check engine CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1609 of 2438

CRANKSHAFT SERVICE

CRANKSHAFT MAIN BEARINGS

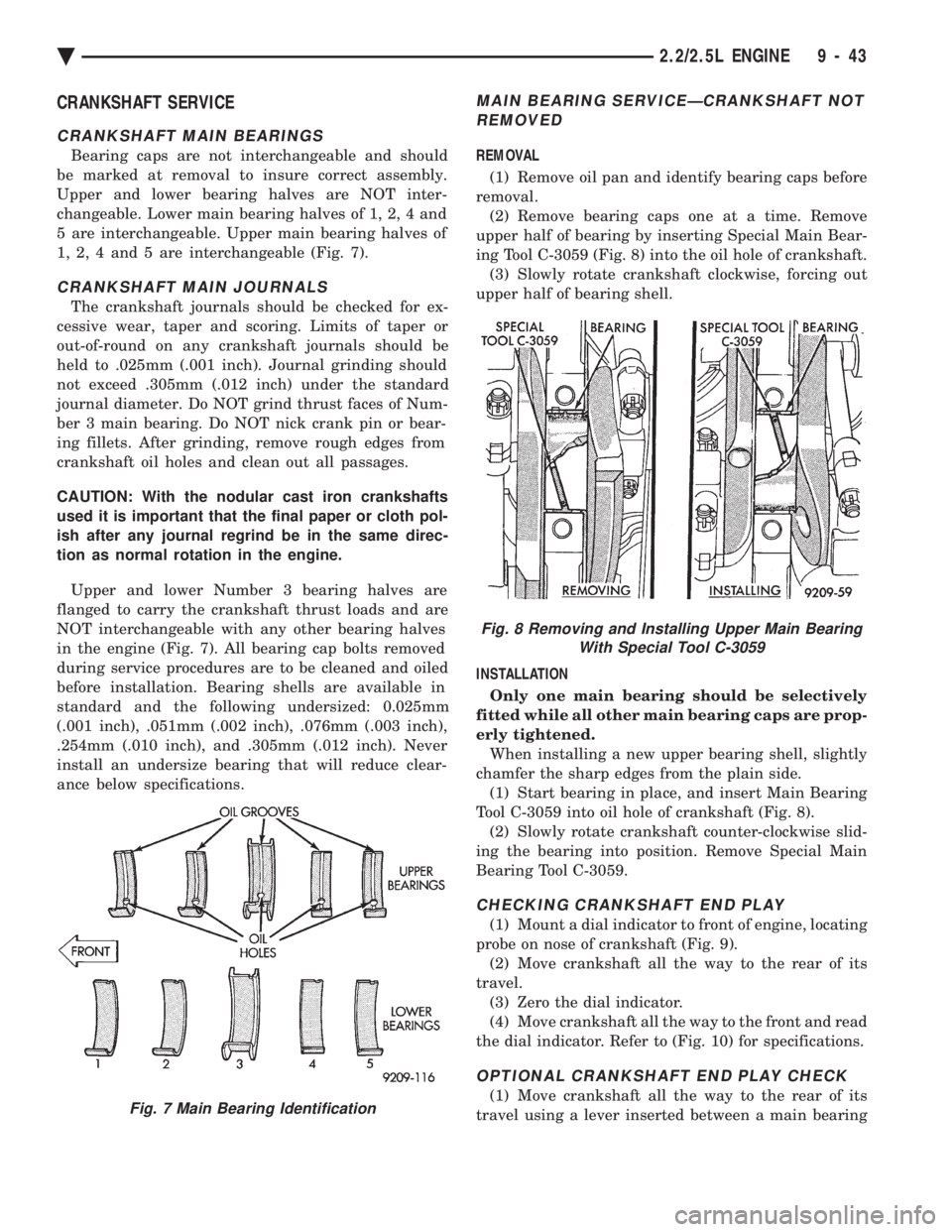

Bearing caps are not interchangeable and should

be marked at removal to insure correct assembly.

Upper and lower bearing halves are NOT inter-

changeable. Lower main bearing halves of 1, 2, 4 and

5 are interchangeable. Upper main bearing halves of

1, 2, 4 and 5 are interchangeable (Fig. 7).

CRANKSHAFT MAIN JOURNALS

The crankshaft journals should be checked for ex-

cessive wear, taper and scoring. Limits of taper or

out-of-round on any crankshaft journals should be

held to .025mm (.001 inch). Journal grinding should

not exceed .305mm (.012 inch) under the standard

journal diameter. Do NOT grind thrust faces of Num-

ber 3 main bearing. Do NOT nick crank pin or bear-

ing fillets. After grinding, remove rough edges from

crankshaft oil holes and clean out all passages.

CAUTION: With the nodular cast iron crankshafts

used it is important that the final paper or cloth pol-

ish after any journal regrind be in the same direc-

tion as normal rotation in the engine.

Upper and lower Number 3 bearing halves are

flanged to carry the crankshaft thrust loads and are

NOT interchangeable with any other bearing halves

in the engine (Fig. 7). All bearing cap bolts removed

during service procedures are to be cleaned and oiled

before installation. Bearing shells are available in

standard and the following undersized: 0.025mm

(.001 inch), .051mm (.002 inch), .076mm (.003 inch),

.254mm (.010 inch), and .305mm (.012 inch). Never

install an undersize bearing that will reduce clear-

ance below specifications.

