wheel CHEVROLET DYNASTY 1993 Owners Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 238 of 2438

In order to effectively diagnose an Anti-Lock Brake

System (ABS) condition. It is important to read Sec-

tion 1 of this manual, Anti-Lock Brake System De-

scription. This section will give you information on

the function of the ABS components. Then follow the

diagnostic procedures outlined in this section. Many conditions that generate customer com-

plaints of the ABS system may be normal operating

conditions. These conditions though are judged to be

a problem due to unfamiliarity with the ABS system.

These conditions can be recognized without perform-

ing extensive diagnostic work, given adequate under-

standing of operating principles and performance

characteristics of the ABS system. See Section 1 of

this manual to familiarize yourself with the operat-

ing principles of the ABS system.

DEFINITIONS

Several abbreviations are used in this manual.

They are presented here for reference.

² CABÐController Anti-Lock Brake

² ABSÐAnti-Lock Brake System

² PSIÐPounds per Square Inch (pressure)

² WSSÐWheel Speed Sensor

ABS CONTROLLER ANTI-LOCK BRAKE (CAB) SER-

VICE PRECAUTIONS

The ABS system uses an electronic control module,

the (CAB). This module is designed to withstand nor-

mal current draws associated with vehicle operation.

However care must be taken to avoid overloading the

(CAB) circuits. In testing for open or short circuits, do

not ground or apply voltage to any of the circuits unless

instructed to do so by the appropriate diagnostic pro-

cedure. These circuits should only be tested using a

high impedance multi-meter, special tools or the DRB

II tester as described in this section. Power should

never be removed or applied to any control module with

the ignition in the ON position. Before removing or

connecting battery cables, fuses, or connectors, always

turn the ignition to the OFF position.

ABS SYSTEM GENERAL SERVICE PRECAUTIONS

TEST DRIVING ABS COMPLAINT VEHICLES

Most ABS complaints will require a test drive as a

part of the diagnostic procedure. The purpose of the

test drive is to duplicate the condition. Before test driving a brake complaint vehicle,

especially if the Red Brake Warning Lamp is on.

Test the brake function at low speed to be sure

that the car will stop normally. Remember that

conditions that result in illumination of the Red

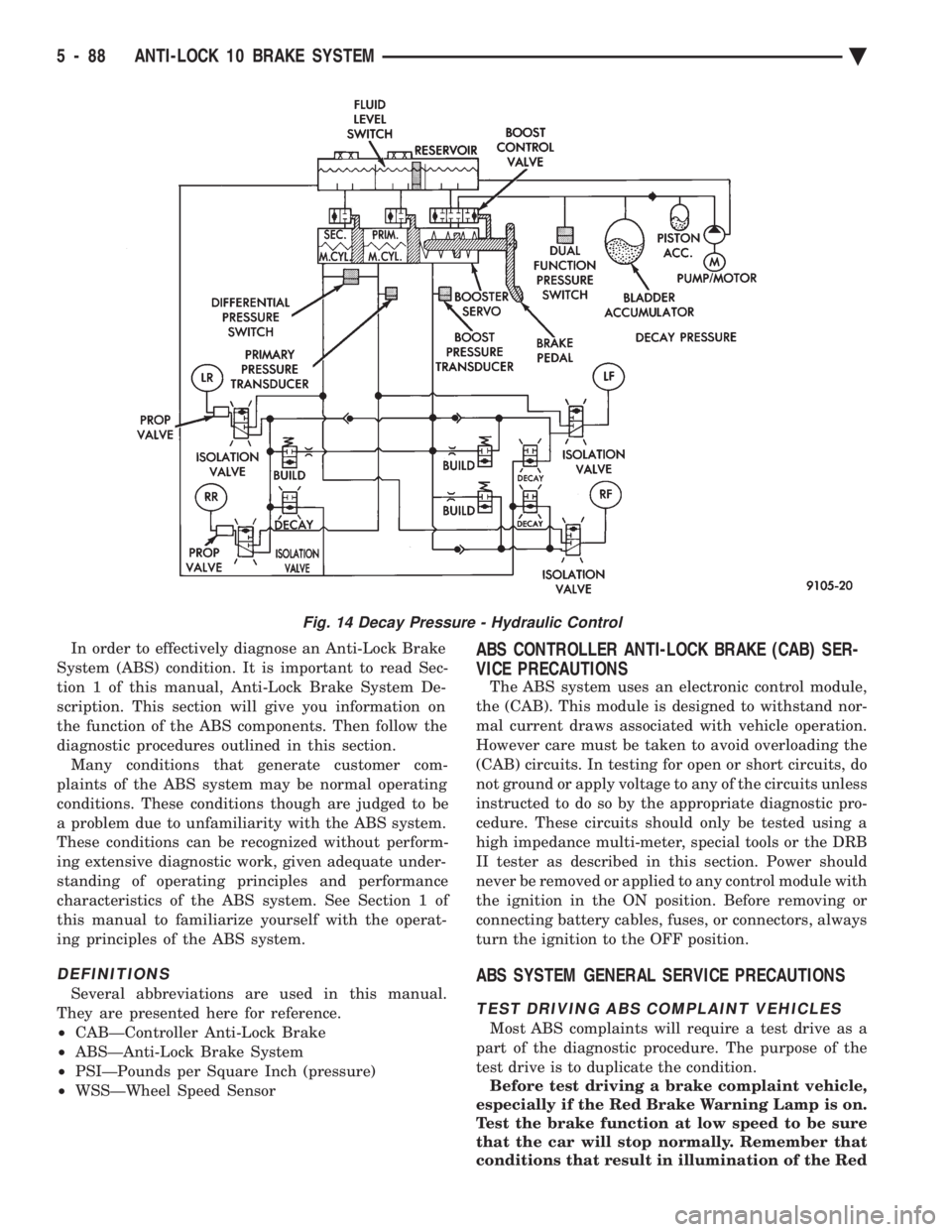

Fig. 14 Decay Pressure - Hydraulic Control

5 - 88 ANTI-LOCK 10 BRAKE SYSTEM Ä

Page 239 of 2438

Brake Warning Lamp may indicate reduced

braking ability. The following procedure should

be used to test drive an ABS complaint:(1) Ignition on. Turn the ignition to the ON position

without starting the car and wait until the Red Brake

Warning Lamp and Amber Anti-Lock Warning Lamp

turn off. This will allow the pump to charge the

accumulator to operating pressure. If the warning

lamp(s) do not turn off, go to step 3. (2) Ignition off for 15 seconds.

(3) Start car. Wait for displays to return to normal

operating mode before proceeding. (4) With Shift lever in PARK, slowly depress brake

pedal and release. (5) Drive vehicle a short distance. During this test

drive, be sure that the vehicle achieves at least 20 mph.

Then brake to at least one complete stop and accelerate

slowly back up to at least 20 mph. (6) If a functional problem with the A.B.S. system is

determined while test driving a vehicle. Refer to the

Bendix Anti-Lock 10 Diagnostics Manual for required

test procedures and proper use of the DRB II tester.

CAUTION: The following are general precautions that

should be observed when servicing and diagnosing

the ABS system and/or other vehicle systems. Failure

to observe these precautions may result in ABS

system damage.

(1) If welding work is to be performed on the vehicle

using an arc welder, the (CAB) should be disconnected

before the welding operation begins. (2) The (CAB) and hydraulic assembly 10 way con-

nectors should never be connected or disconnected with

the ignition on. (3) Some components of the ABS system are not

serviced separately and must be serviced as complete

assemblies. Do not disassemble any component which

is designated as non-serviceable. (4) Always de-pressurize the Hydraulic Accu-

mulator when performing any work that re-

quires disconnecting any hydraulic tube, flex

hose or fitting. The ABS system uses brake fluid

at high pressure. Failure to de-pressurize the

accumulator may result in personal injury

and/or damage to painted surfaces. Brake fluid will damage painted surfaces. If brake

fluid is spilled on any painted surfaces, wash off with

water immediately.

