battery replacement CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 408 of 2438

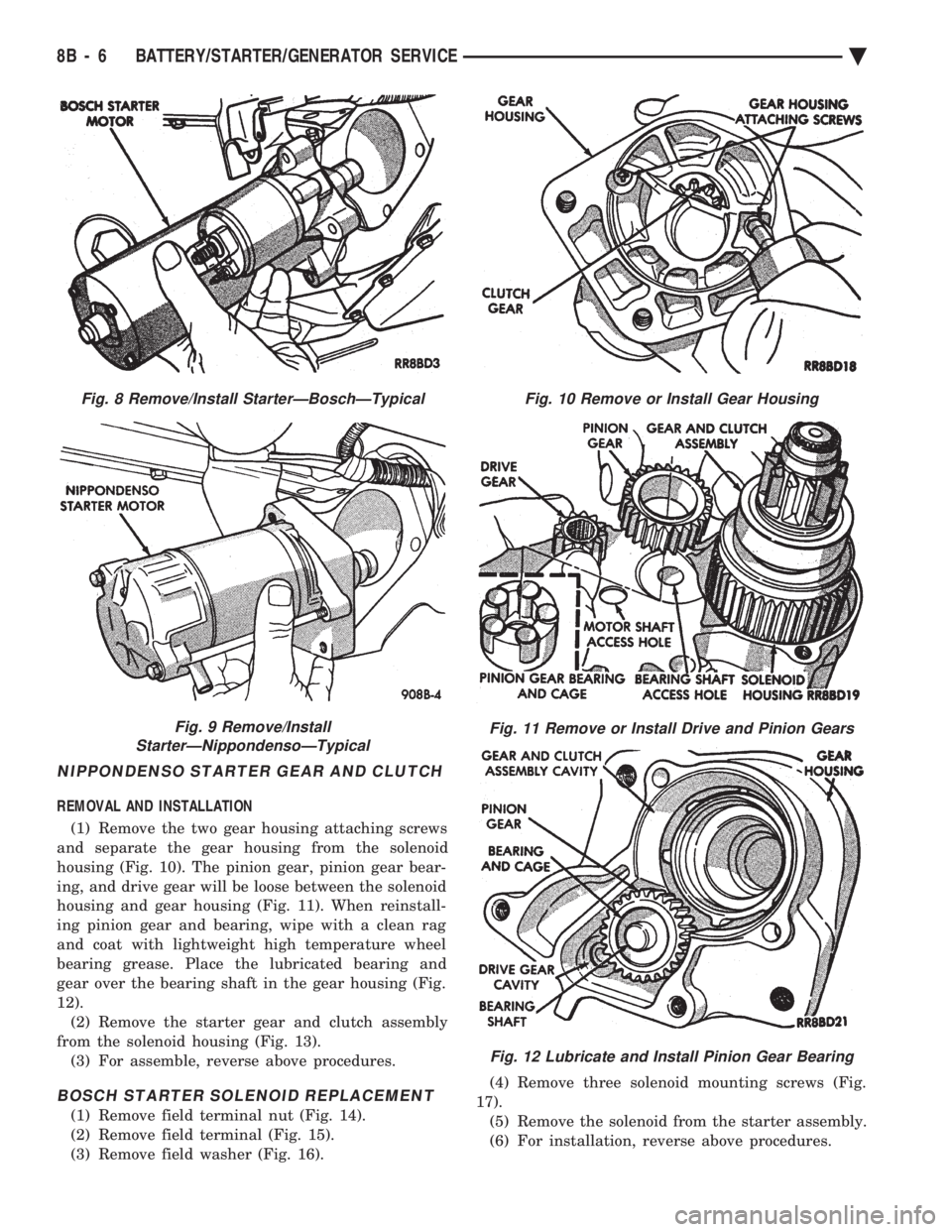

NIPPONDENSO STARTER GEAR AND CLUTCH

REMOVAL AND INSTALLATION (1) Remove the two gear housing attaching screws

and separate the gear housing from the solenoid

housing (Fig. 10). The pinion gear, pinion gear bear-

ing, and drive gear will be loose between the solenoid

housing and gear housing (Fig. 11). When reinstall-

ing pinion gear and bearing, wipe with a clean rag

and coat with lightweight high temperature wheel

bearing grease. Place the lubricated bearing and

gear over the bearing shaft in the gear housing (Fig.

12). (2) Remove the starter gear and clutch assembly

from the solenoid housing (Fig. 13). (3) For assemble, reverse above procedures.