MAIN BEARING SERVICEÐCRANKSHAFT NOT REMOVED

REMOVAL

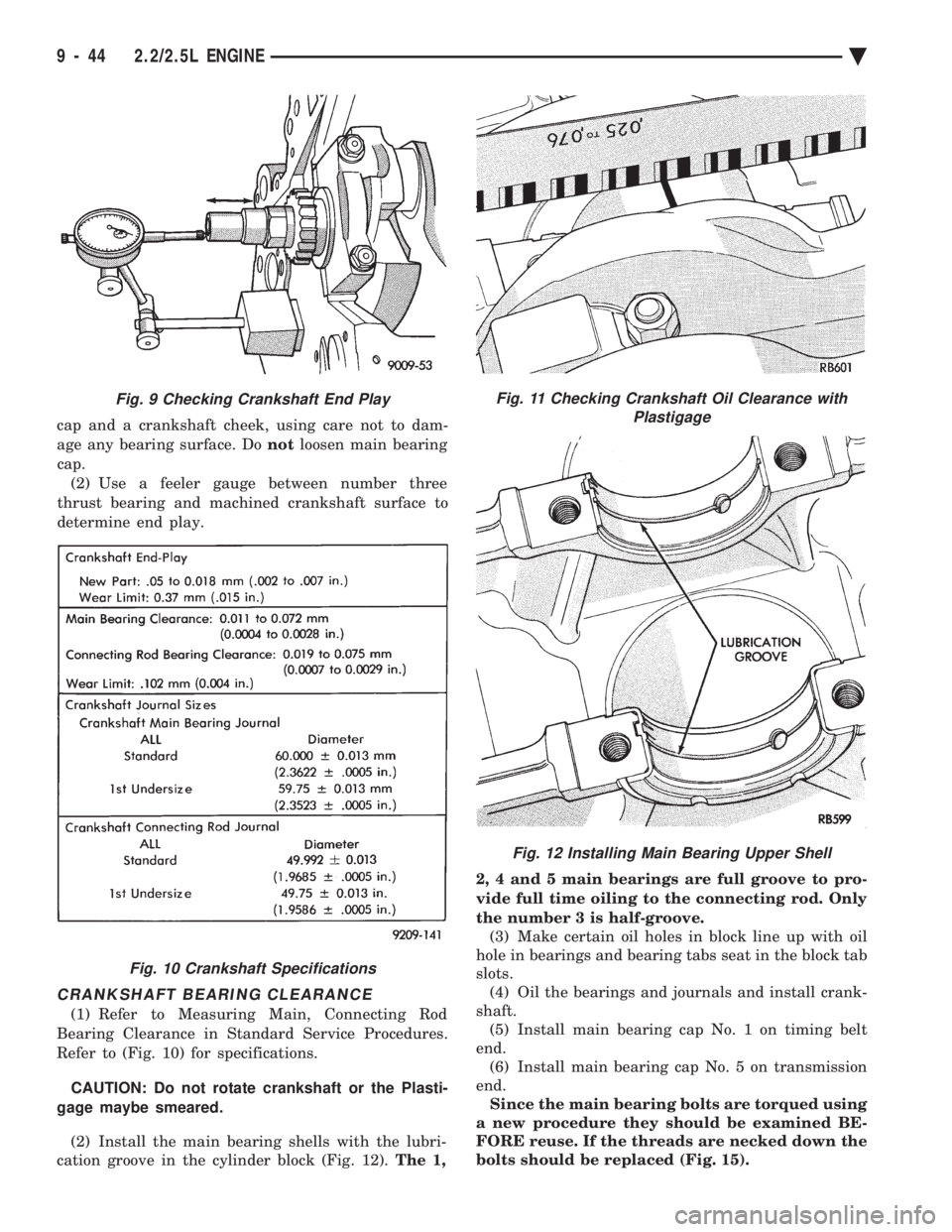

(1) Remove oil pan and identify bearing caps before

removal. (2) Remove bearing caps one at a time. Remove

upper half of bearing by inserting Special Main Bear-

ing Tool C-3059 (Fig. 8) into the oil hole of crankshaft. (3) Slowly rotate crankshaft clockwise, forcing out

upper half of bearing shell.

INSTALLATION Only one main bearing should be selectively

fitted while all other main bearing caps are prop-

erly tightened. When installing a new upper bearing shell, slightly

chamfer the sharp edges from the plain side. (1) Start bearing in place, and insert Main Bearing

Tool C-3059 into oil hole of crankshaft (Fig. 8). (2) Slowly rotate crankshaft counter-clockwise slid-

ing the bearing into position. Remove Special Main

Bearing Tool C-3059.