DE-PRESSURIZING HYDRAULIC ACCUMULA- TOR

The ABS pump/motor assembly keeps the hydraulic

accumulator charged between approximately 11,032

and 13,790 kPa (1600 and 2000 psi) anytime key is in the ON position. The pump/motor assembly

cannot run if the ignition is off or either battery ca-

ble is disconnected. Unless otherwise specified, the hydraulic accumu-

lator should be de-pressurized before disassembling

any portion of the hydraulic system. The following

procedure should be used to de-pressurize the hy-

draulic accumulator: (1) With ignition off, or either battery cable discon-

nected, pump the brake pedal a minimum of 40 times

using approximately 50 pounds of pedal force. A no-

ticeable change in pedal feel will occur when the ac-

cumulator becomes discharged. (2) When a definite increase in pedal effort is felt,

pump the pedal a few additional times. This will in-

sure removal of all hydraulic pressure from the

brake system.

WHEEL SPEED SENSOR CABLES

Proper installation of wheel speed sensor cables is

critical to continued ABS system operation. Be sure

that cables are installed and routed properly. Failure

to install cables in their retainers, as shown in Sec-

tion 3 of this manual. May result in contact with

moving parts or over extension of cables, resulting in

an open circuit.

MECHANICAL DIAGNOSTICS AND SERVICE

PROCEDURES

SPECIAL SERVICE TOOLS

Some diagnostic procedures in this section require

the use of special service tools. Each of these tools is

described below.

DRB II DIAGNOSTIC TESTER

Some of the diagnostic procedures that are ex-

plained in this section require the use of the DRB II

DIAGNOSTICS TESTER to insure that proper diag-

nostics are performed. Refer to those sections for

proper testing procedures and the DRB II manual for

its proper operational information.

MST-6163 PRESSURE TESTER

Some diagnostic procedures in this manual require

the use of the MST-6163 pressure gauge and adaptor

(Fig. 2). Pressure Gauge, Special Tool MST-6163 is

required to measure accumulator pressure during

certain phases of ABS operation. The pressure gauge

and adaptor should be installed as follows: (1) De-pressurize the accumulator by pumping the

brake pedal a minimum of 40 times with the ignition

off. The procedure is fully explained under De-Pres-

surizing Hydraulic Accumulator which is described

earlier in this System Diagnosis Section.

Ä ANTI-LOCK 10 BRAKE SYSTEM 5 - 89

Page 244 of 2438

pressurized. When a definite increase in pedal effort

is felt, pump pedal a few additional times. This will

insure removal of all hydraulic pressure from the

brake system.(2) Thoroughly clean both reservoir caps and sur-

rounding area of reservoir before cap removal. This

will avoid getting dirt into the reservoir and brake

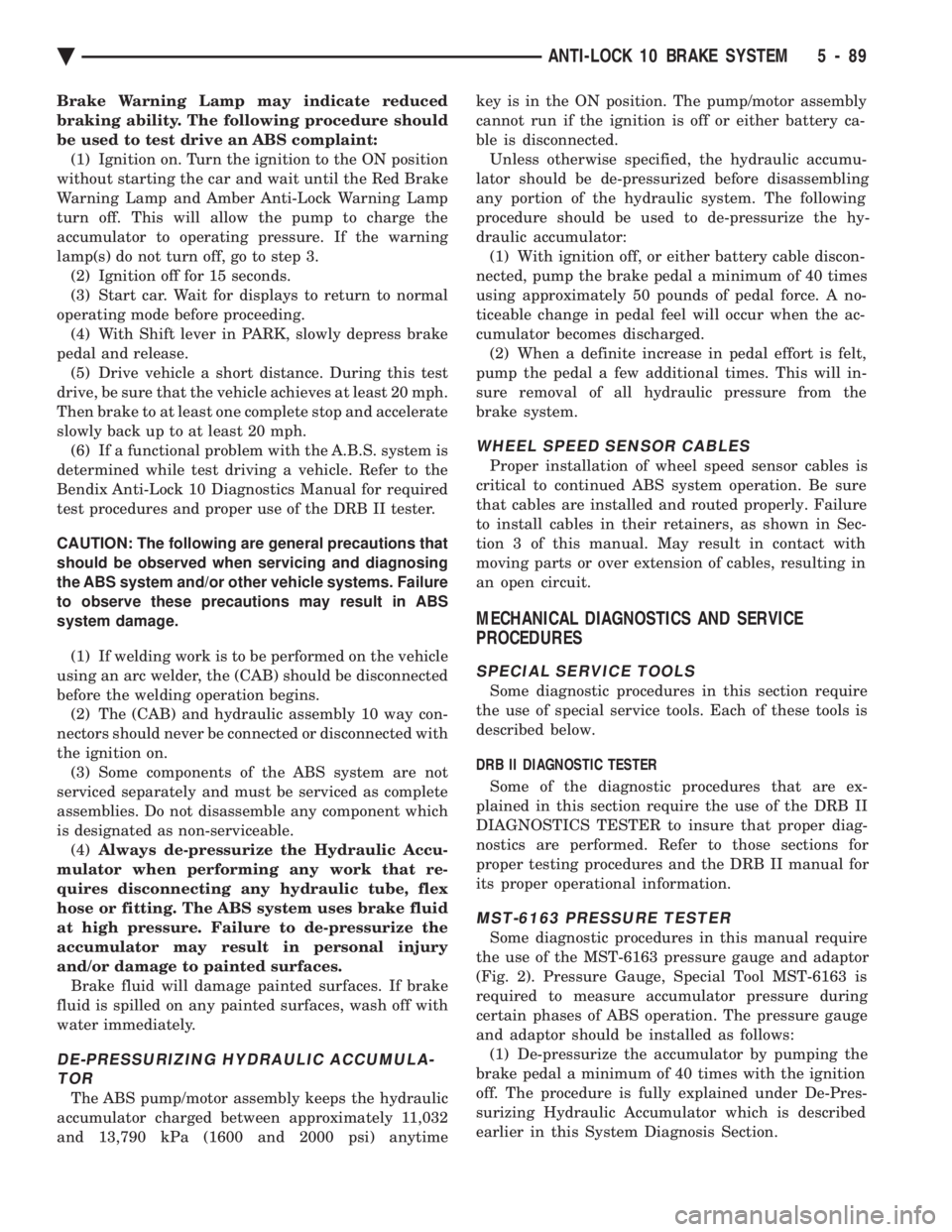

fluid. (3) Inspect the fluid level, see instructions on top

of reservoir (Fill To Top Of The White Screen In

Front Filter/Strainer). (4) Fill reservoir to top of white screen on filter/

strainer (Fig. 1) as required. Use only brake fluid

conforming to DOT 3 specifications such as Mopar t

or an Equivalent.

(5) Replace reservoir cap.

BLEEDING ABS BRAKE SYSTEM

The Anti-Lock brake system must be bled anytime

air is permitted to enter the brake hydraulic system,

due to disconnection of brake lines or hoses for ser-

vice. It is important to note that excessive air in the

brake system may set a primary pressure/delta P

fault in the (CAB). Refer to Diagnosis, for further in-

formation. Pressure bleeding or manual bleeding procedures

can be used when bleeding the (ABS) hydraulic sys-

tem, after brake lines or hoses have been discon-

nected. Bleeding the (ABS) hydraulic system is also

necessary after the replacement of the hydraulic as-

sembly or wheel brakes. During bleeding operations, be sure that the brake

fluid level remains close to the FULL level in the

reservoir. Check the fluid level periodically during the bleeding procedure and add only DOT 3 brake

fluid to the reservoir as required.

