light CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 595 of 2438

² If no short to ground at connector, check speaker

resistance at amplifier connector for an reading of

three to five ohms.

² If resistance is OK, refer to Radio Diagnosis. If ra-

dio checks OK, replace amplifier.

² If resistance is less than three ohms check

speaker. Check across the speaker connector if less

than three ohms replace speaker. If resistance is OK

repair wires

CONDITION: MECHANICAL NOISE DISTORTION

² Check trim for loose parts and speaker attach-

ments for buzzes

² Remove speaker still connected and listen for dis-

tortion. Distortion replace speaker.

CONDITION: ONE SPEAKER NON-OPERATIVE

² Remove output signal connector from amplifier

and check for three to five ohms resistance to the

non-operative speaker. Refer to Fig. 34 for the appro-

priate pin numbers.

² If resistance is less than three ohms, test speaker

for resistance.

² If OK repair wire. If not replace speaker.

CONDITION: ALL SPEAKERS NON-OPERATIVE

²Check radio for being ON, are the display lights

on

² Radio not ON, refer to Radio Diagnosis

² Check Amplifier Connectors and wires for proper

connection

² Check pin 9 and pin 27 for battery voltage

² If voltage OK replace amplifier ²

If pin 27 has battery voltage and pin 9 has 0 volt-

age. Refer to Power Antenna Diagnosis and test volt-

age at antenna relay.

² If pin 9 has battery voltage and pin 27 has 0 volt-

age. Check pin 27 for short to ground.

² If shorted to ground repair wire

² If no short to ground check fuse cavity number 16

for blown fuse.

² If fuse blows again replace amplifier

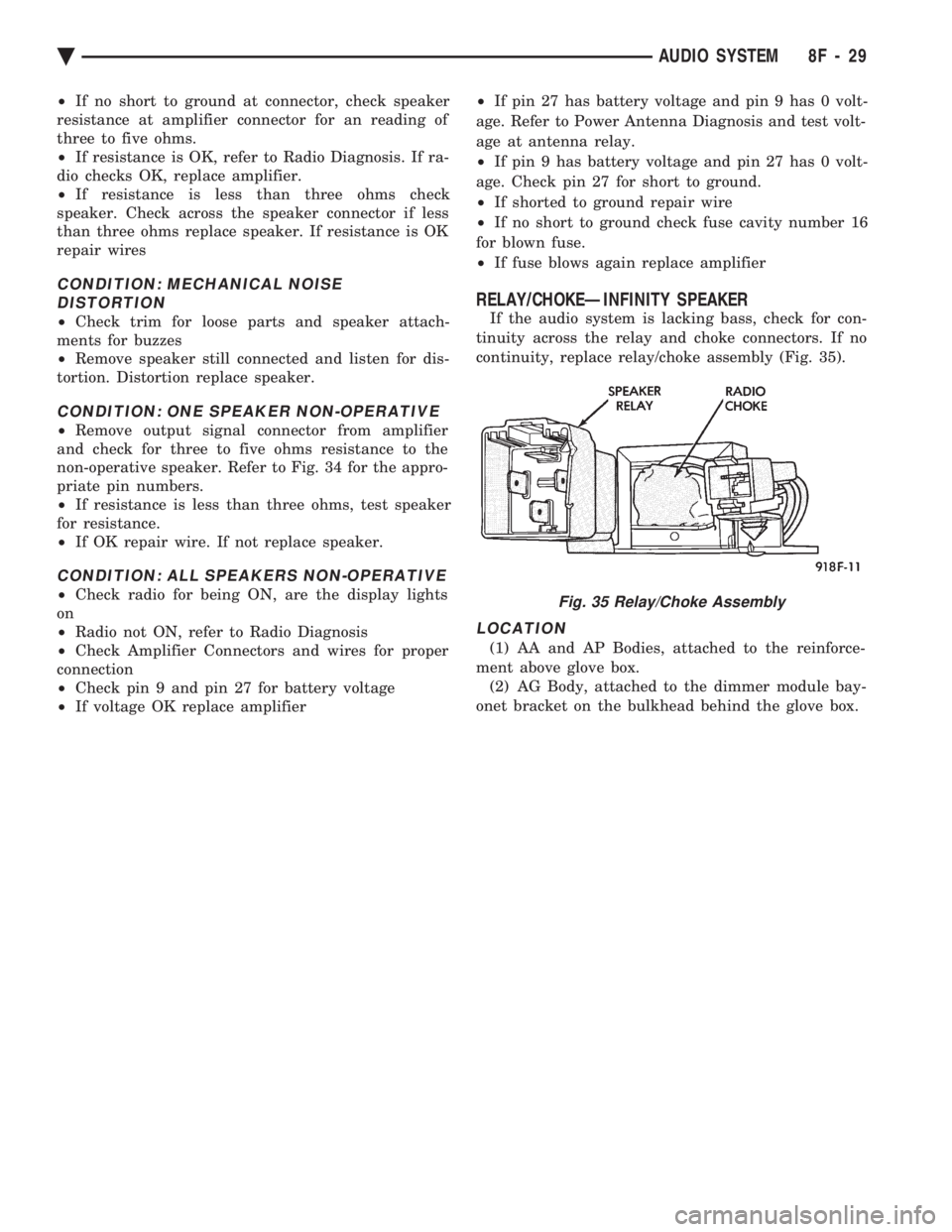

RELAY/CHOKEÐINFINITY SPEAKER

If the audio system is lacking bass, check for con-

tinuity across the relay and choke connectors. If no

continuity, replace relay/choke assembly (Fig. 35).

LOCATION

(1) AA and AP Bodies, attached to the reinforce-

ment above glove box. (2) AG Body, attached to the dimmer module bay-

onet bracket on the bulkhead behind the glove box.

Fig. 35 Relay/Choke Assembly

Ä AUDIO SYSTEM 8F - 29

Page 597 of 2438

HORNS

CONTENTS

page page

GENERAL INFORMATION .................. 1

HORN SWITCH REPLACEMENT ............ 3 TESTING HORN SYSTEM

................. 1

GENERAL INFORMATION

WARNING: ON VEHICLES EQUIPPED WITH AIR

BAG, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

STEERING WHEEL OR COLUMN REMOVAL PROCE-

DURES.