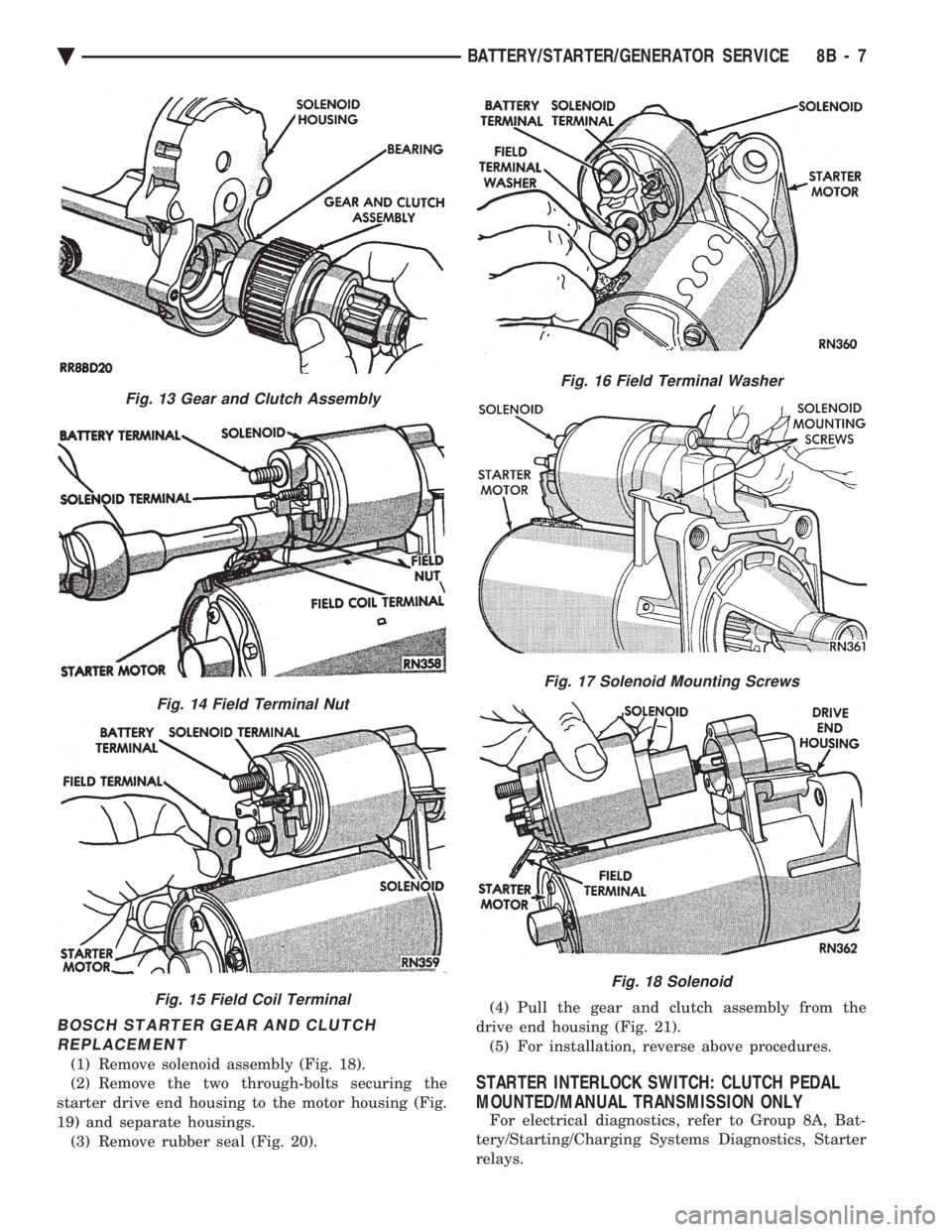

BOSCH STARTER SOLENOID REPLACEMENT

(1) Remove field terminal nut (Fig. 14).

(2) Remove field terminal (Fig. 15).

(3) Remove field washer (Fig. 16). (4) Remove three solenoid mounting screws (Fig.

17). (5) Remove the solenoid from the starter assembly.

(6) For installation, reverse above procedures.

Fig. 8 Remove/Install StarterÐBoschÐTypical

Fig. 9 Remove/Install

StarterÐNippondensoÐTypical

Fig. 10 Remove or Install Gear Housing

Fig. 11 Remove or Install Drive and Pinion Gears

Fig. 12 Lubricate and Install Pinion Gear Bearing

8B - 6 BATTERY/STARTER/GENERATOR SERVICE Ä

Page 409 of 2438

BOSCH STARTER GEAR AND CLUTCH REPLACEMENT

(1) Remove solenoid assembly (Fig. 18).

(2) Remove the two through-bolts securing the

starter drive end housing to the motor housing (Fig.

19) and separate housings. (3) Remove rubber seal (Fig. 20). (4) Pull the gear and clutch assembly from the

drive end housing (Fig. 21). (5) For installation, reverse above procedures.

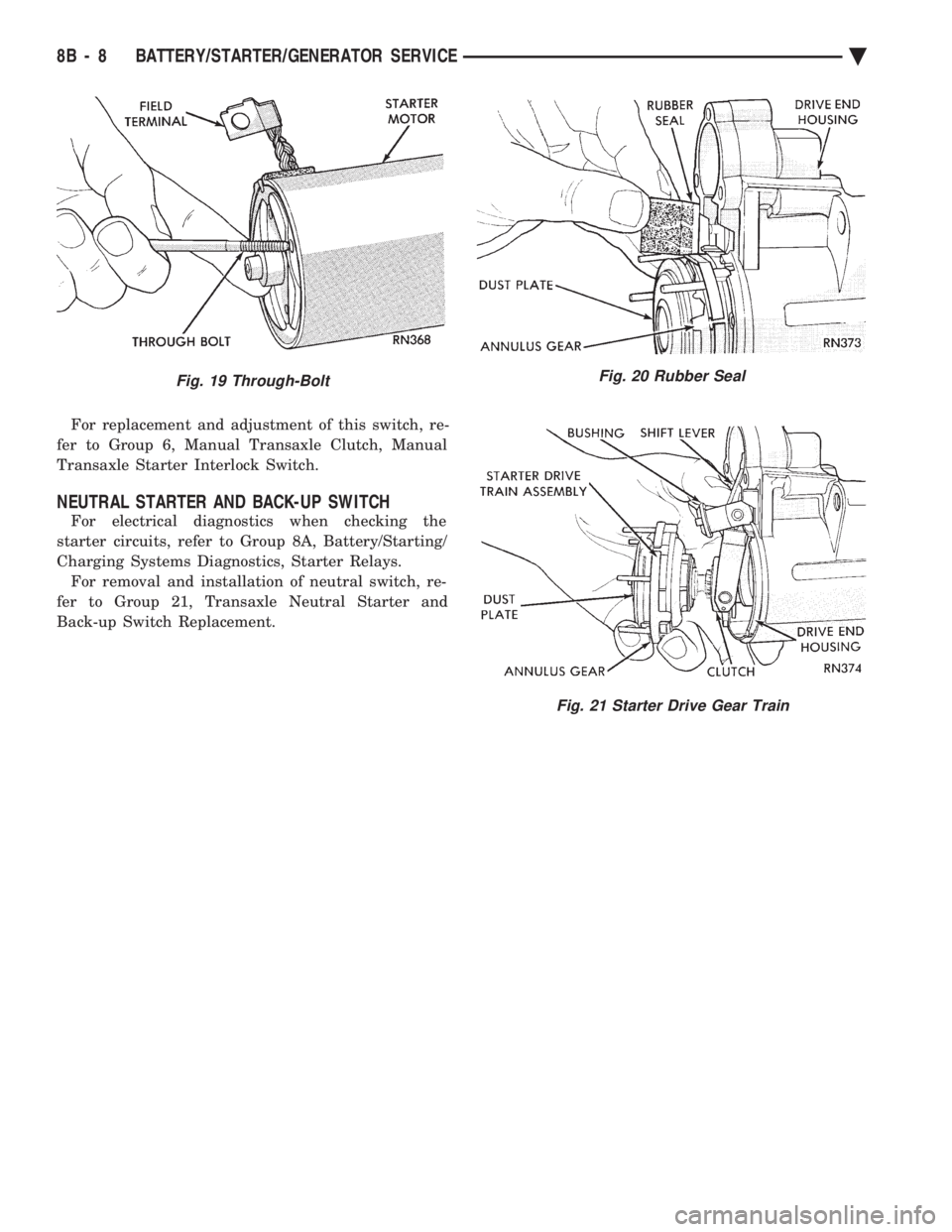

STARTER INTERLOCK SWITCH: CLUTCH PEDAL

MOUNTED/MANUAL TRANSMISSION ONLY

For electrical diagnostics, refer to Group 8A, Bat-

tery/Starting/Charging Systems Diagnostics, Starter

relays.

Fig. 13 Gear and Clutch Assembly

Fig. 14 Field Terminal Nut

Fig. 15 Field Coil Terminal

Fig. 16 Field Terminal Washer

Fig. 17 Solenoid Mounting Screws

Fig. 18 Solenoid

Ä BATTERY/STARTER/GENERATOR SERVICE 8B - 7

Page 410 of 2438

For replacement and adjustment of this switch, re-

fer to Group 6, Manual Transaxle Clutch, Manual

Transaxle Starter Interlock Switch.

