engine CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 653 of 2438

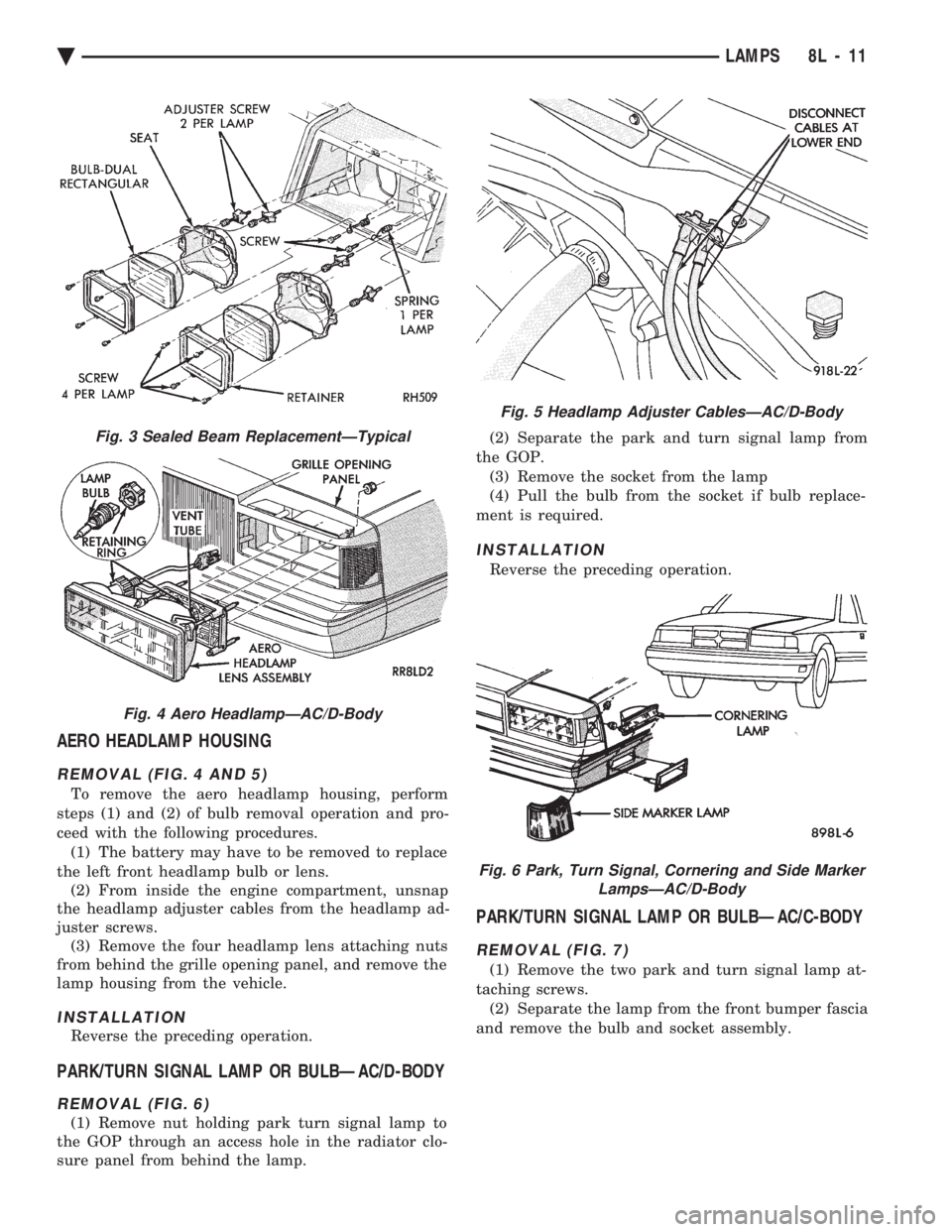

AERO HEADLAMP HOUSING

REMOVAL (FIG. 4 AND 5)

To remove the aero headlamp housing, perform

steps (1) and (2) of bulb removal operation and pro-

ceed with the following procedures. (1) The battery may have to be removed to replace

the left front headlamp bulb or lens. (2) From inside the engine compartment, unsnap

the headlamp adjuster cables from the headlamp ad-

juster screws. (3) Remove the four headlamp lens attaching nuts

from behind the grille opening panel, and remove the

lamp housing from the vehicle.

INSTALLATION

Reverse the preceding operation.

PARK/TURN SIGNAL LAMP OR BULBÐAC/D-BODY

REMOVAL (FIG. 6)

(1) Remove nut holding park turn signal lamp to

the GOP through an access hole in the radiator clo-

sure panel from behind the lamp. (2) Separate the park and turn signal lamp from

the GOP. (3) Remove the socket from the lamp

(4) Pull the bulb from the socket if bulb replace-

ment is required.

INSTALLATION

Reverse the preceding operation.

PARK/TURN SIGNAL LAMP OR BULBÐAC/C-BODY

REMOVAL (FIG. 7)

(1) Remove the two park and turn signal lamp at-

taching screws. (2) Separate the lamp from the front bumper fascia

and remove the bulb and socket assembly.

Fig. 3 Sealed Beam ReplacementÐTypical

Fig. 4 Aero HeadlampÐAC/D-Body

Fig. 5 Headlamp Adjuster CablesÐAC/D-Body

Fig. 6 Park, Turn Signal, Cornering and Side Marker LampsÐAC/D-Body

Ä LAMPS 8L - 11

Page 661 of 2438

EXTERIOR LAMPSÐAP BODY INDEX

page page

Center High Mounted Stop Lamp (CHMSL)Ð AP/24-44-Body ......................... 21

Center High Mounted Stop Lamp BulbÐ AP/24-44-Body ......................... 21

Fog Lamp Bulb .......................... 21

Fog Lamps ............................. 21

Front Side Marker Lamp or Bulb ............. 20

Headlamp Bulb .......................... 19 Headlamp Diagnosis

...................... 19

Headlamp Housing ....................... 19

License Plate Lamp or Bulb ................ 20

Park and Turn Signal Lamp or Bulb .......... 20

Tail, Stop, Turn Signal, Back-Up and Side Marker Lamp ................................ 20

Tail, Stop, Turn Signal, Back-Up and Side Marker Lamp Bulbs ........................... 20

HEADLAMP DIAGNOSIS

For headlamp diagnosis, refer to the headlamp di-

agnosis chart at the beginning of this group. Refer to

Wiring Diagrams manual for circuit and component

locations.

