wheel CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 289 of 2438

SERVICE ADJUSTMENTS INDEX

page page

Bleeding Bendix Antilock 4 Brake System ....... 3

Master Cylinder Fluid Level .................. 3 Testing for Fluid Contamination

............... 4

MASTER CYLINDER FLUID LEVEL

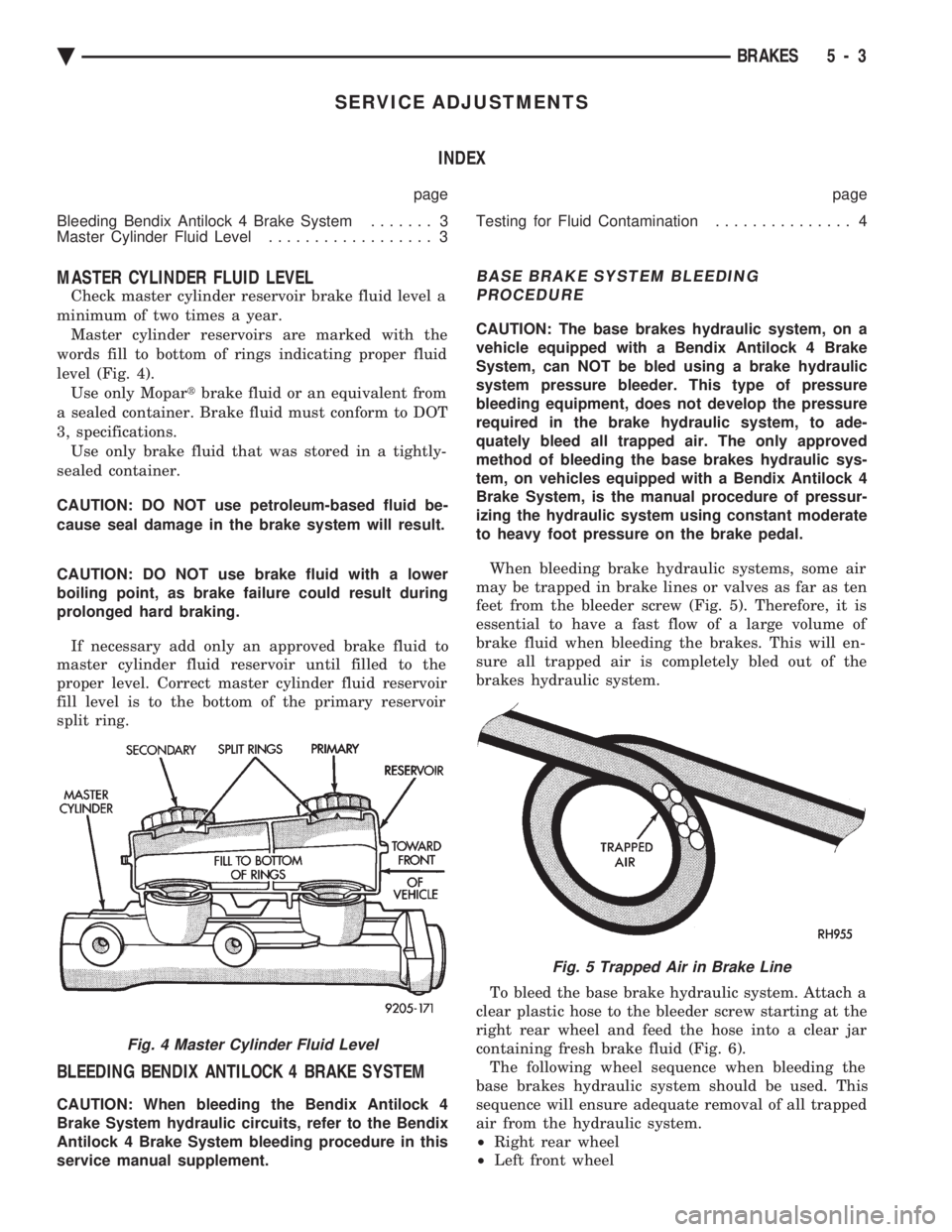

Check master cylinder reservoir brake fluid level a

minimum of two times a year. Master cylinder reservoirs are marked with the

words fill to bottom of rings indicating proper fluid

level (Fig. 4). Use only Mopar tbrake fluid or an equivalent from

a sealed container. Brake fluid must conform to DOT

3, specifications. Use only brake fluid that was stored in a tightly-

sealed container.

CAUTION: DO NOT use petroleum-based fluid be-

cause seal damage in the brake system will result.

CAUTION: DO NOT use brake fluid with a lower

boiling point, as brake failure could result during

prolonged hard braking.

If necessary add only an approved brake fluid to

master cylinder fluid reservoir until filled to the

proper level. Correct master cylinder fluid reservoir

fill level is to the bottom of the primary reservoir

split ring.

BLEEDING BENDIX ANTILOCK 4 BRAKE SYSTEM

CAUTION: When bleeding the Bendix Antilock 4

Brake System hydraulic circuits, refer to the Bendix

Antilock 4 Brake System bleeding procedure in this

service manual supplement.

BASE BRAKE SYSTEM BLEEDING PROCEDURE

CAUTION: The base brakes hydraulic system, on a

vehicle equipped with a Bendix Antilock 4 Brake

System, can NOT be bled using a brake hydraulic

system pressure bleeder. This type of pressure

bleeding equipment, does not develop the pressure

required in the brake hydraulic system, to ade-

quately bleed all trapped air. The only approved

method of bleeding the base brakes hydraulic sys-

tem, on vehicles equipped with a Bendix Antilock 4

Brake System, is the manual procedure of pressur-

izing the hydraulic system using constant moderate

to heavy foot pressure on the brake pedal.

