brake fluid CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1288 of 2438

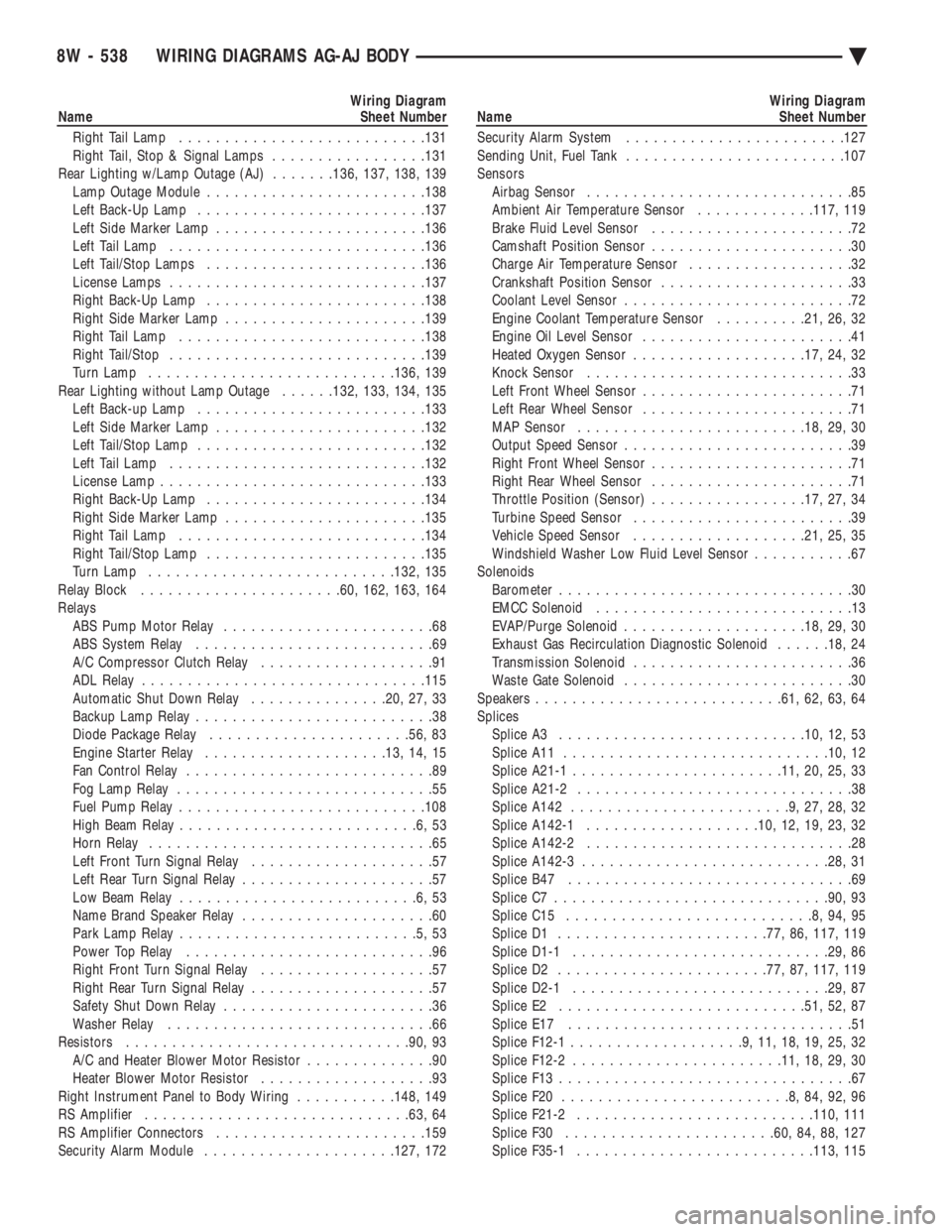

Wiring Diagram

Name Sheet Number

Right Tail Lamp .......................... .131

Right Tail, Stop & Signal Lamps .................131

Rear Lighting w/Lamp Outage (AJ) .......136, 137, 138, 139

Lamp Outage Module ....................... .138

Left Back-Up Lamp ........................ .137

Left Side Marker Lamp ...................... .136

Left Tail Lamp ........................... .136

Left Tail/Stop Lamps ....................... .136

License Lamps ........................... .137

Right Back-Up Lamp ....................... .138

Right Side Marker Lamp ..................... .139

Right Tail Lamp .......................... .138

Right Tail/Stop ........................... .139

Turn Lamp .......................... .136, 139

Rear Lighting without Lamp Outage ......132, 133, 134, 135

Left Back-up Lamp ........................ .133

Left Side Marker Lamp ...................... .132

Left Tail/Stop Lamp ........................ .132

Left Tail Lamp ........................... .132

License Lamp ............................ .133

Right Back-Up Lamp ....................... .134

Right Side Marker Lamp ..................... .135

Right Tail Lamp .......................... .134

Right Tail/Stop Lamp ....................... .135

Turn Lamp .......................... .132, 135

Relay Block ..................... .60, 162, 163, 164

Relays ABS Pump Motor Relay .......................68

ABS System Relay ..........................69

A/C Compressor Clutch Relay ...................91

ADL Relay .............................. .115

Automatic Shut Down Relay ...............20, 27, 33

Backup Lamp Relay ..........................38

Diode Package Relay ..................... .56, 83

Engine Starter Relay ................... .13, 14, 15

Fan Control Relay ...........................89

Fog Lamp Relay ............................55

Fuel Pump Relay .......................... .108

High Beam Relay ..........................6,53

Horn Relay ...............................65

Left Front Turn Signal Relay ....................57

Left Rear Turn Signal Relay .....................57

Low Beam Relay ..........................6,53

Name Brand Speaker Relay .....................60

Park Lamp Relay ..........................5,53

Power Top Relay ...........................96

Right Front Turn Signal Relay ...................57

Right Rear Turn Signal Relay ....................57

Safety Shut Down Relay .......................36

Washer Relay .............................66

Resistors .............................. .90, 93

A/C and Heater Blower Motor Resistor ..............90

Heater Blower Motor Resistor ...................93

Right Instrument Panel to Body Wiring ...........148, 149

RS Amplifier ............................ .63, 64

RS Amplifier Connectors ...................... .159

Security Alarm Module .................... .127, 172Wiring Diagram

Name Sheet Number

Security Alarm System ....................... .127

Sending Unit, Fuel Tank ....................... .107

Sensors Airbag Sensor .............................85

Ambient Air Temperature Sensor .............117, 119

Brake Fluid Level Sensor ......................72

Camshaft Position Sensor ......................30

Charge Air Temperature Sensor ..................32

Crankshaft Position Sensor .....................33

Coolant Level Sensor .........................72

Engine Coolant Temperature Sensor ..........21, 26, 32

Engine Oil Level Sensor .......................41

Heated Oxygen Sensor .................. .17, 24, 32

Knock Sensor .............................33

Left Front Wheel Sensor .......................71

Left Rear Wheel Sensor .......................71

MAP Sensor ........................ .18, 29, 30

Output Speed Sensor .........................39

Right Front Wheel Sensor ......................71

Right Rear Wheel Sensor ......................71

Throttle Position (Sensor) .................17, 27, 34

Turbine Speed Sensor ........................39

Vehicle Speed Sensor .................. .21, 25, 35

Windshield Washer Low Fluid Level Sensor ...........67

