relay CHEVROLET DYNASTY 1993 Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 448 of 2438

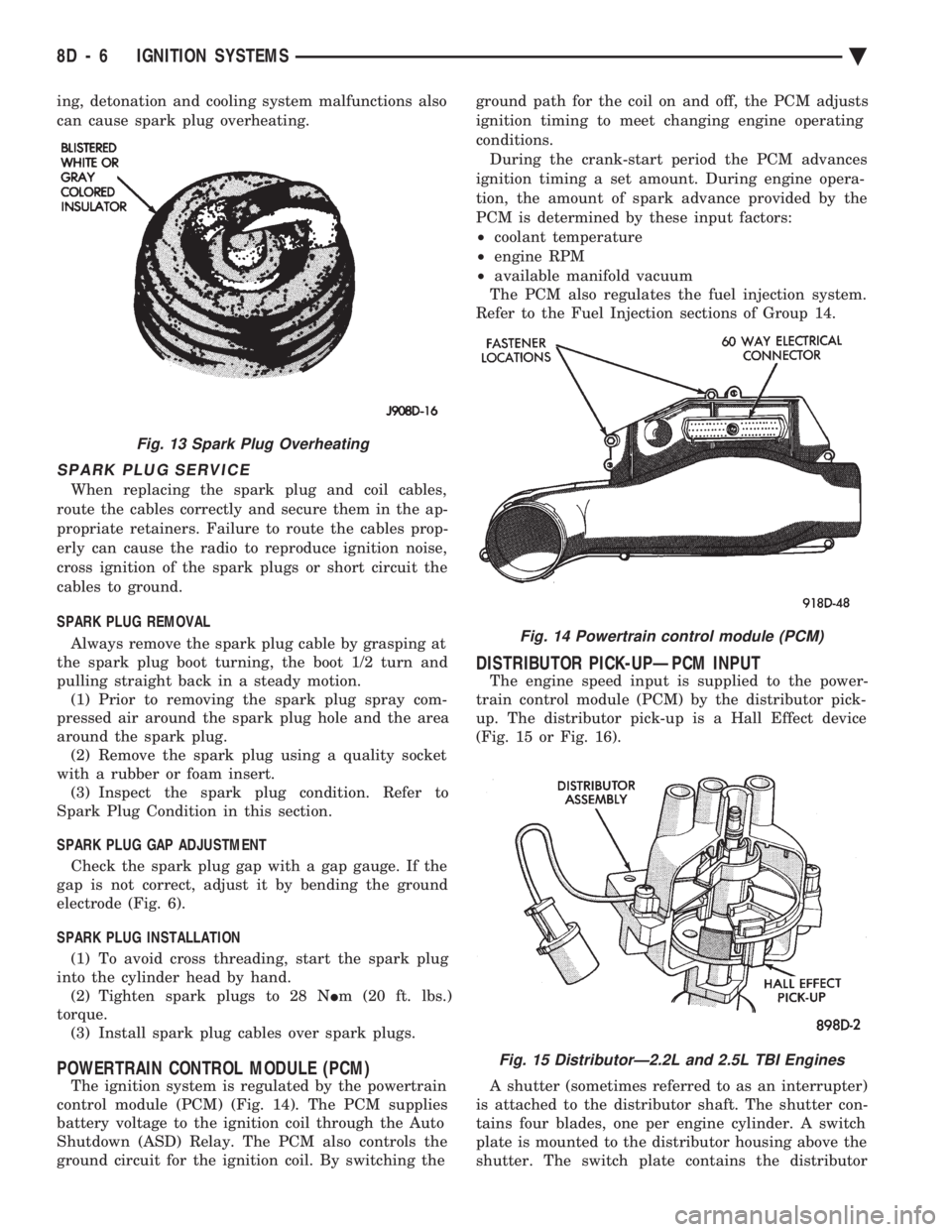

ing, detonation and cooling system malfunctions also

can cause spark plug overheating.

SPARK PLUG SERVICE

When replacing the spark plug and coil cables,

route the cables correctly and secure them in the ap-

propriate retainers. Failure to route the cables prop-

erly can cause the radio to reproduce ignition noise,

cross ignition of the spark plugs or short circuit the

cables to ground.

SPARK PLUG REMOVAL

Always remove the spark plug cable by grasping at

the spark plug boot turning, the boot 1/2 turn and

pulling straight back in a steady motion. (1) Prior to removing the spark plug spray com-

pressed air around the spark plug hole and the area

around the spark plug. (2) Remove the spark plug using a quality socket

with a rubber or foam insert. (3) Inspect the spark plug condition. Refer to

Spark Plug Condition in this section.

SPARK PLUG GAP ADJUSTMENT Check the spark plug gap with a gap gauge. If the

gap is not correct, adjust it by bending the ground

electrode (Fig. 6).

SPARK PLUG INSTALLATION (1) To avoid cross threading, start the spark plug

into the cylinder head by hand. (2) Tighten spark plugs to 28 N Im (20 ft. lbs.)

torque. (3) Install spark plug cables over spark plugs.

POWERTRAIN CONTROL MODULE (PCM)

