light CHEVROLET DYNASTY 1993 Owners Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 474 of 2438

The coil's low primary resistance allows the PCM to

fully charge the coil for each firing.

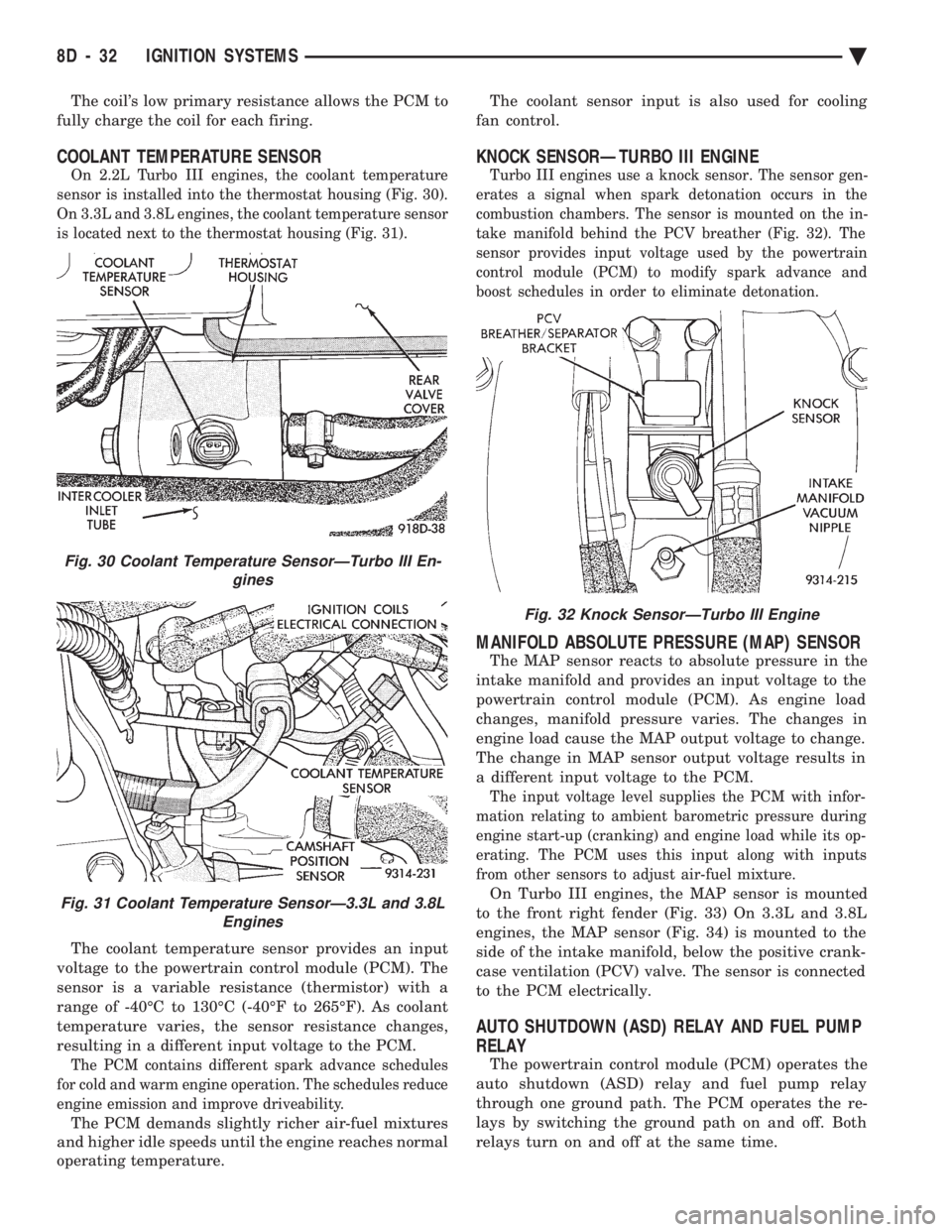

COOLANT TEMPERATURE SENSOR

On 2.2L Turbo III engines, the coolant temperature

sensor is installed into the thermostat housing (Fig. 30).

On 3.3L and 3.8L engines, the coolant temperature sensor

is located next to the thermostat housing (Fig. 31).

The coolant temperature sensor provides an input

voltage to the powertrain control module (PCM). The

sensor is a variable resistance (thermistor) with a

range of -40ÉC to 130ÉC (-40ÉF to 265ÉF). As coolant

temperature varies, the sensor resistance changes,

resulting in a different input voltage to the PCM.

The PCM contains different spark advance schedules

for cold and warm engine operation. The schedules reduce

engine emission and improve driveability.

The PCM demands slightly richer air-fuel mixtures

and higher idle speeds until the engine reaches normal

operating temperature. The coolant sensor input is also used for cooling

fan control.

KNOCK SENSORÐTURBO III ENGINE

Turbo III engines use a knock sensor. The sensor gen-

erates a signal when spark detonation occurs in the

combustion chambers. The sensor is mounted on the in-

take manifold behind the PCV breather (Fig. 32). The

sensor provides input voltage used by the powertrain

control module (PCM) to modify spark advance and

boost schedules in order to eliminate detonation.

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

The MAP sensor reacts to absolute pressure in the

intake manifold and provides an input voltage to the

powertrain control module (PCM). As engine load

changes, manifold pressure varies. The changes in

engine load cause the MAP output voltage to change.

The change in MAP sensor output voltage results in

a different input voltage to the PCM.

The input voltage level supplies the PCM with infor-

mation relating to ambient barometric pressure during

engine start-up (cranking) and engine load while its op-

erating. The PCM uses this input along with inputs

from other sensors to adjust air-fuel mixture.

On Turbo III engines, the MAP sensor is mounted

to the front right fender (Fig. 33) On 3.3L and 3.8L

engines, the MAP sensor (Fig. 34) is mounted to the

side of the intake manifold, below the positive crank-

case ventilation (PCV) valve. The sensor is connected

to the PCM electrically.

AUTO SHUTDOWN (ASD) RELAY AND FUEL PUMP

RELAY

The powertrain control module (PCM) operates the

auto shutdown (ASD) relay and fuel pump relay

through one ground path. The PCM operates the re-

lays by switching the ground path on and off. Both

relays turn on and off at the same time.

