engine coolant CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1894 of 2438

IGNITION SWITCH ON (ZERO RPM) MODE When the multi-port fuel injection system is acti-

vated by the ignition switch, the following actions oc-

cur:

² The PCM determines atmospheric air pressure

from the MAP sensor input to determine basic fuel

strategy.

² The PCM monitors the coolant temperature sensor

and throttle position sensor input. The PCM modifies

fuel strategy based on this input. When the key is in the ON position and the engine

is not running (zero rpm), the auto shutdown (ASD)

relay and fuel pump relay are not energized. There-

fore battery voltage is not supplied to the fuel pump,

ignition coil, fuel injectors or oxygen sensor heating

element.

ENGINE START-UP MODE

This is an OPEN LOOP mode. The following ac-

tions occur when the starter motor is engaged. If the PCM receives the camshaft position sensor

and crankshaft position sensor signals, it energizes

the auto shutdown (ASD) relay and fuel pump relay.

These relays supply battery voltage to the fuel pump,

fuel injectors, ignition coil, and oxygen sensor heat-

ing element. If the PCM does not receive the cam-

shaft position sensor and crankshaft position sensor

signals within approximately one second, it de-ener-

gizes the ASD relay and fuel pump relay. The PCM energizes all six injectors until it deter-

mines crankshaft position from the camshaft position

sensor and crankshaft position sensor signals. The

PCM determines crankshaft position within 1 engine

revolution. After determining crankshaft position, the PCM

begins energizing the injectors in sequence. The PCM

adjusts injector pulse width and controls injector syn-

chronization by turning the individual ground paths

to the injectors On and Off. When the engine idles within 664 RPM of its tar-

get RPM, the PCM compares current MAP sensor

value with the atmospheric pressure value received

during the Ignition Switch On (Zero RPM) mode. If

the PCM does not detect a minimum difference be-

tween the two values, it sets a MAP fault into mem-

ory. Once the ASD and fuel pump relays have been en-

ergized, the PCM:

² Determines injector pulse width based on battery

voltage, coolant temperature, engine rpm and the

number of engine revolutions since cranking was ini-

tiated.

ENGINE WARM-UP MODE This is a OPEN LOOP mode. The following inputs

are received by the PCM:

² engine coolant temperature ²

manifold absolute pressure (MAP)

² engine speed (crankshaft position sensor)

² throttle position

² A/C switch

² battery voltage

The PCM adjusts injector pulse width and controls

injector synchronization by turning the individual

ground paths to the injectors On and Off. The PCM adjusts ignition timing and engine idle

speed. Engine idle speed is adjusted through the idle

air control motor.

CRUISE OR IDLE MODE

When the engine is at operating temperature this

is a CLOSED LOOP mode. During cruising speed the

following inputs are received by the PCM:

² engine coolant temperature

² manifold absolute pressure

² engine speed (crankshaft position sensor)

² throttle position

² exhaust gas oxygen content

² A/C control positions

² battery voltage

The PCM adjusts injector pulse width and controls

injector synchronization by turning the individual

ground paths to the injectors On and Off. The PCM adjusts engine idle speed and ignition

timing. The PCM adjusts the air/fuel ratio according

to the oxygen content in the exhaust gas.

ACCELERATION MODE This is a CLOSED LOOP mode. The PCM recog-

nizes an abrupt increase in throttle position or MAP

pressure as a demand for increased engine output

and vehicle acceleration. The PCM increases injector

pulse width in response to increased fuel demand.

DECELERATION MODE This is a CLOSED LOOP mode. During decelera-

tion the following inputs are received by the PCM:

² engine coolant temperature

² manifold absolute pressure

² engine speed

² throttle position

² exhaust gas oxygen content

² A/C control positions

² battery voltage

The PCM may receive a closed throttle input from

the throttle position sensor (TPS) when it senses an

abrupt decrease in manifold pressure. This indicates

a hard deceleration. The PCM will reduce injector

pulse width. This helps maintain better control of the

air-fuel mixture (as sensed through the O

2sensor).

During a closed throttle deceleration condition, the

PCM grounds the exhaust gas recirculation (EGR)

solenoid. When the solenoid is grounded, EGR func-

tion stops.

14 - 154 FUEL SYSTEMS Ä

Page 1895 of 2438

WIDE OPEN THROTTLE MODE This is an OPEN LOOP mode. During wide-open-

throttle operation, the following inputs are received

by the PCM:

² battery voltage

² engine coolant temperature

² manifold absolute pressure

² engine speed

² throttle position

When the PCM senses wide open throttle condition

through the throttle position sensor (TPS) it will:

² De-energize the air conditioning relay. This dis-

ables the air conditioning system.

² Provide a ground for the electrical EGR transducer

(EET) solenoid. When the PCM grounds the solenoid,

the EGR system stops operating. The exhaust gas oxygen content input is not ac-

cepted by the PCM during wide open throttle opera-

tion. The PCM will adjust injector pulse width to

supply a predetermined amount of additional fuel.

IGNITION SWITCH OFF MODE When the ignition switch is turned to the OFF po-

sition, the following occurs:

² All outputs are turned off.

² No inputs are monitored.

² The PCM shuts down.

