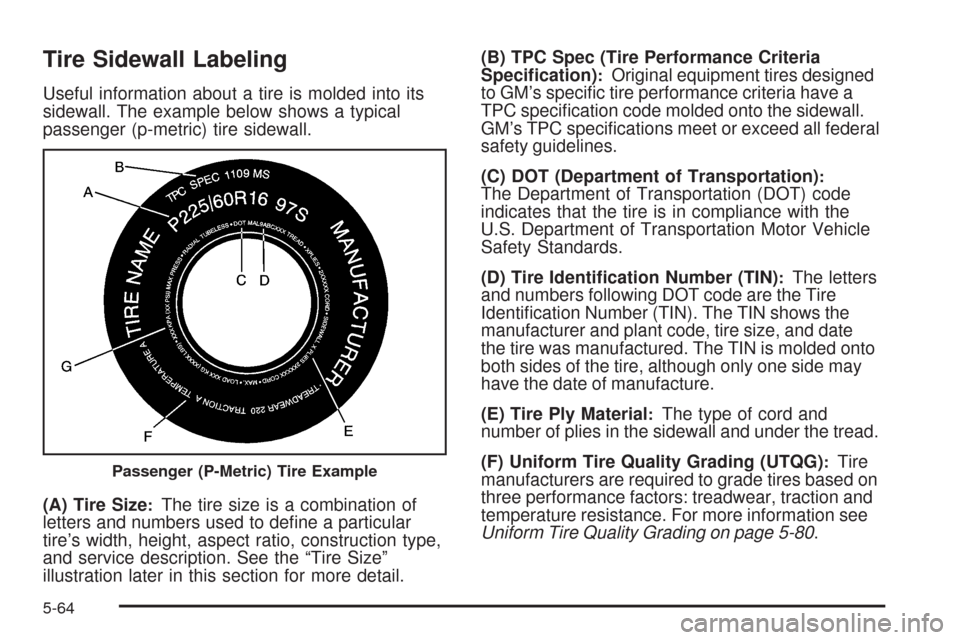

Tire Sidewall Labeling

Useful information about a tire is molded into its

sidewall. The example below shows a typical

passenger (p-metric) tire sidewall.

(A) Tire Size

:The tire size is a combination of

letters and numbers used to de�ne a particular

tire’s width, height, aspect ratio, construction type,

and service description. See the “Tire Size”

illustration later in this section for more detail.(B) TPC Spec (Tire Performance Criteria

Speci�cation)

:Original equipment tires designed

to GM’s speci�c tire performance criteria have a

TPC speci�cation code molded onto the sidewall.

GM’s TPC speci�cations meet or exceed all federal

safety guidelines.

(C) DOT (Department of Transportation)

:The Department of Transportation (DOT) code

indicates that the tire is in compliance with the

U.S. Department of Transportation Motor Vehicle

Safety Standards.

(D) Tire Identi�cation Number (TIN)

:The letters

and numbers following DOT code are the Tire

Identi�cation Number (TIN). The TIN shows the

manufacturer and plant code, tire size, and date

the tire was manufactured. The TIN is molded onto

both sides of the tire, although only one side may

have the date of manufacture.

(E) Tire Ply Material

:The type of cord and

number of plies in the sidewall and under the tread.

(F) Uniform Tire Quality Grading (UTQG)

:Tire

manufacturers are required to grade tires based on

three performance factors: treadwear, traction and

temperature resistance. For more information see

Uniform Tire Quality Grading on page 5-80.Passenger (P-Metric) Tire Example

5-64

Page 337 of 434

(G) Maximum Cold In�ation Load Limit:Maximum load that can be carried and the

maximum pressure needed to support that load.