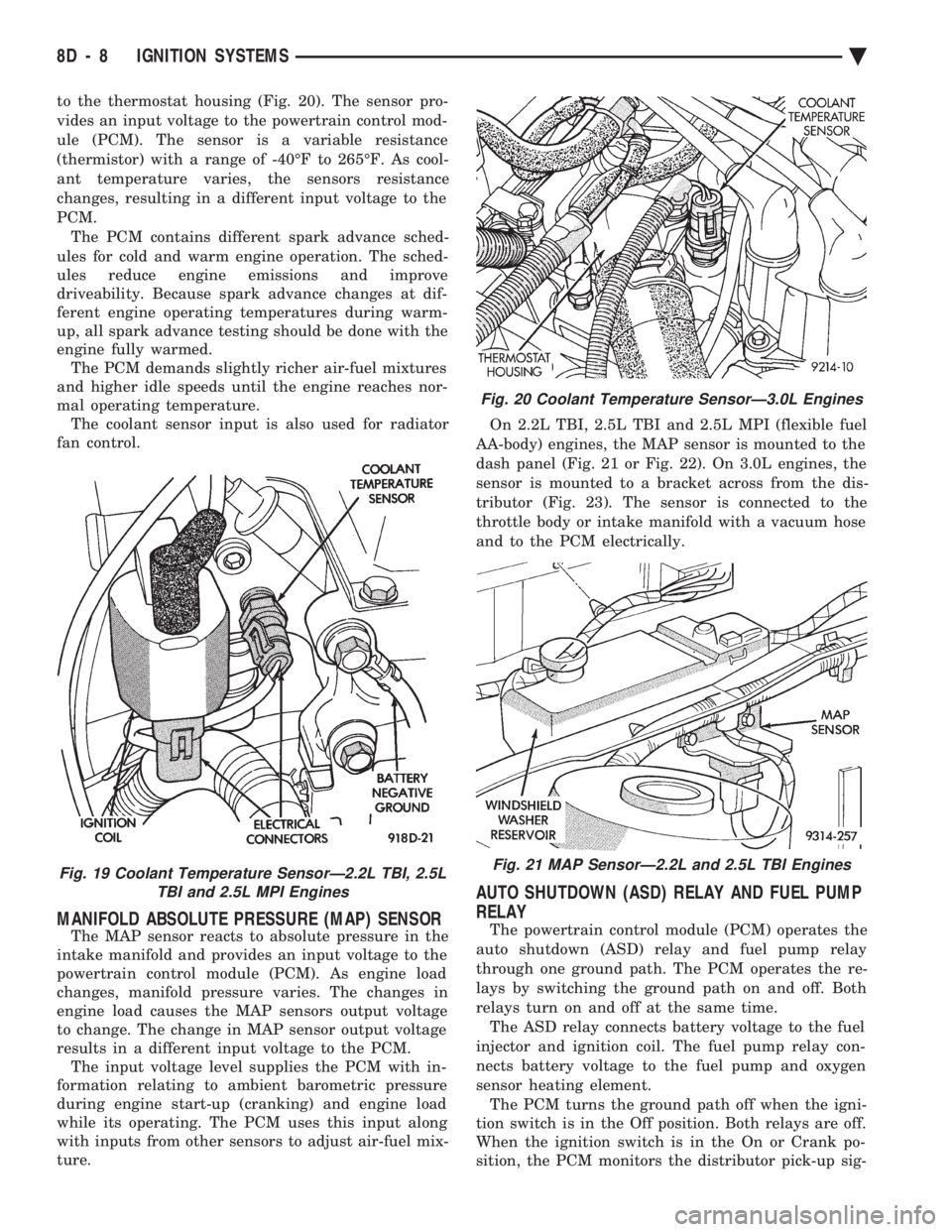

The ignition system is regulated by the powertrain

control module (PCM) (Fig. 14). The PCM supplies

battery voltage to the ignition coil through the Auto

Shutdown (ASD) Relay. The PCM also controls the

ground circuit for the ignition coil. By switching the ground path for the coil on and off, the PCM adjusts

ignition timing to meet changing engine operating

conditions.

During the crank-start period the PCM advances

ignition timing a set amount. During engine opera-

tion, the amount of spark advance provided by the

PCM is determined by these input factors:

² coolant temperature

² engine RPM

² available manifold vacuum

The PCM also regulates the fuel injection system.

Refer to the Fuel Injection sections of Group 14.

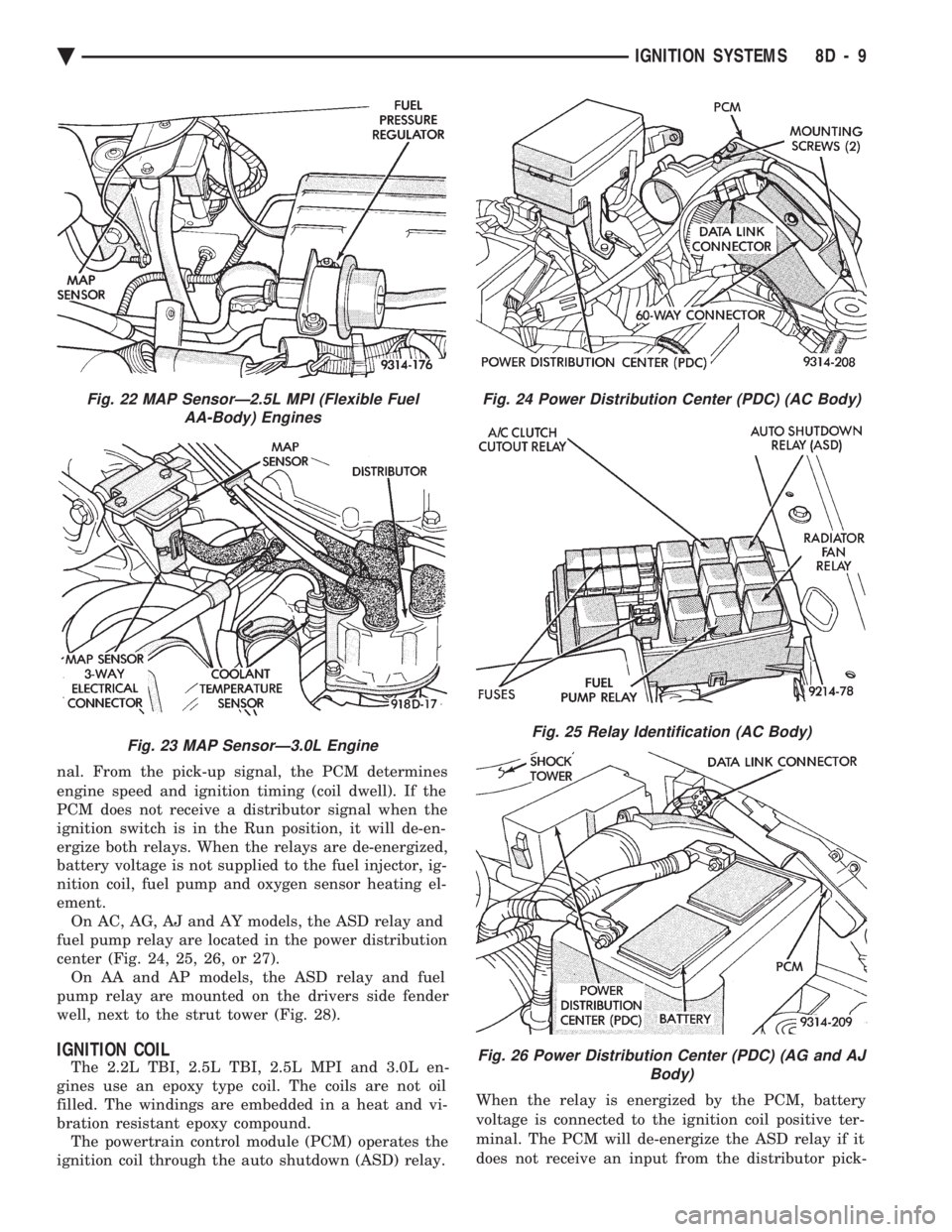

DISTRIBUTOR PICK-UPÐPCM INPUT

The engine speed input is supplied to the power-

train control module (PCM) by the distributor pick-

up. The distributor pick-up is a Hall Effect device

(Fig. 15 or Fig. 16).

A shutter (sometimes referred to as an interrupter)

is attached to the distributor shaft. The shutter con-

tains four blades, one per engine cylinder. A switch

plate is mounted to the distributor housing above the

shutter. The switch plate contains the distributor

Fig. 14 Powertrain control module (PCM)

Fig. 15 DistributorÐ2.2L and 2.5L TBI Engines

Fig. 13 Spark Plug Overheating

8D - 6 IGNITION SYSTEMS Ä

Page 450 of 2438

to the thermostat housing (Fig. 20). The sensor pro-

vides an input voltage to the powertrain control mod-

ule (PCM). The sensor is a variable resistance

(thermistor) with a range of -40ÉF to 265ÉF. As cool-

ant temperature varies, the sensors resistance

changes, resulting in a different input voltage to the

PCM. The PCM contains different spark advance sched-

ules for cold and warm engine operation. The sched-

ules reduce engine emissions and improve

driveability. Because spark advance changes at dif-

ferent engine operating temperatures during warm-

up, all spark advance testing should be done with the

engine fully warmed. The PCM demands slightly richer air-fuel mixtures

and higher idle speeds until the engine reaches nor-

mal operating temperature. The coolant sensor input is also used for radiator

fan control.