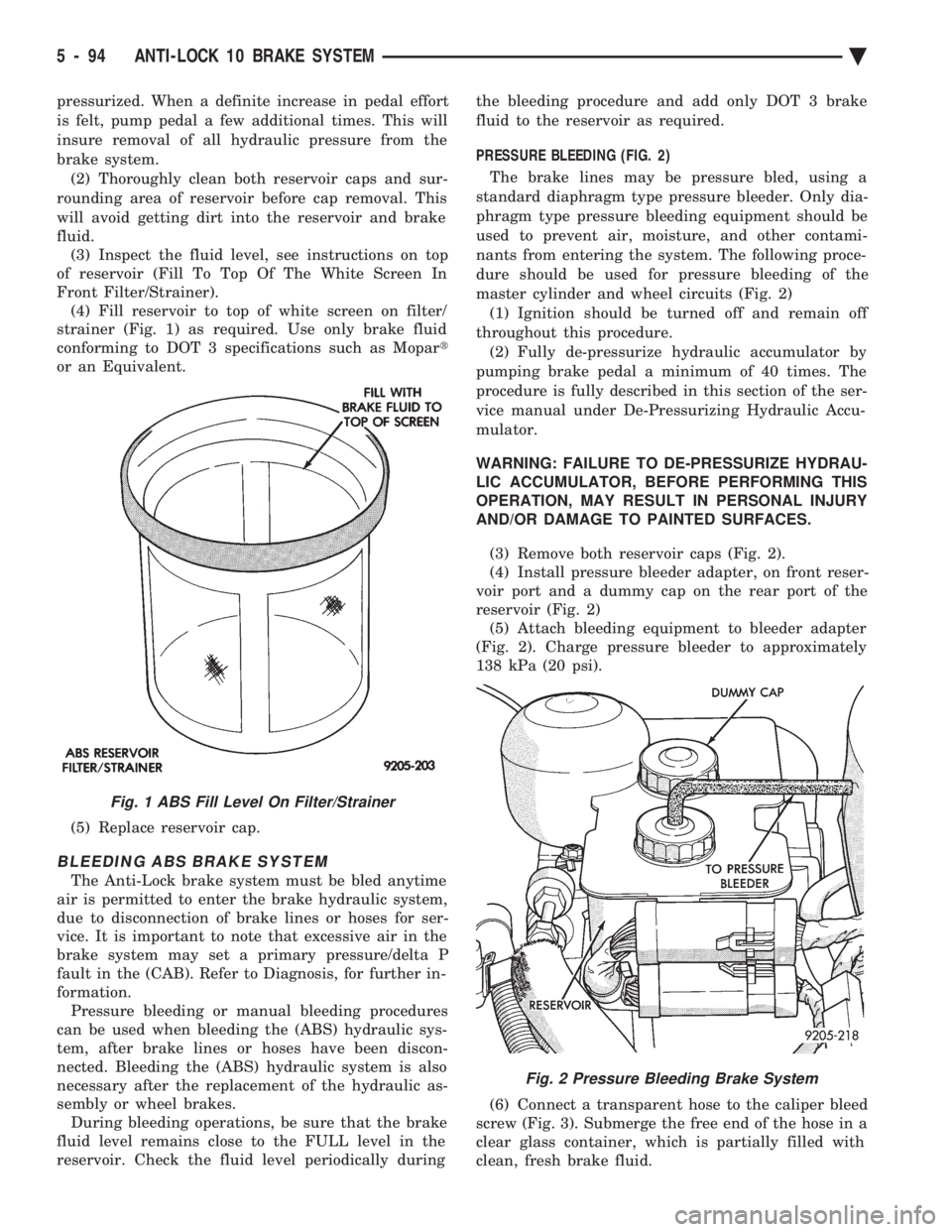

PRESSURE BLEEDING (FIG. 2)

The brake lines may be pressure bled, using a

standard diaphragm type pressure bleeder. Only dia-

phragm type pressure bleeding equipment should be

used to prevent air, moisture, and other contami-

nants from entering the system. The following proce-

dure should be used for pressure bleeding of the

master cylinder and wheel circuits (Fig. 2) (1) Ignition should be turned off and remain off

throughout this procedure. (2) Fully de-pressurize hydraulic accumulator by

pumping brake pedal a minimum of 40 times. The

procedure is fully described in this section of the ser-

vice manual under De-Pressurizing Hydraulic Accu-

mulator.

WARNING: FAILURE TO DE-PRESSURIZE HYDRAU-

LIC ACCUMULATOR, BEFORE PERFORMING THIS

OPERATION, MAY RESULT IN PERSONAL INJURY

AND/OR DAMAGE TO PAINTED SURFACES.

(3) Remove both reservoir caps (Fig. 2).

(4) Install pressure bleeder adapter, on front reser-

voir port and a dummy cap on the rear port of the

reservoir (Fig. 2) (5) Attach bleeding equipment to bleeder adapter

(Fig. 2). Charge pressure bleeder to approximately

138 kPa (20 psi).

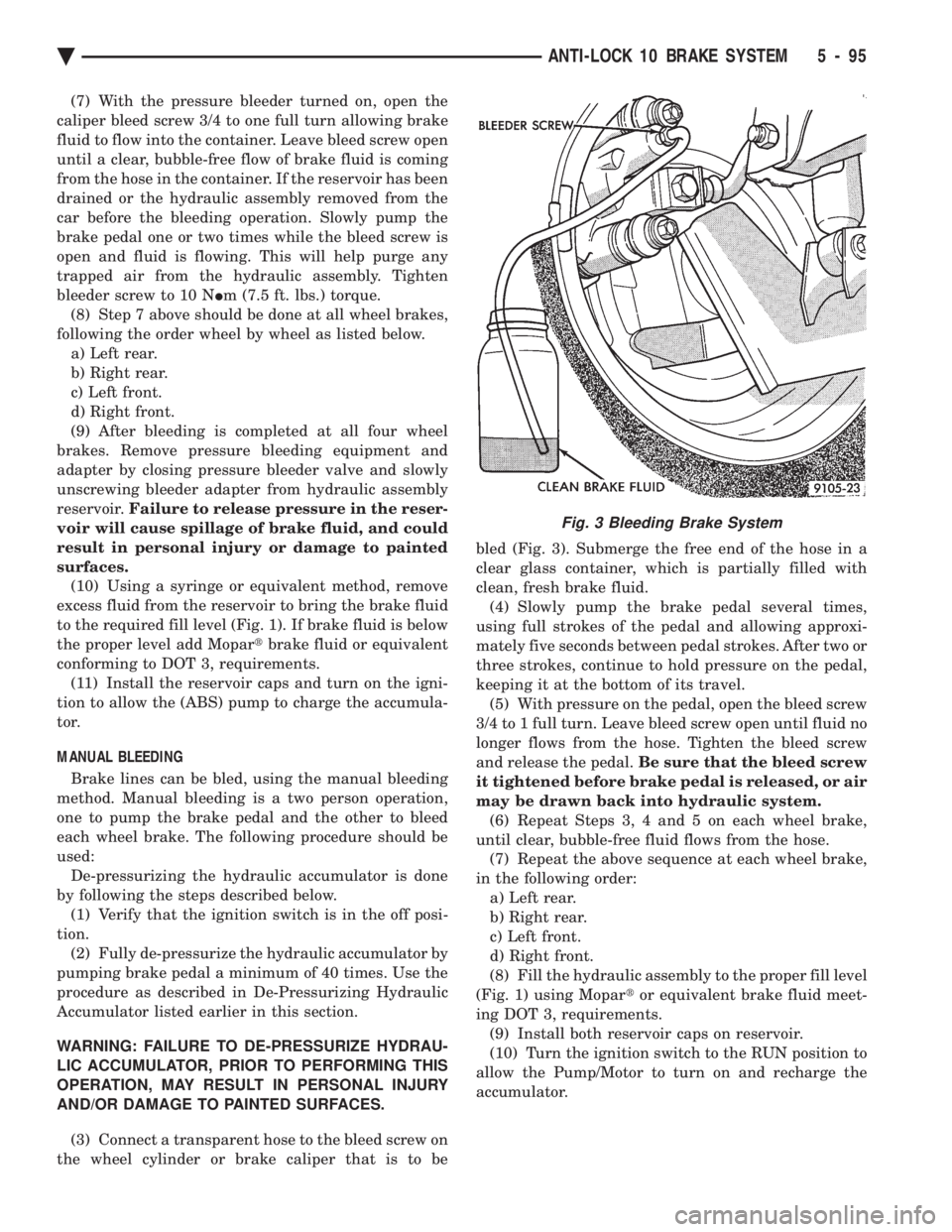

(6) Connect a transparent hose to the caliper bleed

screw (Fig. 3). Submerge the free end of the hose in a

clear glass container, which is partially filled with

clean, fresh brake fluid.

Fig. 1 ABS Fill Level On Filter/Strainer

Fig. 2 Pressure Bleeding Brake System

5 - 94 ANTI-LOCK 10 BRAKE SYSTEM Ä

Page 245 of 2438

(7) With the pressure bleeder turned on, open the

caliper bleed screw 3/4 to one full turn allowing brake

fluid to flow into the container. Leave bleed screw open

until a clear, bubble-free flow of brake fluid is coming

from the hose in the container. If the reservoir has been

drained or the hydraulic assembly removed from the

car before the bleeding operation. Slowly pump the

brake pedal one or two times while the bleed screw is

open and fluid is flowing. This will help purge any

trapped air from the hydraulic assembly. Tighten

bleeder screw to 10 N Im (7.5 ft. lbs.) torque.

