light CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 97 of 2438

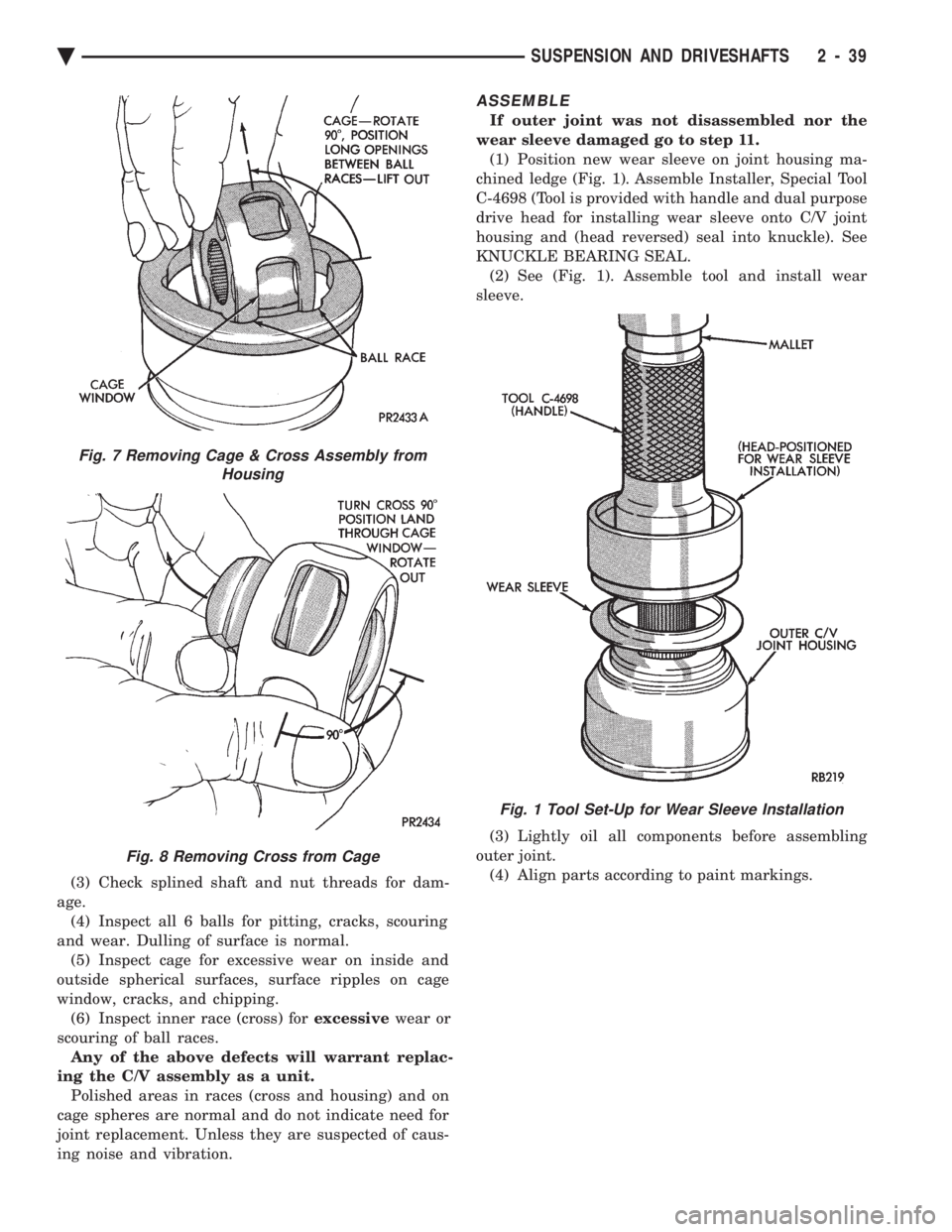

(3) Check splined shaft and nut threads for dam-

age. (4) Inspect all 6 balls for pitting, cracks, scouring

and wear. Dulling of surface is normal. (5) Inspect cage for excessive wear on inside and

outside spherical surfaces, surface ripples on cage

window, cracks, and chipping. (6) Inspect inner race (cross) for excessivewear or

scouring of ball races. Any of the above defects will warrant replac-

ing the C/V assembly as a unit. Polished areas in races (cross and housing) and on

cage spheres are normal and do not indicate need for

joint replacement. Unless they are suspected of caus-

ing noise and vibration.

ASSEMBLE

If outer joint was not disassembled nor the

wear sleeve damaged go to step 11. (1) Position new wear sleeve on joint housing ma-

chined ledge (Fig. 1). Assemble Installer, Special Tool

C-4698 (Tool is provided with handle and dual purpose

drive head for installing wear sleeve onto C/V joint

housing and (head reversed) seal into knuckle). See

KNUCKLE BEARING SEAL. (2) See (Fig. 1). Assemble tool and install wear

sleeve.

(3) Lightly oil all components before assembling

outer joint. (4) Align parts according to paint markings.