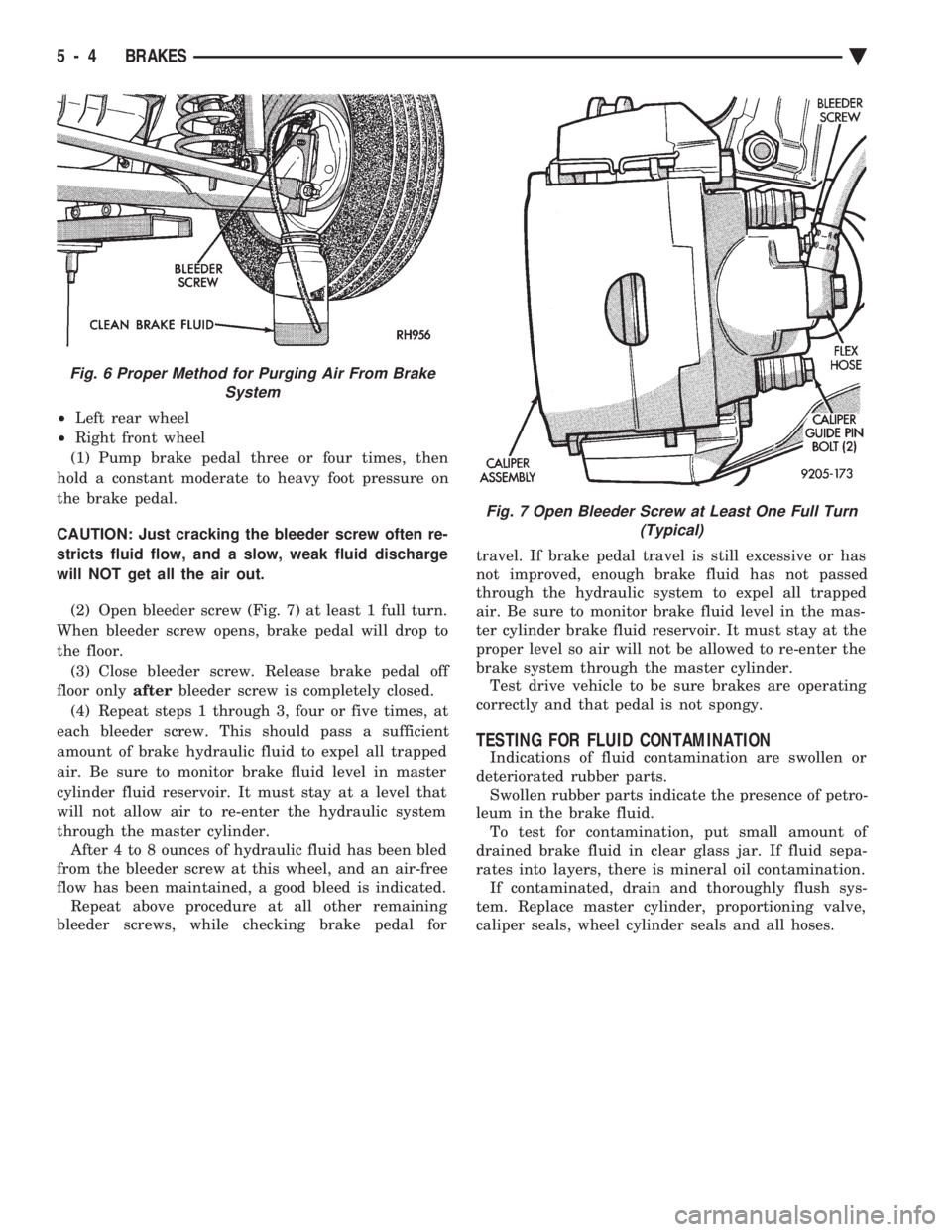

When bleeding brake hydraulic systems, some air

may be trapped in brake lines or valves as far as ten

feet from the bleeder screw (Fig. 5). Therefore, it is

essential to have a fast flow of a large volume of

brake fluid when bleeding the brakes. This will en-

sure all trapped air is completely bled out of the

brakes hydraulic system.

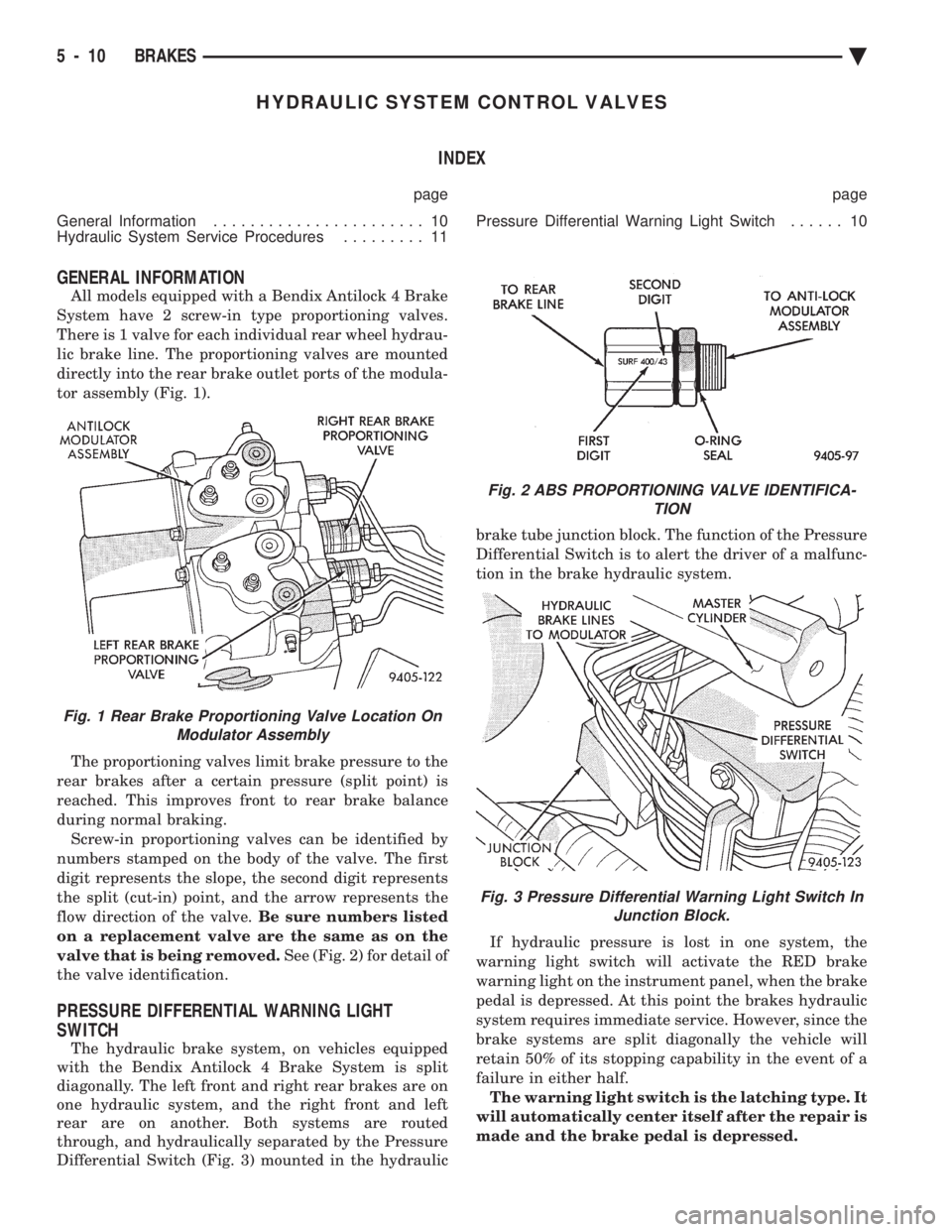

To bleed the base brake hydraulic system. Attach a

clear plastic hose to the bleeder screw starting at the

right rear wheel and feed the hose into a clear jar

containing fresh brake fluid (Fig. 6). The following wheel sequence when bleeding the

base brakes hydraulic system should be used. This

sequence will ensure adequate removal of all trapped

air from the hydraulic system.

² Right rear wheel

² Left front wheel

Fig. 4 Master Cylinder Fluid Level

Fig. 5 Trapped Air in Brake Line

Ä BRAKES 5 - 3

Page 290 of 2438

² Left rear wheel

² Right front wheel

(1) Pump brake pedal three or four times, then

hold a constant moderate to heavy foot pressure on

the brake pedal.

CAUTION: Just cracking the bleeder screw often re-

stricts fluid flow, and a slow, weak fluid discharge

will NOT get all the air out.

(2) Open bleeder screw (Fig. 7) at least 1 full turn.

When bleeder screw opens, brake pedal will drop to

the floor. (3) Close bleeder screw. Release brake pedal off

floor only afterbleeder screw is completely closed.

(4) Repeat steps 1 through 3, four or five times, at

each bleeder screw. This should pass a sufficient

amount of brake hydraulic fluid to expel all trapped

air. Be sure to monitor brake fluid level in master

cylinder fluid reservoir. It must stay at a level that

will not allow air to re-enter the hydraulic system

through the master cylinder. After 4 to 8 ounces of hydraulic fluid has been bled

from the bleeder screw at this wheel, and an air-free

flow has been maintained, a good bleed is indicated. Repeat above procedure at all other remaining

bleeder screws, while checking brake pedal for travel. If brake pedal travel is still excessive or has

not improved, enough brake fluid has not passed

through the hydraulic system to expel all trapped

air. Be sure to monitor brake fluid level in the mas-

ter cylinder brake fluid reservoir. It must stay at the

proper level so air will not be allowed to re-enter the

brake system through the master cylinder. Test drive vehicle to be sure brakes are operating

correctly and that pedal is not spongy.

TESTING FOR FLUID CONTAMINATION

Indications of fluid contamination are swollen or

deteriorated rubber parts. Swollen rubber parts indicate the presence of petro-

leum in the brake fluid. To test for contamination, put small amount of

drained brake fluid in clear glass jar. If fluid sepa-

rates into layers, there is mineral oil contamination. If contaminated, drain and thoroughly flush sys-

tem. Replace master cylinder, proportioning valve,

caliper seals, wheel cylinder seals and all hoses.