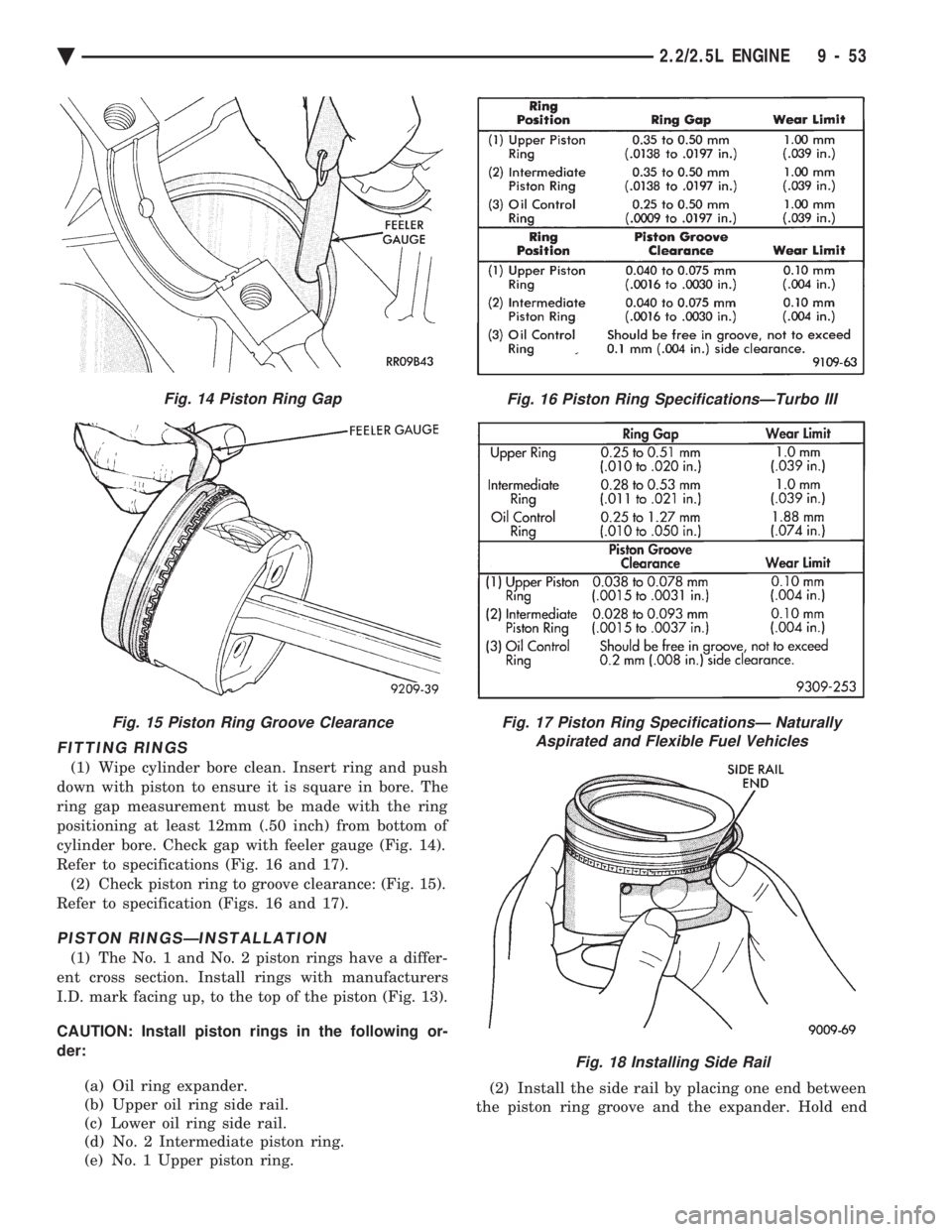

CHECKING CRANKSHAFT END PLAY

(1) Mount a dial indicator to front of engine, locating

probe on nose of crankshaft (Fig. 9). (2) Move crankshaft all the way to the rear of its

travel. (3) Zero the dial indicator.

(4) Move crankshaft all the way to the front and read

the dial indicator. Refer to (Fig. 10) for specifications.

OPTIONAL CRANKSHAFT END PLAY CHECK

(1) Move crankshaft all the way to the rear of its

travel using a lever inserted between a main bearingFig. 7 Main Bearing Identification

Fig. 8 Removing and Installing Upper Main Bearing With Special Tool C-3059

Ä 2.2/2.5L ENGINE 9 - 43

Page 1610 of 2438

cap and a crankshaft cheek, using care not to dam-

age any bearing surface. Do notloosen main bearing

cap. (2) Use a feeler gauge between number three

thrust bearing and machined crankshaft surface to

determine end play.

CRANKSHAFT BEARING CLEARANCE

(1) Refer to Measuring Main, Connecting Rod

Bearing Clearance in Standard Service Procedures.

Refer to (Fig. 10) for specifications.

CAUTION: Do not rotate crankshaft or the Plasti-

gage maybe smeared.

(2) Install the main bearing shells with the lubri-

cation groove in the cylinder block (Fig. 12). The 1, 2, 4 and 5 main bearings are full groove to pro-

vide full time oiling to the connecting rod. Only

the number 3 is half-groove.

(3) Make certain oil holes in block line up with oil

hole in bearings and bearing tabs seat in the block tab

slots. (4) Oil the bearings and journals and install crank-

shaft. (5) Install main bearing cap No. 1 on timing belt

end. (6) Install main bearing cap No. 5 on transmission

end. Since the main bearing bolts are torqued using

a new procedure they should be examined BE-

FORE reuse. If the threads are necked down the

bolts should be replaced (Fig. 15).

Fig. 9 Checking Crankshaft End Play

Fig. 10 Crankshaft Specifications

Fig. 11 Checking Crankshaft Oil Clearance with Plastigage

Fig. 12 Installing Main Bearing Upper Shell

9 - 44 2.2/2.5L ENGINE Ä

Page 1611 of 2438

Necking can be checked by holding a scale or straight

edge against the threads or by running a M11 x 1.50

nut the full length of the thread. If all the threads

do not contact the scale or if the nut does not run

down smoothly the bolt should be replaced. (7) Before installing the bolts the threads should be

oiled with engine oil. (8) Install both bolts in each cap finger tight, then

alternately torque each bolt to assemble the cap prop-

erly. (9) Tighten the bolts to 41 N Im plus 1/4 turn (30

ft.lbs. plus 1/4 turn). (Fig. 14)

BALANCE SHAFTS

2.2L Turbo III and 2.5L engines are equipped with

two counter rotating balance shafts installed in a

carrier attached to the lower crankcase (Fig. 1). The shafts are interconnected through gears. These

gears are driven by a short chain from the crank-

shaft, to rotate at two times crankshaft speed. This

counterbalances certain engine reciprocating forces.

REMOVAL

Refer to Engine Lubrication and Timing System

and Seals Service of this group for removal procedure

of necessary components to repair balance shafts.

(1) Remove chain cover, guide and tensioner (Fig.

16). Also see Carrier Assembly Removal for service

procedures requiring only temporary relocation of as-

sembly. (2) Remove balance shaft gear and chain sprocket

retaining screws and crankshaft chain sprocket torx

screws. Remove chain and sprocket assembly. (Fig.

17) (3) Remove gear cover retaining stud (double

ended to also retain chain guide). Remove cover and

balance shaft gears (Fig. 18). (4) Remove carrier rear cover and balance shafts.

(Fig. 19). (5) Remove six carrier to crankcase attaching bolts

to separate carrier (Fig. 1).

Fig. 16 Chain Cover, Guide and Tensioner

Fig. 13 Main Bearing Caps

Fig. 14 Installing Main Bearing Caps

Fig. 15 Checking Bolts For Stretching (Necked down)

Ä 2.2/2.5L ENGINE 9 - 45

Page 1616 of 2438

CYLINDER BLOCK CLEANING AND INSPECTION

(1) Clean cylinder block thoroughly and check all

core hole plugs for evidence of leaking. (2) If new core plugs are installed, Refer to Engine

Core Oil and Cam Plugs. (3) Examine block and cylinder bores for cracks or

fractures.