Solenoids Barometer ................................30

EMCC Solenoid ............................13

EVAP/Purge Solenoid ................... .18, 29, 30

Exhaust Gas Recirculation Diagnostic Solenoid ......18, 24

Transmission Solenoid ........................36

Waste Gate Solenoid .........................30

Speakers .......................... .61, 62, 63, 64

Splices Splice A3 .......................... .10, 12, 53

Splice A11 ............................ .10, 12

Splice A21-1 ...................... .11, 20, 25, 33

Splice A21-2 ..............................38

Splice A142 ........................9,27,28,32

Splice A142-1 .................. .10, 12, 19, 23, 32

Splice A142-2 .............................28

Splice A142-3 .......................... .28, 31

Splice B47 ...............................69

Splice C7 ............................. .90, 93

Splice C15 ...........................8,94,95

Splice D1 ...................... .77, 86, 117, 119

Splice D1-1 ........................... .29, 86

Splice D2 ...................... .77, 87, 117, 119

Splice D2-1 ........................... .29, 87

Splice E2 .......................... .51, 52, 87

Splice E17 ...............................51

Splice F12-1 ...................9,11,18,19,25,32

Splice F12-2 ...................... .11, 18, 29, 30

Splice F13 ................................67

Splice F20 .........................8,84,92,96

Splice F21-2 ......................... .110, 111

Splice F30 ...................... .60, 84, 88, 127

Splice F35-1 ......................... .113, 115

8W - 538 WIRING DIAGRAMS AG-AJ BODY Ä

Page 1290 of 2438

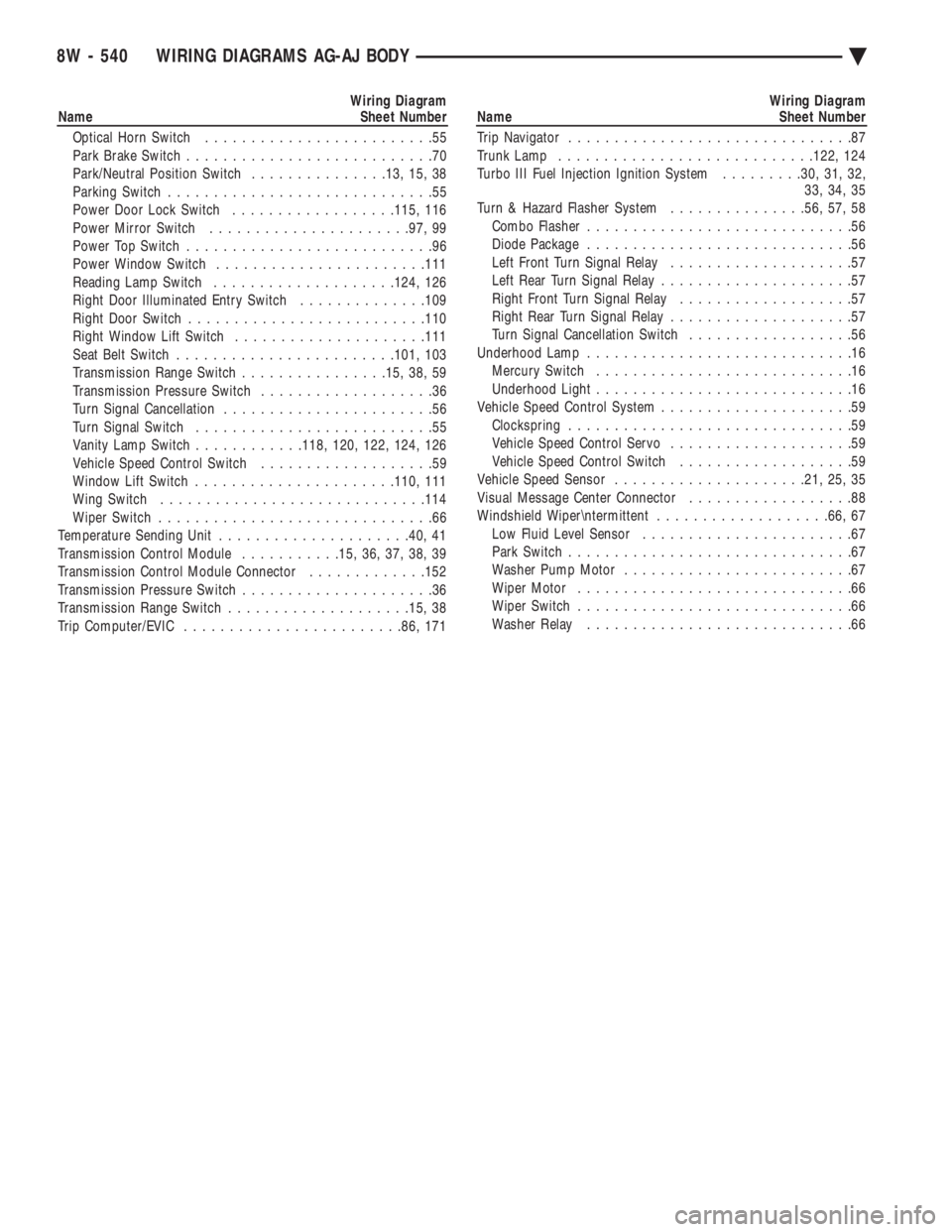

Wiring Diagram

Name Sheet Number

Optical Horn Switch .........................55

Park Brake Switch ...........................70

Park/Neutral Position Switch ...............13, 15, 38

Parking Switch .............................55

Power Door Lock Switch ..................115, 116

Power Mirror Switch ..................... .97, 99

Power Top Switch ...........................96

Power Window Switch ...................... .111

Reading Lamp Switch ................... .124, 126

Right Door Illuminated Entry Switch ..............109

Right Door Switch ......................... .110

Right Window Lift Switch .................... .111

Seat Belt Switch ....................... .101, 103

Transmission Range Switch ................15, 38, 59

Transmission Pressure Switch ...................36

Turn Signal Cancellation .......................56

Turn Signal Switch ..........................55

Vanity Lamp Switch ............118, 120, 122, 124, 126

Vehicle Speed Control Switch ...................59

Window Lift Switch ..................... .110, 111

Wing Switch ............................ .114

Wiper Switch ..............................66

Temperature Sending Unit .................... .40, 41

Transmission Control Module ...........15, 36, 37, 38, 39

Transmission Control Module Connector .............152

Transmission Pressure Switch .....................36

Transmission Range Switch ................... .15, 38

Trip Computer/EVIC ....................... .86, 171Wiring Diagram

Name Sheet Number

Trip Navigator ...............................87

Trunk Lamp ........................... .122, 124

Turbo III Fuel Injection Ignition System .........30, 31, 32,

33, 34, 35

Turn & Hazard Flasher System ...............56, 57, 58

Combo Flasher .............................56

Diode Package .............................56

Left Front Turn Signal Relay ....................57

Left Rear Turn Signal Relay .....................57

Right Front Turn Signal Relay ...................57

Right Rear Turn Signal Relay ....................57

Turn Signal Cancellation Switch ..................56

Underhood Lamp .............................16

Mercury Switch ............................16

Underhood Light ............................16

Vehicle Speed Control System .....................59

Clockspring ...............................59

Vehicle Speed Control Servo ....................59

Vehicle Speed Control Switch ...................59

Vehicle Speed Sensor .................... .21, 25, 35

Visual Message Center Connector ..................88

Windshield Wiper

