jump start CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 394 of 2438

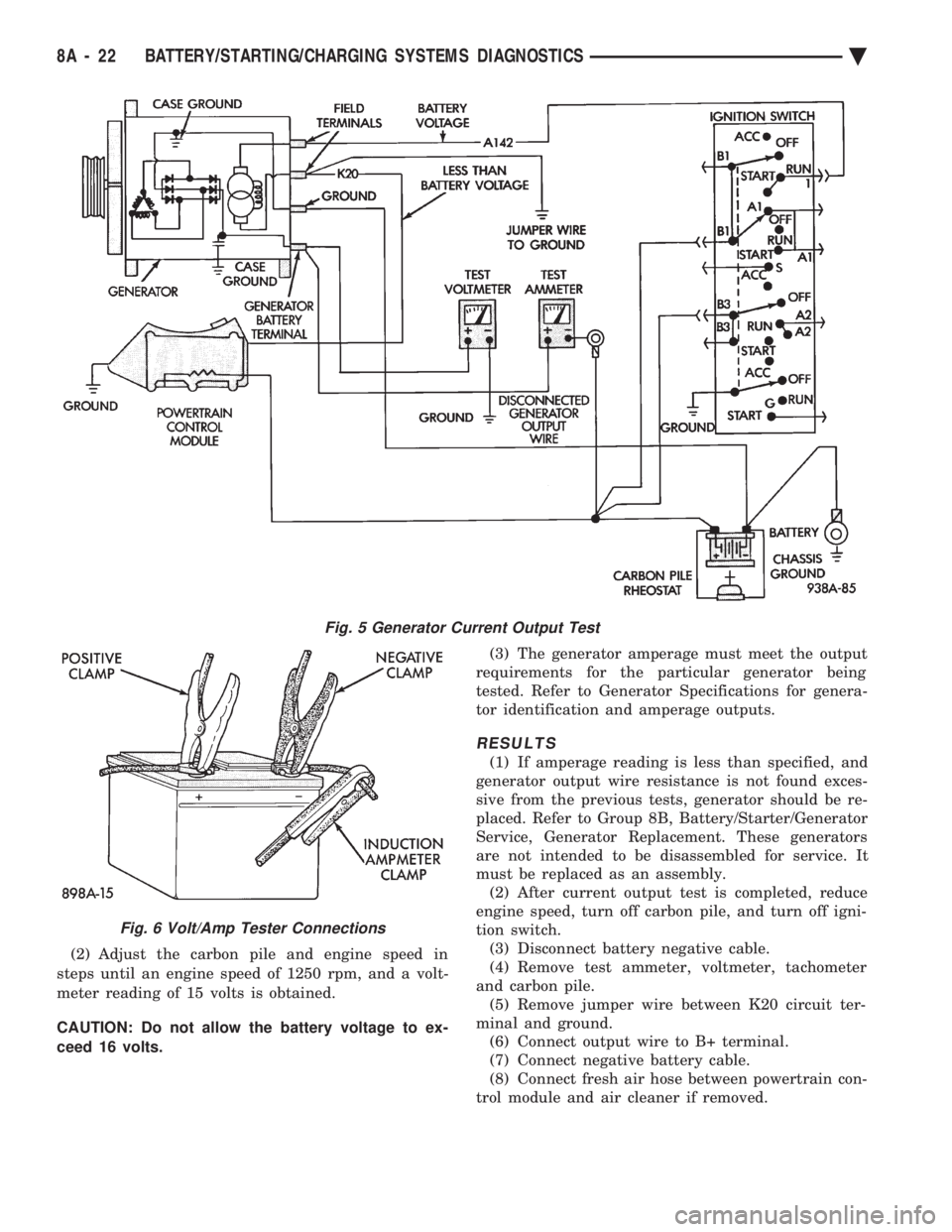

(2) Adjust the carbon pile and engine speed in

steps until an engine speed of 1250 rpm, and a volt-

meter reading of 15 volts is obtained.

CAUTION: Do not allow the battery voltage to ex-

ceed 16 volts. (3) The generator amperage must meet the output

requirements for the particular generator being

tested. Refer to Generator Specifications for genera-

tor identification and amperage outputs.

RESULTS

(1) If amperage reading is less than specified, and

generator output wire resistance is not found exces-

sive from the previous tests, generator should be re-

placed. Refer to Group 8B, Battery/Starter/Generator

Service, Generator Replacement. These generators

are not intended to be disassembled for service. It

must be replaced as an assembly. (2) After current output test is completed, reduce

engine speed, turn off carbon pile, and turn off igni-

tion switch. (3) Disconnect battery negative cable.

(4) Remove test ammeter, voltmeter, tachometer

and carbon pile. (5) Remove jumper wire between K20 circuit ter-

minal and ground. (6) Connect output wire to B+ terminal.

(7) Connect negative battery cable.

(8) Connect fresh air hose between powertrain con-

trol module and air cleaner if removed.

Fig. 5 Generator Current Output Test

Fig. 6 Volt/Amp Tester Connections

8A - 22 BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS Ä

Page 454 of 2438

make sure that the spark plugs are firing. Inspect the

distributor rotor, cap, spark plug cables, and spark

plugs. If they are in proper working order, the ignition

system is not the reason why the engine will not start.

Inspect the fuel system and engine for proper opera-

tion.

FAILURE TO START TESTÐ2.5L TBI AND 3.0L

ENGINES

Before proceeding with this test make sure

Testing For Spark At Coil has been performed.

Failure to do this may lead to unnecessary diag-

nostic time and wrong test results.

WARNING: BE SURE TO APPLY PARKING BRAKE

AND/OR BLOCK WHEELS BEFORE PERFORMING

ANY TEST WITH THE ENGINE RUNNING.