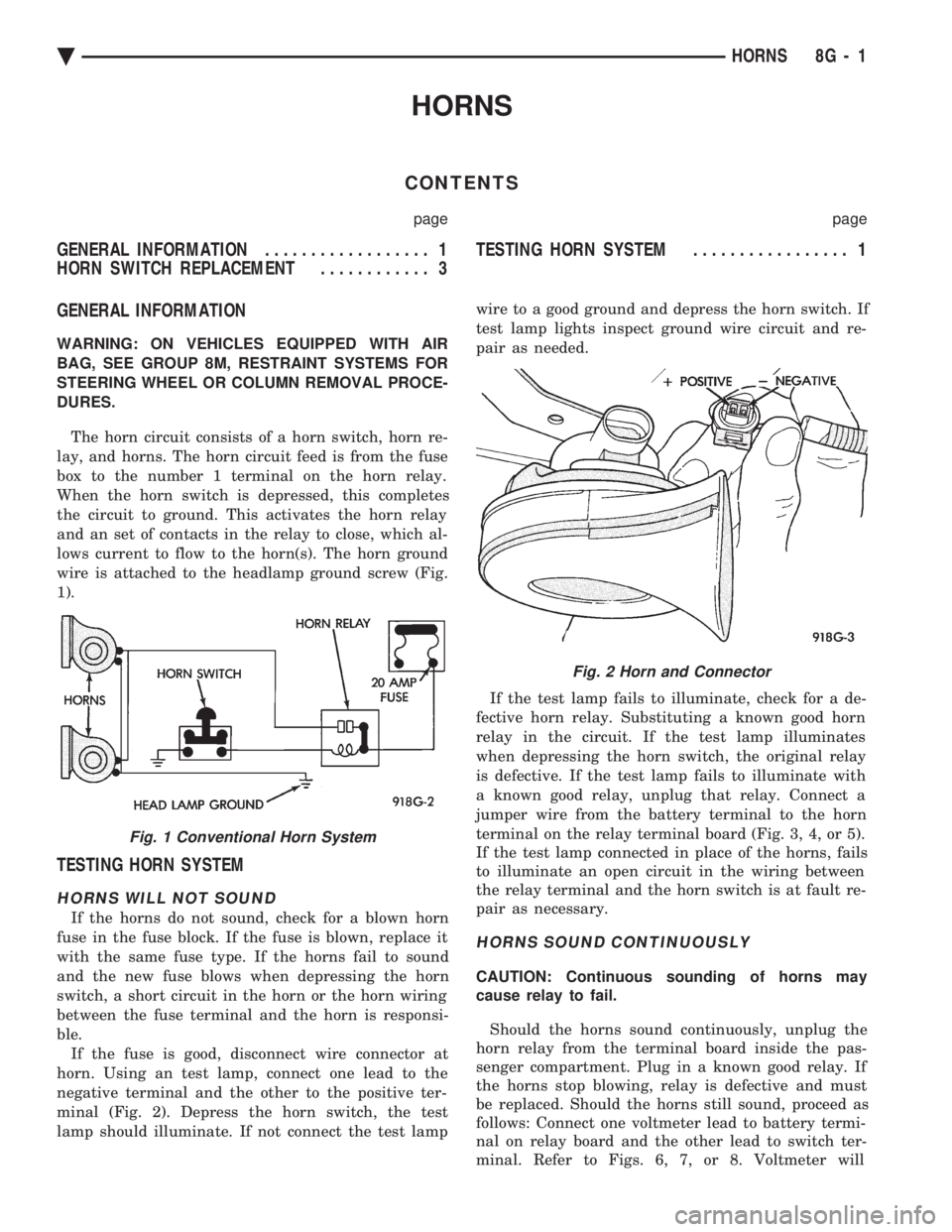

The horn circuit consists of a horn switch, horn re-

lay, and horns. The horn circuit feed is from the fuse

box to the number 1 terminal on the horn relay.

When the horn switch is depressed, this completes

the circuit to ground. This activates the horn relay

and an set of contacts in the relay to close, which al-

lows current to flow to the horn(s). The horn ground

wire is attached to the headlamp ground screw (Fig.

1).

TESTING HORN SYSTEM

HORNS WILL NOT SOUND

If the horns do not sound, check for a blown horn

fuse in the fuse block. If the fuse is blown, replace it

with the same fuse type. If the horns fail to sound

and the new fuse blows when depressing the horn

switch, a short circuit in the horn or the horn wiring

between the fuse terminal and the horn is responsi-

ble. If the fuse is good, disconnect wire connector at

horn. Using an test lamp, connect one lead to the

negative terminal and the other to the positive ter-

minal (Fig. 2). Depress the horn switch, the test

lamp should illuminate. If not connect the test lamp wire to a good ground and depress the horn switch. If

test lamp lights inspect ground wire circuit and re-

pair as needed.

If the test lamp fails to illuminate, check for a de-

fective horn relay. Substituting a known good horn

relay in the circuit. If the test lamp illuminates

when depressing the horn switch, the original relay

is defective. If the test lamp fails to illuminate with

a known good relay, unplug that relay. Connect a

jumper wire from the battery terminal to the horn

terminal on the relay terminal board (Fig. 3, 4, or 5).

If the test lamp connected in place of the horns, fails

to illuminate an open circuit in the wiring between

the relay terminal and the horn switch is at fault re-

pair as necessary.

HORNS SOUND CONTINUOUSLY

CAUTION: Continuous sounding of horns may

cause relay to fail.

Should the horns sound continuously, unplug the

horn relay from the terminal board inside the pas-

senger compartment. Plug in a known good relay. If

the horns stop blowing, relay is defective and must

be replaced. Should the horns still sound, proceed as

follows: Connect one voltmeter lead to battery termi-

nal on relay board and the other lead to switch ter-

minal. Refer to Figs. 6, 7, or 8. Voltmeter will

Fig. 1 Conventional Horn System

Fig. 2 Horn and Connector

Ä HORNS 8G - 1

Page 605 of 2438

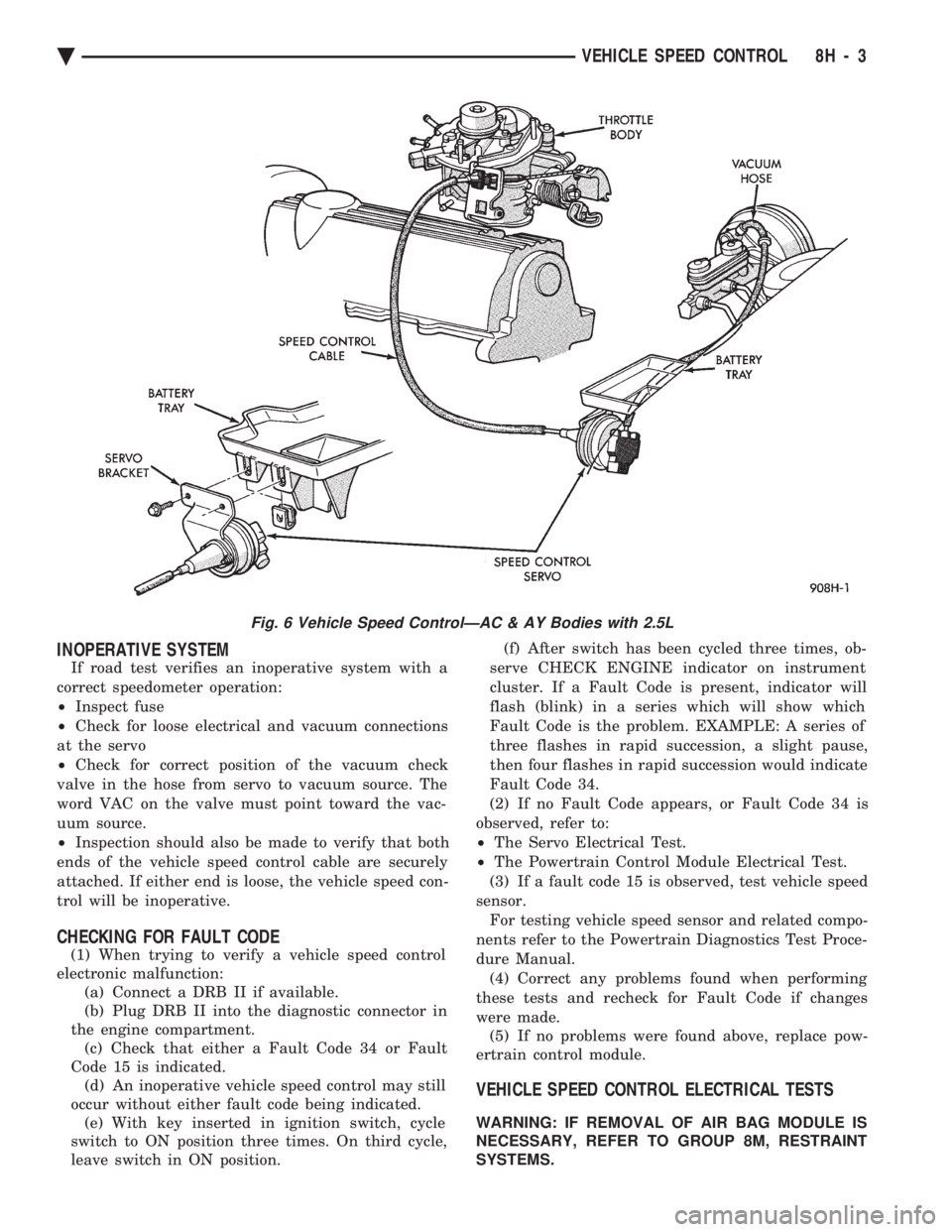

INOPERATIVE SYSTEM

If road test verifies an inoperative system with a

correct speedometer operation:

² Inspect fuse

² Check for loose electrical and vacuum connections

at the servo

² Check for correct position of the vacuum check

valve in the hose from servo to vacuum source. The

word VAC on the valve must point toward the vac-

uum source.