Fig. 6 Proper Method for Purging Air From Brake System

Fig. 7 Open Bleeder Screw at Least One Full Turn(Typical)

5 - 4 BRAKES Ä

Page 296 of 2438

HYDRAULIC SYSTEM CONTROL VALVES INDEX

page page

General Information ....................... 10

Hydraulic System Service Procedures ......... 11 Pressure Differential Warning Light Switch

...... 10

GENERAL INFORMATION

All models equipped with a Bendix Antilock 4 Brake

System have 2 screw-in type proportioning valves.

There is 1 valve for each individual rear wheel hydrau-

lic brake line. The proportioning valves are mounted

directly into the rear brake outlet ports of the modula-

tor assembly (Fig. 1).

The proportioning valves limit brake pressure to the

rear brakes after a certain pressure (split point) is

reached. This improves front to rear brake balance

during normal braking. Screw-in proportioning valves can be identified by

numbers stamped on the body of the valve. The first

digit represents the slope, the second digit represents

the split (cut-in) point, and the arrow represents the

flow direction of the valve. Be sure numbers listed

on a replacement valve are the same as on the

valve that is being removed. See (Fig. 2) for detail of

the valve identification.

PRESSURE DIFFERENTIAL WARNING LIGHT

SWITCH

The hydraulic brake system, on vehicles equipped

with the Bendix Antilock 4 Brake System is split

diagonally. The left front and right rear brakes are on

one hydraulic system, and the right front and left

rear are on another. Both systems are routed

through, and hydraulically separated by the Pressure

Differential Switch (Fig. 3) mounted in the hydraulic brake tube junction block. The function of the Pressure

Differential Switch is to alert the driver of a malfunc-

tion in the brake hydraulic system.

If hydraulic pressure is lost in one system, the

warning light switch will activate the RED brake

warning light on the instrument panel, when the brake

pedal is depressed. At this point the brakes hydraulic

system requires immediate service. However, since the

brake systems are split diagonally the vehicle will

retain 50% of its stopping capability in the event of a

failure in either half. The warning light switch is the latching type. It

will automatically center itself after the repair is

made and the brake pedal is depressed.

Fig. 1 Rear Brake Proportioning Valve Location On Modulator Assembly

Fig. 2 ABS PROPORTIONING VALVE IDENTIFICA- TION

Fig. 3 Pressure Differential Warning Light Switch InJunction Block.

5 - 10 BRAKES Ä

Page 297 of 2438

The instrument panel bulb can be checked each

time the ignition switch is turned to the start posi-

tion or the parking brake is set.

HYDRAULIC SYSTEM SERVICE PROCEDURES

BRAKE WARNING SYSTEM

CHECKING BRAKE WARNING SWITCH UNIT

The Red Brake Warning light will come on when the

parking brake is applied with the ignition key turned

ON. The same light will also illuminate should one of

the two service brake hydraulic systems fail.

CAUTION:Make sure air does not enter the hydraulic

system during this test procedure. See bleeding with-

out a pressure bleeder at the beginning of this section

for master cylinder fluid level checking procedures.

To test the service brake warning system lamp.

Raise vehicle on a hoist and open a wheel cylinder

bleeder while a helper depresses the brake pedal and

observes the warning light.

If light fails to come on, inspect for a burned out bulb,

disconnected socket, or a broken or disconnected wire at

the switch. If the bulb is not burned out and the wire

continuity is not interrupted. Check the service brake

warning switch operation with a test lamp between the

switch terminal and a known good ground. Be sure to

fill master cylinder and bleed brake system after correc-

tion has been made, if necessary.

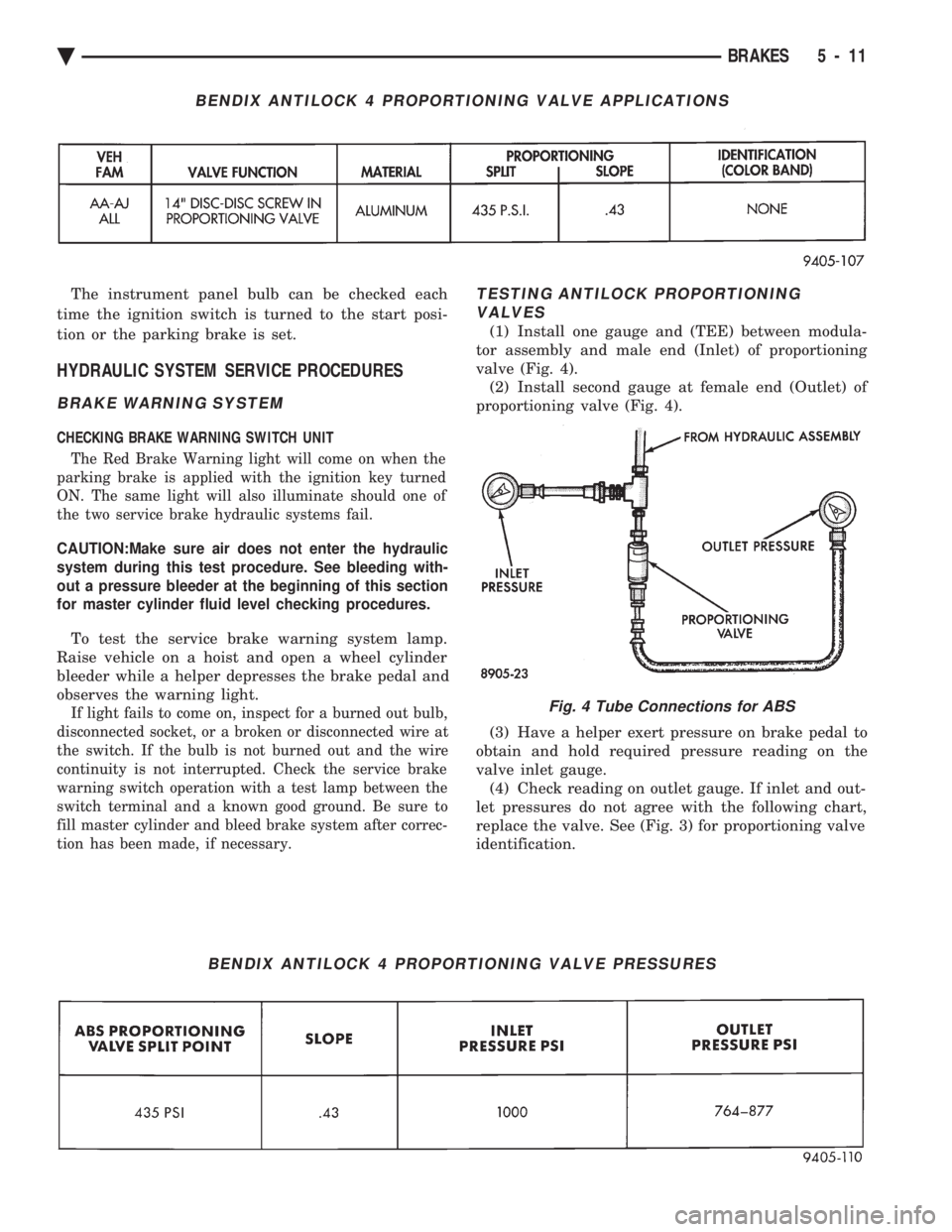

TESTING ANTILOCK PROPORTIONING VALVES

(1) Install one gauge and (TEE) between modula-

tor assembly and male end (Inlet) of proportioning

valve (Fig. 4). (2) Install second gauge at female end (Outlet) of

proportioning valve (Fig. 4).

(3) Have a helper exert pressure on brake pedal to

obtain and hold required pressure reading on the

valve inlet gauge. (4) Check reading on outlet gauge. If inlet and out-

let pressures do not agree with the following chart,

replace the valve. See (Fig. 3) for proportioning valve

identification.