termittent ...................66, 67

Low Fluid Level Sensor .......................67

Park Switch ...............................67

Washer Pump Motor .........................67

Wiper Motor ..............................66

Wiper Switch ..............................66

Washer Relay .............................66

8W - 540 WIRING DIAGRAMS AG-AJ BODY Ä

Page 1469 of 2438

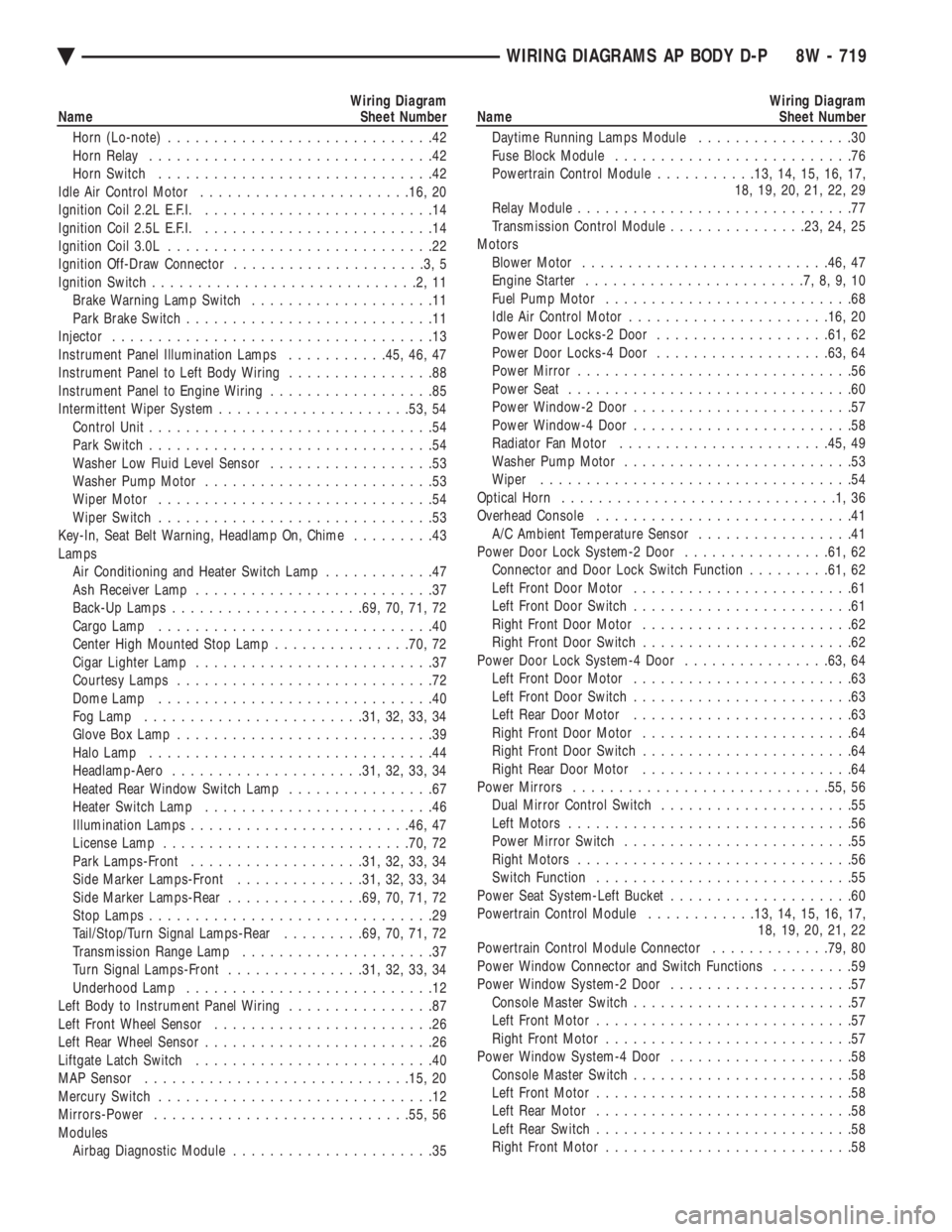

Wiring Diagram

Name Sheet Number

Horn (Lo-note) .............................42

Horn Relay ...............................42

Horn Switch ..............................42

Idle Air Control Motor ...................... .16, 20

Ignition Coil 2.2L E.F.I. .........................14

Ignition Coil 2.5L E.F.I. .........................14

Ignition Coil 3.0L .............................22

Ignition Off-Draw Connector .....................3,5

Ignition Switch .............................2,11

Brake Warning Lamp Switch ....................11

Park Brake Switch ...........................11

Injector ...................................13

Instrument Panel Illumination Lamps ...........45, 46, 47

Instrument Panel to Left Body Wiring ................88

Instrument Panel to Engine Wiring ..................85

Intermittent Wiper System .................... .53, 54

Control Unit ...............................54

Park Switch ...............................54

Washer Low Fluid Level Sensor ..................53

Washer Pump Motor .........................53

Wiper Motor ..............................54

Wiper Switch ..............................53

Key-In, Seat Belt Warning, Headlamp On, Chime .........43

Lamps Air Conditioning and Heater Switch Lamp ............47

Ash Receiver Lamp ..........................37

Back-Up Lamps .................... .69, 70, 71, 72

Cargo Lamp ..............................40

Center High Mounted Stop Lamp ...............70, 72

Cigar Lighter Lamp ..........................37

Courtesy Lamps ............................72

Dome Lamp ..............................40

Fog Lamp ....................... .31, 32, 33, 34

Glove Box Lamp ............................39

Halo Lamp ...............................44

Headlamp-Aero .................... .31, 32, 33, 34

Heated Rear Window Switch Lamp ................67

Heater Switch Lamp .........................46

Illumination Lamps ....................... .46, 47

License Lamp .......................... .70, 72

Park Lamps-Front .................. .31, 32, 33, 34

Side Marker Lamps-Front ..............31, 32, 33, 34

Side Marker Lamps-Rear ...............69, 70, 71, 72

Stop Lamps ...............................29

Tail/Stop/Turn Signal Lamps-Rear .........69, 70, 71, 72

Transmission Range Lamp .....................37

Turn Signal Lamps-Front ...............31, 32, 33, 34

Underhood Lamp ...........................12

Left Body to Instrument Panel Wiring ................87

Left Front Wheel Sensor ........................26

Left Rear Wheel Sensor .........................26

Liftgate Latch Switch ..........................40

MAP Sensor ............................ .15, 20

Mercury Switch ..............................12

Mirrors-Power ........................... .55, 56

Modules Airbag Diagnostic Module ......................35Wiring Diagram

Name Sheet Number

Daytime Running Lamps Module .................30

Fuse Block Module ..........................76

Powertrain Control Module ...........13, 14, 15, 16, 17,

18, 19, 20, 21, 22, 29

Relay Module ..............................77

Transmission Control Module ...............23, 24, 25

Motors Blower Motor .......................... .46, 47

Engine Starter ........................7,8,9,10

Fuel Pump Motor ...........................68

Idle Air Control Motor ..................... .16, 20

Power Door Locks-2 Door .................. .61, 62

Power Door Locks-4 Door .................. .63, 64

Power Mirror ..............................56

Power Seat ...............................60

Power Window-2 Door ........................57

Power Window-4 Door ........................58

Radiator Fan Motor ...................... .45, 49

Washer Pump Motor .........................53

Wiper ..................................54

Optical Horn ..............................1,36

