engine coolant CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1844 of 2438

SYSTEM TESTS

Apply parking brake and/or block wheels be-

fore performing idle check or adjustment, or any

engine running tests.

OBTAINING DIAGNOSTIC TROUBLE CODES

(1) Connect DRBII scan tool to the data link connec-

tor (Fig. 1). (2) Start the engine if possible, cycle the trans mis-

sion selector and the A/Cswitch if applicable. Shut off

the engine. (3) Turn the ignition switch on, access Read Fault

Screen. Record all the fault messages shown on the

DRBII scan tool. Observe the malfunction indicator

lamp (check engine lamp on the instrument panel). The

lamp should light for 2 seconds then go out (bulb

check). Diagnostic trouble code erasure: access erase

diagnostic trouble code data.

STATE DISPLAY TEST MODE

The switch inputs used by the powertrain control

module (PCM) have only two recognized states, HIGH

and LOW. For this reason, the PCM cannot recognize

the difference between a selected switch position ver-

sus an open circuit, a short circuit, or a defective

switch. If the display changes, assume the entire

switch circuit to the PCM is functional. From the state

display screen access either State Display Inputs and

Outputs or State Display Sensors.

STATE DISPLAY INPUTS AND OUTPUTS

Connect the DRBII scan tool to the vehicle and access

the State Display screen. Then access Inputs and

Outputs. The following is a list of the engine control

system functions accessible through the Inputs and

Outputs screen. Speed Control Resume

Brake Switch

Speed Control On/Off

Speed Control Set

A/C Switch Sense

S/C Vent Solenoid S/C Vacuum Solenoid

A/C Clutch Relay

Baro Read Solenoid

Wastegate Solenoid

Auto Shutdown Relay

Radiator Fan Relay

Purge Solenoid

Malfunction Indicator Lamp (Check Engine Lamp)

STATE DISPLAY SENSORS

Connect the DRBII scan tool to the vehicle and ac-

cess the State Display screen. Then access Sensor

Display. The following is a list of the engine control

system functions accessible through the Sensor Dis-

play screen. Oxygen Sensor Signal

Coolant Temperature

Coolant Temp Sensor

Throttle Position

Minimum Throttle

Knock Sensor Signal

Battery Voltage

MAP Sensor Reading

Idle Air Control Motor Position

Adaptive Fuel Factor

Barometric Pressure

Min Airflow Idle Spd (speed)

Engine Speed

DIS Sensor Status

Fault #1 Key-On Info

Module Spark Advance

Cyl 1 Knock Retard

Cyl 2 Knock Retard

Cyl 3 Knock Retard

Cyl 4 Knock Retard

Boost Pressure Goal

Charge Temperature

Charge Temp Sensor

Speed Control Target

Fault #2 Key-on Info

Fault #3 Key-on Info

Speed Control Status

Charging System Goal

Theft Alarm Status

DIAGNOSTIC TROUBLE CODE DESCRIPTION (CON'T)

14 - 104 FUEL SYSTEMS Ä

Page 1853 of 2438

3.0L MULTI-PORT FUEL INJECTIONÐSYSTEM OPERATION INDEX

page page

Air Conditioning (A/C) Clutch Relay (AA, AG, AJ Body)ÐPCM Output .................... 118

Air Conditioning (A/C) Clutch Relay (AC Body) ÐPCM Output ........................ 118

Air Conditioning Switch Sense (AA, AG, AJ Body)ÐPCM Input ..................... 115

Air Conditioning Switch Sense (AC Body)ÐPCM Input ................................ 115

Auto Shutdown (ASD) Relay and Fuel Pump RelayÐPCM Output .................... 119

Battery VoltageÐPCM Input ............... 115

Brake SwitchÐPCM Input ................. 115

CCD Bus .............................. 113

Data Link ConnectorÐPCM Output .......... 120

Distributor Pick-UpÐPCM Input ............. 115

Duty Cycle Evap Canister Purge Solenoid ÐPCM Output ........................ 119

Engine Coolant Temperature Sensor ÐPCM Input ......................... 115

Fuel InjectorsÐPCM Output ............... 120

Fuel Pressure Regulator .................. 124

Fuel Supply Circuit ...................... 123

General Information ...................... 113 Generator FieldÐPCM Output

.............. 118

Heated Oxygen Sensor (O

2Sensor)

ÐPCM Input ......................... 116

Idle Air Control MotorÐPCM Output ......... 119

Ignition CoilÐPCM Output ................. 121

Malfunction Indicator Lamp (Check Engine Lamp)ÐPCM Output ................... 120