Fig. 32 Knock SensorÐTurbo III Engine

Fig. 30 Coolant Temperature SensorÐTurbo III En- gines

Fig. 31 Coolant Temperature SensorÐ3.3L and 3.8LEngines

8D - 32 IGNITION SYSTEMS Ä

Page 479 of 2438

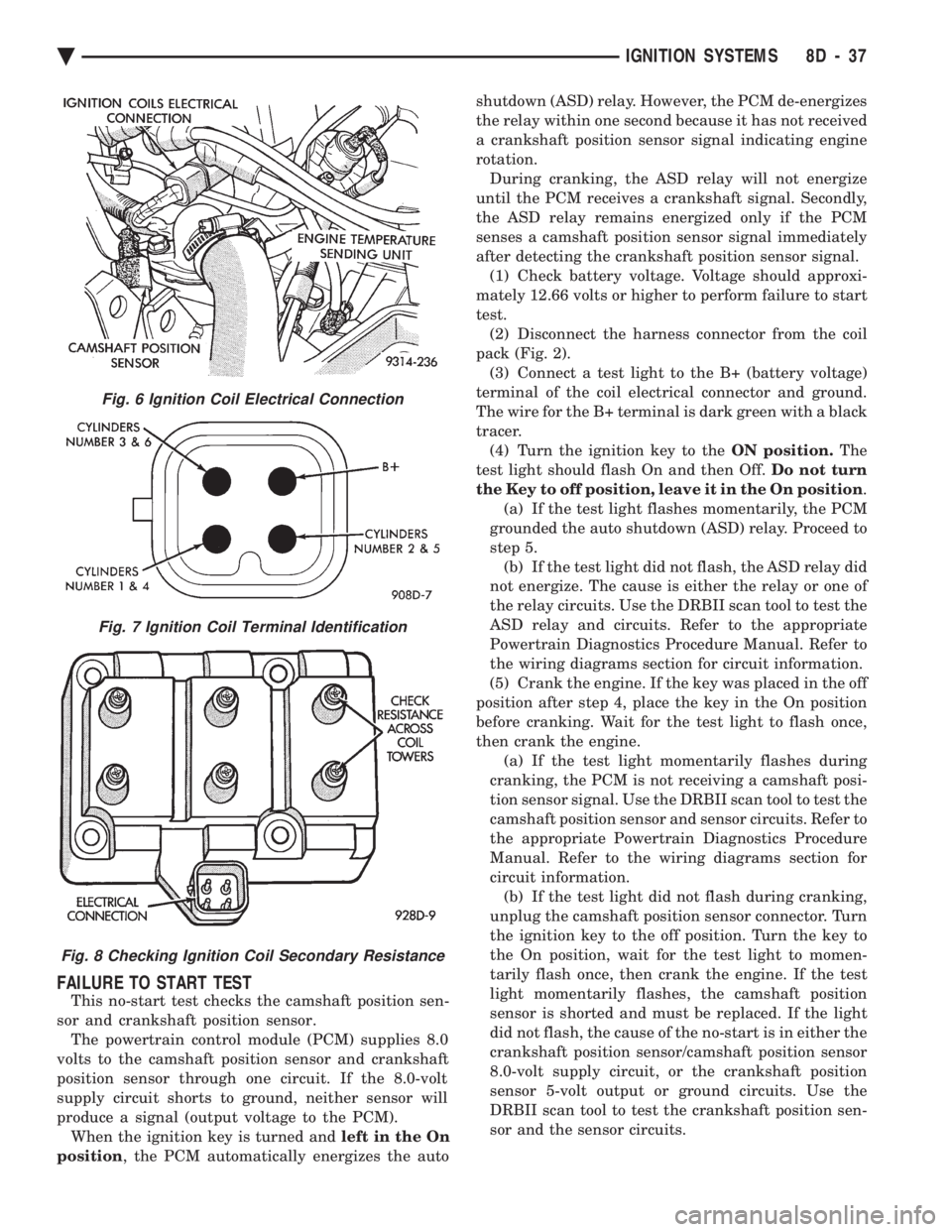

FAILURE TO START TEST

This no-start test checks the camshaft position sen-

sor and crankshaft position sensor. The powertrain control module (PCM) supplies 8.0

volts to the camshaft position sensor and crankshaft

position sensor through one circuit. If the 8.0-volt

supply circuit shorts to ground, neither sensor will

produce a signal (output voltage to the PCM). When the ignition key is turned and left in the On

position , the PCM automatically energizes the auto shutdown (ASD) relay. However, the PCM de-energizes

the relay within one second because it has not received

a crankshaft position sensor signal indicating engine

rotation.

During cranking, the ASD relay will not energize

until the PCM receives a crankshaft signal. Secondly,

the ASD relay remains energized only if the PCM

senses a camshaft position sensor signal immediately

after detecting the crankshaft position sensor signal. (1) Check battery voltage. Voltage should approxi-

mately 12.66 volts or higher to perform failure to start

test. (2) Disconnect the harness connector from the coil

pack (Fig. 2). (3) Connect a test light to the B+ (battery voltage)

terminal of the coil electrical connector and ground.

The wire for the B+ terminal is dark green with a black

tracer. (4) Turn the ignition key to the ON position.The

test light should flash On and then Off. Do not turn

the Key to off position, leave it in the On position .

(a) If the test light flashes momentarily, the PCM

grounded the auto shutdown (ASD) relay. Proceed to

step 5. (b) If the test light did not flash, the ASD relay did

not energize. The cause is either the relay or one of

the relay circuits. Use the DRBII scan tool to test the

ASD relay and circuits. Refer to the appropriate

Powertrain Diagnostics Procedure Manual. Refer to

the wiring diagrams section for circuit information.

(5) Crank the engine. If the key was placed in the off

position after step 4, place the key in the On position

before cranking. Wait for the test light to flash once,

then crank the engine. (a) If the test light momentarily flashes during

cranking, the PCM is not receiving a camshaft posi-

tion sensor signal. Use the DRBII scan tool to test the

camshaft position sensor and sensor circuits. Refer to

the appropriate Powertrain Diagnostics Procedure

Manual. Refer to the wiring diagrams section for

circuit information. (b) If the test light did not flash during cranking,

unplug the camshaft position sensor connector. Turn

the ignition key to the off position. Turn the key to

the On position, wait for the test light to momen-

tarily flash once, then crank the engine. If the test

light momentarily flashes, the camshaft position

sensor is shorted and must be replaced. If the light

did not flash, the cause of the no-start is in either the

crankshaft position sensor/camshaft position sensor

8.0-volt supply circuit, or the crankshaft position

sensor 5-volt output or ground circuits. Use the

DRBII scan tool to test the crankshaft position sen-

sor and the sensor circuits.

Fig. 6 Ignition Coil Electrical Connection

Fig. 7 Ignition Coil Terminal Identification

Fig. 8 Checking Ignition Coil Secondary Resistance

Ä IGNITION SYSTEMS 8D - 37

Page 483 of 2438

(2) With engine running, move test probe along

entire length of all cables (approximately 0 to 1/8

inch gap). If punctures or cracks are present there

will be a noticeable spark jump from the faulty area

to the probe. Cracked, leaking or faulty cables should

be replaced. Use the following procedure when removing the

high tension cable from the spark plug. First, remove

the cable from the retaining bracket. Then grasp the

terminal as close as possible to the spark plug. Ro-

tate the cover (boot) slightly and pull straight back.

Do not use pliers and do not pull the cable at an

angle. Doing so will damage the insulation, cable

terminal or the spark plug insulator. Wipe spark

plug insulator clean before reinstalling cable

and cover. Resistance cables are identified by the words Elec-

tronic Suppression .

Use an ohmmeter to check cables for opens, loose

terminals or high resistance. (a) Remove cable from spark plug.

(b) Remove cable from the coil tower.

(c) Connect the ohmmeter between spark plug

end terminal and the coil end terminal. Resistance

should be within tolerance shown in the cable re-

sistance chart. If resistance is not within tolerance,

replace cable assembly. Test all spark plug cables

in same manner.

SPARK PLUG SERVICE

When replacing the spark plug cables, route the ca-

bles correctly and secure them in the appropriate re-

tainers. Incorrectly routed cables can cause the radio

to reproduce ignition noise. It can also cause cross ig-

nition of the spark plugs or short circuit the cables to

ground.

SPARK PLUG REMOVAL

Always remove cables by grasping at boot, rotating

the boot 1/2 turn, and pulling straight back in a

steady motion. (1) Prior to removing the spark plug spray com-

pressed air around the spark plug hole and the area

around the spark plug. (2) Remove the spark plug using a quality socket

with a rubber or foam insert. (3) Inspect the spark plug condition. Refer to

Spark Plug Condition in this section.

