relay CHEVROLET DYNASTY 1993 Owners Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 721 of 2438

(3) Use an ohmmeter to test the wiring between

the door switch and the control module in the driv-

er's seat. The circuits should be disconnected from

their components at each end. Repair the wiring as

required for open circuits, terminal push outs, or bad

crimps. If the circuits are good to the control module

but the function is still missing, replace the control

module.

CONDITION: NO MOVEMENT OF THE SEAT, RELAYS CAN BE HEARD CLICKING WHENTHE SEAT SWITCH IS ACTIVATED.

PROCEDURE

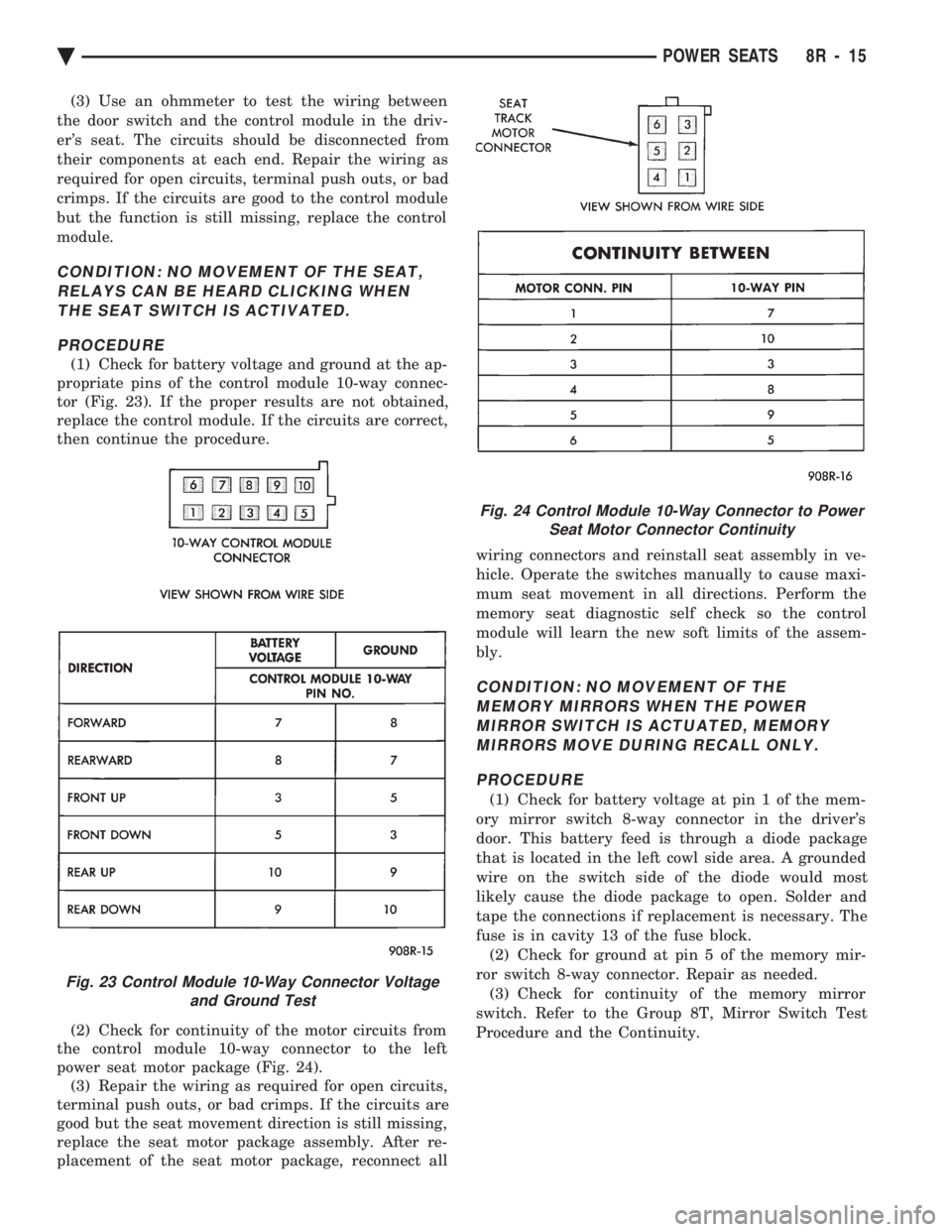

(1) Check for battery voltage and ground at the ap-

propriate pins of the control module 10-way connec-

tor (Fig. 23). If the proper results are not obtained,

replace the control module. If the circuits are correct,

then continue the procedure.

(2) Check for continuity of the motor circuits from

the control module 10-way connector to the left

power seat motor package (Fig. 24). (3) Repair the wiring as required for open circuits,

terminal push outs, or bad crimps. If the circuits are

good but the seat movement direction is still missing,

replace the seat motor package assembly. After re-

placement of the seat motor package, reconnect all wiring connectors and reinstall seat assembly in ve-

hicle. Operate the switches manually to cause maxi-

mum seat movement in all directions. Perform the

memory seat diagnostic self check so the control

module will learn the new soft limits of the assem-

bly.

CONDITION: NO MOVEMENT OF THE MEMORY MIRRORS WHEN THE POWERMIRROR SWITCH IS ACTUATED, MEMORYMIRRORS MOVE DURING RECALL ONLY.