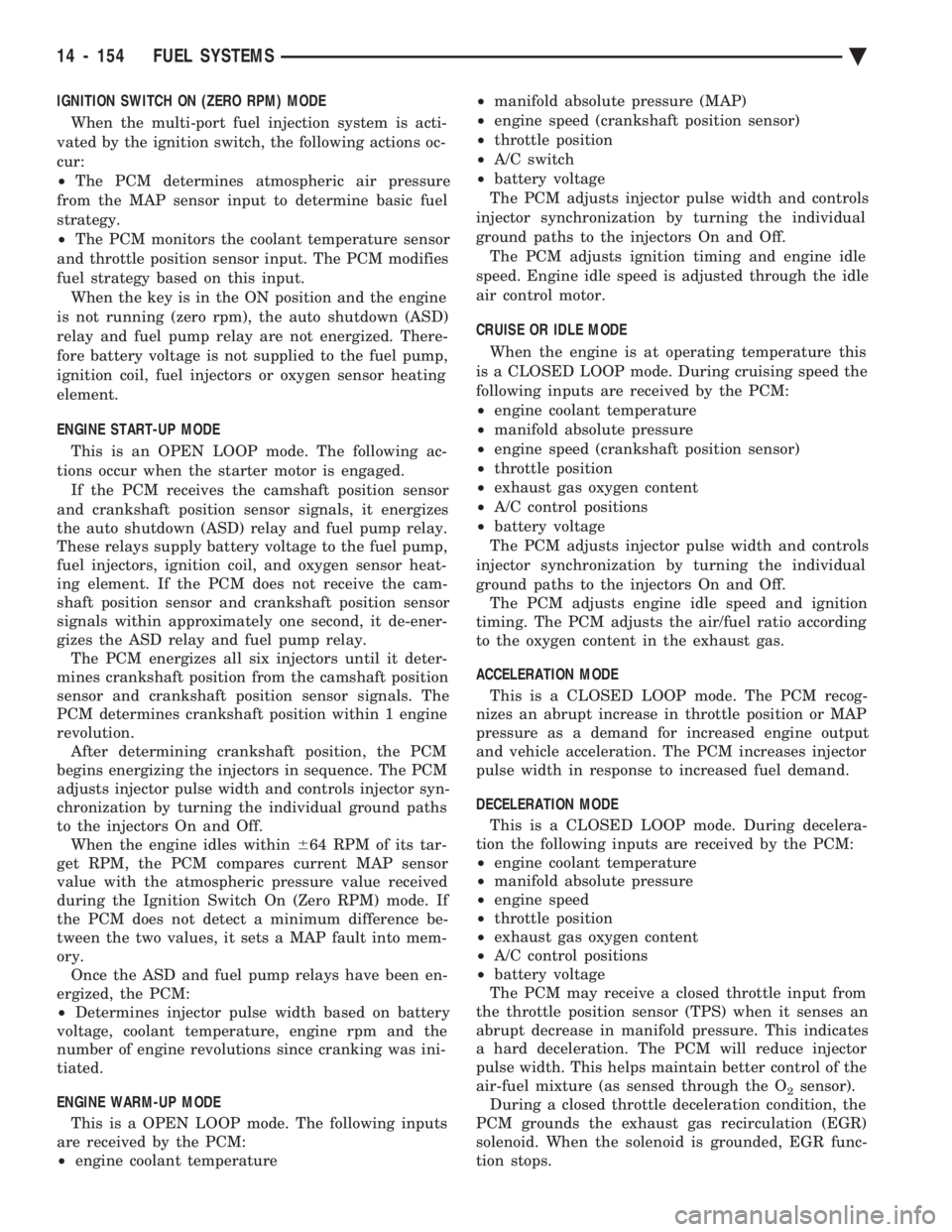

THROTTLE BODY

The throttle body assembly is located on the left

side of the intake manifold plenum (Fig. 19). The

throttle body houses the throttle position sensor and

the idle air control motor. Air flow through the throt- tle body is controlled by a cable operated throttle

blade located in the base of the throttle body.

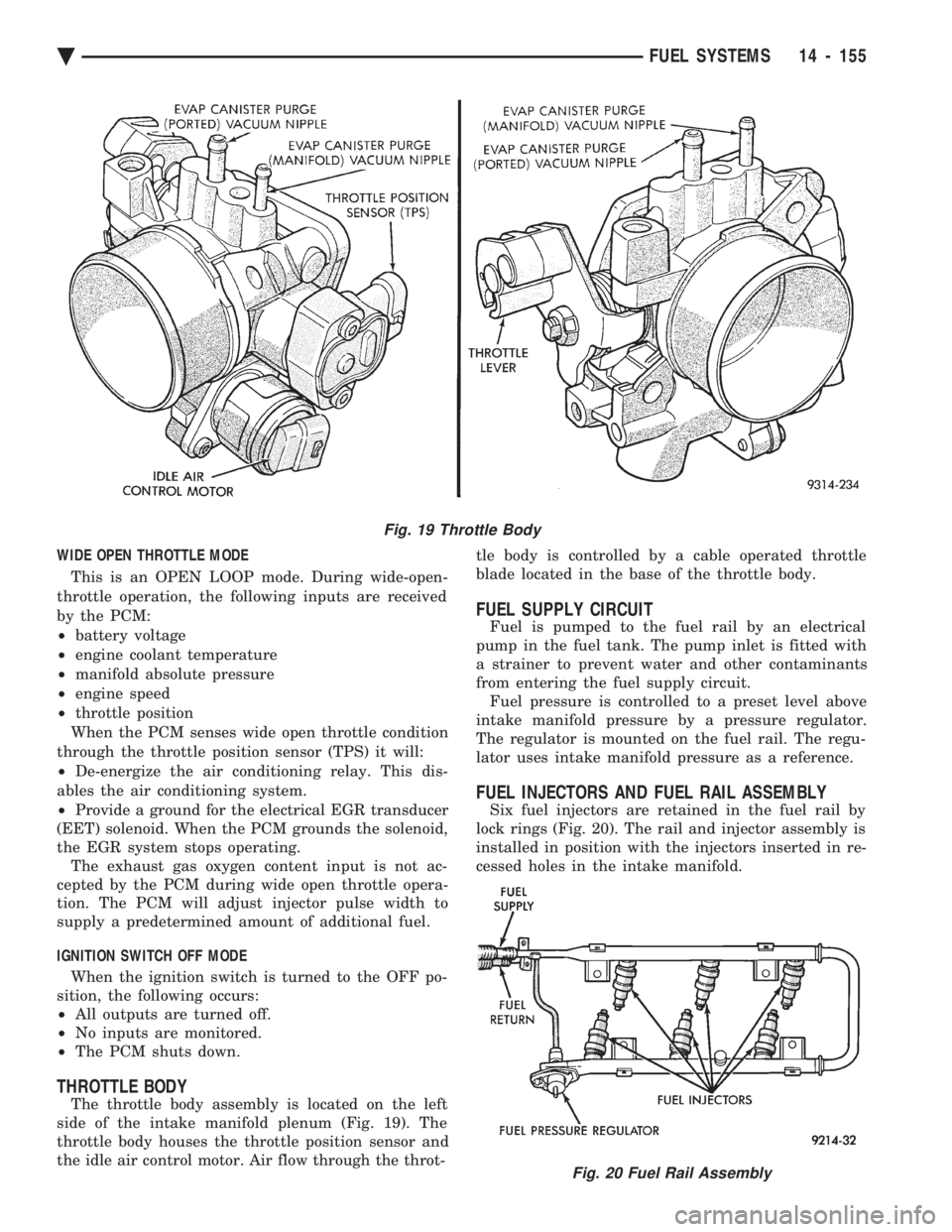

FUEL SUPPLY CIRCUIT

Fuel is pumped to the fuel rail by an electrical

pump in the fuel tank. The pump inlet is fitted with

a strainer to prevent water and other contaminants

from entering the fuel supply circuit. Fuel pressure is controlled to a preset level above

intake manifold pressure by a pressure regulator.

The regulator is mounted on the fuel rail. The regu-

lator uses intake manifold pressure as a reference.

FUEL INJECTORS AND FUEL RAIL ASSEMBLY

Six fuel injectors are retained in the fuel rail by

lock rings (Fig. 20). The rail and injector assembly is

installed in position with the injectors inserted in re-

cessed holes in the intake manifold.