² Inspection should also be made to verify that both

ends of the vehicle speed control cable are securely

attached. If either end is loose, the vehicle speed con-

trol will be inoperative.

CHECKING FOR FAULT CODE

(1) When trying to verify a vehicle speed control

electronic malfunction: (a) Connect a DRB II if available.

(b) Plug DRB II into the diagnostic connector in

the engine compartment. (c) Check that either a Fault Code 34 or Fault

Code 15 is indicated. (d) An inoperative vehicle speed control may still

occur without either fault code being indicated. (e) With key inserted in ignition switch, cycle

switch to ON position three times. On third cycle,

leave switch in ON position. (f) After switch has been cycled three times, ob-

serve CHECK ENGINE indicator on instrument

cluster. If a Fault Code is present, indicator will

flash (blink) in a series which will show which

Fault Code is the problem. EXAMPLE: A series of

three flashes in rapid succession, a slight pause,

then four flashes in rapid succession would indicate

Fault Code 34.

(2) If no Fault Code appears, or Fault Code 34 is

observed, refer to:

² The Servo Electrical Test.

² The Powertrain Control Module Electrical Test.

(3) If a fault code 15 is observed, test vehicle speed

sensor. For testing vehicle speed sensor and related compo-

nents refer to the Powertrain Diagnostics Test Proce-

dure Manual. (4) Correct any problems found when performing

these tests and recheck for Fault Code if changes

were made. (5) If no problems were found above, replace pow-

ertrain control module.

VEHICLE SPEED CONTROL ELECTRICAL TESTS

WARNING: IF REMOVAL OF AIR BAG MODULE IS

NECESSARY, REFER TO GROUP 8M, RESTRAINT

SYSTEMS.

Fig. 6 Vehicle Speed ControlÐAC & AY Bodies with 2.5L

Ä VEHICLE SPEED CONTROL 8H - 3

Page 625 of 2438

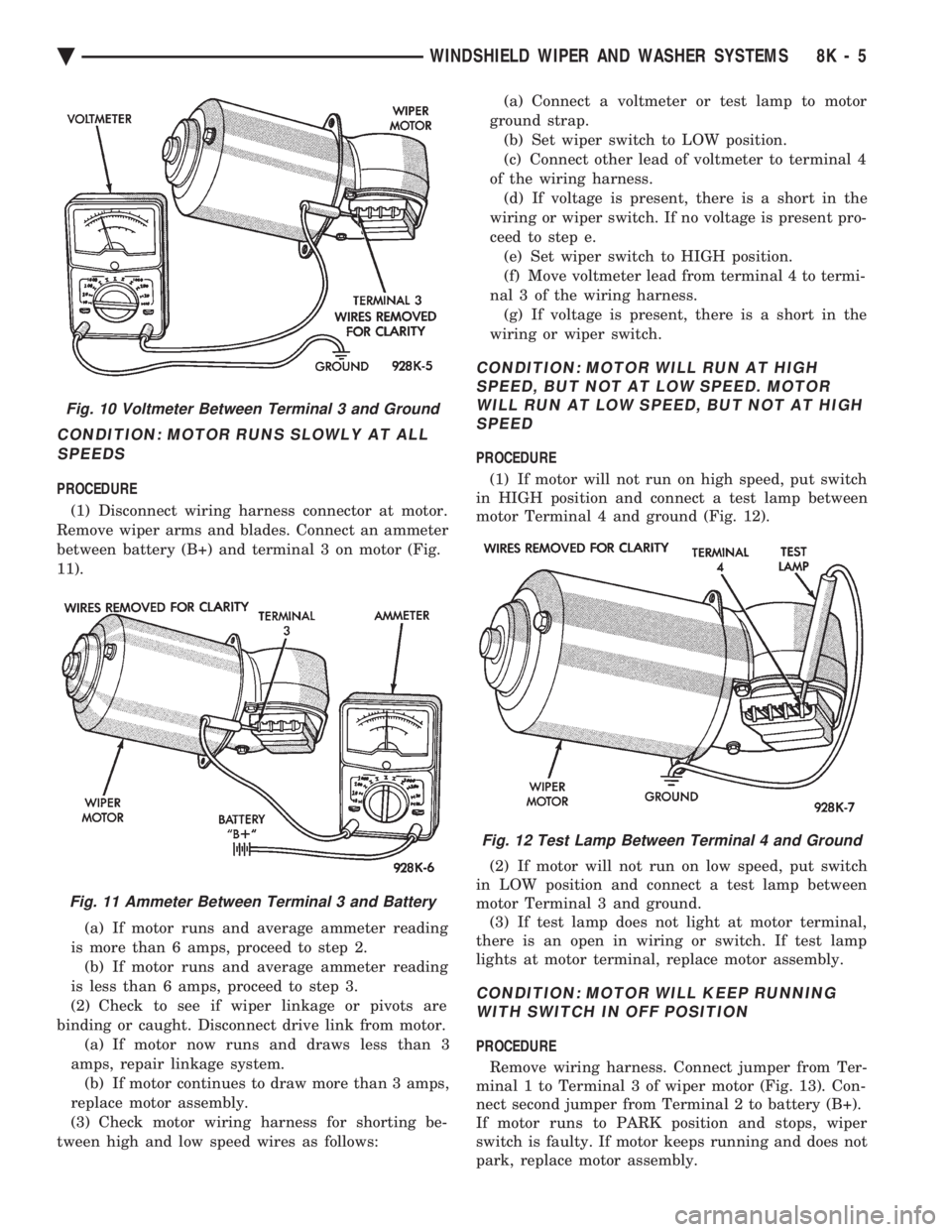

CONDITION: MOTOR RUNS SLOWLY AT ALL SPEEDS

PROCEDURE

(1) Disconnect wiring harness connector at motor.

Remove wiper arms and blades. Connect an ammeter

between battery (B+) and terminal 3 on motor (Fig.

11).

(a) If motor runs and average ammeter reading

is more than 6 amps, proceed to step 2. (b) If motor runs and average ammeter reading

is less than 6 amps, proceed to step 3.

(2) Check to see if wiper linkage or pivots are

binding or caught. Disconnect drive link from motor. (a) If motor now runs and draws less than 3

amps, repair linkage system. (b) If motor continues to draw more than 3 amps,

replace motor assembly.

(3) Check motor wiring harness for shorting be-

tween high and low speed wires as follows: (a) Connect a voltmeter or test lamp to motor

ground strap. (b) Set wiper switch to LOW position.

(c) Connect other lead of voltmeter to terminal 4

of the wiring harness. (d) If voltage is present, there is a short in the

wiring or wiper switch. If no voltage is present pro-

ceed to step e. (e) Set wiper switch to HIGH position.