PROCEDURE

(1) Check for battery voltage at pin 1 of the mem-

ory mirror switch 8-way connector in the driver's

door. This battery feed is through a diode package

that is located in the left cowl side area. A grounded

wire on the switch side of the diode would most

likely cause the diode package to open. Solder and

tape the connections if replacement is necessary. The

fuse is in cavity 13 of the fuse block. (2) Check for ground at pin 5 of the memory mir-

ror switch 8-way connector. Repair as needed. (3) Check for continuity of the memory mirror

switch. Refer to the Group 8T, Mirror Switch Test

Procedure and the Continuity.

Fig. 23 Control Module 10-Way Connector Voltage and Ground Test

Fig. 24 Control Module 10-Way Connector to PowerSeat Motor Connector Continuity

Ä POWER SEATS 8R - 15

Page 739 of 2438

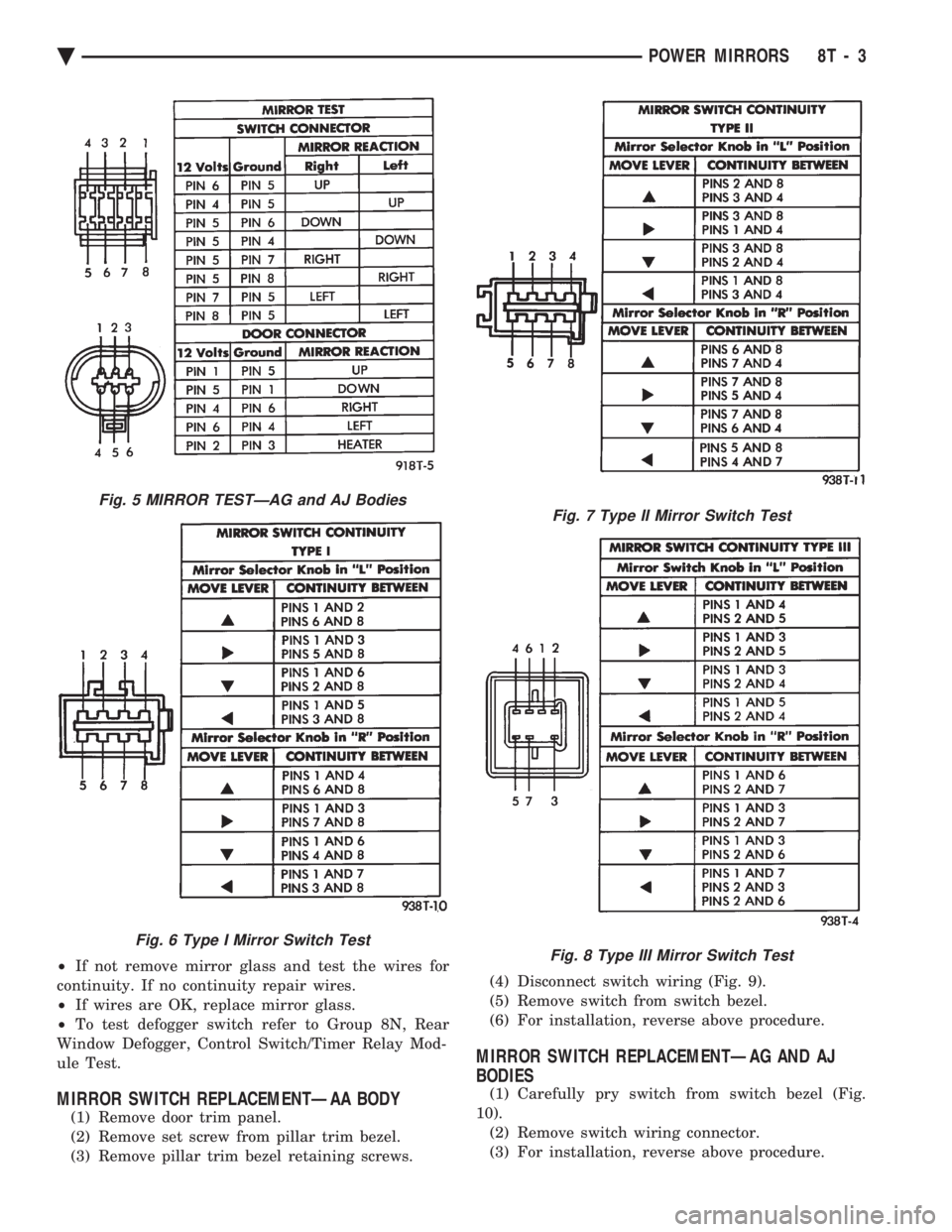

² If not remove mirror glass and test the wires for

continuity. If no continuity repair wires.

² If wires are OK, replace mirror glass.

² To test defogger switch refer to Group 8N, Rear

Window Defogger, Control Switch/Timer Relay Mod-

ule Test.

MIRROR SWITCH REPLACEMENTÐAA BODY

(1) Remove door trim panel.

(2) Remove set screw from pillar trim bezel.

(3) Remove pillar trim bezel retaining screws. (4) Disconnect switch wiring (Fig. 9).

(5) Remove switch from switch bezel.

(6) For installation, reverse above procedure.

MIRROR SWITCH REPLACEMENTÐAG AND AJ

BODIES

(1) Carefully pry switch from switch bezel (Fig.

10). (2) Remove switch wiring connector.

(3) For installation, reverse above procedure.