HEADLAMP BULB

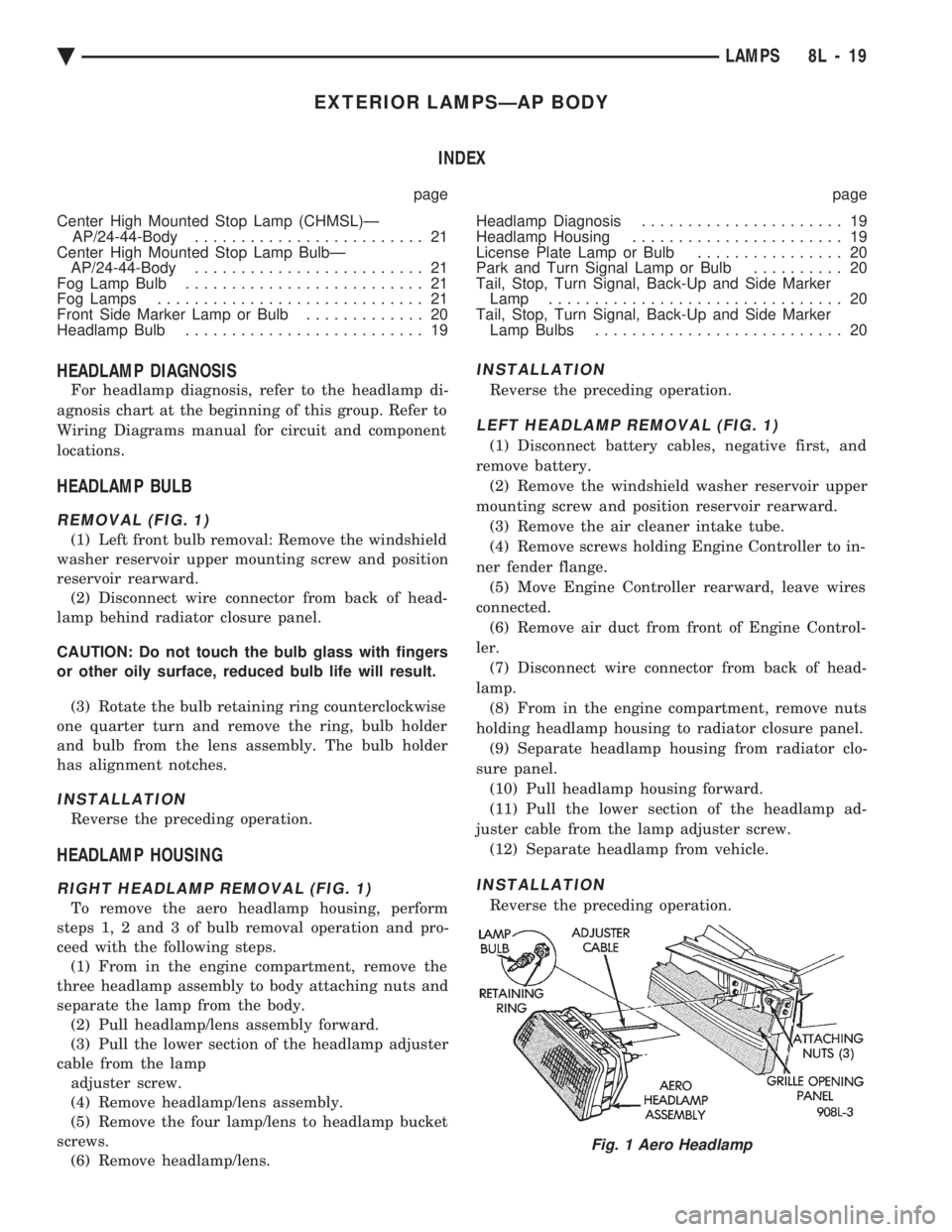

REMOVAL (FIG. 1)

(1) Left front bulb removal: Remove the windshield

washer reservoir upper mounting screw and position

reservoir rearward. (2) Disconnect wire connector from back of head-

lamp behind radiator closure panel.

CAUTION: Do not touch the bulb glass with fingers

or other oily surface, reduced bulb life will result.

(3) Rotate the bulb retaining ring counterclockwise

one quarter turn and remove the ring, bulb holder

and bulb from the lens assembly. The bulb holder

has alignment notches.

INSTALLATION

Reverse the preceding operation.

HEADLAMP HOUSING

RIGHT HEADLAMP REMOVAL (FIG. 1)

To remove the aero headlamp housing, perform

steps 1, 2 and 3 of bulb removal operation and pro-

ceed with the following steps. (1) From in the engine compartment, remove the

three headlamp assembly to body attaching nuts and

separate the lamp from the body. (2) Pull headlamp/lens assembly forward.

(3) Pull the lower section of the headlamp adjuster

cable from the lamp adjuster screw.

(4) Remove headlamp/lens assembly.

(5) Remove the four lamp/lens to headlamp bucket

screws. (6) Remove headlamp/lens.

INSTALLATION

Reverse the preceding operation.

LEFT HEADLAMP REMOVAL (FIG. 1)

(1) Disconnect battery cables, negative first, and

remove battery. (2) Remove the windshield washer reservoir upper

mounting screw and position reservoir rearward. (3) Remove the air cleaner intake tube.

(4) Remove screws holding Engine Controller to in-

ner fender flange. (5) Move Engine Controller rearward, leave wires

connected. (6) Remove air duct from front of Engine Control-

ler. (7) Disconnect wire connector from back of head-

lamp. (8) From in the engine compartment, remove nuts

holding headlamp housing to radiator closure panel. (9) Separate headlamp housing from radiator clo-

sure panel. (10) Pull headlamp housing forward.

(11) Pull the lower section of the headlamp ad-

juster cable from the lamp adjuster screw. (12) Separate headlamp from vehicle.

INSTALLATION

Reverse the preceding operation.

Fig. 1 Aero Headlamp

Ä LAMPS 8L - 19

Page 680 of 2438

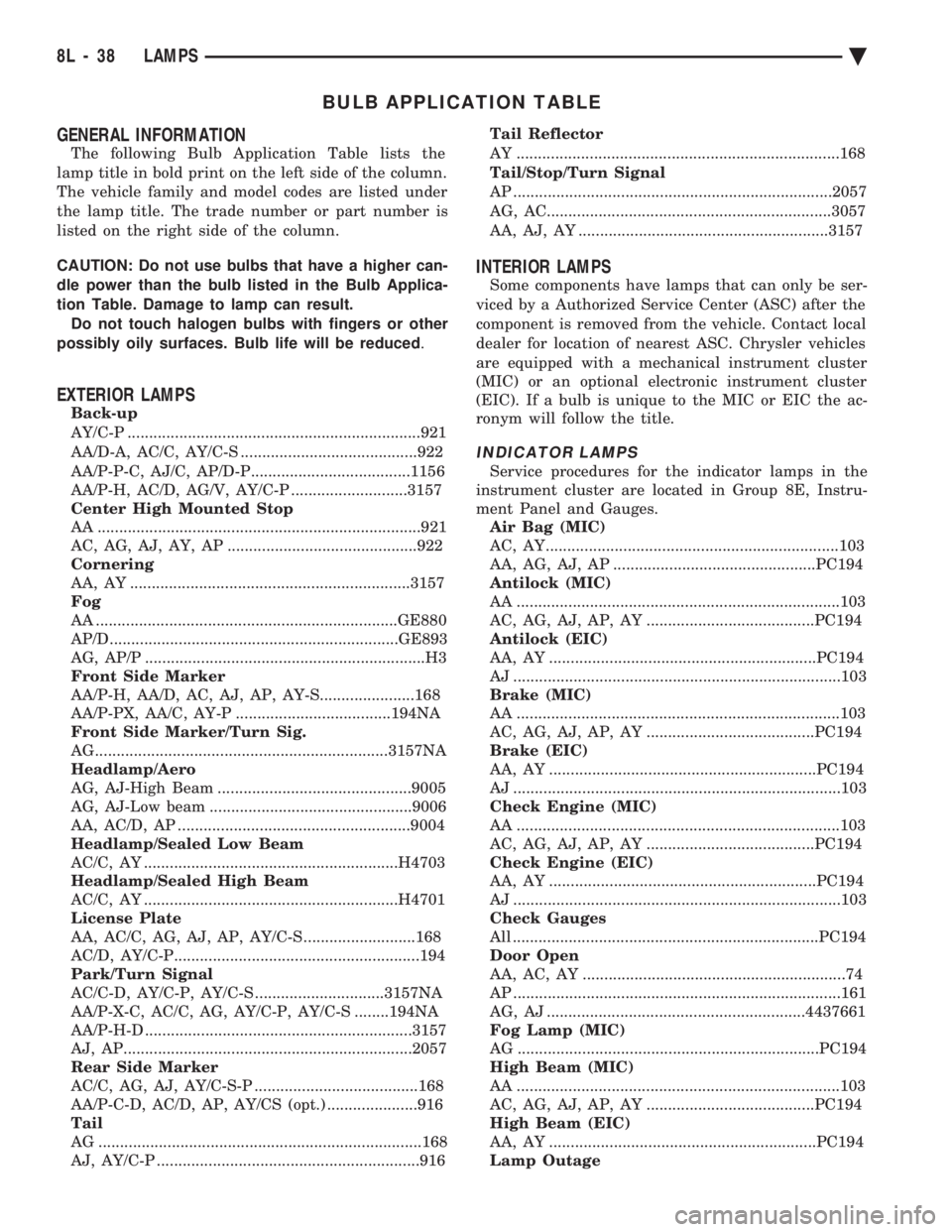

BULB APPLICATION TABLE

GENERAL INFORMATION

The following Bulb Application Table lists the

lamp title in bold print on the left side of the column.

The vehicle family and model codes are listed under

the lamp title. The trade number or part number is

listed on the right side of the column.

