check engine CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 2410 of 2438

Engine speed may drop quickly or engine may even

stall. This indicates that EGR gas is flowing through

the system.If both the EGR Gas Flow Check, System Check

and Diagnosis Chart are completed satisfactorily,

then the EGR system functions normally. If engine speed does not drop off when performing

the test, remove both the EGR valve and EGR tube

and check for plugged passages. Also, check the in-

take manifold inlet passage. Clean or replace these

components for restoration of proper flow.

EGR VALVE SERVICEÐ2.2L AND 2.5L TBI

ENGINES

REMOVAL

(1) Disconnect electrical connector and vacuum

line from the electric EGR transducer (Fig. 12). (2) Remove EGR valve bolts from intake manifold.

(3) Remove EGR valve from intake manifold.

(4) Clean gasket surface and discard old gasket.

Check for any signs of leakage or cracked surfaces.

INSTALLATION

(1) Assemble EGR valve with new gasket onto the

intake manifold. (2) Install EGR valve mounting bolts. Tighten to

22 N Im (200 in. lbs.) torque.

(3) Reconnect vacuum line and electrical connector

to Electric EGR Transducer.

EGR TUBE SERVICEÐ2.2L AND 2.5L TBI ENGINES

REMOVAL

(1) Remove EGR tube attaching bolts from intake

and exhaust manifolds. (2) Remove EGR tube.

(3) Clean intake and exhaust manifold gasket sur-

faces and EGR tube flange gasket surfaces. Discard

old gaskets. (4) Check for signs of leakage or cracked surfaces

on either manifolds or tube. Replace as necessary.

INSTALLATION

(1) Loosely position EGR tube and new gaskets in

place on intake and exhaust manifolds. Install

mounting bolts. (2) Tighten attaching bolts to 22 N Im (200 in. lbs.)

torque.