Fig. 19 Throttle Body

Fig. 20 Fuel Rail Assembly

Ä FUEL SYSTEMS 14 - 155

Page 1897 of 2438

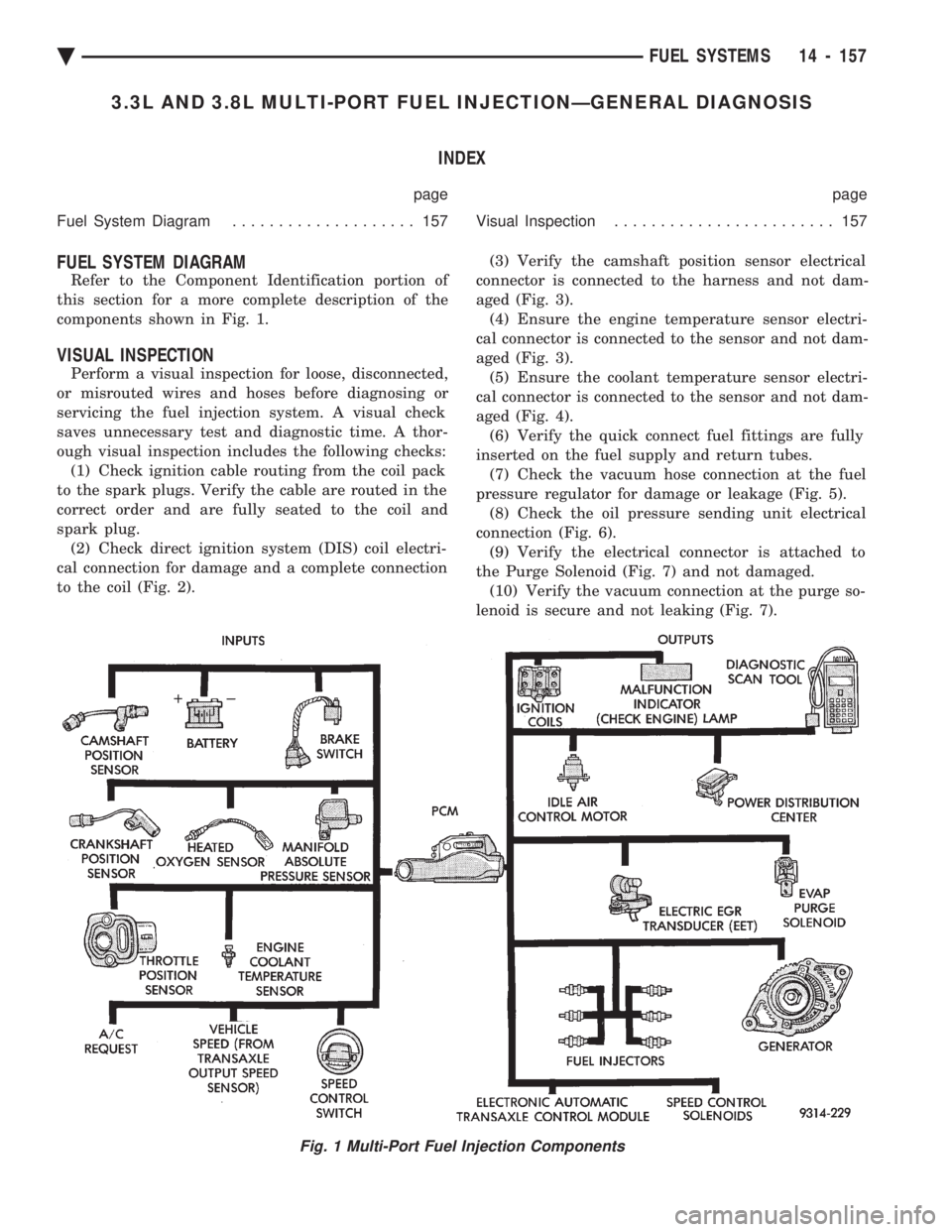

3.3L AND 3.8L MULTI-PORT FUEL INJECTIONÐGENERAL DIAGNOSIS INDEX

page page

Fuel System Diagram .................... 157 Visual Inspection........................ 157

FUEL SYSTEM DIAGRAM

Refer to the Component Identification portion of

this section for a more complete description of the

components shown in Fig. 1.

VISUAL INSPECTION

Perform a visual inspection for loose, disconnected,

or misrouted wires and hoses before diagnosing or

servicing the fuel injection system. A visual check

saves unnecessary test and diagnostic time. A thor-

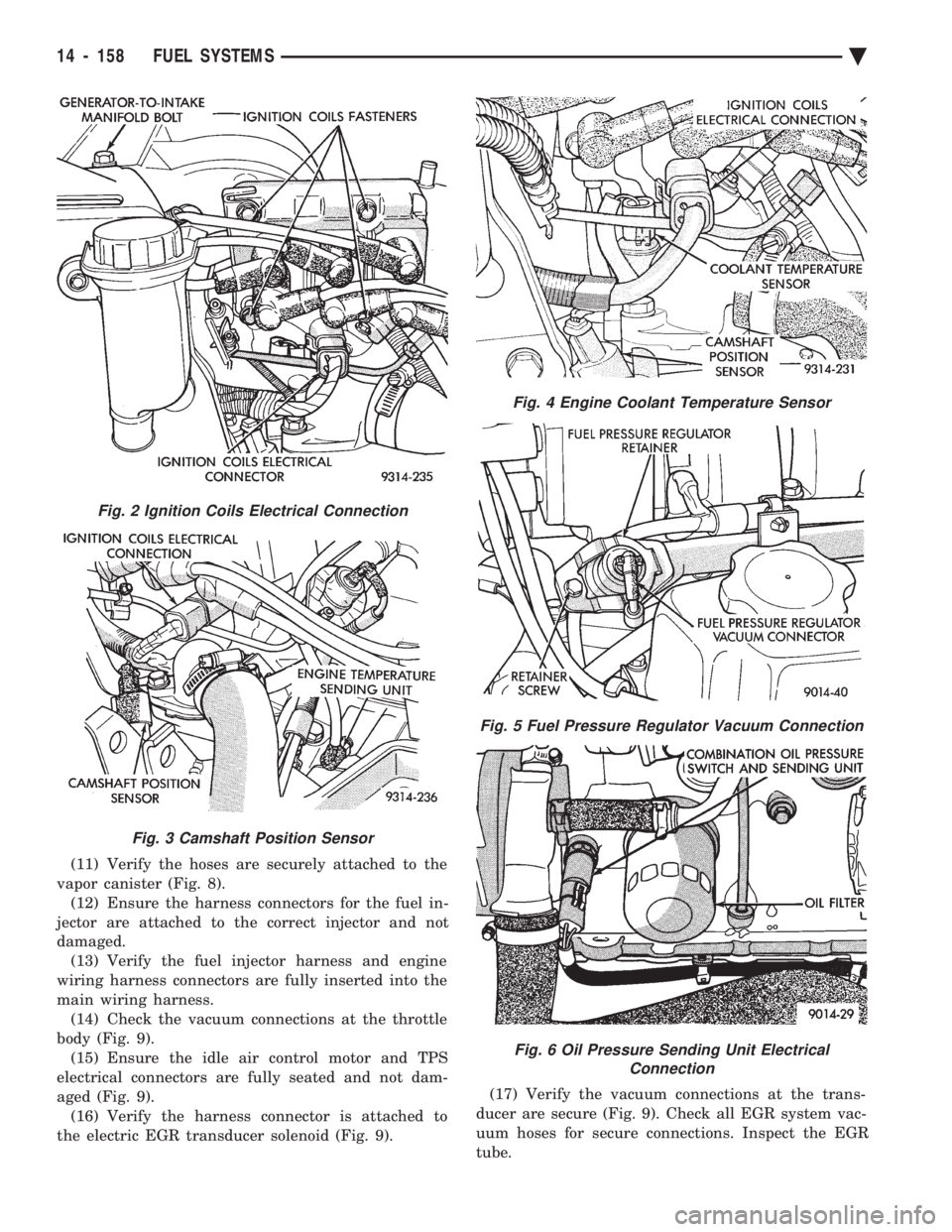

ough visual inspection includes the following checks: (1) Check ignition cable routing from the coil pack

to the spark plugs. Verify the cable are routed in the

correct order and are fully seated to the coil and

spark plug. (2) Check direct ignition system (DIS) coil electri-

cal connection for damage and a complete connection

to the coil (Fig. 2). (3) Verify the camshaft position sensor electrical

connector is connected to the harness and not dam-

aged (Fig. 3). (4) Ensure the engine temperature sensor electri-

cal connector is connected to the sensor and not dam-

aged (Fig. 3). (5) Ensure the coolant temperature sensor electri-

cal connector is connected to the sensor and not dam-

aged (Fig. 4). (6) Verify the quick connect fuel fittings are fully

inserted on the fuel supply and return tubes. (7) Check the vacuum hose connection at the fuel

pressure regulator for damage or leakage (Fig. 5). (8) Check the oil pressure sending unit electrical

connection (Fig. 6). (9) Verify the electrical connector is attached to

the Purge Solenoid (Fig. 7) and not damaged. (10) Verify the vacuum connection at the purge so-

lenoid is secure and not leaking (Fig. 7).