Fig. 7 Removing Cage & Cross Assembly from Housing

Fig. 8 Removing Cross from Cage

Fig. 1 Tool Set-Up for Wear Sleeve Installation

Ä SUSPENSION AND DRIVESHAFTS 2 - 39

Page 103 of 2438

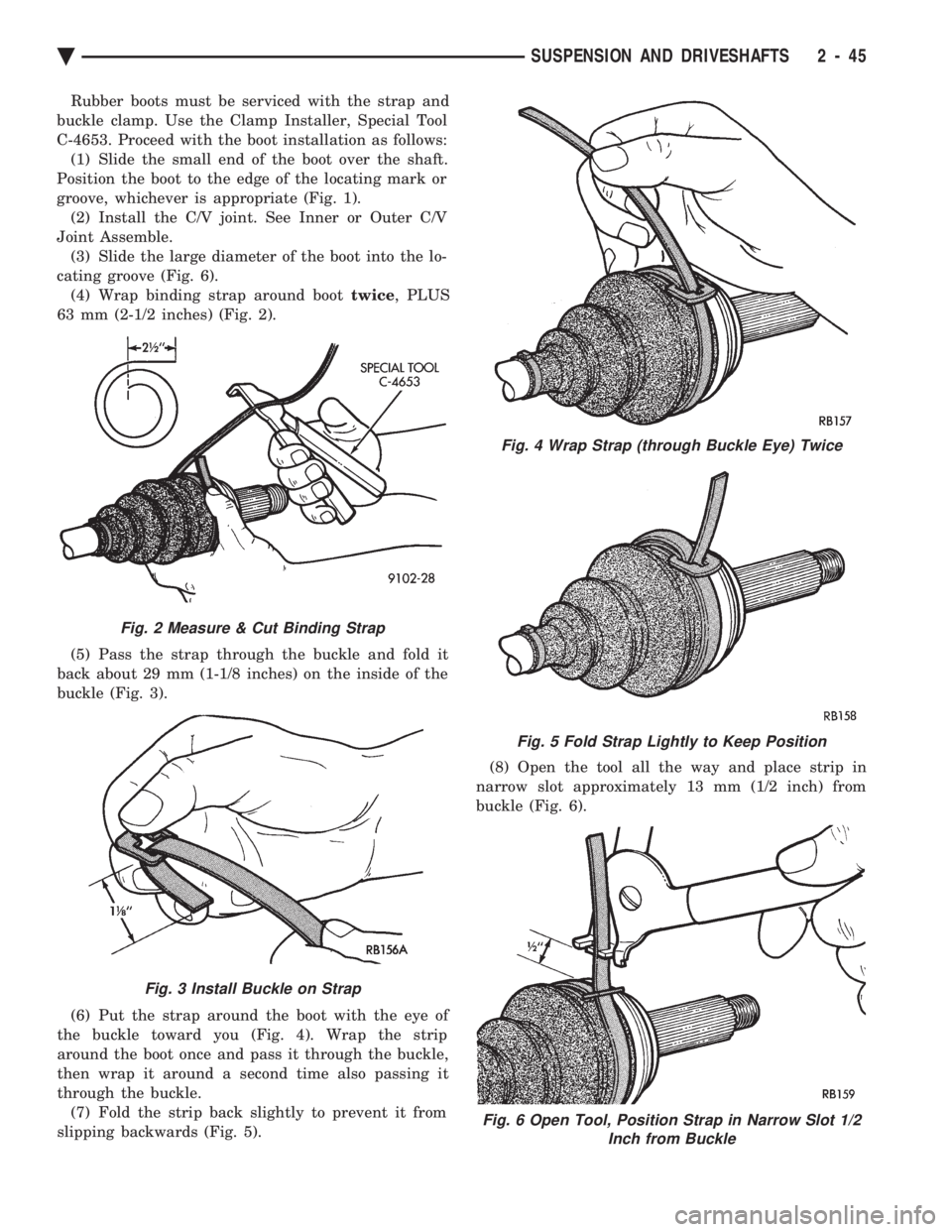

Rubber boots must be serviced with the strap and

buckle clamp. Use the Clamp Installer, Special Tool

C-4653. Proceed with the boot installation as follows: (1) Slide the small end of the boot over the shaft.

Position the boot to the edge of the locating mark or

groove, whichever is appropriate (Fig. 1). (2) Install the C/V joint. See Inner or Outer C/V

Joint Assemble. (3) Slide the large diameter of the boot into the lo-

cating groove (Fig. 6). (4) Wrap binding strap around boot twice, PLUS

63 mm (2-1/2 inches) (Fig. 2).

(5) Pass the strap through the buckle and fold it

back about 29 mm (1-1/8 inches) on the inside of the

buckle (Fig. 3).

(6) Put the strap around the boot with the eye of

the buckle toward you (Fig. 4). Wrap the strip

around the boot once and pass it through the buckle,

then wrap it around a second time also passing it

through the buckle. (7) Fold the strip back slightly to prevent it from

slipping backwards (Fig. 5). (8) Open the tool all the way and place strip in

narrow slot approximately 13 mm (1/2 inch) from

buckle (Fig. 6).