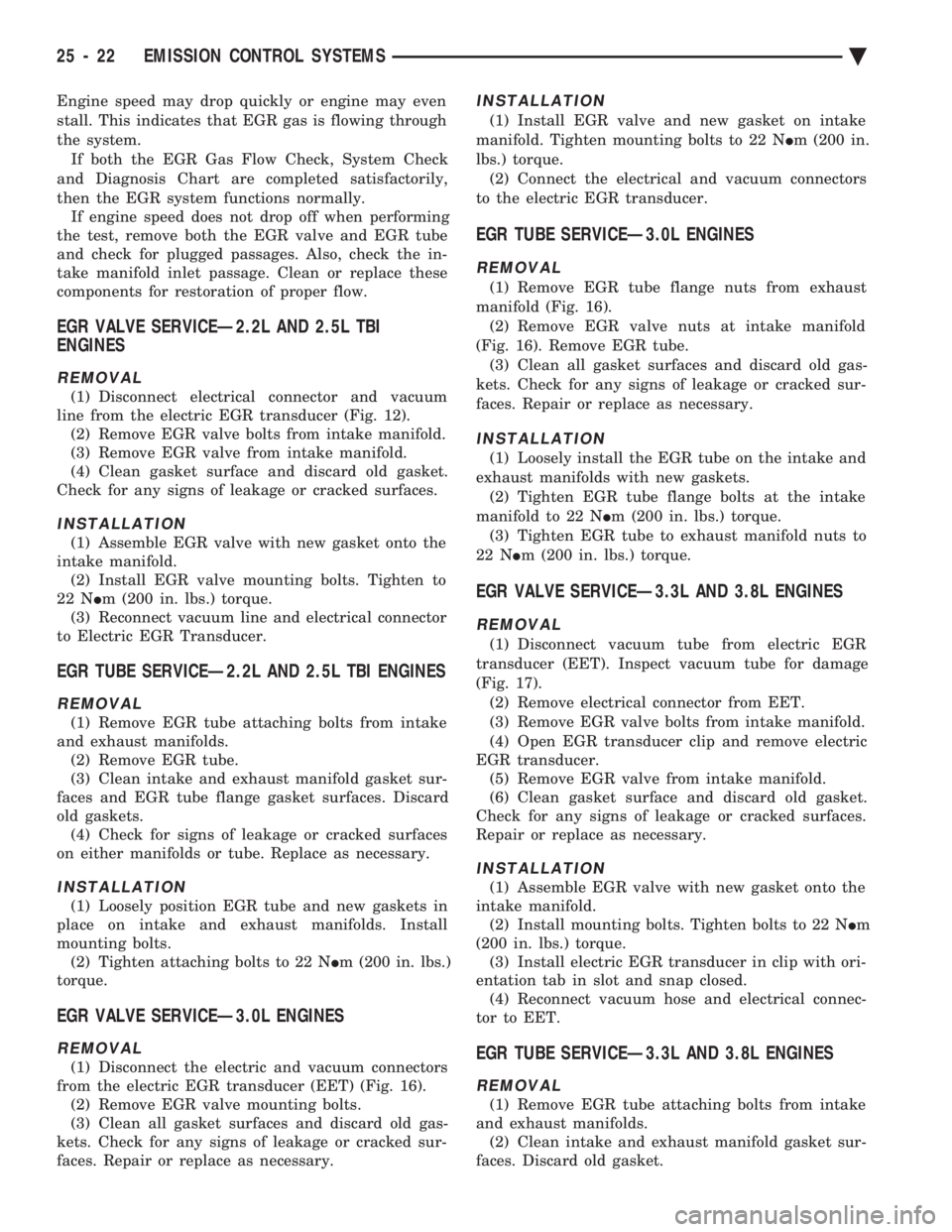

EGR VALVE SERVICEÐ3.0L ENGINES

REMOVAL

(1) Disconnect the electric and vacuum connectors

from the electric EGR transducer (EET) (Fig. 16). (2) Remove EGR valve mounting bolts.

(3) Clean all gasket surfaces and discard old gas-

kets. Check for any signs of leakage or cracked sur-

faces. Repair or replace as necessary.

INSTALLATION

(1) Install EGR valve and new gasket on intake

manifold. Tighten mounting bolts to 22 N Im (200 in.

lbs.) torque. (2) Connect the electrical and vacuum connectors

to the electric EGR transducer.

EGR TUBE SERVICEÐ3.0L ENGINES

REMOVAL

(1) Remove EGR tube flange nuts from exhaust

manifold (Fig. 16). (2) Remove EGR valve nuts at intake manifold

(Fig. 16). Remove EGR tube. (3) Clean all gasket surfaces and discard old gas-

kets. Check for any signs of leakage or cracked sur-

faces. Repair or replace as necessary.

INSTALLATION

(1) Loosely install the EGR tube on the intake and

exhaust manifolds with new gaskets. (2) Tighten EGR tube flange bolts at the intake

manifold to 22 N Im (200 in. lbs.) torque.