Fig. 1 Multi-Port Fuel Injection Components

Ä FUEL SYSTEMS 14 - 157

Page 1898 of 2438

(11) Verify the hoses are securely attached to the

vapor canister (Fig. 8). (12) Ensure the harness connectors for the fuel in-

jector are attached to the correct injector and not

damaged. (13) Verify the fuel injector harness and engine

wiring harness connectors are fully inserted into the

main wiring harness. (14) Check the vacuum connections at the throttle

body (Fig. 9). (15) Ensure the idle air control motor and TPS

electrical connectors are fully seated and not dam-

aged (Fig. 9). (16) Verify the harness connector is attached to

the electric EGR transducer solenoid (Fig. 9). (17) Verify the vacuum connections at the trans-

ducer are secure (Fig. 9). Check all EGR system vac-

uum hoses for secure connections. Inspect the EGR

tube.

Fig. 2 Ignition Coils Electrical Connection

Fig. 3 Camshaft Position Sensor

Fig. 4 Engine Coolant Temperature Sensor

Fig. 5 Fuel Pressure Regulator Vacuum Connection

Fig. 6 Oil Pressure Sending Unit Electrical Connection

14 - 158 FUEL SYSTEMS Ä

Page 1906 of 2438

S/C Vacuum Solenoid

A/C Clutch Relay

EGR Solenoid

Auto Shutdown Relay

Radiator Fan Relay

Purge Solenoid

Malfunction Indicator Lamp (Check Engine Lamp)

STATE DISPLAY SENSORS

Connect the DRBII scan tool to the vehicle and ac-

cess the State Display screen. Then access Sensor

Display. The following is a list of the engine control

system functions accessible through the Sensor Dis-

play screen. Oxygen Sensor Signal

Engine Coolant Temperature

Engine Coolant Temp Sensor

Throttle Position

Minimum Throttle

Battery Voltage

MAP Sensor Reading

Idle Air Control Motor Position

Adaptive Fuel Factor

Barometric Pressure

Min Airflow Idle Spd (speed)

Engine Speed

DIS Sensor Status

Fault #1 Key-On Info

Module Spark Advance

Speed Control Target

Fault #2 Key-on Info

Fault #3 Key-on Info

Speed Control Status

Speed Control Switch Voltage

Charging System Goal

Theft Alarm Status

Map Sensor Voltage

Vehicle Speed

Oxygen Sensor State

MAP Gauge Reading

Throttle Opening (percentage)

Total Spark Advance

CIRCUIT ACTUATION TEST MODE

The circuit actuation test mode checks for proper

operation of output circuits or devices which the pow-

ertrain control module (PCM) cannot internally rec-

ognize. The PCM can attempt to activate these

outputs and allow an observer to verify proper oper-

ation. Most of the tests provide an audible or visual

indication of device operation (click of relay contacts,

spray fuel, etc.). Except for intermittent conditions, if

a device functions properly during testing, assume

the device, its associated wiring, and driver circuit

working correctly.

OBTAINING CIRCUIT ACTUATION TEST

Connect the DRBII scan tool to the vehicle and ac-

cess the Actuators screen. The following is a list of

the engine control system functions accessible

through Actuators screens. Stop All Tests

Ignition Coil #1

Ignition Coil #2

Ignition Coil #3

Fuel Injector #1

Fuel Injector #2

Fuel Injector #3

Fuel Injector #4

Fuel Injector #5

Fuel Injector #6

Idle Air Control Motor Open/Close

Radiator Fan Relay

A/C Clutch Relay

Auto Shutdown Relay

EVAP Purge Solenoid

S/C Servo Solenoids

Generator Field

EGR Solenoid

All Solenoids/Relays

ASD Fuel System Test

Speed Control Vacuum Solenoid

Speed Control Vent Solenoid

THROTTLE BODY MINIMUM AIR FLOW CHECK

PROCEDURE

(1) Warm engine in Park or Neutral until the cool-

ing fan has cycled on and off at least once. (2) Ensure that all accessories are off.

(3) Shut off engine.

(4) Disconnect the PCV valve hose from the intake

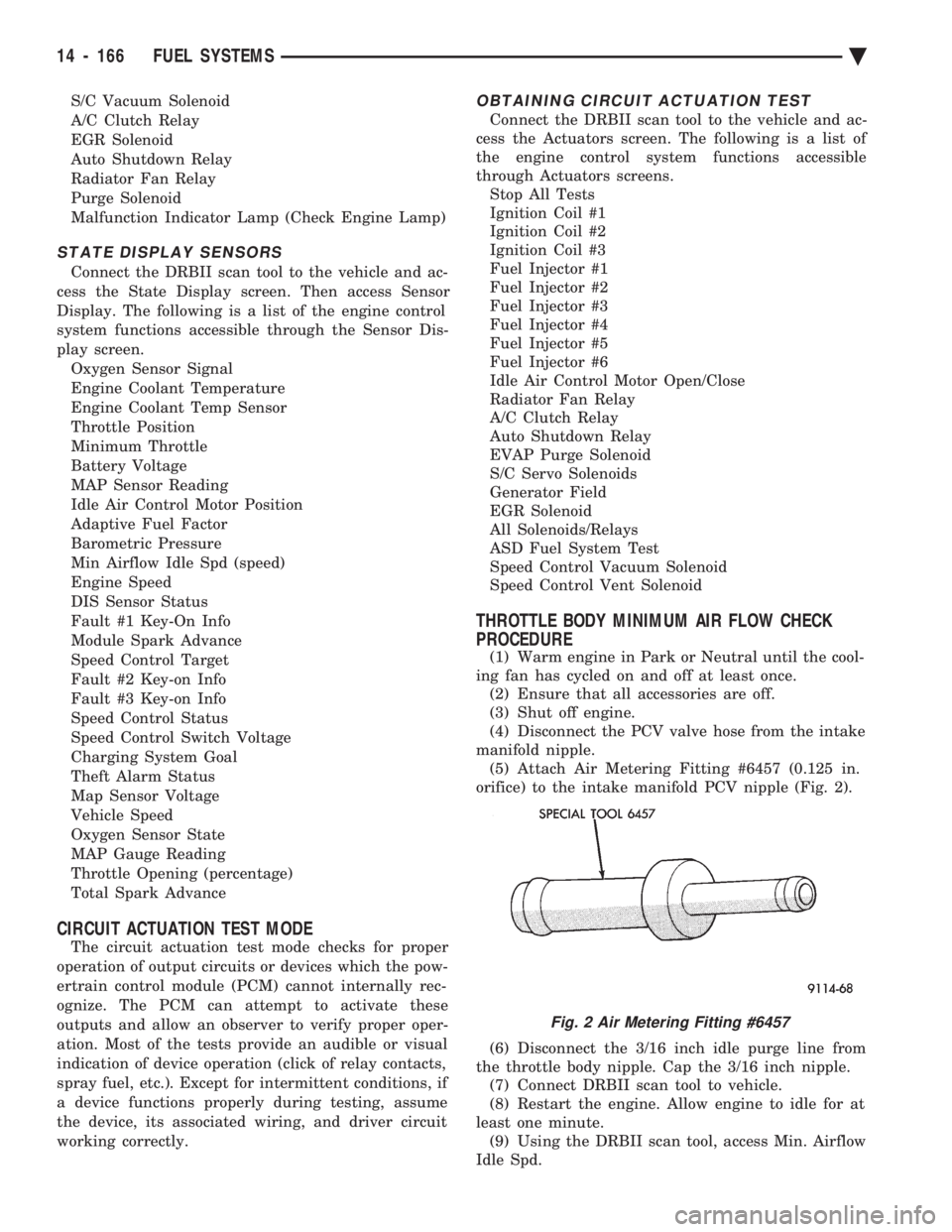

manifold nipple. (5) Attach Air Metering Fitting #6457 (0.125 in.

orifice) to the intake manifold PCV nipple (Fig. 2).