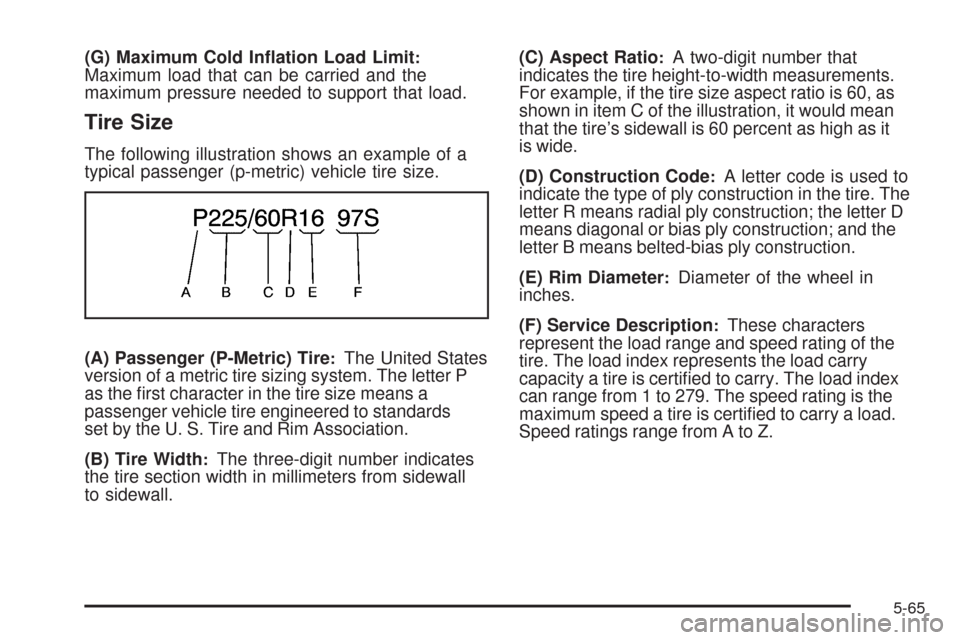

Tire Size

The following illustration shows an example of a

typical passenger (p-metric) vehicle tire size.

(A) Passenger (P-Metric) Tire

:The United States

version of a metric tire sizing system. The letter P

as the �rst character in the tire size means a

passenger vehicle tire engineered to standards

set by the U. S. Tire and Rim Association.

(B) Tire Width

:The three-digit number indicates

the tire section width in millimeters from sidewall

to sidewall.(C) Aspect Ratio

:A two-digit number that

indicates the tire height-to-width measurements.

For example, if the tire size aspect ratio is 60, as

shown in item C of the illustration, it would mean

that the tire’s sidewall is 60 percent as high as it

is wide.

(D) Construction Code

:A letter code is used to

indicate the type of ply construction in the tire. The

letter R means radial ply construction; the letter D

means diagonal or bias ply construction; and the

letter B means belted-bias ply construction.

(E) Rim Diameter

:Diameter of the wheel in

inches.

(F) Service Description

:These characters

represent the load range and speed rating of the

tire. The load index represents the load carry

capacity a tire is certi�ed to carry. The load index

can range from 1 to 279. The speed rating is the

maximum speed a tire is certi�ed to carry a load.

Speed ratings range from A to Z.

5-65

Page 341 of 434

Run-Flat Tires

This vehicle, when new, had run-�at tires. There is no

spare tire, no tire changing equipment, and no place

to store a tire in the vehicle. Run-�at tires perform

so well without any air that a Tire Pressure Monitor

System (TPMS) is used to alert you if a tire has

lost pressure.

{CAUTION:

When the low tire warning light is displayed on

the instrument panel cluster, your vehicle’s handling

capabilities will be reduced during severe

maneuvers. If you drive too fast, you could lose

control of your vehicle. You or others could be

injured. Do not drive over 55 mph (90 km/h)

when the low tire warning light is displayed.

Drive cautiously and check your tire pressures

as soon as you can.

If a tire goes �at, you will not need to stop on the side of

the road to change the tire. You can just keep on driving.

The shorter the distance you drive and the slower thespeed, the greater the chance that the tire will not have

to be replaced. If you drive on a de�ated run-�at tire

for 25 miles (40 km) or less and at speeds of 55 mph

(90 km/h) or less, there is a good chance that the tire

can be repaired. The tires on coupe, convertible and

Z06 models can operate effectively with no air pressure

for up to 100 miles (160 km) at speeds up to 55 mph

(90 km/h), but the tire would then have to be replaced.

The tires on ZR1 models can operate effectively with no

air pressure for up to 50 miles (80 km) at speeds up to

55 mph (90 km/h), but the tire would then have to be

replaced. When a tire is �lled with air, it provides a

cushion between the road and the wheel. Because you

will not have this cushion when driving on a de�ated tire,

try to avoid potholes that could damage your wheel and

require replacement of it.

Some road hazards can damage a tire beyond repair.

This damage could occur even before you have driven

on the tire in a de�ated condition. When a tire has

been damaged, or if you have driven any distance

on a run-�at tire, check with an authorized run-�at tire

service center to determine whether the tire can be

repaired or should be replaced. To maintain your

vehicle’s run-�at feature, all replacement tires must

be self-supporting tires. As soon as possible, contact

the nearest authorized GM or run-�at servicing

facility for inspection and repair or replacement.

5-69