Manifold Absolute Pressure (MAP) Sensor ÐPCM Input ......................... 116

Modes of Operation ...................... 121

Park/Neutral SwitchÐPCM Input ............ 117

Part Throttle Unlock SolenoidÐPCM Output . . . 121

Powertrain Control Module ................. 113

Radiator Fan RelayÐPCM Output ........... 121

Speed Control SolenoidsÐPCM Output ....... 121

Speed ControlÐPCM Input ................ 117

System Diagnosis ....................... 113

TachometerÐPCM Output ................. 121

Throttle Body ........................... 123

Throttle Position Sensor (TPS)ÐPCM Input .... 117

Transaxle Control ModuleÐPCM Output ...... 120

Vehicle Speed and Distance InputÐPCM Input . 118

Vehicle Speed SensorÐPCM Input .......... 118

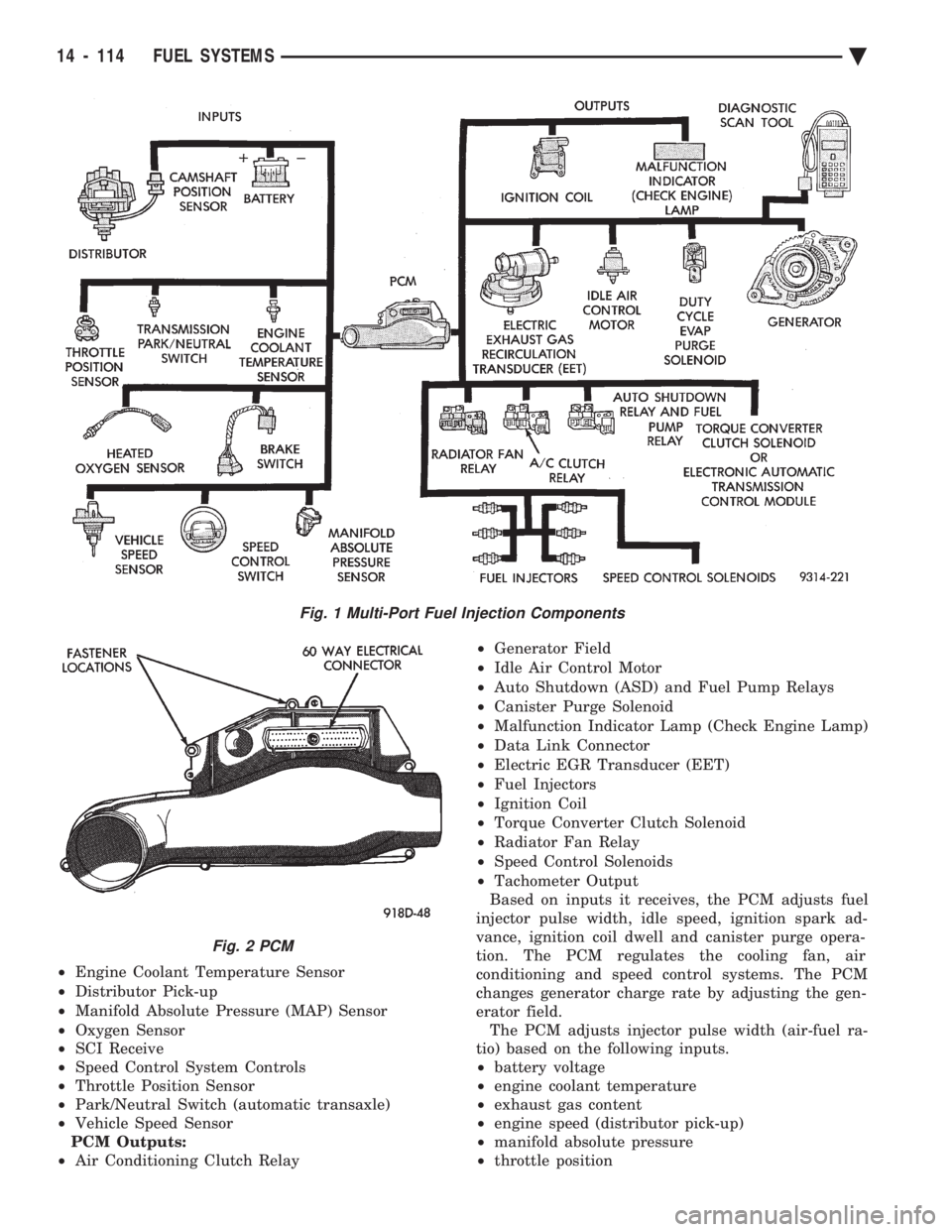

GENERAL INFORMATION

The 3.0L engine uses a sequential Multi-Port Elec-

tronic Fuel Injection system (Fig. 1). The MPI system

is computer regulated and provides precise air/fuel

ratios for all driving conditions. The MPI system is operated by the powertrain con-

trol module (PCM). The PCM regulates ignition timing, air-fuel ratio,

emission control devices, cooling fan, charging sys-

tem, idle speed and speed control. Various sensors

provide the inputs necessary for the PCM to correctly

operate these systems. In addition to the sensors,

various switches also provide inputs to the PCM. All inputs to the PCM are converted into signals.

The PCM can adapt its programming to meet chang-

ing operating conditions. Fuel is injected into the intake port above the in-

take valve in precise metered amounts through elec-

trically operated injectors. The PCM fires the

injectors in a specific sequence. The PCM maintains

an air fuel ratio of 14.7 parts air to 1 part fuel by

constantly adjusting injector pulse width. Injector

pulse width is the length of time the injector is ener-

gized. The PCM adjusts injector pulse width by opening

and closing the ground path to the injector. Engine

RPM (speed) and manifold absolute pressure (air

density) are the primary inputs that determine injec-

tor pulse width.

SYSTEM DIAGNOSIS

The powertrain control module (PCM) tests many

of its own input and output circuits. If a fault is

found in a major system, the information is stored in

memory. Technicians can display fault information

through the malfunction indicator lamp (instrument

panel Check Engine lamp) or by connecting the

DRBII scan tool. For diagnostic trouble code informa-

tion, refer to the 3.0 Multi-Port Fuel InjectionÐOn-

Board Diagnostics section of this group.

CCD BUS

Various modules exchange information through a

communications port called the CCD Bus. The pow-

ertrain control module (PCM) transmits the malfunc-

tion indicator (instrument panel check engine lamp)

On/Off signal, engine RPM and vehicle load data on

the CCD Bus.

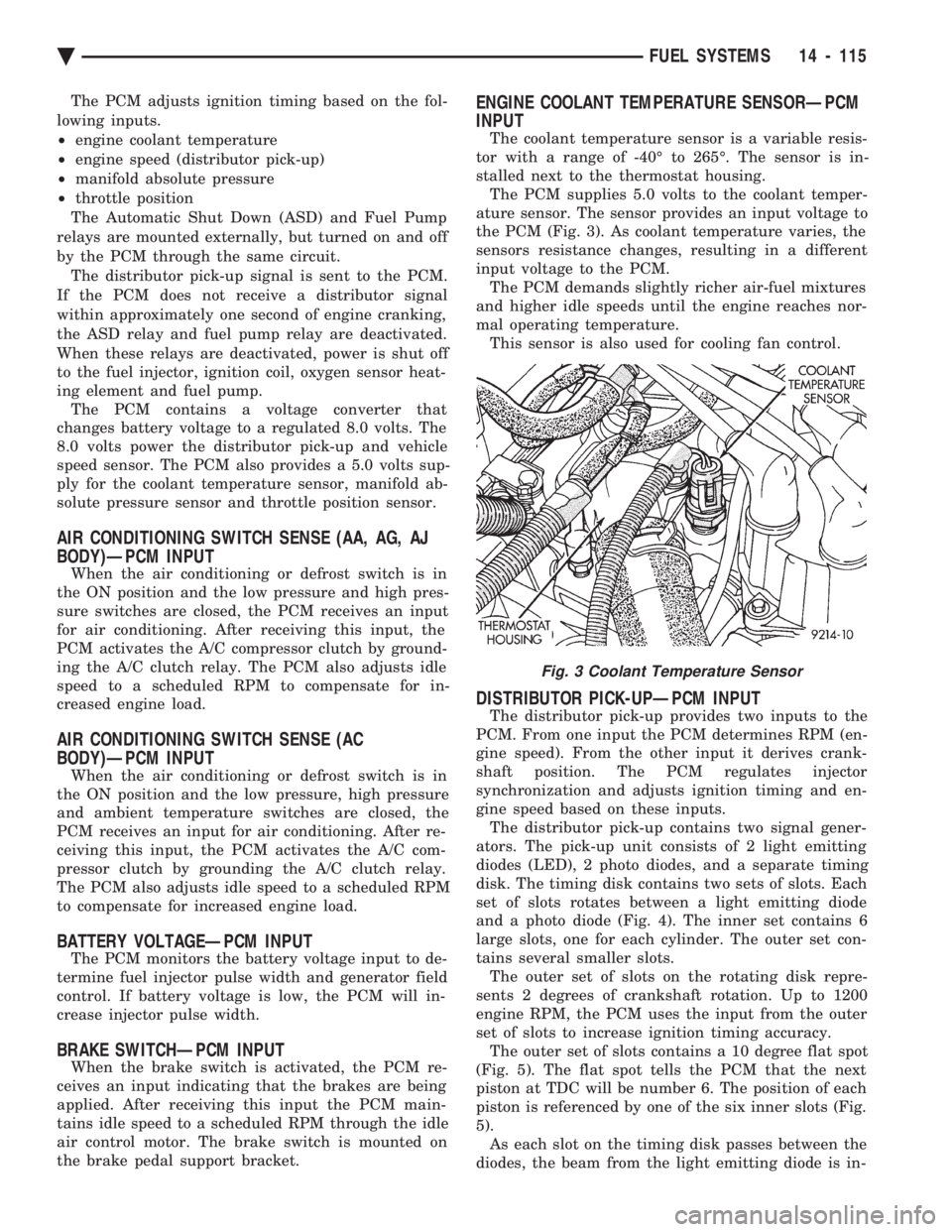

POWERTRAIN CONTROL MODULE

The powertrain control module (PCM) is a digital

computer containing a microprocessor (Fig. 2). The

PCM receives input signals from various switches

and sensors that are referred to as PCM Inputs.