(6) Disconnect the 3/16 inch idle purge line from

the throttle body nipple. Cap the 3/16 inch nipple. (7) Connect DRBII scan tool to vehicle.

(8) Restart the engine. Allow engine to idle for at

least one minute. (9) Using the DRBII scan tool, access Min. Airflow

Idle Spd.

Fig. 2 Air Metering Fitting #6457

14 - 166 FUEL SYSTEMS Ä

Page 1912 of 2438

(12) Remove the fuel hose quick connect fittings

from the chassis tubes. Refer to Fuel Hoses, Clamps

and Quick Connect Fittings in the Fuel Delivery

Section of this Group. Place a shop towel under the

connections to absorb any fuel spilled. fittings. (13) Remove direct ignition system (DIS) coils and

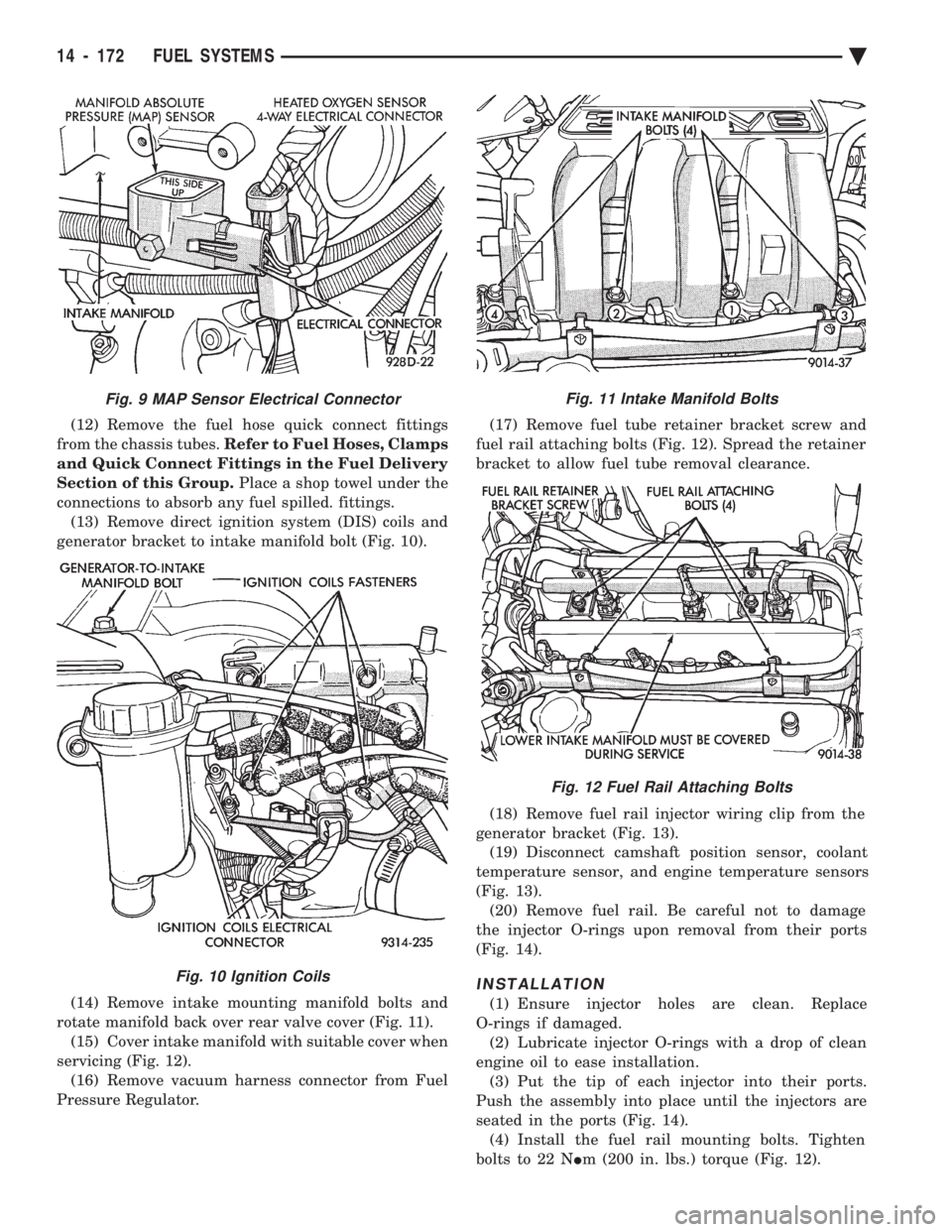

generator bracket to intake manifold bolt (Fig. 10).

(14) Remove intake mounting manifold bolts and

rotate manifold back over rear valve cover (Fig. 11). (15) Cover intake manifold with suitable cover when

servicing (Fig. 12). (16) Remove vacuum harness connector from Fuel

Pressure Regulator. (17) Remove fuel tube retainer bracket screw and

fuel rail attaching bolts (Fig. 12). Spread the retainer

bracket to allow fuel tube removal clearance.