(f) Move voltmeter lead from terminal 4 to termi-

nal 3 of the wiring harness. (g) If voltage is present, there is a short in the

wiring or wiper switch.

CONDITION: MOTOR WILL RUN AT HIGH SPEED, BUT NOT AT LOW SPEED. MOTORWILL RUN AT LOW SPEED, BUT NOT AT HIGHSPEED

PROCEDURE

(1) If motor will not run on high speed, put switch

in HIGH position and connect a test lamp between

motor Terminal 4 and ground (Fig. 12).

(2) If motor will not run on low speed, put switch

in LOW position and connect a test lamp between

motor Terminal 3 and ground. (3) If test lamp does not light at motor terminal,

there is an open in wiring or switch. If test lamp

lights at motor terminal, replace motor assembly.

CONDITION: MOTOR WILL KEEP RUNNING WITH SWITCH IN OFF POSITION

PROCEDURE

Remove wiring harness. Connect jumper from Ter-

minal 1 to Terminal 3 of wiper motor (Fig. 13). Con-

nect second jumper from Terminal 2 to battery (B+).

If motor runs to PARK position and stops, wiper

switch is faulty. If motor keeps running and does not

park, replace motor assembly.

Fig. 10 Voltmeter Between Terminal 3 and Ground

Fig. 11 Ammeter Between Terminal 3 and Battery

Fig. 12 Test Lamp Between Terminal 4 and Ground

Ä WINDSHIELD WIPER AND WASHER SYSTEMS 8K - 5

Page 650 of 2438

INSTALLATION

Reverse the preceding operation.

TAIL, STOP AND TURN SIGNAL AND BACK-UP

LAMP

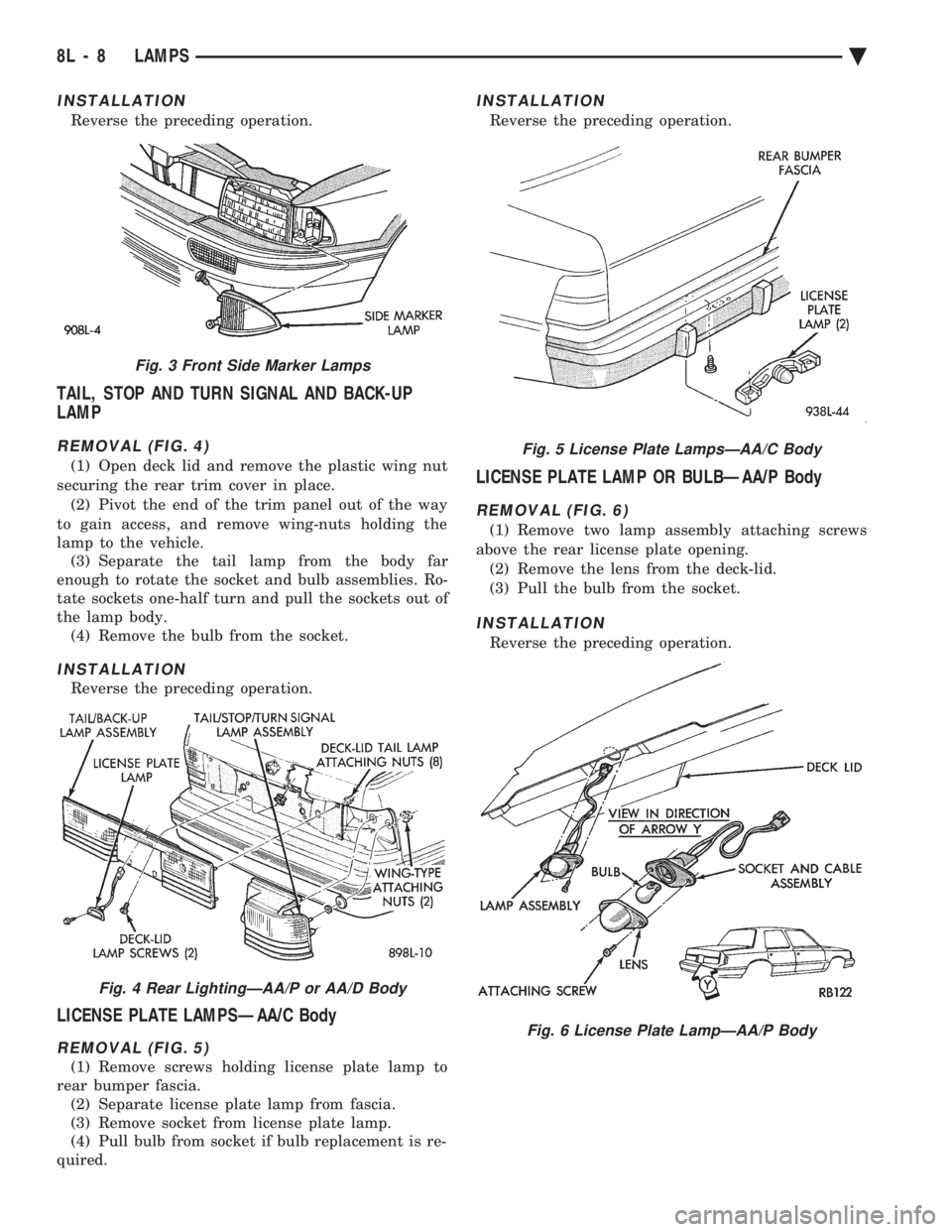

REMOVAL (FIG. 4)

(1) Open deck lid and remove the plastic wing nut

securing the rear trim cover in place. (2) Pivot the end of the trim panel out of the way

to gain access, and remove wing-nuts holding the

lamp to the vehicle. (3) Separate the tail lamp from the body far

enough to rotate the socket and bulb assemblies. Ro-

tate sockets one-half turn and pull the sockets out of

the lamp body. (4) Remove the bulb from the socket.

INSTALLATION

Reverse the preceding operation.

LICENSE PLATE LAMPSÐAA/C Body

REMOVAL (FIG. 5)

(1) Remove screws holding license plate lamp to

rear bumper fascia. (2) Separate license plate lamp from fascia.

(3) Remove socket from license plate lamp.

(4) Pull bulb from socket if bulb replacement is re-

quired.

INSTALLATION

Reverse the preceding operation.

LICENSE PLATE LAMP OR BULBÐAA/P Body

REMOVAL (FIG. 6)

(1) Remove two lamp assembly attaching screws

above the rear license plate opening. (2) Remove the lens from the deck-lid.

(3) Pull the bulb from the socket.

INSTALLATION

Reverse the preceding operation.