Based on these inputs, the PCM adjusts various en-

gine and vehicle operations through devices referred

to as PCM Outputs. PCM Inputs:

² Air Conditioning Controls

² Battery Voltage

² Brake Switch

Ä FUEL SYSTEMS 14 - 113

Page 1854 of 2438

² Engine Coolant Temperature Sensor

² Distributor Pick-up

² Manifold Absolute Pressure (MAP) Sensor

² Oxygen Sensor

² SCI Receive

² Speed Control System Controls

² Throttle Position Sensor

² Park/Neutral Switch (automatic transaxle)

² Vehicle Speed Sensor

PCM Outputs:

² Air Conditioning Clutch Relay ²

Generator Field

² Idle Air Control Motor

² Auto Shutdown (ASD) and Fuel Pump Relays

² Canister Purge Solenoid

² Malfunction Indicator Lamp (Check Engine Lamp)

² Data Link Connector

² Electric EGR Transducer (EET)

² Fuel Injectors

² Ignition Coil

² Torque Converter Clutch Solenoid

² Radiator Fan Relay

² Speed Control Solenoids

² Tachometer Output

Based on inputs it receives, the PCM adjusts fuel

injector pulse width, idle speed, ignition spark ad-

vance, ignition coil dwell and canister purge opera-

tion. The PCM regulates the cooling fan, air

conditioning and speed control systems. The PCM

changes generator charge rate by adjusting the gen-

erator field. The PCM adjusts injector pulse width (air-fuel ra-

tio) based on the following inputs.

² battery voltage

² engine coolant temperature

² exhaust gas content

² engine speed (distributor pick-up)

² manifold absolute pressure

² throttle position

Fig. 1 Multi-Port Fuel Injection Components

Fig. 2 PCM

14 - 114 FUEL SYSTEMS Ä

Page 1855 of 2438

The PCM adjusts ignition timing based on the fol-

lowing inputs.

² engine coolant temperature

² engine speed (distributor pick-up)

² manifold absolute pressure

² throttle position

The Automatic Shut Down (ASD) and Fuel Pump

relays are mounted externally, but turned on and off

by the PCM through the same circuit. The distributor pick-up signal is sent to the PCM.

If the PCM does not receive a distributor signal

within approximately one second of engine cranking,

the ASD relay and fuel pump relay are deactivated.

When these relays are deactivated, power is shut off

to the fuel injector, ignition coil, oxygen sensor heat-

ing element and fuel pump. The PCM contains a voltage converter that

changes battery voltage to a regulated 8.0 volts. The

8.0 volts power the distributor pick-up and vehicle

speed sensor. The PCM also provides a 5.0 volts sup-

ply for the coolant temperature sensor, manifold ab-

solute pressure sensor and throttle position sensor.

AIR CONDITIONING SWITCH SENSE (AA, AG, AJ

BODY)ÐPCM INPUT

When the air conditioning or defrost switch is in

the ON position and the low pressure and high pres-

sure switches are closed, the PCM receives an input

for air conditioning. After receiving this input, the

PCM activates the A/C compressor clutch by ground-

ing the A/C clutch relay. The PCM also adjusts idle

speed to a scheduled RPM to compensate for in-

creased engine load.

AIR CONDITIONING SWITCH SENSE (AC

BODY)ÐPCM INPUT

When the air conditioning or defrost switch is in

the ON position and the low pressure, high pressure

and ambient temperature switches are closed, the

PCM receives an input for air conditioning. After re-

ceiving this input, the PCM activates the A/C com-

pressor clutch by grounding the A/C clutch relay.

The PCM also adjusts idle speed to a scheduled RPM

to compensate for increased engine load.

BATTERY VOLTAGEÐPCM INPUT

The PCM monitors the battery voltage input to de-

termine fuel injector pulse width and generator field

control. If battery voltage is low, the PCM will in-

crease injector pulse width.

BRAKE SWITCHÐPCM INPUT

When the brake switch is activated, the PCM re-

ceives an input indicating that the brakes are being

applied. After receiving this input the PCM main-

tains idle speed to a scheduled RPM through the idle

air control motor. The brake switch is mounted on

the brake pedal support bracket.

ENGINE COOLANT TEMPERATURE SENSORÐPCM

INPUT

The coolant temperature sensor is a variable resis-

tor with a range of -40É to 265É. The sensor is in-

stalled next to the thermostat housing. The PCM supplies 5.0 volts to the coolant temper-

ature sensor. The sensor provides an input voltage to

the PCM (Fig. 3). As coolant temperature varies, the

sensors resistance changes, resulting in a different

input voltage to the PCM. The PCM demands slightly richer air-fuel mixtures

and higher idle speeds until the engine reaches nor-

mal operating temperature. This sensor is also used for cooling fan control.

DISTRIBUTOR PICK-UPÐPCM INPUT

The distributor pick-up provides two inputs to the

PCM. From one input the PCM determines RPM (en-

gine speed). From the other input it derives crank-

shaft position. The PCM regulates injector

synchronization and adjusts ignition timing and en-

gine speed based on these inputs. The distributor pick-up contains two signal gener-

ators. The pick-up unit consists of 2 light emitting

diodes (LED), 2 photo diodes, and a separate timing

disk. The timing disk contains two sets of slots. Each

set of slots rotates between a light emitting diode

and a photo diode (Fig. 4). The inner set contains 6

large slots, one for each cylinder. The outer set con-

tains several smaller slots. The outer set of slots on the rotating disk repre-

sents 2 degrees of crankshaft rotation. Up to 1200

engine RPM, the PCM uses the input from the outer

set of slots to increase ignition timing accuracy. The outer set of slots contains a 10 degree flat spot

(Fig. 5). The flat spot tells the PCM that the next

piston at TDC will be number 6. The position of each

piston is referenced by one of the six inner slots (Fig.