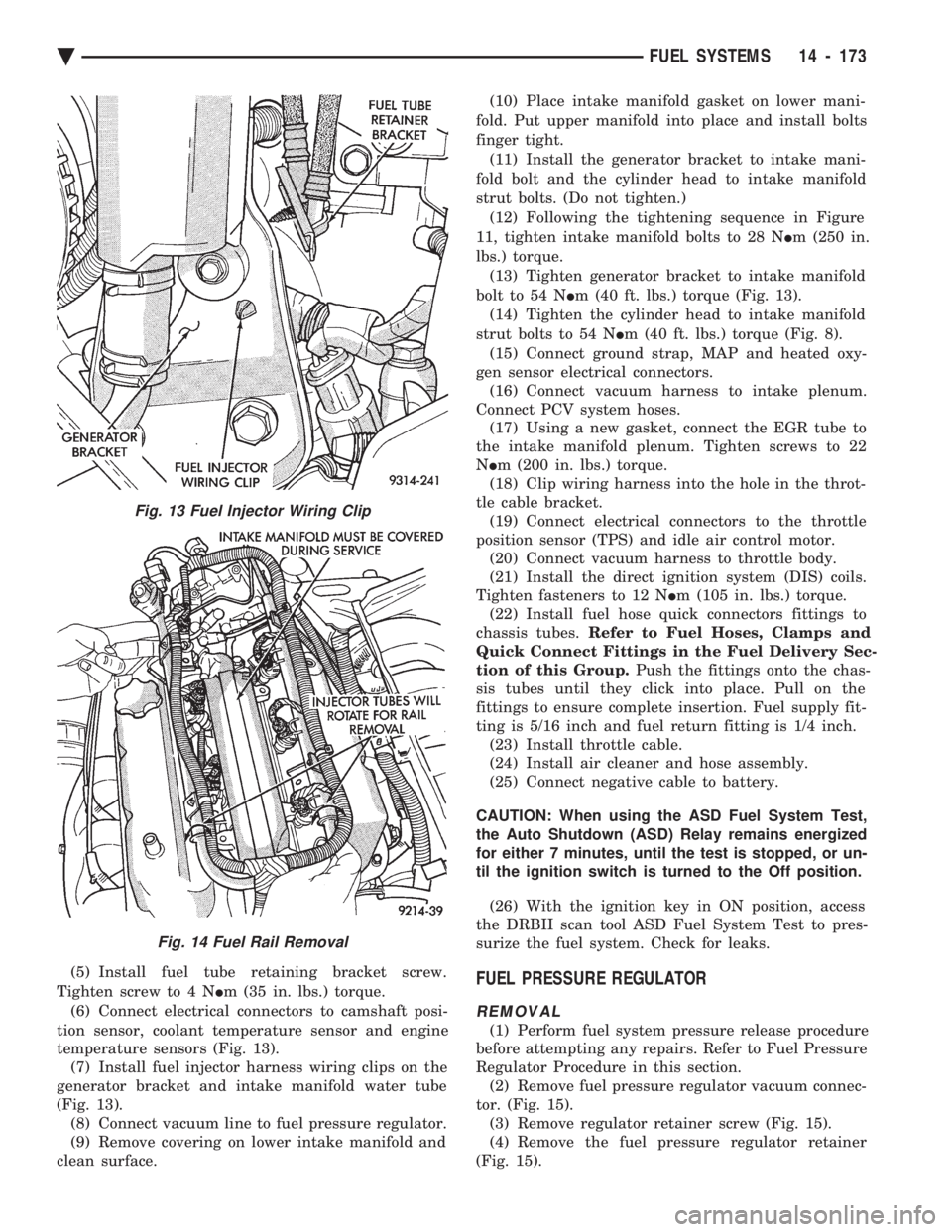

(18) Remove fuel rail injector wiring clip from the

generator bracket (Fig. 13). (19) Disconnect camshaft position sensor, coolant

temperature sensor, and engine temperature sensors

(Fig. 13). (20) Remove fuel rail. Be careful not to damage

the injector O-rings upon removal from their ports

(Fig. 14).

INSTALLATION

(1) Ensure injector holes are clean. Replace

O-rings if damaged. (2) Lubricate injector O-rings with a drop of clean

engine oil to ease installation. (3) Put the tip of each injector into their ports.

Push the assembly into place until the injectors are

seated in the ports (Fig. 14). (4) Install the fuel rail mounting bolts. Tighten

bolts to 22 N Im (200 in. lbs.) torque (Fig. 12).

Fig. 11 Intake Manifold Bolts

Fig. 12 Fuel Rail Attaching Bolts

Fig. 9 MAP Sensor Electrical Connector

Fig. 10 Ignition Coils

14 - 172 FUEL SYSTEMS Ä

Page 1913 of 2438

(5) Install fuel tube retaining bracket screw.

Tighten screw to 4 N Im (35 in. lbs.) torque.

(6) Connect electrical connectors to camshaft posi-

tion sensor, coolant temperature sensor and engine

temperature sensors (Fig. 13). (7) Install fuel injector harness wiring clips on the

generator bracket and intake manifold water tube

(Fig. 13). (8) Connect vacuum line to fuel pressure regulator.

(9) Remove covering on lower intake manifold and

clean surface. (10) Place intake manifold gasket on lower mani-

fold. Put upper manifold into place and install bolts

finger tight. (11) Install the generator bracket to intake mani-

fold bolt and the cylinder head to intake manifold

strut bolts. (Do not tighten.) (12) Following the tightening sequence in Figure

11, tighten intake manifold bolts to 28 N Im (250 in.

lbs.) torque. (13) Tighten generator bracket to intake manifold

bolt to 54 N Im (40 ft. lbs.) torque (Fig. 13).

(14) Tighten the cylinder head to intake manifold

strut bolts to 54 N Im (40 ft. lbs.) torque (Fig. 8).

(15) Connect ground strap, MAP and heated oxy-

gen sensor electrical connectors. (16) Connect vacuum harness to intake plenum.

Connect PCV system hoses. (17) Using a new gasket, connect the EGR tube to

the intake manifold plenum. Tighten screws to 22

N Im (200 in. lbs.) torque.

(18) Clip wiring harness into the hole in the throt-

tle cable bracket. (19) Connect electrical connectors to the throttle

position sensor (TPS) and idle air control motor. (20) Connect vacuum harness to throttle body.

(21) Install the direct ignition system (DIS) coils.

Tighten fasteners to 12 N Im (105 in. lbs.) torque.

(22) Install fuel hose quick connectors fittings to

chassis tubes. Refer to Fuel Hoses, Clamps and

Quick Connect Fittings in the Fuel Delivery Sec-

tion of this Group. Push the fittings onto the chas-

sis tubes until they click into place. Pull on the

fittings to ensure complete insertion. Fuel supply fit-

ting is 5/16 inch and fuel return fitting is 1/4 inch. (23) Install throttle cable.

(24) Install air cleaner and hose assembly.

(25) Connect negative cable to battery.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or un-

til the ignition switch is turned to the Off position.

(26) With the ignition key in ON position, access

the DRBII scan tool ASD Fuel System Test to pres-

surize the fuel system. Check for leaks.FUEL PRESSURE REGULATOR

REMOVAL

(1) Perform fuel system pressure release procedure

before attempting any repairs. Refer to Fuel Pressure

Regulator Procedure in this section. (2) Remove fuel pressure regulator vacuum connec-

tor. (Fig. 15). (3) Remove regulator retainer screw (Fig. 15).

(4) Remove the fuel pressure regulator retainer

(Fig. 15).

Fig. 13 Fuel Injector Wiring Clip

Fig. 14 Fuel Rail Removal

Ä FUEL SYSTEMS 14 - 173

Page 2047 of 2438

OPERATION

The 41TE transaxle provides forward ratios of 2.84,

1.57, 1.00, and 0.69 with torque converter clutch

available in 2nd, direct, or overdrive gear; the Re-

verse ratio is 2.21. The shift lever is conventional

with six positions: P, R, N, OD, 3, and L. When OD

is selected the transaxle shifts normally through all

four speeds with torque converter clutch available in

overdrive; this position is recommended for most

driving. The 3 position is tailored for use in hilly or

mountainous driving. When 3 is selected, the trans-

mission uses only 1st, 2nd, and direct gears with

2nd-direct shift delayed to 40 mph or greater. When

operating in 3 or L positions torque converter clutch

application occurs in direct gear for improved trans-

mission cooling under heavy loads. If high engine

coolant temperature occurs, the torque converter

clutch will also engage in 2nd gear. The L position

provides maximum engine braking for descending

steep grades. Unlike most current transaxles, up-

shifts are provided to 2nd or direct gear at peak en-

gine speeds if the accelerator is depressed. This

provides engine over-speed protection and maximum

performance.