(1) Battery voltage must be at least 12.4 volts to

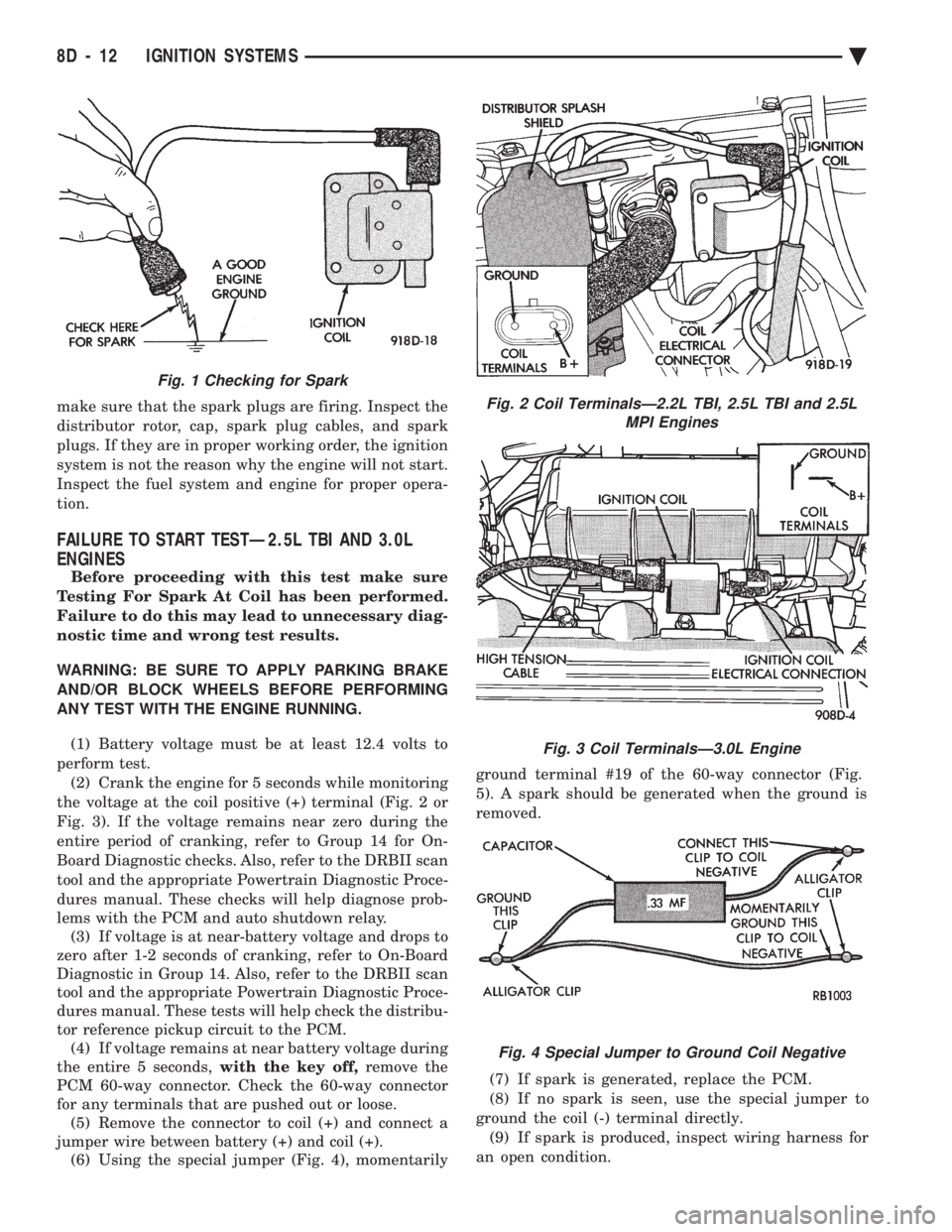

perform test. (2) Crank the engine for 5 seconds while monitoring

the voltage at the coil positive (+) terminal (Fig. 2 or

Fig. 3). If the voltage remains near zero during the

entire period of cranking, refer to Group 14 for On-

Board Diagnostic checks. Also, refer to the DRBII scan

tool and the appropriate Powertrain Diagnostic Proce-

dures manual. These checks will help diagnose prob-

lems with the PCM and auto shutdown relay. (3) If voltage is at near-battery voltage and drops to

zero after 1-2 seconds of cranking, refer to On-Board

Diagnostic in Group 14. Also, refer to the DRBII scan

tool and the appropriate Powertrain Diagnostic Proce-

dures manual. These tests will help check the distribu-

tor reference pickup circuit to the PCM. (4) If voltage remains at near battery voltage during

the entire 5 seconds, with the key off,remove the

PCM 60-way connector. Check the 60-way connector

for any terminals that are pushed out or loose. (5) Remove the connector to coil (+) and connect a

jumper wire between battery (+) and coil (+). (6) Using the special jumper (Fig. 4), momentarily ground terminal #19 of the 60-way connector (Fig.

5). A spark should be generated when the ground is

removed.

(7) If spark is generated, replace the PCM.

(8) If no spark is seen, use the special jumper to

ground the coil (-) terminal directly. (9) If spark is produced, inspect wiring harness for

an open condition.

Fig. 2 Coil TerminalsÐ2.2L TBI, 2.5L TBI and 2.5L MPI Engines

Fig. 3 Coil TerminalsÐ3.0L Engine

Fig. 4 Special Jumper to Ground Coil Negative

Fig. 1 Checking for Spark

8D - 12 IGNITION SYSTEMS Ä

Page 483 of 2438

(2) With engine running, move test probe along

entire length of all cables (approximately 0 to 1/8

inch gap). If punctures or cracks are present there

will be a noticeable spark jump from the faulty area

to the probe. Cracked, leaking or faulty cables should

be replaced. Use the following procedure when removing the

high tension cable from the spark plug. First, remove

the cable from the retaining bracket. Then grasp the

terminal as close as possible to the spark plug. Ro-

tate the cover (boot) slightly and pull straight back.

Do not use pliers and do not pull the cable at an

angle. Doing so will damage the insulation, cable

terminal or the spark plug insulator. Wipe spark

plug insulator clean before reinstalling cable

and cover. Resistance cables are identified by the words Elec-

tronic Suppression .

Use an ohmmeter to check cables for opens, loose

terminals or high resistance. (a) Remove cable from spark plug.

(b) Remove cable from the coil tower.

(c) Connect the ohmmeter between spark plug

end terminal and the coil end terminal. Resistance

should be within tolerance shown in the cable re-

sistance chart. If resistance is not within tolerance,

replace cable assembly. Test all spark plug cables

in same manner.

SPARK PLUG SERVICE

When replacing the spark plug cables, route the ca-

bles correctly and secure them in the appropriate re-

tainers. Incorrectly routed cables can cause the radio

to reproduce ignition noise. It can also cause cross ig-

nition of the spark plugs or short circuit the cables to

ground.

SPARK PLUG REMOVAL

Always remove cables by grasping at boot, rotating

the boot 1/2 turn, and pulling straight back in a

steady motion. (1) Prior to removing the spark plug spray com-

pressed air around the spark plug hole and the area

around the spark plug. (2) Remove the spark plug using a quality socket

with a rubber or foam insert. (3) Inspect the spark plug condition. Refer to

Spark Plug Condition in this section.

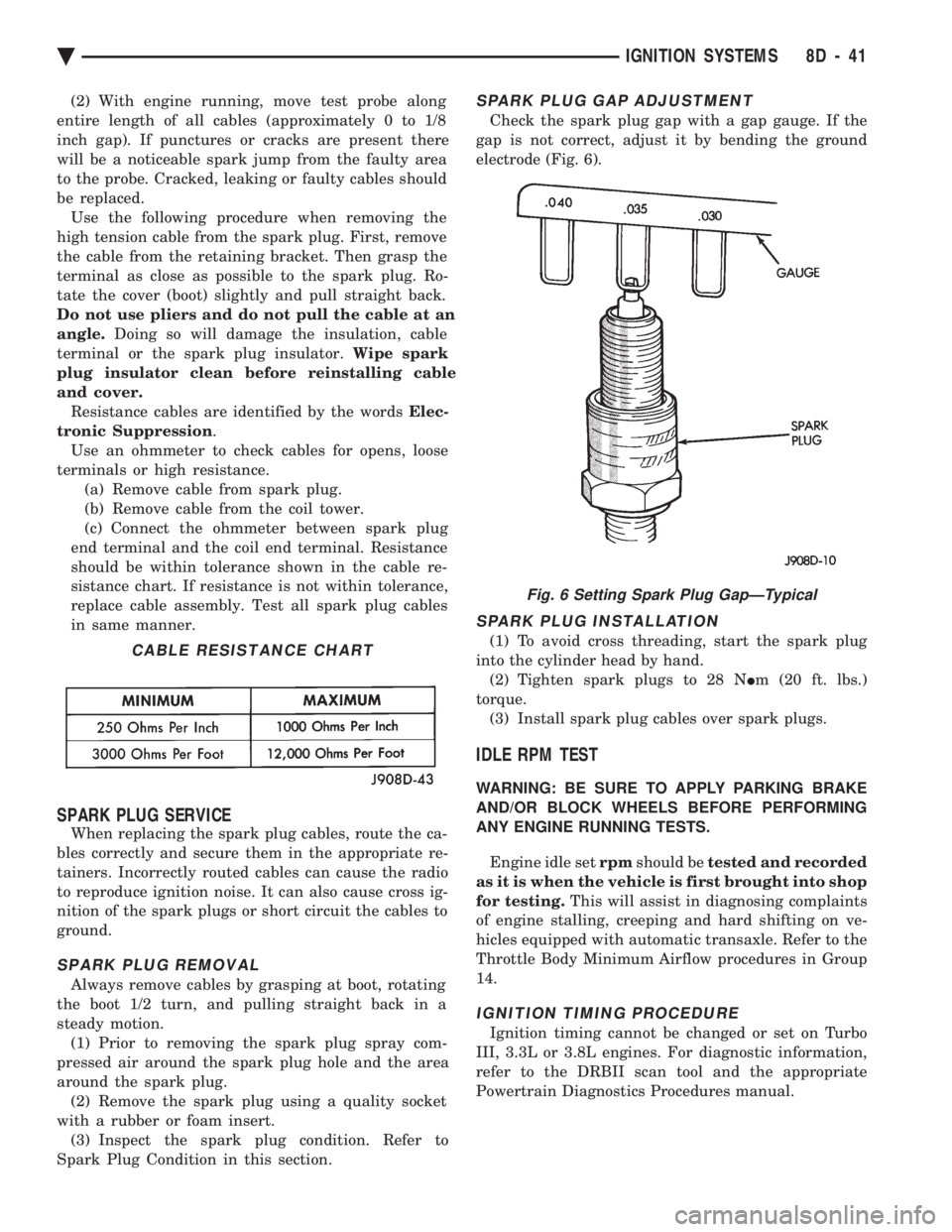

SPARK PLUG GAP ADJUSTMENT

Check the spark plug gap with a gap gauge. If the

gap is not correct, adjust it by bending the ground

electrode (Fig. 6).