(8) Step 7 above should be done at all wheel brakes,

following the order wheel by wheel as listed below. a) Left rear.

b) Right rear.

c) Left front.

d) Right front.

(9) After bleeding is completed at all four wheel

brakes. Remove pressure bleeding equipment and

adapter by closing pressure bleeder valve and slowly

unscrewing bleeder adapter from hydraulic assembly

reservoir. Failure to release pressure in the reser-

voir will cause spillage of brake fluid, and could

result in personal injury or damage to painted

surfaces. (10) Using a syringe or equivalent method, remove

excess fluid from the reservoir to bring the brake fluid

to the required fill level (Fig. 1). If brake fluid is below

the proper level add Mopar tbrake fluid or equivalent

conforming to DOT 3, requirements. (11) Install the reservoir caps and turn on the igni-

tion to allow the (ABS) pump to charge the accumula-

tor.

MANUAL BLEEDING

Brake lines can be bled, using the manual bleeding

method. Manual bleeding is a two person operation,

one to pump the brake pedal and the other to bleed

each wheel brake. The following procedure should be

used: De-pressurizing the hydraulic accumulator is done

by following the steps described below. (1) Verify that the ignition switch is in the off posi-

tion. (2) Fully de-pressurize the hydraulic accumulator by

pumping brake pedal a minimum of 40 times. Use the

procedure as described in De-Pressurizing Hydraulic

Accumulator listed earlier in this section.

WARNING: FAILURE TO DE-PRESSURIZE HYDRAU-

LIC ACCUMULATOR, PRIOR TO PERFORMING THIS

OPERATION, MAY RESULT IN PERSONAL INJURY

AND/OR DAMAGE TO PAINTED SURFACES.

(3) Connect a transparent hose to the bleed screw on

the wheel cylinder or brake caliper that is to be bled (Fig. 3). Submerge the free end of the hose in a

clear glass container, which is partially filled with

clean, fresh brake fluid.

(4) Slowly pump the brake pedal several times,

using full strokes of the pedal and allowing approxi-

mately five seconds between pedal strokes. After two or

three strokes, continue to hold pressure on the pedal,

keeping it at the bottom of its travel. (5) With pressure on the pedal, open the bleed screw

3/4 to 1 full turn. Leave bleed screw open until fluid no

longer flows from the hose. Tighten the bleed screw

and release the pedal. Be sure that the bleed screw

it tightened before brake pedal is released, or air

may be drawn back into hydraulic system. (6) Repeat Steps 3, 4 and 5 on each wheel brake,

until clear, bubble-free fluid flows from the hose. (7) Repeat the above sequence at each wheel brake,

in the following order: a) Left rear.

b) Right rear.

c) Left front.

d) Right front.

(8) Fill the hydraulic assembly to the proper fill level

(Fig. 1) using Mopar tor equivalent brake fluid meet-

ing DOT 3, requirements. (9) Install both reservoir caps on reservoir.

(10) Turn the ignition switch to the RUN position to

allow the Pump/Motor to turn on and recharge the

accumulator.

Fig. 3 Bleeding Brake System

Ä ANTI-LOCK 10 BRAKE SYSTEM 5 - 95

Page 254 of 2438

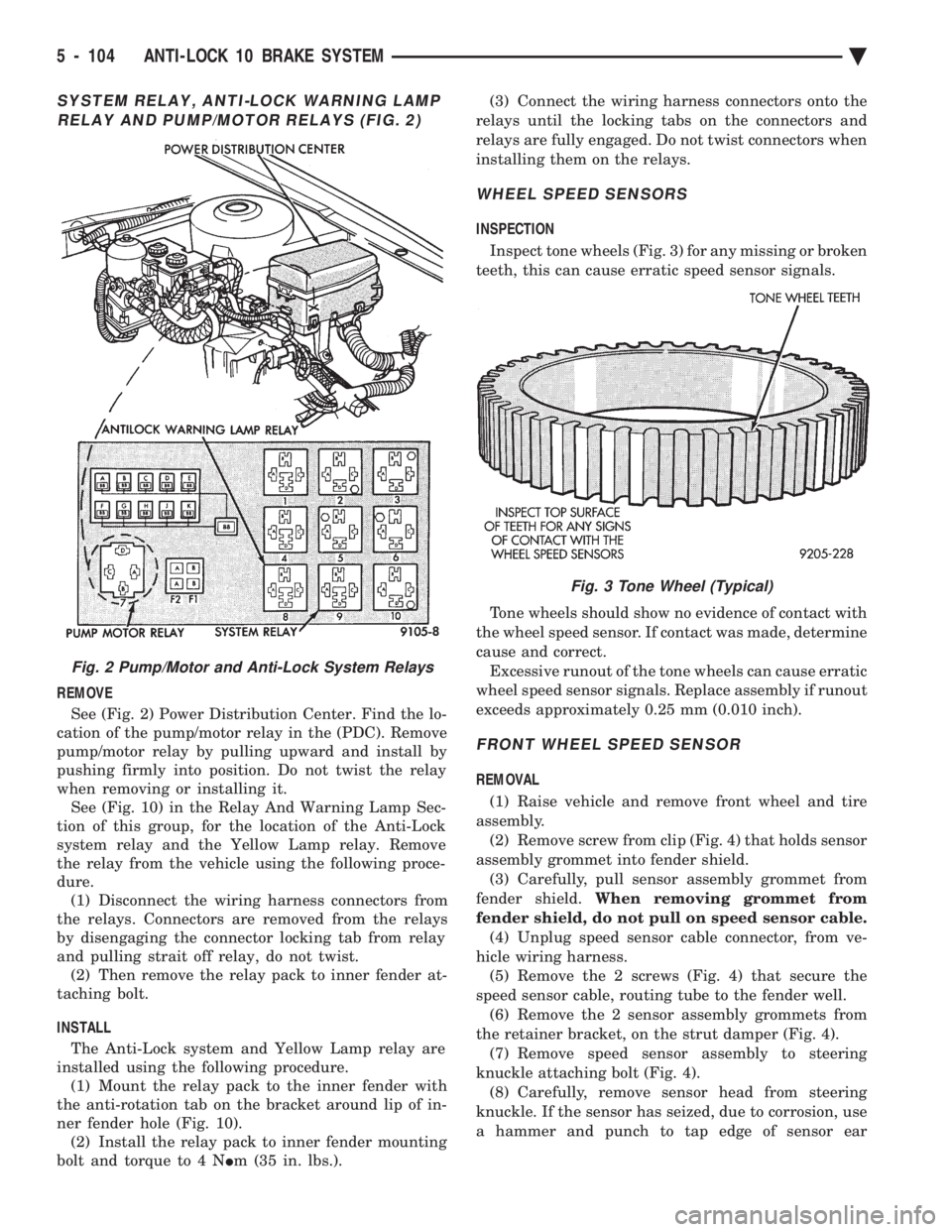

SYSTEM RELAY, ANTI-LOCK WARNING LAMP RELAY AND PUMP/MOTOR RELAYS (FIG. 2)

REMOVE

See (Fig. 2) Power Distribution Center. Find the lo-

cation of the pump/motor relay in the (PDC). Remove

pump/motor relay by pulling upward and install by

pushing firmly into position. Do not twist the relay

when removing or installing it. See (Fig. 10) in the Relay And Warning Lamp Sec-

tion of this group, for the location of the Anti-Lock

system relay and the Yellow Lamp relay. Remove

the relay from the vehicle using the following proce-

dure. (1) Disconnect the wiring harness connectors from

the relays. Connectors are removed from the relays

by disengaging the connector locking tab from relay

and pulling strait off relay, do not twist. (2) Then remove the relay pack to inner fender at-

taching bolt.

INSTALL The Anti-Lock system and Yellow Lamp relay are

installed using the following procedure. (1) Mount the relay pack to the inner fender with

the anti-rotation tab on the bracket around lip of in-

ner fender hole (Fig. 10). (2) Install the relay pack to inner fender mounting

bolt and torque to 4 N Im (35 in. lbs.). (3) Connect the wiring harness connectors onto the

relays until the locking tabs on the connectors and

relays are fully engaged. Do not twist connectors when

installing them on the relays.