5). As each slot on the timing disk passes between the

diodes, the beam from the light emitting diode is in-

Fig. 3 Coolant Temperature Sensor

Ä FUEL SYSTEMS 14 - 115

Page 1859 of 2438

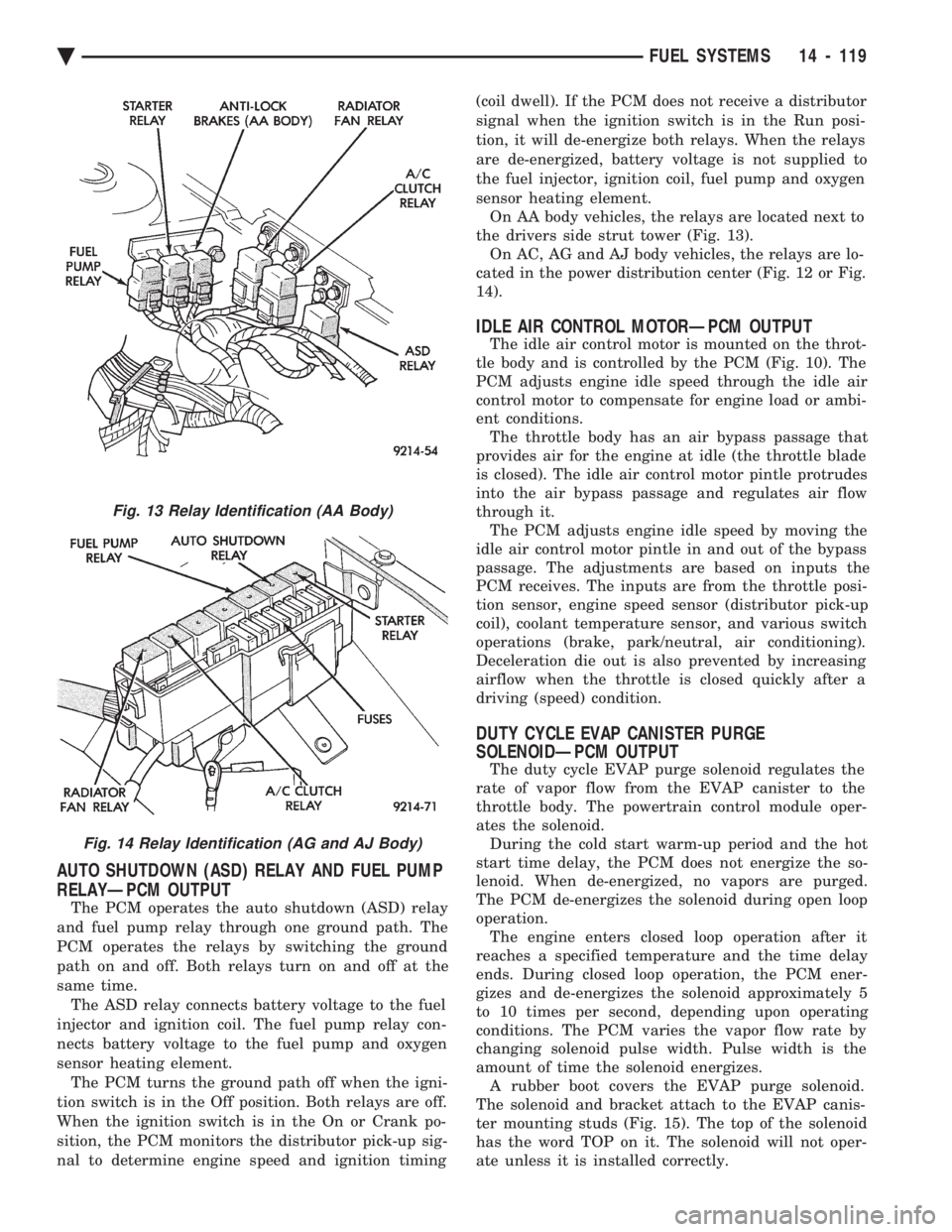

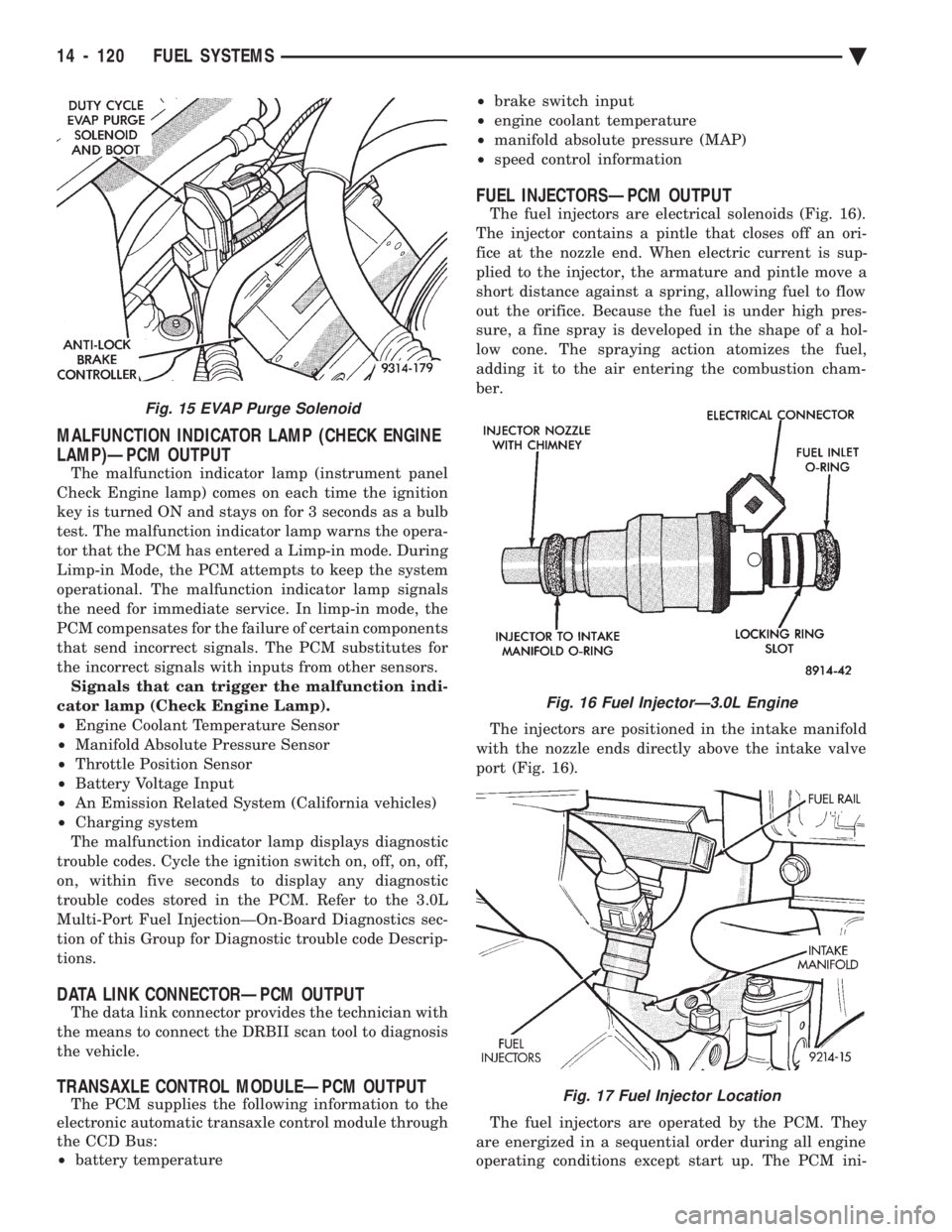

AUTO SHUTDOWN (ASD) RELAY AND FUEL PUMP

RELAYÐPCM OUTPUT

The PCM operates the auto shutdown (ASD) relay

and fuel pump relay through one ground path. The

PCM operates the relays by switching the ground

path on and off. Both relays turn on and off at the

same time. The ASD relay connects battery voltage to the fuel

injector and ignition coil. The fuel pump relay con-

nects battery voltage to the fuel pump and oxygen

sensor heating element. The PCM turns the ground path off when the igni-

tion switch is in the Off position. Both relays are off.

When the ignition switch is in the On or Crank po-

sition, the PCM monitors the distributor pick-up sig-

nal to determine engine speed and ignition timing (coil dwell). If the PCM does not receive a distributor

signal when the ignition switch is in the Run posi-

tion, it will de-energize both relays. When the relays

are de-energized, battery voltage is not supplied to

the fuel injector, ignition coil, fuel pump and oxygen

sensor heating element. On AA body vehicles, the relays are located next to

the drivers side strut tower (Fig. 13). On AC, AG and AJ body vehicles, the relays are lo-

cated in the power distribution center (Fig. 12 or Fig.

14).

IDLE AIR CONTROL MOTORÐPCM OUTPUT

The idle air control motor is mounted on the throt-

tle body and is controlled by the PCM (Fig. 10). The

PCM adjusts engine idle speed through the idle air

control motor to compensate for engine load or ambi-

ent conditions. The throttle body has an air bypass passage that

provides air for the engine at idle (the throttle blade

is closed). The idle air control motor pintle protrudes

into the air bypass passage and regulates air flow

through it. The PCM adjusts engine idle speed by moving the

idle air control motor pintle in and out of the bypass

passage. The adjustments are based on inputs the

PCM receives. The inputs are from the throttle posi-

tion sensor, engine speed sensor (distributor pick-up

coil), coolant temperature sensor, and various switch

operations (brake, park/neutral, air conditioning).