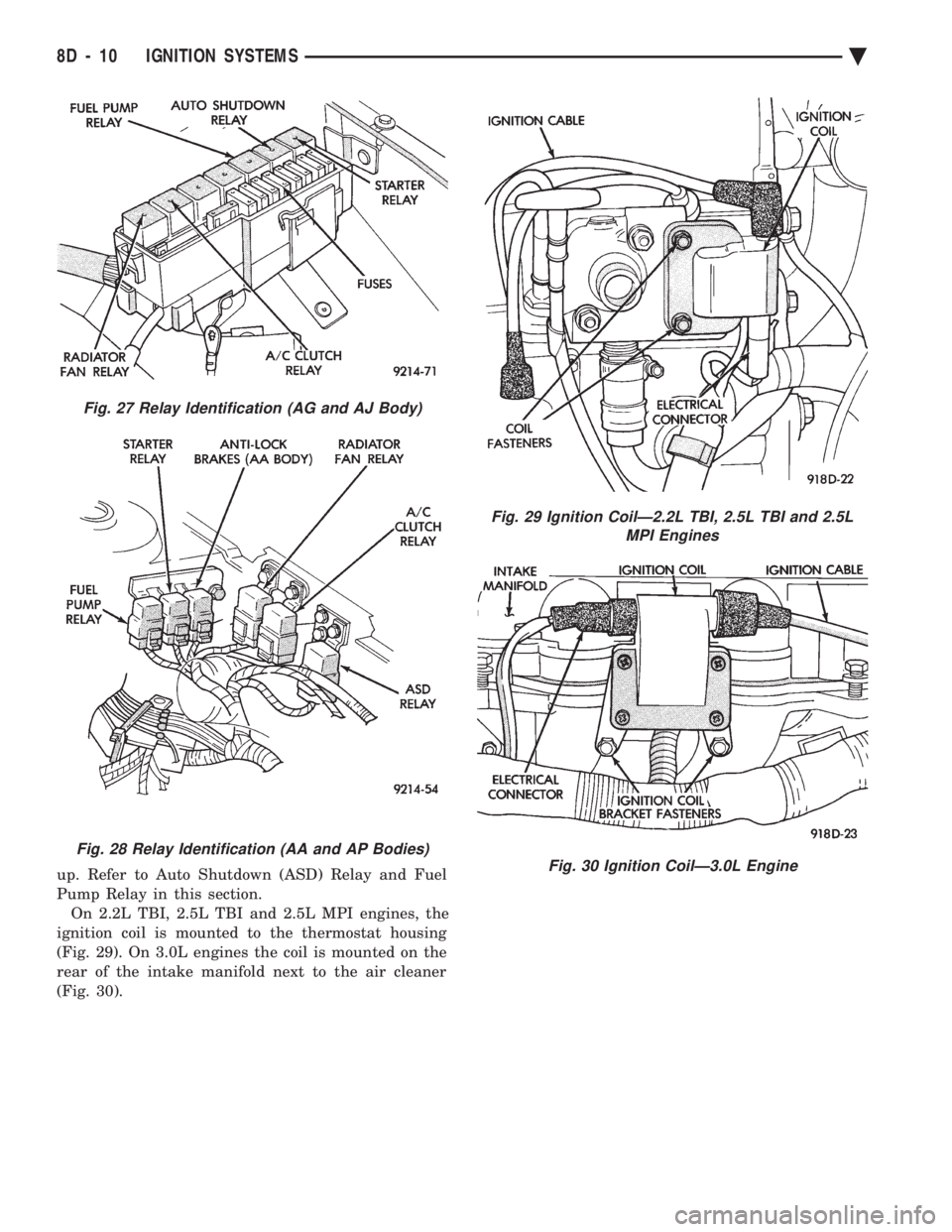

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

The MAP sensor reacts to absolute pressure in the

intake manifold and provides an input voltage to the

powertrain control module (PCM). As engine load

changes, manifold pressure varies. The changes in

engine load causes the MAP sensors output voltage

to change. The change in MAP sensor output voltage

results in a different input voltage to the PCM. The input voltage level supplies the PCM with in-

formation relating to ambient barometric pressure

during engine start-up (cranking) and engine load

while its operating. The PCM uses this input along

with inputs from other sensors to adjust air-fuel mix-

ture. On 2.2L TBI, 2.5L TBI and 2.5L MPI (flexible fuel

AA-body) engines, the MAP sensor is mounted to the

dash panel (Fig. 21 or Fig. 22). On 3.0L engines, the

sensor is mounted to a bracket across from the dis-

tributor (Fig. 23). The sensor is connected to the

throttle body or intake manifold with a vacuum hose

and to the PCM electrically.

AUTO SHUTDOWN (ASD) RELAY AND FUEL PUMP

RELAY

The powertrain control module (PCM) operates the

auto shutdown (ASD) relay and fuel pump relay

through one ground path. The PCM operates the re-

lays by switching the ground path on and off. Both

relays turn on and off at the same time. The ASD relay connects battery voltage to the fuel

injector and ignition coil. The fuel pump relay con-

nects battery voltage to the fuel pump and oxygen

sensor heating element. The PCM turns the ground path off when the igni-

tion switch is in the Off position. Both relays are off.