NEUTRAL STARTER AND BACK-UP SWITCH

For electrical diagnostics when checking the

starter circuits, refer to Group 8A, Battery/Starting/

Charging Systems Diagnostics, Starter Relays. For removal and installation of neutral switch, re-

fer to Group 21, Transaxle Neutral Starter and

Back-up Switch Replacement.

Fig. 19 Through-BoltFig. 20 Rubber Seal

Fig. 21 Starter Drive Gear Train

8B - 8 BATTERY/STARTER/GENERATOR SERVICE Ä

Page 411 of 2438

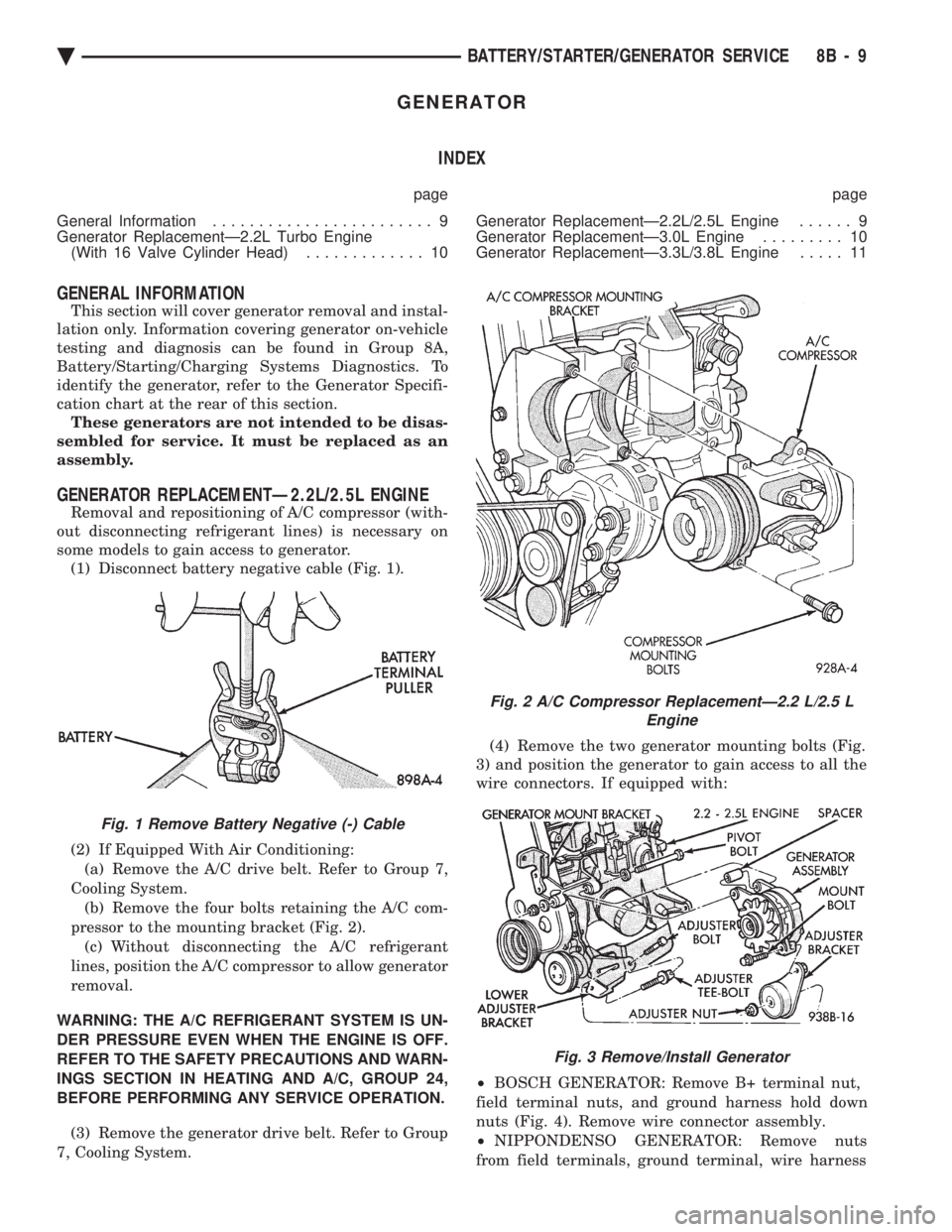

GENERATOR INDEX

page page

General Information ........................ 9

Generator ReplacementÐ2.2L Turbo Engine (With 16 Valve Cylinder Head) ............. 10 Generator ReplacementÐ2.2L/2.5L Engine

...... 9

Generator ReplacementÐ3.0L Engine ......... 10

Generator ReplacementÐ3.3L/3.8L Engine ..... 11

GENERAL INFORMATION

This section will cover generator removal and instal-

lation only. Information covering generator on-vehicle

testing and diagnosis can be found in Group 8A,

Battery/Starting/Charging Systems Diagnostics. To

identify the generator, refer to the Generator Specifi-

cation chart at the rear of this section. These generators are not intended to be disas-

sembled for service. It must be replaced as an

assembly.

GENERATOR REPLACEMENTÐ2.2L/2.5L ENGINE

Removal and repositioning of A/C compressor (with-

out disconnecting refrigerant lines) is necessary on

some models to gain access to generator. (1) Disconnect battery negative cable (Fig. 1).

(2) If Equipped With Air Conditioning:

(a) Remove the A/C drive belt. Refer to Group 7,

Cooling System. (b) Remove the four bolts retaining the A/C com-

pressor to the mounting bracket (Fig. 2). (c) Without disconnecting the A/C refrigerant

lines, position the A/C compressor to allow generator

removal.

WARNING: THE A/C REFRIGERANT SYSTEM IS UN-

DER PRESSURE EVEN WHEN THE ENGINE IS OFF.

REFER TO THE SAFETY PRECAUTIONS AND WARN-

INGS SECTION IN HEATING AND A/C, GROUP 24,

BEFORE PERFORMING ANY SERVICE OPERATION. (3) Remove the generator drive belt. Refer to Group

7, Cooling System. (4) Remove the two generator mounting bolts (Fig.