SPARK PLUG INSTALLATION

(1) To avoid cross threading, start the spark plug

into the cylinder head by hand. (2) Tighten spark plugs to 28 N Im (20 ft. lbs.)

torque. (3) Install spark plug cables over spark plugs.

IDLE RPM TEST

WARNING: BE SURE TO APPLY PARKING BRAKE

AND/OR BLOCK WHEELS BEFORE PERFORMING

ANY ENGINE RUNNING TESTS.

Engine idle set rpmshould be tested and recorded

as it is when the vehicle is first brought into shop

for testing. This will assist in diagnosing complaints

of engine stalling, creeping and hard shifting on ve-

hicles equipped with automatic transaxle. Refer to the

Throttle Body Minimum Airflow procedures in Group

14.

IGNITION TIMING PROCEDURE

Ignition timing cannot be changed or set on Turbo

III, 3.3L or 3.8L engines. For diagnostic information,

refer to the DRBII scan tool and the appropriate

Powertrain Diagnostics Procedures manual.

CABLE RESISTANCE CHART

Fig. 6 Setting Spark Plug GapÐTypical

Ä IGNITION SYSTEMS 8D - 41

Page 495 of 2438

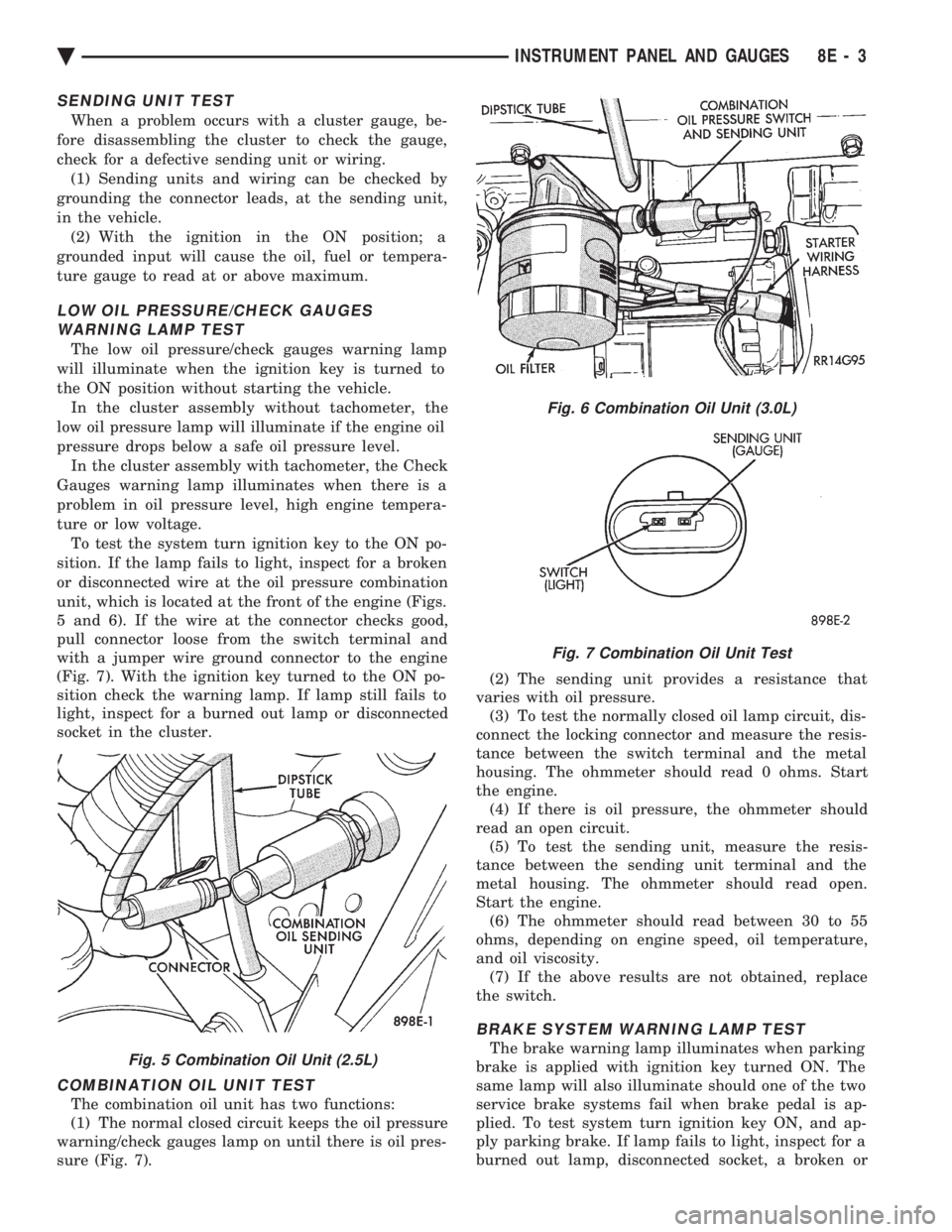

SENDING UNIT TEST

When a problem occurs with a cluster gauge, be-

fore disassembling the cluster to check the gauge,

check for a defective sending unit or wiring. (1) Sending units and wiring can be checked by

grounding the connector leads, at the sending unit,

in the vehicle. (2) With the ignition in the ON position; a

grounded input will cause the oil, fuel or tempera-

ture gauge to read at or above maximum.

LOW OIL PRESSURE/CHECK GAUGES WARNING LAMP TEST

The low oil pressure/check gauges warning lamp

will illuminate when the ignition key is turned to

the ON position without starting the vehicle. In the cluster assembly without tachometer, the

low oil pressure lamp will illuminate if the engine oil

pressure drops below a safe oil pressure level. In the cluster assembly with tachometer, the Check

Gauges warning lamp illuminates when there is a

problem in oil pressure level, high engine tempera-

ture or low voltage. To test the system turn ignition key to the ON po-

sition. If the lamp fails to light, inspect for a broken

or disconnected wire at the oil pressure combination

unit, which is located at the front of the engine (Figs.

5 and 6). If the wire at the connector checks good,

pull connector loose from the switch terminal and

with a jumper wire ground connector to the engine

(Fig. 7). With the ignition key turned to the ON po-

sition check the warning lamp. If lamp still fails to

light, inspect for a burned out lamp or disconnected

socket in the cluster.

COMBINATION OIL UNIT TEST

The combination oil unit has two functions:

(1) The normal closed circuit keeps the oil pressure

warning/check gauges lamp on until there is oil pres-

sure (Fig. 7). (2) The sending unit provides a resistance that

varies with oil pressure. (3) To test the normally closed oil lamp circuit, dis-

connect the locking connector and measure the resis-

tance between the switch terminal and the metal

housing. The ohmmeter should read 0 ohms. Start

the engine. (4) If there is oil pressure, the ohmmeter should

read an open circuit. (5) To test the sending unit, measure the resis-

tance between the sending unit terminal and the

metal housing. The ohmmeter should read open.

Start the engine. (6) The ohmmeter should read between 30 to 55

ohms, depending on engine speed, oil temperature,

and oil viscosity. (7) If the above results are not obtained, replace

the switch.

BRAKE SYSTEM WARNING LAMP TEST

The brake warning lamp illuminates when parking

brake is applied with ignition key turned ON. The

same lamp will also illuminate should one of the two

service brake systems fail when brake pedal is ap-

plied. To test system turn ignition key ON, and ap-

ply parking brake. If lamp fails to light, inspect for a

burned out lamp, disconnected socket, a broken orFig. 5 Combination Oil Unit (2.5L)

Fig. 6 Combination Oil Unit (3.0L)

Fig. 7 Combination Oil Unit Test

Ä INSTRUMENT PANEL AND GAUGES 8E - 3

Page 539 of 2438

(3) With the ignition switch ON, an open (discon-

nected sending unit wire) causes the oil, fuel or tem-

perature gauge to read below low, empty or cold

indicators. (4) If steps 2 and 3 check OK, refer to the individ-

ual sending unit test procedures.