Fig. 3 Front Side Marker Lamps

Fig. 4 Rear LightingÐAA/P or AA/D Body

Fig. 5 License Plate LampsÐAA/C Body

Fig. 6 License Plate LampÐAA/P Body

8L - 8 LAMPS Ä

Page 652 of 2438

EXTERIOR LAMPSÐAC BODY INDEX

page page

Aero Headlamp Bulb ...................... 10

Aero Headlamp Housing ................... 11

Aero HeadlampsÐAC/D-Body ............... 10

Center High Mounted Stop Lamp (CHMSL) ..... 13

Center High-Mounted Stop Lamp (CHMSL) Bulb . 13

Cornering Lamp Assembly .................. 12

Cornering Lamp Bulb ..................... 12

Front Side Marker BulbÐAC/C-Body .......... 12

Front Side Marker LampÐAC/C-Body ......... 12

Headlamp Diagnosis ...................... 10 Headlamp Sealed BeamÐAC/C Body

......... 10

License Plate Lamp/Bulb ................... 13

Park/Turn Signal Lamp or BulbÐAC/C-Body .... 11

Park/Turn Signal Lamp or BulbÐAC/D-Body .... 11

Rear Side Marker Lamp BulbÐAC/C-Body ..... 13

Rear Side Marker LampÐAC/C-Body ......... 13

Tail, Stop, Turn Signal, Back-Up and Side Marker LampÐAC/D-Body ...................... 12

Tail, Stop, Turn Signal, Back-Up LampÐAC/C or AY/S-Body ............................ 12

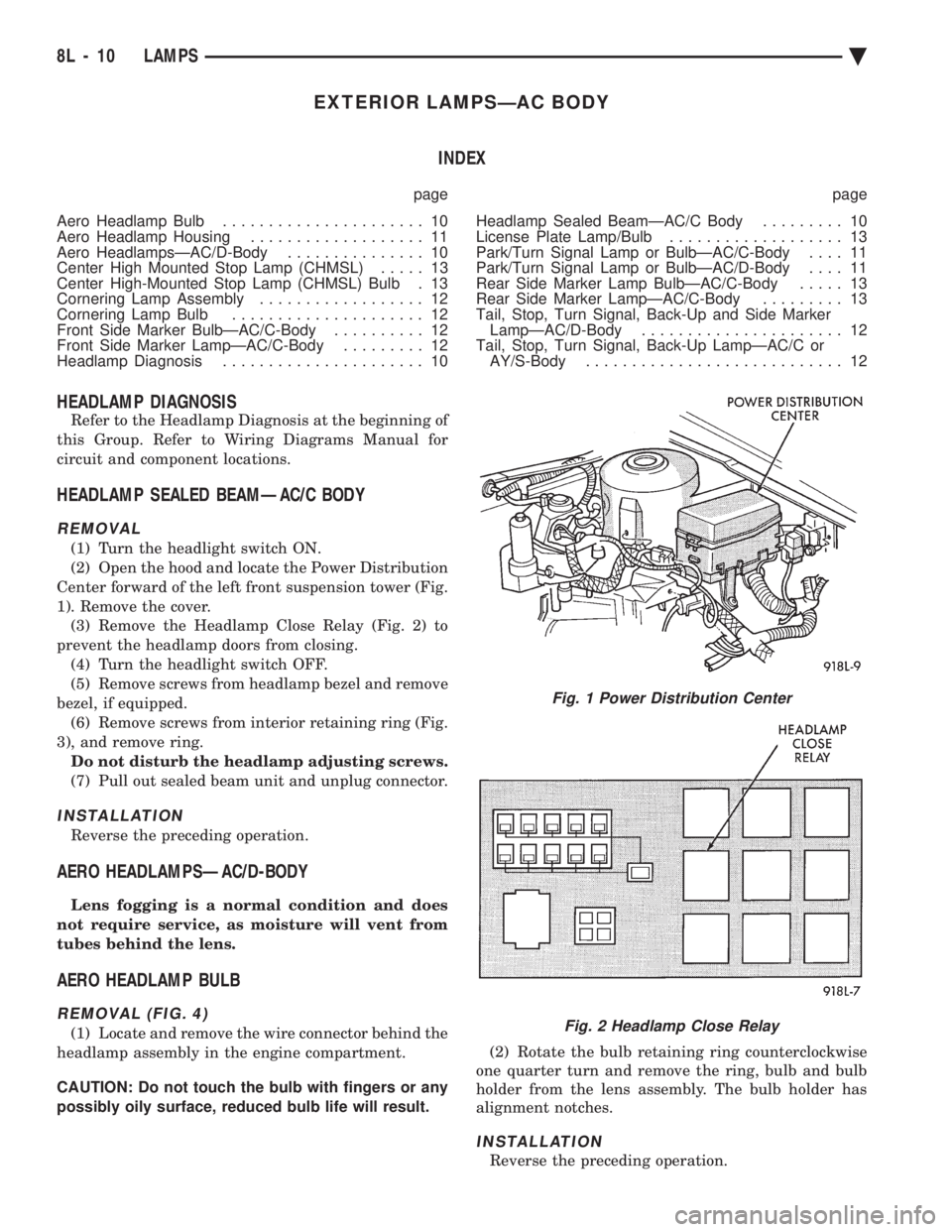

HEADLAMP DIAGNOSIS

Refer to the Headlamp Diagnosis at the beginning of

this Group. Refer to Wiring Diagrams Manual for

circuit and component locations.

HEADLAMP SEALED BEAMÐAC/C BODY

REMOVAL

(1) Turn the headlight switch ON.

(2) Open the hood and locate the Power Distribution

Center forward of the left front suspension tower (Fig.

1). Remove the cover. (3) Remove the Headlamp Close Relay (Fig. 2) to

prevent the headlamp doors from closing. (4) Turn the headlight switch OFF.

(5) Remove screws from headlamp bezel and remove

bezel, if equipped. (6) Remove screws from interior retaining ring (Fig.

3), and remove ring. Do not disturb the headlamp adjusting screws.

(7) Pull out sealed beam unit and unplug connector.

INSTALLATION

Reverse the preceding operation.

AERO HEADLAMPSÐAC/D-BODY

Lens fogging is a normal condition and does

not require service, as moisture will vent from

tubes behind the lens.

AERO HEADLAMP BULB

REMOVAL (FIG. 4)

(1) Locate and remove the wire connector behind the

headlamp assembly in the engine compartment.

CAUTION: Do not touch the bulb with fingers or any

possibly oily surface, reduced bulb life will result. (2) Rotate the bulb retaining ring counterclockwise

one quarter turn and remove the ring, bulb and bulb

holder from the lens assembly. The bulb holder has

alignment notches.

INSTALLATION

Reverse the preceding operation.