3) and position the generator to gain access to all the

wire connectors. If equipped with:

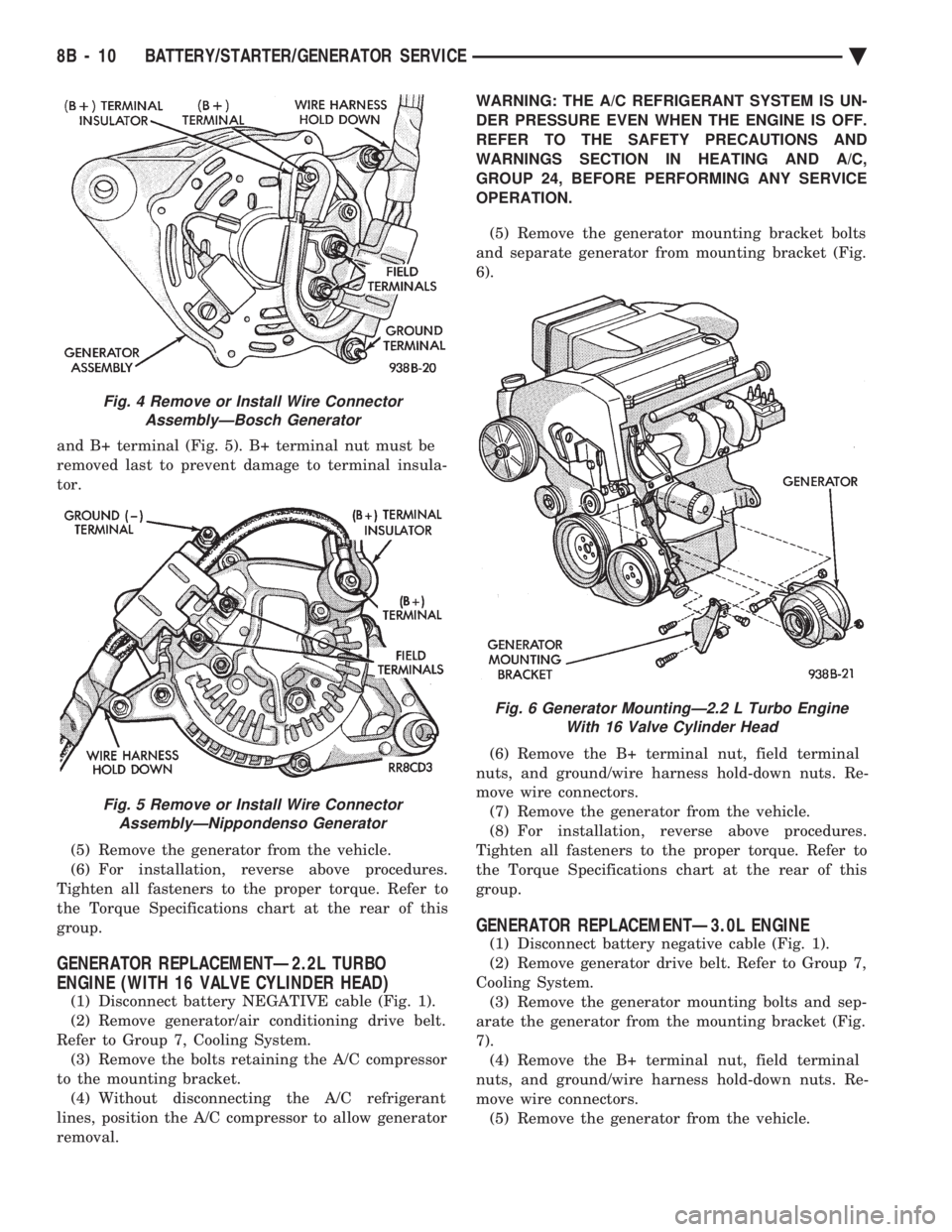

² BOSCH GENERATOR: Remove B+ terminal nut,

field terminal nuts, and ground harness hold down

nuts (Fig. 4). Remove wire connector assembly.

² NIPPONDENSO GENERATOR: Remove nuts

from field terminals, ground terminal, wire harness

Fig. 1 Remove Battery Negative (-) Cable

Fig. 2 A/C Compressor ReplacementÐ2.2 L/2.5 L Engine

Fig. 3 Remove/Install Generator

Ä BATTERY/STARTER/GENERATOR SERVICE 8B - 9

Page 412 of 2438

and B+ terminal (Fig. 5). B+ terminal nut must be

removed last to prevent damage to terminal insula-

tor. (5) Remove the generator from the vehicle.

(6) For installation, reverse above procedures.

Tighten all fasteners to the proper torque. Refer to

the Torque Specifications chart at the rear of this

group.

GENERATOR REPLACEMENTÐ2.2L TURBO

ENGINE (WITH 16 VALVE CYLINDER HEAD)

(1) Disconnect battery NEGATIVE cable (Fig. 1).

(2) Remove generator/air conditioning drive belt.

Refer to Group 7, Cooling System. (3) Remove the bolts retaining the A/C compressor

to the mounting bracket. (4) Without disconnecting the A/C refrigerant

lines, position the A/C compressor to allow generator

removal. WARNING: THE A/C REFRIGERANT SYSTEM IS UN-

DER PRESSURE EVEN WHEN THE ENGINE IS OFF.

REFER TO THE SAFETY PRECAUTIONS AND

WARNINGS SECTION IN HEATING AND A/C,

GROUP 24, BEFORE PERFORMING ANY SERVICE

OPERATION.