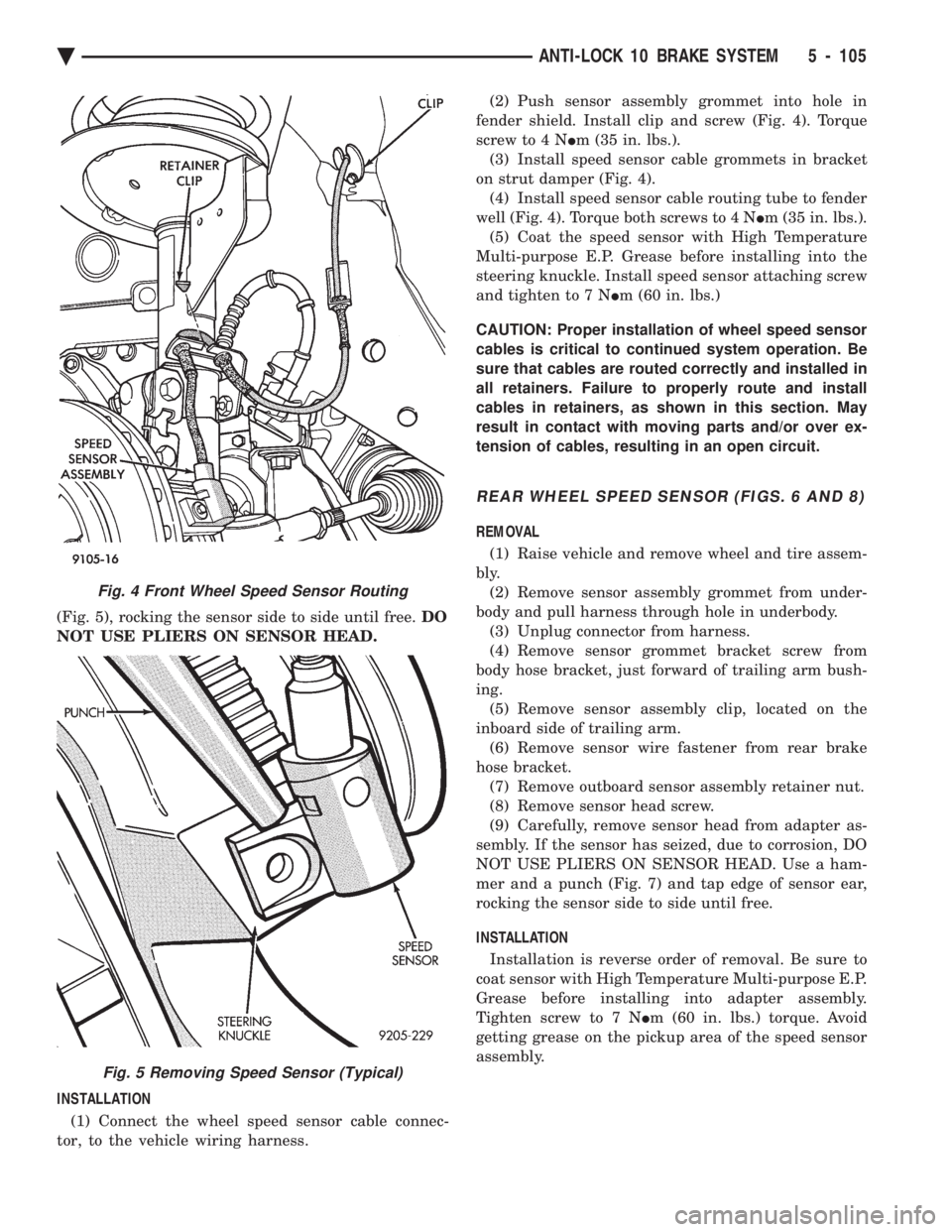

WHEEL SPEED SENSORS

INSPECTION

Inspect tone wheels (Fig. 3) for any missing or broken

teeth, this can cause erratic speed sensor signals.

Tone wheels should show no evidence of contact with

the wheel speed sensor. If contact was made, determine

cause and correct. Excessive runout of the tone wheels can cause erratic

wheel speed sensor signals. Replace assembly if runout

exceeds approximately 0.25 mm (0.010 inch).

FRONT WHEEL SPEED SENSOR

REMOVAL

(1) Raise vehicle and remove front wheel and tire

assembly. (2) Remove screw from clip (Fig. 4) that holds sensor

assembly grommet into fender shield. (3) Carefully, pull sensor assembly grommet from

fender shield. When removing grommet from

fender shield, do not pull on speed sensor cable. (4) Unplug speed sensor cable connector, from ve-

hicle wiring harness. (5) Remove the 2 screws (Fig. 4) that secure the

speed sensor cable, routing tube to the fender well. (6) Remove the 2 sensor assembly grommets from

the retainer bracket, on the strut damper (Fig. 4). (7) Remove speed sensor assembly to steering

knuckle attaching bolt (Fig. 4). (8) Carefully, remove sensor head from steering

knuckle. If the sensor has seized, due to corrosion, use

a hammer and punch to tap edge of sensor ear

Fig. 2 Pump/Motor and Anti-Lock System Relays

Fig. 3 Tone Wheel (Typical)

5 - 104 ANTI-LOCK 10 BRAKE SYSTEM Ä

Page 255 of 2438

(Fig. 5), rocking the sensor side to side until free. DO

NOT USE PLIERS ON SENSOR HEAD.

INSTALLATION (1) Connect the wheel speed sensor cable connec-

tor, to the vehicle wiring harness. (2) Push sensor assembly grommet into hole in

fender shield. Install clip and screw (Fig. 4). Torque

screw to 4 N Im (35 in. lbs.).

(3) Install speed sensor cable grommets in bracket

on strut damper (Fig. 4). (4) Install speed sensor cable routing tube to fender

well (Fig. 4). Torque both screws to 4 N Im (35 in. lbs.).

(5) Coat the speed sensor with High Temperature

Multi-purpose E.P. Grease before installing into the

steering knuckle. Install speed sensor attaching screw

and tighten to 7 N Im (60 in. lbs.)

CAUTION: Proper installation of wheel speed sensor

cables is critical to continued system operation. Be

sure that cables are routed correctly and installed in

all retainers. Failure to properly route and install

cables in retainers, as shown in this section. May

result in contact with moving parts and/or over ex-

tension of cables, resulting in an open circuit.