When the ignition switch is in the On or Crank po-

sition, the PCM monitors the distributor pick-up sig-

Fig. 19 Coolant Temperature SensorÐ2.2L TBI, 2.5L TBI and 2.5L MPI Engines

Fig. 20 Coolant Temperature SensorÐ3.0L Engines

Fig. 21 MAP SensorÐ2.2L and 2.5L TBI Engines

8D - 8 IGNITION SYSTEMS Ä

Page 451 of 2438

nal. From the pick-up signal, the PCM determines

engine speed and ignition timing (coil dwell). If the

PCM does not receive a distributor signal when the

ignition switch is in the Run position, it will de-en-

ergize both relays. When the relays are de-energized,

battery voltage is not supplied to the fuel injector, ig-

nition coil, fuel pump and oxygen sensor heating el-

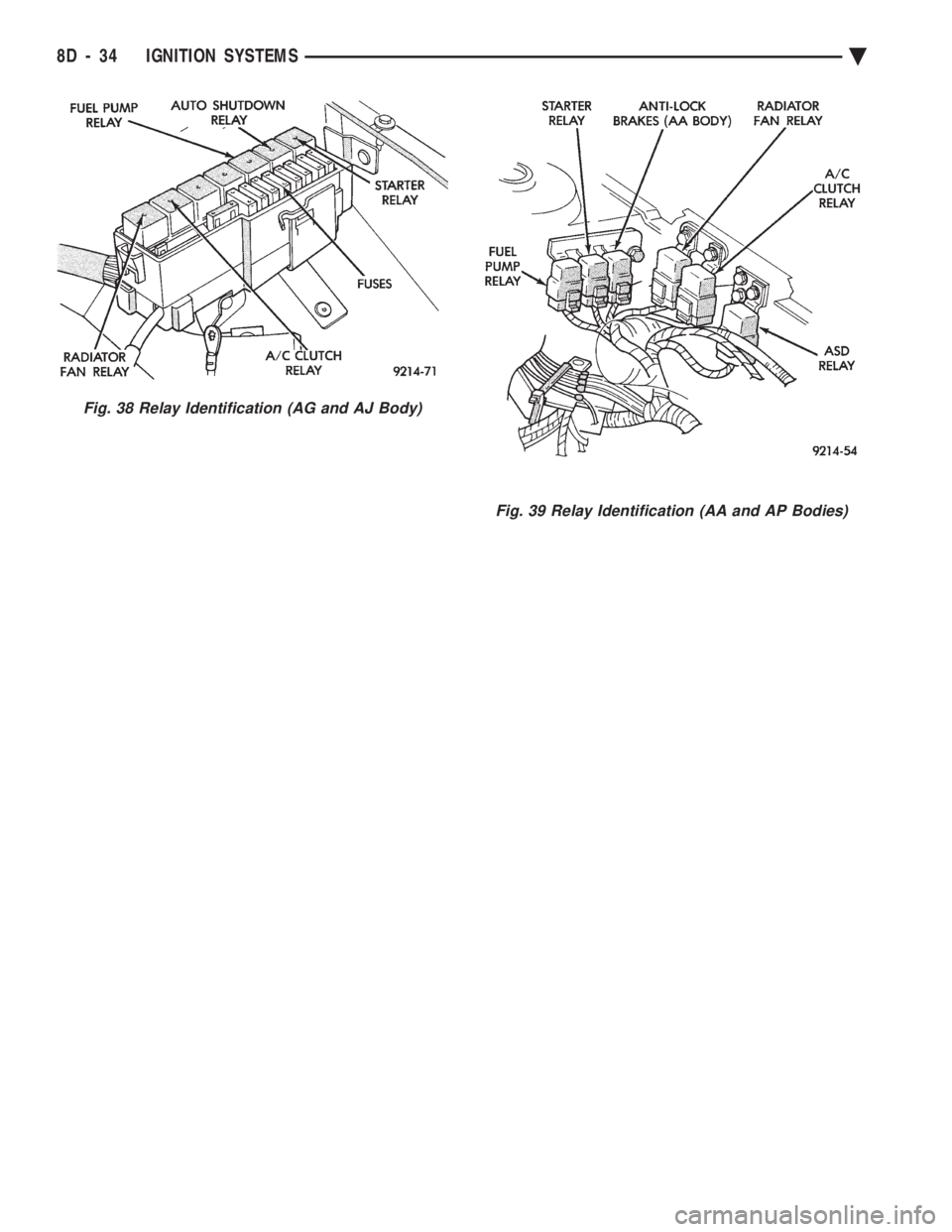

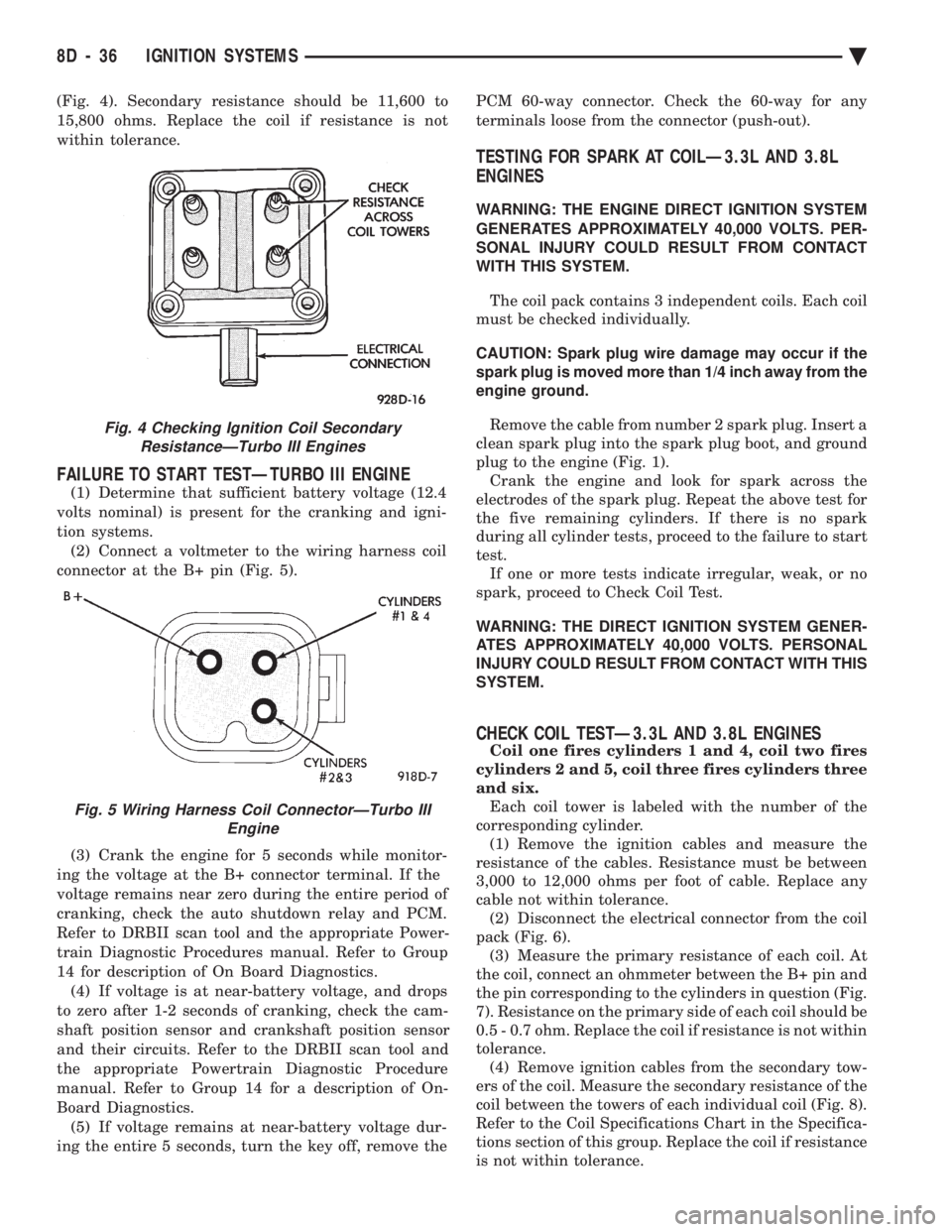

ement. On AC, AG, AJ and AY models, the ASD relay and

fuel pump relay are located in the power distribution

center (Fig. 24, 25, 26, or 27). On AA and AP models, the ASD relay and fuel

pump relay are mounted on the drivers side fender

well, next to the strut tower (Fig. 28).

IGNITION COIL

The 2.2L TBI, 2.5L TBI, 2.5L MPI and 3.0L en-

gines use an epoxy type coil. The coils are not oil

filled. The windings are embedded in a heat and vi-

bration resistant epoxy compound. The powertrain control module (PCM) operates the

ignition coil through the auto shutdown (ASD) relay. When the relay is energized by the PCM, battery

voltage is connected to the ignition coil positive ter-

minal. The PCM will de-energize the ASD relay if it

does not receive an input from the distributor pick-

Fig. 22 MAP SensorÐ2.5L MPI (Flexible Fuel AA-Body) Engines

Fig. 23 MAP SensorÐ3.0L Engine

Fig. 24 Power Distribution Center (PDC) (AC Body)

Fig. 25 Relay Identification (AC Body)

Fig. 26 Power Distribution Center (PDC) (AG and AJ Body)

Ä IGNITION SYSTEMS 8D - 9

Page 452 of 2438

up. Refer to Auto Shutdown (ASD) Relay and Fuel

Pump Relay in this section.On 2.2L TBI, 2.5L TBI and 2.5L MPI engines, the

ignition coil is mounted to the thermostat housing

(Fig. 29). On 3.0L engines the coil is mounted on the

rear of the intake manifold next to the air cleaner

(Fig. 30).