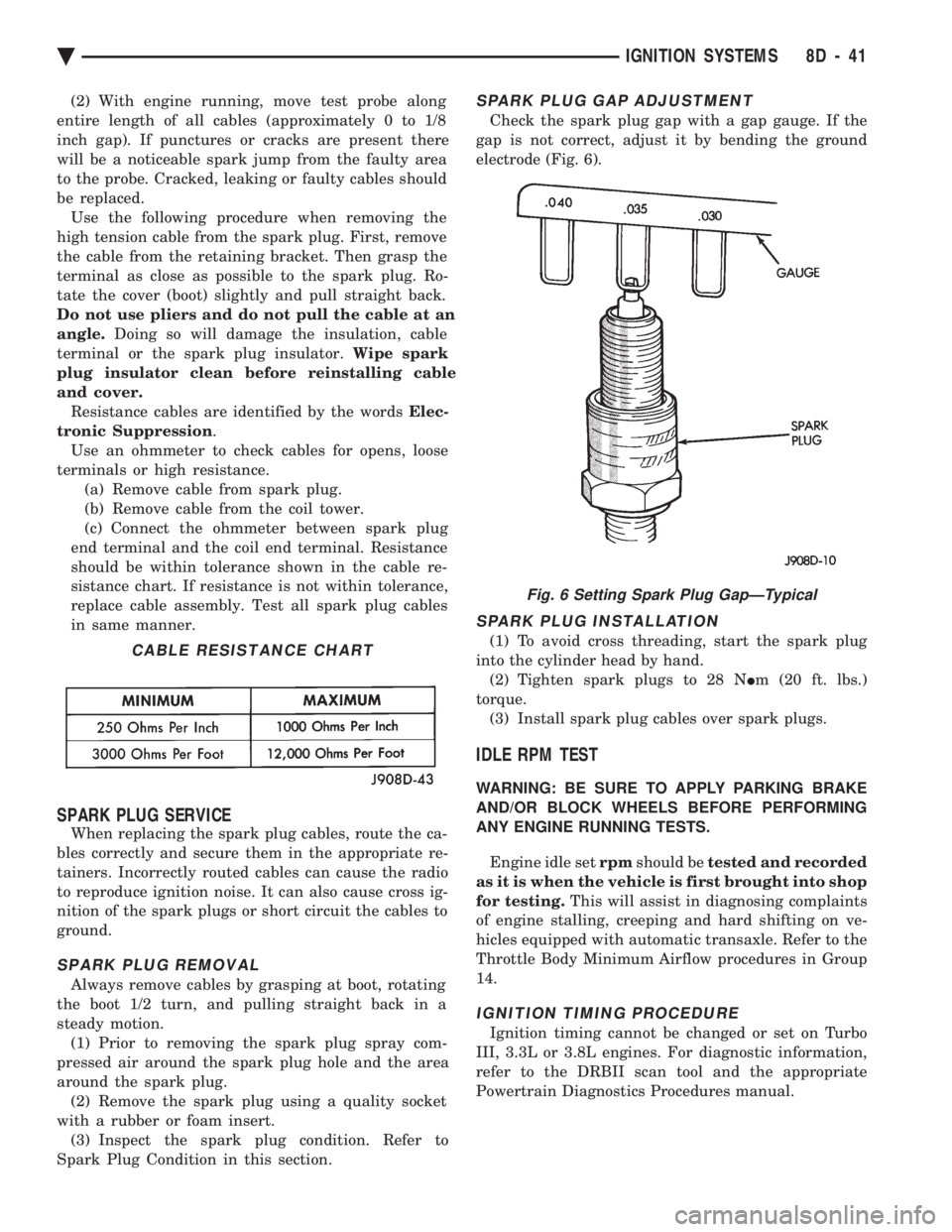

SPARK PLUG GAP ADJUSTMENT

Check the spark plug gap with a gap gauge. If the

gap is not correct, adjust it by bending the ground

electrode (Fig. 6).

SPARK PLUG INSTALLATION

(1) To avoid cross threading, start the spark plug

into the cylinder head by hand. (2) Tighten spark plugs to 28 N Im (20 ft. lbs.)

torque. (3) Install spark plug cables over spark plugs.

IDLE RPM TEST

WARNING: BE SURE TO APPLY PARKING BRAKE

AND/OR BLOCK WHEELS BEFORE PERFORMING

ANY ENGINE RUNNING TESTS.

Engine idle set rpmshould be tested and recorded

as it is when the vehicle is first brought into shop

for testing. This will assist in diagnosing complaints

of engine stalling, creeping and hard shifting on ve-

hicles equipped with automatic transaxle. Refer to the

Throttle Body Minimum Airflow procedures in Group

14.

IGNITION TIMING PROCEDURE

Ignition timing cannot be changed or set on Turbo

III, 3.3L or 3.8L engines. For diagnostic information,

refer to the DRBII scan tool and the appropriate

Powertrain Diagnostics Procedures manual.

CABLE RESISTANCE CHART

Fig. 6 Setting Spark Plug GapÐTypical

Ä IGNITION SYSTEMS 8D - 41

Page 485 of 2438

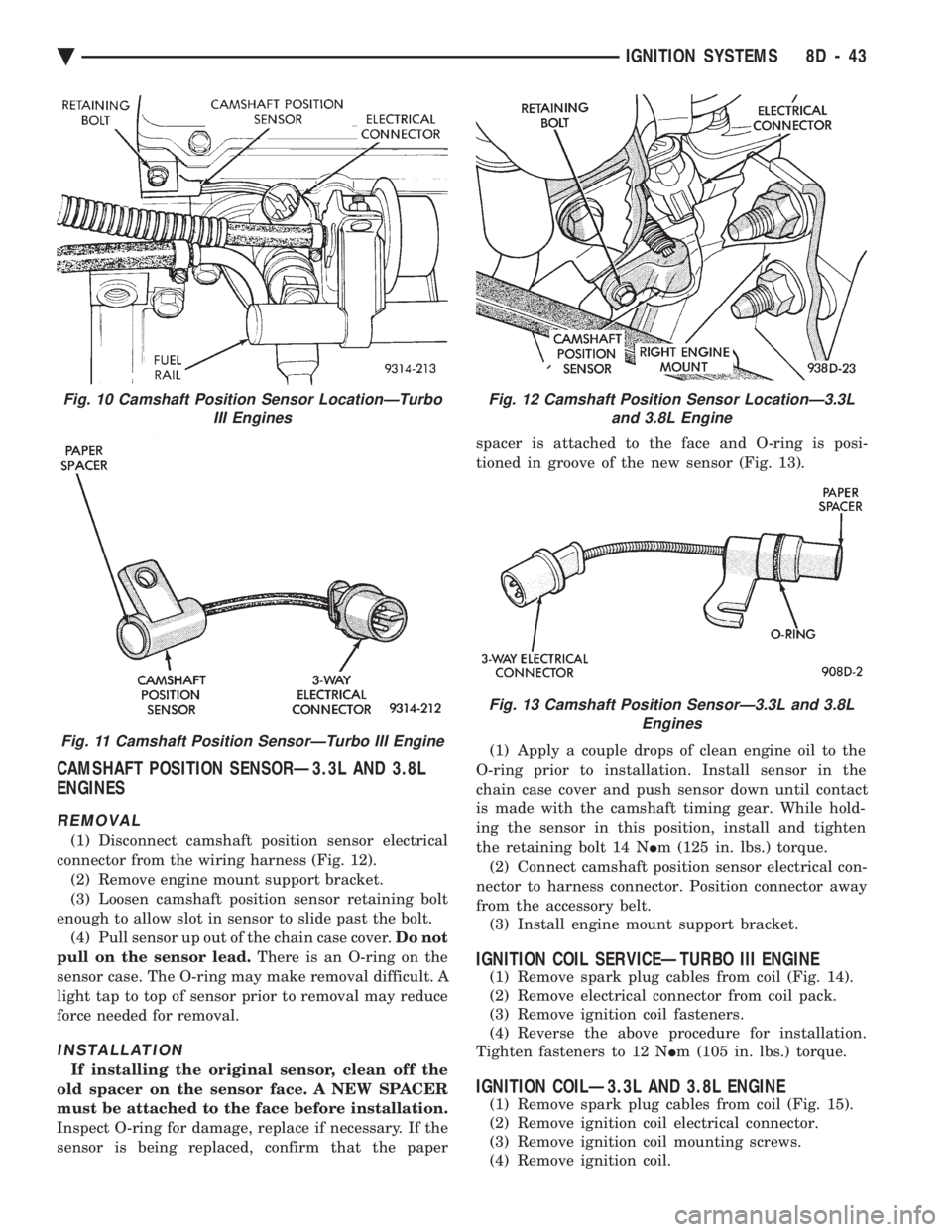

CAMSHAFT POSITION SENSORÐ3.3L AND 3.8L

ENGINES

REMOVAL

(1) Disconnect camshaft position sensor electrical

connector from the wiring harness (Fig. 12). (2) Remove engine mount support bracket.