Fig. 2 Measure & Cut Binding Strap

Fig. 3 Install Buckle on Strap

Fig. 4 Wrap Strap (through Buckle Eye) Twice

Fig. 5 Fold Strap Lightly to Keep Position

Fig. 6 Open Tool, Position Strap in Narrow Slot 1/2 Inch from Buckle

Ä SUSPENSION AND DRIVESHAFTS 2 - 45

Page 104 of 2438

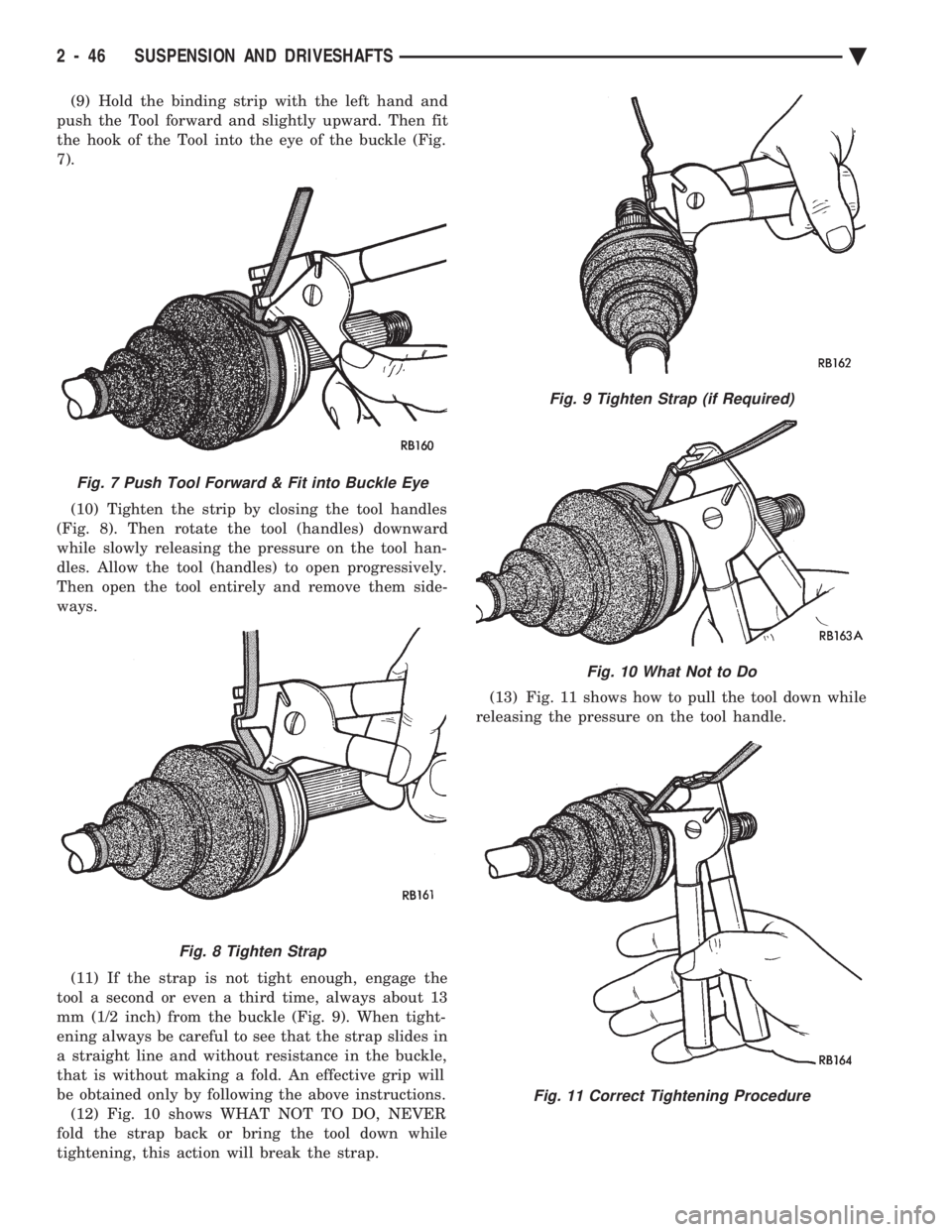

(9) Hold the binding strip with the left hand and

push the Tool forward and slightly upward. Then fit

the hook of the Tool into the eye of the buckle (Fig.

7).

(10) Tighten the strip by closing the tool handles

(Fig. 8). Then rotate the tool (handles) downward

while slowly releasing the pressure on the tool han-

dles. Allow the tool (handles) to open progressively.

Then open the tool entirely and remove them side-

ways.

(11) If the strap is not tight enough, engage the

tool a second or even a third time, always about 13

mm (1/2 inch) from the buckle (Fig. 9). When tight-

ening always be careful to see that the strap slides in

a straight line and without resistance in the buckle,

that is without making a fold. An effective grip will

be obtained only by following the above instructions. (12) Fig. 10 shows WHAT NOT TO DO, NEVER

fold the strap back or bring the tool down while

tightening, this action will break the strap. (13) Fig. 11 shows how to pull the tool down while

releasing the pressure on the tool handle.