Fig. 28 Relay Identification (AA and AP Bodies)

Fig. 29 Ignition CoilÐ2.2L TBI, 2.5L TBI and 2.5L MPI Engines

Fig. 30 Ignition CoilÐ3.0L Engine

Fig. 27 Relay Identification (AG and AJ Body)

8D - 10 IGNITION SYSTEMS Ä

Page 454 of 2438

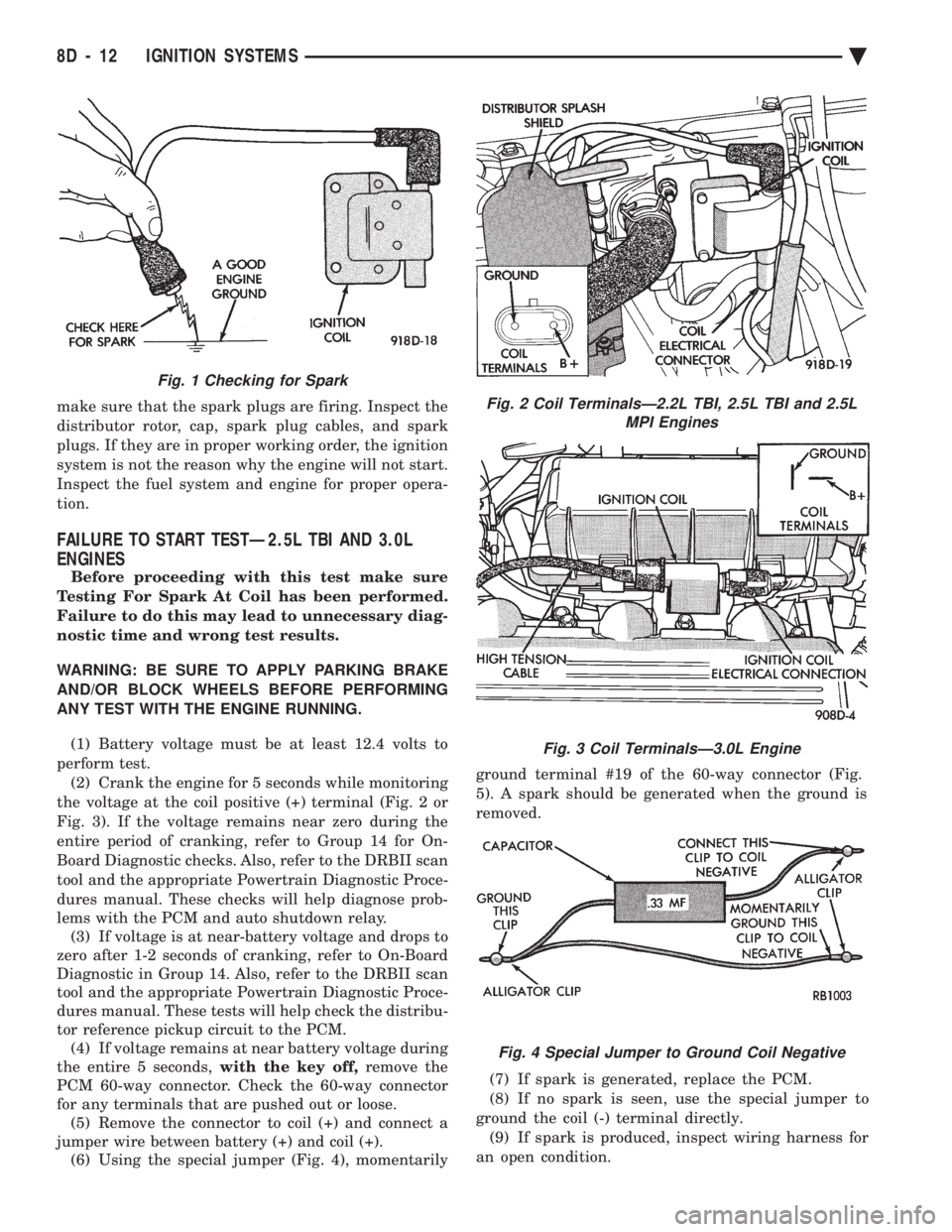

make sure that the spark plugs are firing. Inspect the

distributor rotor, cap, spark plug cables, and spark

plugs. If they are in proper working order, the ignition

system is not the reason why the engine will not start.

Inspect the fuel system and engine for proper opera-

tion.

FAILURE TO START TESTÐ2.5L TBI AND 3.0L

ENGINES

Before proceeding with this test make sure

Testing For Spark At Coil has been performed.

Failure to do this may lead to unnecessary diag-

nostic time and wrong test results.

WARNING: BE SURE TO APPLY PARKING BRAKE

AND/OR BLOCK WHEELS BEFORE PERFORMING

ANY TEST WITH THE ENGINE RUNNING.

(1) Battery voltage must be at least 12.4 volts to

perform test. (2) Crank the engine for 5 seconds while monitoring

the voltage at the coil positive (+) terminal (Fig. 2 or

Fig. 3). If the voltage remains near zero during the

entire period of cranking, refer to Group 14 for On-

Board Diagnostic checks. Also, refer to the DRBII scan

tool and the appropriate Powertrain Diagnostic Proce-

dures manual. These checks will help diagnose prob-

lems with the PCM and auto shutdown relay. (3) If voltage is at near-battery voltage and drops to

zero after 1-2 seconds of cranking, refer to On-Board

Diagnostic in Group 14. Also, refer to the DRBII scan

tool and the appropriate Powertrain Diagnostic Proce-

dures manual. These tests will help check the distribu-

tor reference pickup circuit to the PCM. (4) If voltage remains at near battery voltage during

the entire 5 seconds, with the key off,remove the

PCM 60-way connector. Check the 60-way connector

for any terminals that are pushed out or loose. (5) Remove the connector to coil (+) and connect a

jumper wire between battery (+) and coil (+). (6) Using the special jumper (Fig. 4), momentarily ground terminal #19 of the 60-way connector (Fig.

5). A spark should be generated when the ground is

removed.

(7) If spark is generated, replace the PCM.

(8) If no spark is seen, use the special jumper to

ground the coil (-) terminal directly. (9) If spark is produced, inspect wiring harness for

an open condition.