CAUTION: Do not use bulbs that have a higher can-

dle power than the bulb listed in the Bulb Applica-

tion Table. Damage to lamp can result. Do not touch halogen bulbs with fingers or other

possibly oily surfaces. Bulb life will be reduced .

EXTERIOR LAMPS

Back-up

AY/C-P ....................................................................921

AA/D-A, AC/C, AY/C-S .........................................922

AA/P-P-C, AJ/C, AP/D-P.....................................1156

AA/P-H, AC/D, AG/V, AY/C-P ...........................3157

Center High Mounted Stop

AA ...........................................................................921

AC, AG, AJ, AY, AP ............................................922

Cornering

AA, AY .................................................................3157

Fog

AA ......................................................................GE880

AP/D...................................................................GE893

AG, AP/P .................................................................H3

Front Side Marker

AA/P-H, AA/D, AC, AJ, AP, AY-S......................168

AA/P-PX, AA/C, AY-P ....................................194NA

Front Side Marker/Turn Sig.

AG....................................................................3157NA

Headlamp/Aero

AG, AJ-High Beam .............................................9005

AG, AJ-Low beam ...............................................9006

AA, AC/D, AP ......................................................9004

Headlamp/Sealed Low Beam

AC/C, AY ...........................................................H4703

Headlamp/Sealed High Beam

AC/C, AY ...........................................................H4701

License Plate

AA, AC/C, AG, AJ, AP, AY/C-S ..........................168

AC/D, AY/C-P.........................................................194

Park/Turn Signal

AC/C-D, AY/C-P, AY/C-S ..............................3157NA

AA/P-X-C, AC/C, AG, AY/C-P, AY/C-S ........194NA

AA/P-H-D ..............................................................3157

AJ, AP...................................................................2057

Rear Side Marker

AC/C, AG, AJ, AY/C-S-P ......................................168

AA/P-C-D, AC/D, AP, AY/CS (opt.) .....................916

Tail

AG ...........................................................................168

AJ, AY/C-P .............................................................916 Tail Reflector

AY ...........................................................................168

Tail/Stop/Turn Signal

AP ..........................................................................2057

AG, AC..................................................................3057

AA, AJ, AY ..........................................................3157

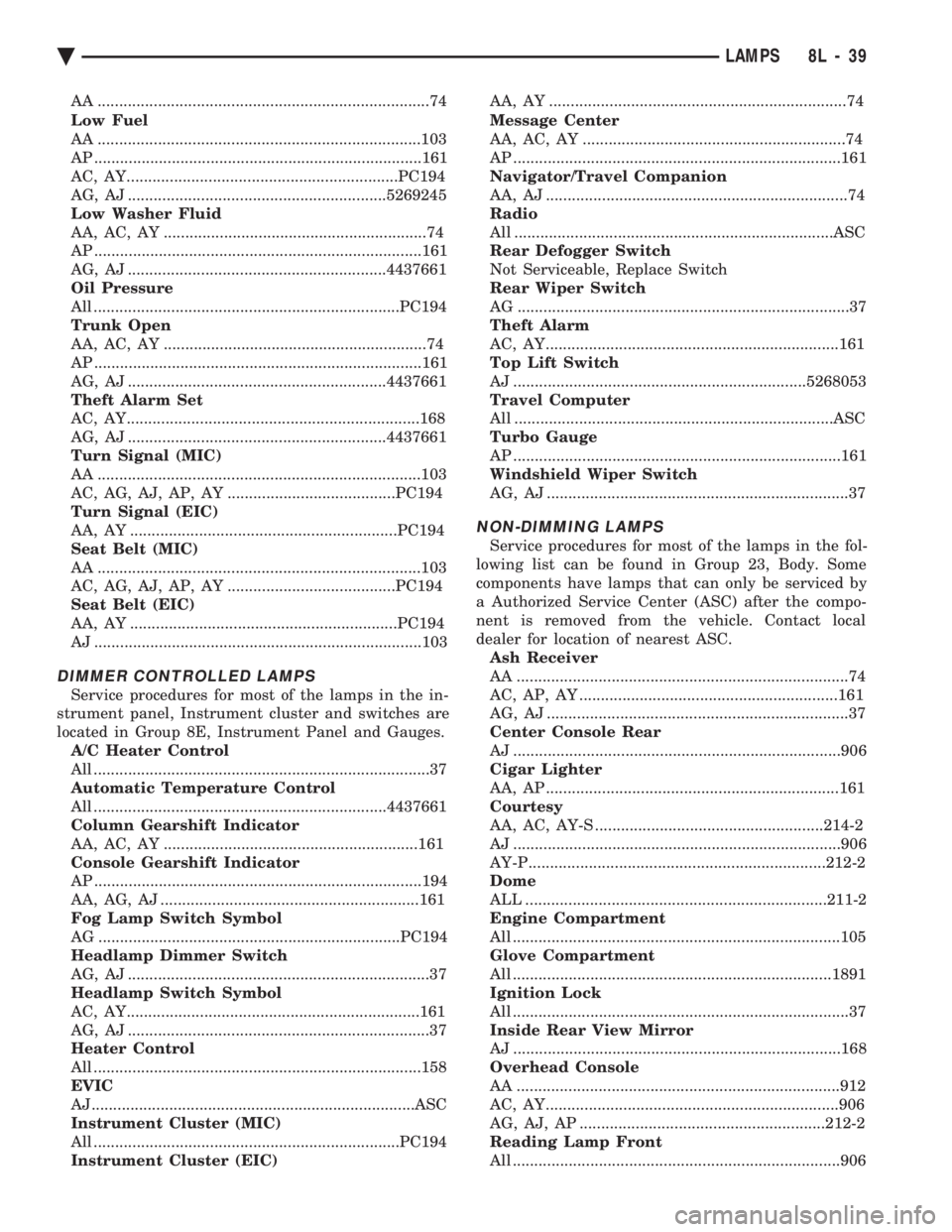

INTERIOR LAMPS

Some components have lamps that can only be ser-

viced by a Authorized Service Center (ASC) after the

component is removed from the vehicle. Contact local

dealer for location of nearest ASC. Chrysler vehicles

are equipped with a mechanical instrument cluster

(MIC) or an optional electronic instrument cluster

(EIC). If a bulb is unique to the MIC or EIC the ac-

ronym will follow the title.

INDICATOR LAMPS

Service procedures for the indicator lamps in the

instrument cluster are located in Group 8E, Instru-

ment Panel and Gauges. Air Bag (MIC)

AC, AY....................................................................103

AA, AG, AJ, AP ...............................................PC194

Antilock (MIC)

AA ...........................................................................103

AC, AG, AJ, AP, AY .......................................PC194

Antilock (EIC)

AA, AY ..............................................................PC194

AJ ............................................................................103

Brake (MIC)

AA ...........................................................................103

AC, AG, AJ, AP, AY .......................................PC194

Brake (EIC)

AA, AY ..............................................................PC194

AJ ............................................................................103

Check Engine (MIC)

AA ...........................................................................103

AC, AG, AJ, AP, AY .......................................PC194

Check Engine (EIC)

AA, AY ..............................................................PC194

AJ ............................................................................103

Check Gauges

All .......................................................................PC194

Door Open

AA, AC, AY .............................................................74

AP ............................................................................161

AG, AJ ............................................................4437661

Fog Lamp (MIC)

AG ......................................................................PC194

High Beam (MIC)

AA ...........................................................................103

AC, AG, AJ, AP, AY .......................................PC194

High Beam (EIC)

AA, AY ..............................................................PC194

Lamp Outage

8L - 38 LAMPS Ä

Page 681 of 2438

AA .............................................................................74

Low Fuel

AA ...........................................................................103

AP ............................................................................161

AC, AY...............................................................PC194

AG, AJ ............................................................5269245

Low Washer Fluid

AA, AC, AY .............................................................74

AP ............................................................................161

AG, AJ ............................................................4437661

Oil Pressure

All .......................................................................PC194

Trunk Open

AA, AC, AY .............................................................74

AP ............................................................................161

AG, AJ ............................................................4437661

Theft Alarm Set

AC, AY....................................................................168

AG, AJ ............................................................4437661

Turn Signal (MIC)