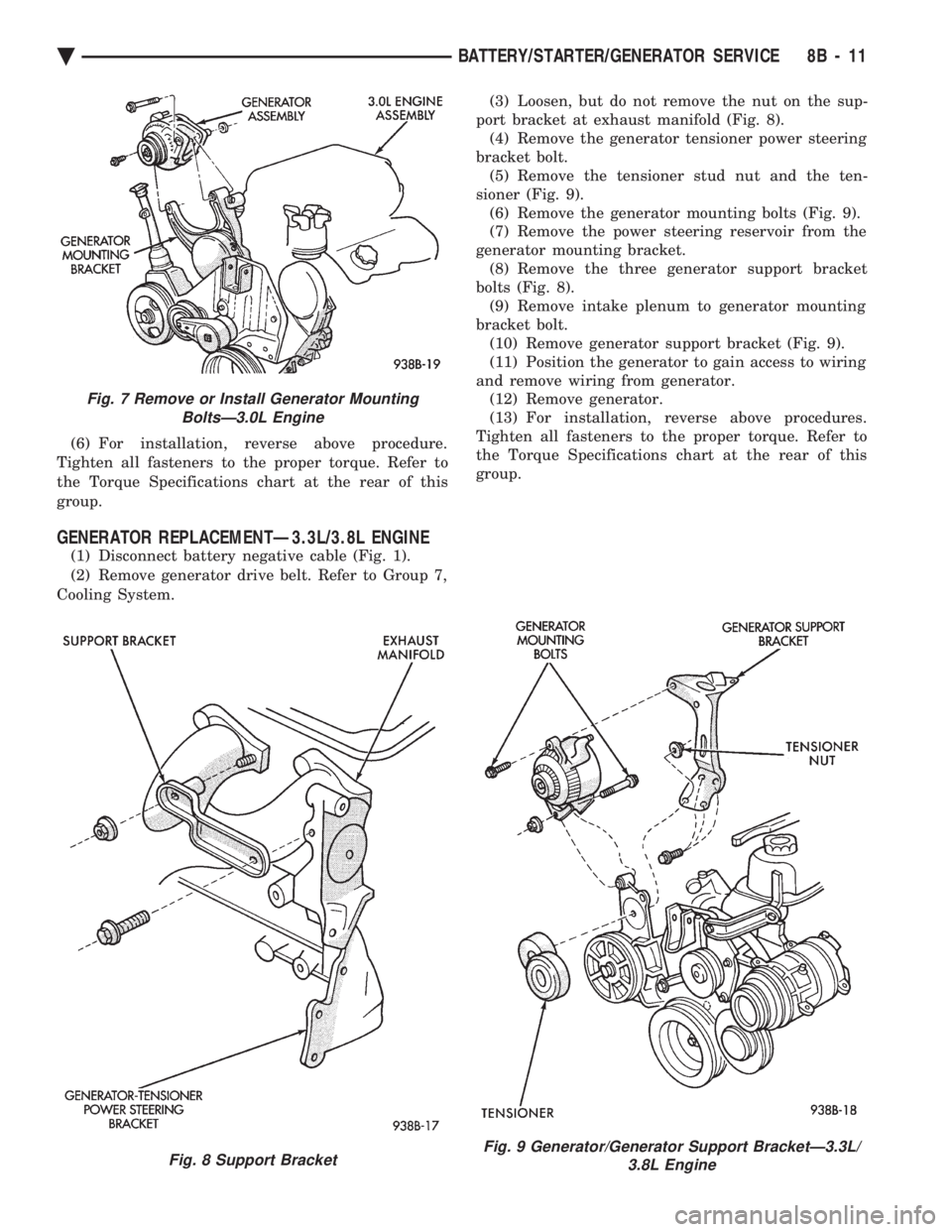

(5) Remove the generator mounting bracket bolts

and separate generator from mounting bracket (Fig.

6).

(6) Remove the B+ terminal nut, field terminal

nuts, and ground/wire harness hold-down nuts. Re-

move wire connectors. (7) Remove the generator from the vehicle.

(8) For installation, reverse above procedures.

Tighten all fasteners to the proper torque. Refer to

the Torque Specifications chart at the rear of this

group.

GENERATOR REPLACEMENTÐ3.0L ENGINE

(1) Disconnect battery negative cable (Fig. 1).

(2) Remove generator drive belt. Refer to Group 7,

Cooling System. (3) Remove the generator mounting bolts and sep-

arate the generator from the mounting bracket (Fig.

7). (4) Remove the B+ terminal nut, field terminal

nuts, and ground/wire harness hold-down nuts. Re-

move wire connectors. (5) Remove the generator from the vehicle.

Fig. 4 Remove or Install Wire Connector AssemblyÐBosch Generator

Fig. 5 Remove or Install Wire ConnectorAssemblyÐNippondenso Generator

Fig. 6 Generator MountingÐ2.2 L Turbo Engine With 16 Valve Cylinder Head

8B - 10 BATTERY/STARTER/GENERATOR SERVICE Ä

Page 413 of 2438

(6) For installation, reverse above procedure.

Tighten all fasteners to the proper torque. Refer to

the Torque Specifications chart at the rear of this

group.

GENERATOR REPLACEMENTÐ3.3L/3.8L ENGINE

(1) Disconnect battery negative cable (Fig. 1).

(2) Remove generator drive belt. Refer to Group 7,

Cooling System. (3) Loosen, but do not remove the nut on the sup-

port bracket at exhaust manifold (Fig. 8). (4) Remove the generator tensioner power steering

bracket bolt. (5) Remove the tensioner stud nut and the ten-

sioner (Fig. 9). (6) Remove the generator mounting bolts (Fig. 9).

(7) Remove the power steering reservoir from the

generator mounting bracket. (8) Remove the three generator support bracket

bolts (Fig. 8). (9) Remove intake plenum to generator mounting

bracket bolt. (10) Remove generator support bracket (Fig. 9).

(11) Position the generator to gain access to wiring

and remove wiring from generator. (12) Remove generator.

(13) For installation, reverse above procedures.

Tighten all fasteners to the proper torque. Refer to

the Torque Specifications chart at the rear of this

group.

Fig. 7 Remove or Install Generator Mounting BoltsÐ3.0L Engine

Fig. 8 Support BracketFig. 9 Generator/Generator Support BracketÐ3.3L/ 3.8L Engine

Ä BATTERY/STARTER/GENERATOR SERVICE 8B - 11

Page 501 of 2438

(3) When testing temperature, allow the engine to

run until the vehicle reaches a normal operating

temperature. Turn ignition OFF, and remove gauge

from cluster. (a) Testing oil pressure gauge, engine needs to

be running. (b) Measure and record the resistance between

sending unit pin and ground pin of the gauge in

question. Refer to Gauge Calibration. (c) It is important to have the same engine tem-

perature and engine speed when checking temper-

ature and oil pressure gauges position. The time

between gauge position reading and sending unit

measuring should be kept to a minimum. (d) If resistance and gauge position are not sim-

ilar, replace gauge. (e) If OK, test resistance from the sending unit

to the cluster connector. (f) If resistance reading is different, check

printed circuit board for contact to cluster connec-

tor. (g) If OK and contacts are not distorted, replace

printed circuit board. (h) If everything checks out OK, refer to sending

unit test.

(4) If fuel gauge does not meet specifications, refer

to Group 14, Fuel for the test procedure.