Deceleration die out is also prevented by increasing

airflow when the throttle is closed quickly after a

driving (speed) condition.

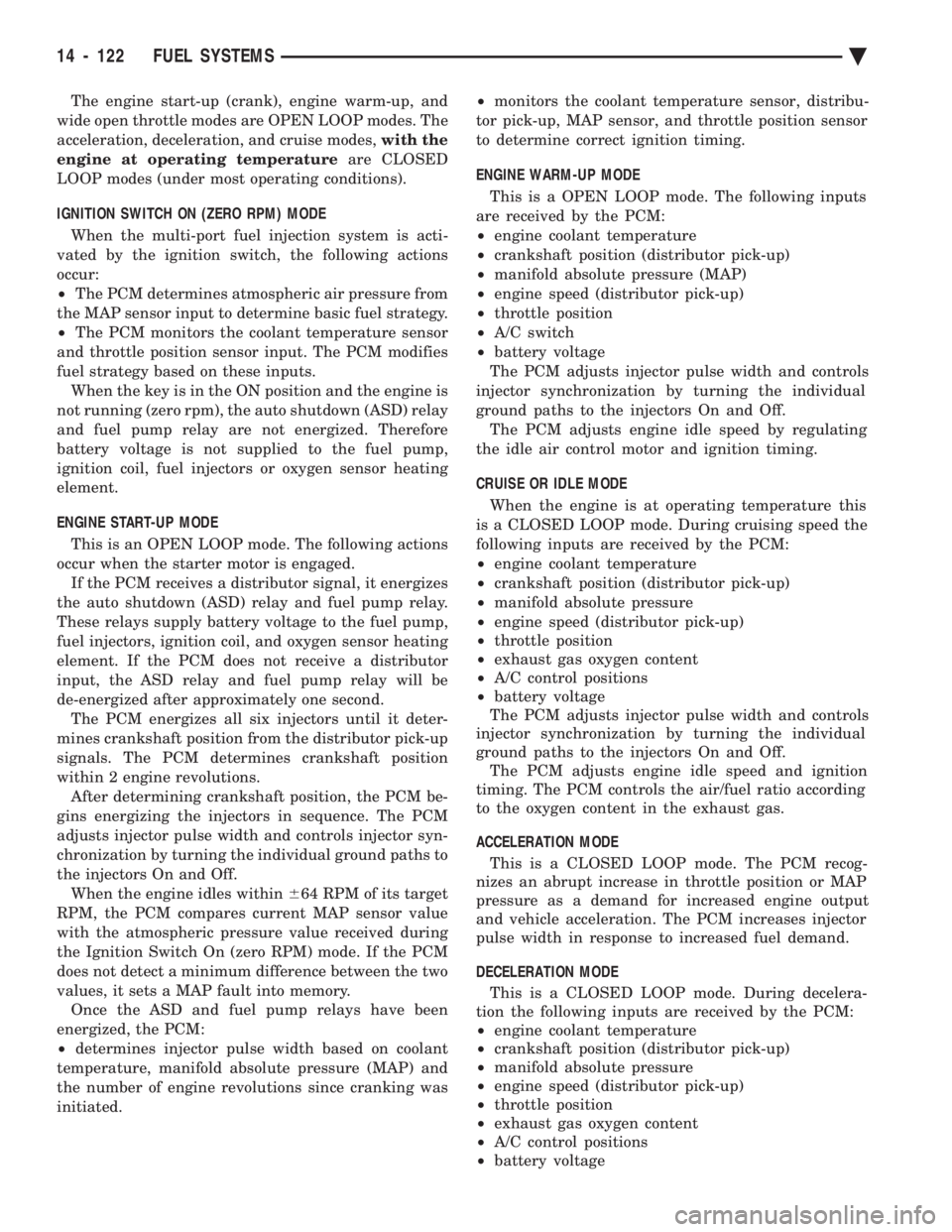

DUTY CYCLE EVAP CANISTER PURGE

SOLENOIDÐPCM OUTPUT

The duty cycle EVAP purge solenoid regulates the

rate of vapor flow from the EVAP canister to the

throttle body. The powertrain control module oper-

ates the solenoid. During the cold start warm-up period and the hot

start time delay, the PCM does not energize the so-

lenoid. When de-energized, no vapors are purged.

The PCM de-energizes the solenoid during open loop

operation. The engine enters closed loop operation after it

reaches a specified temperature and the time delay

ends. During closed loop operation, the PCM ener-

gizes and de-energizes the solenoid approximately 5

to 10 times per second, depending upon operating

conditions. The PCM varies the vapor flow rate by

changing solenoid pulse width. Pulse width is the

amount of time the solenoid energizes. A rubber boot covers the EVAP purge solenoid.

The solenoid and bracket attach to the EVAP canis-

ter mounting studs (Fig. 15). The top of the solenoid

has the word TOP on it. The solenoid will not oper-

ate unless it is installed correctly.

Fig. 13 Relay Identification (AA Body)

Fig. 14 Relay Identification (AG and AJ Body)

Ä FUEL SYSTEMS 14 - 119

Page 1860 of 2438

MALFUNCTION INDICATOR LAMP (CHECK ENGINE

LAMP)ÐPCM OUTPUT

The malfunction indicator lamp (instrument panel

Check Engine lamp) comes on each time the ignition

key is turned ON and stays on for 3 seconds as a bulb

test. The malfunction indicator lamp warns the opera-

tor that the PCM has entered a Limp-in mode. During

Limp-in Mode, the PCM attempts to keep the system

operational. The malfunction indicator lamp signals

the need for immediate service. In limp-in mode, the

PCM compensates for the failure of certain components

that send incorrect signals. The PCM substitutes for

the incorrect signals with inputs from other sensors. Signals that can trigger the malfunction indi-

cator lamp (Check Engine Lamp).

² Engine Coolant Temperature Sensor

² Manifold Absolute Pressure Sensor

² Throttle Position Sensor

² Battery Voltage Input

² An Emission Related System (California vehicles)

² Charging system

The malfunction indicator lamp displays diagnostic

trouble codes. Cycle the ignition switch on, off, on, off,

on, within five seconds to display any diagnostic

trouble codes stored in the PCM. Refer to the 3.0L

Multi-Port Fuel InjectionÐOn-Board Diagnostics sec-

tion of this Group for Diagnostic trouble code Descrip-

tions.

DATA LINK CONNECTORÐPCM OUTPUT

The data link connector provides the technician with

the means to connect the DRBII scan tool to diagnosis

the vehicle.

TRANSAXLE CONTROL MODULEÐPCM OUTPUT

The PCM supplies the following information to the

electronic automatic transaxle control module through

the CCD Bus:

² battery temperature ²

brake switch input

² engine coolant temperature

² manifold absolute pressure (MAP)

² speed control information

FUEL INJECTORSÐPCM OUTPUT

The fuel injectors are electrical solenoids (Fig. 16).

The injector contains a pintle that closes off an ori-

fice at the nozzle end. When electric current is sup-

plied to the injector, the armature and pintle move a

short distance against a spring, allowing fuel to flow

out the orifice. Because the fuel is under high pres-

sure, a fine spray is developed in the shape of a hol-

low cone. The spraying action atomizes the fuel,

adding it to the air entering the combustion cham-

ber.

The injectors are positioned in the intake manifold

with the nozzle ends directly above the intake valve

port (Fig. 16).