AA ...........................................................................103

AC, AG, AJ, AP, AY .......................................PC194

Turn Signal (EIC)

AA, AY ..............................................................PC194

Seat Belt (MIC)

AA ...........................................................................103

AC, AG, AJ, AP, AY .......................................PC194

Seat Belt (EIC)

AA, AY ..............................................................PC194

AJ ............................................................................103

DIMMER CONTROLLED LAMPS

Service procedures for most of the lamps in the in-

strument panel, Instrument cluster and switches are

located in Group 8E, Instrument Panel and Gauges. A/C Heater Control

All ..............................................................................37

Automatic Temperature Control

All ....................................................................4437661

Column Gearshift Indicator

AA, AC, AY ...........................................................161

Console Gearshift Indicator

AP ............................................................................194

AA, AG, AJ ............................................................161

Fog Lamp Switch Symbol

AG ......................................................................PC194

Headlamp Dimmer Switch

AG, AJ ......................................................................37

Headlamp Switch Symbol

AC, AY....................................................................161

AG, AJ ......................................................................37

Heater Control

All ............................................................................158

EVIC

AJ...........................................................................ASC

Instrument Cluster (MIC)

All .......................................................................PC194

Instrument Cluster (EIC) AA, AY .....................................................................74

Message Center

AA, AC, AY .............................................................74

AP ............................................................................161

Navigator/Travel Companion

AA, AJ ......................................................................74

Radio

All ..........................................................................ASC

Rear Defogger Switch

Not Serviceable, Replace Switch

Rear Wiper Switch

AG .............................................................................37

Theft Alarm

AC, AY....................................................................161

Top Lift Switch

AJ ....................................................................5268053

Travel Computer

All ..........................................................................ASC

Turbo Gauge

AP ............................................................................161

Windshield Wiper Switch

AG, AJ ......................................................................37

NON-DIMMING LAMPS

Service procedures for most of the lamps in the fol-

lowing list can be found in Group 23, Body. Some

components have lamps that can only be serviced by

a Authorized Service Center (ASC) after the compo-

nent is removed from the vehicle. Contact local

dealer for location of nearest ASC. Ash Receiver

AA .............................................................................74

AC, AP, AY ............................................................161

AG, AJ ......................................................................37

Center Console Rear

AJ ............................................................................906

Cigar Lighter

AA, AP ....................................................................161

Courtesy

AA, AC, AY-S .....................................................214-2

AJ ............................................................................906

AY-P.....................................................................212-2

Dome

ALL ......................................................................211-2

Engine Compartment

All ............................................................................105

Glove Compartment

All ..........................................................................1891

Ignition Lock

All ..............................................................................37

Inside Rear View Mirror

AJ ............................................................................168

Overhead Console

AA ...........................................................................912

AC, AY....................................................................906

AG, AJ, AP .........................................................212-2

Reading Lamp Front

All ............................................................................906

Ä LAMPS 8L - 39

Page 686 of 2438

AIR BAG MODULE

WARNING: BEFORE BEGINNING ANY AIR BAG

SYSTEM REMOVAL OR INSTALLATION PROCE-

DURES, REMOVE AND ISOLATE THE BATTERY

NEGATIVE (-) CABLE (GROUND) FROM THE VEHI-

CLE BATTERY. THIS IS THE ONLY SURE WAY TO

DISABLE THE AIR BAG SYSTEM. FAILURE TO DO

THIS COULD RESULT IN ACCIDENTAL AIR BAG

DEPLOYMENT AND POSSIBLE PERSONAL INJURY. UNDEPLOYED AIR BAG REMOVAL FROM THE

STEERING WHEEL: DISCONNECT BATTERY

GROUND CABLE AND ISOLATE. ALLOW SYS-

TEM CAPACITOR TO DISCHARGE FOR TWO

MINUTES. BEGIN AIR BAG REMOVAL.

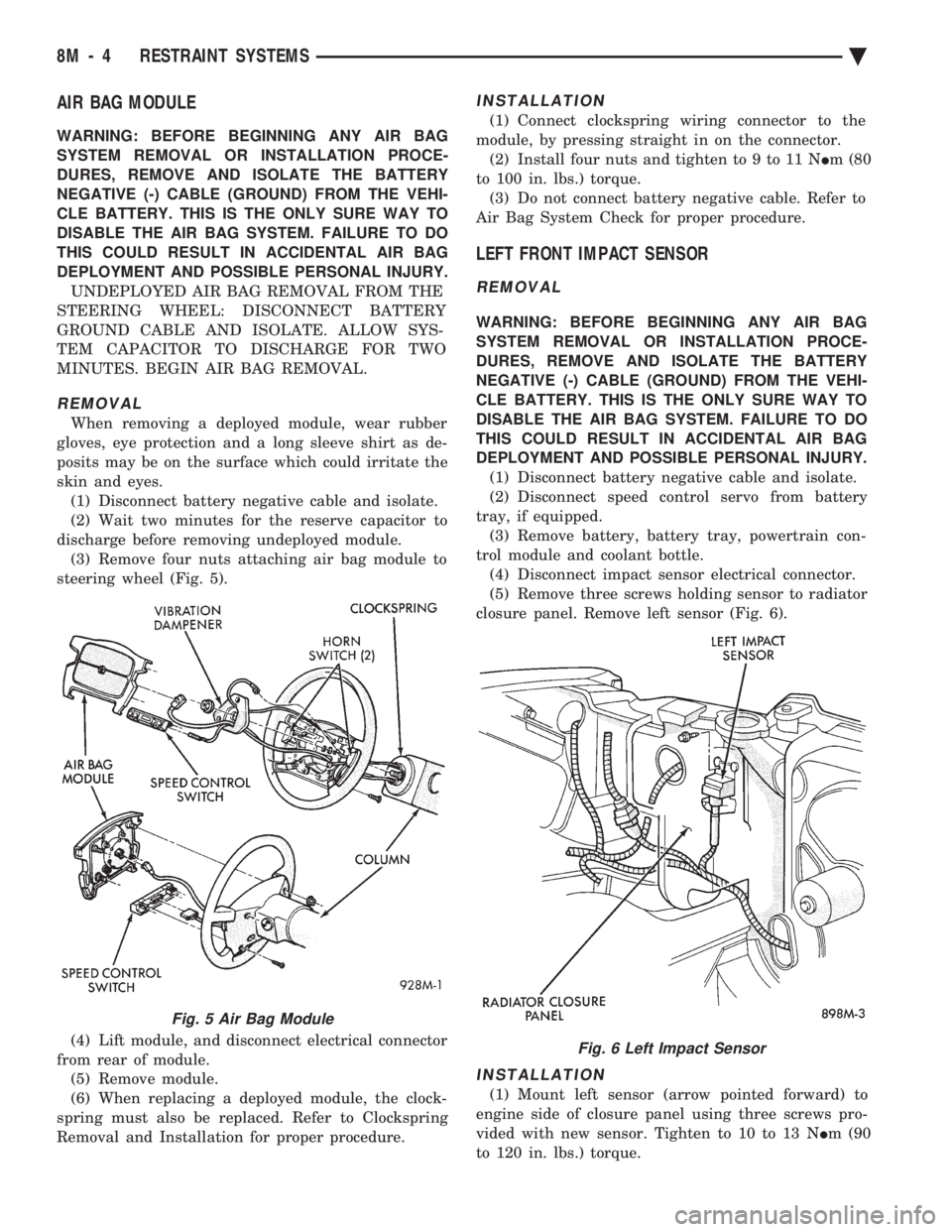

REMOVAL

When removing a deployed module, wear rubber

gloves, eye protection and a long sleeve shirt as de-

posits may be on the surface which could irritate the

skin and eyes. (1) Disconnect battery negative cable and isolate.

(2) Wait two minutes for the reserve capacitor to

discharge before removing undeployed module. (3) Remove four nuts attaching air bag module to

steering wheel (Fig. 5).

(4) Lift module, and disconnect electrical connector

from rear of module. (5) Remove module.

(6) When replacing a deployed module, the clock-

spring must also be replaced. Refer to Clockspring

Removal and Installation for proper procedure.