CLUTCH AND GEAR

The transaxle consists of:

² Three multiple disc input clutches

² Two multiple disc grounded clutches

² Four hydraulic accumulators

² Two planetary gear sets

This provides four forward ratios and a reverse ra-

tio. The clutch-apply pistons were designed with cen-

trifugally balanced oil cavities so that quick response

and good control can be achieved at any speed. A

push/pull piston is incorporated for two of the three

input clutches.

CAUTION: Some clutch packs appear similar, but

they are not the same. Do not interchange clutch

components as they might fail.

HYDRAULICS

The hydraulics of the transaxle provide the manual

shift lever select function, main line pressure regula-

tion, and torque converter and cooler flow control.

Oil flow to the friction elements is controlled directly

by four solenoid valves. The hydraulics also include a

unique logic-controlled ``solenoid torque converter

clutch control valve''. This valve locks out the 1st

gear reaction element with the application of 2nd, di-

rect, or overdrive gear elements. It also redirects the

1st gear solenoid output so that it can control torque

converter clutch operation. To regain access to 1st

gear, a special sequence of solenoid commands must

be used to unlock and move the solenoid torque con-

verter clutch control valve. This precludes any appli- cation of the 1st gear reaction element with other

elements applied. It also allows one solenoid to con-

trol two friction elements.

Small, high-rate accumulators are provided in each

controlled friction element circuit. These serve to ab-

sorb the pressure responses, and allow the controls to

read and respond to changes that are occurring.

SOLENOIDS

Since the solenoid valves perform virtually all con-

trol functions, these valves must be extremely dura-

ble and tolerant of normal dirt particles. For that

reason hardened-steel poppet and ball valves are

used. These are free from any close operating clear-

ances, and the solenoids operate the valves directly

without any intermediate element. Direct operation

means that these units must have very high output

so that they can close against the sizeable flow areas

and high line pressures. Fast response is also re-

quired to meet the control requirements. Two of the solenoids are normally-venting and two

are normally-applying; this was done to provide a de-

fault mode of operation. With no electrical power, the

transmission provides 2nd gear in OD, 3,orLshift

lever positions. All other transmission lever positions

will operate normally. The choice of 2nd gear was

made to provide adequate breakaway performance

while still accommodating highway speeds.

SENSORS

There are three pressure switches to identify sole-

noid application and two speed sensors to read input

(torque converter turbine) and output (parking sprag)

speeds. There is also a position switch to indicate the

manual shift lever position. The pressure switches

are incorporated in an assembly with the solenoids.

Engine speed, throttle position, temperature, etc., are

also observed. Some of these signals are read directly

from the engine control sensors; others are read from

a multiplex circuit with the powertrain control mod-

ule.

ELECTRONICS

The 41TE transmission control module is located

underhood in a potted, die-cast aluminum housing

with a sealed, 60-way connector.

ELECTRONIC MODULATED CONVERTER CLUTCH (EMCC)

The EMCC enables the torque converter clutch to

partially engage between 23 to 47 MPH before full

engagement at about 50 MPH and beyond. This fea-

ture is on all vehicles equipped with the 41TE tran-

saxle.

ADAPTIVE CONTROLS

These controls function by reading the input and

output speeds over 140 times a second and respond-

Ä TRANSAXLE 21 - 87

Page 2059 of 2438

CAUTION: If the vehicle is equipped with two oil

coolers (one in the radiator tank, one in front of the

radiator) they must be flushed separately. Do not

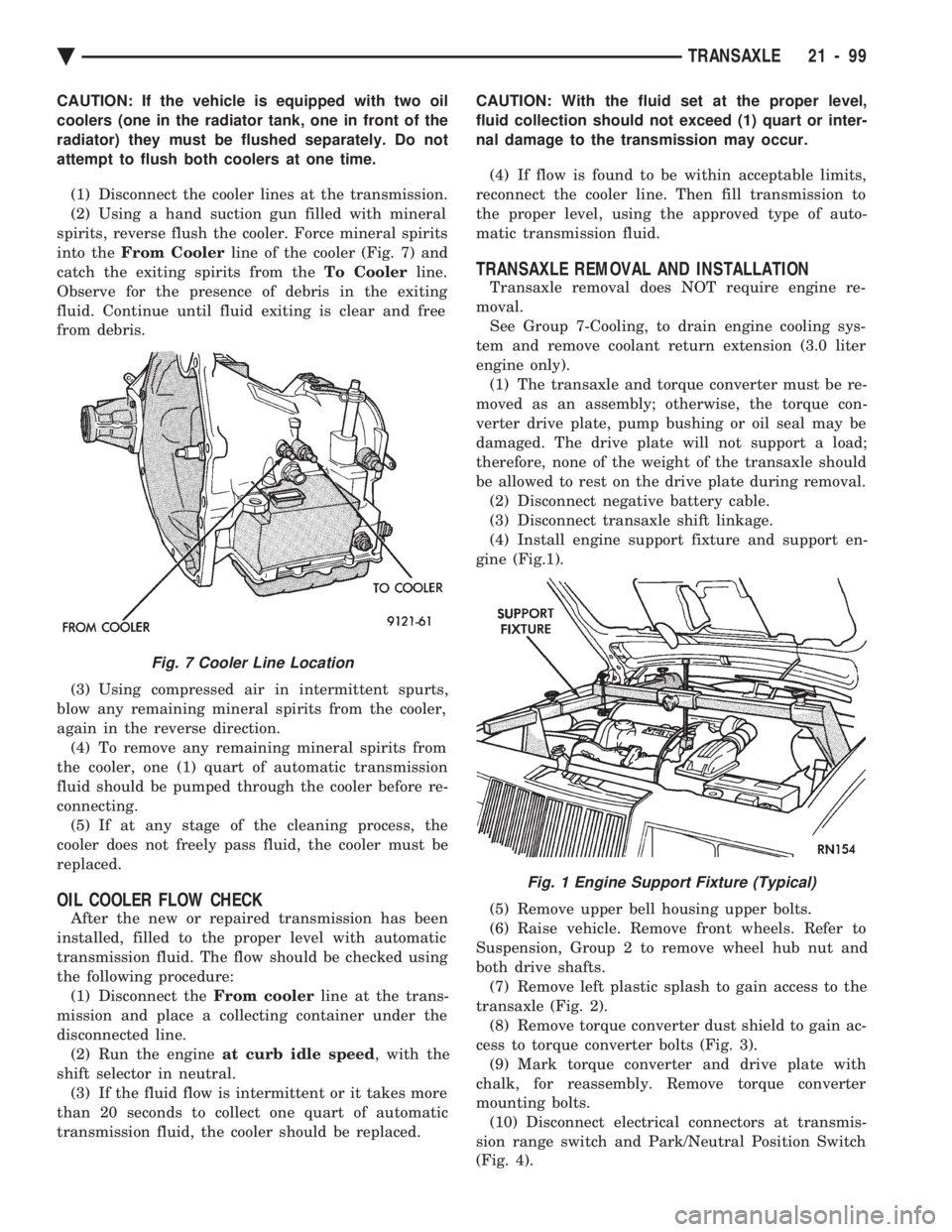

attempt to flush both coolers at one time. (1) Disconnect the cooler lines at the transmission.

(2) Using a hand suction gun filled with mineral

spirits, reverse flush the cooler. Force mineral spirits

into the From Cooler line of the cooler (Fig. 7) and

catch the exiting spirits from the To Coolerline.