Fig. 5 MIRROR TESTÐAG and AJ Bodies

Fig. 6 Type I Mirror Switch Test

Fig. 7 Type II Mirror Switch Test

Fig. 8 Type III Mirror Switch Test

Ä POWER MIRRORS 8T - 3

Page 744 of 2438

(2) The headlamps and parking lamps should turn

ON for about five seconds.

² AUTO MIRROR LED

² DARK LED

² AUTO LAMP LED

² The LED indicators blink for about 5 seconds.

² If the three indicators continue to blink consider-

ably longer than 5 seconds, then the mirror assembly

is defective. (3) The mirror should change to dim state.(a) Place shift selector in reverse (R), with igni-

tion switch ON:

² AUTO MIRROR LED indicator ON

² DARK LED indicator flashing

² Lasting about 15 seconds

(b) The mirror should slowly change to bright

state. (c) If the ignition is not turned OFF within the

15 second time period, the mirror will reset to its

previous setting.

The previous conditions are OK, the mirror is op-

erating properly. If not OK, continue with voltage tests below.

VOLTAGE TEST

To test for voltage insert voltmeter probe into wire

end of connector to contact terminal. Pin 1 ignition voltage (a) Ignition switch OFF, zero volts.

(b) Ignition switch ON, battery voltage.

Pin 2 battery voltage (a) Battery voltage at all times.

(b) No voltage, check 15 amp. fuse.

Pin 3 Ground (a) Continuity to ground.

(b) No voltage

Pin 4 Reverse over-ride (a) Ignition OFF, zero voltage.

(b) Ignition ON shift selector in Reverse (R), bat-

tery voltage. (c) Ignition ON shift selector in any position

other than Reverse (R), zero voltage.

Pin 5 Headlamp relay (a) Battery voltage at all times from headlamp

relay. (b) No battery voltage, test headlamp relay.

Pin 6 Park lamp relay (a) Ignition switch ON, battery voltage feed from

park lamp relay. (b) Ignition switch OFF, zero voltage.

(c) Ignition ON, No battery voltage test park

lamp relay.

If Voltage Test are OK, replace mirror assembly.

If not OK, refer to Wiring Diagrams manual.

8T - 8 POWER MIRRORS Ä

Page 745 of 2438

CHIME WARNING/REMINDER SYSTEM

CONTENTS

page page

BODY CONTROLLER REPLACEMENT ........ 5

CHIME MODULE REPLACEMENT AA and AP BODIES .............................. 5

CHIME SYSTEM DIAGNOSISÐAA AND AP BODIES .............................. 2

CHIME SYSTEM DIAGNOSISÐAC, AG, AJ AND AY BODIES ....................... 3

CHIME WARNING/REMINDER SYSTEM TEST . 1 GENERAL INFORMATION

.................. 1

HEADLAMP SWITCH REPLACEMENT ........ 5

KEY-IN SWITCH REPLACEMENT ............ 5

SEAT BELT BUCKLE REPLACEMENT ........ 5

SEAT BELT BUCKLE SWITCH TEST BUZZER SYSTEM .............................. 1

SERVICE PROCEDURES ................... 5

TIMED BUZZER-RELAY TESTÐAP BODY ..... 1

GENERAL INFORMATION

WARNING: ON VEHICLES EQUIPPED WITH AN AIR

BAG REFER TO THE AIR BAG PORTION OF THIS

SECTION FOR STEERING WHEEL OR SWITCH RE-

MOVAL AND INSTALLATION PROCEDURES.

BUZZER SYSTEM

The seat belt warning system uses both visual and

audible signals. A combined seat belt and key warn-

ing buzzer with a red light on the instrument panel. The system will always illuminate the seat belt

warning lamp for four to eight seconds when the ig-

nition switch is turned to the ON position. Also, only

if the driver does not fasten his seat belt, the buzzer

will sound during the same time interval. Passenger

belts are not connected to the system. A timed buzzer-relay is used to operate the system

for the time period. It consists of a time delay mech-

anism and buzzer assembly. Only the driver's seat

belt buckle has a switch that is connected to the sys-

tem.

CHIME WARNING/REMINDER SYSTEM

The chime warning/reminder system is similar in

operation to the buzzer system except for a more

pleasant sounding tone. This chime type tone sounds

for all three warning/reminder conditions; namely

headlamps left on, keys left in ignition and fasten

seat belt.