Overhead Console ............................41

A/C Ambient Temperature Sensor .................41

Power Door Lock System-2 Door ................61, 62

Connector and Door Lock Switch Function .........61, 62

Left Front Door Motor ........................61

Left Front Door Switch ........................61

Right Front Door Motor .......................62

Right Front Door Switch .......................62

Power Door Lock System-4 Door ................63, 64

Left Front Door Motor ........................63

Left Front Door Switch ........................63

Left Rear Door Motor ........................63

Right Front Door Motor .......................64

Right Front Door Switch .......................64

Right Rear Door Motor .......................64

Power Mirrors ........................... .55, 56

Dual Mirror Control Switch .....................55

Left Motors ...............................56

Power Mirror Switch .........................55

Right Motors ..............................56

Switch Function ............................55

Power Seat System-Left Bucket ....................60

Powertrain Control Module ............13, 14, 15, 16, 17,

18, 19, 20, 21, 22

Powertrain Control Module Connector .............79, 80

Power Window Connector and Switch Functions .........59

Power Window System-2 Door ....................57

Console Master Switch ........................57

Left Front Motor ............................57

Right Front Motor ...........................57

Power Window System-4 Door ....................58

Console Master Switch ........................58

Left Front Motor ............................58

Left Rear Motor ............................58

Left Rear Switch ............................58

Right Front Motor ...........................58

Ä WIRING DIAGRAMS AP BODY D-P 8W - 719

Page 2000 of 2438

FLUID LEVEL AND CONDITION

The transmission and differential sump have a

common oil sump with a communicating opening

between the two. Before removing the dipstick, wipe all dirt off of the

protective disc and the dipstick handle. The torque converter will fill in both the PPark or N

Neutral positions. Place the selector lever in PPark to

check fluid level. Inspect fluid level on dipstick every six months.

Allow the engine to idle for at least one minute

with vehicle on level ground. This will assure

complete oil level stabilization between differen-

tial and transmission. A properly filled transaxle

will read near the addmark when fluid temperature is

21 degrees Celsius (70 degrees Fahrenheit). When the

transaxle reaches operating temperature the fluid

should be in the HOTregion.

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with the

fluid. As in any hydraulic system, air bubbles make the

fluid spongy, therefore, pressures will be low and build

up slowly. Improper filling can also raise the fluid level too

high. When the transaxle has too much fluid, the gears

churn up foam and cause the same conditions which

occur with a low fluid level. In either case, the air bubbles can cause overheating,

fluid oxidation, and varnishing, which can interfere

with normal valve, clutch, and servo operation. Foam-

ing can also result in fluid escaping from the transaxle

vent (dipstick handle) where it may be mistaken for a

leak. Along with fluid level, it is important to check the

condition of the fluid. When the fluid smells burned,

and is contaminated with metal or friction material

particles, a complete transaxle overhaul is needed. Be

sure to examine the fluid on the dipstick closely. If

there is any doubt about its condition, drain out a

sample for a double check. After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

SELECTION OF LUBRICANT

It is important that the proper lubricant be used in

these transmissions. MOPAR tATF PLUS (Automatic

Transmission Fluid-Type 7176) should be used to aid in

assuring optimum transmission performance. Fluids of

the type labeled DEXRON II Automatic Transmission

Fluid should be used only if the recommended fluid is

not available. It is important that the transmission

fluid be maintained at the prescribed level using the

recommended fluids.