BENDIX ANTILOCK 4 PROPORTIONING VALVE APPLICATIONS

BENDIX ANTILOCK 4 PROPORTIONING VALVE PRESSURES

Fig. 4 Tube Connections for ABS

Ä BRAKES 5 - 11

Page 298 of 2438

BENDIX ANTILOCK 4 BRAKE SYSTEM INDEX

page page

ABS Brake System Diagnostic Features ....... 24

ABS Computer System Service Precautions .... 23

ABS General Service Precautions ............ 23

Antilock Brake System Components .......... 16

Antilock Brake System Definitions ............ 14

Antilock Brakes Operation and Performance .... 15

Antilock System Relays and Warning Lamps .... 19

Bendix Antilock 4 Brake System Diagnostics .... 22

Bleeding Bendix Antilock 4 Brake System ...... 25

Controller Antilock Brake Cab ............... 18

Diagnostic Connector ..................... 19 Electronic Components

.................... 41

General Information ....................... 12

Hydraulic Circuits and Valve Operation ........ 20

Major Components ....................... 14

Mechanical Diagnostics and Service Procedures . 24

Normal Brake System Function .............. 14

On-Car ABS Brake System Service ........... 25

Specifications ........................... 46

System Self-Diagnostics ................... 15

Vehicle Performance ...................... 15

Warning Systems Operation ................ 16

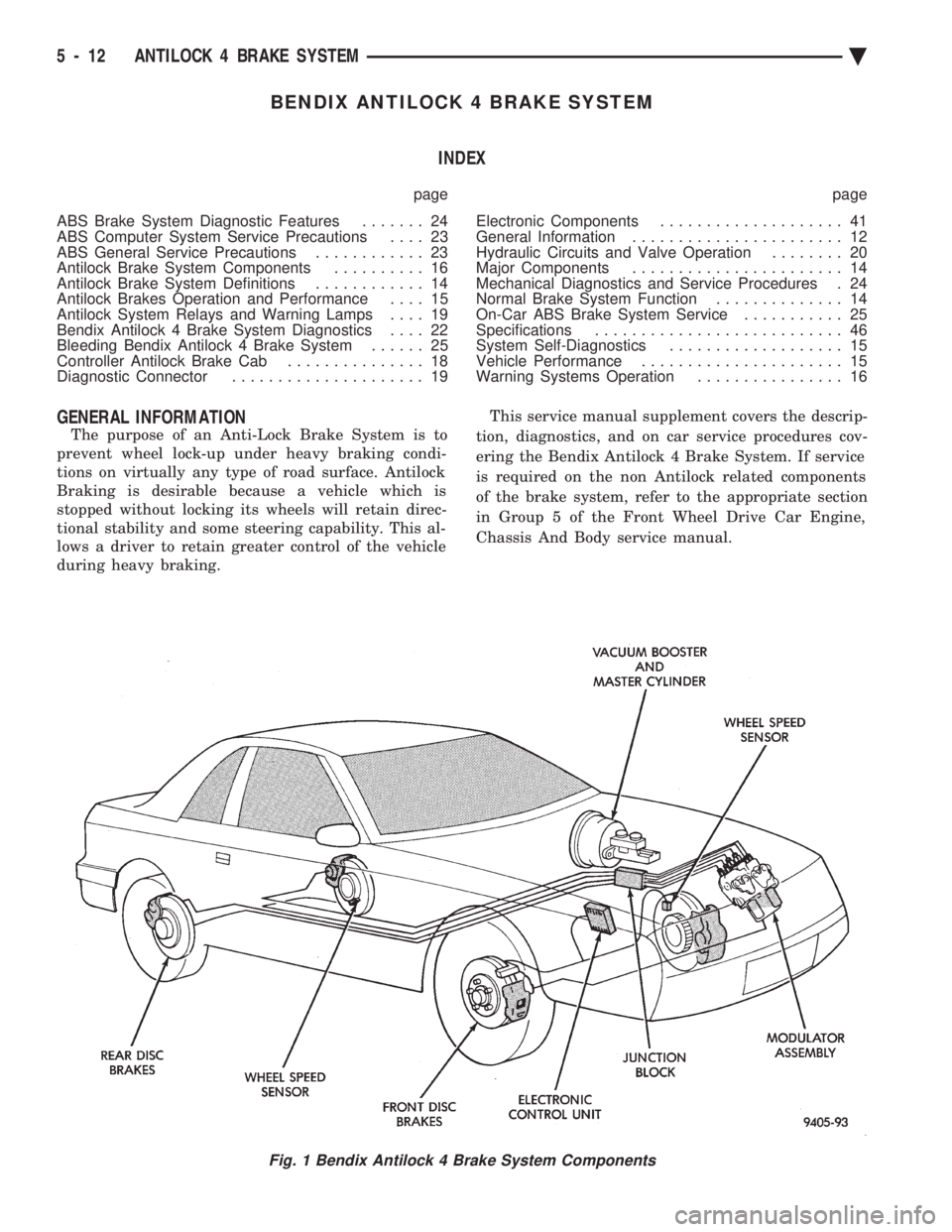

GENERAL INFORMATION

The purpose of an Anti-Lock Brake System is to

prevent wheel lock-up under heavy braking condi-

tions on virtually any type of road surface. Antilock

Braking is desirable because a vehicle which is

stopped without locking its wheels will retain direc-

tional stability and some steering capability. This al-

lows a driver to retain greater control of the vehicle

during heavy braking. This service manual supplement covers the descrip-

tion, diagnostics, and on car service procedures cov-

ering the Bendix Antilock 4 Brake System. If service

is required on the non Antilock related components

of the brake system, refer to the appropriate section

in Group 5 of the Front Wheel Drive Car Engine,

Chassis And Body service manual.

Fig. 1 Bendix Antilock 4 Brake System Components

5 - 12 ANTILOCK 4 BRAKE SYSTEM Ä

Page 300 of 2438

ANTILOCK BRAKE SYSTEM DEFINITIONS

In this section of the manual several abbreviations

are used for the components that are in the Bendix An-

tilock 4 Brake System, they are listed below for your

reference.

² CABÐController Antilock Brake

² ABSÐAntilock Brake System

² PSIÐPounds per Square Inch (pressure)

² WSSÐWheel Speed Sensor

² ACÐAlternating Current

NORMAL BRAKE SYSTEM FUNCTION

Under normal braking conditions, the Bendix An-

tilock 4 Brake System functions the same as a stan-

dard non-Antilock brake system.

When a wheel locking tendency is detected during a

brake application, the vehicle brake system will enter

the Antilock mode. During Antilock Braking, hydraulic

pressure in the four wheel circuits is modulated to pre-

vent wheels from locking. Each wheel circuit is de-

signed with a set of electrical valves and hydraulic line

to provide modulation, although for vehicle stability,

both rear wheel valves receive the same electrical sig-

nal. The system can modulate pressure at each wheel,

depending on signals generated by the wheel speed sen-

sors (WSS) and received at the CAB.

MAJOR COMPONENTS

The following is a list of major system components.

Details of all components can be found later in this

section. See (Fig. 1) for the general location of the

components in the vehicle.