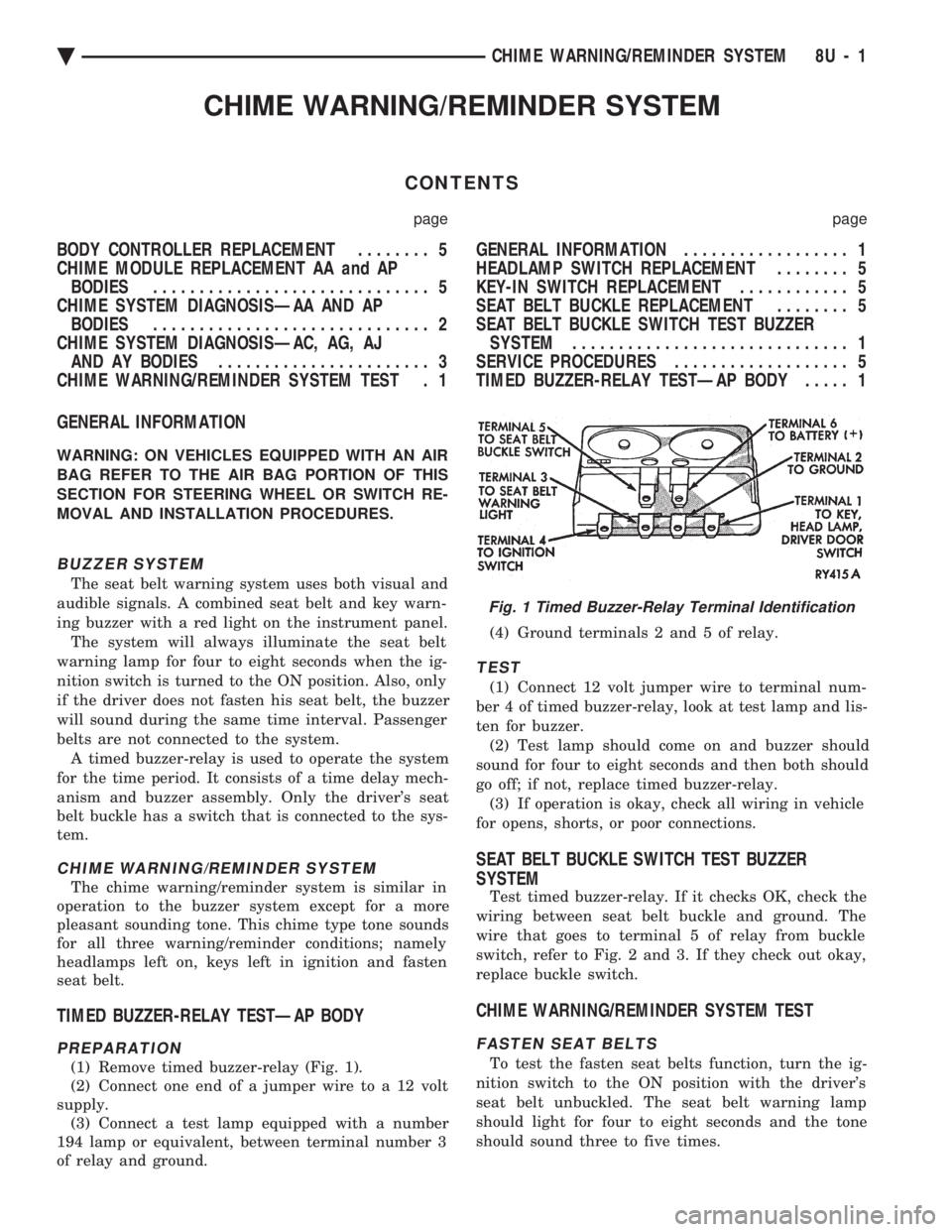

TIMED BUZZER-RELAY TESTÐAP BODY

PREPARATION

(1) Remove timed buzzer-relay (Fig. 1).

(2) Connect one end of a jumper wire to a 12 volt

supply. (3) Connect a test lamp equipped with a number

194 lamp or equivalent, between terminal number 3

of relay and ground. (4) Ground terminals 2 and 5 of relay.

TEST

(1) Connect 12 volt jumper wire to terminal num-

ber 4 of timed buzzer-relay, look at test lamp and lis-

ten for buzzer. (2) Test lamp should come on and buzzer should

sound for four to eight seconds and then both should

go off; if not, replace timed buzzer-relay. (3) If operation is okay, check all wiring in vehicle

for opens, shorts, or poor connections.

SEAT BELT BUCKLE SWITCH TEST BUZZER

SYSTEM

Test timed buzzer-relay. If it checks OK, check the

wiring between seat belt buckle and ground. The

wire that goes to terminal 5 of relay from buckle

switch, refer to Fig. 2 and 3. If they check out okay,

replace buckle switch.

CHIME WARNING/REMINDER SYSTEM TEST

FASTEN SEAT BELTS

To test the fasten seat belts function, turn the ig-

nition switch to the ON position with the driver's

seat belt unbuckled. The seat belt warning lamp

should light for four to eight seconds and the tone

should sound three to five times.