FUEL TANK SENDING UNIT TEST

Refer to Group 14, Fuel for test procedure.

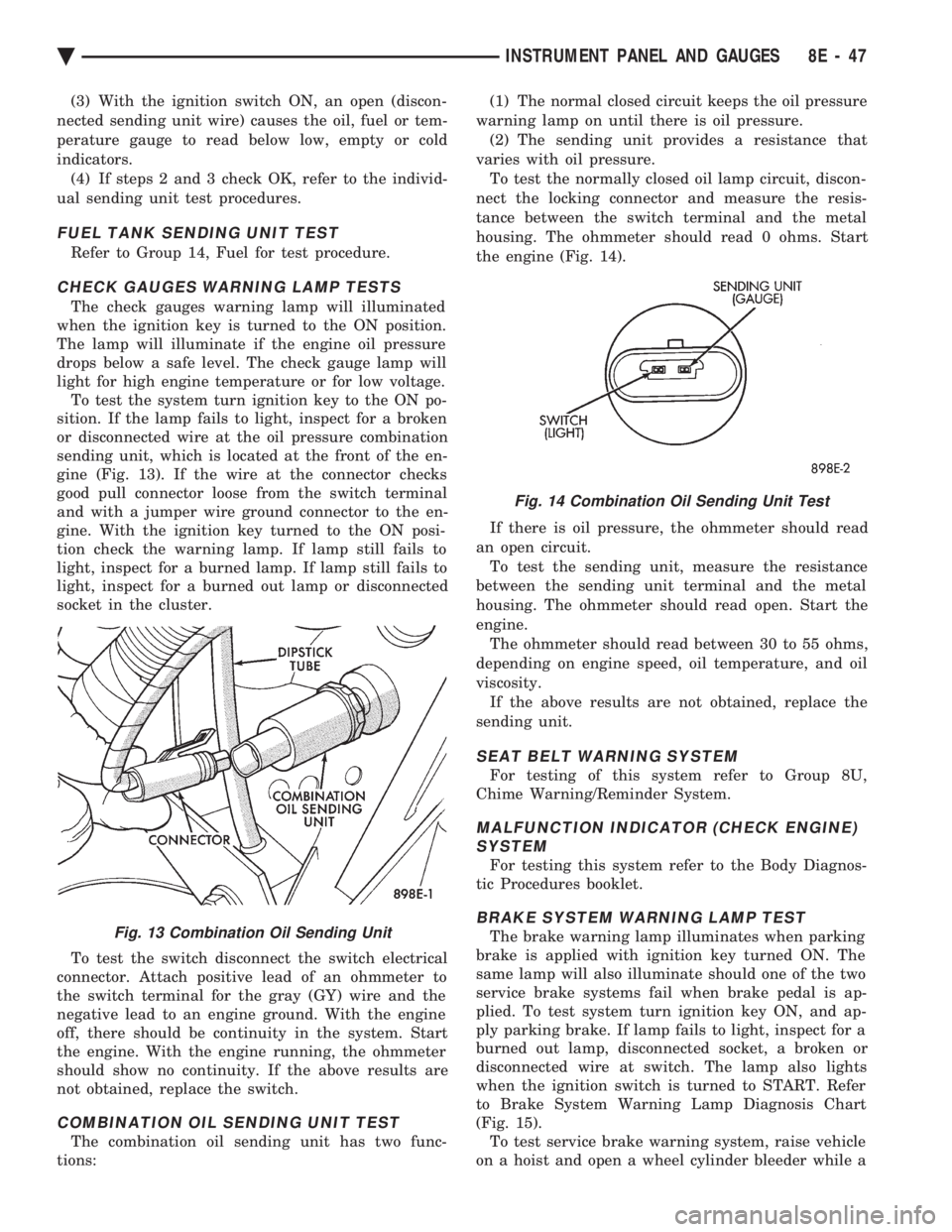

CHECK GAUGES WARNING LAMP TESTS

The check gauges warning lamp will illuminated

when the ignition key is turned to the ON position.

The lamp will illuminate if the engine oil pressure

drops below a safe level. The check gauge lamp will

light for high engine temperature or for low voltage. To test the system turn ignition key to the ON po-

sition. If the lamp fails to light, inspect for a broken

or disconnected wire at the oil pressure combination

sending unit, which is located at the front of the en-

gine (Fig. 13). If the wire at the connector checks

good pull connector loose from the switch terminal

and with a jumper wire ground connector to the en-

gine. With the ignition key turned to the ON posi-

tion check the warning lamp. If lamp still fails to

light, inspect for a burned lamp. If lamp still fails to

light, inspect for a burned out lamp or disconnected

socket in the cluster.

To test the switch disconnect the switch electrical

connector. Attach positive lead of an ohmmeter to

the switch terminal for the gray (GY) wire and the

negative lead to an engine ground. With the engine

off, there should be continuity in the system. Start

the engine. With the engine running, the ohmmeter

should show no continuity. If the above results are

not obtained, replace the switch.

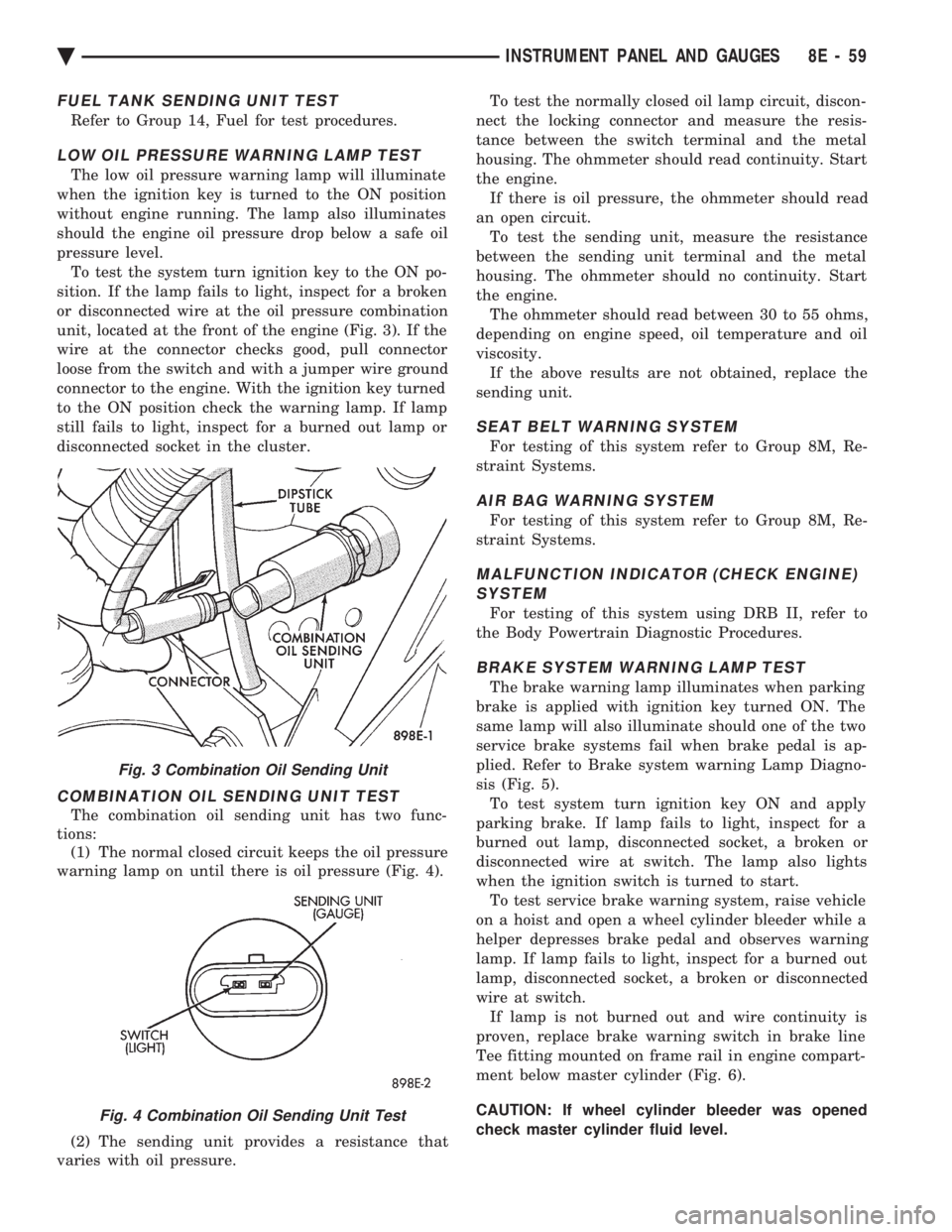

COMBINATION OIL SENDING UNIT TEST

The combination oil sending unit has two func-

tions: (1) The normal closed circuit keeps the oil pressure

warning lamp on until there is oil pressure. (2) The sending unit provides a resistance that

varies with oil pressure. To test the normally closed oil lamp circuit, discon-

nect the locking connector and measure the resis-

tance between the switch terminal and the metal

housing. The ohmmeter should read 0 ohms. Start

the engine (Fig. 14).