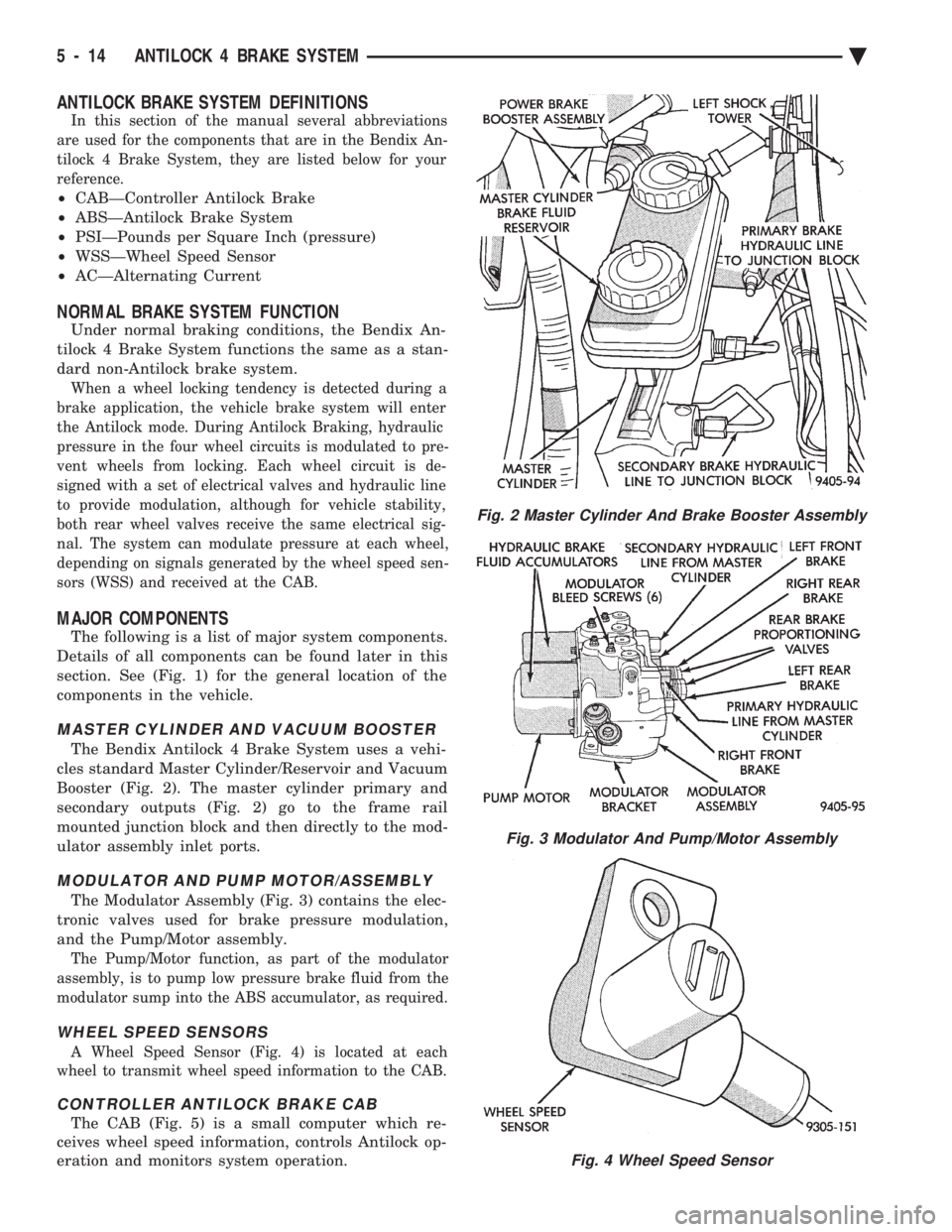

MASTER CYLINDER AND VACUUM BOOSTER

The Bendix Antilock 4 Brake System uses a vehi-

cles standard Master Cylinder/Reservoir and Vacuum

Booster (Fig. 2). The master cylinder primary and

secondary outputs (Fig. 2) go to the frame rail

mounted junction block and then directly to the mod-

ulator assembly inlet ports.

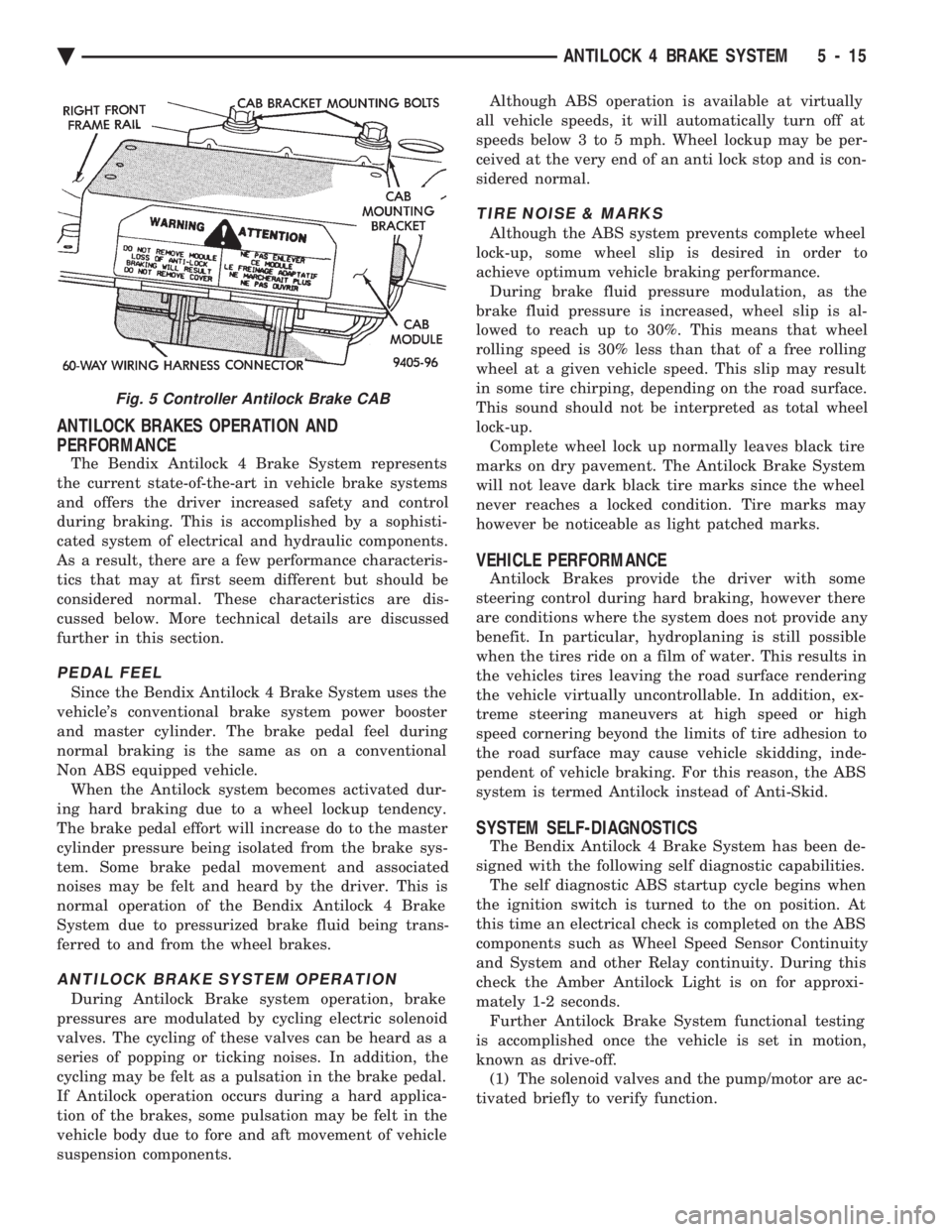

MODULATOR AND PUMP MOTOR/ASSEMBLY

The Modulator Assembly (Fig. 3) contains the elec-

tronic valves used for brake pressure modulation,

and the Pump/Motor assembly.

The Pump/Motor function, as part of the modulator

assembly, is to pump low pressure brake fluid from the

modulator sump into the ABS accumulator, as required.