Fig. 1 Timed Buzzer-Relay Terminal Identification

Ä CHIME WARNING/REMINDER SYSTEM 8U - 1

Page 751 of 2438

GENERAL INFORMATION

CONTENTS

page page

CIRCUIT IDENTIFICATION ................. 3

COMPONENT IDENTIFICATION ............. 3

CONNECTORS ........................... 4

FUSIBLE LINKS ......................... 4

HARNESS REPAIR ....................... 4

LOCATING A SYSTEM .................... 3 SECONDARY IGNITION WIRING

............ 1

SPLICE LOCATIONS ...................... 3

SYMBOLS, FUSES AND RELAYS ........... 7

TROUBLESHOOTING WIRING PROBLEMS .... 4

WIRE CODE IDENTIFICATION .............. 2

WIRING DIAGRAM SHEETS AND INDEXES . . . 1

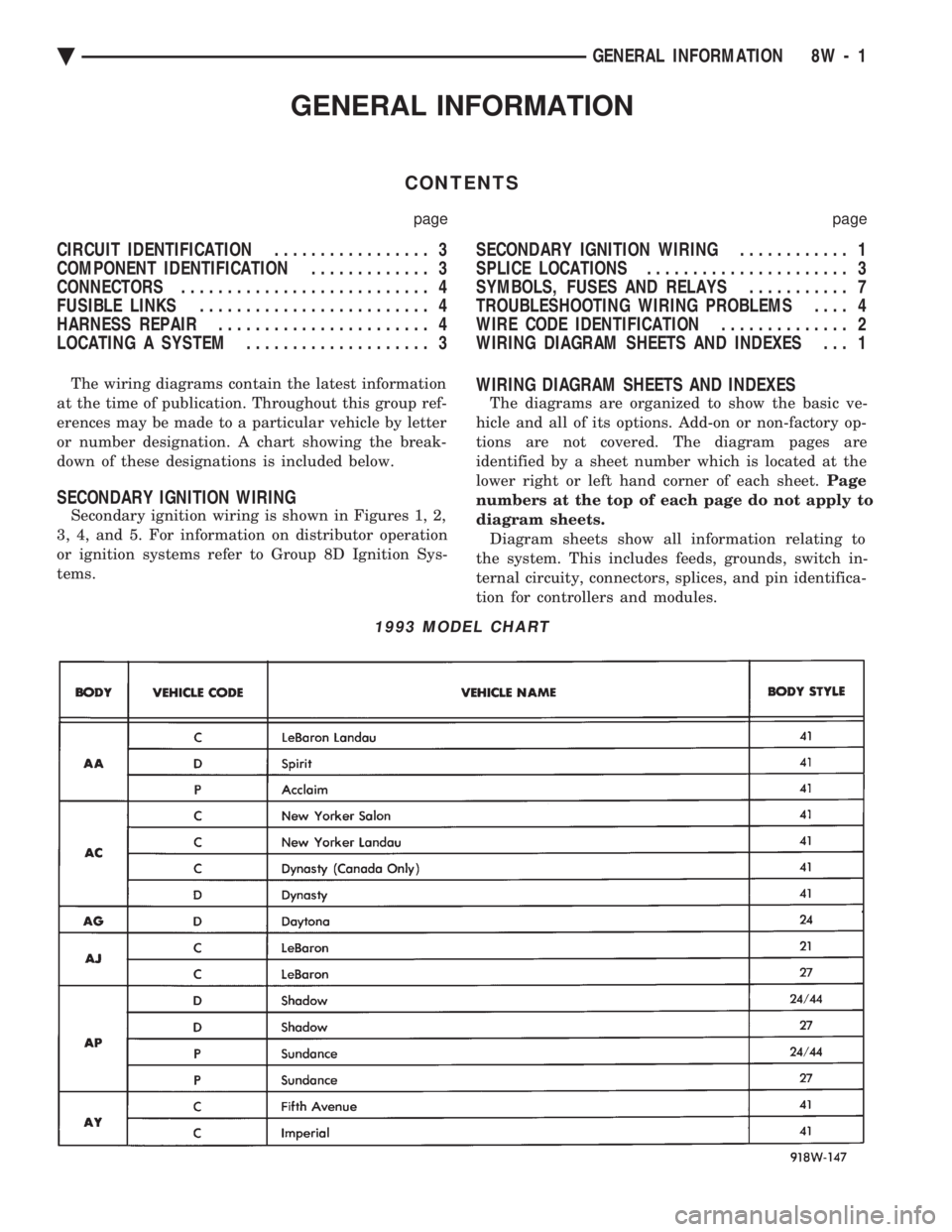

The wiring diagrams contain the latest information

at the time of publication. Throughout this group ref-

erences may be made to a particular vehicle by letter

or number designation. A chart showing the break-

down of these designations is included below.

SECONDARY IGNITION WIRING

Secondary ignition wiring is shown in Figures 1, 2,

3, 4, and 5. For information on distributor operation

or ignition systems refer to Group 8D Ignition Sys-

tems.

WIRING DIAGRAM SHEETS AND INDEXES

The diagrams are organized to show the basic ve-

hicle and all of its options. Add-on or non-factory op-

tions are not covered. The diagram pages are

identified by a sheet number which is located at the

lower right or left hand corner of each sheet. Page

numbers at the top of each page do not apply to

diagram sheets. Diagram sheets show all information relating to

the system. This includes feeds, grounds, switch in-

ternal circuity, connectors, splices, and pin identifica-

tion for controllers and modules.

1993 MODEL CHART

Ä GENERAL INFORMATION 8W - 1

Page 757 of 2438

(14) Center the heat shrink tubing over the joint

and heat using a heat gun. Heat the joint until the

tubing is tightly sealed and sealant comes out of both

ends of the tubing. (15) Insert the repaired wire into the connector.

(16) Install the connector locking wedge and recon-

nect the connector to its mating half. (17) Re-tape the wire harness starting 1-1/2 inches

behind the connector and 2 inches past the repair. (18) Connect battery and test all affected systems.

SYMBOLS, FUSES AND RELAYS

Various symbols are used throughout the wiring

diagrams. These symbols can be identified by refer-

ring to the symbol identification chart (Fig. 15). For fuse block, relay bank, or power distribution

center information refer to the fuse charts and relay

bank section.

CAUTION: When replacing a blown fuse it is impor-

tant to replace it with a fuse having the correct am-

perage rating. The use of a fuse with a rating other

than indicated may result in an electrical overload.

If a proper rated fuse continues to blow, it indicates

a problem that should be corrected.