Fig. 2 Coil TerminalsÐ2.2L TBI, 2.5L TBI and 2.5L MPI Engines

Fig. 3 Coil TerminalsÐ3.0L Engine

Fig. 4 Special Jumper to Ground Coil Negative

Fig. 1 Checking for Spark

8D - 12 IGNITION SYSTEMS Ä

Page 466 of 2438

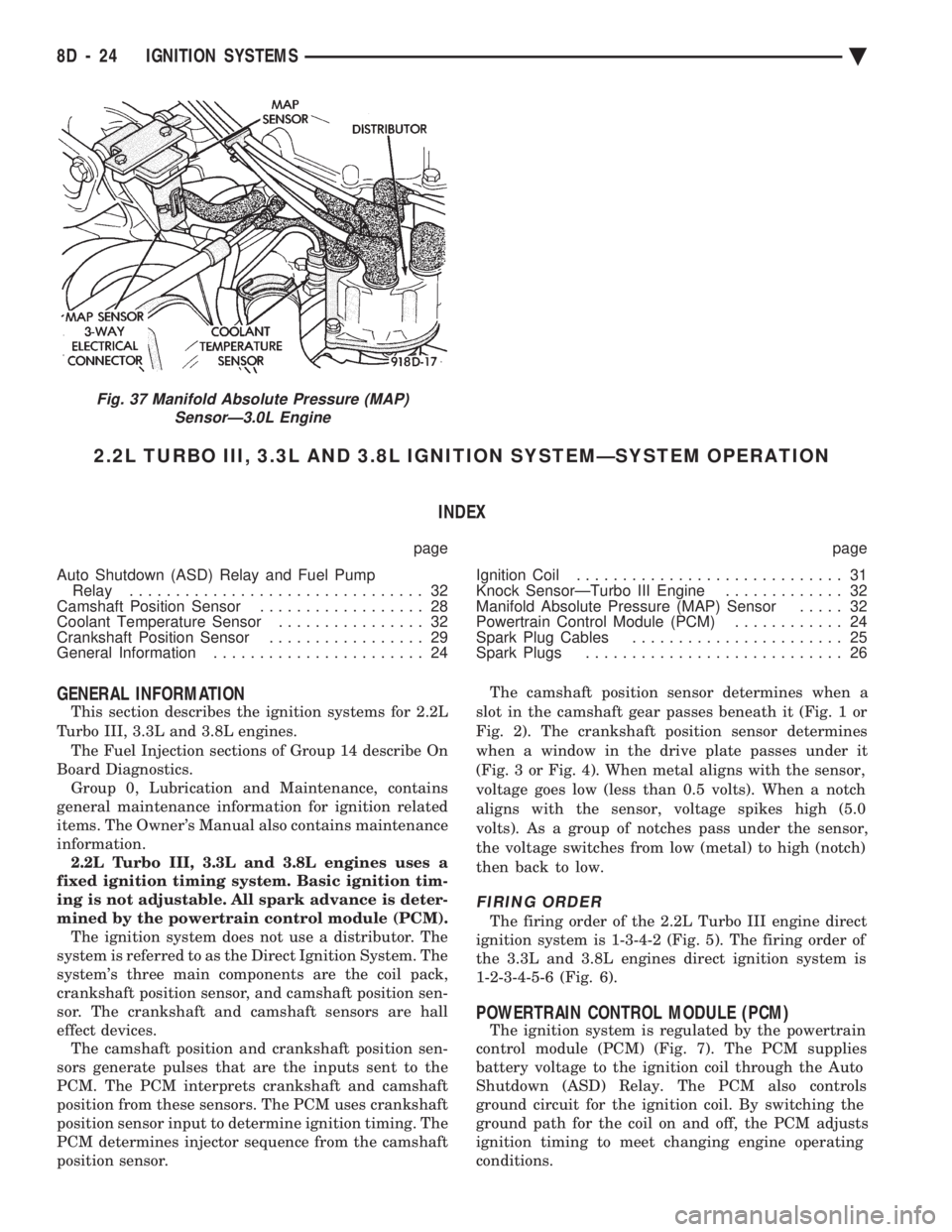

2.2L TURBO III, 3.3L AND 3.8L IGNITION SYSTEMÐSYSTEM OPERATION INDEX

page page

Auto Shutdown (ASD) Relay and Fuel Pump Relay ................................ 32

Camshaft Position Sensor .................. 28

Coolant Temperature Sensor ................ 32

Crankshaft Position Sensor ................. 29

General Information ....................... 24 Ignition Coil

............................. 31

Knock SensorÐTurbo III Engine ............. 32

Manifold Absolute Pressure (MAP) Sensor ..... 32

Powertrain Control Module (PCM) ............ 24

Spark Plug Cables ....................... 25

Spark Plugs ............................ 26

GENERAL INFORMATION

This section describes the ignition systems for 2.2L

Turbo III, 3.3L and 3.8L engines. The Fuel Injection sections of Group 14 describe On

Board Diagnostics. Group 0, Lubrication and Maintenance, contains

general maintenance information for ignition related

items. The Owner's Manual also contains maintenance

information. 2.2L Turbo III, 3.3L and 3.8L engines uses a

fixed ignition timing system. Basic ignition tim-

ing is not adjustable. All spark advance is deter-

mined by the powertrain control module (PCM). The ignition system does not use a distributor. The

system is referred to as the Direct Ignition System. The

system's three main components are the coil pack,

crankshaft position sensor, and camshaft position sen-

sor. The crankshaft and camshaft sensors are hall

effect devices. The camshaft position and crankshaft position sen-

sors generate pulses that are the inputs sent to the

PCM. The PCM interprets crankshaft and camshaft

position from these sensors. The PCM uses crankshaft

position sensor input to determine ignition timing. The

PCM determines injector sequence from the camshaft

position sensor. The camshaft position sensor determines when a

slot in the camshaft gear passes beneath it (Fig. 1 or

Fig. 2). The crankshaft position sensor determines

when a window in the drive plate passes under it

(Fig. 3 or Fig. 4). When metal aligns with the sensor,

voltage goes low (less than 0.5 volts). When a notch

aligns with the sensor, voltage spikes high (5.0

volts). As a group of notches pass under the sensor,

the voltage switches from low (metal) to high (notch)

then back to low.

FIRING ORDER

The firing order of the 2.2L Turbo III engine direct

ignition system is 1-3-4-2 (Fig. 5). The firing order of

the 3.3L and 3.8L engines direct ignition system is

1-2-3-4-5-6 (Fig. 6).

POWERTRAIN CONTROL MODULE (PCM)

The ignition system is regulated by the powertrain

control module (PCM) (Fig. 7). The PCM supplies

battery voltage to the ignition coil through the Auto

Shutdown (ASD) Relay. The PCM also controls

ground circuit for the ignition coil. By switching the

ground path for the coil on and off, the PCM adjusts

ignition timing to meet changing engine operating

conditions.

Fig. 37 Manifold Absolute Pressure (MAP) SensorÐ3.0L Engine

8D - 24 IGNITION SYSTEMS Ä

Page 474 of 2438

The coil's low primary resistance allows the PCM to

fully charge the coil for each firing.