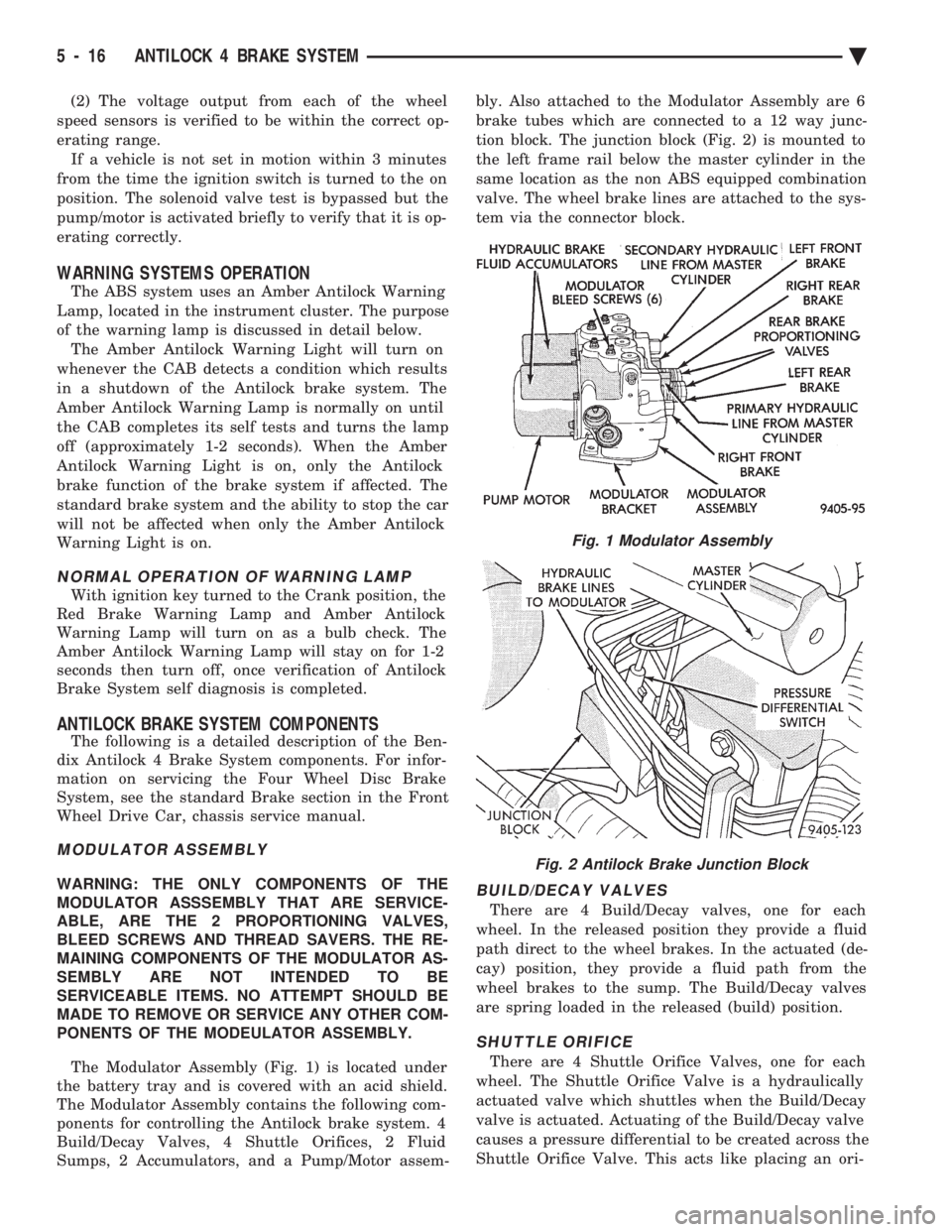

WHEEL SPEED SENSORS

A Wheel Speed Sensor (Fig. 4) is located at each

wheel to transmit wheel speed information to the CAB.

CONTROLLER ANTILOCK BRAKE CAB

The CAB (Fig. 5) is a small computer which re-

ceives wheel speed information, controls Antilock op-

eration and monitors system operation.

Fig. 2 Master Cylinder And Brake Booster Assembly

Fig. 3 Modulator And Pump/Motor Assembly

Fig. 4 Wheel Speed Sensor

5 - 14 ANTILOCK 4 BRAKE SYSTEM Ä

Page 301 of 2438

ANTILOCK BRAKES OPERATION AND

PERFORMANCE

The Bendix Antilock 4 Brake System represents

the current state-of-the-art in vehicle brake systems

and offers the driver increased safety and control

during braking. This is accomplished by a sophisti-

cated system of electrical and hydraulic components.

As a result, there are a few performance characteris-

tics that may at first seem different but should be

considered normal. These characteristics are dis-

cussed below. More technical details are discussed

further in this section.

PEDAL FEEL

Since the Bendix Antilock 4 Brake System uses the

vehicle's conventional brake system power booster

and master cylinder. The brake pedal feel during

normal braking is the same as on a conventional

Non ABS equipped vehicle. When the Antilock system becomes activated dur-

ing hard braking due to a wheel lockup tendency.

The brake pedal effort will increase do to the master

cylinder pressure being isolated from the brake sys-

tem. Some brake pedal movement and associated

noises may be felt and heard by the driver. This is

normal operation of the Bendix Antilock 4 Brake

System due to pressurized brake fluid being trans-

ferred to and from the wheel brakes.

ANTILOCK BRAKE SYSTEM OPERATION

During Antilock Brake system operation, brake

pressures are modulated by cycling electric solenoid

valves. The cycling of these valves can be heard as a

series of popping or ticking noises. In addition, the

cycling may be felt as a pulsation in the brake pedal.

If Antilock operation occurs during a hard applica-

tion of the brakes, some pulsation may be felt in the

vehicle body due to fore and aft movement of vehicle

suspension components. Although ABS operation is available at virtually

all vehicle speeds, it will automatically turn off at

speeds below 3 to 5 mph. Wheel lockup may be per-

ceived at the very end of an anti lock stop and is con-

sidered normal.

TIRE NOISE & MARKS

Although the ABS system prevents complete wheel

lock-up, some wheel slip is desired in order to

achieve optimum vehicle braking performance. During brake fluid pressure modulation, as the

brake fluid pressure is increased, wheel slip is al-

lowed to reach up to 30%. This means that wheel

rolling speed is 30% less than that of a free rolling

wheel at a given vehicle speed. This slip may result

in some tire chirping, depending on the road surface.

This sound should not be interpreted as total wheel

lock-up. Complete wheel lock up normally leaves black tire

marks on dry pavement. The Antilock Brake System

will not leave dark black tire marks since the wheel

never reaches a locked condition. Tire marks may

however be noticeable as light patched marks.

VEHICLE PERFORMANCE

Antilock Brakes provide the driver with some

steering control during hard braking, however there

are conditions where the system does not provide any

benefit. In particular, hydroplaning is still possible

when the tires ride on a film of water. This results in

the vehicles tires leaving the road surface rendering

the vehicle virtually uncontrollable. In addition, ex-

treme steering maneuvers at high speed or high

speed cornering beyond the limits of tire adhesion to

the road surface may cause vehicle skidding, inde-

pendent of vehicle braking. For this reason, the ABS

system is termed Antilock instead of Anti-Skid.

SYSTEM SELF-DIAGNOSTICS

The Bendix Antilock 4 Brake System has been de-

signed with the following self diagnostic capabilities. The self diagnostic ABS startup cycle begins when

the ignition switch is turned to the on position. At

this time an electrical check is completed on the ABS

components such as Wheel Speed Sensor Continuity

and System and other Relay continuity. During this

check the Amber Antilock Light is on for approxi-

mately 1-2 seconds. Further Antilock Brake System functional testing

is accomplished once the vehicle is set in motion,

known as drive-off. (1) The solenoid valves and the pump/motor are ac-

tivated briefly to verify function.

Fig. 5 Controller Antilock Brake CAB

Ä ANTILOCK 4 BRAKE SYSTEM 5 - 15

Page 302 of 2438

(2) The voltage output from each of the wheel

speed sensors is verified to be within the correct op-

erating range. If a vehicle is not set in motion within 3 minutes

from the time the ignition switch is turned to the on

position. The solenoid valve test is bypassed but the

pump/motor is activated briefly to verify that it is op-

erating correctly.

WARNING SYSTEMS OPERATION

The ABS system uses an Amber Antilock Warning

Lamp, located in the instrument cluster. The purpose

of the warning lamp is discussed in detail below. The Amber Antilock Warning Light will turn on

whenever the CAB detects a condition which results

in a shutdown of the Antilock brake system. The

Amber Antilock Warning Lamp is normally on until

the CAB completes its self tests and turns the lamp

off (approximately 1-2 seconds). When the Amber

Antilock Warning Light is on, only the Antilock

brake function of the brake system if affected. The

standard brake system and the ability to stop the car

will not be affected when only the Amber Antilock

Warning Light is on.