Fig. 7 Push Tool Forward & Fit into Buckle Eye

Fig. 8 Tighten Strap

Fig. 9 Tighten Strap (if Required)

Fig. 10 What Not to Do

Fig. 11 Correct Tightening Procedure

2 - 46 SUSPENSION AND DRIVESHAFTS Ä

Page 109 of 2438

to the road surface. While being able to twist as one

wheel moves vertically with respect to the other.Roll resistance is provided partly by the axle's re-

sistance to twist. But primarily by a torque tube or

rod (depending on the suspension option called for)

running through the channel and attached rigidly to

its end plates by welding. Because the torque tube/

rod is an integral part of the axle assembly, it cannot

be individually replaced. The spindles are bolted to the axle end (spindle

mounting) plates and can be individually replaced if

required. Rear wheel alignment changes require the

use of shims between the spindle and axle end plates.

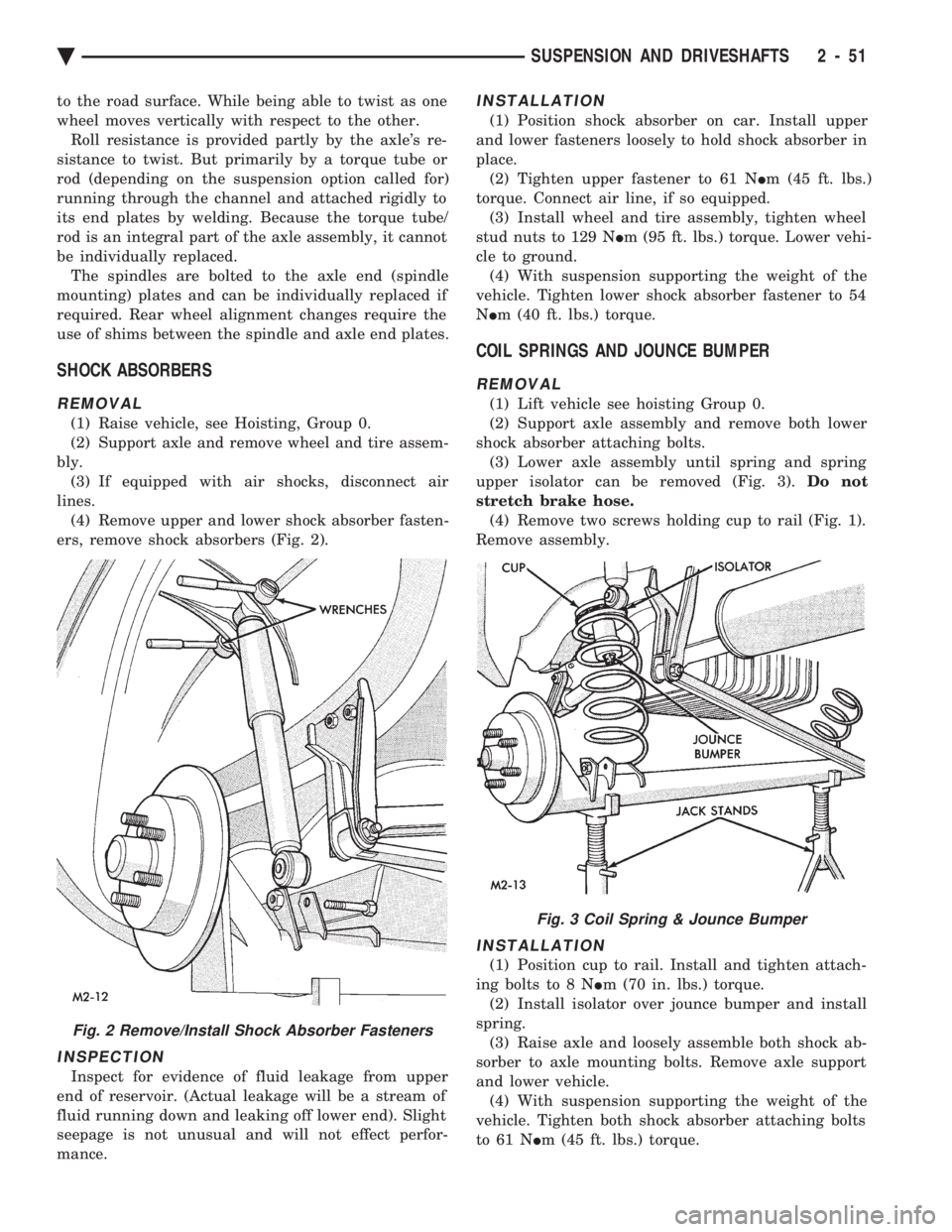

SHOCK ABSORBERS

REMOVAL

(1) Raise vehicle, see Hoisting, Group 0.

(2) Support axle and remove wheel and tire assem-

bly. (3) If equipped with air shocks, disconnect air

lines. (4) Remove upper and lower shock absorber fasten-

ers, remove shock absorbers (Fig. 2).

INSPECTION

Inspect for evidence of fluid leakage from upper

end of reservoir. (Actual leakage will be a stream of

fluid running down and leaking off lower end). Slight

seepage is not unusual and will not effect perfor-

mance.