(3) Tighten EGR tube to exhaust manifold nuts to

22 N Im (200 in. lbs.) torque.

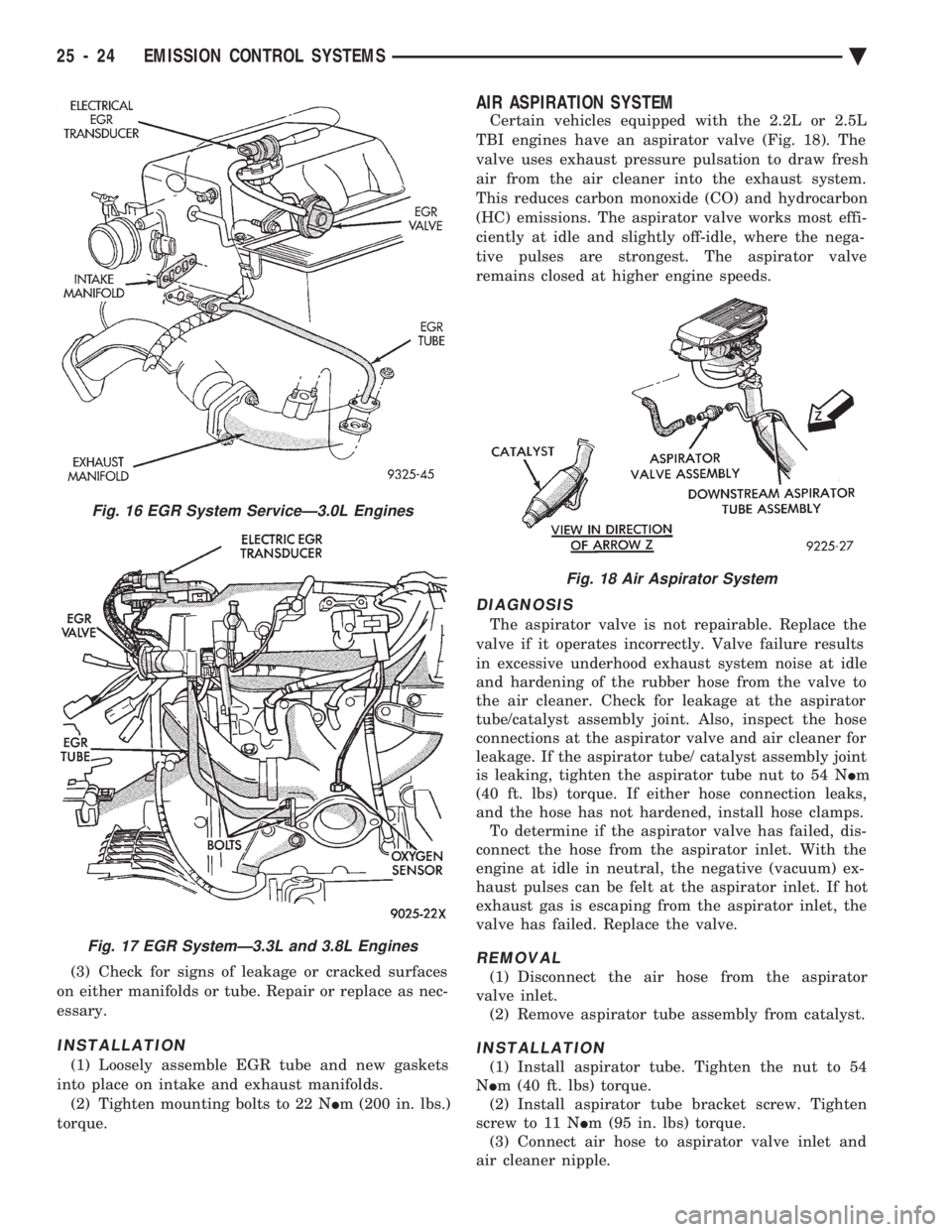

EGR VALVE SERVICEÐ3.3L AND 3.8L ENGINES

REMOVAL

(1) Disconnect vacuum tube from electric EGR

transducer (EET). Inspect vacuum tube for damage

(Fig. 17). (2) Remove electrical connector from EET.

(3) Remove EGR valve bolts from intake manifold.

(4) Open EGR transducer clip and remove electric

EGR transducer. (5) Remove EGR valve from intake manifold.

(6) Clean gasket surface and discard old gasket.

Check for any signs of leakage or cracked surfaces.

Repair or replace as necessary.

INSTALLATION

(1) Assemble EGR valve with new gasket onto the

intake manifold. (2) Install mounting bolts. Tighten bolts to 22 N Im

(200 in. lbs.) torque. (3) Install electric EGR transducer in clip with ori-

entation tab in slot and snap closed. (4) Reconnect vacuum hose and electrical connec-

tor to EET.

EGR TUBE SERVICEÐ3.3L AND 3.8L ENGINES

REMOVAL

(1) Remove EGR tube attaching bolts from intake

and exhaust manifolds. (2) Clean intake and exhaust manifold gasket sur-

faces. Discard old gasket.

25 - 22 EMISSION CONTROL SYSTEMS Ä

Page 2412 of 2438

(3) Check for signs of leakage or cracked surfaces

on either manifolds or tube. Repair or replace as nec-

essary.

INSTALLATION

(1) Loosely assemble EGR tube and new gaskets

into place on intake and exhaust manifolds. (2) Tighten mounting bolts to 22 N Im (200 in. lbs.)

torque.