Fig. 1 Power Distribution Center

Fig. 2 Headlamp Close Relay

8L - 10 LAMPS Ä

Page 655 of 2438

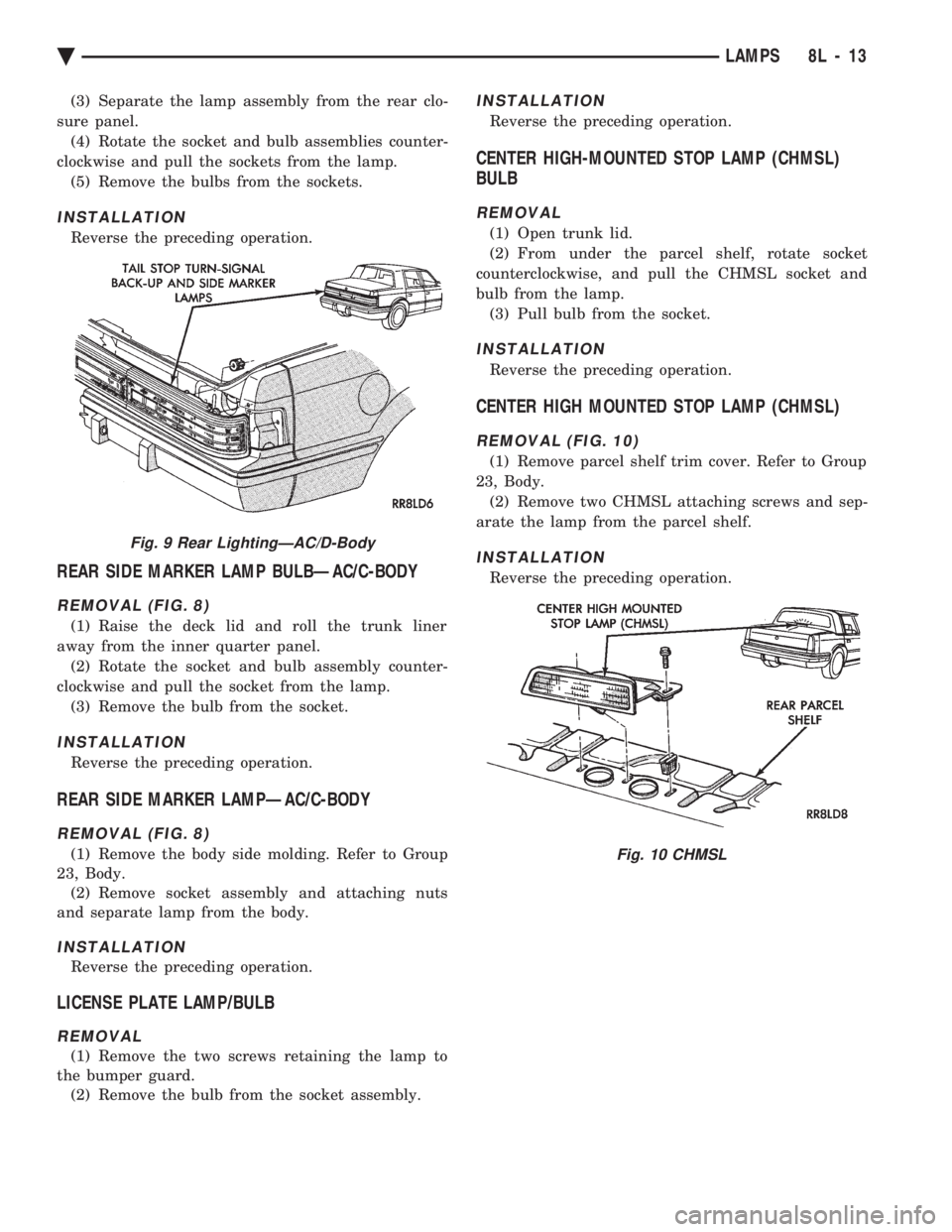

(3) Separate the lamp assembly from the rear clo-

sure panel. (4) Rotate the socket and bulb assemblies counter-

clockwise and pull the sockets from the lamp. (5) Remove the bulbs from the sockets.

INSTALLATION

Reverse the preceding operation.

REAR SIDE MARKER LAMP BULBÐAC/C-BODY

REMOVAL (FIG. 8)

(1) Raise the deck lid and roll the trunk liner

away from the inner quarter panel. (2) Rotate the socket and bulb assembly counter-

clockwise and pull the socket from the lamp. (3) Remove the bulb from the socket.

INSTALLATION

Reverse the preceding operation.

REAR SIDE MARKER LAMPÐAC/C-BODY

REMOVAL (FIG. 8)

(1) Remove the body side molding. Refer to Group

23, Body. (2) Remove socket assembly and attaching nuts

and separate lamp from the body.

INSTALLATION

Reverse the preceding operation.

LICENSE PLATE LAMP/BULB

REMOVAL

(1) Remove the two screws retaining the lamp to

the bumper guard. (2) Remove the bulb from the socket assembly.

INSTALLATION

Reverse the preceding operation.

CENTER HIGH-MOUNTED STOP LAMP (CHMSL)

BULB

REMOVAL

(1) Open trunk lid.

(2) From under the parcel shelf, rotate socket

counterclockwise, and pull the CHMSL socket and

bulb from the lamp. (3) Pull bulb from the socket.

INSTALLATION

Reverse the preceding operation.

CENTER HIGH MOUNTED STOP LAMP (CHMSL)

REMOVAL (FIG. 10)

(1) Remove parcel shelf trim cover. Refer to Group

23, Body. (2) Remove two CHMSL attaching screws and sep-

arate the lamp from the parcel shelf.

INSTALLATION

Reverse the preceding operation.

Fig. 9 Rear LightingÐAC/D-Body

Fig. 10 CHMSL

Ä LAMPS 8L - 13

Page 664 of 2438

EXTERIOR LAMPSÐAY-BODY INDEX

page page

Center High Mounted Stop Lamp ............ 24

Center High Mounted Stop Lamp Bulb (CHMSL) . 24

Cornering Lamp or BulbÐAY/C-P-Body ........ 24

Front Side Marker BulbÐAY/C-P-Body ........ 23

Front Side Marker LampÐAY/C-P-Body ....... 23

General Information ....................... 22

Headlamp Diagnosis ...................... 22 Headlamps

............................. 22

License Plate Lamp or BulbÐAY/C-P-Body ..... 24

Park, Turn Signal Lamp or BulbÐAY/C-P-Body . . 22

Sealed Beam ........................... 22

Tail, Stop, Turn Signal, Side Marker and Back-Up Lamp or BulbÐAY/C-P-Body .............. 24

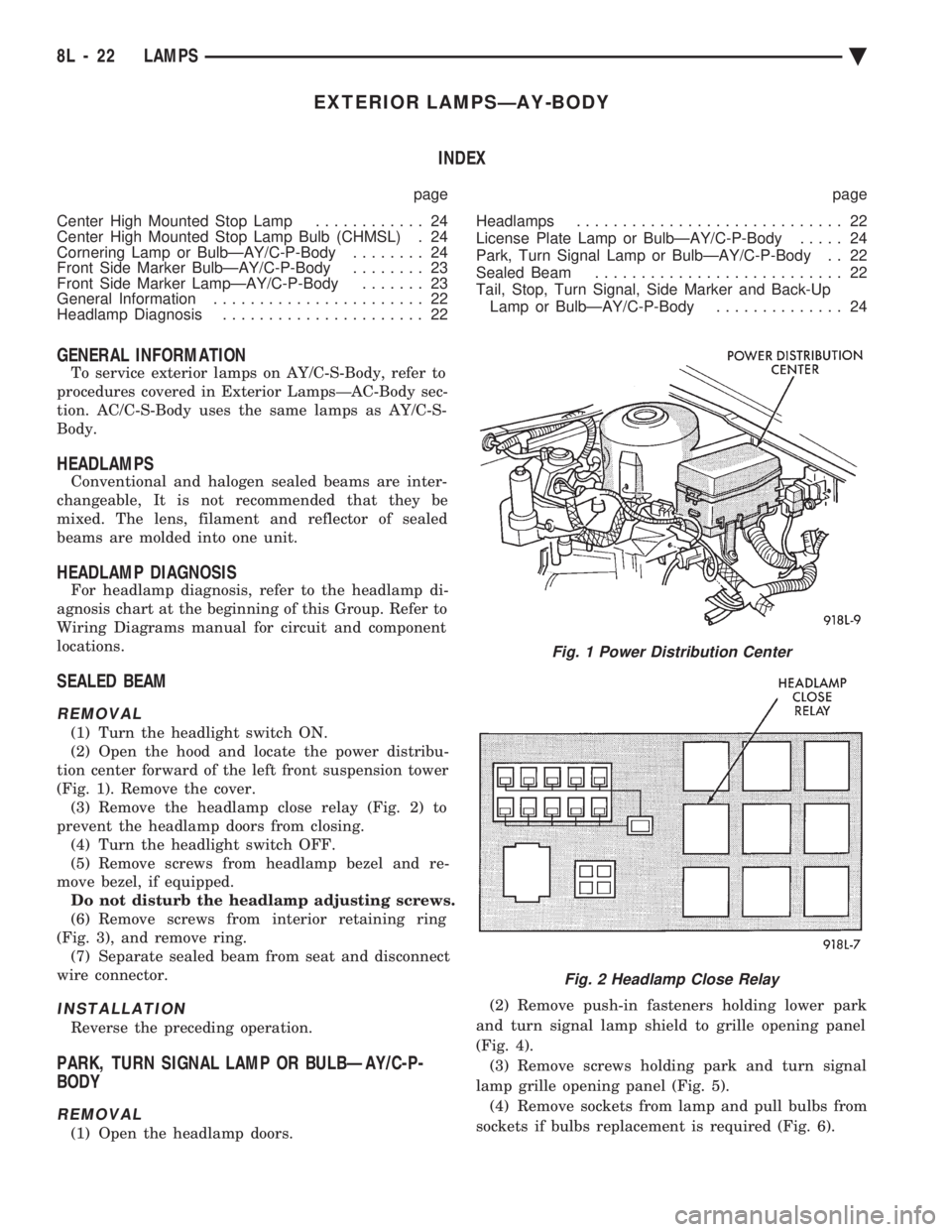

GENERAL INFORMATION

To service exterior lamps on AY/C-S-Body, refer to

procedures covered in Exterior LampsÐAC-Body sec-

tion. AC/C-S-Body uses the same lamps as AY/C-S-

Body.