If there is oil pressure, the ohmmeter should read

an open circuit. To test the sending unit, measure the resistance

between the sending unit terminal and the metal

housing. The ohmmeter should read open. Start the

engine. The ohmmeter should read between 30 to 55 ohms,

depending on engine speed, oil temperature, and oil

viscosity. If the above results are not obtained, replace the

sending unit.

SEAT BELT WARNING SYSTEM

For testing of this system refer to Group 8U,

Chime Warning/Reminder System.

MALFUNCTION INDICATOR (CHECK ENGINE) SYSTEM

For testing this system refer to the Body Diagnos-

tic Procedures booklet.

BRAKE SYSTEM WARNING LAMP TEST

The brake warning lamp illuminates when parking

brake is applied with ignition key turned ON. The

same lamp will also illuminate should one of the two

service brake systems fail when brake pedal is ap-

plied. To test system turn ignition key ON, and ap-

ply parking brake. If lamp fails to light, inspect for a

burned out lamp, disconnected socket, a broken or

disconnected wire at switch. The lamp also lights

when the ignition switch is turned to START. Refer

to Brake System Warning Lamp Diagnosis Chart

(Fig. 15). To test service brake warning system, raise vehicle

on a hoist and open a wheel cylinder bleeder while aFig. 13 Combination Oil Sending Unit

Fig. 14 Combination Oil Sending Unit Test

Ä INSTRUMENT PANEL AND GAUGES 8E - 47

Page 551 of 2438

FUEL TANK SENDING UNIT TEST

Refer to Group 14, Fuel for test procedures.

LOW OIL PRESSURE WARNING LAMP TEST

The low oil pressure warning lamp will illuminate

when the ignition key is turned to the ON position

without engine running. The lamp also illuminates

should the engine oil pressure drop below a safe oil

pressure level. To test the system turn ignition key to the ON po-

sition. If the lamp fails to light, inspect for a broken

or disconnected wire at the oil pressure combination

unit, located at the front of the engine (Fig. 3). If the

wire at the connector checks good, pull connector

loose from the switch and with a jumper wire ground

connector to the engine. With the ignition key turned

to the ON position check the warning lamp. If lamp

still fails to light, inspect for a burned out lamp or

disconnected socket in the cluster.

COMBINATION OIL SENDING UNIT TEST

The combination oil sending unit has two func-

tions: (1) The normal closed circuit keeps the oil pressure

warning lamp on until there is oil pressure (Fig. 4).

(2) The sending unit provides a resistance that

varies with oil pressure. To test the normally closed oil lamp circuit, discon-

nect the locking connector and measure the resis-

tance between the switch terminal and the metal

housing. The ohmmeter should read continuity. Start

the engine. If there is oil pressure, the ohmmeter should read

an open circuit. To test the sending unit, measure the resistance

between the sending unit terminal and the metal

housing. The ohmmeter should no continuity. Start

the engine. The ohmmeter should read between 30 to 55 ohms,

depending on engine speed, oil temperature and oil

viscosity. If the above results are not obtained, replace the

sending unit.

SEAT BELT WARNING SYSTEM

For testing of this system refer to Group 8M, Re-

straint Systems.

AIR BAG WARNING SYSTEM

For testing of this system refer to Group 8M, Re-

straint Systems.

MALFUNCTION INDICATOR (CHECK ENGINE) SYSTEM

For testing of this system using DRB II, refer to

the Body Powertrain Diagnostic Procedures.

BRAKE SYSTEM WARNING LAMP TEST

The brake warning lamp illuminates when parking

brake is applied with ignition key turned ON. The

same lamp will also illuminate should one of the two

service brake systems fail when brake pedal is ap-

plied. Refer to Brake system warning Lamp Diagno-

sis (Fig. 5). To test system turn ignition key ON and apply

parking brake. If lamp fails to light, inspect for a

burned out lamp, disconnected socket, a broken or

disconnected wire at switch. The lamp also lights

when the ignition switch is turned to start. To test service brake warning system, raise vehicle

on a hoist and open a wheel cylinder bleeder while a

helper depresses brake pedal and observes warning

lamp. If lamp fails to light, inspect for a burned out

lamp, disconnected socket, a broken or disconnected

wire at switch. If lamp is not burned out and wire continuity is

proven, replace brake warning switch in brake line

Tee fitting mounted on frame rail in engine compart-

ment below master cylinder (Fig. 6).

CAUTION: If wheel cylinder bleeder was opened

check master cylinder fluid level.

Fig. 3 Combination Oil Sending Unit

Fig. 4 Combination Oil Sending Unit Test

Ä INSTRUMENT PANEL AND GAUGES 8E - 59

Page 703 of 2438

VEHICLE THEFT SECURITY SYSTEM

CONTENTS

page page

GENERAL INFORMATION .................. 1

SECURITY SYSTEM DOOR SWITCH REPLACEMENT ........................ 2

SECURITY SYSTEM HOOD SWITCH REPLACEMENT ........................ 2 SYSTEM SELF-TESTS

.................... 1

VEHICLE THEFT SECURITY SYSTEM MODULE REPLACEMENT ........................ 2

WHAT WILL TRIGGER THE SYSTEM ........ 1

GENERAL INFORMATION

JUMP-STARTING, VEHICLE EQUIPPED

WITH THEFT SECURITY SYSTEM . After the

booster battery has been connected, the Theft System

must be turned OFF. Using the key, lock then un-

lock either front door. This turns the Theft System

OFF and the remainder of the Jump-Starting proce-

dure can be followed. If this procedure is not followed, the Theft System

electronics will prevent the engine from starting. If a new Powertrain Control Module is installed,

the engine has to be cranked 20 times before the

alarm system activated. This passive system is designed to protect against

whole vehicle theft. The system monitors vehicle

doors, hood, trunk key cylinder, and ignition action

for unauthorized operation. The alarm activates by

sounding the horn, flashing the park and tail lamps,

and providing an engine kill feature (Fig. 1). Passive arming occurs upon normal vehicle exit,

open door, lock with power locks, close door. The SET

lamp in the panel will flash for 15 seconds, indicat-

ing that arming is in progress. If no monitored sys-

tems are activated during this period, the system

will arm. If the hood or trunk key cylinder switches

are not sensed by the system. The SET lamp will re-

main lit during the arming process, although the sys-

tem will still arm. The system is to be considered as

an active armed system when using the Remote Key-

less Entry. If the SET lamp does not illuminate at all

upon door closing it indicates that the system is not

arming. Passive disarming occurs upon normal vehicle en-

try unlocking either door with the key, or unlocking

using the Remote Keyless transmitter. This disarm-

ing will also halt the alarm once it has been acti-

vated. Whenever the battery is disconnected and recon-

nected, the Vehicle Theft Security System enters

power up alarm mode which flashes the park and tail

lamps and prevents the engine from running. To exit

this mode, the system must be disarmed as men-

tioned above. A tamper alert exists to notify the driver that the

alarm had been activated, and the alarm has since

timed-out for more than 18 minutes. This alert con-

sists of 3 horn pulses when the vehicle is disarmed. The alarm system will not arm if the doors are

manually locked, providing a manual override of the

alarm.

WHAT WILL TRIGGER THE SYSTEM

One of the following actions will trigger the system

while it is armed. Without properly disarming sys-

tem, by using the key or the remote transmitter. (1) Opening the HOOD.

(2) Opening any DOOR.

(3) Removing the TRUNK KEY CYLINDER.