Ä GENERAL INFORMATION 8W - 7

Page 759 of 2438

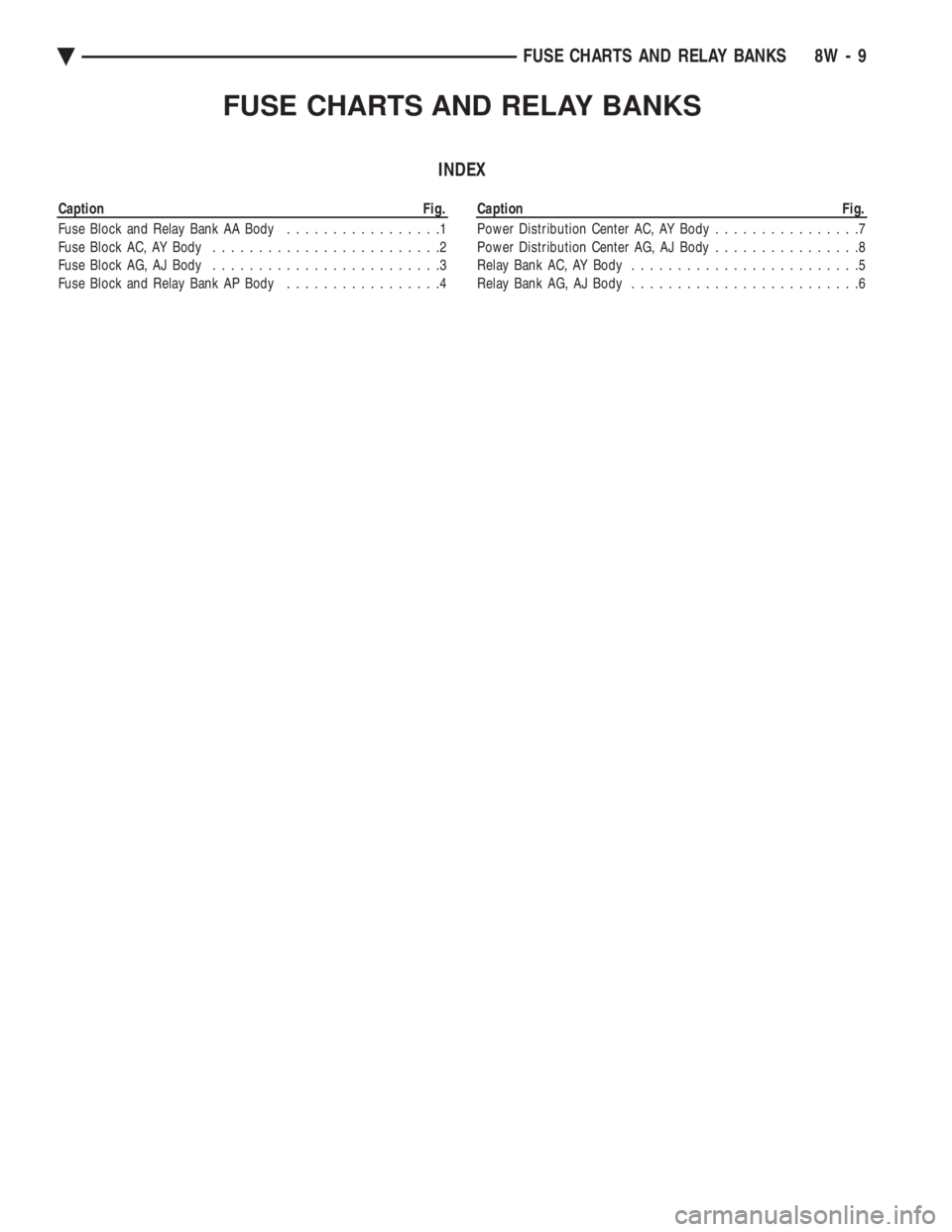

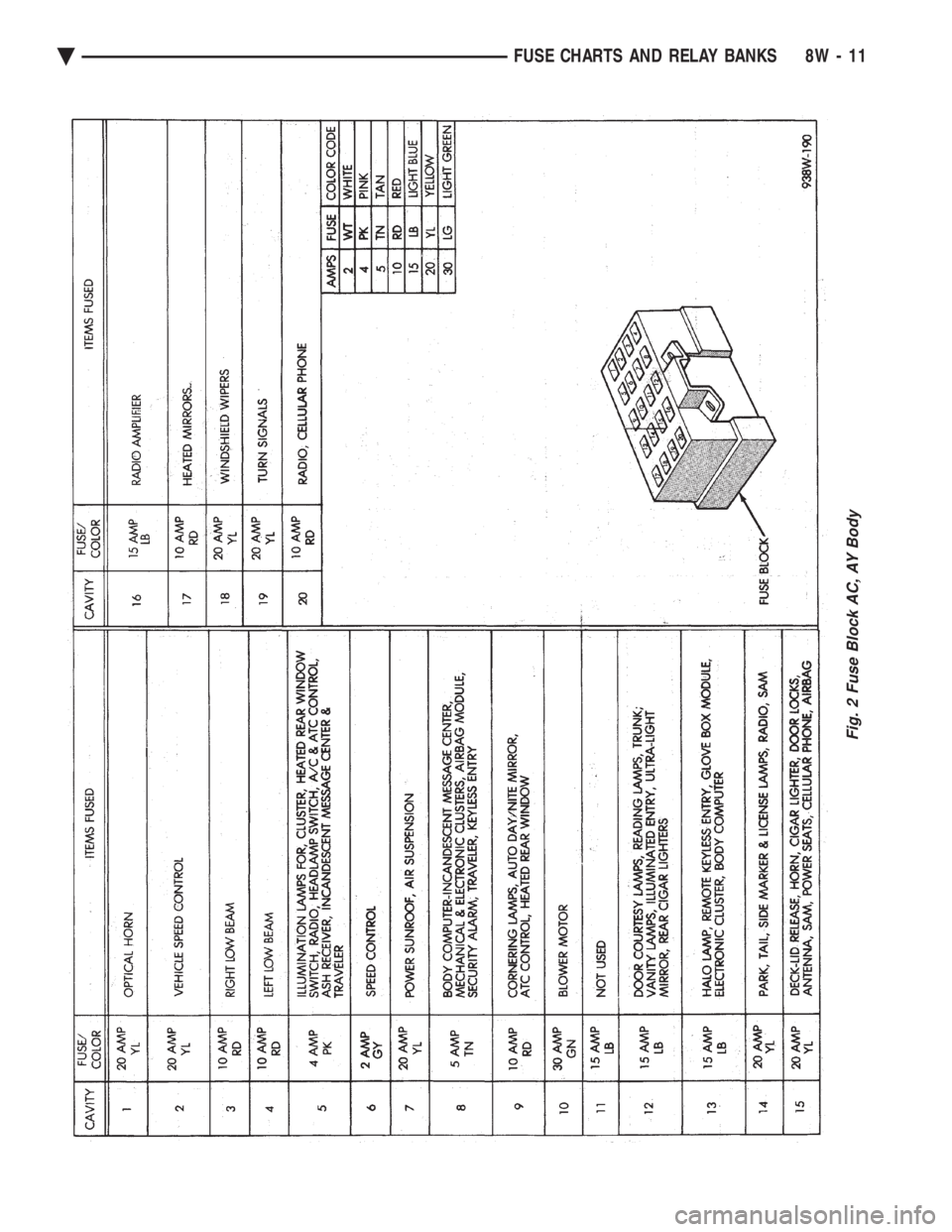