CYLINDER BORE INSPECTION

The cylinder walls should be checked for out-of-

round and taper with Tool C-119 (Fig. 5). The cylin-

der bore out-of-round is 0.050 mm (.002 inch)

maximum and cylinder bore taper is .125 mm (.005

inch) maximum. If the cylinder walls are badly

scuffed or scored, the cylinder block should be re-

bored and honed, and new pistons and rings fitted.

Whatever type of boring equipment is used, boring

and honing operation should be closely coordinated

with the fitting of pistons and rings in order that

specified clearances may be maintained. Refer to Honing Cylinder Bores outlined in the Standard

Service Procedures for specification and proce-

dures.

Measure the cylinder bore at three levels in direc-

tions A and B (Fig. 5). Top measurement should be

10mm ( 3/8 inch) down and bottom measurement

should be 10mm ( 3/8 inch.) up from bottom of bore.

Refer to (Fig. 6) for specifications.

SIZING PISTONS

Piston and cylinder wall must be clean and dry.

Piston diameter should be measured 90 degrees to

piston pin at size location shown in (Fig. 7). Cylinder

bores should be measured halfway down the cylinder

bore and transverse to the engine crankshaft center

line shown in (Fig. 5). Refer to (Fig. 6) for specifica-

Fig. 5 Checking Cylinder Bore Size

Fig. 6 Piston Size Location and Clearance Chart

Fig. 4 Connecting Rod Protectors

9 - 50 2.2/2.5L ENGINE Ä

Page 1618 of 2438

PISTON PINS

DISASSEMBLY Turbo III engine piston-pin-connecting rod assem-

blies should not be disassembled unless a malfunc-

tion is present or a damaged assembly component is

to be replaced. WARNING: APPROVED SAFETY GLASSES

MUST BE WORN DURING PISTON LOCK

RING REMOVAL OR INSTALLATION TO PRE-

VENT POSSIBLE INJURY FROM FLYING

PARTS.

(1) Carefully, remove piston pin lock rings from

piston, using a small screwdriver in removal notch

(Fig. 10). (2) Discard used lock ring.

(3) Following lock ring removal, attempt to slide

pin out of piston. If pin does not slide out freely by

hand;

² Check for burr on outer edge of lock ring groove. If

one is present, carefully scrape burr away with a

knife or other hand tool, being careful not to damage

lock ring retaining groove. (4) Slide out piston pin to complete disassembly.

(5) Inspect components, discard damaged or exces-

sively worn parts refer to specifications (Fig. 12). If a

piston is replaced, a new pin should be used.

PISTON PINS

REASSEMBLY

(1) Different lock rings are used for turbocharged

engine applications. Consult the Service Note, pro- vided with the lock ring service package, to select

the correct lock rings from the package for your ap-

plication.

(2) Carefully, install one NEWlock ring with gap

towards piston top in lock ring groove. Do not rein-

stall used lock rings. (3) Position connecting rod and slide in lightly oil

piston pinch (4) Install second NEWlock ring with gap towards

piston top in lock ring groove, use small screwdriver

if needed.

CAUTION: BOTH lock rings must be FULLY

SEATED in lock ring grooves or engine failure will

occur.

(5) Check piston pin end play pin movement be-

tween lock rings in assembly.

PISTON RINGÐREMOVAL

(1) ID mark on face of upper and intermediate pis-

ton rings must point toward piston crown. (2) Using a suitable ring expander, remove upper

and intermediate piston rings (Fig. 13). (3) Remove the upper oil ring side rail, lower oil

ring side rail and then oil ring expander from piston. (4) Clean ring grooves of any carbon deposits.

Fig. 11 Engine Piston PinsÐTurbo III, Naturally Aspirated and Flexible Fuel Vehicles