INSTALLATION

(1) Connect clockspring wiring connector to the

module, by pressing straight in on the connector. (2) Install four nuts and tighten to 9 to 11 N Im (80

to 100 in. lbs.) torque. (3) Do not connect battery negative cable. Refer to

Air Bag System Check for proper procedure.

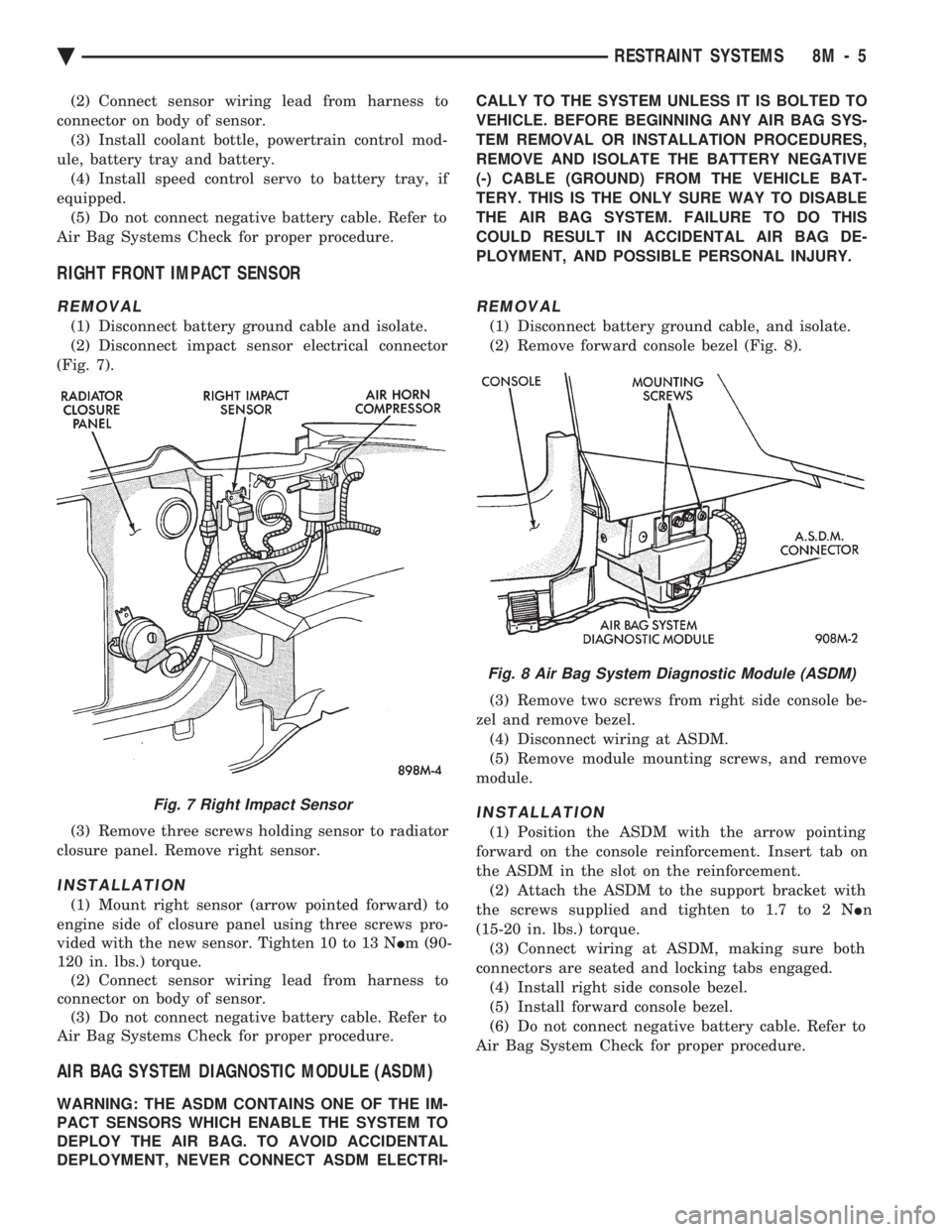

LEFT FRONT IMPACT SENSOR

REMOVAL

WARNING: BEFORE BEGINNING ANY AIR BAG

SYSTEM REMOVAL OR INSTALLATION PROCE-

DURES, REMOVE AND ISOLATE THE BATTERY

NEGATIVE (-) CABLE (GROUND) FROM THE VEHI-

CLE BATTERY. THIS IS THE ONLY SURE WAY TO

DISABLE THE AIR BAG SYSTEM. FAILURE TO DO

THIS COULD RESULT IN ACCIDENTAL AIR BAG

DEPLOYMENT AND POSSIBLE PERSONAL INJURY. (1) Disconnect battery negative cable and isolate.

(2) Disconnect speed control servo from battery

tray, if equipped. (3) Remove battery, battery tray, powertrain con-

trol module and coolant bottle. (4) Disconnect impact sensor electrical connector.

(5) Remove three screws holding sensor to radiator

closure panel. Remove left sensor (Fig. 6).

INSTALLATION

(1) Mount left sensor (arrow pointed forward) to

engine side of closure panel using three screws pro-

vided with new sensor. Tighten to 10 to 13 N Im (90

to 120 in. lbs.) torque.

Fig. 5 Air Bag Module

Fig. 6 Left Impact Sensor

8M - 4 RESTRAINT SYSTEMS Ä

Page 687 of 2438

(2) Connect sensor wiring lead from harness to

connector on body of sensor. (3) Install coolant bottle, powertrain control mod-

ule, battery tray and battery. (4) Install speed control servo to battery tray, if

equipped. (5) Do not connect negative battery cable. Refer to

Air Bag Systems Check for proper procedure.