SPECIAL ADDITIVES

Chrysler Corporation does not recommend the addi-

tion of any fluids to the transmission, other than the

automatic transmission fluid listed above. An ex- ception to this policy is the use of special dyes to aid in

detecting fluid leaks. The use of transmission sealers

should be avoided, since they may adversely affect

seals.

FLUID AND FILTER CHANGE

When the factory fill fluid is changed, only

fluids of the type labeled MOPAR tATF PLUS

(Automatic Transmission fluid) Type 7176 should

be used. A band adjustment and filter change

should be made at the time of the oil change. The

magnet (on the inside of the oil pan) should also

be cleaned with a clean, dry cloth. If the transaxle is disassembled for any reason,

the fluid and filter should be changed, and the

band(s) adjusted.

FLUID DRAIN AND REFILL

(1) Raise vehicle on a hoist (See Lubrication, Group

0). Place a drain container with a large opening, under

transaxle oil pan. (2) Loosen pan bolts and tap the pan at one corner to

break it loose allowing fluid to drain, then remove the

oil pan. (3) Install a new filter and gasket on bottom of the

valve body and tighten retaining screws to 5 N Im (40

in. lbs.). (4) Clean the oil pan and magnet. Reinstall pan

using new MOPAR tAdhesive sealant. Tighten oil pan

bolts to 19 N Im (165 in. lbs.).

(5) Pour four quarts of MOPAR tATF PLUS (Auto-

matic Transmission Fluid) Type 7176 through the

dipstick opening. (6) Start engine and allow to idle for at least one

minute. Then, with parking and service brakes ap-

plied, move selector lever momentarily to each posi-

tion, ending in the park or neutral position. (7) Add sufficient fluid to bring level to 1/8 inch

below the ADD mark. Recheck fluid level after transaxle is at normal

operating temperature. The level should be in the HOT

region (Fig. 1). To prevent dirt from entering transaxle, make cer-

tain that dipstick is full seated into the dipstick open-

ing.

TORQUE CONVERTER CLUTCH SOLENOID WIRING

CONNECTOR

If wiring connector is unplugged, the torque con-

verter clutch will not operate (Fig. 2).

ROAD TEST

Prior to performing a road test, be certain that the

fluid level and condition, and control cable adjustments

have been checked and approved. During the road test, the transaxle should be oper-

ated in each position to check for slipping and any

variation in shifting.

21 - 40 TRANSAXLE Ä

Page 2053 of 2438

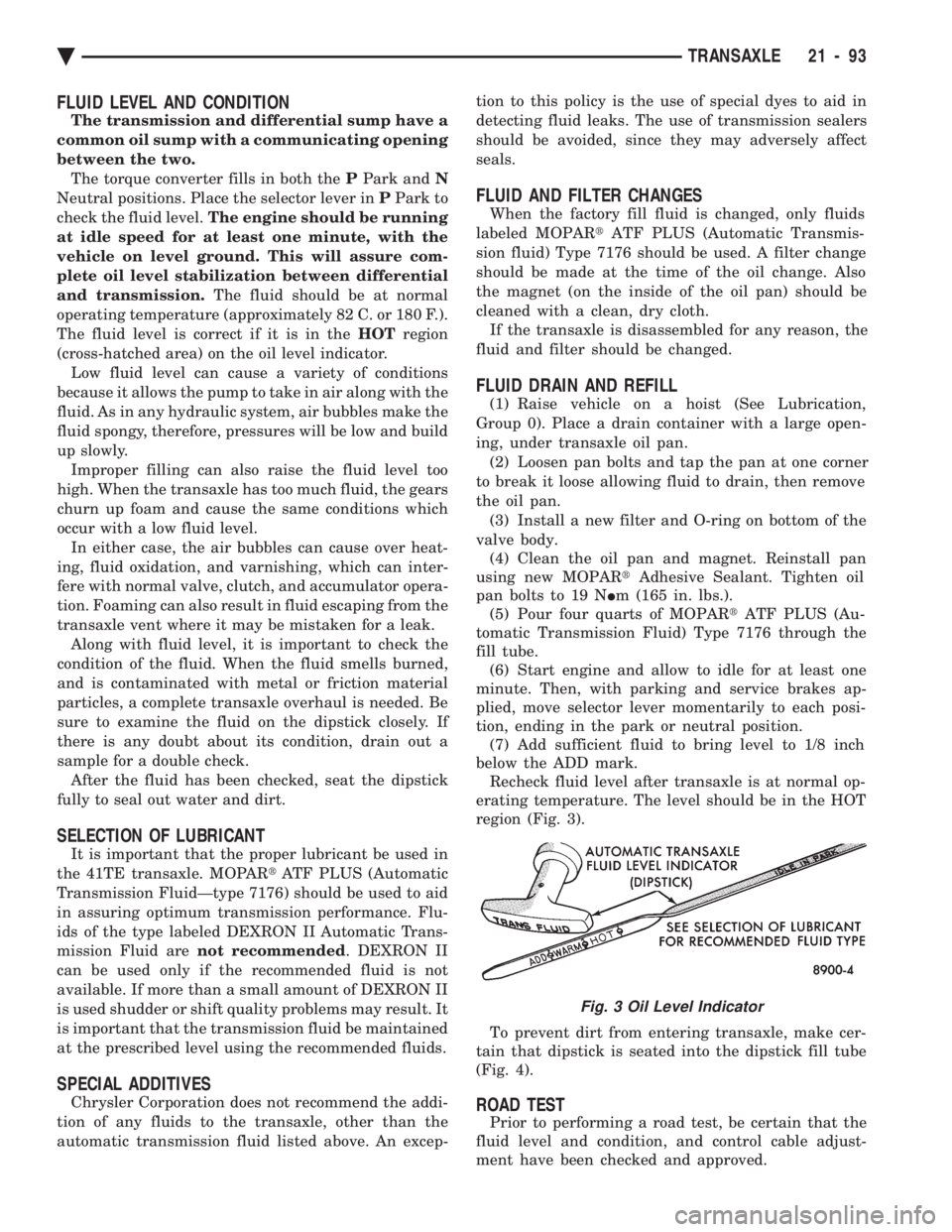

FLUID LEVEL AND CONDITION

The transmission and differential sump have a

common oil sump with a communicating opening

between the two. The torque converter fills in both the PPark and N

Neutral positions. Place the selector lever in PPark to

check the fluid level. The engine should be running

at idle speed for at least one minute, with the

vehicle on level ground. This will assure com-

plete oil level stabilization between differential

and transmission. The fluid should be at normal

operating temperature (approximately 82 C. or 180 F.).