Fig. 12 Piston Pin Specifications

Fig. 13 Piston RingsÐRemoving and Installing

9 - 52 2.2/2.5L ENGINE Ä

Page 1619 of 2438

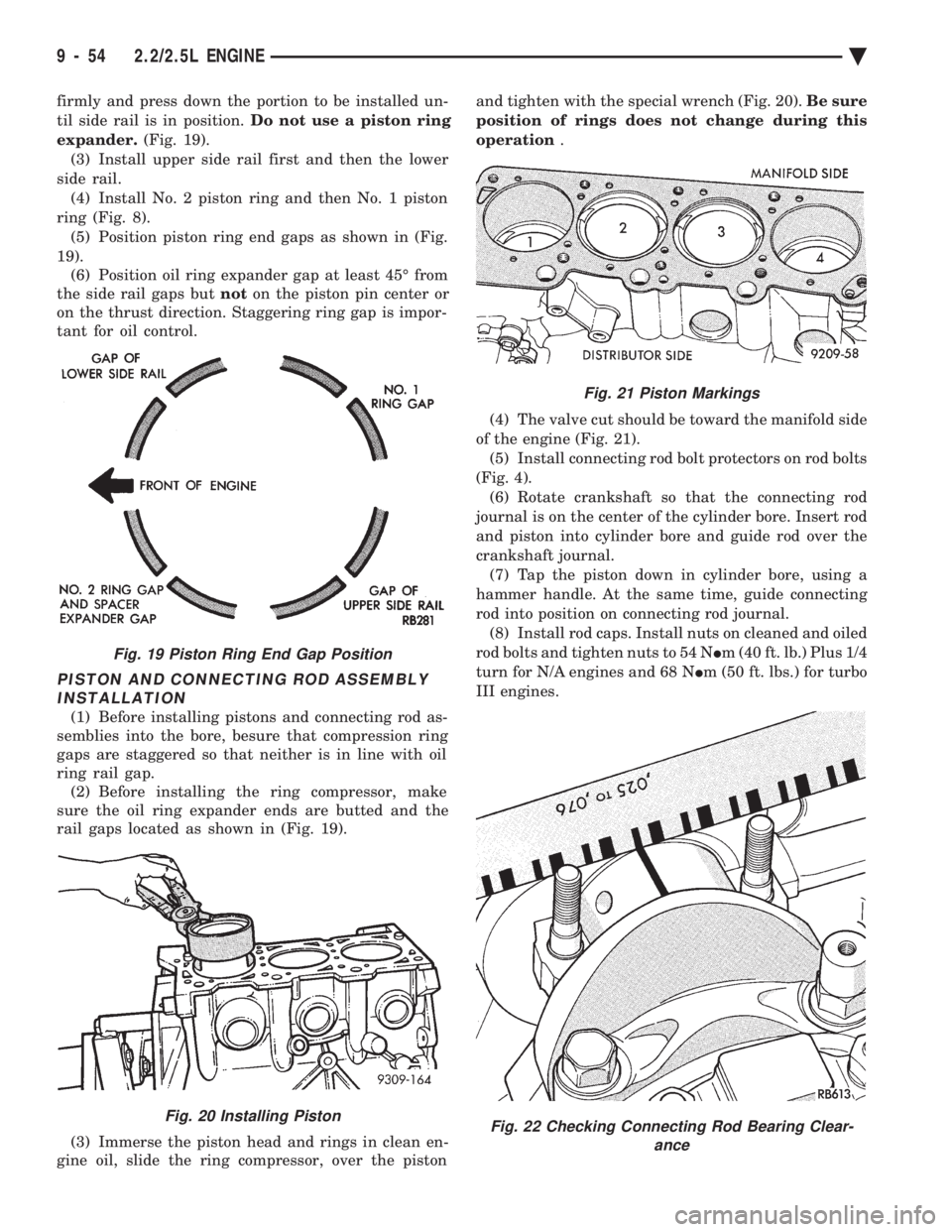

FITTING RINGS

(1) Wipe cylinder bore clean. Insert ring and push

down with piston to ensure it is square in bore. The

ring gap measurement must be made with the ring

positioning at least 12mm (.50 inch) from bottom of

cylinder bore. Check gap with feeler gauge (Fig. 14).

Refer to specifications (Fig. 16 and 17). (2) Check piston ring to groove clearance: (Fig. 15).

Refer to specification (Figs. 16 and 17).

PISTON RINGSÐINSTALLATION

(1) The No. 1 and No. 2 piston rings have a differ-

ent cross section. Install rings with manufacturers

I.D. mark facing up, to the top of the piston (Fig. 13).

CAUTION: Install piston rings in the following or-

der:

(a) Oil ring expander.

(b) Upper oil ring side rail.

(c) Lower oil ring side rail.

(d) No. 2 Intermediate piston ring.

(e) No. 1 Upper piston ring. (2) Install the side rail by placing one end between

the piston ring groove and the expander. Hold end

Fig. 16 Piston Ring SpecificationsÐTurbo III

Fig. 17 Piston Ring SpecificationsÐ Naturally Aspirated and Flexible Fuel Vehicles

Fig. 18 Installing Side Rail

Fig. 14 Piston Ring Gap

Fig. 15 Piston Ring Groove Clearance

Ä 2.2/2.5L ENGINE 9 - 53

Page 1620 of 2438

firmly and press down the portion to be installed un-

til side rail is in position. Do not use a piston ring

expander. (Fig. 19).

(3) Install upper side rail first and then the lower

side rail. (4) Install No. 2 piston ring and then No. 1 piston

ring (Fig. 8). (5) Position piston ring end gaps as shown in (Fig.

19). (6) Position oil ring expander gap at least 45É from

the side rail gaps but noton the piston pin center or

on the thrust direction. Staggering ring gap is impor-

tant for oil control.

PISTON AND CONNECTING ROD ASSEMBLY INSTALLATION

(1) Before installing pistons and connecting rod as-

semblies into the bore, besure that compression ring

gaps are staggered so that neither is in line with oil

ring rail gap. (2) Before installing the ring compressor, make

sure the oil ring expander ends are butted and the

rail gaps located as shown in (Fig. 19).

(3) Immerse the piston head and rings in clean en-

gine oil, slide the ring compressor, over the piston and tighten with the special wrench (Fig. 20).

Be sure

position of rings does not change during this

operation .

(4) The valve cut should be toward the manifold side

of the engine (Fig. 21). (5) Install connecting rod bolt protectors on rod bolts

(Fig. 4). (6) Rotate crankshaft so that the connecting rod

journal is on the center of the cylinder bore. Insert rod

and piston into cylinder bore and guide rod over the

crankshaft journal. (7) Tap the piston down in cylinder bore, using a

hammer handle. At the same time, guide connecting

rod into position on connecting rod journal. (8) Install rod caps. Install nuts on cleaned and oiled

rod bolts and tighten nuts to 54 N Im (40 ft. lb.) Plus 1/4

turn for N/A engines and 68 N Im (50 ft. lbs.) for turbo

III engines.

Fig. 19 Piston Ring End Gap Position

Fig. 20 Installing Piston

Fig. 21 Piston Markings

Fig. 22 Checking Connecting Rod Bearing Clear- ance

9 - 54 2.2/2.5L ENGINE Ä

Page 1621 of 2438

CONNECTING RODS

(1) Follow procedure specified in the Standard Ser-

vice Procedures Section for Measuring Main Bearing

Clearance and Connecting Rod Bearing Clearance

(Fig. 22). Refer to specifications (Fig. 25).

CAUTION: Do not rotate crankshaft or the Plastic-

Gage may be smeared.

The rod bearing bolts should be examined be-

fore reuse. If the threads are necked down the

bolts should be replaced (Fig. 23). Necking can be checked by holding a scale or straight

edge against the threads. If all the threads do not

contact the scale the bolt should be replaced.

(2) Before installing the nuts the threads should be

oiled with engine oil.

(3) Install nuts on each bolt finger tight than alter-

nately torque each nut to assemble the cap properly.

(4) Tighten the nuts to 54 N Im PLUS 1/4 turn (40 ft.

lbs. PLUS 1/4 turn) for N/A engines Do not use a

torque wrench for last step. and 68 NIm (50 ft. lbs.)