NORMAL OPERATION OF WARNING LAMP

With ignition key turned to the Crank position, the

Red Brake Warning Lamp and Amber Antilock

Warning Lamp will turn on as a bulb check. The

Amber Antilock Warning Lamp will stay on for 1-2

seconds then turn off, once verification of Antilock

Brake System self diagnosis is completed.

ANTILOCK BRAKE SYSTEM COMPONENTS

The following is a detailed description of the Ben-

dix Antilock 4 Brake System components. For infor-

mation on servicing the Four Wheel Disc Brake

System, see the standard Brake section in the Front

Wheel Drive Car, chassis service manual.

MODULATOR ASSEMBLY

WARNING: THE ONLY COMPONENTS OF THE

MODULATOR ASSSEMBLY THAT ARE SERVICE-

ABLE, ARE THE 2 PROPORTIONING VALVES,

BLEED SCREWS AND THREAD SAVERS. THE RE-

MAINING COMPONENTS OF THE MODULATOR AS-

SEMBLY ARE NOT INTENDED TO BE

SERVICEABLE ITEMS. NO ATTEMPT SHOULD BE

MADE TO REMOVE OR SERVICE ANY OTHER COM-

PONENTS OF THE MODEULATOR ASSEMBLY.

The Modulator Assembly (Fig. 1) is located under

the battery tray and is covered with an acid shield.

The Modulator Assembly contains the following com-

ponents for controlling the Antilock brake system. 4

Build/Decay Valves, 4 Shuttle Orifices, 2 Fluid

Sumps, 2 Accumulators, and a Pump/Motor assem- bly. Also attached to the Modulator Assembly are 6

brake tubes which are connected to a 12 way junc-

tion block. The junction block (Fig. 2) is mounted to

the left frame rail below the master cylinder in the

same location as the non ABS equipped combination

valve. The wheel brake lines are attached to the sys-

tem via the connector block.BUILD/DECAY VALVES

There are 4 Build/Decay valves, one for each

wheel. In the released position they provide a fluid

path direct to the wheel brakes. In the actuated (de-

cay) position, they provide a fluid path from the

wheel brakes to the sump. The Build/Decay valves

are spring loaded in the released (build) position.

SHUTTLE ORIFICE

There are 4 Shuttle Orifice Valves, one for each

wheel. The Shuttle Orifice Valve is a hydraulically

actuated valve which shuttles when the Build/Decay

valve is actuated. Actuating of the Build/Decay valve

causes a pressure differential to be created across the

Shuttle Orifice Valve. This acts like placing an ori-

Fig. 1 Modulator Assembly

Fig. 2 Antilock Brake Junction Block

5 - 16 ANTILOCK 4 BRAKE SYSTEM Ä

Page 303 of 2438

fice (restriction) in the line between the wheel and

the Build/Decay Valve. This restriction provides a

controlled build rate to each wheel brake during an

Antilock stop. The Shuttle Orifice Valve will remain

in the orificed position until the ABS cycle is com-

plete. When the ABS cycle has been completed the

Build/Decay valves will return to their released posi-

tion which will equalize the pressure across the

Shuttle Orifice Valves. When the pressure equalizes,

the spring loaded Shuttle Orifice valves will return

to the unrestricted position.

FLUID SUMPS

There are two Fluid Sumps in the Hydraulic As-

sembly, one for the primary and secondary hydraulic

circuits. The Fluid Sumps store the brake fluid that

is decayed from the wheel brakes during an ABS cy-

cle. This fluid is then pumped to an accumulator

and/or the hydraulic system in order to provide build

pressure. The typical pressure in the sumps is 50 psi,

during ABS operation only.

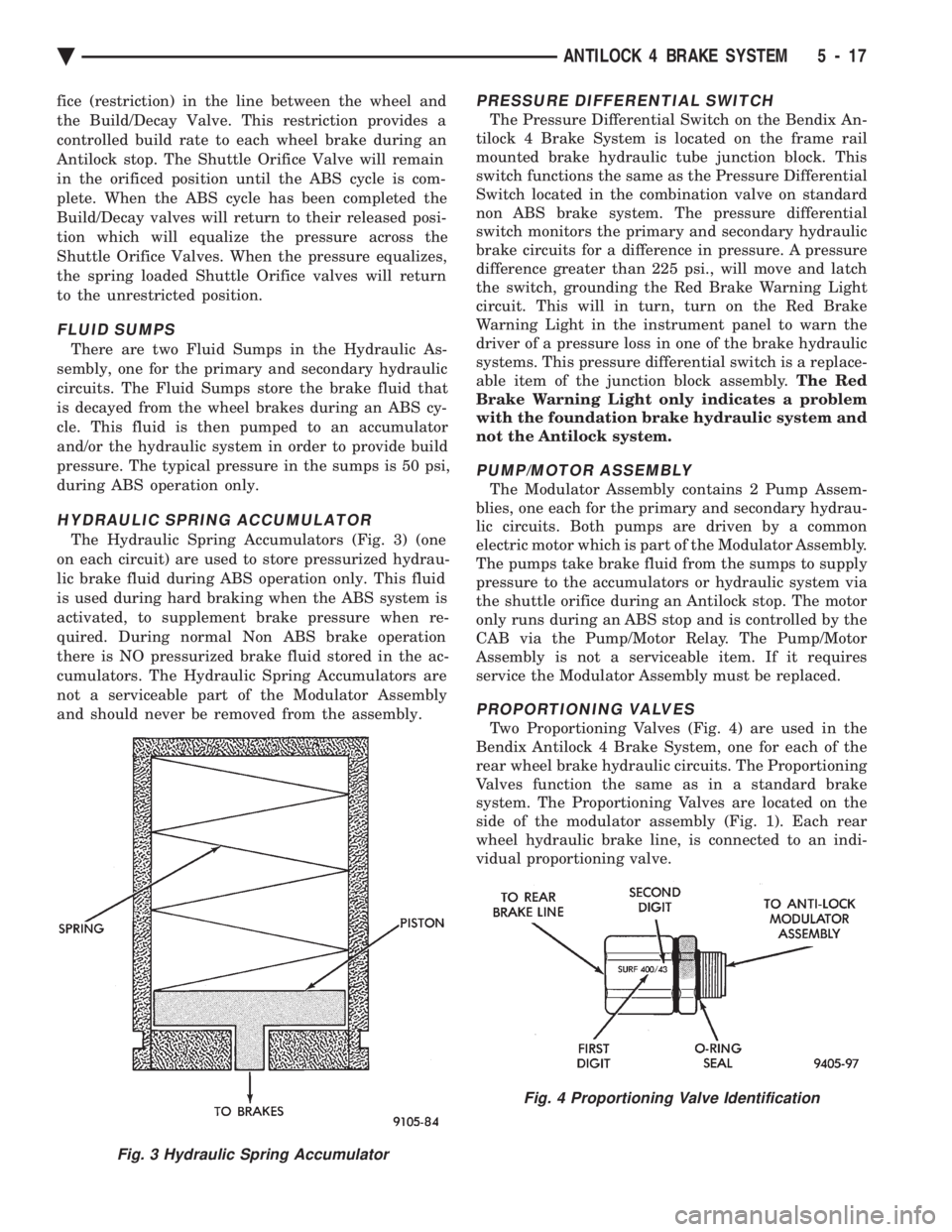

HYDRAULIC SPRING ACCUMULATOR

The Hydraulic Spring Accumulators (Fig. 3) (one

on each circuit) are used to store pressurized hydrau-

lic brake fluid during ABS operation only. This fluid

is used during hard braking when the ABS system is

activated, to supplement brake pressure when re-

quired. During normal Non ABS brake operation

there is NO pressurized brake fluid stored in the ac-

cumulators. The Hydraulic Spring Accumulators are

not a serviceable part of the Modulator Assembly

and should never be removed from the assembly.