(3) Loosen camshaft position sensor retaining bolt

enough to allow slot in sensor to slide past the bolt. (4) Pull sensor up out of the chain case cover. Do not

pull on the sensor lead. There is an O-ring on the

sensor case. The O-ring may make removal difficult. A

light tap to top of sensor prior to removal may reduce

force needed for removal.

INSTALLATION

If installing the original sensor, clean off the

old spacer on the sensor face. A NEW SPACER

must be attached to the face before installation.

Inspect O-ring for damage, replace if necessary. If the

sensor is being replaced, confirm that the paper spacer is attached to the face and O-ring is posi-

tioned in groove of the new sensor (Fig. 13).

(1) Apply a couple drops of clean engine oil to the

O-ring prior to installation. Install sensor in the

chain case cover and push sensor down until contact

is made with the camshaft timing gear. While hold-

ing the sensor in this position, install and tighten

the retaining bolt 14 N Im (125 in. lbs.) torque.

(2) Connect camshaft position sensor electrical con-

nector to harness connector. Position connector away

from the accessory belt. (3) Install engine mount support bracket.

IGNITION COIL SERVICEÐTURBO III ENGINE

(1) Remove spark plug cables from coil (Fig. 14).

(2) Remove electrical connector from coil pack.

(3) Remove ignition coil fasteners.

(4) Reverse the above procedure for installation.

Tighten fasteners to 12 N Im (105 in. lbs.) torque.

IGNITION COILÐ3.3L AND 3.8L ENGINE

(1) Remove spark plug cables from coil (Fig. 15).

(2) Remove ignition coil electrical connector.

(3) Remove ignition coil mounting screws.

(4) Remove ignition coil.

Fig. 12 Camshaft Position Sensor LocationÐ3.3L and 3.8L Engine

Fig. 13 Camshaft Position SensorÐ3.3L and 3.8L Engines

Fig. 10 Camshaft Position Sensor LocationÐTurboIII Engines

Fig. 11 Camshaft Position SensorÐTurbo III Engine

Ä IGNITION SYSTEMS 8D - 43

Page 487 of 2438

IGNITION SWITCH

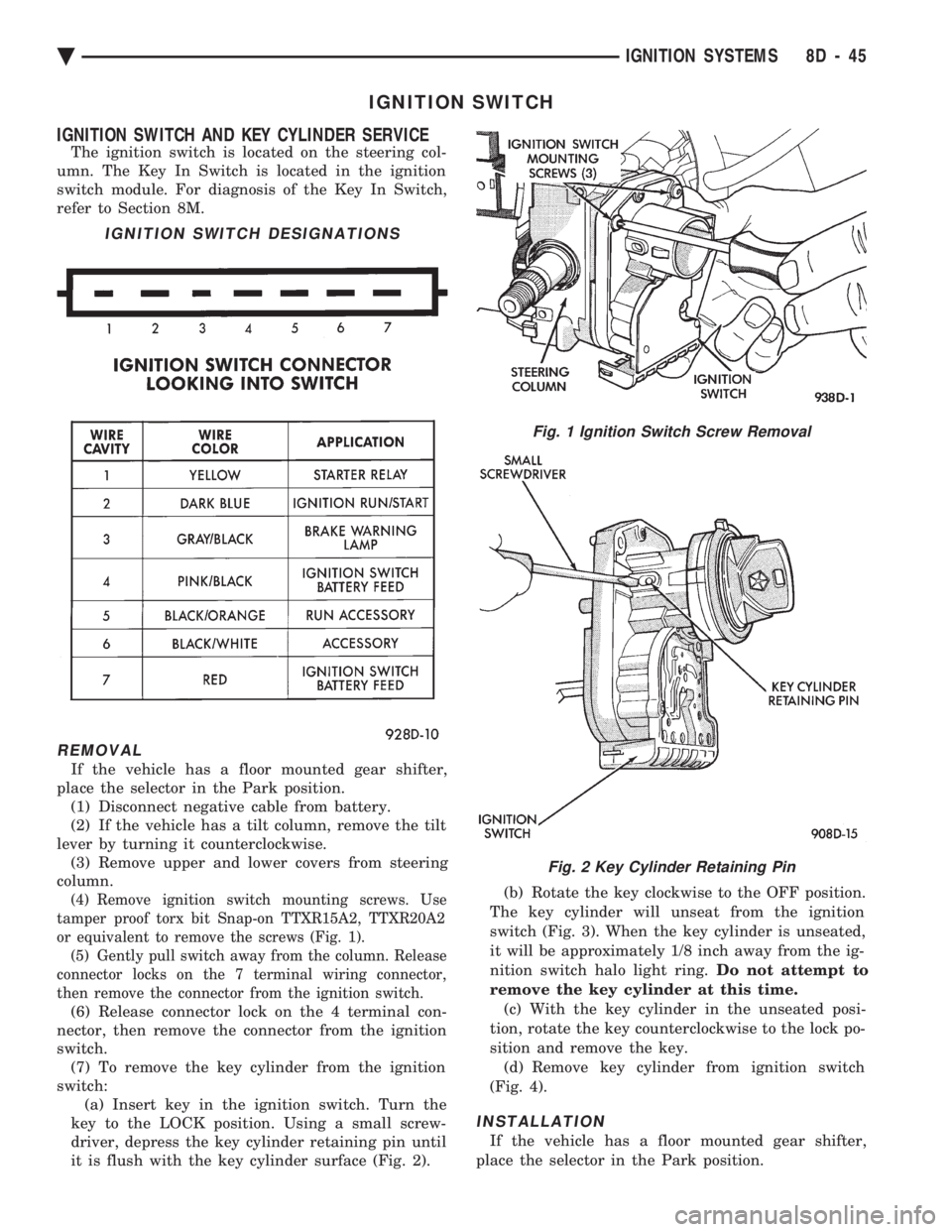

IGNITION SWITCH AND KEY CYLINDER SERVICE

The ignition switch is located on the steering col-

umn. The Key In Switch is located in the ignition

switch module. For diagnosis of the Key In Switch,

refer to Section 8M.

REMOVAL

If the vehicle has a floor mounted gear shifter,

place the selector in the Park position. (1) Disconnect negative cable from battery.

(2) If the vehicle has a tilt column, remove the tilt

lever by turning it counterclockwise. (3) Remove upper and lower covers from steering

column.

(4) Remove ignition switch mounting screws. Use

tamper proof torx bit Snap-on TTXR15A2, TTXR20A2

or equivalent to remove the screws (Fig. 1). (5) Gently pull switch away from the column. Release

connector locks on the 7 terminal wiring connector,

then remove the connector from the ignition switch.