The fluid level is correct if it is in the HOTregion

(cross-hatched area) on the oil level indicator. Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with the

fluid. As in any hydraulic system, air bubbles make the

fluid spongy, therefore, pressures will be low and build

up slowly. Improper filling can also raise the fluid level too

high. When the transaxle has too much fluid, the gears

churn up foam and cause the same conditions which

occur with a low fluid level. In either case, the air bubbles can cause over heat-

ing, fluid oxidation, and varnishing, which can inter-

fere with normal valve, clutch, and accumulator opera-

tion. Foaming can also result in fluid escaping from the

transaxle vent where it may be mistaken for a leak. Along with fluid level, it is important to check the

condition of the fluid. When the fluid smells burned,

and is contaminated with metal or friction material

particles, a complete transaxle overhaul is needed. Be

sure to examine the fluid on the dipstick closely. If

there is any doubt about its condition, drain out a

sample for a double check. After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

SELECTION OF LUBRICANT

It is important that the proper lubricant be used in

the 41TE transaxle. MOPAR tATF PLUS (Automatic

Transmission FluidÐtype 7176) should be used to aid

in assuring optimum transmission performance. Flu-

ids of the type labeled DEXRON II Automatic Trans-

mission Fluid are not recommended . DEXRON II

can be used only if the recommended fluid is not

available. If more than a small amount of DEXRON II

is used shudder or shift quality problems may result. It

is important that the transmission fluid be maintained

at the prescribed level using the recommended fluids.

SPECIAL ADDITIVES

Chrysler Corporation does not recommend the addi-

tion of any fluids to the transaxle, other than the

automatic transmission fluid listed above. An excep- tion to this policy is the use of special dyes to aid in

detecting fluid leaks. The use of transmission sealers

should be avoided, since they may adversely affect

seals.

FLUID AND FILTER CHANGES

When the factory fill fluid is changed, only fluids

labeled MOPAR tATF PLUS (Automatic Transmis-

sion fluid) Type 7176 should be used. A filter change

should be made at the time of the oil change. Also

the magnet (on the inside of the oil pan) should be

cleaned with a clean, dry cloth. If the transaxle is disassembled for any reason, the

fluid and filter should be changed.

FLUID DRAIN AND REFILL

(1) Raise vehicle on a hoist (See Lubrication,

Group 0). Place a drain container with a large open-

ing, under transaxle oil pan. (2) Loosen pan bolts and tap the pan at one corner

to break it loose allowing fluid to drain, then remove

the oil pan. (3) Install a new filter and O-ring on bottom of the

valve body. (4) Clean the oil pan and magnet. Reinstall pan

using new MOPAR tAdhesive Sealant. Tighten oil

pan bolts to 19 N Im (165 in. lbs.).

(5) Pour four quarts of MOPAR tATF PLUS (Au-

tomatic Transmission Fluid) Type 7176 through the

fill tube. (6) Start engine and allow to idle for at least one

minute. Then, with parking and service brakes ap-

plied, move selector lever momentarily to each posi-

tion, ending in the park or neutral position. (7) Add sufficient fluid to bring level to 1/8 inch

below the ADD mark. Recheck fluid level after transaxle is at normal op-

erating temperature. The level should be in the HOT

region (Fig. 3).

To prevent dirt from entering transaxle, make cer-

tain that dipstick is seated into the dipstick fill tube

(Fig. 4).

ROAD TEST

Prior to performing a road test, be certain that the

fluid level and condition, and control cable adjust-

ment have been checked and approved.