INSTALLATION

(1) Position shock absorber on car. Install upper

and lower fasteners loosely to hold shock absorber in

place. (2) Tighten upper fastener to 61 N Im (45 ft. lbs.)

torque. Connect air line, if so equipped. (3) Install wheel and tire assembly, tighten wheel

stud nuts to 129 N Im (95 ft. lbs.) torque. Lower vehi-

cle to ground. (4) With suspension supporting the weight of the

vehicle. Tighten lower shock absorber fastener to 54

N Im (40 ft. lbs.) torque.

COIL SPRINGS AND JOUNCE BUMPER

REMOVAL

(1) Lift vehicle see hoisting Group 0.

(2) Support axle assembly and remove both lower

shock absorber attaching bolts. (3) Lower axle assembly until spring and spring

upper isolator can be removed (Fig. 3). Do not

stretch brake hose. (4) Remove two screws holding cup to rail (Fig. 1).

Remove assembly.

INSTALLATION

(1) Position cup to rail. Install and tighten attach-

ing bolts to 8 N Im (70 in. lbs.) torque.

(2) Install isolator over jounce bumper and install

spring. (3) Raise axle and loosely assemble both shock ab-

sorber to axle mounting bolts. Remove axle support

and lower vehicle. (4) With suspension supporting the weight of the

vehicle. Tighten both shock absorber attaching bolts

to 61 N Im (45 ft. lbs.) torque.

Fig. 2 Remove/Install Shock Absorber Fasteners

Fig. 3 Coil Spring & Jounce Bumper

Ä SUSPENSION AND DRIVESHAFTS 2 - 51

Page 111 of 2438

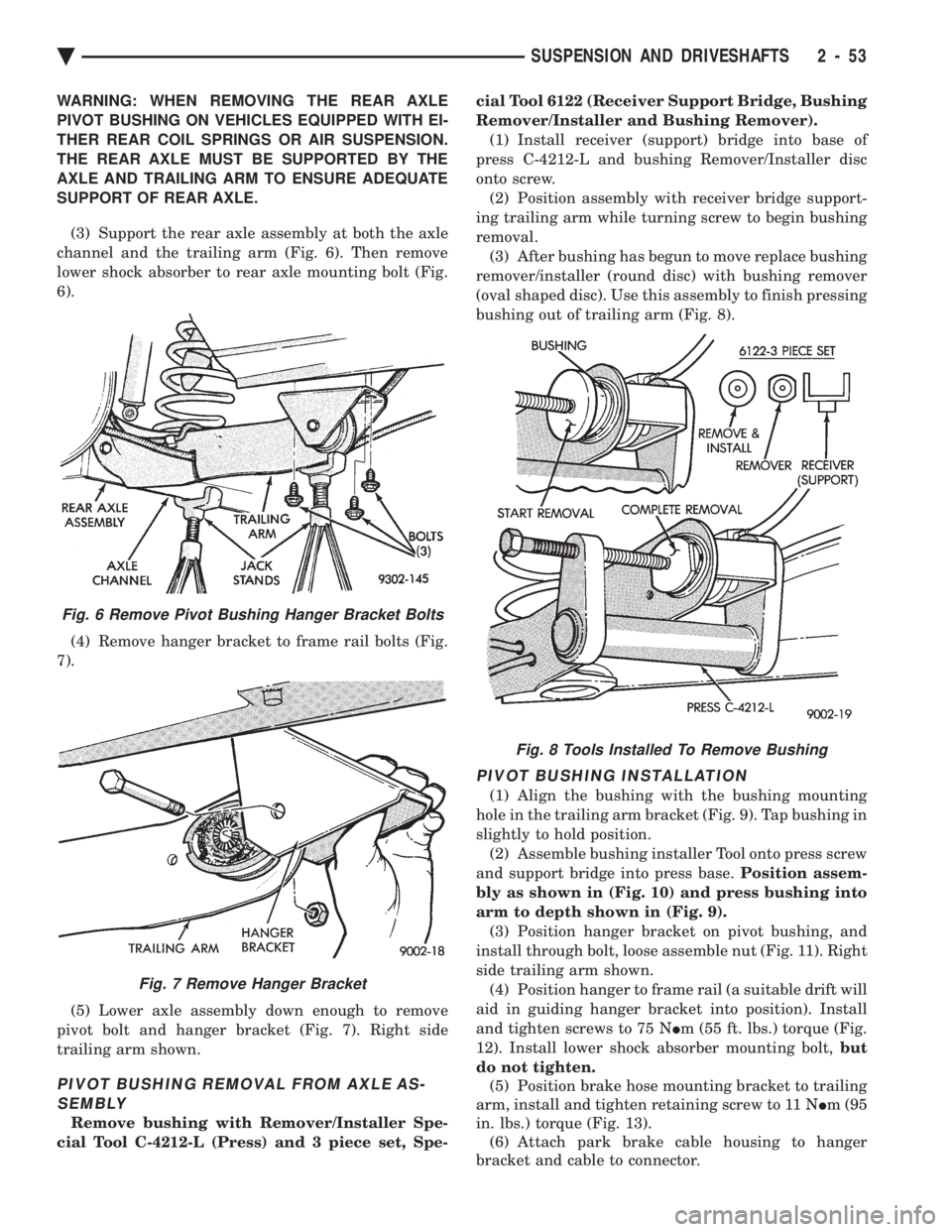

WARNING: WHEN REMOVING THE REAR AXLE

PIVOT BUSHING ON VEHICLES EQUIPPED WITH EI-

THER REAR COIL SPRINGS OR AIR SUSPENSION.