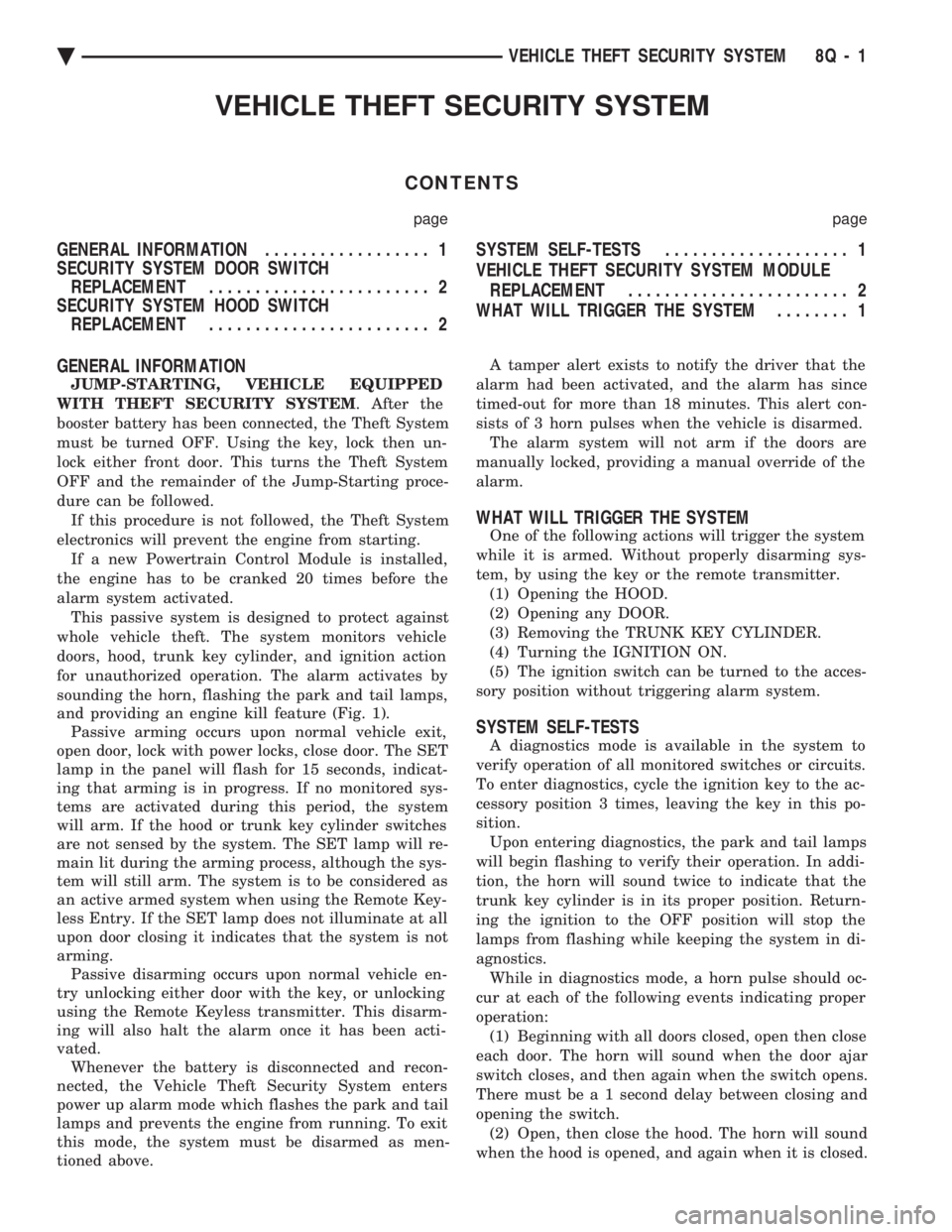

RIGHT FRONT IMPACT SENSOR

REMOVAL

(1) Disconnect battery ground cable and isolate.

(2) Disconnect impact sensor electrical connector

(Fig. 7).

(3) Remove three screws holding sensor to radiator

closure panel. Remove right sensor.

INSTALLATION

(1) Mount right sensor (arrow pointed forward) to

engine side of closure panel using three screws pro-

vided with the new sensor. Tighten 10 to 13 N Im (90-

120 in. lbs.) torque. (2) Connect sensor wiring lead from harness to

connector on body of sensor. (3) Do not connect negative battery cable. Refer to

Air Bag Systems Check for proper procedure.

AIR BAG SYSTEM DIAGNOSTIC MODULE (ASDM)

WARNING: THE ASDM CONTAINS ONE OF THE IM-

PACT SENSORS WHICH ENABLE THE SYSTEM TO

DEPLOY THE AIR BAG. TO AVOID ACCIDENTAL

DEPLOYMENT, NEVER CONNECT ASDM ELECTRI- CALLY TO THE SYSTEM UNLESS IT IS BOLTED TO

VEHICLE. BEFORE BEGINNING ANY AIR BAG SYS-

TEM REMOVAL OR INSTALLATION PROCEDURES,

REMOVE AND ISOLATE THE BATTERY NEGATIVE

(-) CABLE (GROUND) FROM THE VEHICLE BAT-

TERY. THIS IS THE ONLY SURE WAY TO DISABLE

THE AIR BAG SYSTEM. FAILURE TO DO THIS

COULD RESULT IN ACCIDENTAL AIR BAG DE-

PLOYMENT, AND POSSIBLE PERSONAL INJURY.

REMOVAL

(1) Disconnect battery ground cable, and isolate.

(2) Remove forward console bezel (Fig. 8).

(3) Remove two screws from right side console be-

zel and remove bezel. (4) Disconnect wiring at ASDM.

(5) Remove module mounting screws, and remove

module.

INSTALLATION

(1) Position the ASDM with the arrow pointing

forward on the console reinforcement. Insert tab on

the ASDM in the slot on the reinforcement. (2) Attach the ASDM to the support bracket with

the screws supplied and tighten to 1.7 to 2 N In

(15-20 in. lbs.) torque. (3) Connect wiring at ASDM, making sure both

connectors are seated and locking tabs engaged. (4) Install right side console bezel.

(5) Install forward console bezel.

(6) Do not connect negative battery cable. Refer to

Air Bag System Check for proper procedure.

Fig. 7 Right Impact Sensor

Fig. 8 Air Bag System Diagnostic Module (ASDM)

Ä RESTRAINT SYSTEMS 8M - 5

Page 703 of 2438

VEHICLE THEFT SECURITY SYSTEM

CONTENTS

page page

GENERAL INFORMATION .................. 1

SECURITY SYSTEM DOOR SWITCH REPLACEMENT ........................ 2

SECURITY SYSTEM HOOD SWITCH REPLACEMENT ........................ 2 SYSTEM SELF-TESTS

.................... 1

VEHICLE THEFT SECURITY SYSTEM MODULE REPLACEMENT ........................ 2

WHAT WILL TRIGGER THE SYSTEM ........ 1

GENERAL INFORMATION

JUMP-STARTING, VEHICLE EQUIPPED

WITH THEFT SECURITY SYSTEM . After the

booster battery has been connected, the Theft System

must be turned OFF. Using the key, lock then un-

lock either front door. This turns the Theft System

OFF and the remainder of the Jump-Starting proce-

dure can be followed. If this procedure is not followed, the Theft System

electronics will prevent the engine from starting. If a new Powertrain Control Module is installed,

the engine has to be cranked 20 times before the

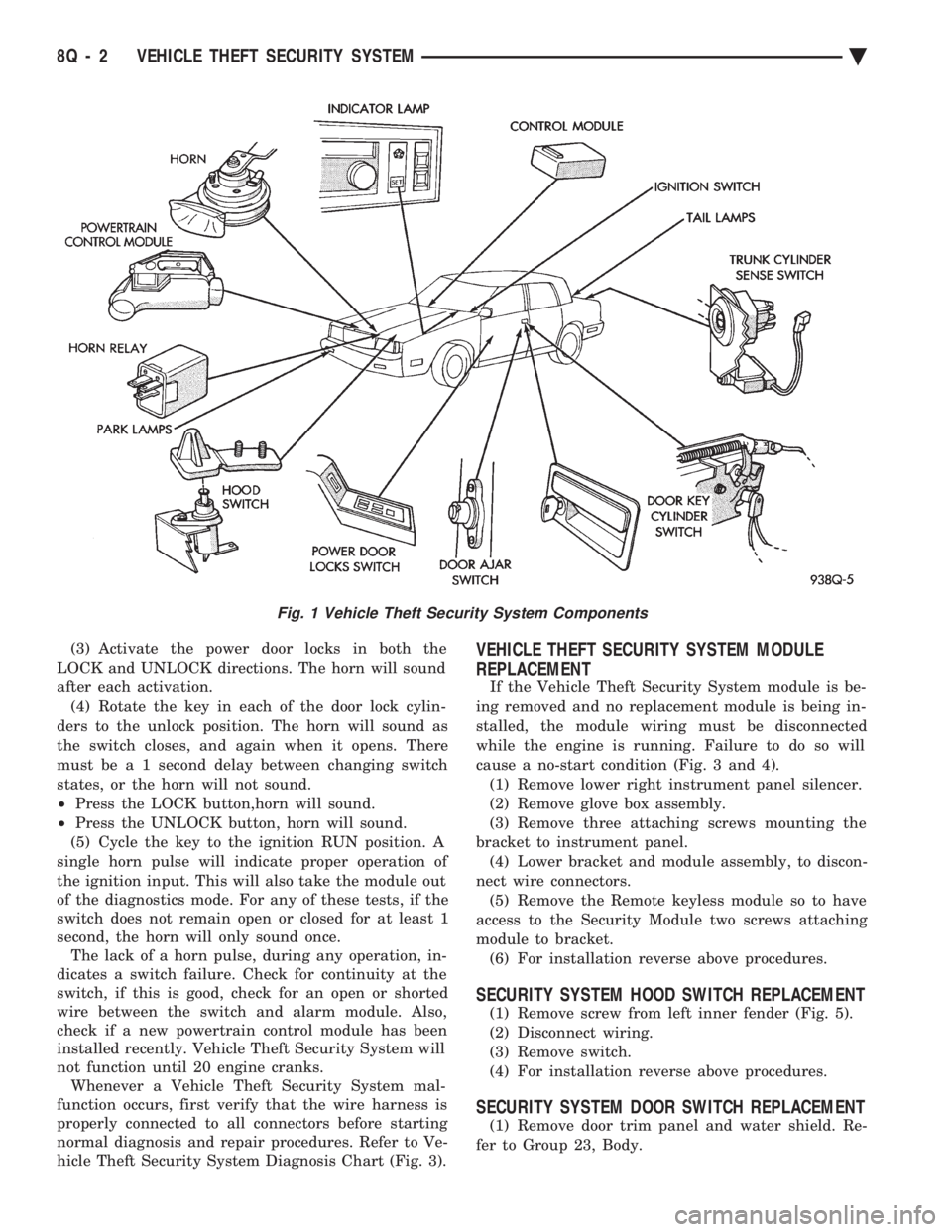

alarm system activated. This passive system is designed to protect against

whole vehicle theft. The system monitors vehicle

doors, hood, trunk key cylinder, and ignition action

for unauthorized operation. The alarm activates by

sounding the horn, flashing the park and tail lamps,

and providing an engine kill feature (Fig. 1). Passive arming occurs upon normal vehicle exit,