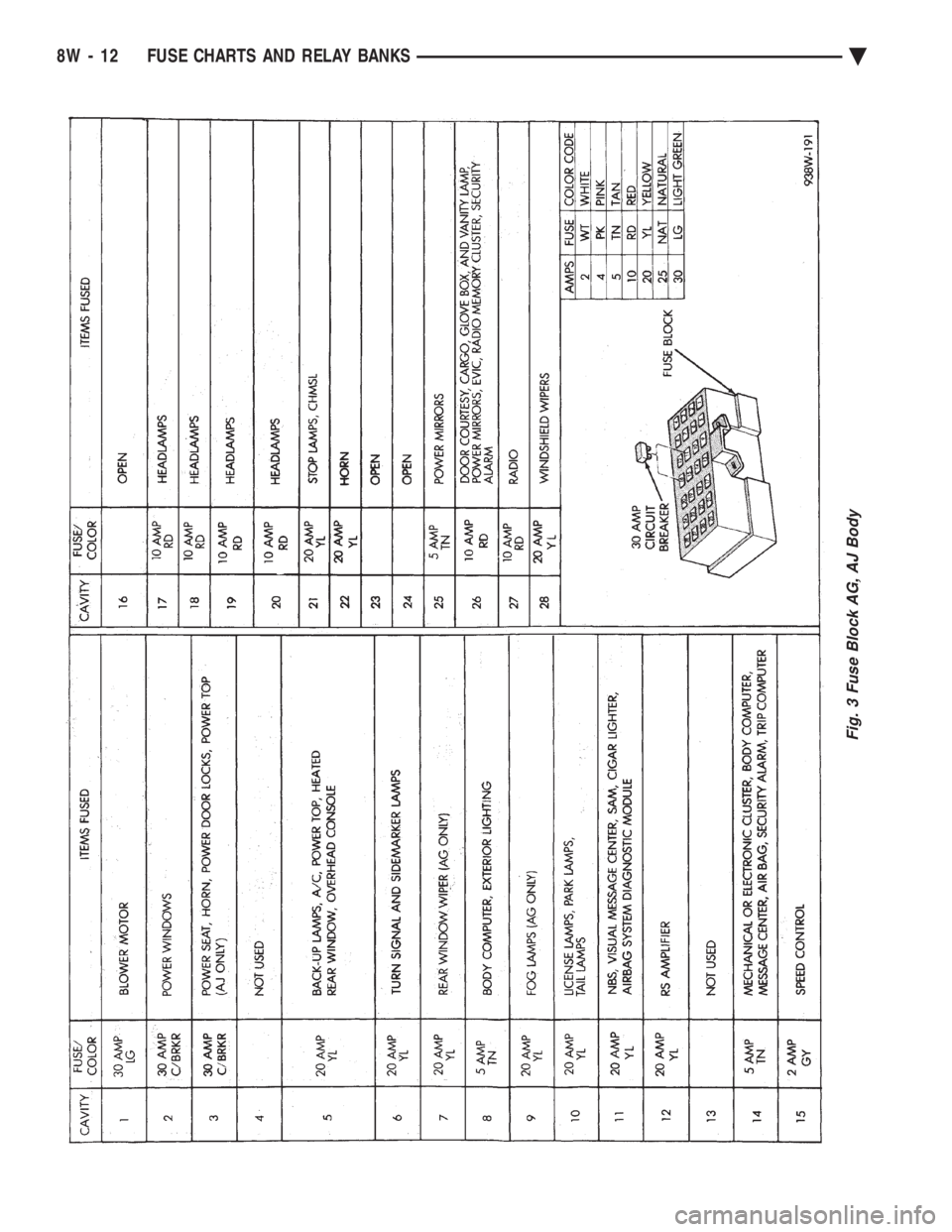

FUSE CHARTS AND RELAY BANKS

INDEX

Caption Fig.