THE REAR AXLE MUST BE SUPPORTED BY THE

AXLE AND TRAILING ARM TO ENSURE ADEQUATE

SUPPORT OF REAR AXLE.

(3) Support the rear axle assembly at both the axle

channel and the trailing arm (Fig. 6). Then remove

lower shock absorber to rear axle mounting bolt (Fig.

6).

(4) Remove hanger bracket to frame rail bolts (Fig.

7).

(5) Lower axle assembly down enough to remove

pivot bolt and hanger bracket (Fig. 7). Right side

trailing arm shown.

PIVOT BUSHING REMOVAL FROM AXLE AS- SEMBLY

Remove bushing with Remover/Installer Spe-

cial Tool C-4212-L (Press) and 3 piece set, Spe- cial Tool 6122 (Receiver Support Bridge, Bushing

Remover/Installer and Bushing Remover). (1) Install receiver (support) bridge into base of

press C-4212-L and bushing Remover/Installer disc

onto screw. (2) Position assembly with receiver bridge support-

ing trailing arm while turning screw to begin bushing

removal. (3) After bushing has begun to move replace bushing

remover/installer (round disc) with bushing remover

(oval shaped disc). Use this assembly to finish pressing

bushing out of trailing arm (Fig. 8).

PIVOT BUSHING INSTALLATION

(1) Align the bushing with the bushing mounting

hole in the trailing arm bracket (Fig. 9). Tap bushing in

slightly to hold position. (2) Assemble bushing installer Tool onto press screw

and support bridge into press base. Position assem-

bly as shown in (Fig. 10) and press bushing into

arm to depth shown in (Fig. 9). (3) Position hanger bracket on pivot bushing, and

install through bolt, loose assemble nut (Fig. 11). Right

side trailing arm shown. (4) Position hanger to frame rail (a suitable drift will

aid in guiding hanger bracket into position). Install

and tighten screws to 75 N Im (55 ft. lbs.) torque (Fig.

12). Install lower shock absorber mounting bolt, but

do not tighten. (5) Position brake hose mounting bracket to trailing

arm, install and tighten retaining screw to 11 N Im (95

in. lbs.) torque (Fig. 13). (6) Attach park brake cable housing to hanger

bracket and cable to connector.