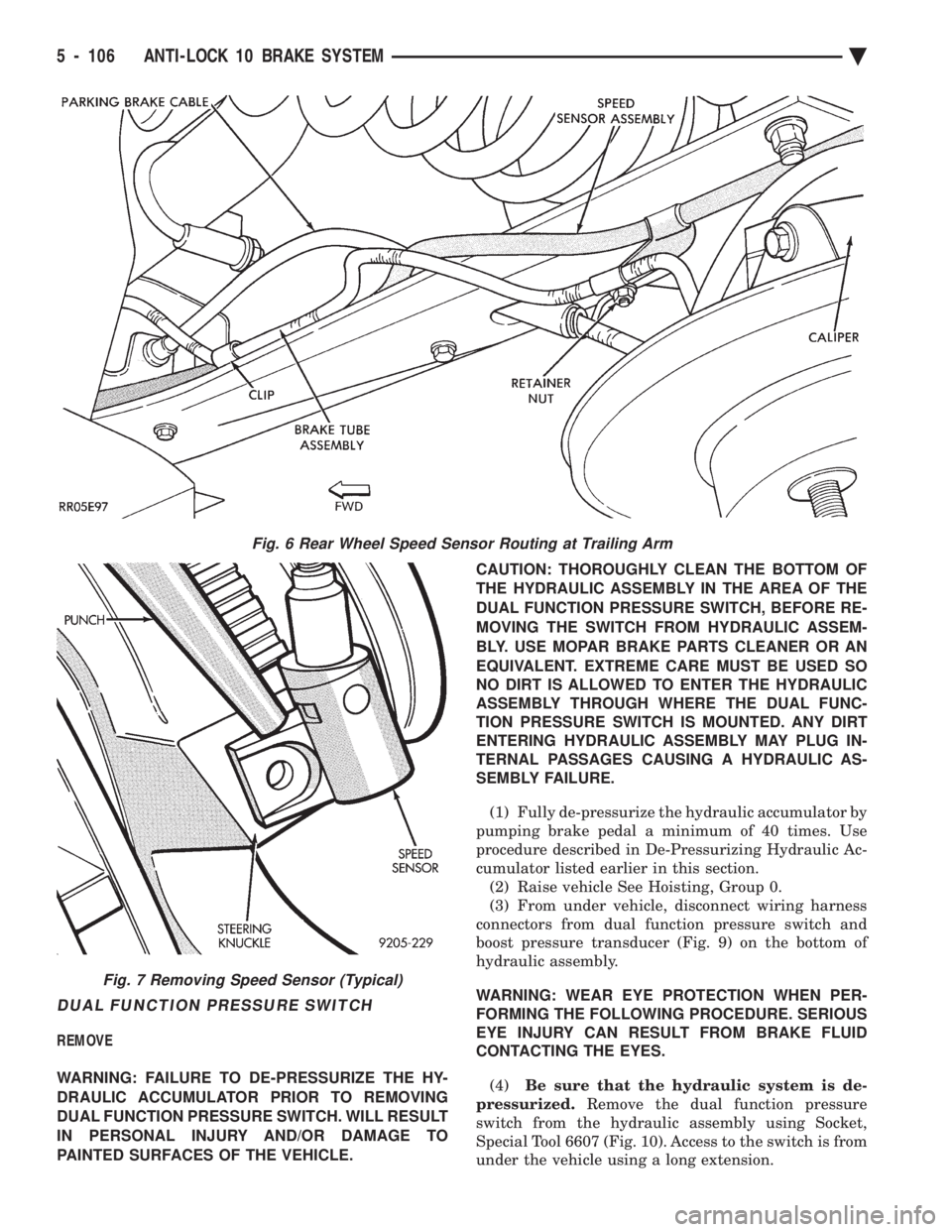

REAR WHEEL SPEED SENSOR (FIGS. 6 AND 8)

REMOVAL

(1) Raise vehicle and remove wheel and tire assem-

bly. (2) Remove sensor assembly grommet from under-

body and pull harness through hole in underbody. (3) Unplug connector from harness.

(4) Remove sensor grommet bracket screw from

body hose bracket, just forward of trailing arm bush-

ing. (5) Remove sensor assembly clip, located on the

inboard side of trailing arm. (6) Remove sensor wire fastener from rear brake

hose bracket. (7) Remove outboard sensor assembly retainer nut.

(8) Remove sensor head screw.

(9) Carefully, remove sensor head from adapter as-

sembly. If the sensor has seized, due to corrosion, DO

NOT USE PLIERS ON SENSOR HEAD. Use a ham-

mer and a punch (Fig. 7) and tap edge of sensor ear,

rocking the sensor side to side until free.

INSTALLATION

Installation is reverse order of removal. Be sure to

coat sensor with High Temperature Multi-purpose E.P.

Grease before installing into adapter assembly.

Tighten screw to 7 N Im (60 in. lbs.) torque. Avoid

getting grease on the pickup area of the speed sensor

assembly.

Fig. 4 Front Wheel Speed Sensor Routing

Fig. 5 Removing Speed Sensor (Typical)

Ä ANTI-LOCK 10 BRAKE SYSTEM 5 - 105

Page 256 of 2438

DUAL FUNCTION PRESSURE SWITCH

REMOVE

WARNING: FAILURE TO DE-PRESSURIZE THE HY-

DRAULIC ACCUMULATOR PRIOR TO REMOVING

DUAL FUNCTION PRESSURE SWITCH. WILL RESULT

IN PERSONAL INJURY AND/OR DAMAGE TO

PAINTED SURFACES OF THE VEHICLE. CAUTION: THOROUGHLY CLEAN THE BOTTOM OF

THE HYDRAULIC ASSEMBLY IN THE AREA OF THE

DUAL FUNCTION PRESSURE SWITCH, BEFORE RE-

MOVING THE SWITCH FROM HYDRAULIC ASSEM-

BLY. USE MOPAR BRAKE PARTS CLEANER OR AN

EQUIVALENT. EXTREME CARE MUST BE USED SO

NO DIRT IS ALLOWED TO ENTER THE HYDRAULIC

ASSEMBLY THROUGH WHERE THE DUAL FUNC-

TION PRESSURE SWITCH IS MOUNTED. ANY DIRT

ENTERING HYDRAULIC ASSEMBLY MAY PLUG IN-

TERNAL PASSAGES CAUSING A HYDRAULIC AS-

SEMBLY FAILURE.

(1) Fully de-pressurize the hydraulic accumulator by

pumping brake pedal a minimum of 40 times. Use

procedure described in De-Pressurizing Hydraulic Ac-

cumulator listed earlier in this section. (2) Raise vehicle See Hoisting, Group 0.

(3) From under vehicle, disconnect wiring harness

connectors from dual function pressure switch and

boost pressure transducer (Fig. 9) on the bottom of

hydraulic assembly.

WARNING: WEAR EYE PROTECTION WHEN PER-

FORMING THE FOLLOWING PROCEDURE. SERIOUS

EYE INJURY CAN RESULT FROM BRAKE FLUID

CONTACTING THE EYES.

(4) Be sure that the hydraulic system is de-

pressurized. Remove the dual function pressure

switch from the hydraulic assembly using Socket,

Special Tool 6607 (Fig. 10). Access to the switch is from

under the vehicle using a long extension.

Fig. 6 Rear Wheel Speed Sensor Routing at Trailing Arm

Fig. 7 Removing Speed Sensor (Typical)