The fuel injectors are operated by the PCM. They

are energized in a sequential order during all engine

operating conditions except start up. The PCM ini-

Fig. 16 Fuel InjectorÐ3.0L Engine

Fig. 17 Fuel Injector Location

Fig. 15 EVAP Purge Solenoid

14 - 120 FUEL SYSTEMS Ä

Page 1862 of 2438

The engine start-up (crank), engine warm-up, and

wide open throttle modes are OPEN LOOP modes. The

acceleration, deceleration, and cruise modes, with the

engine at operating temperature are CLOSED

LOOP modes (under most operating conditions).

IGNITION SWITCH ON (ZERO RPM) MODE

When the multi-port fuel injection system is acti-

vated by the ignition switch, the following actions

occur:

² The PCM determines atmospheric air pressure from

the MAP sensor input to determine basic fuel strategy.

² The PCM monitors the coolant temperature sensor

and throttle position sensor input. The PCM modifies

fuel strategy based on these inputs. When the key is in the ON position and the engine is

not running (zero rpm), the auto shutdown (ASD) relay

and fuel pump relay are not energized. Therefore

battery voltage is not supplied to the fuel pump,

ignition coil, fuel injectors or oxygen sensor heating

element.

ENGINE START-UP MODE

This is an OPEN LOOP mode. The following actions

occur when the starter motor is engaged. If the PCM receives a distributor signal, it energizes

the auto shutdown (ASD) relay and fuel pump relay.

These relays supply battery voltage to the fuel pump,

fuel injectors, ignition coil, and oxygen sensor heating

element. If the PCM does not receive a distributor

input, the ASD relay and fuel pump relay will be

de-energized after approximately one second. The PCM energizes all six injectors until it deter-

mines crankshaft position from the distributor pick-up

signals. The PCM determines crankshaft position

within 2 engine revolutions. After determining crankshaft position, the PCM be-

gins energizing the injectors in sequence. The PCM

adjusts injector pulse width and controls injector syn-

chronization by turning the individual ground paths to

the injectors On and Off. When the engine idles within 664 RPM of its target

RPM, the PCM compares current MAP sensor value

with the atmospheric pressure value received during

the Ignition Switch On (zero RPM) mode. If the PCM

does not detect a minimum difference between the two

values, it sets a MAP fault into memory. Once the ASD and fuel pump relays have been

energized, the PCM:

² determines injector pulse width based on coolant

temperature, manifold absolute pressure (MAP) and

the number of engine revolutions since cranking was

initiated. ²

monitors the coolant temperature sensor, distribu-

tor pick-up, MAP sensor, and throttle position sensor

to determine correct ignition timing.

ENGINE WARM-UP MODE

This is a OPEN LOOP mode. The following inputs

are received by the PCM:

² engine coolant temperature

² crankshaft position (distributor pick-up)

² manifold absolute pressure (MAP)

² engine speed (distributor pick-up)

² throttle position

² A/C switch

² battery voltage

The PCM adjusts injector pulse width and controls

injector synchronization by turning the individual

ground paths to the injectors On and Off. The PCM adjusts engine idle speed by regulating

the idle air control motor and ignition timing.

CRUISE OR IDLE MODE

When the engine is at operating temperature this

is a CLOSED LOOP mode. During cruising speed the

following inputs are received by the PCM:

² engine coolant temperature

² crankshaft position (distributor pick-up)

² manifold absolute pressure

² engine speed (distributor pick-up)

² throttle position

² exhaust gas oxygen content

² A/C control positions

² battery voltage

The PCM adjusts injector pulse width and controls

injector synchronization by turning the individual

ground paths to the injectors On and Off. The PCM adjusts engine idle speed and ignition

timing. The PCM controls the air/fuel ratio according

to the oxygen content in the exhaust gas.

ACCELERATION MODE This is a CLOSED LOOP mode. The PCM recog-

nizes an abrupt increase in throttle position or MAP

pressure as a demand for increased engine output

and vehicle acceleration. The PCM increases injector

pulse width in response to increased fuel demand.

DECELERATION MODE This is a CLOSED LOOP mode. During decelera-

tion the following inputs are received by the PCM:

² engine coolant temperature

² crankshaft position (distributor pick-up)

² manifold absolute pressure

² engine speed (distributor pick-up)

² throttle position

² exhaust gas oxygen content

² A/C control positions

² battery voltage

14 - 122 FUEL SYSTEMS Ä

Page 1863 of 2438

The PCM may receive a closed throttle input from

the throttle position sensor (TPS) when it senses an

abrupt decrease in manifold pressure. This indicates

a hard deceleration. The PCM may reduce injector

firing to once per engine revolution. This helps main-

tain better control of the air-fuel mixture. During a deceleration condition, the PCM grounds

the exhaust gas recirculation (EGR) solenoid. When

the PCM grounds the solenoid, preventing EGR.

WIDE OPEN THROTTLE MODE This is an OPEN LOOP mode. During wide-open-

throttle operation, the following inputs are received

by the PCM:

² engine coolant temperature

² crankshaft position (distributor pick-up)

² manifold absolute pressure

² engine speed (distributor pick-up)

² throttle position

When the PCM senses wide open throttle condition

through the throttle position sensor (TPS) it will:

² Provide a ground for the electrical EGR transducer

(EET) solenoid. When the PCM grounds the solenoid,

the EGR system stops operating.

² De-energize the air conditioning relay. This dis-

ables the air conditioning system. The exhaust gas oxygen content input is not ac-

cepted by the PCM during wide open throttle opera- tion. The PCM will adjust injector pulse width to

supply a predetermined amount of additional fuel.

IGNITION SWITCH OFF MODE

When the ignition switch is turned to the OFF po-

sition, the following occurs:

² All outputs are turned off.

² No inputs are monitored.

² The PCM shuts down.