open door, lock with power locks, close door. The SET

lamp in the panel will flash for 15 seconds, indicat-

ing that arming is in progress. If no monitored sys-

tems are activated during this period, the system

will arm. If the hood or trunk key cylinder switches

are not sensed by the system. The SET lamp will re-

main lit during the arming process, although the sys-

tem will still arm. The system is to be considered as

an active armed system when using the Remote Key-

less Entry. If the SET lamp does not illuminate at all

upon door closing it indicates that the system is not

arming. Passive disarming occurs upon normal vehicle en-

try unlocking either door with the key, or unlocking

using the Remote Keyless transmitter. This disarm-

ing will also halt the alarm once it has been acti-

vated. Whenever the battery is disconnected and recon-

nected, the Vehicle Theft Security System enters

power up alarm mode which flashes the park and tail

lamps and prevents the engine from running. To exit

this mode, the system must be disarmed as men-

tioned above. A tamper alert exists to notify the driver that the

alarm had been activated, and the alarm has since

timed-out for more than 18 minutes. This alert con-

sists of 3 horn pulses when the vehicle is disarmed. The alarm system will not arm if the doors are

manually locked, providing a manual override of the

alarm.

WHAT WILL TRIGGER THE SYSTEM

One of the following actions will trigger the system

while it is armed. Without properly disarming sys-

tem, by using the key or the remote transmitter. (1) Opening the HOOD.

(2) Opening any DOOR.

(3) Removing the TRUNK KEY CYLINDER.

(4) Turning the IGNITION ON.

(5) The ignition switch can be turned to the acces-

sory position without triggering alarm system.

SYSTEM SELF-TESTS

A diagnostics mode is available in the system to

verify operation of all monitored switches or circuits.

To enter diagnostics, cycle the ignition key to the ac-

cessory position 3 times, leaving the key in this po-

sition. Upon entering diagnostics, the park and tail lamps

will begin flashing to verify their operation. In addi-

tion, the horn will sound twice to indicate that the

trunk key cylinder is in its proper position. Return-

ing the ignition to the OFF position will stop the

lamps from flashing while keeping the system in di-

agnostics. While in diagnostics mode, a horn pulse should oc-

cur at each of the following events indicating proper

operation: (1) Beginning with all doors closed, open then close

each door. The horn will sound when the door ajar

switch closes, and then again when the switch opens.

There must b e a 1 second delay between closing and

opening the switch. (2) Open, then close the hood. The horn will sound

when the hood is opened, and again when it is closed.

Ä VEHICLE THEFT SECURITY SYSTEM 8Q - 1

Page 704 of 2438

(3) Activate the power door locks in both the

LOCK and UNLOCK directions. The horn will sound

after each activation. (4) Rotate the key in each of the door lock cylin-

ders to the unlock position. The horn will sound as

the switch closes, and again when it opens. There

must b e a 1 second delay between changing switch

states, or the horn will not sound.

² Press the LOCK button,horn will sound.

² Press the UNLOCK button, horn will sound.

(5) Cycle the key to the ignition RUN position. A

single horn pulse will indicate proper operation of

the ignition input. This will also take the module out

of the diagnostics mode. For any of these tests, if the

switch does not remain open or closed for at least 1

second, the horn will only sound once. The lack of a horn pulse, during any operation, in-

dicates a switch failure. Check for continuity at the

switch, if this is good, check for an open or shorted

wire between the switch and alarm module. Also,

check if a new powertrain control module has been

installed recently. Vehicle Theft Security System will

not function until 20 engine cranks. Whenever a Vehicle Theft Security System mal-

function occurs, first verify that the wire harness is

properly connected to all connectors before starting

normal diagnosis and repair procedures. Refer to Ve-

hicle Theft Security System Diagnosis Chart (Fig. 3).VEHICLE THEFT SECURITY SYSTEM MODULE

REPLACEMENT

If the Vehicle Theft Security System module is be-

ing removed and no replacement module is being in-

stalled, the module wiring must be disconnected

while the engine is running. Failure to do so will

cause a no-start condition (Fig. 3 and 4). (1) Remove lower right instrument panel silencer.

(2) Remove glove box assembly.

(3) Remove three attaching screws mounting the

bracket to instrument panel. (4) Lower bracket and module assembly, to discon-

nect wire connectors. (5) Remove the Remote keyless module so to have

access to the Security Module two screws attaching

module to bracket. (6) For installation reverse above procedures.

SECURITY SYSTEM HOOD SWITCH REPLACEMENT

(1) Remove screw from left inner fender (Fig. 5).

(2) Disconnect wiring.

(3) Remove switch.

(4) For installation reverse above procedures.

SECURITY SYSTEM DOOR SWITCH REPLACEMENT

(1) Remove door trim panel and water shield. Re-

fer to Group 23, Body.