(6) Release connector lock on the 4 terminal con-

nector, then remove the connector from the ignition

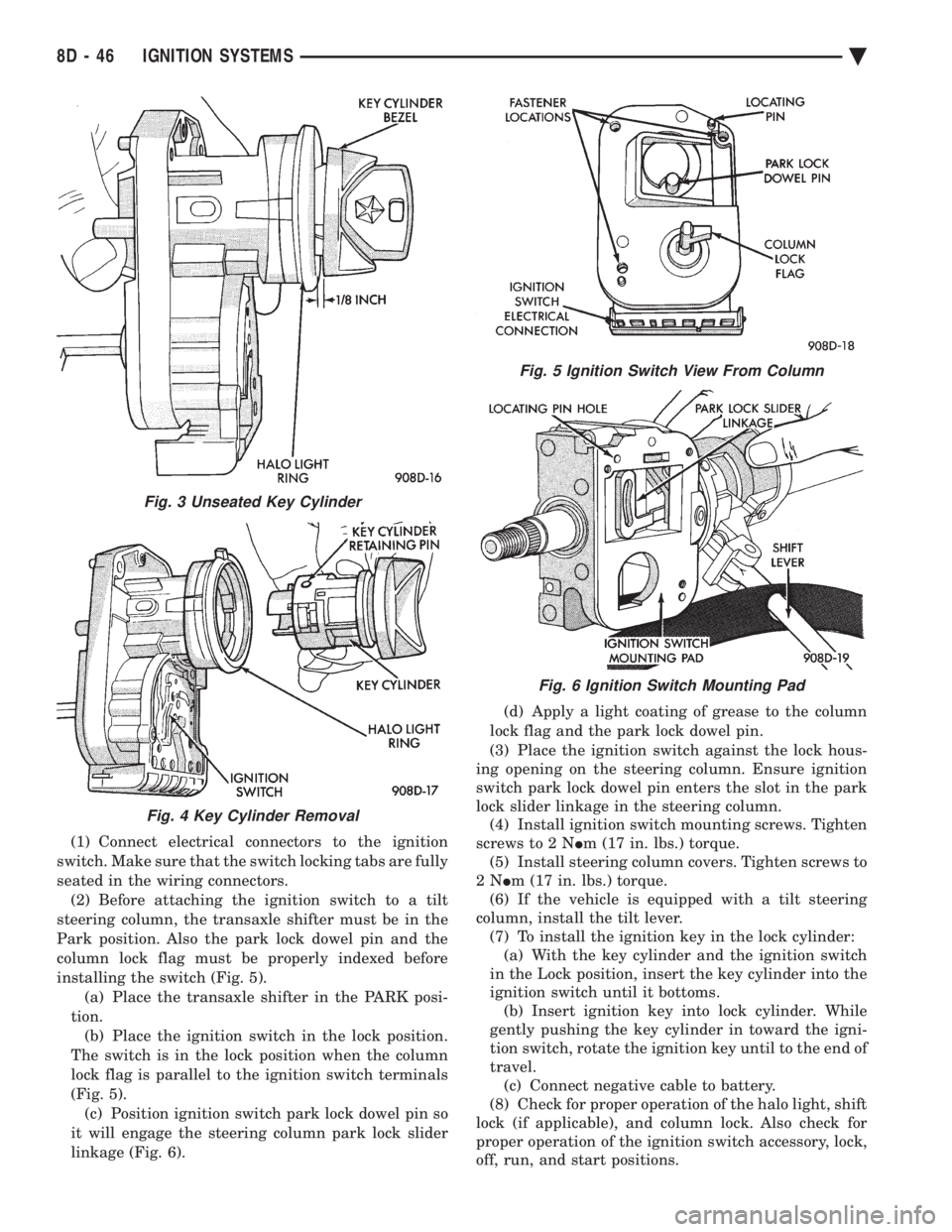

switch. (7) To remove the key cylinder from the ignition

switch: (a) Insert key in the ignition switch. Turn the

key to the LOCK position. Using a small screw-

driver, depress the key cylinder retaining pin until

it is flush with the key cylinder surface (Fig. 2). (b) Rotate the key clockwise to the OFF position.

The key cylinder will unseat from the ignition

switch (Fig. 3). When the key cylinder is unseated,

it will be approximately 1/8 inch away from the ig-

nition switch halo light ring. Do not attempt to

remove the key cylinder at this time. (c) With the key cylinder in the unseated posi-

tion, rotate the key counterclockwise to the lock po-

sition and remove the key. (d) Remove key cylinder from ignition switch

(Fig. 4).

INSTALLATION

If the vehicle has a floor mounted gear shifter,

place the selector in the Park position.

IGNITION SWITCH DESIGNATIONS

Fig. 1 Ignition Switch Screw Removal

Fig. 2 Key Cylinder Retaining Pin

Ä IGNITION SYSTEMS 8D - 45

Page 488 of 2438

(1) Connect electrical connectors to the ignition

switch. Make sure that the switch locking tabs are fully

seated in the wiring connectors. (2) Before attaching the ignition switch to a tilt

steering column, the transaxle shifter must be in the

Park position. Also the park lock dowel pin and the

column lock flag must be properly indexed before

installing the switch (Fig. 5). (a) Place the transaxle shifter in the PARK posi-

tion. (b) Place the ignition switch in the lock position.

The switch is in the lock position when the column

lock flag is parallel to the ignition switch terminals

(Fig. 5). (c) Position ignition switch park lock dowel pin so

it will engage the steering column park lock slider

linkage (Fig. 6). (d) Apply a light coating of grease to the column

lock flag and the park lock dowel pin.

(3) Place the ignition switch against the lock hous-

ing opening on the steering column. Ensure ignition

switch park lock dowel pin enters the slot in the park

lock slider linkage in the steering column. (4) Install ignition switch mounting screws. Tighten

screws to 2 N Im (17 in. lbs.) torque.

(5) Install steering column covers. Tighten screws to

2N Im (17 in. lbs.) torque.

(6) If the vehicle is equipped with a tilt steering

column, install the tilt lever. (7) To install the ignition key in the lock cylinder:(a) With the key cylinder and the ignition switch

in the Lock position, insert the key cylinder into the

ignition switch until it bottoms. (b) Insert ignition key into lock cylinder. While

gently pushing the key cylinder in toward the igni-

tion switch, rotate the ignition key until to the end of

travel. (c) Connect negative cable to battery.

(8) Check for proper operation of the halo light, shift

lock (if applicable), and column lock. Also check for

proper operation of the ignition switch accessory, lock,

off, run, and start positions.