5 - 106 ANTI-LOCK 10 BRAKE SYSTEM Ä

Page 263 of 2438

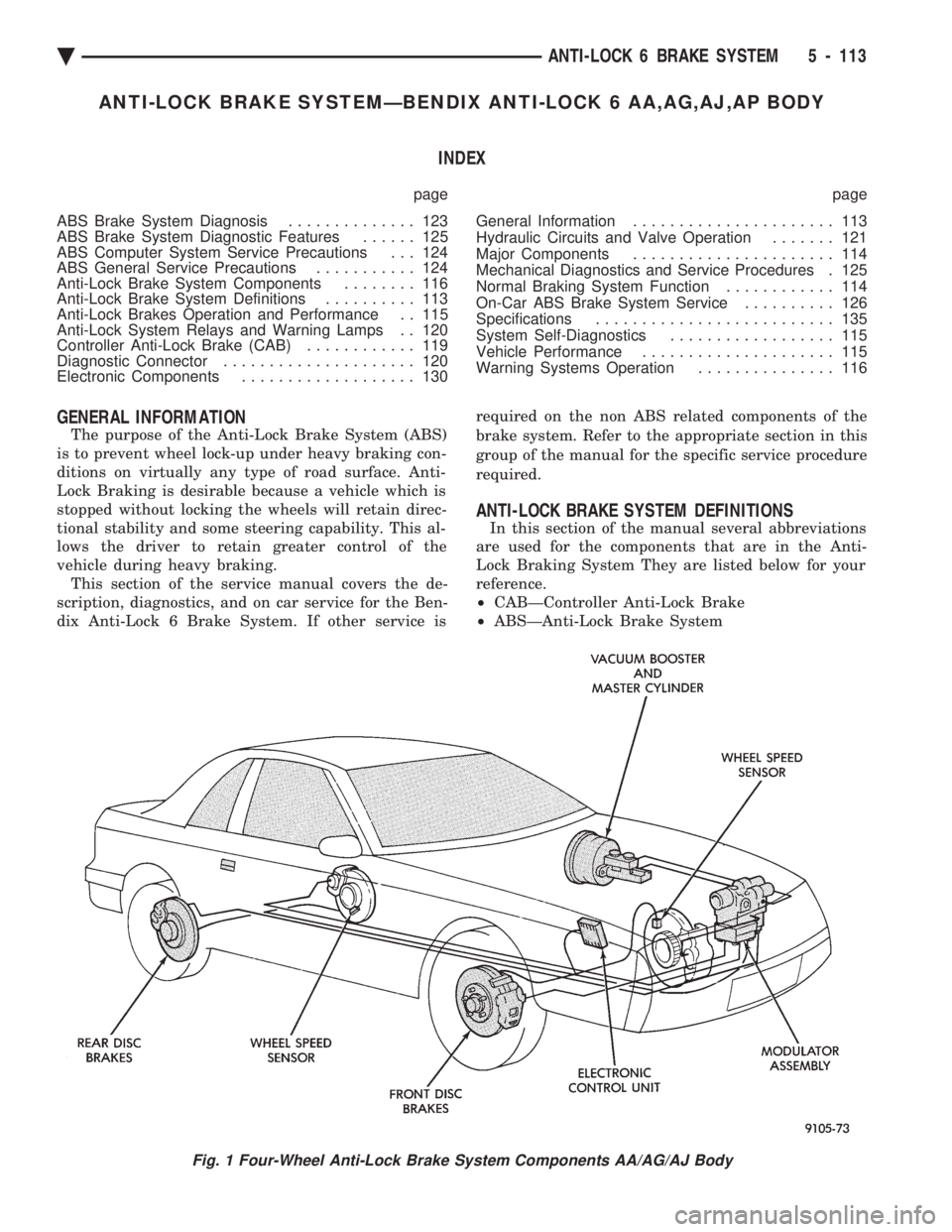

ANTI-LOCK BRAKE SYSTEMÐBENDIX ANTI-LOCK 6 AA,AG,AJ,AP BODY INDEX

page page

ABS Brake System Diagnosis .............. 123

ABS Brake System Diagnostic Features ...... 125

ABS Computer System Service Precautions . . . 124

ABS General Service Precautions ........... 124

Anti-Lock Brake System Components ........ 116

Anti-Lock Brake System Definitions .......... 113

Anti-Lock Brakes Operation and Performance . . 115

Anti-Lock System Relays and Warning Lamps . . 120

Controller Anti-Lock Brake (CAB) ............ 119

Diagnostic Connector ..................... 120

Electronic Components ................... 130 General Information

...................... 113

Hydraulic Circuits and Valve Operation ....... 121

Major Components ...................... 114

Mechanical Diagnostics and Service Procedures . 125

Normal Braking System Function ............ 114

On-Car ABS Brake System Service .......... 126

Specifications .......................... 135

System Self-Diagnostics .................. 115

Vehicle Performance ..................... 115

Warning Systems Operation ............... 116

GENERAL INFORMATION

The purpose of the Anti-Lock Brake System (ABS)

is to prevent wheel lock-up under heavy braking con-

ditions on virtually any type of road surface. Anti-

Lock Braking is desirable because a vehicle which is

stopped without locking the wheels will retain direc-

tional stability and some steering capability. This al-

lows the driver to retain greater control of the

vehicle during heavy braking. This section of the service manual covers the de-

scription, diagnostics, and on car service for the Ben-

dix Anti-Lock 6 Brake System. If other service is required on the non ABS related components of the

brake system. Refer to the appropriate section in this

group of the manual for the specific service procedure

required.

ANTI-LOCK BRAKE SYSTEM DEFINITIONS

In this section of the manual several abbreviations

are used for the components that are in the Anti-

Lock Braking System They are listed below for your

reference.

² CABÐController Anti-Lock Brake

² ABSÐAnti-Lock Brake System

Fig. 1 Four-Wheel Anti-Lock Brake System Components AA/AG/AJ Body

Ä ANTI-LOCK 6 BRAKE SYSTEM 5 - 113

Page 264 of 2438

² PSIÐPounds per Square Inch (pressure)

² WSSÐWheel Speed Sensor

NORMAL BRAKING SYSTEM FUNCTION

Under normal braking conditions, the ABS System

functions the same as a standard brake system with

a diagonally split master cylinder and conventional

vacuum assist. If a wheel locking tendency is detected during a

brake application, the system will enter Anti-Lock

mode. During Anti-Lock Braking, hydraulic pressure

in the four wheel circuits is modulated to prevent

any wheel from locking. Each wheel circuit is de-

signed with a set of electrical valves and hydraulic

line to provide modulation, although for vehicle sta-

bility, both rear wheel valves receive the same elec-

trical signal. The system can build or reduce

pressure at each wheel, depending on signals gener-

ated by the wheel speed sensors (WSS) at each wheel

and received at the Controller Anti-Lock Brake

(CAB).

MAJOR COMPONENTS

The following is a list of major system components.

Details of all components can be found later in this

section. See (Fig. 1) for the general location of the

components in the vehicle.

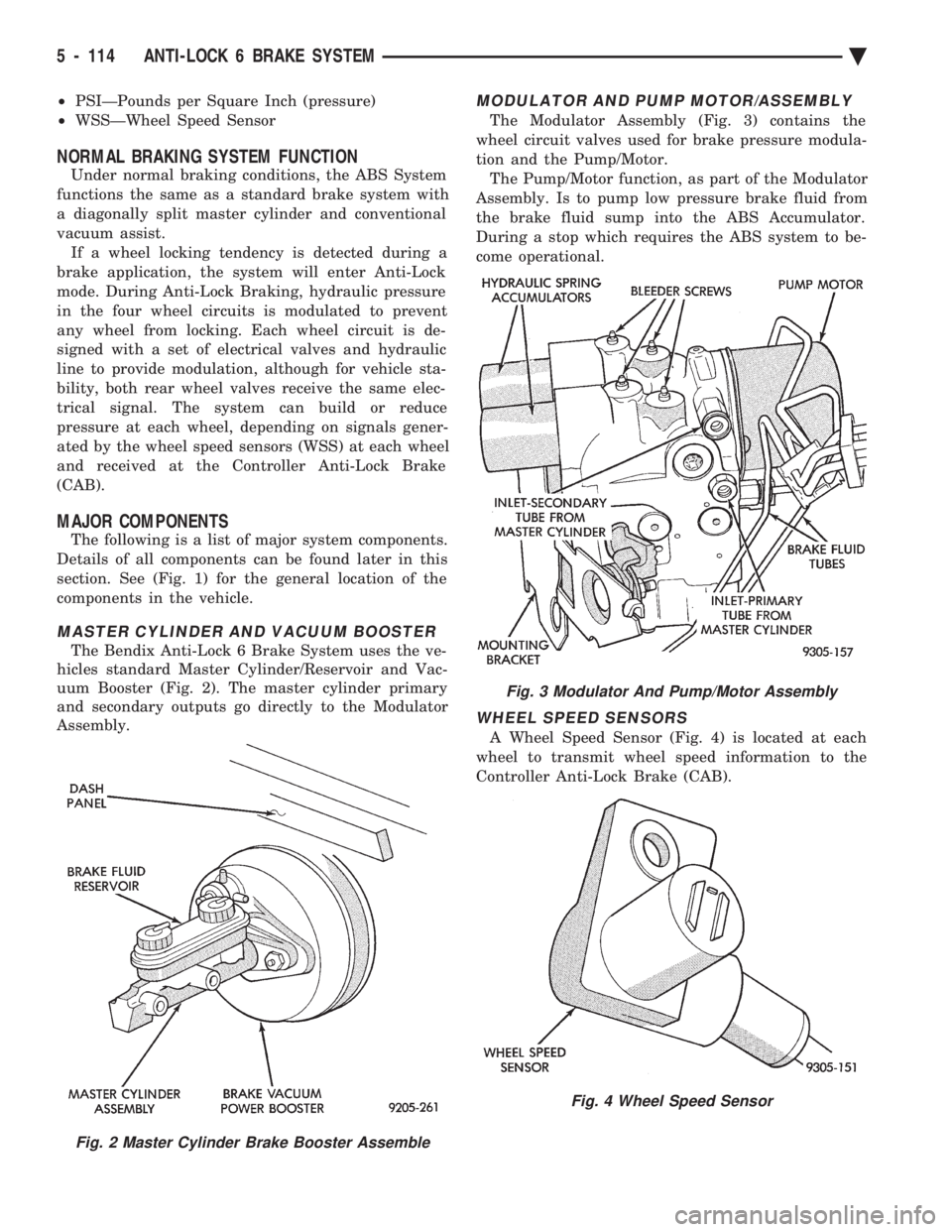

MASTER CYLINDER AND VACUUM BOOSTER

The Bendix Anti-Lock 6 Brake System uses the ve-

hicles standard Master Cylinder/Reservoir and Vac-

uum Booster (Fig. 2). The master cylinder primary

and secondary outputs go directly to the Modulator

Assembly.

MODULATOR AND PUMP MOTOR/ASSEMBLY

The Modulator Assembly (Fig. 3) contains the

wheel circuit valves used for brake pressure modula-

tion and the Pump/Motor. The Pump/Motor function, as part of the Modulator

Assembly. Is to pump low pressure brake fluid from

the brake fluid sump into the ABS Accumulator.