Observe for the presence of debris in the exiting

fluid. Continue until fluid exiting is clear and free

from debris.

(3) Using compressed air in intermittent spurts,

blow any remaining mineral spirits from the cooler,

again in the reverse direction. (4) To remove any remaining mineral spirits from

the cooler, one (1) quart of automatic transmission

fluid should be pumped through the cooler before re-

connecting. (5) If at any stage of the cleaning process, the

cooler does not freely pass fluid, the cooler must be

replaced.

OIL COOLER FLOW CHECK

After the new or repaired transmission has been

installed, filled to the proper level with automatic

transmission fluid. The flow should be checked using

the following procedure: (1) Disconnect the From coolerline at the trans-

mission and place a collecting container under the

disconnected line. (2) Run the engine at curb idle speed , with the

shift selector in neutral. (3) If the fluid flow is intermittent or it takes more

than 20 seconds to collect one quart of automatic

transmission fluid, the cooler should be replaced. CAUTION: With the fluid set at the proper level,

fluid collection should not exceed (1) quart or inter-

nal damage to the transmission may occur.

(4) If flow is found to be within acceptable limits,

reconnect the cooler line. Then fill transmission to

the proper level, using the approved type of auto-

matic transmission fluid.

TRANSAXLE REMOVAL AND INSTALLATION

Transaxle removal does NOT require engine re-

moval. See Group 7-Cooling, to drain engine cooling sys-

tem and remove coolant return extension (3.0 liter

engine only). (1) The transaxle and torque converter must be re-

moved as an assembly; otherwise, the torque con-

verter drive plate, pump bushing or oil seal may be

damaged. The drive plate will not support a load;

therefore, none of the weight of the transaxle should

be allowed to rest on the drive plate during removal. (2) Disconnect negative battery cable.

(3) Disconnect transaxle shift linkage.

(4) Install engine support fixture and support en-

gine (Fig.1).

(5) Remove upper bell housing upper bolts.

(6) Raise vehicle. Remove front wheels. Refer to

Suspension, Group 2 to remove wheel hub nut and

both drive shafts. (7) Remove left plastic splash to gain access to the

transaxle (Fig. 2). (8) Remove torque converter dust shield to gain ac-

cess to torque converter bolts (Fig. 3). (9) Mark torque converter and drive plate with

chalk, for reassembly. Remove torque converter

mounting bolts. (10) Disconnect electrical connectors at transmis-

sion range switch and Park/Neutral Position Switch

(Fig. 4).

Fig. 7 Cooler Line Location

Fig. 1 Engine Support Fixture (Typical)

Ä TRANSAXLE 21 - 99

Page 2307 of 2438

SAFETY PRECAUTIONS AND WARNINGS

WARNING: WEAR EYE PROTECTION WHEN SER-

VICING THE AIR CONDITIONING REFRIGERANT

SYSTEM. SERIOUS EYE INJURY CAN RESULT

FROM EYE CONTACT WITH REFRIGERANT. IF EYE

CONTACT IS MADE, SEEK MEDICAL ATTENTION

IMMEDIATELY. DO NOT EXPOSE REFRIGERANT TO OPEN

FLAME. POISONOUS GAS IS CREATED WHEN RE-

FRIGERANT IS BURNED. AN ELECTRONIC TYPE

LEAK DETECTOR IS RECOMMENDED. LARGE AMOUNTS OF REFRIGERANT RELEASED

IN A CLOSED WORK AREA WILL DISPLACE THE

OXYGEN AND CAUSE SUFFOCATION. THE EVAPORATION RATE OF (R-12) REFRIGER-

ANT AT AVERAGE TEMPERATURE AND ALTITUDE

IS EXTREMELY HIGH. AS A RESULT, ANYTHING

THAT COMES IN CONTACT WITH THE REFRIGER-

ANT WILL FREEZE. ALWAYS PROTECT SKIN OR

DELICATE OBJECTS FROM DIRECT CONTACT

WITH REFRIGERANT.

CAUTION: Liquid refrigerant is corrosive to metal

surfaces. Follow the operating instructions supplied

with equipment being used.

COOLING SYSTEM PRECAUTIONS

WARNING: ANTIFREEZE IS AN ETHYLENE GLYCOL

BASE COOLANT AND IS HARMFUL IF SWAL-

LOWED OR INHALED. IF SWALLOWED, DRINK

TWO GLASSES OF WATER AND INDUCE VOMIT-

ING. IF INHALED, MOVE TO FRESH AIR AREA.

SEEK MEDICAL ATTENTION IMMEDIATELY. DO NOT STORE IN OPEN OR UNMARKED CON-

TAINERS. WASH SKIN AND CLOTHING THOROUGHLY AF-

TER COMING IN CONTACT WITH ETHYLENE GLY-

COL. KEEP OUT OF REACH OF CHILDREN AND PETS.

DO NOT OPEN A COOLING SYSTEM WHEN THE

ENGINE IS AT RUNNING TEMPERATURE. PER-

SONAL INJURY CAN RESULT.

The engine cooling system is designed to develop

internal pressure of 97 to 123 kPa (14 to 18 psi). Al-

low the vehicle 15 minutes (or until a safe tempera-

ture and pressure are attained) before opening the

cooling system. Refer to Group 7, Cooling System.

HANDLING TUBING AND FITTINGS

Kinks in the refrigerant tubing or sharp bends in

the refrigerant hose lines will greatly reduce the ca-

pacity of the entire system. High pressures are pro-

duced in the system when it is operating. Extreme

care must be exercised to make sure that all connec-

tions are pressure tight. Dirt and moisture can enter

the system when it is opened for repair or replace-

ment of lines or components. The refrigerant oil will

absorb moisture readily out of the air. This moisture

will convert into acids within a closed system. The following precautions must be observed:

The system must be completely empty before open-

ing any fitting or connection in the refrigeration sys-

tem. Open fittings with caution even after the

system has been emptied. If any pressure is noticed

as a fitting is loosened, allow trapped pressure to

bleed off very slowly. A good rule for the flexible hose lines is to keep the

radius of all bends at least 10 times the diameter of

the hose. Sharper bends will reduce the flow of re-

frigerant. The flexible hose lines should be routed so

they are at least 3 inches (80 mm) from the exhaust

manifold. Inspect all flexible hose lines to make sure

they are in good condition and properly routed. Unified plumbing connections with aluminum gas-

kets cannot be serviced with O-rings. These gaskets

are not reusable and do not require lubrication be-

fore installing. The use of correct wrenches when making connec-

tions is very important. Improper wrenches or im-

proper use of wrenches can damage the fittings. The A/C system will remain chemical stabile as

long as pure-moisture-free R-12 and refrigerant oil is

used. Abnormal amounts of dirt, moisture or air can

upset the chemical stability. This condition could

cause operational troubles or even serious damage if

present in more than very small quantities. When it is necessary to open the refrigeration sys-

tem, have everything needed to service the system

ready. The system should not be left open any longer

than necessary. Cap or plug all lines and fittings as

soon as they are opened to prevent the entrance or

dirt and moisture. All lines and components in parts

stock should be capped or sealed until they are ready

to be used. All tools, including the refrigerant dispensing man-

ifold, the manifold gauge set, and test hoses should

be kept clean and dry.

Fig. 6 Heater only or HeaterÐA/C Controls

Ä HEATING AND AIR CONDITIONING 24 - 3