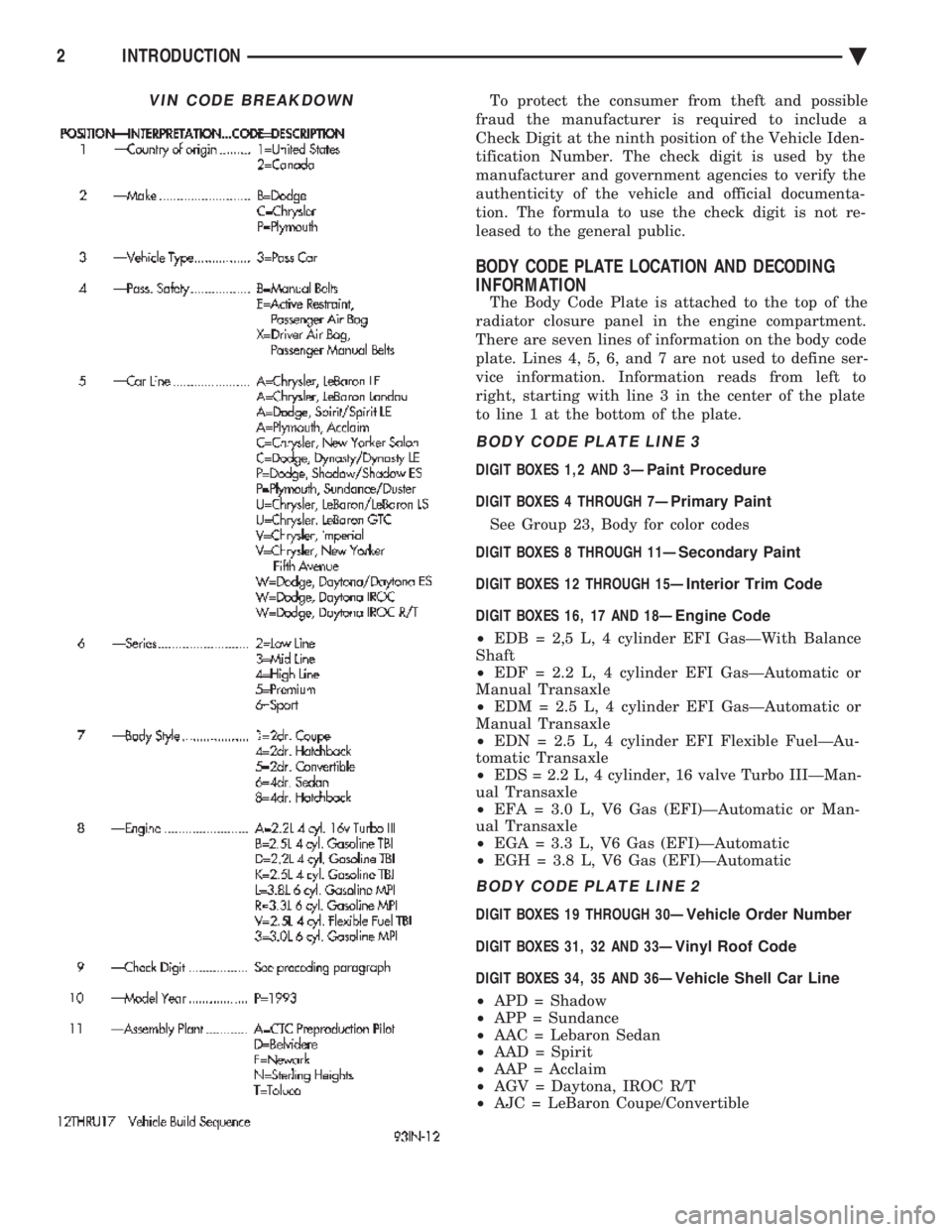

AIR ASPIRATION SYSTEM

Certain vehicles equipped with the 2.2L or 2.5L

TBI engines have an aspirator valve (Fig. 18). The

valve uses exhaust pressure pulsation to draw fresh

air from the air cleaner into the exhaust system.

This reduces carbon monoxide (CO) and hydrocarbon

(HC) emissions. The aspirator valve works most effi-

ciently at idle and slightly off-idle, where the nega-

tive pulses are strongest. The aspirator valve

remains closed at higher engine speeds.