(4) Turning the IGNITION ON.

(5) The ignition switch can be turned to the acces-

sory position without triggering alarm system.

SYSTEM SELF-TESTS

A diagnostics mode is available in the system to

verify operation of all monitored switches or circuits.

To enter diagnostics, cycle the ignition key to the ac-

cessory position 3 times, leaving the key in this po-

sition. Upon entering diagnostics, the park and tail lamps

will begin flashing to verify their operation. In addi-

tion, the horn will sound twice to indicate that the

trunk key cylinder is in its proper position. Return-

ing the ignition to the OFF position will stop the

lamps from flashing while keeping the system in di-

agnostics. While in diagnostics mode, a horn pulse should oc-

cur at each of the following events indicating proper

operation: (1) Beginning with all doors closed, open then close

each door. The horn will sound when the door ajar

switch closes, and then again when the switch opens.

There must b e a 1 second delay between closing and

opening the switch. (2) Open, then close the hood. The horn will sound

when the hood is opened, and again when it is closed.

Ä VEHICLE THEFT SECURITY SYSTEM 8Q - 1

Page 743 of 2438

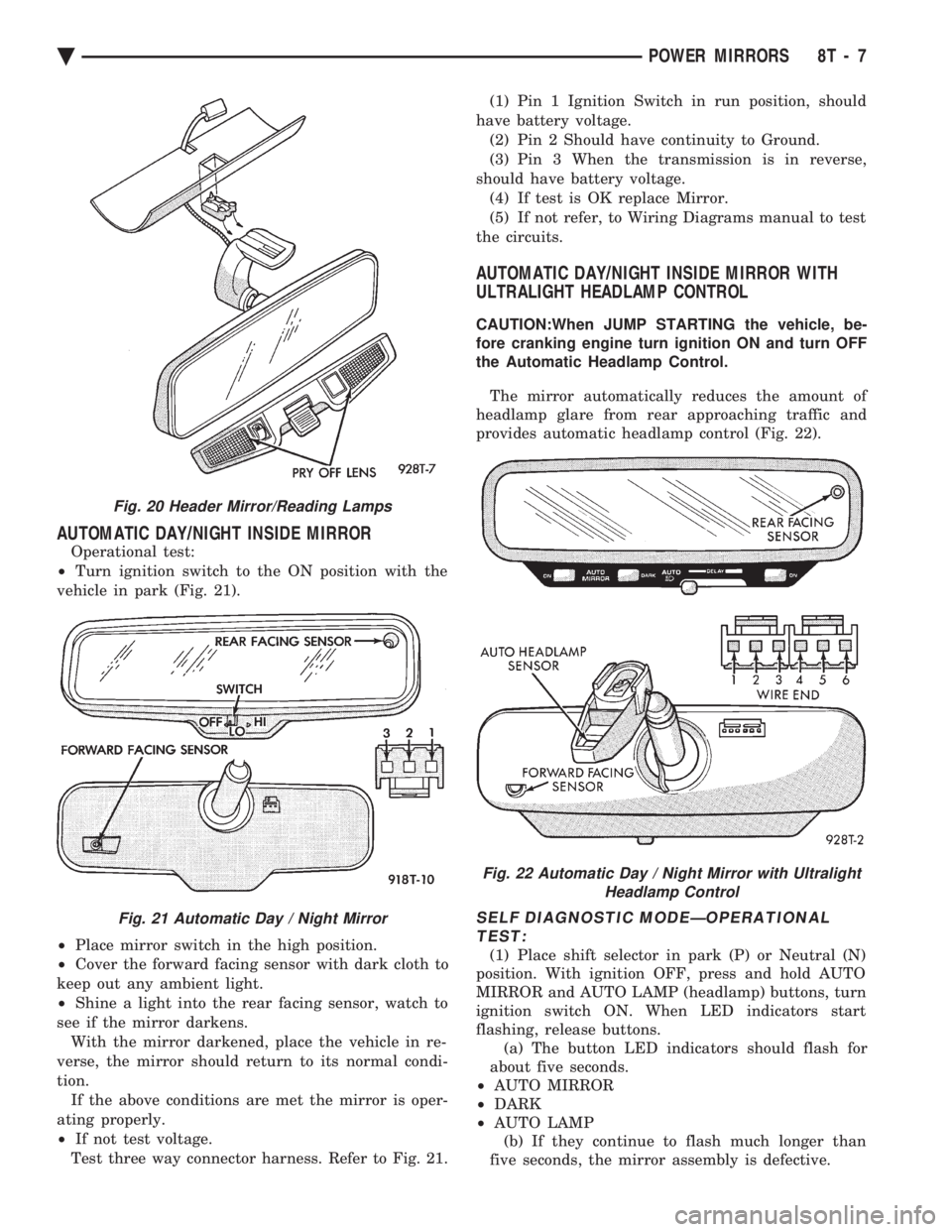

AUTOMATIC DAY/NIGHT INSIDE MIRROR

Operational test:

² Turn ignition switch to the ON position with the

vehicle in park (Fig. 21).

² Place mirror switch in the high position.

² Cover the forward facing sensor with dark cloth to

keep out any ambient light.

² Shine a light into the rear facing sensor, watch to

see if the mirror darkens. With the mirror darkened, place the vehicle in re-

verse, the mirror should return to its normal condi-

tion. If the above conditions are met the mirror is oper-

ating properly.

² If not test voltage.

Test three way connector harness. Refer to Fig. 21. (1) Pin 1 Ignition Switch in run position, should

have battery voltage. (2) Pin 2 Should have continuity to Ground.

(3) Pin 3 When the transmission is in reverse,

should have battery voltage. (4) If test is OK replace Mirror.

(5) If not refer, to Wiring Diagrams manual to test

the circuits.

AUTOMATIC DAY/NIGHT INSIDE MIRROR WITH

ULTRALIGHT HEADLAMP CONTROL

CAUTION:When JUMP STARTING the vehicle, be-

fore cranking engine turn ignition ON and turn OFF

the Automatic Headlamp Control.

The mirror automatically reduces the amount of

headlamp glare from rear approaching traffic and

provides automatic headlamp control (Fig. 22).

SELF DIAGNOSTIC MODEÐOPERATIONAL TEST:

(1) Place shift selector in park (P) or Neutral (N)

position. With ignition OFF, press and hold AUTO

MIRROR and AUTO LAMP (headlamp) buttons, turn

ignition switch ON. When LED indicators start

flashing, release buttons. (a) The button LED indicators should flash for

about five seconds.

² AUTO MIRROR

² DARK

² AUTO LAMP

(b) If they continue to flash much longer than

five seconds, the mirror assembly is defective.