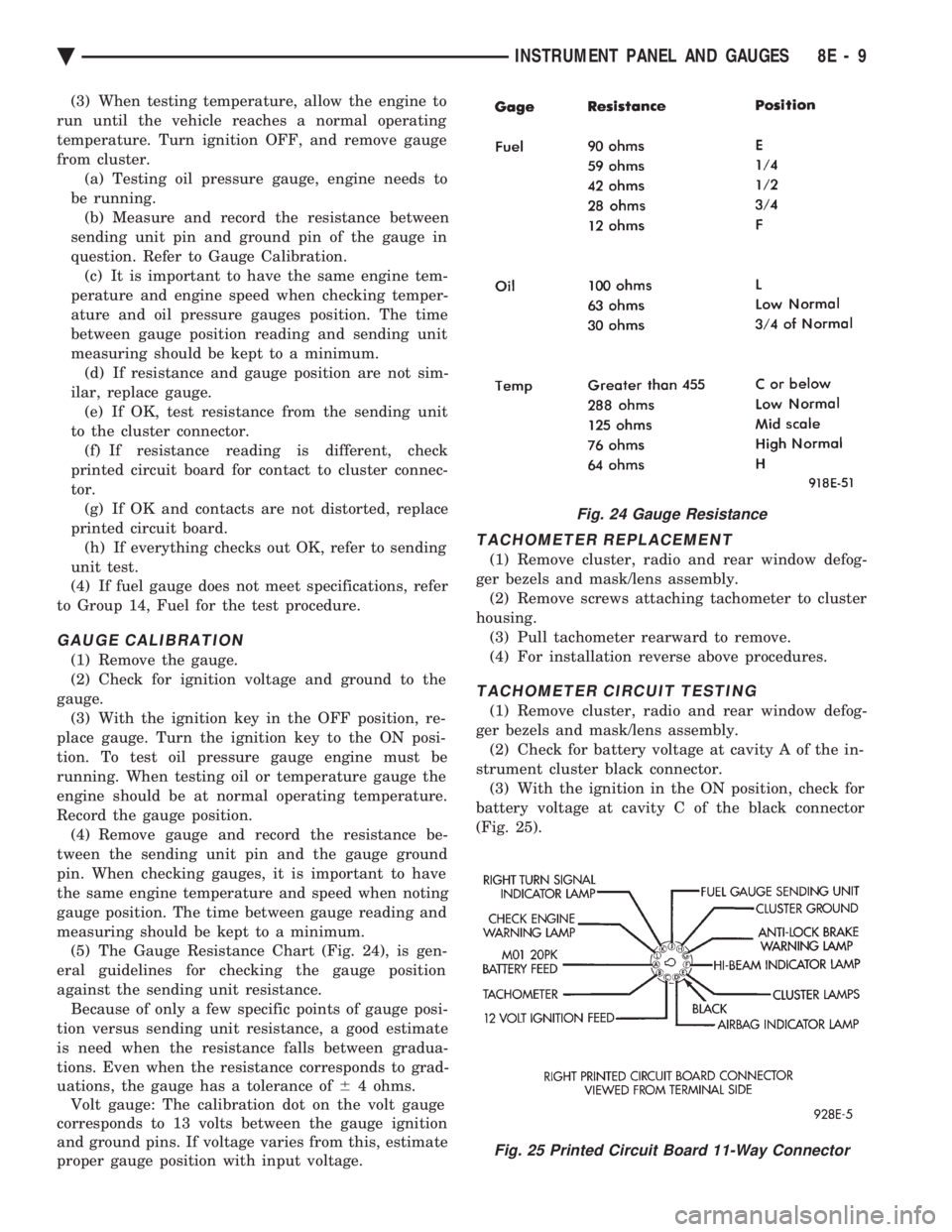

GAUGE CALIBRATION

(1) Remove the gauge.

(2) Check for ignition voltage and ground to the

gauge. (3) With the ignition key in the OFF position, re-

place gauge. Turn the ignition key to the ON posi-

tion. To test oil pressure gauge engine must be

running. When testing oil or temperature gauge the

engine should be at normal operating temperature.

Record the gauge position. (4) Remove gauge and record the resistance be-

tween the sending unit pin and the gauge ground

pin. When checking gauges, it is important to have

the same engine temperature and speed when noting

gauge position. The time between gauge reading and

measuring should be kept to a minimum. (5) The Gauge Resistance Chart (Fig. 24), is gen-

eral guidelines for checking the gauge position

against the sending unit resistance. Because of only a few specific points of gauge posi-

tion versus sending unit resistance, a good estimate

is need when the resistance falls between gradua-

tions. Even when the resistance corresponds to grad-

uations, the gauge has a tolerance of 64 ohms.

Volt gauge: The calibration dot on the volt gauge

corresponds to 13 volts between the gauge ignition

and ground pins. If voltage varies from this, estimate

proper gauge position with input voltage.

TACHOMETER REPLACEMENT

(1) Remove cluster, radio and rear window defog-

ger bezels and mask/lens assembly. (2) Remove screws attaching tachometer to cluster

housing. (3) Pull tachometer rearward to remove.

(4) For installation reverse above procedures.

TACHOMETER CIRCUIT TESTING

(1) Remove cluster, radio and rear window defog-

ger bezels and mask/lens assembly. (2) Check for battery voltage at cavity A of the in-

strument cluster black connector. (3) With the ignition in the ON position, check for

battery voltage at cavity C of the black connector

(Fig. 25).

Fig. 24 Gauge Resistance

Fig. 25 Printed Circuit Board 11-Way Connector

Ä INSTRUMENT PANEL AND GAUGES 8E - 9

Page 503 of 2438

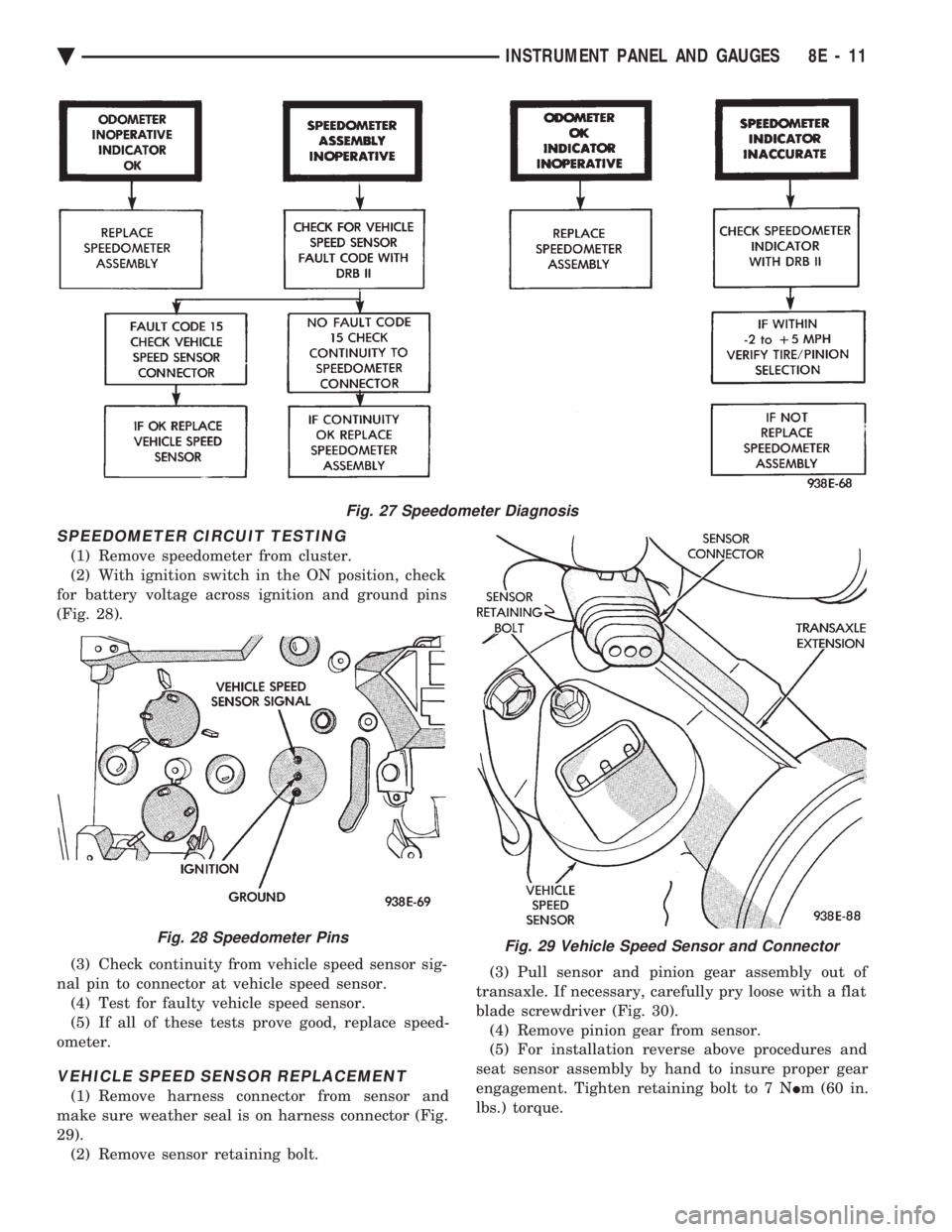

SPEEDOMETER CIRCUIT TESTING

(1) Remove speedometer from cluster.