Fig. 3 Oil Level Indicator

Ä TRANSAXLE 21 - 93

Page 2055 of 2438

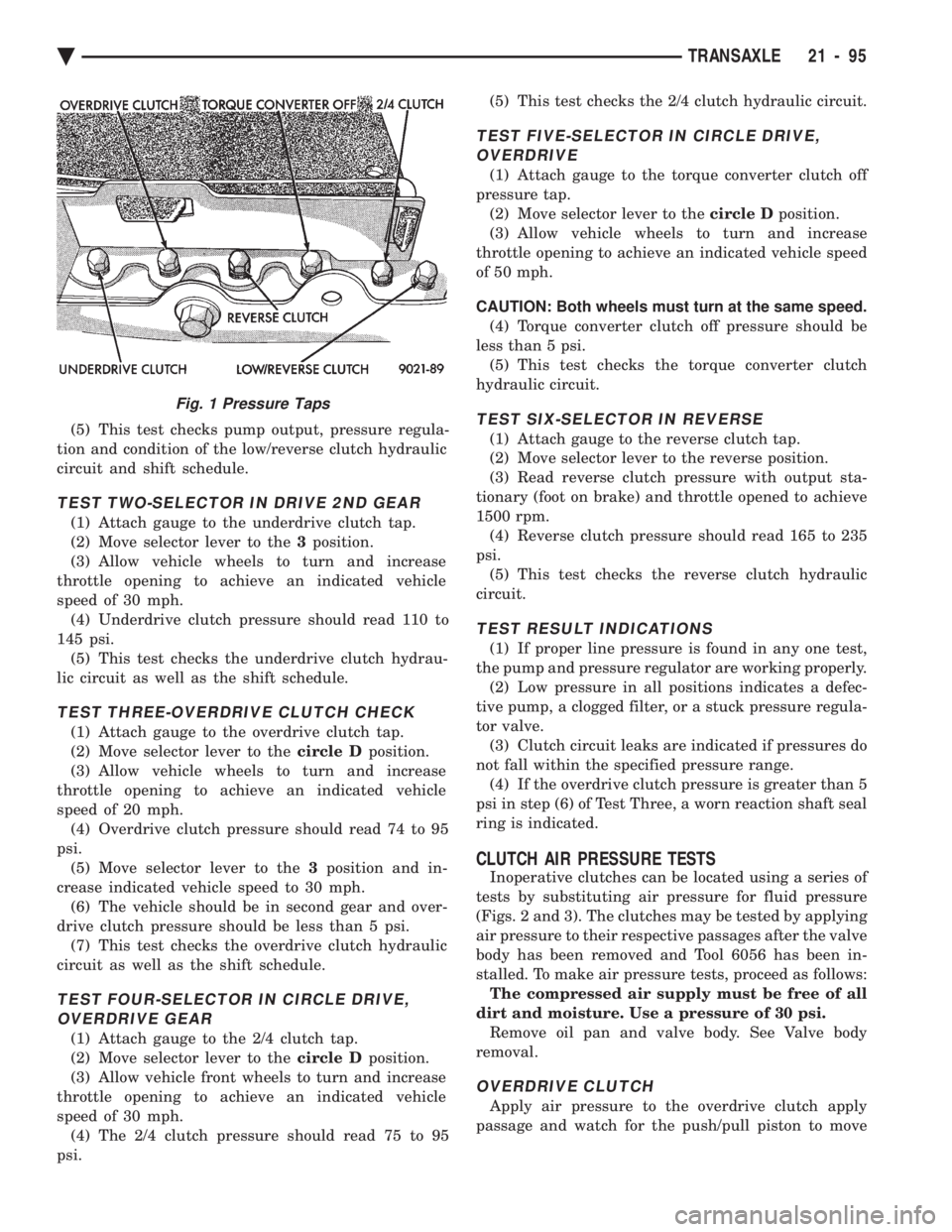

(5) This test checks pump output, pressure regula-

tion and condition of the low/reverse clutch hydraulic

circuit and shift schedule.

TEST TWO-SELECTOR IN DRIVE 2ND GEAR

(1) Attach gauge to the underdrive clutch tap.

(2) Move selector lever to the 3position.

(3) Allow vehicle wheels to turn and increase

throttle opening to achieve an indicated vehicle

speed of 30 mph. (4) Underdrive clutch pressure should read 110 to

145 psi. (5) This test checks the underdrive clutch hydrau-

lic circuit as well as the shift schedule.

TEST THREE-OVERDRIVE CLUTCH CHECK

(1) Attach gauge to the overdrive clutch tap.

(2) Move selector lever to the circle Dposition.

(3) Allow vehicle wheels to turn and increase

throttle opening to achieve an indicated vehicle

speed of 20 mph. (4) Overdrive clutch pressure should read 74 to 95

psi. (5) Move selector lever to the 3position and in-

crease indicated vehicle speed to 30 mph. (6) The vehicle should be in second gear and over-

drive clutch pressure should be less than 5 psi. (7) This test checks the overdrive clutch hydraulic

circuit as well as the shift schedule.

TEST FOUR-SELECTOR IN CIRCLE DRIVE, OVERDRIVE GEAR

(1) Attach gauge to the 2/4 clutch tap.

(2) Move selector lever to the circle Dposition.

(3) Allow vehicle front wheels to turn and increase

throttle opening to achieve an indicated vehicle

speed of 30 mph. (4) The 2/4 clutch pressure should read 75 to 95

psi. (5) This test checks the 2/4 clutch hydraulic circuit.

TEST FIVE-SELECTOR IN CIRCLE DRIVE,

OVERDRIVE

(1) Attach gauge to the torque converter clutch off

pressure tap. (2) Move selector lever to the circle Dposition.

(3) Allow vehicle wheels to turn and increase

throttle opening to achieve an indicated vehicle speed

of 50 mph.

CAUTION: Both wheels must turn at the same speed. (4) Torque converter clutch off pressure should be

less than 5 psi. (5) This test checks the torque converter clutch

hydraulic circuit.

TEST SIX-SELECTOR IN REVERSE

(1) Attach gauge to the reverse clutch tap.

(2) Move selector lever to the reverse position.

(3) Read reverse clutch pressure with output sta-

tionary (foot on brake) and throttle opened to achieve

1500 rpm. (4) Reverse clutch pressure should read 165 to 235

psi. (5) This test checks the reverse clutch hydraulic

circuit.

TEST RESULT INDICATIONS

(1) If proper line pressure is found in any one test,

the pump and pressure regulator are working properly. (2) Low pressure in all positions indicates a defec-

tive pump, a clogged filter, or a stuck pressure regula-

tor valve. (3) Clutch circuit leaks are indicated if pressures do

not fall within the specified pressure range. (4) If the overdrive clutch pressure is greater than 5

psi in step (6) of Test Three, a worn reaction shaft seal

ring is indicated.

CLUTCH AIR PRESSURE TESTS

Inoperative clutches can be located using a series of

tests by substituting air pressure for fluid pressure

(Figs. 2 and 3). The clutches may be tested by applying

air pressure to their respective passages after the valve

body has been removed and Tool 6056 has been in-

stalled. To make air pressure tests, proceed as follows: The compressed air supply must be free of all

dirt and moisture. Use a pressure of 30 psi. Remove oil pan and valve body. See Valve body

removal.