Fig. 20 Header Mirror/Reading Lamps

Fig. 21 Automatic Day / Night Mirror

Fig. 22 Automatic Day / Night Mirror with Ultralight Headlamp Control

Ä POWER MIRRORS 8T - 7

Page 1284 of 2438

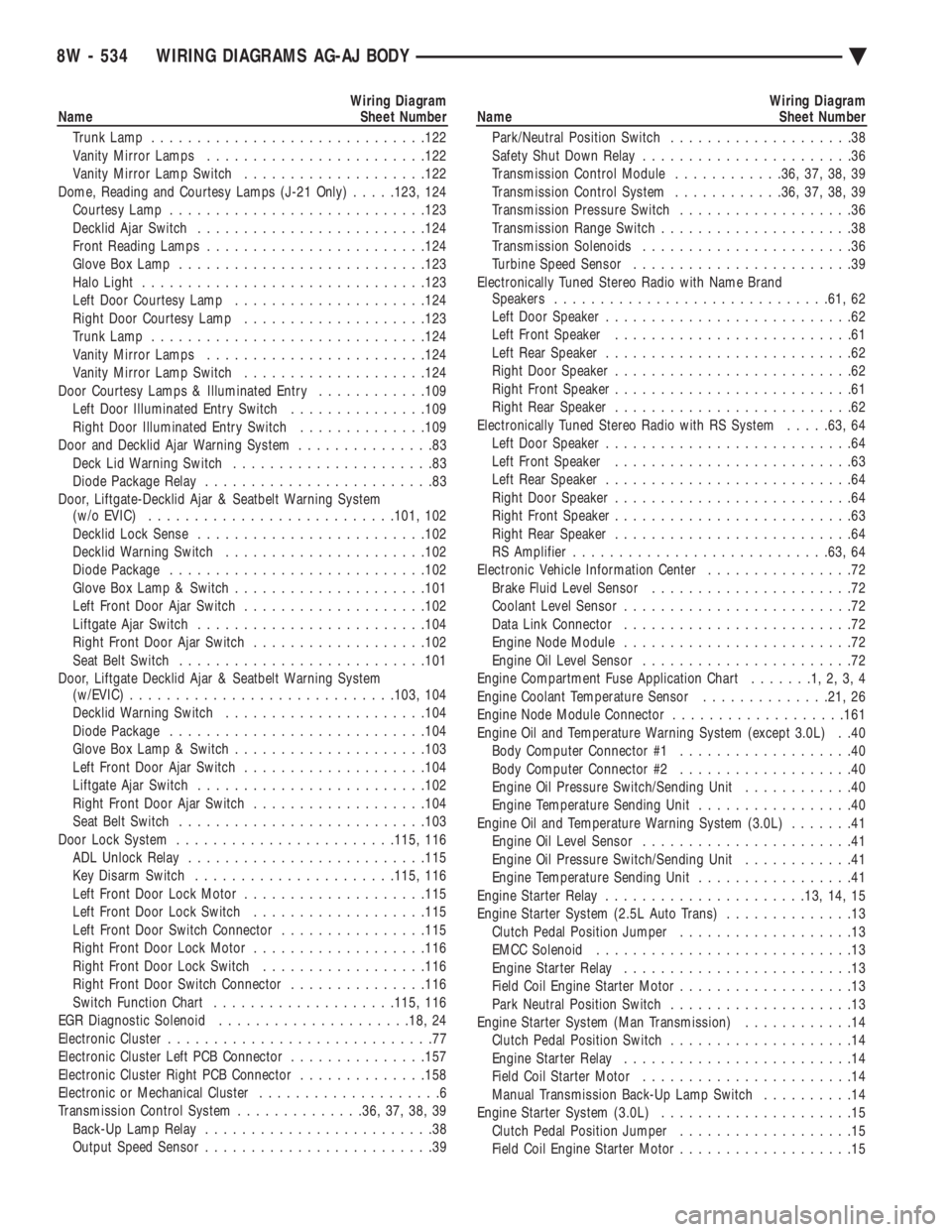

Wiring Diagram

Name Sheet Number

Trunk Lamp ............................. .122

Vanity Mirror Lamps ....................... .122

Vanity Mirror Lamp Switch ................... .122

Dome, Reading and Courtesy Lamps (J-21 Only) .....123, 124

Courtesy Lamp ........................... .123

Decklid Ajar Switch ........................ .124

Front Reading Lamps ....................... .124

Glove Box Lamp .......................... .123

Halo Light .............................. .123

Left Door Courtesy Lamp .................... .124

Right Door Courtesy Lamp ................... .123

Trunk Lamp ............................. .124

Vanity Mirror Lamps ....................... .124

Vanity Mirror Lamp Switch ................... .124

Door Courtesy Lamps & Illuminated Entry ............109

Left Door Illuminated Entry Switch ...............109

Right Door Illuminated Entry Switch ..............109

Door and Decklid Ajar Warning System ...............83

Deck Lid Warning Switch ......................83

Diode Package Relay .........................83

Door, Liftgate-Decklid Ajar & Seatbelt Warning System (w/o EVIC) .......................... .101, 102

Decklid Lock Sense ........................ .102

Decklid Warning Switch ..................... .102

Diode Package ........................... .102

Glove Box Lamp & Switch .................... .101

Left Front Door Ajar Switch ................... .102

Liftgate Ajar Switch ........................ .104

Right Front Door Ajar Switch ...................102

Seat Belt Switch .......................... .101

Door, Liftgate Decklid Ajar & Seatbelt Warning System (w/EVIC) ............................ .103, 104

Decklid Warning Switch ..................... .104

Diode Package ........................... .104

Glove Box Lamp & Switch .................... .103

Left Front Door Ajar Switch ................... .104

Liftgate Ajar Switch ........................ .102

Right Front Door Ajar Switch ...................104

Seat Belt Switch .......................... .103

Door Lock System ....................... .115, 116

ADL Unlock Relay ......................... .115

Key Disarm Switch ..................... .115, 116

Left Front Door Lock Motor ................... .115

Left Front Door Lock Switch ...................115

Left Front Door Switch Connector ................115

Right Front Door Lock Motor ...................116

Right Front Door Lock Switch ..................116

Right Front Door Switch Connector ...............116

Switch Function Chart ................... .115, 116

EGR Diagnostic Solenoid .................... .18, 24

Electronic Cluster .............................77

Electronic Cluster Left PCB Connector ...............157

Electronic Cluster Right PCB Connector ..............158

Electronic or Mechanical Cluster ....................6

Transmission Control System ..............36, 37, 38, 39

Back-Up Lamp Relay .........................38

Output Speed Sensor .........................39Wiring Diagram

Name Sheet Number

Park/Neutral Position Switch ....................38

Safety Shut Down Relay .......................36

Transmission Control Module ............36, 37, 38, 39

Transmission Control System ............36, 37, 38, 39

Transmission Pressure Switch ...................36

Transmission Range Switch .....................38

Transmission Solenoids .......................36

Turbine Speed Sensor ........................39

Electronically Tuned Stereo Radio with Name Brand Speakers ............................. .61, 62

Left Door Speaker ...........................62

Left Front Speaker ..........................61

Left Rear Speaker ...........................62

Right Door Speaker ..........................62

Right Front Speaker ..........................61

Right Rear Speaker ..........................62

Electronically Tuned Stereo Radio with RS System .....63, 64

Left Door Speaker ...........................64

Left Front Speaker ..........................63

Left Rear Speaker ...........................64

Right Door Speaker ..........................64

Right Front Speaker ..........................63

Right Rear Speaker ..........................64

RS Amplifier ........................... .63, 64

Electronic Vehicle Information Center ................72

Brake Fluid Level Sensor ......................72

Coolant Level Sensor .........................72

Data Link Connector .........................72

Engine Node Module .........................72

Engine Oil Level Sensor .......................72

Engine Compartment Fuse Application Chart .......1,2,3,4

Engine Coolant Temperature Sensor ..............21, 26

Engine Node Module Connector ...................161

Engine Oil and Temperature Warning System (except 3.0L) . .40 Body Computer Connector #1 ...................40