Fig. 3 Unseated Key Cylinder

Fig. 4 Key Cylinder Removal

Fig. 5 Ignition Switch View From Column

Fig. 6 Ignition Switch Mounting Pad

8D - 46 IGNITION SYSTEMS Ä

Page 494 of 2438

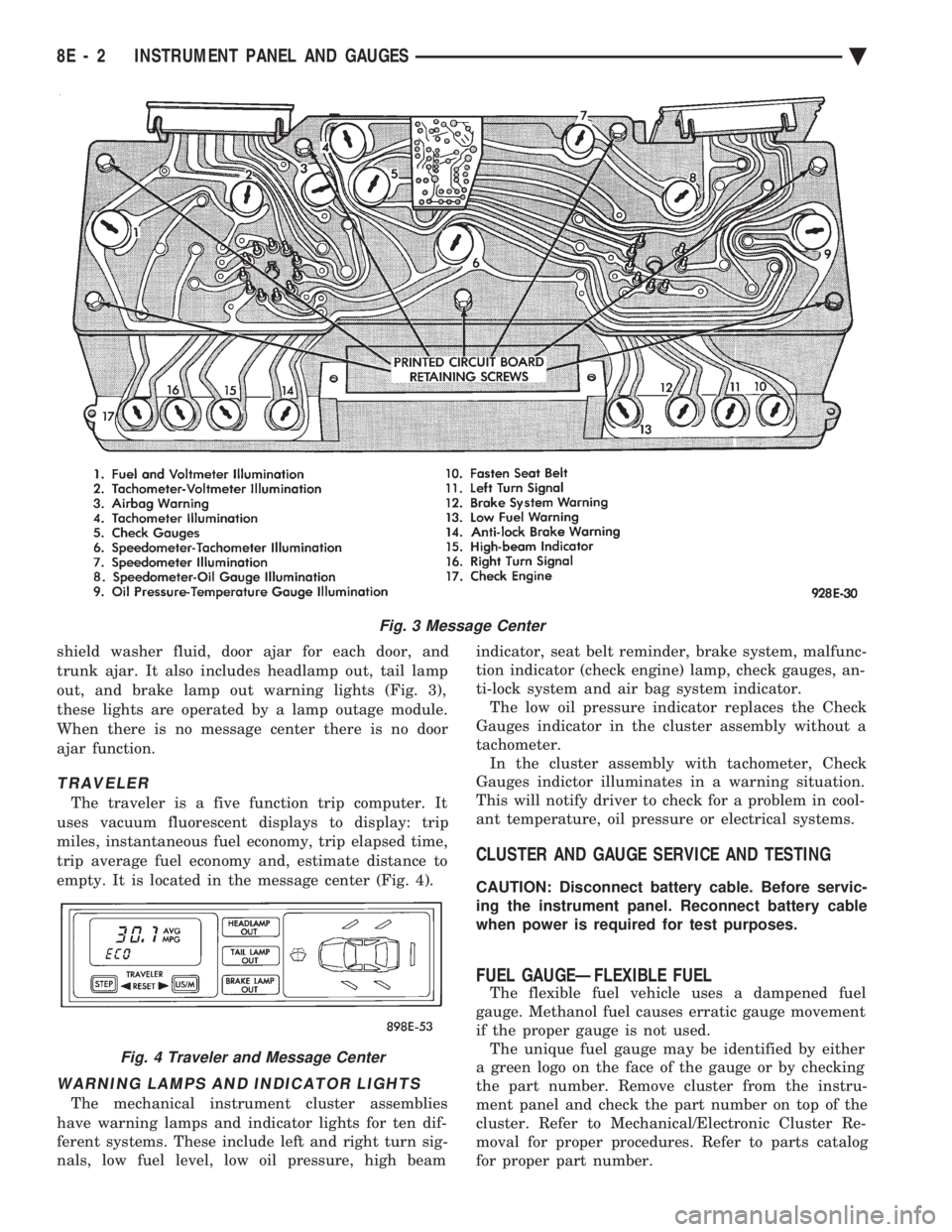

shield washer fluid, door ajar for each door, and

trunk ajar. It also includes headlamp out, tail lamp

out, and brake lamp out warning lights (Fig. 3),

these lights are operated by a lamp outage module.

When there is no message center there is no door

ajar function.

TRAVELER

The traveler is a five function trip computer. It

uses vacuum fluorescent displays to display: trip

miles, instantaneous fuel economy, trip elapsed time,

trip average fuel economy and, estimate distance to

empty. It is located in the message center (Fig. 4).

WARNING LAMPS AND INDICATOR LIGHTS

The mechanical instrument cluster assemblies

have warning lamps and indicator lights for ten dif-

ferent systems. These include left and right turn sig-

nals, low fuel level, low oil pressure, high beam indicator, seat belt reminder, brake system, malfunc-

tion indicator (check engine) lamp, check gauges, an-

ti-lock system and air bag system indicator. The low oil pressure indicator replaces the Check

Gauges indicator in the cluster assembly without a

tachometer. In the cluster assembly with tachometer, Check

Gauges indictor illuminates in a warning situation.

This will notify driver to check for a problem in cool-

ant temperature, oil pressure or electrical systems.

CLUSTER AND GAUGE SERVICE AND TESTING

CAUTION: Disconnect battery cable. Before servic-

ing the instrument panel. Reconnect battery cable

when power is required for test purposes.

FUEL GAUGEÐFLEXIBLE FUEL

The flexible fuel vehicle uses a dampened fuel

gauge. Methanol fuel causes erratic gauge movement

if the proper gauge is not used. The unique fuel gauge may be identified by either

a green logo on the face of the gauge or by checking

the part number. Remove cluster from the instru-

ment panel and check the part number on top of the

cluster. Refer to Mechanical/Electronic Cluster Re-

moval for proper procedures. Refer to parts catalog

for proper part number.

Fig. 3 Message Center

Fig. 4 Traveler and Message Center

8E - 2 INSTRUMENT PANEL AND GAUGES Ä

Page 495 of 2438

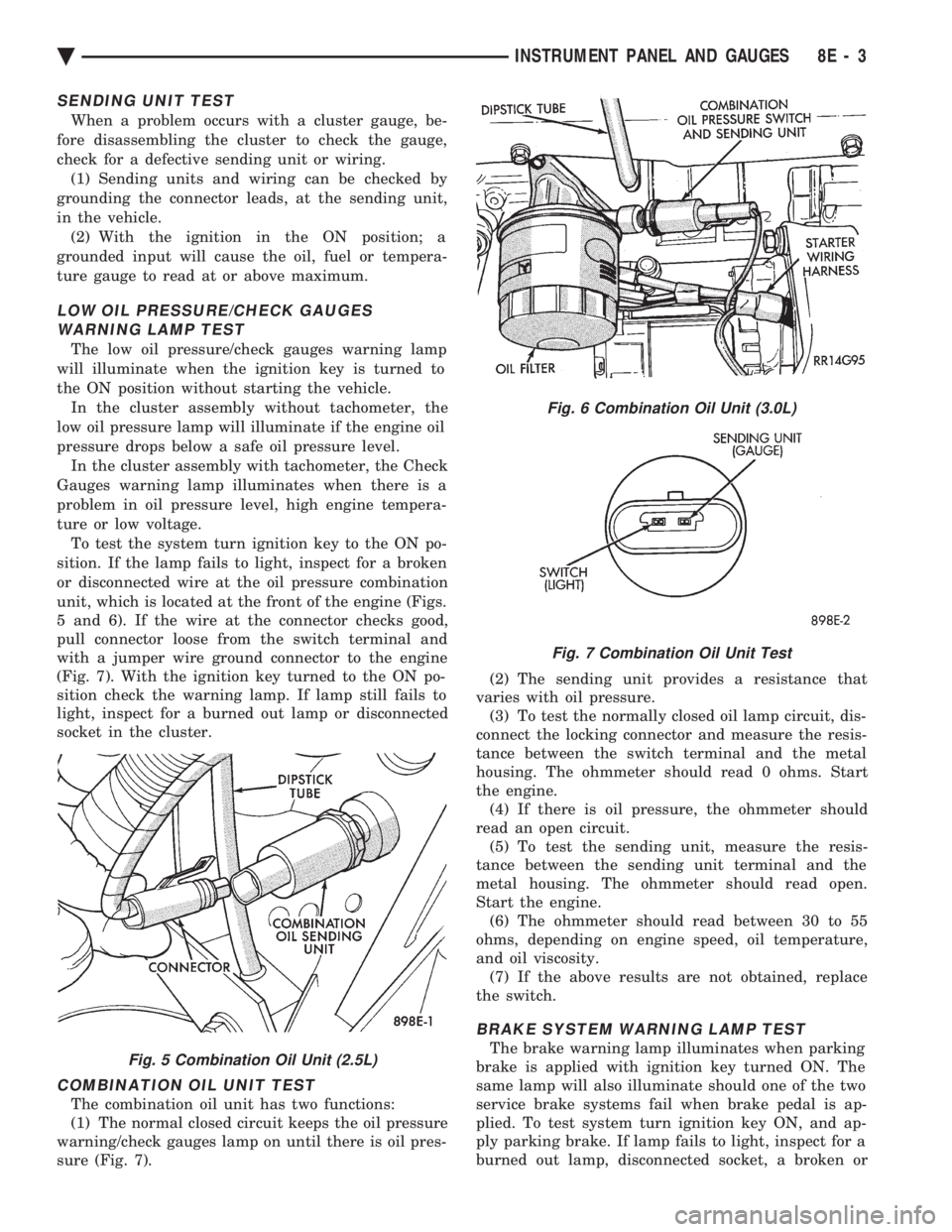

SENDING UNIT TEST

When a problem occurs with a cluster gauge, be-

fore disassembling the cluster to check the gauge,

check for a defective sending unit or wiring. (1) Sending units and wiring can be checked by

grounding the connector leads, at the sending unit,

in the vehicle. (2) With the ignition in the ON position; a

grounded input will cause the oil, fuel or tempera-

ture gauge to read at or above maximum.