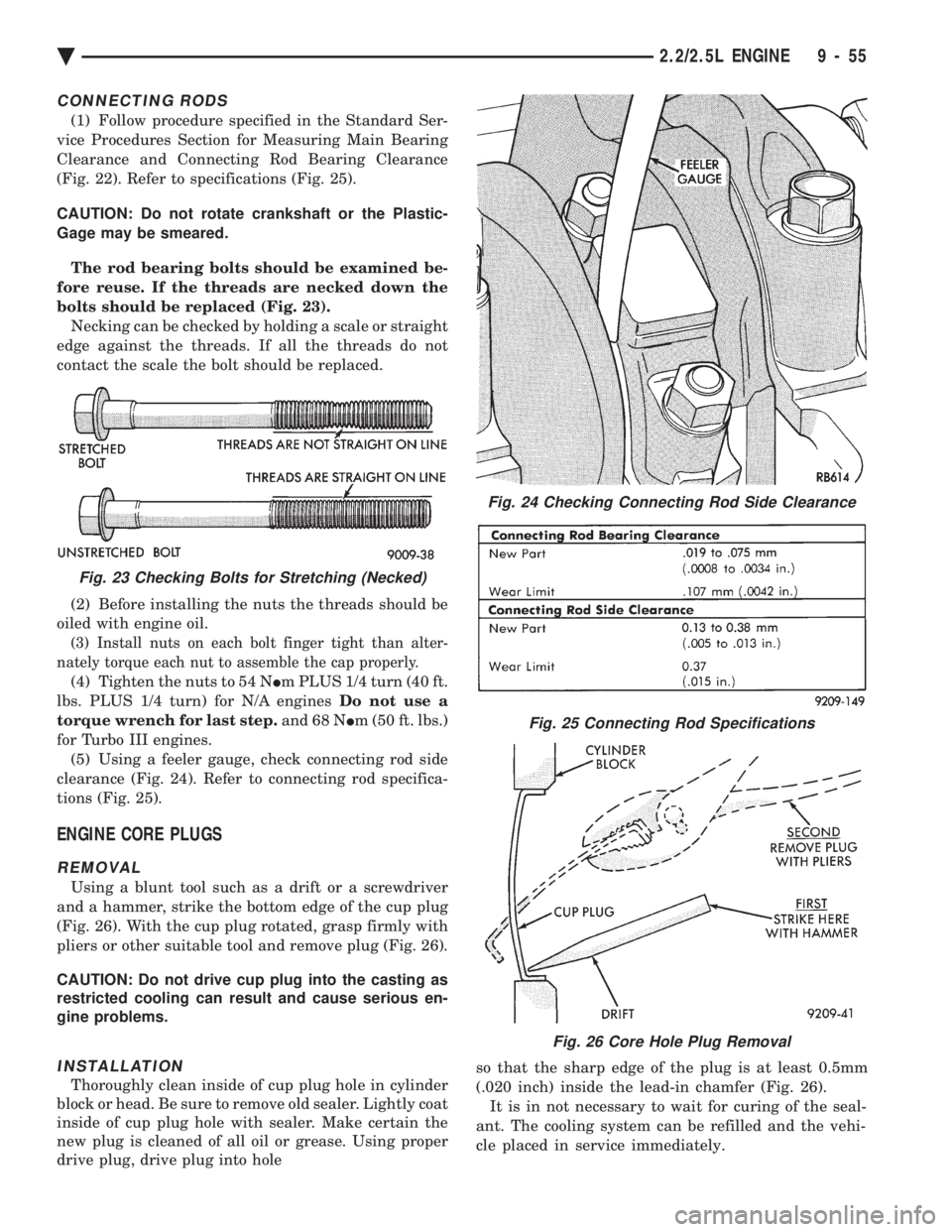

for Turbo III engines. (5) Using a feeler gauge, check connecting rod side

clearance (Fig. 24). Refer to connecting rod specifica-

tions (Fig. 25).

ENGINE CORE PLUGS

REMOVAL

Using a blunt tool such as a drift or a screwdriver

and a hammer, strike the bottom edge of the cup plug

(Fig. 26). With the cup plug rotated, grasp firmly with

pliers or other suitable tool and remove plug (Fig. 26).

CAUTION: Do not drive cup plug into the casting as

restricted cooling can result and cause serious en-

gine problems.

INSTALLATION

Thoroughly clean inside of cup plug hole in cylinder

block or head. Be sure to remove old sealer. Lightly coat

inside of cup plug hole with sealer. Make certain the

new plug is cleaned of all oil or grease. Using proper

drive plug, drive plug into hole so that the sharp edge of the plug is at least 0.5mm

(.020 inch) inside the lead-in chamfer (Fig. 26).

It is in not necessary to wait for curing of the seal-

ant. The cooling system can be refilled and the vehi-

cle placed in service immediately.

Fig. 24 Checking Connecting Rod Side Clearance

Fig. 25 Connecting Rod Specifications

Fig. 26 Core Hole Plug Removal

Fig. 23 Checking Bolts for Stretching (Necked)

Ä 2.2/2.5L ENGINE 9 - 55

Page 1624 of 2438

OIL PAN

A formed steel oil pan provides lower engine pro-

tection as well as serving as the engine oil reservoir

(Fig. 1). Pan side flanges to block are sealed with

gaskets. The oil pickup tube for some 2.2L engines

have a circular strainer and cover. The 2.5L engine

pickup is also unsupported and the lower end has a

box type strainer (Fig. 4).

PRESSURE LUBRICATION

Oil drawn up through the pickup tube is pressur-

ized by the pump and routed through the full flow

filter to the main oil gallery running the length of

the cylinder block (Fig. 2). Modified oil pickup, pump

and check valve provide increased oil flow to the

main oil gallery.

MAIN/ROD BEARINGS

A diagonal hole in each bulkhead feeds oil to each

main bearing. Drilled passages within the crankshaft

route oil from main bearing journals to crankpin

journals.

ACCESSORY SHAFT

Two separate holes supply the accessory shaft for

the N/A engines. For Turbo III engines there is a slot

in the rear shaft bushing that squirts oil onto the

oil pump drive gears (Fig. 2).