DIAGNOSIS

The aspirator valve is not repairable. Replace the

valve if it operates incorrectly. Valve failure results

in excessive underhood exhaust system noise at idle

and hardening of the rubber hose from the valve to

the air cleaner. Check for leakage at the aspirator

tube/catalyst assembly joint. Also, inspect the hose

connections at the aspirator valve and air cleaner for

leakage. If the aspirator tube/ catalyst assembly joint

is leaking, tighten the aspirator tube nut to 54 N Im

(40 ft. lbs) torque. If either hose connection leaks,

and the hose has not hardened, install hose clamps. To determine if the aspirator valve has failed, dis-

connect the hose from the aspirator inlet. With the

engine at idle in neutral, the negative (vacuum) ex-

haust pulses can be felt at the aspirator inlet. If hot

exhaust gas is escaping from the aspirator inlet, the

valve has failed. Replace the valve.

REMOVAL

(1) Disconnect the air hose from the aspirator

valve inlet. (2) Remove aspirator tube assembly from catalyst.

INSTALLATION

(1) Install aspirator tube. Tighten the nut to 54

N Im (40 ft. lbs) torque.

(2) Install aspirator tube bracket screw. Tighten

screw to 11 N Im (95 in. lbs) torque.

(3) Connect air hose to aspirator valve inlet and

air cleaner nipple.

Fig. 16 EGR System ServiceÐ3.0L Engines

Fig. 17 EGR SystemÐ3.3L and 3.8L Engines

Fig. 18 Air Aspirator System

25 - 24 EMISSION CONTROL SYSTEMS Ä

Page 2417 of 2438

To protect the consumer from theft and possible

fraud the manufacturer is required to include a

Check Digit at the ninth position of the Vehicle Iden-

tification Number. The check digit is used by the

manufacturer and government agencies to verify the

authenticity of the vehicle and official documenta-

tion. The formula to use the check digit is not re-

leased to the general public.

BODY CODE PLATE LOCATION AND DECODING

INFORMATION

The Body Code Plate is attached to the top of the

radiator closure panel in the engine compartment.

There are seven lines of information on the body code

plate. Lines 4, 5, 6, and 7 are not used to define ser-

vice information. Information reads from left to

right, starting with line 3 in the center of the plate

to line 1 at the bottom of the plate.

BODY CODE PLATE LINE 3

DIGIT BOXES 1,2 AND 3Ð Paint Procedure

DIGIT BOXES 4 THROUGH 7Ð Primary Paint

See Group 23, Body for color codes

DIGIT BOXES 8 THROUGH 11Ð Secondary Paint

DIGIT BOXES 12 THROUGH 15Ð Interior Trim Code

DIGIT BOXES 16, 17 AND 18Ð Engine Code

² EDB = 2,5 L, 4 cylinder EFI GasÐWith Balance

Shaft

² EDF = 2.2 L, 4 cylinder EFI GasÐAutomatic or

Manual Transaxle

² EDM = 2.5 L, 4 cylinder EFI GasÐAutomatic or

Manual Transaxle

² EDN = 2.5 L, 4 cylinder EFI Flexible FuelÐAu-

tomatic Transaxle

² EDS = 2.2 L, 4 cylinder, 16 valve Turbo IIIÐMan-

ual Transaxle

² EFA = 3.0 L, V6 Gas (EFI)ÐAutomatic or Man-

ual Transaxle

² EGA = 3.3 L, V6 Gas (EFI)ÐAutomatic

² EGH = 3.8 L, V6 Gas (EFI)ÐAutomatic

BODY CODE PLATE LINE 2

DIGIT BOXES 19 THROUGH 30Ð Vehicle Order Number

DIGIT BOXES 31, 32 AND 33Ð Vinyl Roof Code

DIGIT BOXES 34, 35 AND 36Ð Vehicle Shell Car Line

² APD = Shadow

² APP = Sundance

² AAC = Lebaron Sedan

² AAD = Spirit

² AAP = Acclaim

² AGV = Daytona, IROC R/T

² AJC = LeBaron Coupe/Convertible

VIN CODE BREAKDOWN

2 INTRODUCTION Ä