LOW OIL PRESSURE/CHECK GAUGES WARNING LAMP TEST

The low oil pressure/check gauges warning lamp

will illuminate when the ignition key is turned to

the ON position without starting the vehicle. In the cluster assembly without tachometer, the

low oil pressure lamp will illuminate if the engine oil

pressure drops below a safe oil pressure level. In the cluster assembly with tachometer, the Check

Gauges warning lamp illuminates when there is a

problem in oil pressure level, high engine tempera-

ture or low voltage. To test the system turn ignition key to the ON po-

sition. If the lamp fails to light, inspect for a broken

or disconnected wire at the oil pressure combination

unit, which is located at the front of the engine (Figs.

5 and 6). If the wire at the connector checks good,

pull connector loose from the switch terminal and

with a jumper wire ground connector to the engine

(Fig. 7). With the ignition key turned to the ON po-

sition check the warning lamp. If lamp still fails to

light, inspect for a burned out lamp or disconnected

socket in the cluster.

COMBINATION OIL UNIT TEST

The combination oil unit has two functions:

(1) The normal closed circuit keeps the oil pressure

warning/check gauges lamp on until there is oil pres-

sure (Fig. 7). (2) The sending unit provides a resistance that

varies with oil pressure. (3) To test the normally closed oil lamp circuit, dis-

connect the locking connector and measure the resis-

tance between the switch terminal and the metal

housing. The ohmmeter should read 0 ohms. Start

the engine. (4) If there is oil pressure, the ohmmeter should

read an open circuit. (5) To test the sending unit, measure the resis-

tance between the sending unit terminal and the

metal housing. The ohmmeter should read open.

Start the engine. (6) The ohmmeter should read between 30 to 55

ohms, depending on engine speed, oil temperature,

and oil viscosity. (7) If the above results are not obtained, replace

the switch.

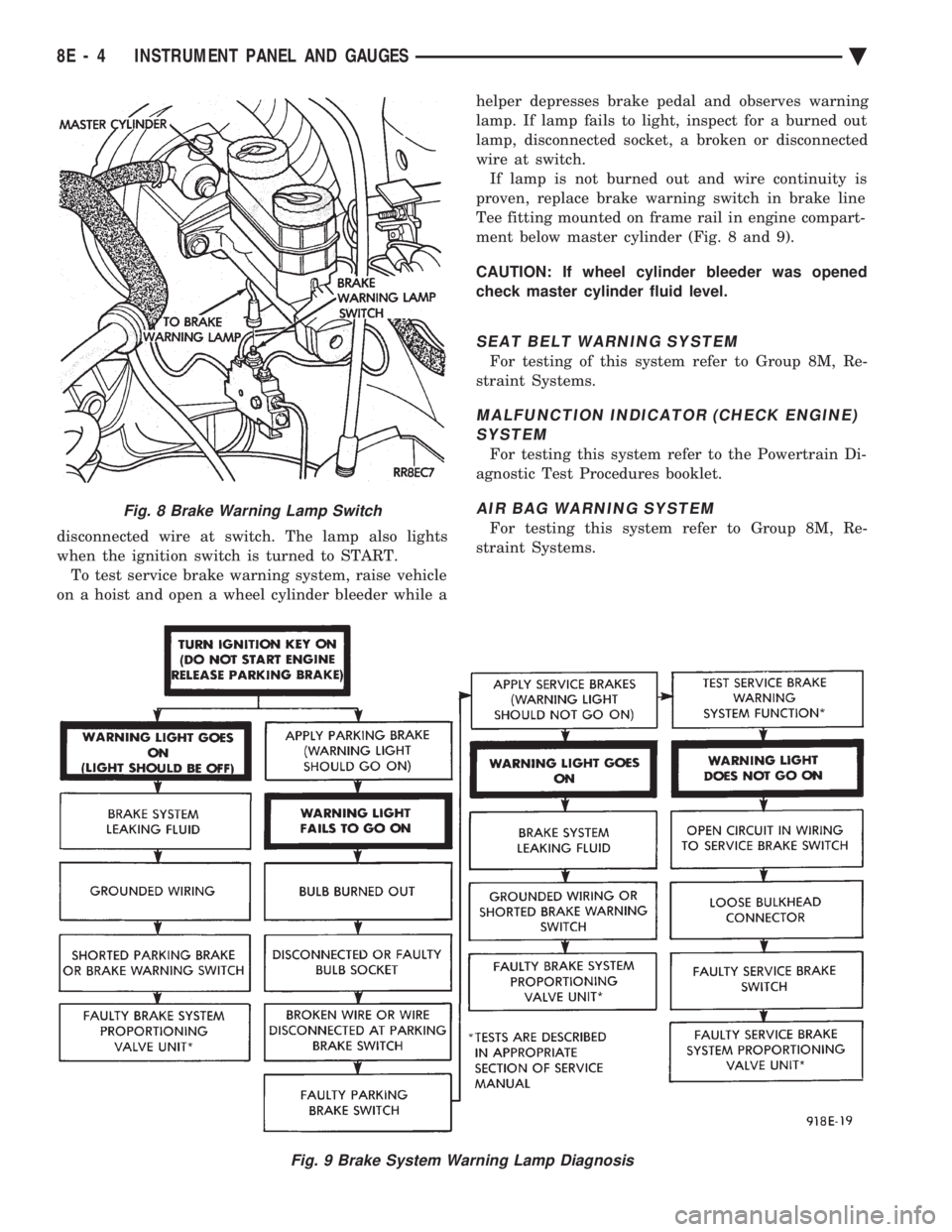

BRAKE SYSTEM WARNING LAMP TEST

The brake warning lamp illuminates when parking

brake is applied with ignition key turned ON. The

same lamp will also illuminate should one of the two

service brake systems fail when brake pedal is ap-

plied. To test system turn ignition key ON, and ap-

ply parking brake. If lamp fails to light, inspect for a

burned out lamp, disconnected socket, a broken orFig. 5 Combination Oil Unit (2.5L)

Fig. 6 Combination Oil Unit (3.0L)

Fig. 7 Combination Oil Unit Test

Ä INSTRUMENT PANEL AND GAUGES 8E - 3

Page 496 of 2438

disconnected wire at switch. The lamp also lights

when the ignition switch is turned to START.To test service brake warning system, raise vehicle

on a hoist and open a wheel cylinder bleeder while a helper depresses brake pedal and observes warning

lamp. If lamp fails to light, inspect for a burned out

lamp, disconnected socket, a broken or disconnected

wire at switch. If lamp is not burned out and wire continuity is

proven, replace brake warning switch in brake line

Tee fitting mounted on frame rail in engine compart-

ment below master cylinder (Fig. 8 and 9).

CAUTION: If wheel cylinder bleeder was opened

check master cylinder fluid level.

SEAT BELT WARNING SYSTEM

For testing of this system refer to Group 8M, Re-

straint Systems.