Fig. 8 Tools Installed To Remove Bushing

Fig. 6 Remove Pivot Bushing Hanger Bracket Bolts

Fig. 7 Remove Hanger Bracket

Ä SUSPENSION AND DRIVESHAFTS 2 - 53

Page 113 of 2438

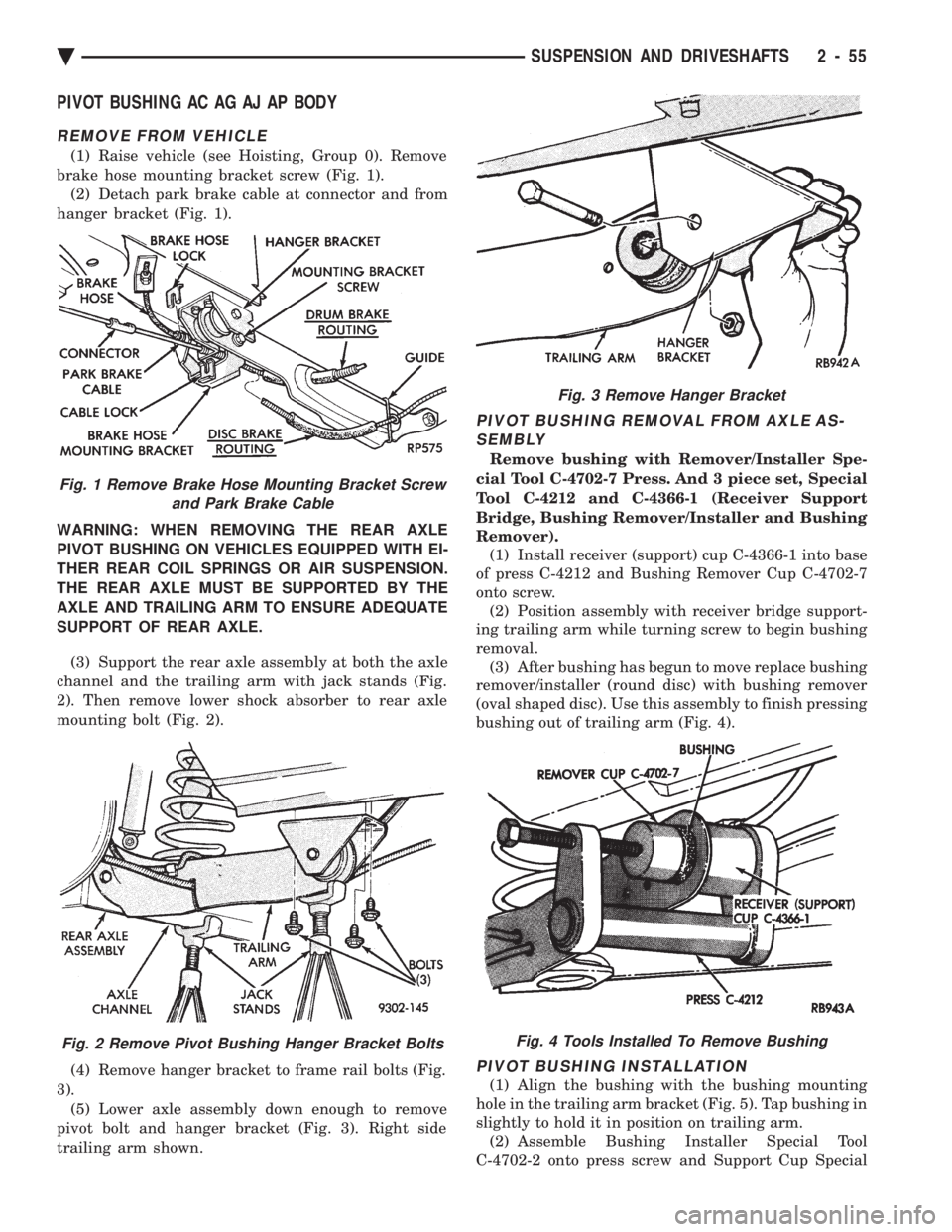

PIVOT BUSHING AC AG AJ AP BODY

REMOVE FROM VEHICLE

(1) Raise vehicle (see Hoisting, Group 0). Remove

brake hose mounting bracket screw (Fig. 1). (2) Detach park brake cable at connector and from

hanger bracket (Fig. 1).

WARNING: WHEN REMOVING THE REAR AXLE

PIVOT BUSHING ON VEHICLES EQUIPPED WITH EI-

THER REAR COIL SPRINGS OR AIR SUSPENSION.

THE REAR AXLE MUST BE SUPPORTED BY THE

AXLE AND TRAILING ARM TO ENSURE ADEQUATE

SUPPORT OF REAR AXLE. (3) Support the rear axle assembly at both the axle

channel and the trailing arm with jack stands (Fig.

2). Then remove lower shock absorber to rear axle

mounting bolt (Fig. 2).

(4) Remove hanger bracket to frame rail bolts (Fig.

3). (5) Lower axle assembly down enough to remove

pivot bolt and hanger bracket (Fig. 3). Right side

trailing arm shown.

PIVOT BUSHING REMOVAL FROM AXLE AS- SEMBLY

Remove bushing with Remover/Installer Spe-

cial Tool C-4702-7 Press. And 3 piece set, Special

Tool C-4212 and C-4366-1 (Receiver Support

Bridge, Bushing Remover/Installer and Bushing

Remover). (1) Install receiver (support) cup C-4366-1 into base

of press C-4212 and Bushing Remover Cup C-4702-7

onto screw. (2) Position assembly with receiver bridge support-

ing trailing arm while turning screw to begin bushing

removal. (3) After bushing has begun to move replace bushing

remover/installer (round disc) with bushing remover

(oval shaped disc). Use this assembly to finish pressing

bushing out of trailing arm (Fig. 4).

PIVOT BUSHING INSTALLATION

(1) Align the bushing with the bushing mounting

hole in the trailing arm bracket (Fig. 5). Tap bushing in

slightly to hold it in position on trailing arm. (2) Assemble Bushing Installer Special Tool