PRESSURE DIFFERENTIAL SWITCH

The Pressure Differential Switch on the Bendix An-

tilock 4 Brake System is located on the frame rail

mounted brake hydraulic tube junction block. This

switch functions the same as the Pressure Differential

Switch located in the combination valve on standard

non ABS brake system. The pressure differential

switch monitors the primary and secondary hydraulic

brake circuits for a difference in pressure. A pressure

difference greater than 225 psi., will move and latch

the switch, grounding the Red Brake Warning Light

circuit. This will in turn, turn on the Red Brake

Warning Light in the instrument panel to warn the

driver of a pressure loss in one of the brake hydraulic

systems. This pressure differential switch is a replace-

able item of the junction block assembly. The Red

Brake Warning Light only indicates a problem

with the foundation brake hydraulic system and

not the Antilock system.

PUMP/MOTOR ASSEMBLY

The Modulator Assembly contains 2 Pump Assem-

blies, one each for the primary and secondary hydrau-

lic circuits. Both pumps are driven by a common

electric motor which is part of the Modulator Assembly.

The pumps take brake fluid from the sumps to supply

pressure to the accumulators or hydraulic system via

the shuttle orifice during an Antilock stop. The motor

only runs during an ABS stop and is controlled by the

CAB via the Pump/Motor Relay. The Pump/Motor

Assembly is not a serviceable item. If it requires

service the Modulator Assembly must be replaced.

PROPORTIONING VALVES

Two Proportioning Valves (Fig. 4) are used in the

Bendix Antilock 4 Brake System, one for each of the

rear wheel brake hydraulic circuits. The Proportioning

Valves function the same as in a standard brake

system. The Proportioning Valves are located on the

side of the modulator assembly (Fig. 1). Each rear

wheel hydraulic brake line, is connected to an indi-

vidual proportioning valve.

Fig. 3 Hydraulic Spring Accumulator

Fig. 4 Proportioning Valve Identification

Ä ANTILOCK 4 BRAKE SYSTEM 5 - 17

Page 304 of 2438

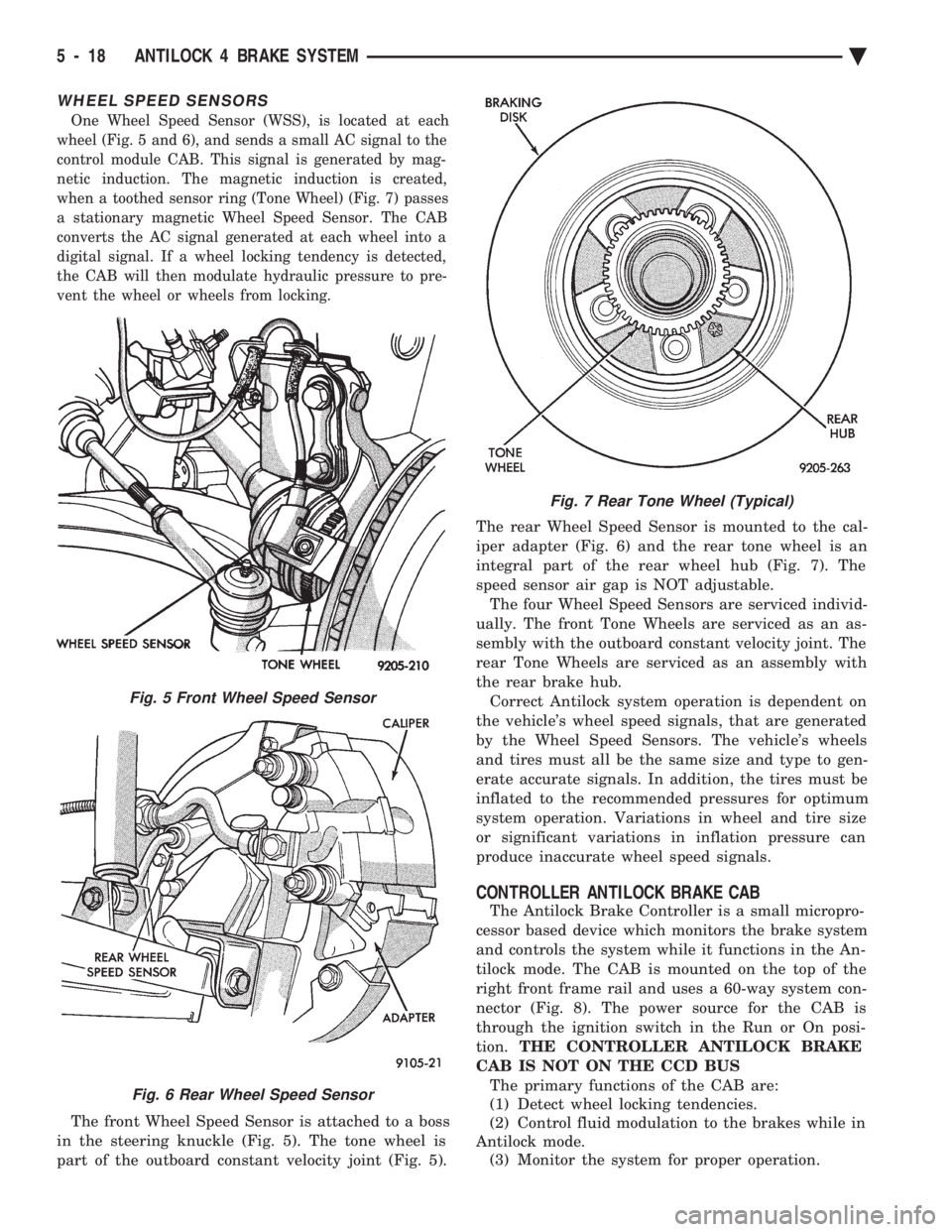

WHEEL SPEED SENSORS

One Wheel Speed Sensor (WSS), is located at each

wheel (Fig. 5 and 6), and sends a small AC signal to the

control module CAB. This signal is generated by mag-

netic induction. The magnetic induction is created,

when a toothed sensor ring (Tone Wheel) (Fig. 7) passes

a stationary magnetic Wheel Speed Sensor. The CAB

converts the AC signal generated at each wheel into a

digital signal. If a wheel locking tendency is detected,

the CAB will then modulate hydraulic pressure to pre-

vent the wheel or wheels from locking.

The front Wheel Speed Sensor is attached to a boss

in the steering knuckle (Fig. 5). The tone wheel is

part of the outboard constant velocity joint (Fig. 5). The rear Wheel Speed Sensor is mounted to the cal-

iper adapter (Fig. 6) and the rear tone wheel is an

integral part of the rear wheel hub (Fig. 7). The

speed sensor air gap is NOT adjustable.

The four Wheel Speed Sensors are serviced individ-

ually. The front Tone Wheels are serviced as an as-

sembly with the outboard constant velocity joint. The

rear Tone Wheels are serviced as an assembly with

the rear brake hub. Correct Antilock system operation is dependent on

the vehicle's wheel speed signals, that are generated

by the Wheel Speed Sensors. The vehicle's wheels

and tires must all be the same size and type to gen-

erate accurate signals. In addition, the tires must be

inflated to the recommended pressures for optimum

system operation. Variations in wheel and tire size

or significant variations in inflation pressure can

produce inaccurate wheel speed signals.

CONTROLLER ANTILOCK BRAKE CAB

The Antilock Brake Controller is a small micropro-

cessor based device which monitors the brake system

and controls the system while it functions in the An-

tilock mode. The CAB is mounted on the top of the

right front frame rail and uses a 60-way system con-

nector (Fig. 8). The power source for the CAB is

through the ignition switch in the Run or On posi-

tion. THE CONTROLLER ANTILOCK BRAKE

CAB IS NOT ON THE CCD BUS The primary functions of the CAB are:

(1) Detect wheel locking tendencies.

(2) Control fluid modulation to the brakes while in

Antilock mode. (3) Monitor the system for proper operation.

Fig. 5 Front Wheel Speed Sensor

Fig. 6 Rear Wheel Speed Sensor

Fig. 7 Rear Tone Wheel (Typical)

5 - 18 ANTILOCK 4 BRAKE SYSTEM Ä