MALFUNCTION INDICATOR (CHECK ENGINE) SYSTEM

For testing this system refer to the Powertrain Di-

agnostic Test Procedures booklet.

AIR BAG WARNING SYSTEM

For testing this system refer to Group 8M, Re-

straint Systems.

Fig. 8 Brake Warning Lamp Switch

Fig. 9 Brake System Warning Lamp Diagnosis

8E - 4 INSTRUMENT PANEL AND GAUGES Ä

Page 507 of 2438

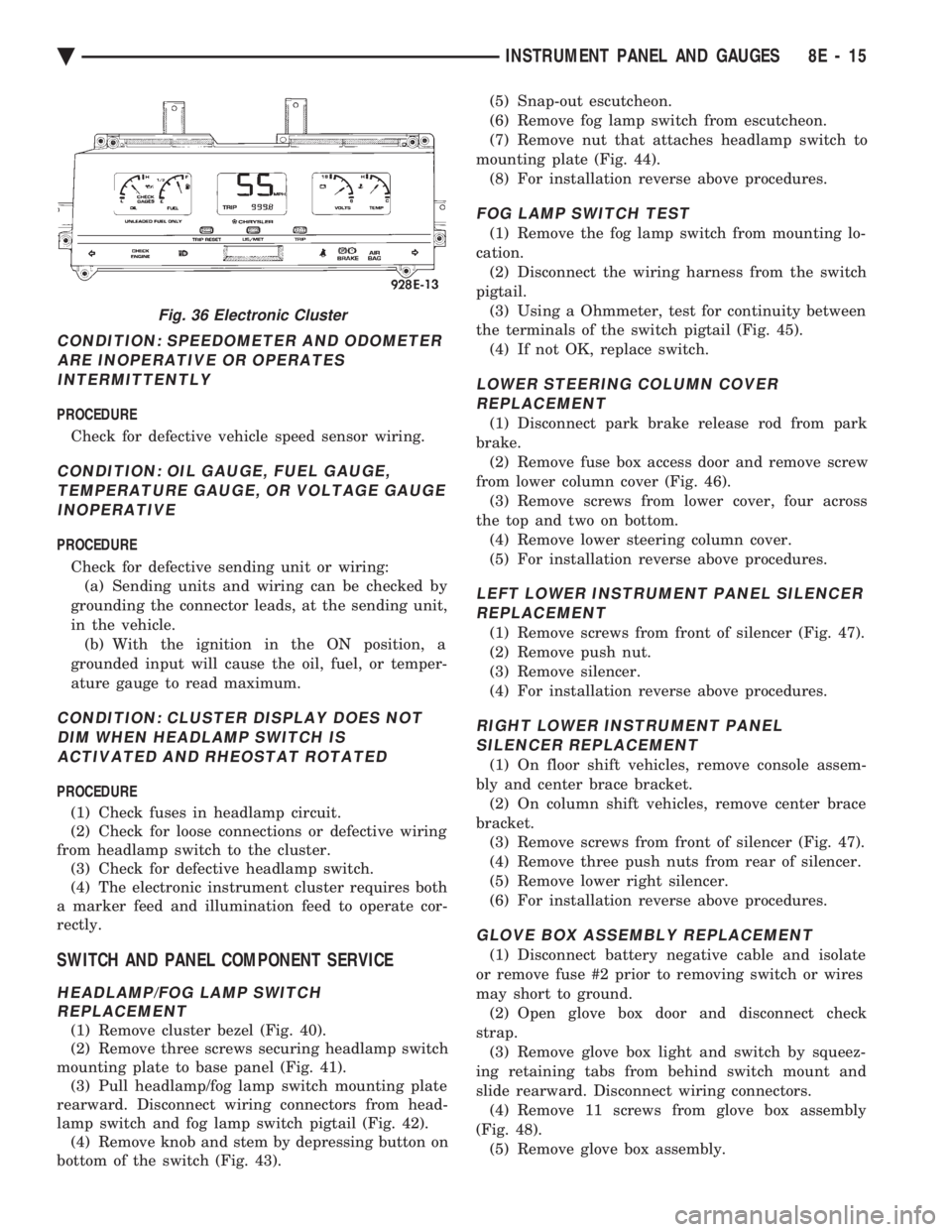

CONDITION: SPEEDOMETER AND ODOMETER ARE INOPERATIVE OR OPERATESINTERMITTENTLY

PROCEDURE

Check for defective vehicle speed sensor wiring.

CONDITION: OIL GAUGE, FUEL GAUGE, TEMPERATURE GAUGE, OR VOLTAGE GAUGEINOPERATIVE

PROCEDURE

Check for defective sending unit or wiring: (a) Sending units and wiring can be checked by

grounding the connector leads, at the sending unit,

in the vehicle. (b) With the ignition in the ON position, a

grounded input will cause the oil, fuel, or temper-

ature gauge to read maximum.

CONDITION: CLUSTER DISPLAY DOES NOT DIM WHEN HEADLAMP SWITCH ISACTIVATED AND RHEOSTAT ROTATED

PROCEDURE

(1) Check fuses in headlamp circuit.

(2) Check for loose connections or defective wiring

from headlamp switch to the cluster. (3) Check for defective headlamp switch.

(4) The electronic instrument cluster requires both

a marker feed and illumination feed to operate cor-

rectly.

SWITCH AND PANEL COMPONENT SERVICE

HEADLAMP/FOG LAMP SWITCH REPLACEMENT

(1) Remove cluster bezel (Fig. 40).

(2) Remove three screws securing headlamp switch

mounting plate to base panel (Fig. 41). (3) Pull headlamp/fog lamp switch mounting plate

rearward. Disconnect wiring connectors from head-

lamp switch and fog lamp switch pigtail (Fig. 42). (4) Remove knob and stem by depressing button on

bottom of the switch (Fig. 43). (5) Snap-out escutcheon.

(6) Remove fog lamp switch from escutcheon.

(7) Remove nut that attaches headlamp switch to

mounting plate (Fig. 44). (8) For installation reverse above procedures.

FOG LAMP SWITCH TEST

(1) Remove the fog lamp switch from mounting lo-

cation. (2) Disconnect the wiring harness from the switch

pigtail. (3) Using a Ohmmeter, test for continuity between

the terminals of the switch pigtail (Fig. 45). (4) If not OK, replace switch.

LOWER STEERING COLUMN COVERREPLACEMENT

(1) Disconnect park brake release rod from park

brake. (2) Remove fuse box access door and remove screw

from lower column cover (Fig. 46). (3) Remove screws from lower cover, four across

the top and two on bottom. (4) Remove lower steering column cover.

(5) For installation reverse above procedures.

LEFT LOWER INSTRUMENT PANEL SILENCER REPLACEMENT

(1) Remove screws from front of silencer (Fig. 47).

(2) Remove push nut.

(3) Remove silencer.

(4) For installation reverse above procedures.

RIGHT LOWER INSTRUMENT PANEL SILENCER REPLACEMENT

(1) On floor shift vehicles, remove console assem-

bly and center brace bracket. (2) On column shift vehicles, remove center brace

bracket. (3) Remove screws from front of silencer (Fig. 47).

(4) Remove three push nuts from rear of silencer.

(5) Remove lower right silencer.

(6) For installation reverse above procedures.

GLOVE BOX ASSEMBLY REPLACEMENT

(1) Disconnect battery negative cable and isolate

or remove fuse #2 prior to removing switch or wires

may short to ground. (2) Open glove box door and disconnect check

strap. (3) Remove glove box light and switch by squeez-

ing retaining tabs from behind switch mount and

slide rearward. Disconnect wiring connectors. (4) Remove 11 screws from glove box assembly

(Fig. 48). (5) Remove glove box assembly.

Fig. 36 Electronic Cluster

Ä INSTRUMENT PANEL AND GAUGES 8E - 15