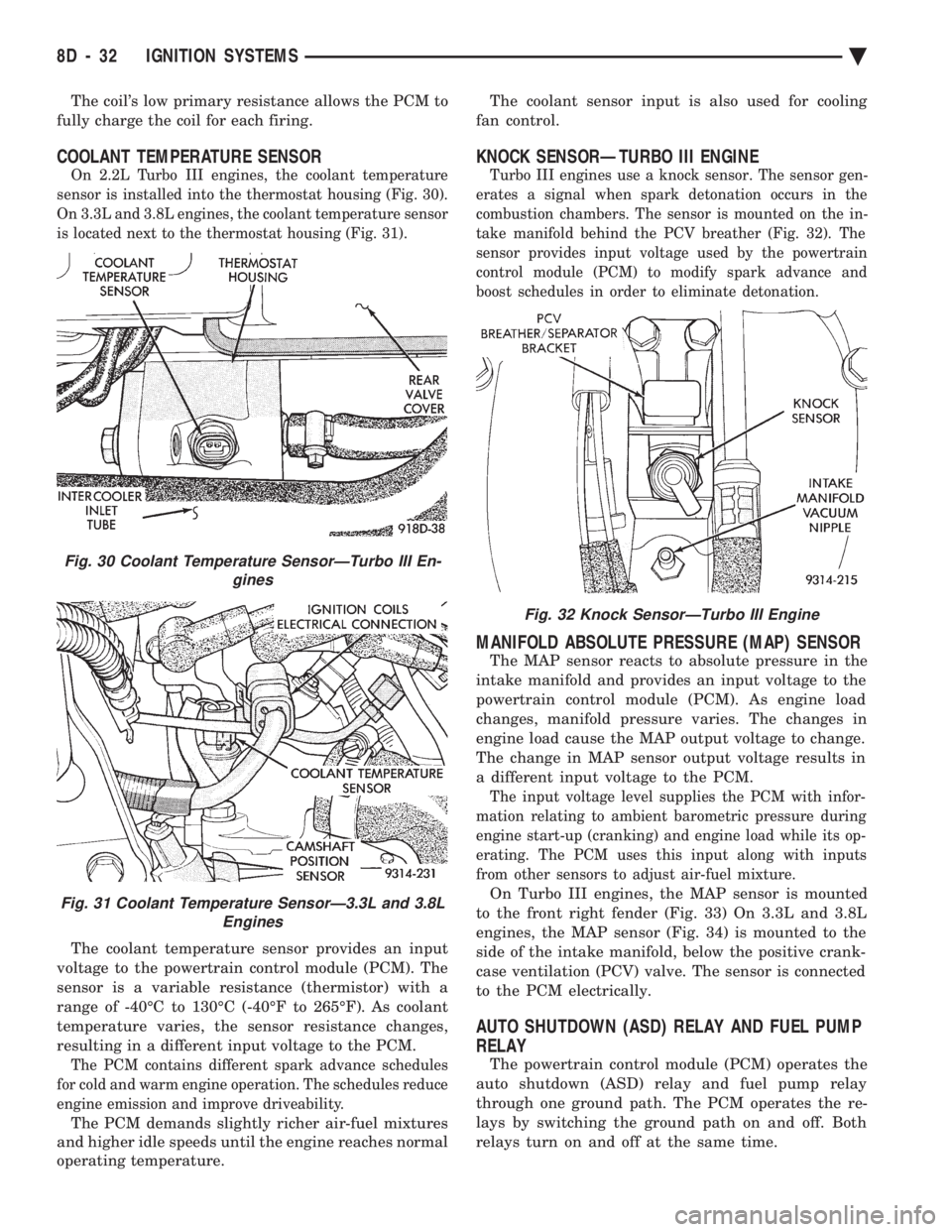

COOLANT TEMPERATURE SENSOR

On 2.2L Turbo III engines, the coolant temperature

sensor is installed into the thermostat housing (Fig. 30).

On 3.3L and 3.8L engines, the coolant temperature sensor

is located next to the thermostat housing (Fig. 31).

The coolant temperature sensor provides an input

voltage to the powertrain control module (PCM). The

sensor is a variable resistance (thermistor) with a

range of -40ÉC to 130ÉC (-40ÉF to 265ÉF). As coolant

temperature varies, the sensor resistance changes,

resulting in a different input voltage to the PCM.

The PCM contains different spark advance schedules

for cold and warm engine operation. The schedules reduce

engine emission and improve driveability.

The PCM demands slightly richer air-fuel mixtures

and higher idle speeds until the engine reaches normal

operating temperature. The coolant sensor input is also used for cooling

fan control.

KNOCK SENSORÐTURBO III ENGINE

Turbo III engines use a knock sensor. The sensor gen-

erates a signal when spark detonation occurs in the

combustion chambers. The sensor is mounted on the in-

take manifold behind the PCV breather (Fig. 32). The

sensor provides input voltage used by the powertrain

control module (PCM) to modify spark advance and

boost schedules in order to eliminate detonation.

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

The MAP sensor reacts to absolute pressure in the

intake manifold and provides an input voltage to the

powertrain control module (PCM). As engine load

changes, manifold pressure varies. The changes in

engine load cause the MAP output voltage to change.

The change in MAP sensor output voltage results in

a different input voltage to the PCM.

The input voltage level supplies the PCM with infor-

mation relating to ambient barometric pressure during

engine start-up (cranking) and engine load while its op-

erating. The PCM uses this input along with inputs

from other sensors to adjust air-fuel mixture.

On Turbo III engines, the MAP sensor is mounted

to the front right fender (Fig. 33) On 3.3L and 3.8L

engines, the MAP sensor (Fig. 34) is mounted to the

side of the intake manifold, below the positive crank-

case ventilation (PCV) valve. The sensor is connected

to the PCM electrically.