HEADLAMPS

Conventional and halogen sealed beams are inter-

changeable, It is not recommended that they be

mixed. The lens, filament and reflector of sealed

beams are molded into one unit.

HEADLAMP DIAGNOSIS

For headlamp diagnosis, refer to the headlamp di-

agnosis chart at the beginning of this Group. Refer to

Wiring Diagrams manual for circuit and component

locations.

SEALED BEAM

REMOVAL

(1) Turn the headlight switch ON.

(2) Open the hood and locate the power distribu-

tion center forward of the left front suspension tower

(Fig. 1). Remove the cover. (3) Remove the headlamp close relay (Fig. 2) to

prevent the headlamp doors from closing. (4) Turn the headlight switch OFF.

(5) Remove screws from headlamp bezel and re-

move bezel, if equipped. Do not disturb the headlamp adjusting screws.

(6) Remove screws from interior retaining ring

(Fig. 3), and remove ring. (7) Separate sealed beam from seat and disconnect

wire connector.

INSTALLATION

Reverse the preceding operation.

PARK, TURN SIGNAL LAMP OR BULBÐAY/C-P-

BODY

REMOVAL

(1) Open the headlamp doors. (2) Remove push-in fasteners holding lower park

and turn signal lamp shield to grille opening panel

(Fig. 4). (3) Remove screws holding park and turn signal

lamp grille opening panel (Fig. 5). (4) Remove sockets from lamp and pull bulbs from

sockets if bulbs replacement is required (Fig. 6).

Fig. 1 Power Distribution Center

Fig. 2 Headlamp Close Relay

8L - 22 LAMPS Ä

Page 666 of 2438

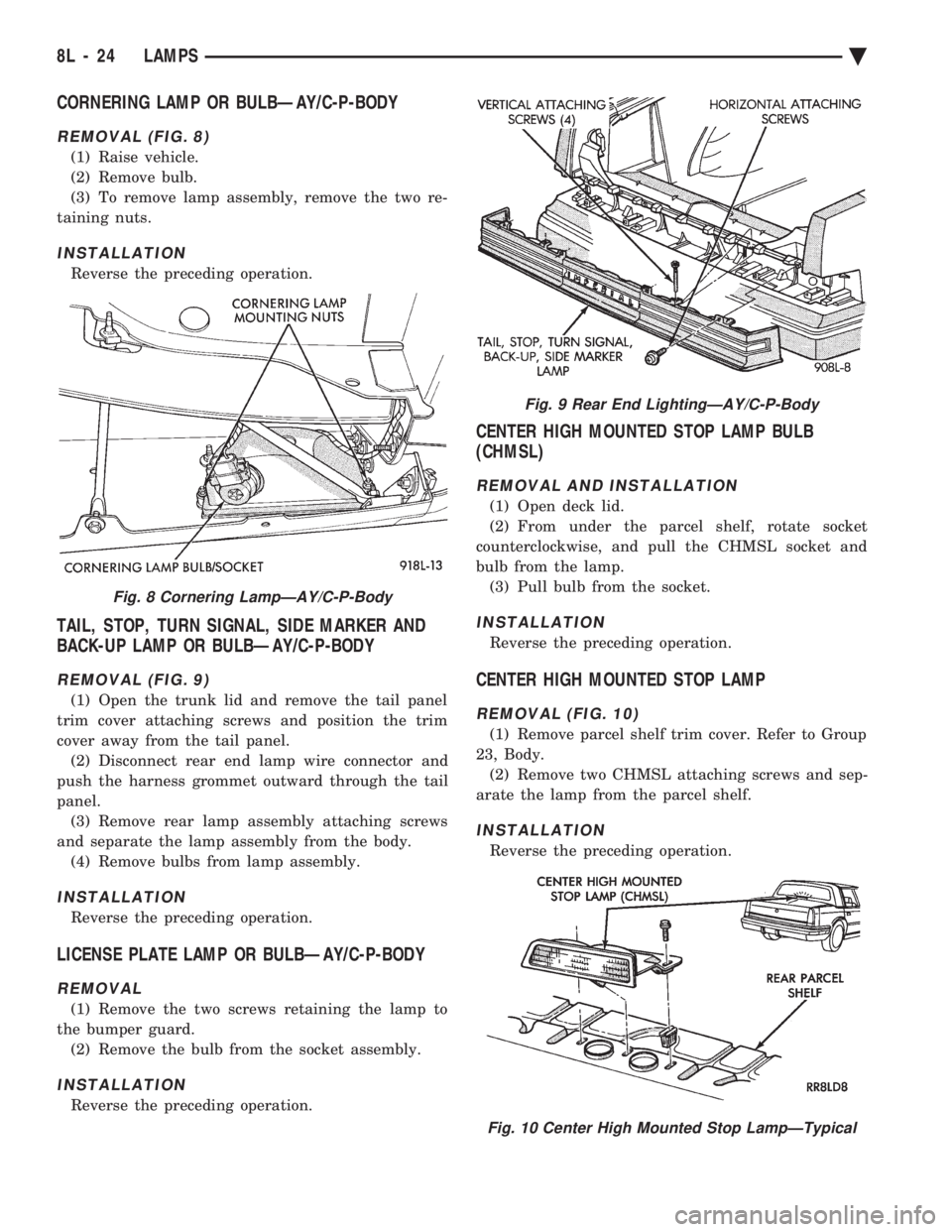

CORNERING LAMP OR BULBÐAY/C-P-BODY

REMOVAL (FIG. 8)

(1) Raise vehicle.

(2) Remove bulb.

(3) To remove lamp assembly, remove the two re-

taining nuts.

INSTALLATION

Reverse the preceding operation.

TAIL, STOP, TURN SIGNAL, SIDE MARKER AND

BACK-UP LAMP OR BULBÐAY/C-P-BODY

REMOVAL (FIG. 9)

(1) Open the trunk lid and remove the tail panel

trim cover attaching screws and position the trim

cover away from the tail panel. (2) Disconnect rear end lamp wire connector and

push the harness grommet outward through the tail

panel. (3) Remove rear lamp assembly attaching screws

and separate the lamp assembly from the body. (4) Remove bulbs from lamp assembly.

INSTALLATION

Reverse the preceding operation.

LICENSE PLATE LAMP OR BULBÐAY/C-P-BODY

REMOVAL

(1) Remove the two screws retaining the lamp to

the bumper guard. (2) Remove the bulb from the socket assembly.

INSTALLATION

Reverse the preceding operation.

CENTER HIGH MOUNTED STOP LAMP BULB

(CHMSL)

REMOVAL AND INSTALLATION

(1) Open deck lid.