During a stop which requires the ABS system to be-

come operational.

WHEEL SPEED SENSORS

A Wheel Speed Sensor (Fig. 4) is located at each

wheel to transmit wheel speed information to the

Controller Anti-Lock Brake (CAB).

Fig. 2 Master Cylinder Brake Booster Assemble

Fig. 3 Modulator And Pump/Motor Assembly

Fig. 4 Wheel Speed Sensor

5 - 114 ANTI-LOCK 6 BRAKE SYSTEM Ä

Page 265 of 2438

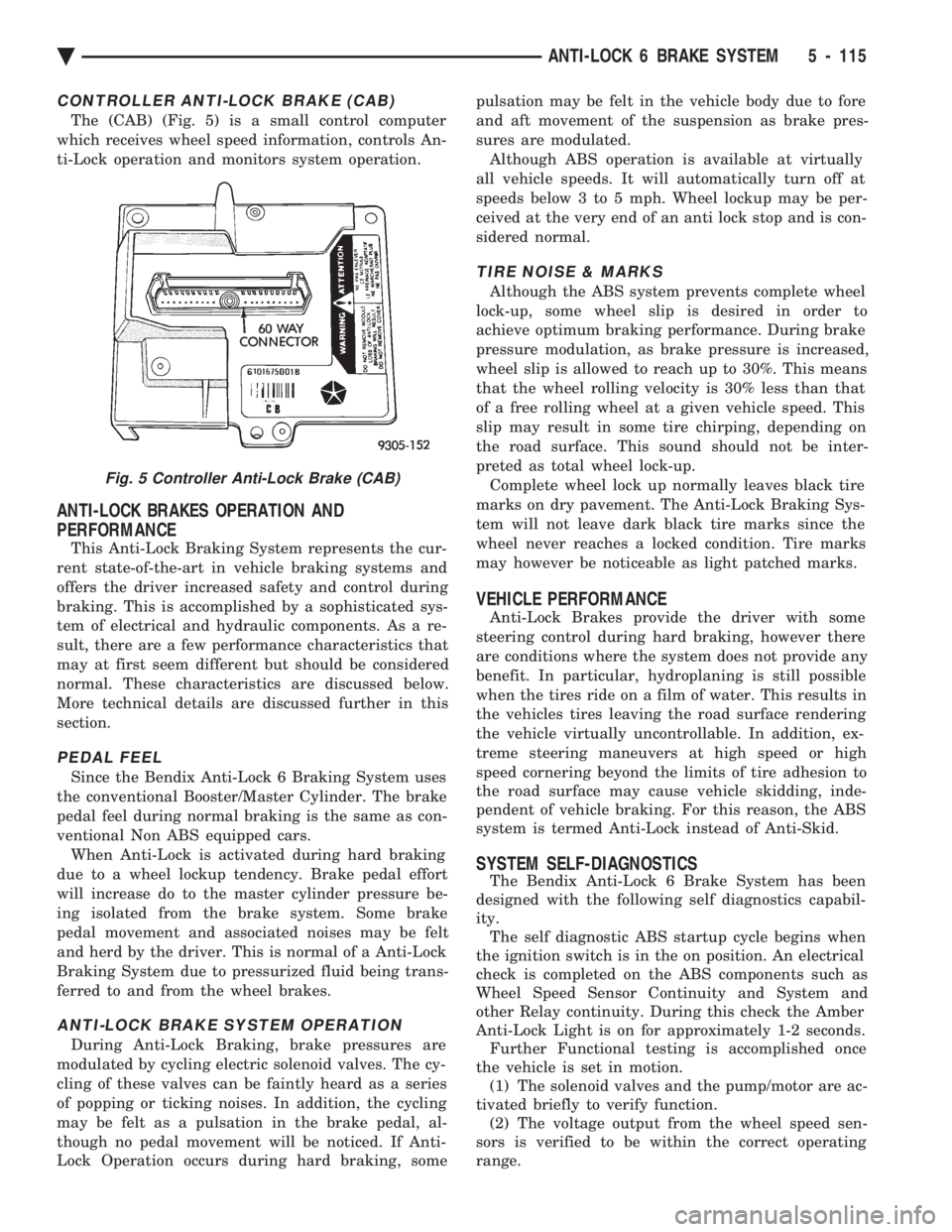

CONTROLLER ANTI-LOCK BRAKE (CAB)

The (CAB) (Fig. 5) is a small control computer

which receives wheel speed information, controls An-

ti-Lock operation and monitors system operation.

ANTI-LOCK BRAKES OPERATION AND

PERFORMANCE

This Anti-Lock Braking System represents the cur-

rent state-of-the-art in vehicle braking systems and

offers the driver increased safety and control during

braking. This is accomplished by a sophisticated sys-

tem of electrical and hydraulic components. As a re-

sult, there are a few performance characteristics that

may at first seem different but should be considered

normal. These characteristics are discussed below.

More technical details are discussed further in this

section.

PEDAL FEEL

Since the Bendix Anti-Lock 6 Braking System uses

the conventional Booster/Master Cylinder. The brake

pedal feel during normal braking is the same as con-

ventional Non ABS equipped cars. When Anti-Lock is activated during hard braking

due to a wheel lockup tendency. Brake pedal effort

will increase do to the master cylinder pressure be-

ing isolated from the brake system. Some brake

pedal movement and associated noises may be felt

and herd by the driver. This is normal of a Anti-Lock

Braking System due to pressurized fluid being trans-

ferred to and from the wheel brakes.

ANTI-LOCK BRAKE SYSTEM OPERATION

During Anti-Lock Braking, brake pressures are

modulated by cycling electric solenoid valves. The cy-

cling of these valves can be faintly heard as a series

of popping or ticking noises. In addition, the cycling

may be felt as a pulsation in the brake pedal, al-

though no pedal movement will be noticed. If Anti-

Lock Operation occurs during hard braking, some pulsation may be felt in the vehicle body due to fore

and aft movement of the suspension as brake pres-

sures are modulated.

Although ABS operation is available at virtually

all vehicle speeds. It will automatically turn off at

speeds below 3 to 5 mph. Wheel lockup may be per-

ceived at the very end of an anti lock stop and is con-

sidered normal.

TIRE NOISE & MARKS

Although the ABS system prevents complete wheel

lock-up, some wheel slip is desired in order to

achieve optimum braking performance. During brake

pressure modulation, as brake pressure is increased,

wheel slip is allowed to reach up to 30%. This means

that the wheel rolling velocity is 30% less than that

of a free rolling wheel at a given vehicle speed. This

slip may result in some tire chirping, depending on

the road surface. This sound should not be inter-

preted as total wheel lock-up. Complete wheel lock up normally leaves black tire

marks on dry pavement. The Anti-Lock Braking Sys-

tem will not leave dark black tire marks since the

wheel never reaches a locked condition. Tire marks

may however be noticeable as light patched marks.

VEHICLE PERFORMANCE

Anti-Lock Brakes provide the driver with some

steering control during hard braking, however there

are conditions where the system does not provide any

benefit. In particular, hydroplaning is still possible

when the tires ride on a film of water. This results in

the vehicles tires leaving the road surface rendering

the vehicle virtually uncontrollable. In addition, ex-

treme steering maneuvers at high speed or high

speed cornering beyond the limits of tire adhesion to

the road surface may cause vehicle skidding, inde-

pendent of vehicle braking. For this reason, the ABS

system is termed Anti-Lock instead of Anti-Skid.

SYSTEM SELF-DIAGNOSTICS

The Bendix Anti-Lock 6 Brake System has been

designed with the following self diagnostics capabil-

ity. The self diagnostic ABS startup cycle begins when

the ignition switch is in the on position. An electrical

check is completed on the ABS components such as

Wheel Speed Sensor Continuity and System and

other Relay continuity. During this check the Amber

Anti-Lock Light is on for approximately 1-2 seconds. Further Functional testing is accomplished once

the vehicle is set in motion. (1) The solenoid valves and the pump/motor are ac-

tivated briefly to verify function. (2) The voltage output from the wheel speed sen-

sors is verified to be within the correct operating

range.

Fig. 5 Controller Anti-Lock Brake (CAB)

Ä ANTI-LOCK 6 BRAKE SYSTEM 5 - 115