OVERDRIVE CLUTCH

Apply air pressure to the overdrive clutch apply

passage and watch for the push/pull piston to move

Fig. 1 Pressure Taps

Ä TRANSAXLE 21 - 95

Page 2058 of 2438

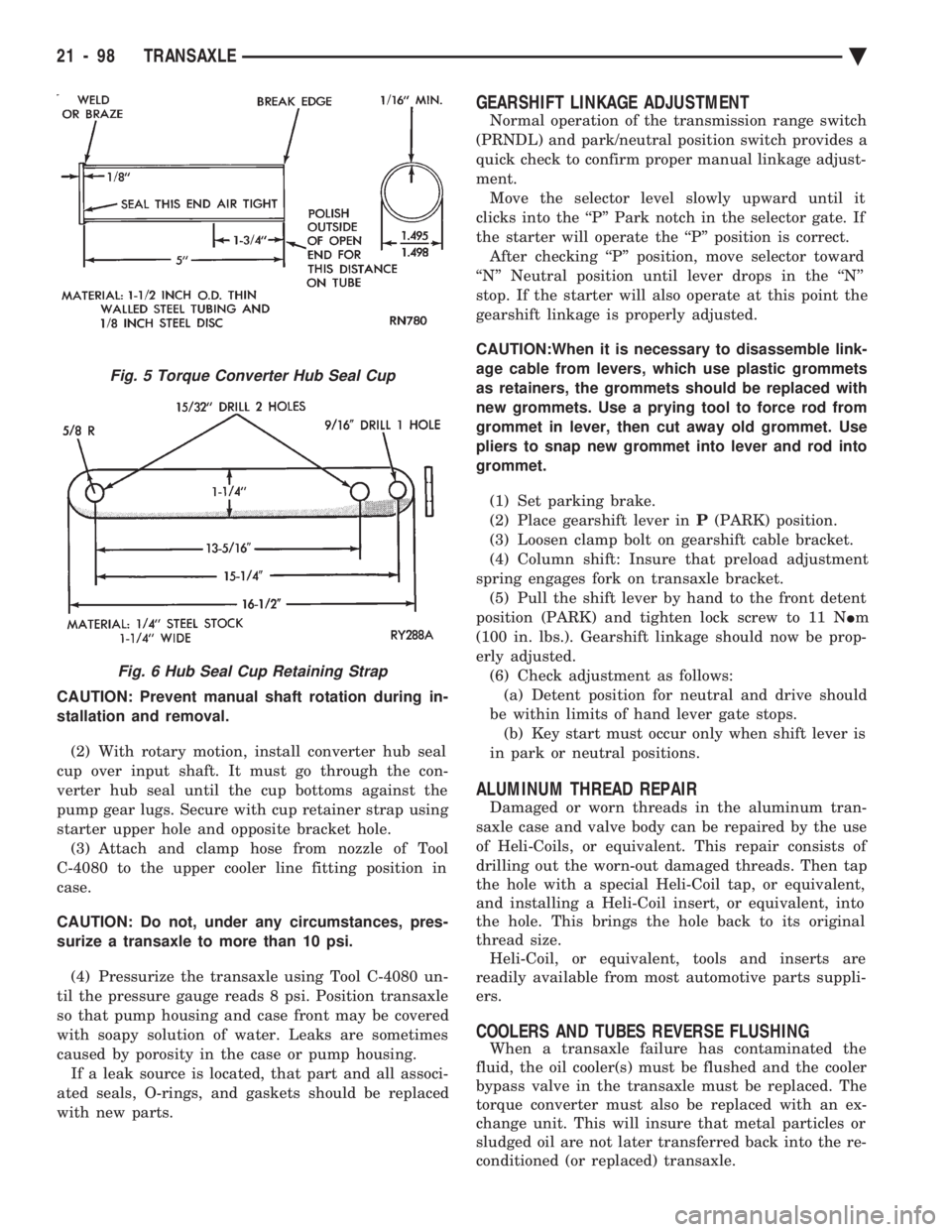

CAUTION: Prevent manual shaft rotation during in-

stallation and removal. (2) With rotary motion, install converter hub seal

cup over input shaft. It must go through the con-

verter hub seal until the cup bottoms against the

pump gear lugs. Secure with cup retainer strap using

starter upper hole and opposite bracket hole. (3) Attach and clamp hose from nozzle of Tool

C-4080 to the upper cooler line fitting position in

case.

CAUTION: Do not, under any circumstances, pres-

surize a transaxle to more than 10 psi.

(4) Pressurize the transaxle using Tool C-4080 un-

til the pressure gauge reads 8 psi. Position transaxle

so that pump housing and case front may be covered

with soapy solution of water. Leaks are sometimes

caused by porosity in the case or pump housing. If a leak source is located, that part and all associ-

ated seals, O-rings, and gaskets should be replaced

with new parts.

GEARSHIFT LINKAGE ADJUSTMENT

Normal operation of the transmission range switch

(PRNDL) and park/neutral position switch provides a

quick check to confirm proper manual linkage adjust-

ment. Move the selector level slowly upward until it

clicks into the ``P'' Park notch in the selector gate. If

the starter will operate the ``P'' position is correct. After checking ``P'' position, move selector toward

``N'' Neutral position until lever drops in the ``N''

stop. If the starter will also operate at this point the

gearshift linkage is properly adjusted.

CAUTION:When it is necessary to disassemble link-

age cable from levers, which use plastic grommets

as retainers, the grommets should be replaced with

new grommets. Use a prying tool to force rod from

grommet in lever, then cut away old grommet. Use

pliers to snap new grommet into lever and rod into

grommet.

(1) Set parking brake.

(2) Place gearshift lever in P(PARK) position.

(3) Loosen clamp bolt on gearshift cable bracket.

(4) Column shift: Insure that preload adjustment

spring engages fork on transaxle bracket. (5) Pull the shift lever by hand to the front detent

position (PARK) and tighten lock screw to 11 N Im

(100 in. lbs.). Gearshift linkage should now be prop-

erly adjusted. (6) Check adjustment as follows:(a) Detent position for neutral and drive should

be within limits of hand lever gate stops. (b) Key start must occur only when shift lever is

in park or neutral positions.

ALUMINUM THREAD REPAIR

Damaged or worn threads in the aluminum tran-

saxle case and valve body can be repaired by the use

of Heli-Coils, or equivalent. This repair consists of

drilling out the worn-out damaged threads. Then tap

the hole with a special Heli-Coil tap, or equivalent,

and installing a Heli-Coil insert, or equivalent, into

the hole. This brings the hole back to its original

thread size. Heli-Coil, or equivalent, tools and inserts are

readily available from most automotive parts suppli-

ers.

COOLERS AND TUBES REVERSE FLUSHING

When a transaxle failure has contaminated the

fluid, the oil cooler(s) must be flushed and the cooler

bypass valve in the transaxle must be replaced. The

torque converter must also be replaced with an ex-

change unit. This will insure that metal particles or

sludged oil are not later transferred back into the re-

conditioned (or replaced) transaxle.

Fig. 5 Torque Converter Hub Seal Cup

Fig. 6 Hub Seal Cup Retaining Strap

21 - 98 TRANSAXLE Ä