Fuse Block and Relay Bank AA Body .................1

Fuse Block AC, AY Body .........................2

Fuse Block AG, AJ Body .........................3

Fuse Block and Relay Bank AP Body .................4Caption Fig.

Power Distribution Center AC, AY Body ................7

Power Distribution Center AG, AJ Body ................8

Relay Bank AC, AY Body .........................5

Relay Bank AG, AJ Body .........................6

Ä FUSE CHARTS AND RELAY BANKS 8W - 9

Page 760 of 2438

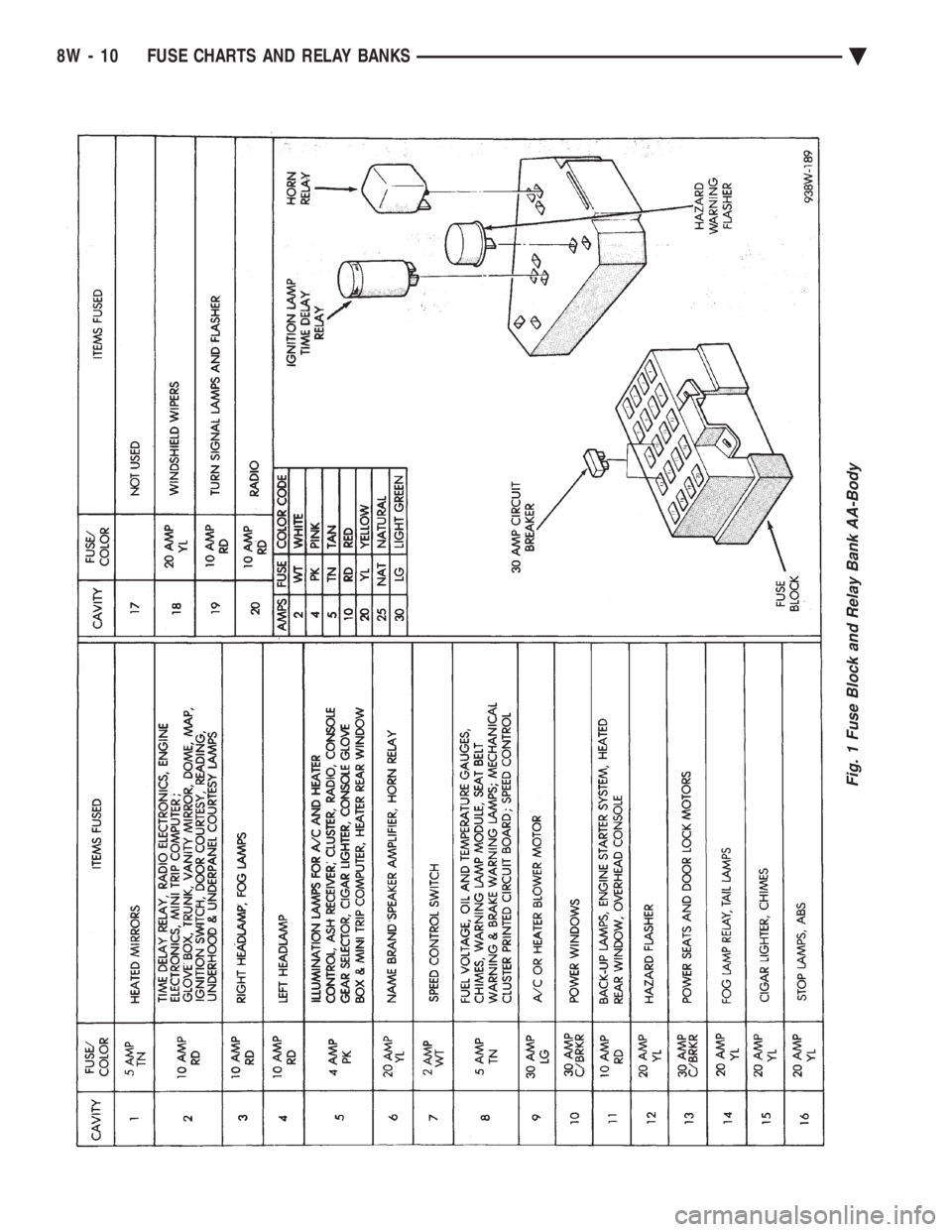

Fig. 1 Fuse Block and Relay Bank AA-Body

8W - 10 FUSE CHARTS AND RELAY BANKS Ä

Page 761 of 2438

Fig. 2 Fuse Block AC, AY Body

Ä FUSE CHARTS AND RELAY BANKS 8W - 11

Page 762 of 2438

Fig. 3 Fuse Block AG, AJ Body

8W - 12 FUSE CHARTS AND RELAY BANKS Ä