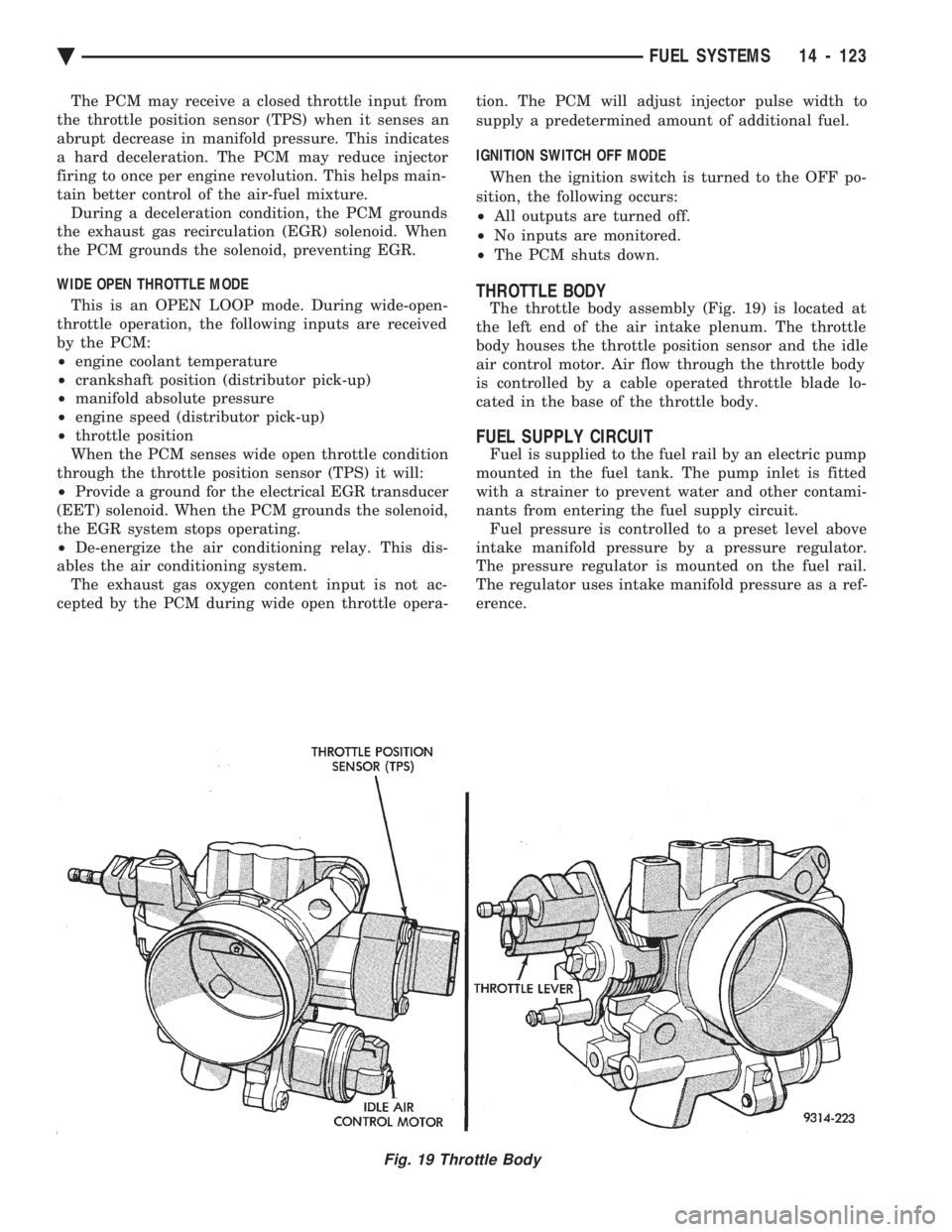

THROTTLE BODY

The throttle body assembly (Fig. 19) is located at

the left end of the air intake plenum. The throttle

body houses the throttle position sensor and the idle

air control motor. Air flow through the throttle body

is controlled by a cable operated throttle blade lo-

cated in the base of the throttle body.

FUEL SUPPLY CIRCUIT

Fuel is supplied to the fuel rail by an electric pump

mounted in the fuel tank. The pump inlet is fitted

with a strainer to prevent water and other contami-

nants from entering the fuel supply circuit. Fuel pressure is controlled to a preset level above

intake manifold pressure by a pressure regulator.

The pressure regulator is mounted on the fuel rail.

The regulator uses intake manifold pressure as a ref-

erence.

Fig. 19 Throttle Body

Ä FUEL SYSTEMS 14 - 123

Page 1866 of 2438

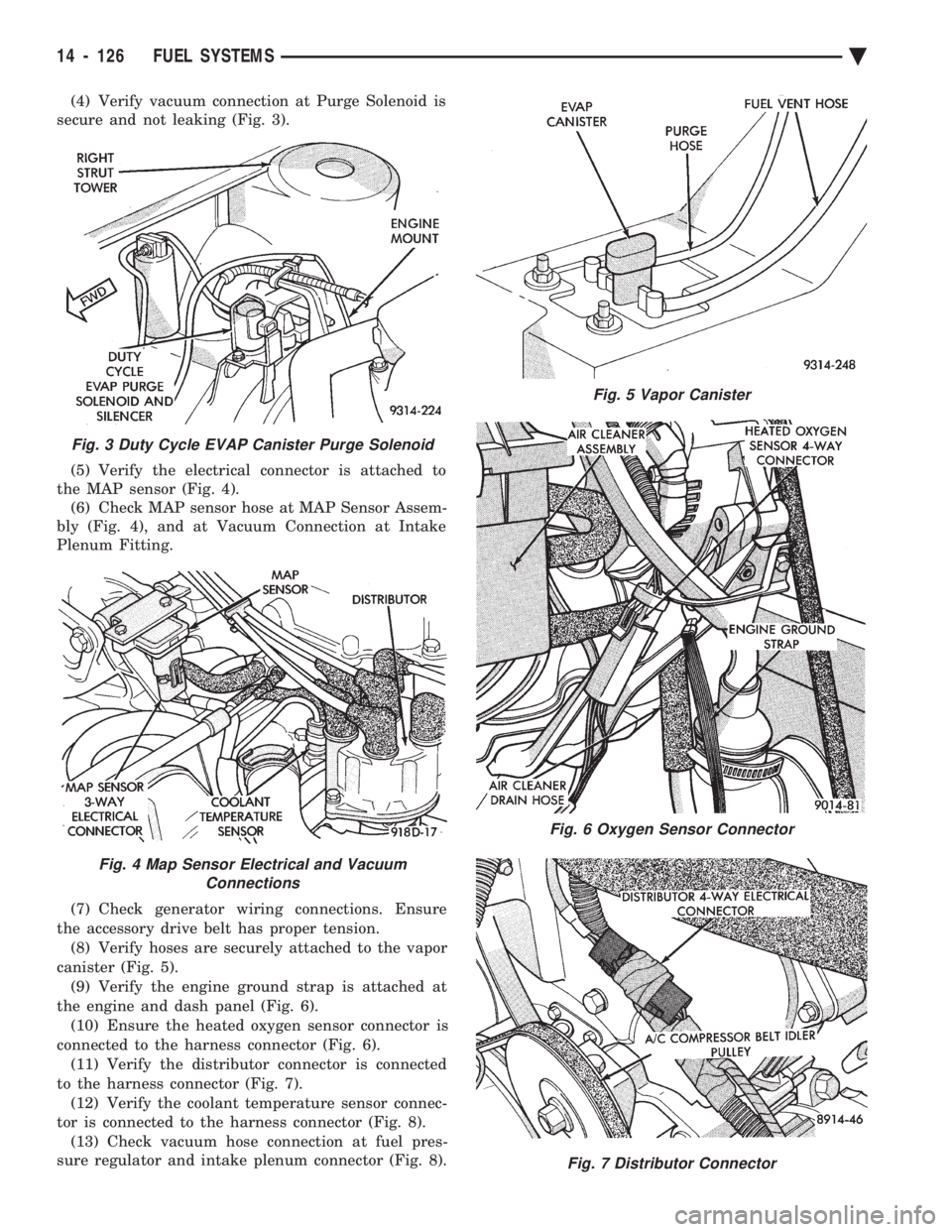

(4) Verify vacuum connection at Purge Solenoid is

secure and not leaking (Fig. 3).

(5) Verify the electrical connector is attached to

the MAP sensor (Fig. 4). (6) Check MAP sensor hose at MAP Sensor Assem-

bly (Fig. 4), and at Vacuum Connection at Intake

Plenum Fitting.

(7) Check generator wiring connections. Ensure

the accessory drive belt has proper tension. (8) Verify hoses are securely attached to the vapor

canister (Fig. 5). (9) Verify the engine ground strap is attached at

the engine and dash panel (Fig. 6). (10) Ensure the heated oxygen sensor connector is

connected to the harness connector (Fig. 6). (11) Verify the distributor connector is connected

to the harness connector (Fig. 7). (12) Verify the coolant temperature sensor connec-

tor is connected to the harness connector (Fig. 8). (13) Check vacuum hose connection at fuel pres-

sure regulator and intake plenum connector (Fig. 8).