(2) With ignition switch in the ON position, check

for battery voltage across ignition and ground pins

(Fig. 28).

(3) Check continuity from vehicle speed sensor sig-

nal pin to connector at vehicle speed sensor. (4) Test for faulty vehicle speed sensor.

(5) If all of these tests prove good, replace speed-

ometer.

VEHICLE SPEED SENSOR REPLACEMENT

(1) Remove harness connector from sensor and

make sure weather seal is on harness connector (Fig.

29). (2) Remove sensor retaining bolt. (3) Pull sensor and pinion gear assembly out of

transaxle. If necessary, carefully pry loose with a flat

blade screwdriver (Fig. 30). (4) Remove pinion gear from sensor.

(5) For installation reverse above procedures and

seat sensor assembly by hand to insure proper gear

engagement. Tighten retaining bolt to 7 N Im (60 in.

lbs.) torque.

Fig. 27 Speedometer Diagnosis

Fig. 28 Speedometer PinsFig. 29 Vehicle Speed Sensor and Connector

Ä INSTRUMENT PANEL AND GAUGES 8E - 11

Page 505 of 2438

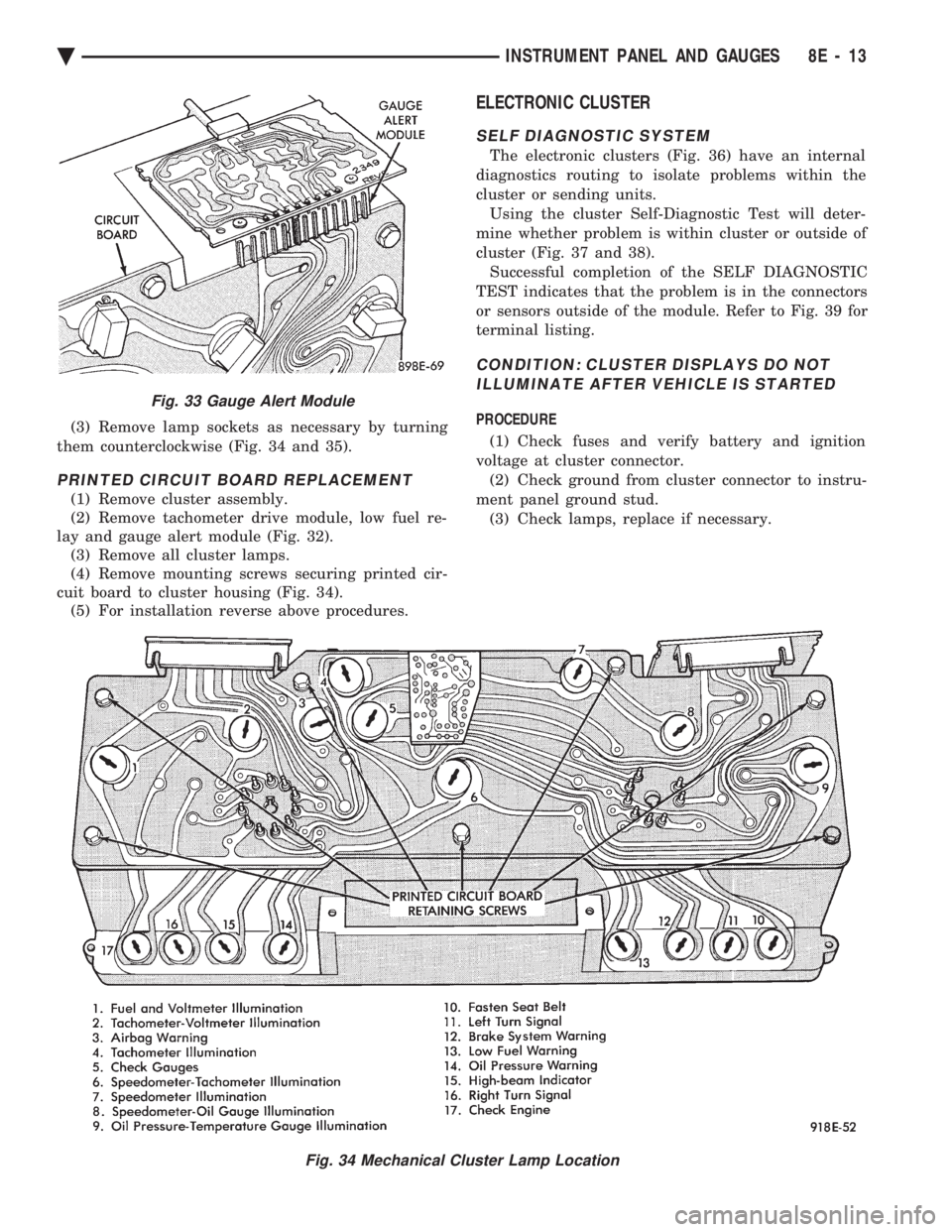

(3) Remove lamp sockets as necessary by turning

them counterclockwise (Fig. 34 and 35).

PRINTED CIRCUIT BOARD REPLACEMENT

(1) Remove cluster assembly.

(2) Remove tachometer drive module, low fuel re-

lay and gauge alert module (Fig. 32). (3) Remove all cluster lamps.

(4) Remove mounting screws securing printed cir-

cuit board to cluster housing (Fig. 34). (5) For installation reverse above procedures.