(2) From under the parcel shelf, rotate socket

counterclockwise, and pull the CHMSL socket and

bulb from the lamp. (3) Pull bulb from the socket.

INSTALLATION

Reverse the preceding operation.

CENTER HIGH MOUNTED STOP LAMP

REMOVAL (FIG. 10)

(1) Remove parcel shelf trim cover. Refer to Group

23, Body. (2) Remove two CHMSL attaching screws and sep-

arate the lamp from the parcel shelf.

INSTALLATION

Reverse the preceding operation.

Fig. 8 Cornering LampÐAY/C-P-Body

Fig. 9 Rear End LightingÐAY/C-P-Body

Fig. 10 Center High Mounted Stop LampÐTypical

8L - 24 LAMPS Ä

Page 669 of 2438

CONCEALED HEADLAMPS INDEX

page page

Concealed Headlamp MotorÐAC-Body ........ 29

Diagnostic Procedures ..................... 27

General Information ....................... 27 Headlamp DoorÐAC-Body

................. 29

Headlamp DoorÐAY Body ................. 29

Headlamp Drive MotorÐAY Body ............ 30

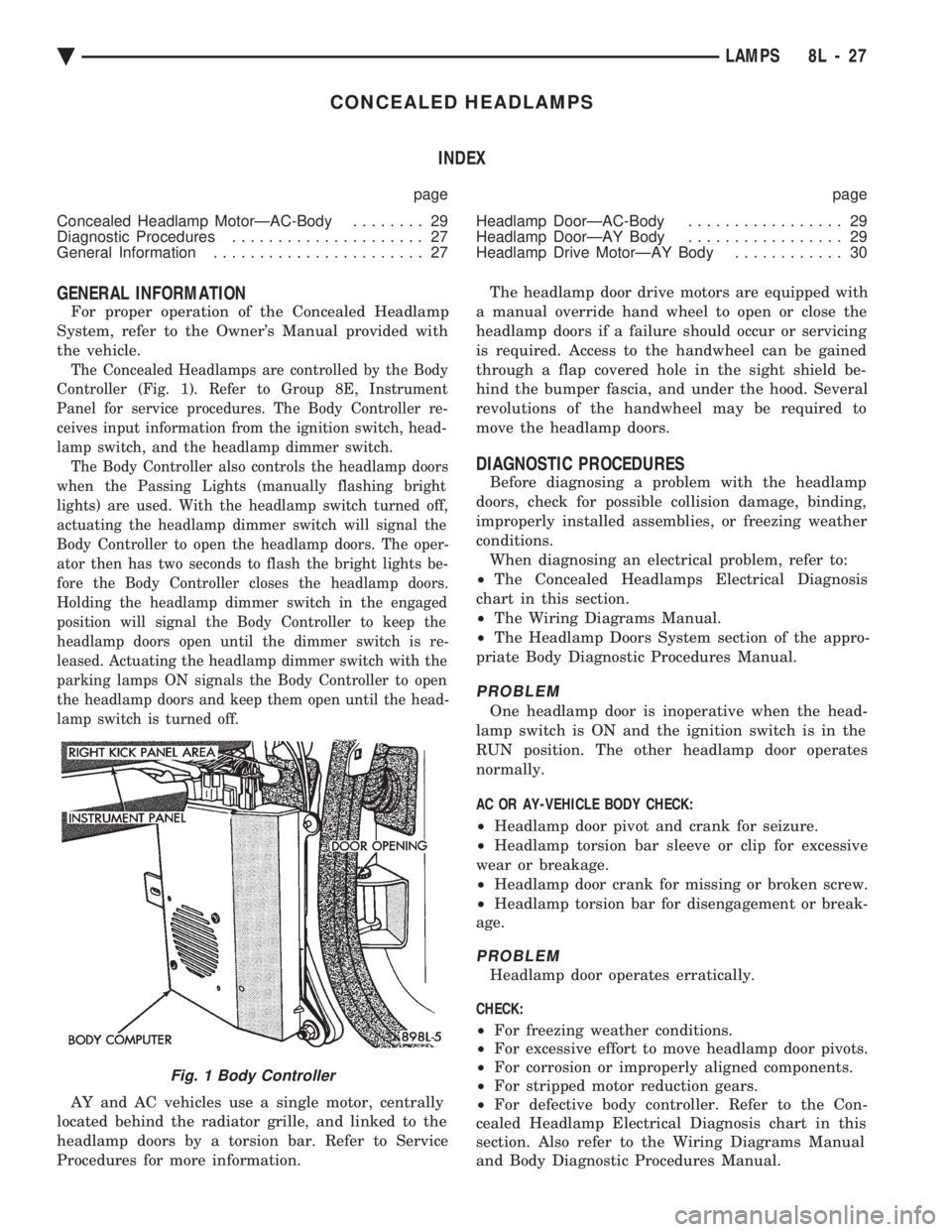

GENERAL INFORMATION

For proper operation of the Concealed Headlamp

System, refer to the Owner's Manual provided with

the vehicle.

The Concealed Headlamps are controlled by the Body

Controller (Fig. 1). Refer to Group 8E, Instrument

Panel for service procedures. The Body Controller re-

ceives input information from the ignition switch, head-

lamp switch, and the headlamp dimmer switch. The Body Controller also controls the headlamp doors

when the Passing Lights (manually flashing bright

lights) are used. With the headlamp switch turned off,

actuating the headlamp dimmer switch will signal the

Body Controller to open the headlamp doors. The oper-

ator then has two seconds to flash the bright lights be-

fore the Body Controller closes the headlamp doors.

Holding the headlamp dimmer switch in the engaged

position will signal the Body Controller to keep the

headlamp doors open until the dimmer switch is re-

leased. Actuating the headlamp dimmer switch with the

parking lamps ON signals the Body Controller to open

the headlamp doors and keep them open until the head-

lamp switch is turned off.

AY and AC vehicles use a single motor, centrally

located behind the radiator grille, and linked to the

headlamp doors by a torsion bar. Refer to Service

Procedures for more information. The headlamp door drive motors are equipped with

a manual override hand wheel to open or close the

headlamp doors if a failure should occur or servicing

is required. Access to the handwheel can be gained

through a flap covered hole in the sight shield be-

hind the bumper fascia, and under the hood. Several

revolutions of the handwheel may be required to

move the headlamp doors.

DIAGNOSTIC PROCEDURES

Before diagnosing a problem with the headlamp

doors, check for possible collision damage, binding,

improperly installed assemblies, or freezing weather

conditions. When diagnosing an electrical problem, refer to:

² The Concealed Headlamps Electrical Diagnosis

chart in this section.

² The Wiring Diagrams Manual.

² The Headlamp Doors System section of the appro-

priate Body Diagnostic Procedures Manual.

PROBLEM

One headlamp door is inoperative when the head-

lamp switch is ON and the ignition switch is in the

RUN position. The other headlamp door operates

normally.

AC OR AY-VEHICLE BODY CHECK:

² Headlamp door pivot and crank for seizure.

² Headlamp torsion bar sleeve or clip for excessive

wear or breakage.

² Headlamp door crank for missing or broken screw.

² Headlamp torsion bar for disengagement or break-

age.

PROBLEM

Headlamp door operates erratically.

CHECK:

² For freezing weather conditions.

² For excessive effort to move headlamp door pivots.

² For corrosion or improperly aligned components.

² For stripped motor reduction gears.

² For defective body controller. Refer to the Con-

cealed Headlamp Electrical Diagnosis chart in this

section. Also refer to the Wiring Diagrams Manual

and Body Diagnostic Procedures Manual.

Fig. 1 Body Controller

Ä LAMPS 8L - 27