Fig. 3 Duty Cycle EVAP Canister Purge Solenoid

Fig. 4 Map Sensor Electrical and Vacuum Connections

Fig. 5 Vapor Canister

Fig. 6 Oxygen Sensor Connector

Fig. 7 Distributor Connector

14 - 126 FUEL SYSTEMS Ä

Page 1874 of 2438

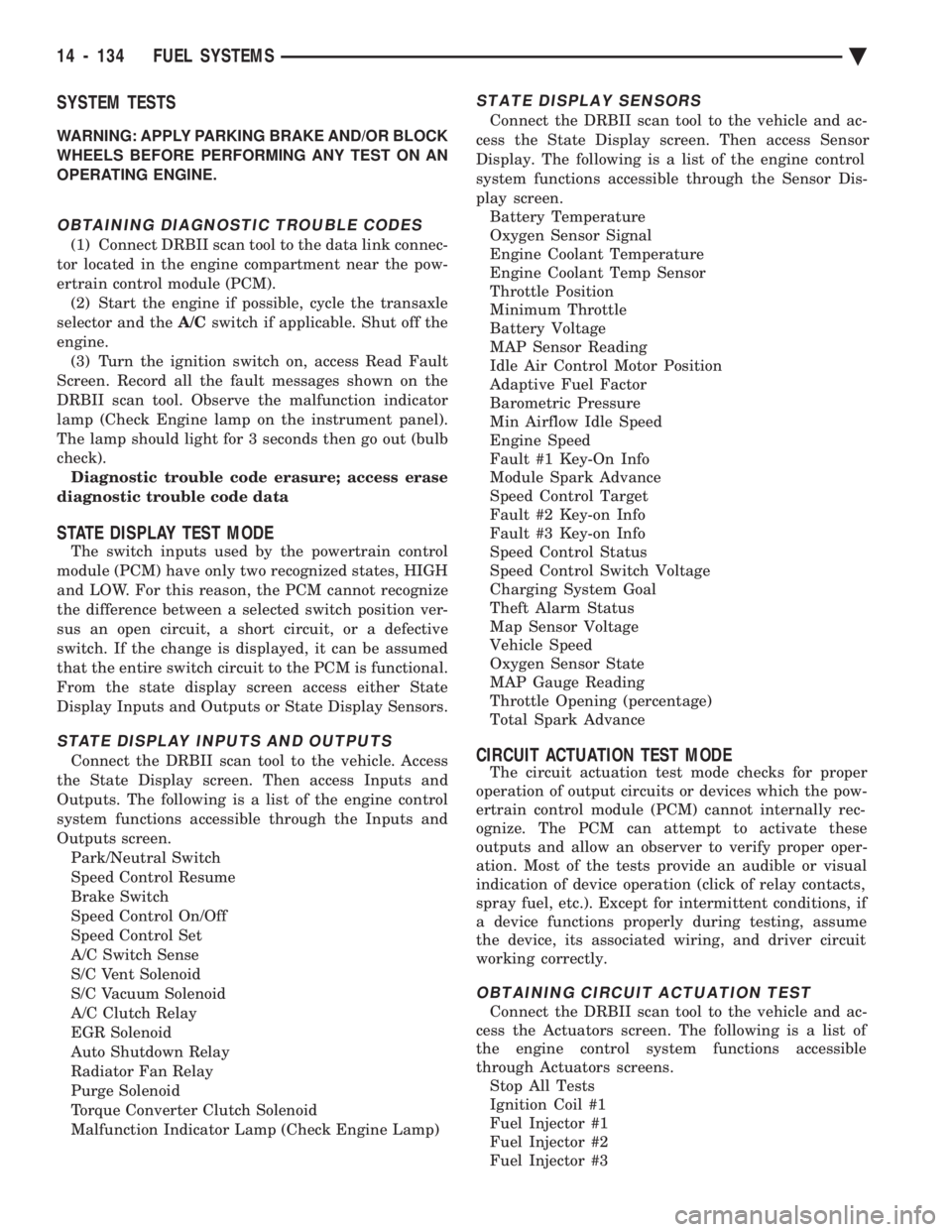

SYSTEM TESTS

WARNING: APPLY PARKING BRAKE AND/OR BLOCK

WHEELS BEFORE PERFORMING ANY TEST ON AN

OPERATING ENGINE.

OBTAINING DIAGNOSTIC TROUBLE CODES

(1) Connect DRBII scan tool to the data link connec-

tor located in the engine compartment near the pow-

ertrain control module (PCM). (2) Start the engine if possible, cycle the transaxle

selector and the A/Cswitch if applicable. Shut off the

engine. (3) Turn the ignition switch on, access Read Fault

Screen. Record all the fault messages shown on the

DRBII scan tool. Observe the malfunction indicator

lamp (Check Engine lamp on the instrument panel).

The lamp should light for 3 seconds then go out (bulb

check). Diagnostic trouble code erasure; access erase

diagnostic trouble code data

STATE DISPLAY TEST MODE

The switch inputs used by the powertrain control

module (PCM) have only two recognized states, HIGH

and LOW. For this reason, the PCM cannot recognize

the difference between a selected switch position ver-

sus an open circuit, a short circuit, or a defective

switch. If the change is displayed, it can be assumed

that the entire switch circuit to the PCM is functional.

From the state display screen access either State

Display Inputs and Outputs or State Display Sensors.

STATE DISPLAY INPUTS AND OUTPUTS

Connect the DRBII scan tool to the vehicle. Access

the State Display screen. Then access Inputs and

Outputs. The following is a list of the engine control

system functions accessible through the Inputs and

Outputs screen. Park/Neutral Switch

Speed Control Resume

Brake Switch

Speed Control On/Off

Speed Control Set

A/C Switch Sense

S/C Vent Solenoid

S/C Vacuum Solenoid

A/C Clutch Relay

EGR Solenoid

Auto Shutdown Relay

Radiator Fan Relay

Purge Solenoid

Torque Converter Clutch Solenoid

Malfunction Indicator Lamp (Check Engine Lamp)

STATE DISPLAY SENSORS

Connect the DRBII scan tool to the vehicle and ac-

cess the State Display screen. Then access Sensor

Display. The following is a list of the engine control

system functions accessible through the Sensor Dis-

play screen. Battery Temperature

Oxygen Sensor Signal

Engine Coolant Temperature

Engine Coolant Temp Sensor

Throttle Position

Minimum Throttle

Battery Voltage

MAP Sensor Reading

Idle Air Control Motor Position

Adaptive Fuel Factor

Barometric Pressure

Min Airflow Idle Speed

Engine Speed

Fault #1 Key-On Info

Module Spark Advance

Speed Control Target

Fault #2 Key-on Info

Fault #3 Key-on Info

Speed Control Status

Speed Control Switch Voltage

Charging System Goal

Theft Alarm Status

Map Sensor Voltage

Vehicle Speed

Oxygen Sensor State

MAP Gauge Reading

Throttle Opening (percentage)

Total Spark Advance

CIRCUIT ACTUATION TEST MODE

The circuit actuation test mode checks for proper

operation of output circuits or devices which the pow-

ertrain control module (PCM) cannot internally rec-

ognize. The PCM can attempt to activate these

outputs and allow an observer to verify proper oper-

ation. Most of the tests provide an audible or visual

indication of device operation (click of relay contacts,

spray fuel, etc.). Except for intermittent conditions, if

a device functions properly during testing, assume

the device, its associated wiring, and driver circuit

working correctly.

OBTAINING CIRCUIT ACTUATION TEST

Connect the DRBII scan tool to the vehicle and ac-

cess the Actuators screen. The following is a list of

the engine control system functions accessible

through Actuators screens. Stop All Tests

Ignition Coil #1

Fuel Injector #1

Fuel Injector #2

Fuel Injector #3

14 - 134 FUEL SYSTEMS Ä