BALANCE SHAFTS

The engine balance shafts are lubricated by an ad-

ditional hole that interconnects a passage in one leg

of the balance shaft carrier to route oil down to the

carrier oil gallery. This gallery directly supplies the

balance shafts front bearings and internal machined

passages in the shafts routes oil from front to rear

shaft bearing journals.

TURBOCHARGER (WHERE EQUIPPED)

If turbocharger equipped, pressurized oil from the

main gallery to sending unit hex fitting is piped from

the fitting to the turbocharger bearing housing.

From the housing a hose and tube connection to a

machined hole in the block provides drainback.

CAMSHAFT/HYDRAULIC LIFTERS

A vertical hole at the number five bulkhead routes

pressurized oil through a restrictor up past a cylinder

head bolt to an oil gallery running the length of the

cylinder head. For 2.2/2.5L and 2.5L FFV engines

hydraulic adjusters are supplied directly from this

gallery while diagonal holes supply oil to the cam-

shaft journals. The camshaft journals are partially

slotted to allow a predetermined amount of pressur-

ized oil to pass into the bearing cap cavities with

small holes directed to spray lubricate the camshaft

lobes. For Turbo III engines oil is supplied thru oil

galleries in the head to the camshafts and rocker arm shafts which feed oil to the lash adjusters. Oil is

feed thru the rocker arms to lubricate the rollers and

the camshaft lobes.

SPLASH LUBRICATION

Oil returning to the pan from pressurized compo-

nents supplies lubrication to the valve stems. Cylinder

bores and wrist pins are splash lubricated from di-

rected holes in the connecting rods.

OIL PAN

REMOVAL

(1) Drain engine oil and remove oil pan.

(2) Clean oil pan and all gasket surfaces.

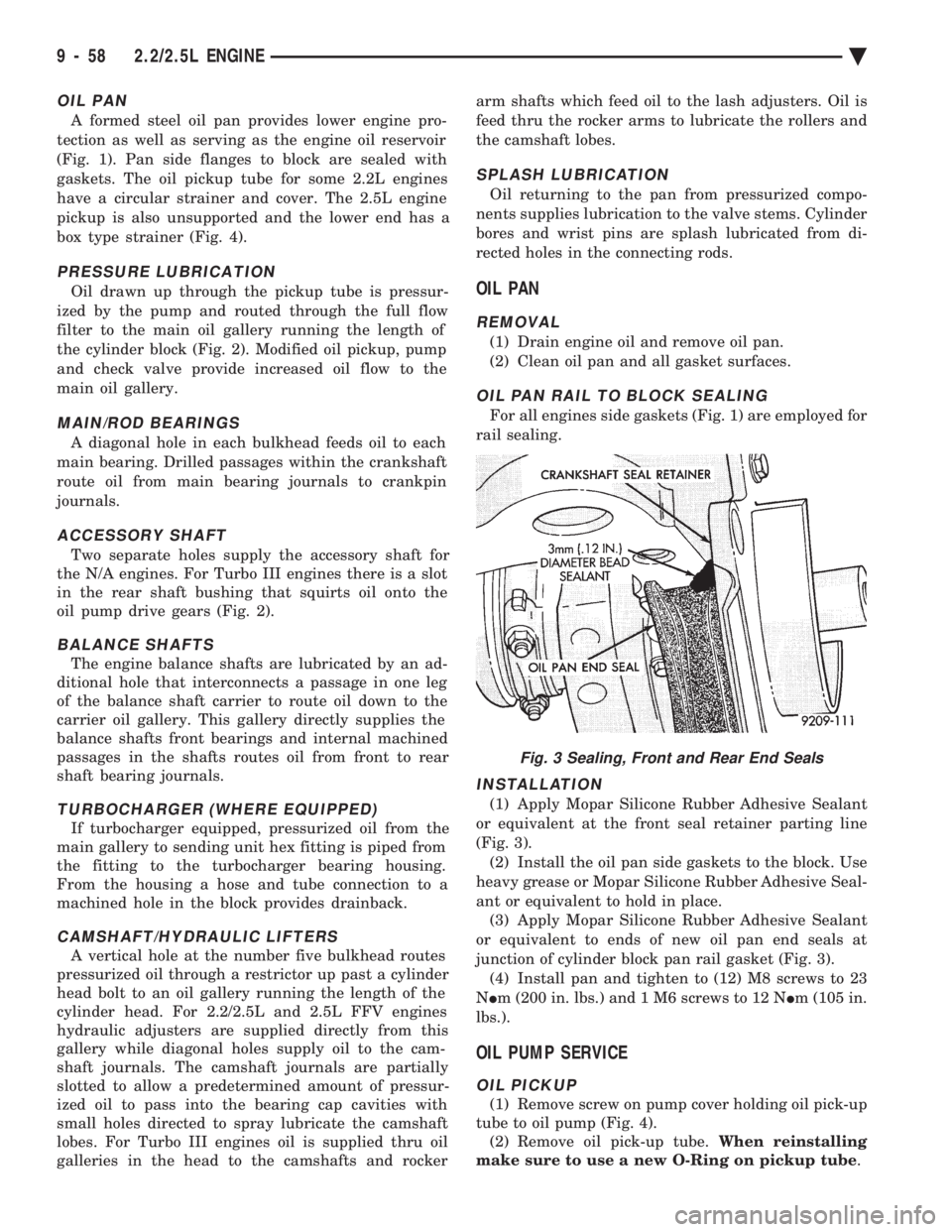

OIL PAN RAIL TO BLOCK SEALING

For all engines side gaskets (Fig. 1) are employed for

rail sealing.

INSTALLATION

(1) Apply Mopar Silicone Rubber Adhesive Sealant

or equivalent at the front seal retainer parting line

(Fig. 3). (2) Install the oil pan side gaskets to the block. Use

heavy grease or Mopar Silicone Rubber Adhesive Seal-

ant or equivalent to hold in place. (3) Apply Mopar Silicone Rubber Adhesive Sealant

or equivalent to ends of new oil pan end seals at

junction of cylinder block pan rail gasket (Fig. 3). (4) Install pan and tighten to (12) M8 screws to 23

N Im (200 in. lbs.) and 1 M6 screws to 12 N Im (105 in.

lbs.).