Fig. 1 Vehicle Theft Security System Components

8Q - 2 VEHICLE THEFT SECURITY SYSTEM Ä

Page 743 of 2438

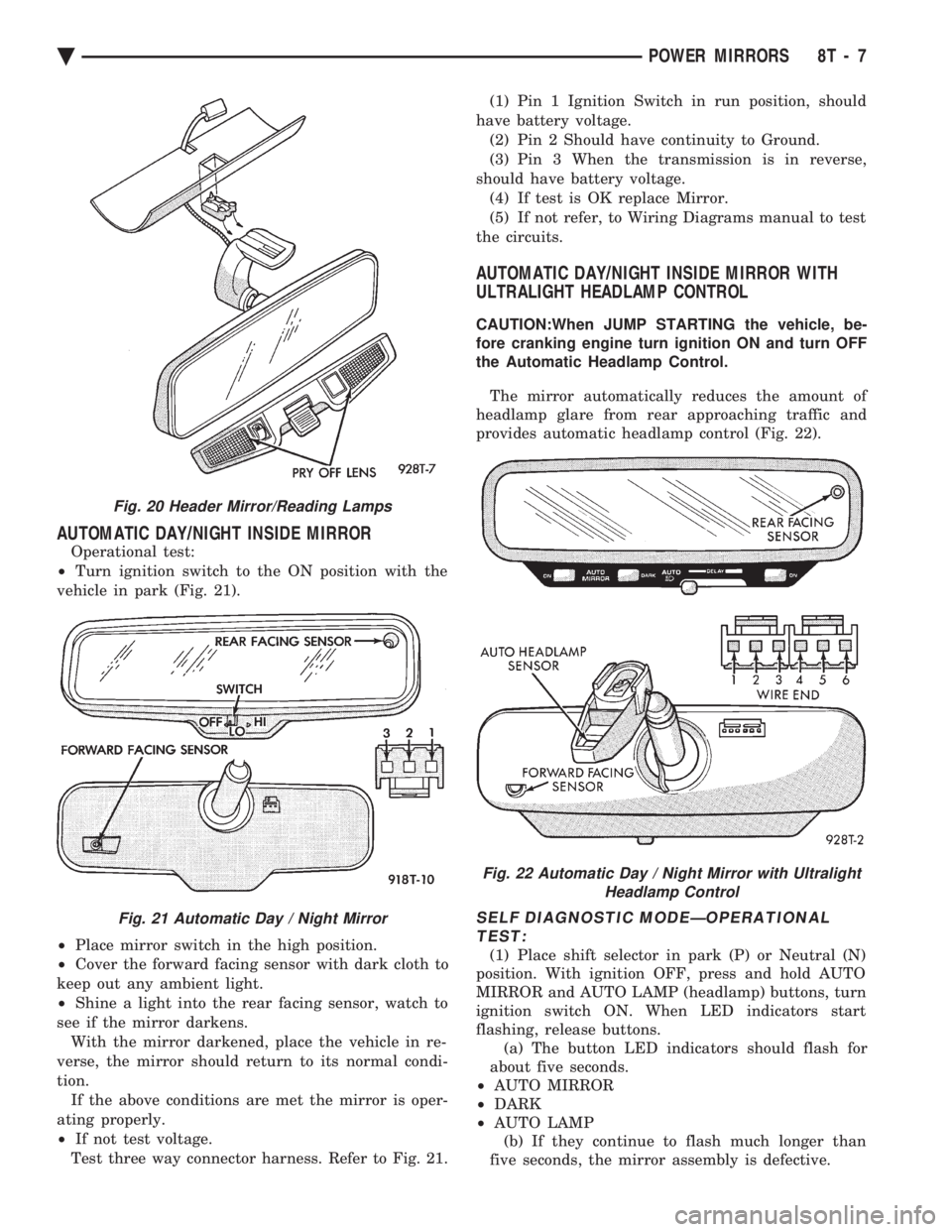

AUTOMATIC DAY/NIGHT INSIDE MIRROR

Operational test:

² Turn ignition switch to the ON position with the

vehicle in park (Fig. 21).

² Place mirror switch in the high position.

² Cover the forward facing sensor with dark cloth to

keep out any ambient light.

² Shine a light into the rear facing sensor, watch to

see if the mirror darkens. With the mirror darkened, place the vehicle in re-

verse, the mirror should return to its normal condi-

tion. If the above conditions are met the mirror is oper-

ating properly.

² If not test voltage.

Test three way connector harness. Refer to Fig. 21. (1) Pin 1 Ignition Switch in run position, should

have battery voltage. (2) Pin 2 Should have continuity to Ground.

(3) Pin 3 When the transmission is in reverse,

should have battery voltage. (4) If test is OK replace Mirror.

(5) If not refer, to Wiring Diagrams manual to test

the circuits.

AUTOMATIC DAY/NIGHT INSIDE MIRROR WITH

ULTRALIGHT HEADLAMP CONTROL

CAUTION:When JUMP STARTING the vehicle, be-

fore cranking engine turn ignition ON and turn OFF

the Automatic Headlamp Control.

The mirror automatically reduces the amount of

headlamp glare from rear approaching traffic and

provides automatic headlamp control (Fig. 22).

SELF DIAGNOSTIC MODEÐOPERATIONAL TEST:

(1) Place shift selector in park (P) or Neutral (N)

position. With ignition OFF, press and hold AUTO

MIRROR and AUTO LAMP (headlamp) buttons, turn

ignition switch ON. When LED indicators start

flashing, release buttons. (a) The button LED indicators should flash for

about five seconds.

² AUTO MIRROR

² DARK

² AUTO LAMP

(b) If they continue to flash much longer than

five seconds, the mirror assembly is defective.

Fig. 20 Header Mirror/Reading Lamps

Fig. 21 Automatic Day / Night Mirror

Fig. 22 Automatic Day / Night Mirror with Ultralight Headlamp Control

Ä POWER MIRRORS 8T - 7

Page 752 of 2438

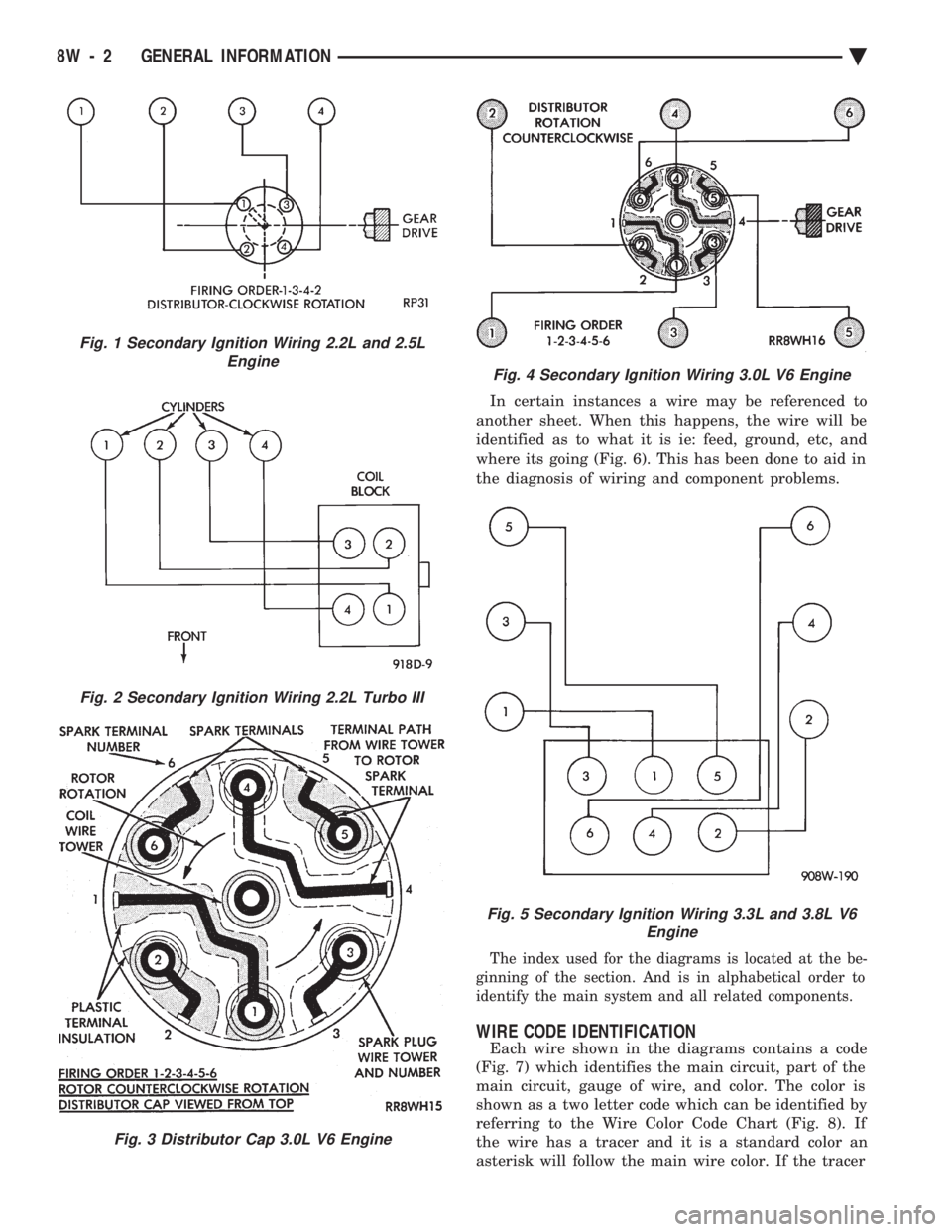

In certain instances a wire may be referenced to

another sheet. When this happens, the wire will be

identified as to what it is ie: feed, ground, etc, and

where its going (Fig. 6). This has been done to aid in

the diagnosis of wiring and component problems.

The index used for the diagrams is located at the be-

ginning of the section. And is in alphabetical order to

identify the main system and all related components.

WIRE CODE IDENTIFICATION

Each wire shown in the diagrams contains a code

(Fig. 7) which identifies the main circuit, part of the

main circuit, gauge of wire, and color. The color is

shown as a two letter code which can be identified by

referring to the Wire Color Code Chart (Fig. 8). If

the wire has a tracer and it is a standard color an

asterisk will follow the main wire color. If the tracer

Fig. 2 Secondary Ignition Wiring 2.2L Turbo III

Fig. 3 Distributor Cap 3.0L V6 Engine

Fig. 1 Secondary Ignition Wiring 2.2L and 2.5L Engine

Fig. 4 Secondary Ignition Wiring 3.0L V6 Engine

Fig. 5 Secondary Ignition Wiring 3.3L and 3.8L V6 Engine

8W - 2 GENERAL INFORMATION Ä