Body Computer Connector #2 ...................40

Engine Oil Pressure Switch/Sending Unit ............40

Engine Temperature Sending Unit .................40

Engine Oil and Temperature Warning System (3.0L) .......41

Engine Oil Level Sensor .......................41

Engine Oil Pressure Switch/Sending Unit ............41

Engine Temperature Sending Unit .................41

Engine Starter Relay ..................... .13, 14, 15

Engine Starter System (2.5L Auto Trans) ..............13

Clutch Pedal Position Jumper ...................13

EMCC Solenoid ............................13

Engine Starter Relay .........................13

Field Coil Engine Starter Motor ...................13

Park Neutral Position Switch ....................13

Engine Starter System (Man Transmission) ............14

Clutch Pedal Position Switch ....................14

Engine Starter Relay .........................14

Field Coil Starter Motor .......................14

Manual Transmission Back-Up Lamp Switch ..........14

Engine Starter System (3.0L) .....................15

Clutch Pedal Position Jumper ...................15

Field Coil Engine Starter Motor ...................15

8W - 534 WIRING DIAGRAMS AG-AJ BODY Ä

Page 1285 of 2438

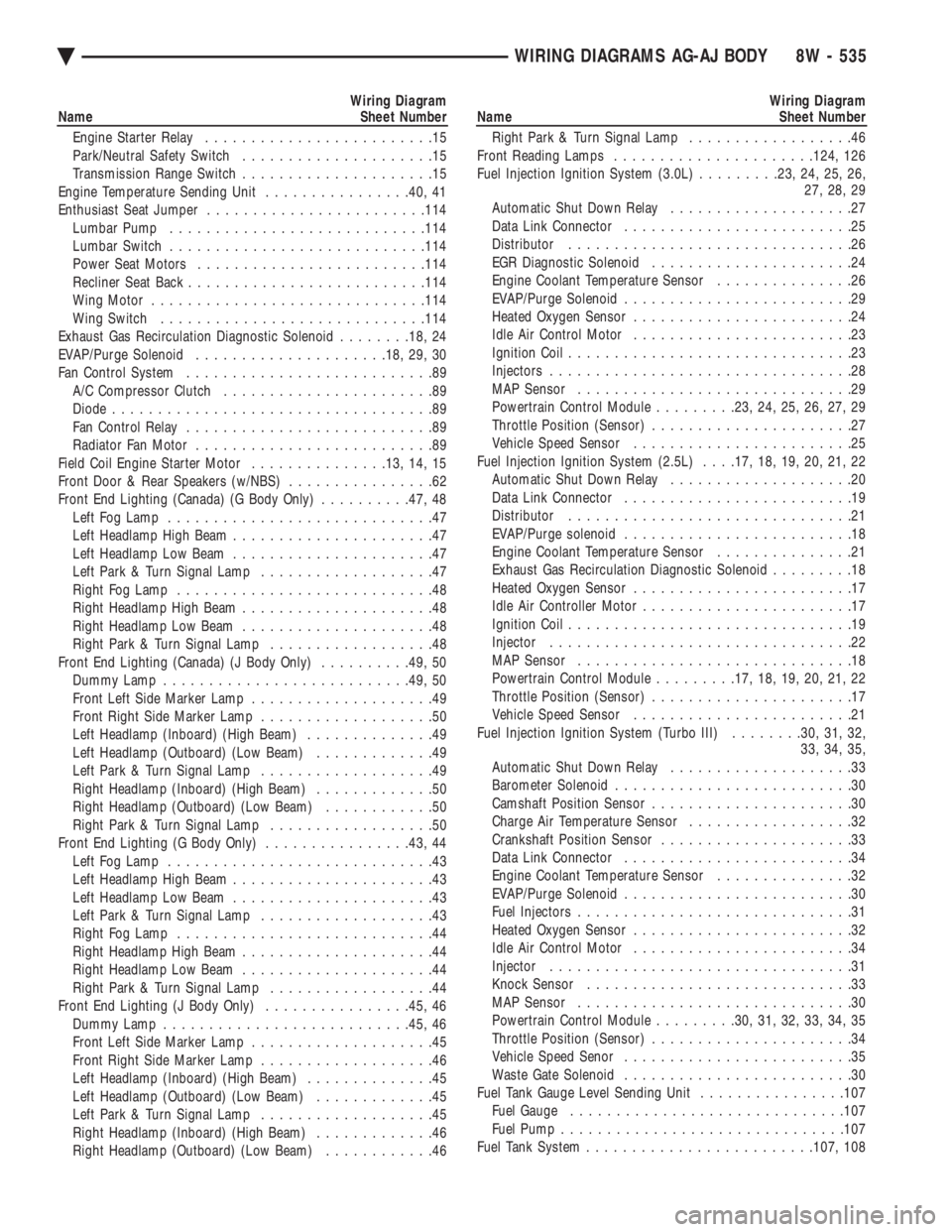

Wiring Diagram

Name Sheet Number

Engine Starter Relay .........................15

Park/Neutral Safety Switch .....................15

Transmission Range Switch .....................15

Engine Temperature Sending Unit ................40, 41

Enthusiast Seat Jumper ....................... .114

Lumbar Pump ........................... .114

Lumbar Switch ........................... .114

Power Seat Motors ........................ .114

Recliner Seat Back ......................... .114

Wing Motor ............................. .114

Wing Switch ............................ .114

Exhaust Gas Recirculation Diagnostic Solenoid ........18, 24

EVAP/Purge Solenoid .................... .18, 29, 30

Fan Control System ...........................89

A/C Compressor Clutch .......................89

Diode ...................................89

Fan Control Relay ...........................89

Radiator Fan Motor ..........................89

Field Coil Engine Starter Motor ...............13, 14, 15

Front Door & Rear Speakers (w/NBS) ................62

Front End Lighting (Canada) (G Body Only) ..........47, 48

Left Fog Lamp .............................47

Left Headlamp High Beam ......................47

Left Headlamp Low Beam ......................47

Left Park & Turn Signal Lamp ...................47

Right Fog Lamp ............................48

Right Headlamp High Beam .....................48

Right Headlamp Low Beam .....................48

Right Park & Turn Signal Lamp ..................48

Front End Lighting (Canada) (J Body Only) ..........49, 50

Dummy Lamp .......................... .49, 50

Front Left Side Marker Lamp ....................49

Front Right Side Marker Lamp ...................50

Left Headlamp (Inboard) (High Beam) ..............49

Left Headlamp (Outboard) (Low Beam) .............49

Left Park & Turn Signal Lamp ...................49

Right Headlamp (Inboard) (High Beam) .............50

Right Headlamp (Outboard) (Low Beam) ............50

Right Park & Turn Signal Lamp ..................50

Front End Lighting (G Body Only) ................43, 44

Left Fog Lamp .............................43

Left Headlamp High Beam ......................43

Left Headlamp Low Beam ......................43

Left Park & Turn Signal Lamp ...................43

Right Fog Lamp ............................44

Right Headlamp High Beam .....................44

Right Headlamp Low Beam .....................44

Right Park & Turn Signal Lamp ..................44

Front End Lighting (J Body Only) ................45, 46

Dummy Lamp .......................... .45, 46

Front Left Side Marker Lamp ....................45

Front Right Side Marker Lamp ...................46

Left Headlamp (Inboard) (High Beam) ..............45

Left Headlamp (Outboard) (Low Beam) .............45

Left Park & Turn Signal Lamp ...................45

Right Headlamp (Inboard) (High Beam) .............46

Right Headlamp (Outboard) (Low Beam) ............46Wiring Diagram

Name Sheet Number

Right Park & Turn Signal Lamp ..................46

Front Reading Lamps ..................... .124, 126

Fuel Injection Ignition System (3.0L) .........23, 24, 25, 26,

27, 28, 29

Automatic Shut Down Relay ....................27

Data Link Connector .........................25

Distributor ...............................26

EGR Diagnostic Solenoid ......................24

Engine Coolant Temperature Sensor ...............26

EVAP/Purge Solenoid .........................29

Heated Oxygen Sensor ........................24

Idle Air Control Motor ........................23

Ignition Coil ...............................23

Injectors .................................28

MAP Sensor ..............................29

Powertrain Control Module .........23, 24, 25, 26, 27, 29

Throttle Position (Sensor) ......................27

Vehicle Speed Sensor ........................25

Fuel Injection Ignition System (2.5L) . . . .17, 18, 19, 20, 21, 22

Automatic Shut Down Relay ....................20

Data Link Connector .........................19

Distributor ...............................21

EVAP/Purge solenoid .........................18

Engine Coolant Temperature Sensor ...............21

Exhaust Gas Recirculation Diagnostic Solenoid .........18

Heated Oxygen Sensor ........................17

Idle Air Controller Motor .......................17

Ignition Coil ...............................19

Injector .................................22

MAP Sensor ..............................18

Powertrain Control Module .........17, 18, 19, 20, 21, 22

Throttle Position (Sensor) ......................17

Vehicle Speed Sensor ........................21

Fuel Injection Ignition System (Turbo III) ........30, 31, 32,

33, 34, 35,

Automatic Shut Down Relay ....................33

Barometer Solenoid ..........................30

Camshaft Position Sensor ......................30

Charge Air Temperature Sensor ..................32

Crankshaft Position Sensor .....................33

Data Link Connector .........................34

Engine Coolant Temperature Sensor ...............32

EVAP/Purge Solenoid .........................30

Fuel Injectors ..............................31

Heated Oxygen Sensor ........................32

Idle Air Control Motor ........................34

Injector .................................31

Knock Sensor .............................33

MAP Sensor ..............................30

Powertrain Control Module .........30, 31, 32, 33, 34, 35

Throttle Position (Sensor) ......................34

Vehicle Speed Senor .........................35

Waste Gate Solenoid .........................30

Fuel Tank Gauge Level Sending Unit ................107

Fuel Gauge ............................. .107

Fuel Pump .............................. .107

Fuel Tank System ........................ .107, 108

Ä WIRING DIAGRAMS AG-AJ BODY 8W - 535