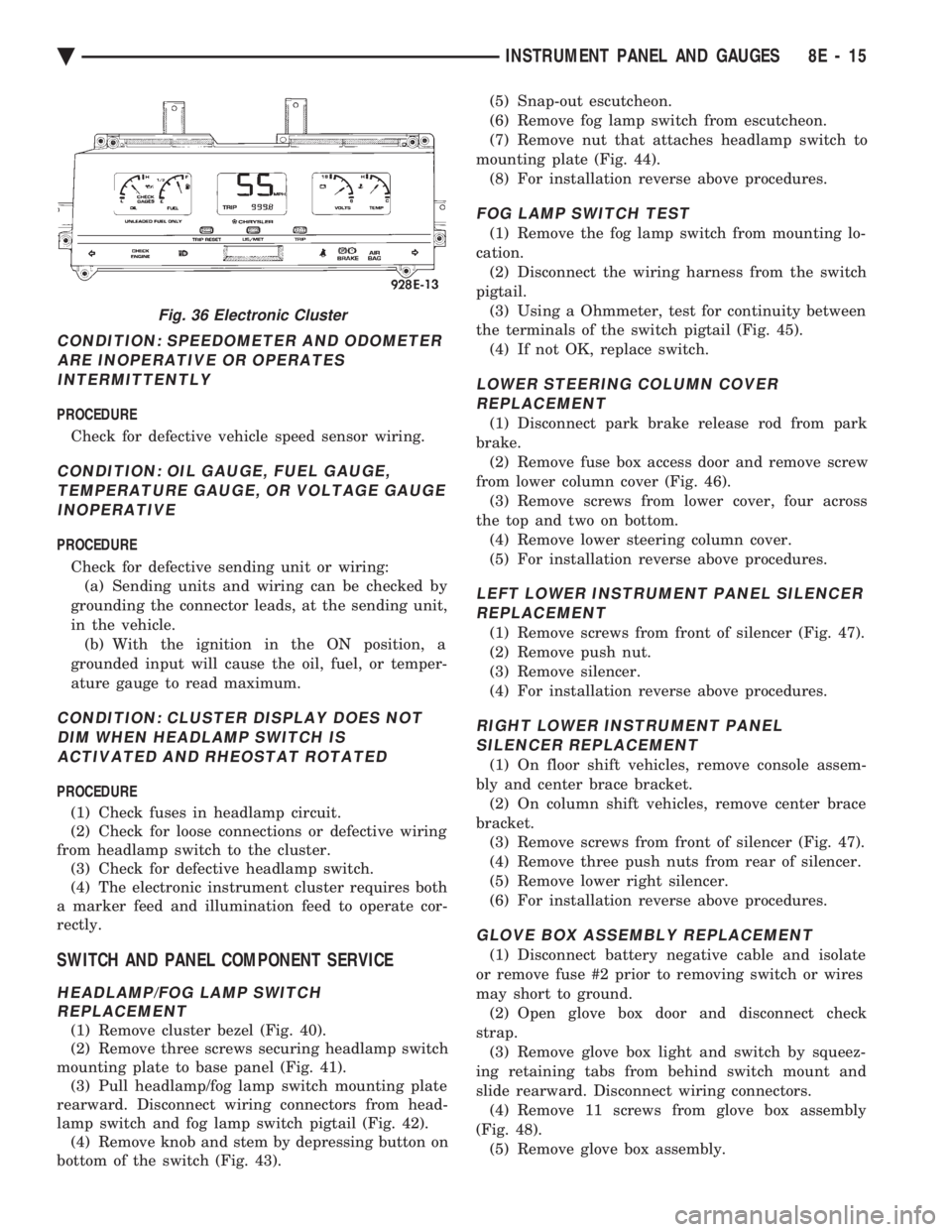

ELECTRONIC CLUSTER

SELF DIAGNOSTIC SYSTEM

The electronic clusters (Fig. 36) have an internal

diagnostics routing to isolate problems within the

cluster or sending units. Using the cluster Self-Diagnostic Test will deter-

mine whether problem is within cluster or outside of

cluster (Fig. 37 and 38). Successful completion of the SELF DIAGNOSTIC

TEST indicates that the problem is in the connectors

or sensors outside of the module. Refer to Fig. 39 for

terminal listing.

CONDITION: CLUSTER DISPLAYS DO NOT ILLUMINATE AFTER VEHICLE IS STARTED

PROCEDURE

(1) Check fuses and verify battery and ignition

voltage at cluster connector. (2) Check ground from cluster connector to instru-

ment panel ground stud. (3) Check lamps, replace if necessary.

Fig. 34 Mechanical Cluster Lamp Location

Fig. 33 Gauge Alert Module

Ä INSTRUMENT PANEL AND GAUGES 8E - 13

Page 507 of 2438

CONDITION: SPEEDOMETER AND ODOMETER ARE INOPERATIVE OR OPERATESINTERMITTENTLY

PROCEDURE

Check for defective vehicle speed sensor wiring.

CONDITION: OIL GAUGE, FUEL GAUGE, TEMPERATURE GAUGE, OR VOLTAGE GAUGEINOPERATIVE

PROCEDURE

Check for defective sending unit or wiring: (a) Sending units and wiring can be checked by

grounding the connector leads, at the sending unit,

in the vehicle. (b) With the ignition in the ON position, a

grounded input will cause the oil, fuel, or temper-

ature gauge to read maximum.

CONDITION: CLUSTER DISPLAY DOES NOT DIM WHEN HEADLAMP SWITCH ISACTIVATED AND RHEOSTAT ROTATED

PROCEDURE

(1) Check fuses in headlamp circuit.

(2) Check for loose connections or defective wiring

from headlamp switch to the cluster. (3) Check for defective headlamp switch.

(4) The electronic instrument cluster requires both

a marker feed and illumination feed to operate cor-

rectly.

SWITCH AND PANEL COMPONENT SERVICE

HEADLAMP/FOG LAMP SWITCH REPLACEMENT

(1) Remove cluster bezel (Fig. 40).

(2) Remove three screws securing headlamp switch

mounting plate to base panel (Fig. 41). (3) Pull headlamp/fog lamp switch mounting plate

rearward. Disconnect wiring connectors from head-

lamp switch and fog lamp switch pigtail (Fig. 42). (4) Remove knob and stem by depressing button on

bottom of the switch (Fig. 43). (5) Snap-out escutcheon.

(6) Remove fog lamp switch from escutcheon.

(7) Remove nut that attaches headlamp switch to

mounting plate (Fig. 44). (8) For installation reverse above procedures.

FOG LAMP SWITCH TEST

(1) Remove the fog lamp switch from mounting lo-

cation. (2) Disconnect the wiring harness from the switch

pigtail. (3) Using a Ohmmeter, test for continuity between

the terminals of the switch pigtail (Fig. 45). (4) If not OK, replace switch.

LOWER STEERING COLUMN COVERREPLACEMENT

(1) Disconnect park brake release rod from park

brake. (2) Remove fuse box access door and remove screw

from lower column cover (Fig. 46). (3) Remove screws from lower cover, four across

the top and two on bottom. (4) Remove lower steering column cover.

(5) For installation reverse above procedures.

LEFT LOWER INSTRUMENT PANEL SILENCER REPLACEMENT

(1) Remove screws from front of silencer (Fig. 47).

(2) Remove push nut.

(3) Remove silencer.

(4) For installation reverse above procedures.

RIGHT LOWER INSTRUMENT PANEL SILENCER REPLACEMENT

(1) On floor shift vehicles, remove console assem-

bly and center brace bracket. (2) On column shift vehicles, remove center brace

bracket. (3) Remove screws from front of silencer (Fig. 47).

(4) Remove three push nuts from rear of silencer.

(5) Remove lower right silencer.

(6) For installation reverse above procedures.

GLOVE BOX ASSEMBLY REPLACEMENT

(1) Disconnect battery negative cable and isolate

or remove fuse #2 prior to removing switch or wires

may short to ground. (2) Open glove box door and disconnect check

strap. (3) Remove glove box light and switch by squeez-

ing retaining tabs from behind switch mount and

slide rearward. Disconnect wiring connectors. (4) Remove 11 screws from glove box assembly

(Fig. 48). (5) Remove glove box assembly.

Fig. 36 Electronic Cluster

Ä INSTRUMENT PANEL AND GAUGES 8E - 15