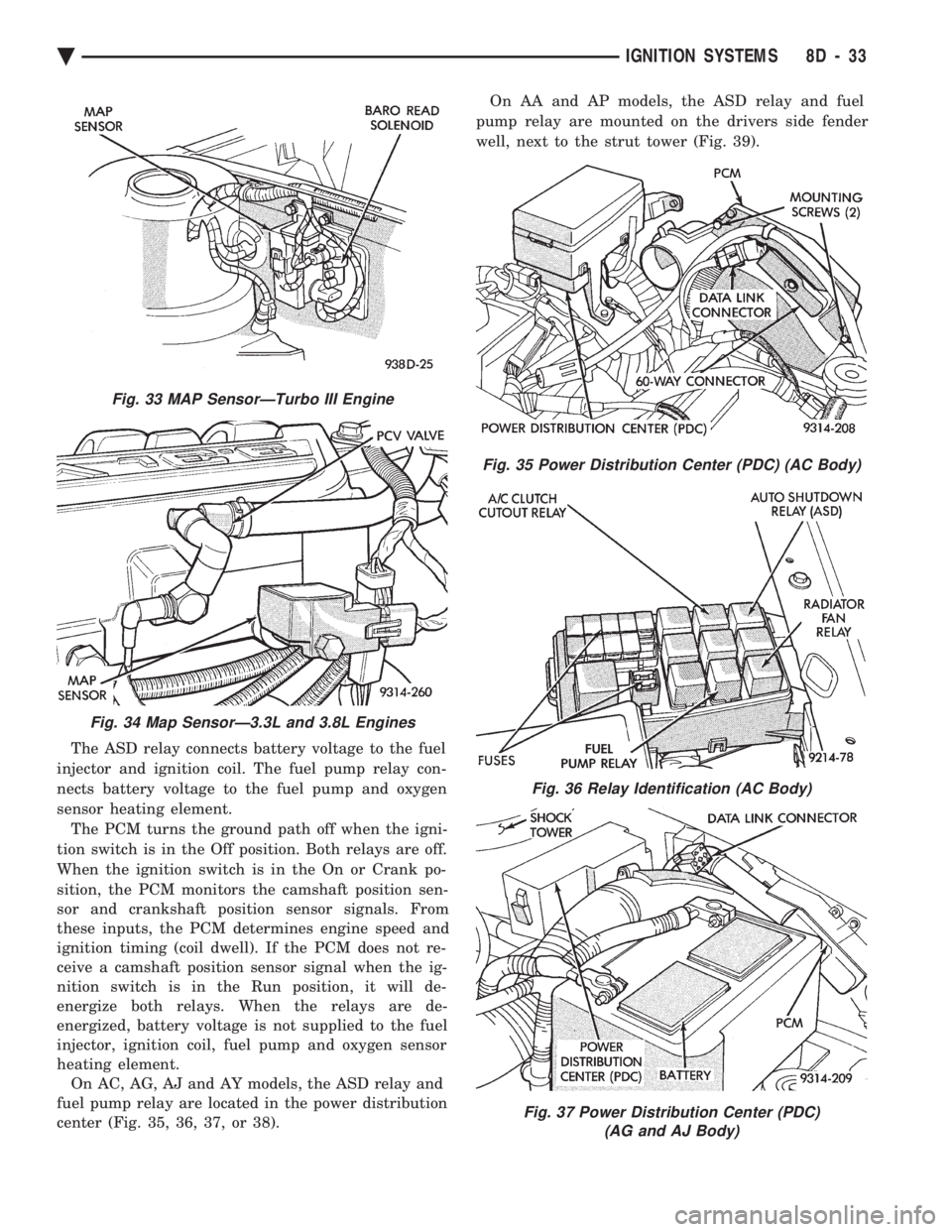

AUTO SHUTDOWN (ASD) RELAY AND FUEL PUMP

RELAY

The powertrain control module (PCM) operates the

auto shutdown (ASD) relay and fuel pump relay

through one ground path. The PCM operates the re-

lays by switching the ground path on and off. Both

relays turn on and off at the same time.

Fig. 32 Knock SensorÐTurbo III Engine

Fig. 30 Coolant Temperature SensorÐTurbo III En- gines

Fig. 31 Coolant Temperature SensorÐ3.3L and 3.8LEngines

8D - 32 IGNITION SYSTEMS Ä

Page 475 of 2438

The ASD relay connects battery voltage to the fuel

injector and ignition coil. The fuel pump relay con-

nects battery voltage to the fuel pump and oxygen

sensor heating element. The PCM turns the ground path off when the igni-

tion switch is in the Off position. Both relays are off.

When the ignition switch is in the On or Crank po-

sition, the PCM monitors the camshaft position sen-

sor and crankshaft position sensor signals. From

these inputs, the PCM determines engine speed and

ignition timing (coil dwell). If the PCM does not re-

ceive a camshaft position sensor signal when the ig-

nition switch is in the Run position, it will de-

energize both relays. When the relays are de-

energized, battery voltage is not supplied to the fuel

injector, ignition coil, fuel pump and oxygen sensor

heating element. On AC, AG, AJ and AY models, the ASD relay and

fuel pump relay are located in the power distribution

center (Fig. 35, 36, 37, or 38). On AA and AP models, the ASD relay and fuel

pump relay are mounted on the drivers side fender

well, next to the strut tower (Fig. 39).

Fig. 33 MAP SensorÐTurbo III Engine

Fig. 34 Map SensorÐ3.3L and 3.8L Engines

Fig. 35 Power Distribution Center (PDC) (AC Body)

Fig. 36 Relay Identification (AC Body)

Fig. 37 Power Distribution Center (PDC) (AG and AJ Body)

Ä IGNITION SYSTEMS 8D - 33

Page 476 of 2438

Fig. 39 Relay Identification (AA and AP Bodies)

Fig. 38 Relay Identification (AG and AJ Body)

8D - 34 IGNITION SYSTEMS Ä

Page 478 of 2438

(Fig. 4). Secondary resistance should be 11,600 to

15,800 ohms. Replace the coil if resistance is not

within tolerance.

FAILURE TO START TESTÐTURBO III ENGINE

(1) Determine that sufficient battery voltage (12.4

volts nominal) is present for the cranking and igni-

tion systems. (2) Connect a voltmeter to the wiring harness coil

connector at the B+ pin (Fig. 5).

(3) Crank the engine for 5 seconds while monitor-

ing the voltage at the B+ connector terminal. If the

voltage remains near zero during the entire period of

cranking, check the auto shutdown relay and PCM.

Refer to DRBII scan tool and the appropriate Power-

train Diagnostic Procedures manual. Refer to Group

14 for description of On Board Diagnostics. (4) If voltage is at near-battery voltage, and drops

to zero after 1-2 seconds of cranking, check the cam-

shaft position sensor and crankshaft position sensor

and their circuits. Refer to the DRBII scan tool and

the appropriate Powertrain Diagnostic Procedure

manual. Refer to Group 14 for a description of On-

Board Diagnostics. (5) If voltage remains at near-battery voltage dur-

ing the entire 5 seconds, turn the key off, remove the PCM 60-way connector. Check the 60-way for any

terminals loose from the connector (push-out).

TESTING FOR SPARK AT COILÐ3.3L AND 3.8L

ENGINES

WARNING: THE ENGINE DIRECT IGNITION SYSTEM

GENERATES APPROXIMATELY 40,000 VOLTS. PER-

SONAL INJURY COULD RESULT FROM CONTACT

WITH THIS SYSTEM.

The coil pack contains 3 independent coils. Each coil

must be checked individually.

CAUTION: Spark plug wire damage may occur if the

spark plug is moved more than 1/4 inch away from the

engine ground.

Remove the cable from number 2 spark plug. Insert a

clean spark plug into the spark plug boot, and ground

plug to the engine (Fig. 1). Crank the engine and look for spark across the

electrodes of the spark plug. Repeat the above test for

the five remaining cylinders. If there is no spark

during all cylinder tests, proceed to the failure to start

test. If one or more tests indicate irregular, weak, or no

spark, proceed to Check Coil Test.

WARNING: THE DIRECT IGNITION SYSTEM GENER-

ATES APPROXIMATELY 40,000 VOLTS. PERSONAL

INJURY COULD RESULT FROM CONTACT WITH THIS

SYSTEM.

CHECK COIL TESTÐ3.3L AND 3.8L ENGINES

Coil one fires cylinders 1 and 4, coil two fires

cylinders 2 and 5, coil three fires cylinders three

and six. Each coil tower is labeled with the number of the

corresponding cylinder. (1) Remove the ignition cables and measure the

resistance of the cables. Resistance must be between

3,000 to 12,000 ohms per foot of cable. Replace any

cable not within tolerance. (2) Disconnect the electrical connector from the coil

pack (Fig. 6). (3) Measure the primary resistance of each coil. At

the coil, connect an ohmmeter between the B+ pin and

the pin corresponding to the cylinders in question (Fig.

7). Resistance on the primary side of each coil should be

0.5 - 0.7 ohm. Replace the coil if resistance is not within

tolerance. (4) Remove ignition cables from the secondary tow-

ers of the coil. Measure the secondary resistance of the

coil between the towers of each individual coil (Fig. 8).

Refer to the Coil Specifications Chart in the Specifica-

tions section of this group. Replace the coil if resistance

is not within tolerance.

Fig. 4 Checking Ignition Coil Secondary ResistanceÐTurbo III Engines

Fig. 5 Wiring Harness Coil ConnectorÐTurbo III Engine

8D - 36 IGNITION SYSTEMS Ä