OIL PUMP SERVICE

OIL PICKUP

(1) Remove screw on pump cover holding oil pick-up

tube to oil pump (Fig. 4). (2) Remove oil pick-up tube. When reinstalling

make sure to use a new O-Ring on pickup tube .

Fig. 3 Sealing, Front and Rear End Seals

9 - 58 2.2/2.5L ENGINE Ä

Page 1626 of 2438

CAUTION: Pump must be held in fully seated posi-

tion (described above) while installing screws. (6) Tighten screws to 23 N Im (200 in. lbs.).

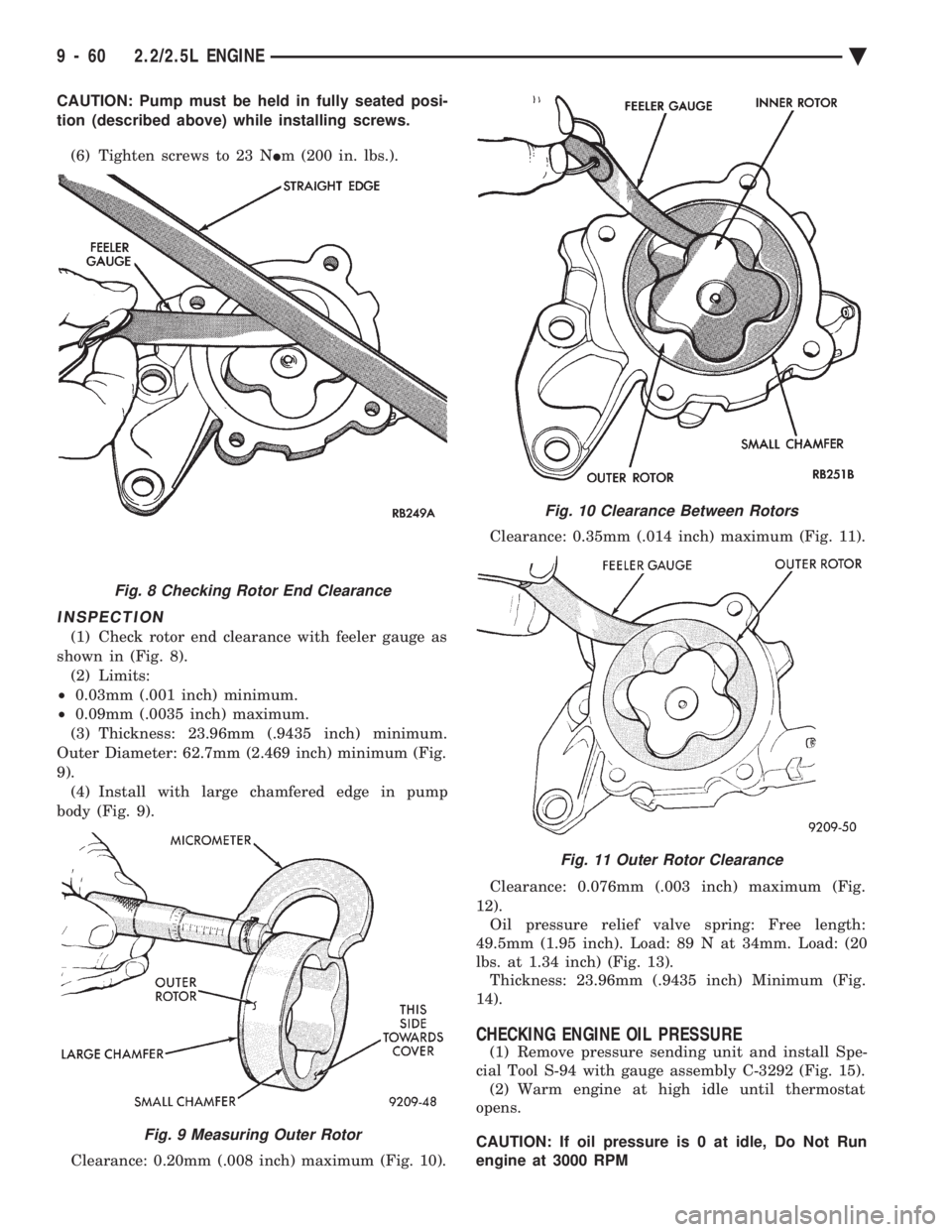

INSPECTION

(1) Check rotor end clearance with feeler gauge as

shown in (Fig. 8). (2) Limits:

² 0.03mm (.001 inch) minimum.

² 0.09mm (.0035 inch) maximum.

(3) Thickness: 23.96mm (.9435 inch) minimum.

Outer Diameter: 62.7mm (2.469 inch) minimum (Fig.

9). (4) Install with large chamfered edge in pump

body (Fig. 9).

Clearance: 0.20mm (.008 inch) maximum (Fig. 10). Clearance: 0.35mm (.014 inch) maximum (Fig. 11).

Clearance: 0.076mm (.003 inch) maximum (Fig.

12). Oil pressure relief valve spring: Free length:

49.5mm (1.95 inch). Load: 89 N at 34mm. Load: (20

lbs. at 1.34 inch) (Fig. 13). Thickness: 23.96mm (.9435 inch) Minimum (Fig.

14).

CHECKING ENGINE OIL PRESSURE

(1) Remove pressure sending unit and install Spe-

cial Tool S-94 with gauge assembly C-3292 (Fig. 15). (2) Warm engine at high idle until thermostat

opens.

CAUTION: If oil pressure is 0 at idle, Do Not Run

engine at 3000 RPM

Fig. 8 Checking Rotor End Clearance

Fig. 9 Measuring Outer Rotor

Fig. 10 Clearance Between Rotors

Fig. 11 Outer Rotor Clearance

9 - 60 2.2/2.5L ENGINE Ä