C-4702-2 onto press screw and Support Cup Special

Fig. 1 Remove Brake Hose Mounting Bracket Screw and Park Brake Cable

Fig. 2 Remove Pivot Bushing Hanger Bracket Bolts

Fig. 3 Remove Hanger Bracket

Fig. 4 Tools Installed To Remove Bushing

Ä SUSPENSION AND DRIVESHAFTS 2 - 55

Page 118 of 2438

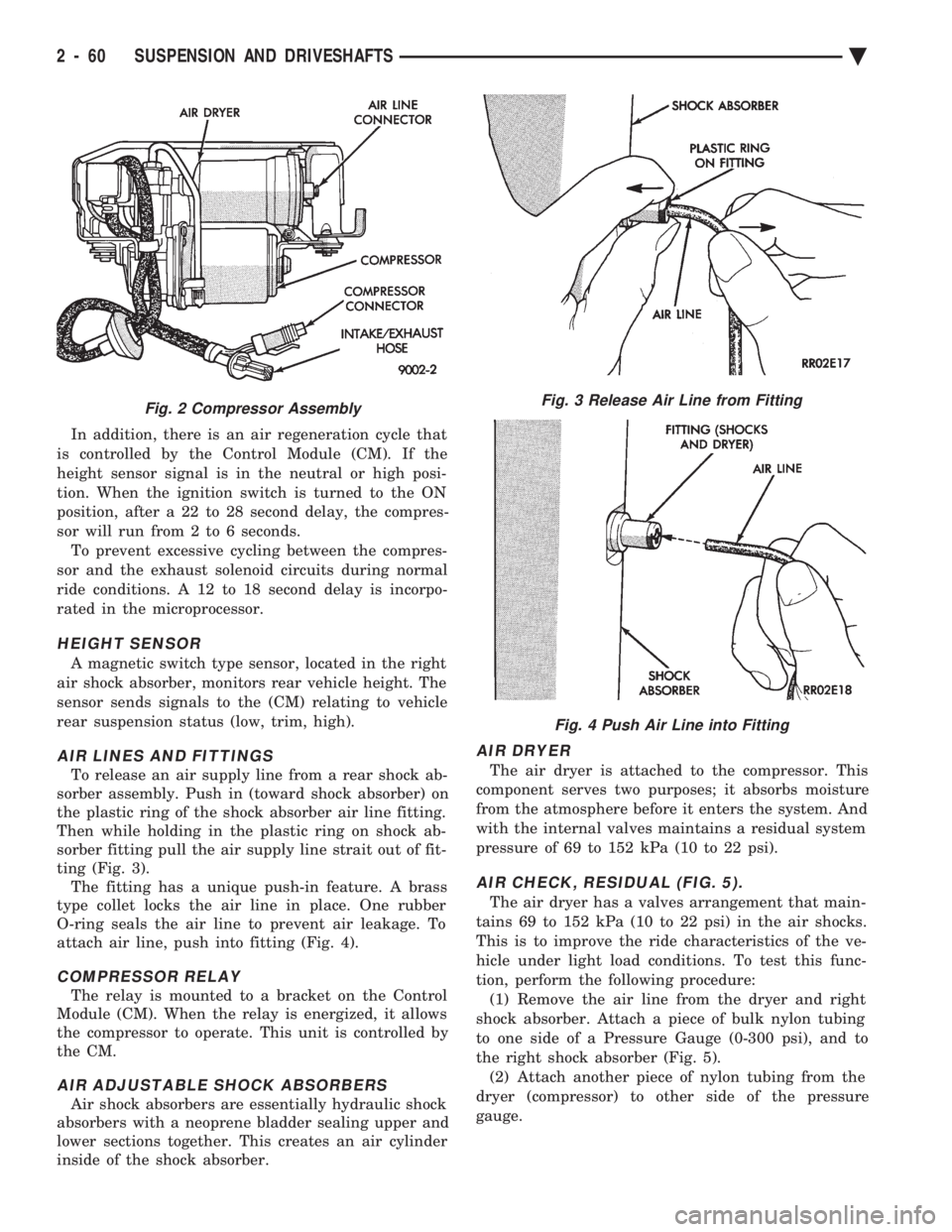

In addition, there is an air regeneration cycle that

is controlled by the Control Module (CM). If the

height sensor signal is in the neutral or high posi-

tion. When the ignition switch is turned to the ON

position, after a 22 to 28 second delay, the compres-

sor will run from 2 to 6 seconds. To prevent excessive cycling between the compres-

sor and the exhaust solenoid circuits during normal

ride conditions. A 12 to 18 second delay is incorpo-

rated in the microprocessor.

HEIGHT SENSOR

A magnetic switch type sensor, located in the right

air shock absorber, monitors rear vehicle height. The

sensor sends signals to the (CM) relating to vehicle

rear suspension status (low, trim, high).

AIR LINES AND FITTINGS

To release an air supply line from a rear shock ab-

sorber assembly. Push in (toward shock absorber) on

the plastic ring of the shock absorber air line fitting.

Then while holding in the plastic ring on shock ab-

sorber fitting pull the air supply line strait out of fit-

ting (Fig. 3). The fitting has a unique push-in feature. A brass

type collet locks the air line in place. One rubber

O-ring seals the air line to prevent air leakage. To

attach air line, push into fitting (Fig. 4).

COMPRESSOR RELAY

The relay is mounted to a bracket on the Control

Module (CM). When the relay is energized, it allows

the compressor to operate. This unit is controlled by

the CM.

AIR ADJUSTABLE SHOCK ABSORBERS

Air shock absorbers are essentially hydraulic shock

absorbers with a neoprene bladder sealing upper and

lower sections together. This creates an air cylinder

inside of the shock absorber.

AIR DRYER

The air dryer is attached to the compressor. This

component serves two purposes; it absorbs moisture

from the atmosphere before it enters the system. And

with the internal valves maintains a residual system

pressure of 69 to 152 kPa (10 to 22 psi).

AIR CHECK, RESIDUAL (FIG. 5).

The air dryer has a valves arrangement that main-

tains 69 to 152 kPa (10 to 22 psi) in the air shocks.

This is to improve the ride characteristics of the ve-

hicle under light load conditions. To test this func-

tion, perform the following procedure: (1) Remove the air line from the dryer and right

shock absorber. Attach a piece of bulk nylon tubing

to one side of a Pressure Gauge (0-300 psi), and to

the right shock absorber (Fig. 5). (2) Attach another piece of nylon tubing from the

dryer (compressor) to other side of the pressure

gauge.

Fig. 2 Compressor AssemblyFig. 3 Release Air Line from Fitting

Fig. 4 Push Air Line into Fitting

2 - 60 SUSPENSION AND DRIVESHAFTS Ä

Page 123 of 2438

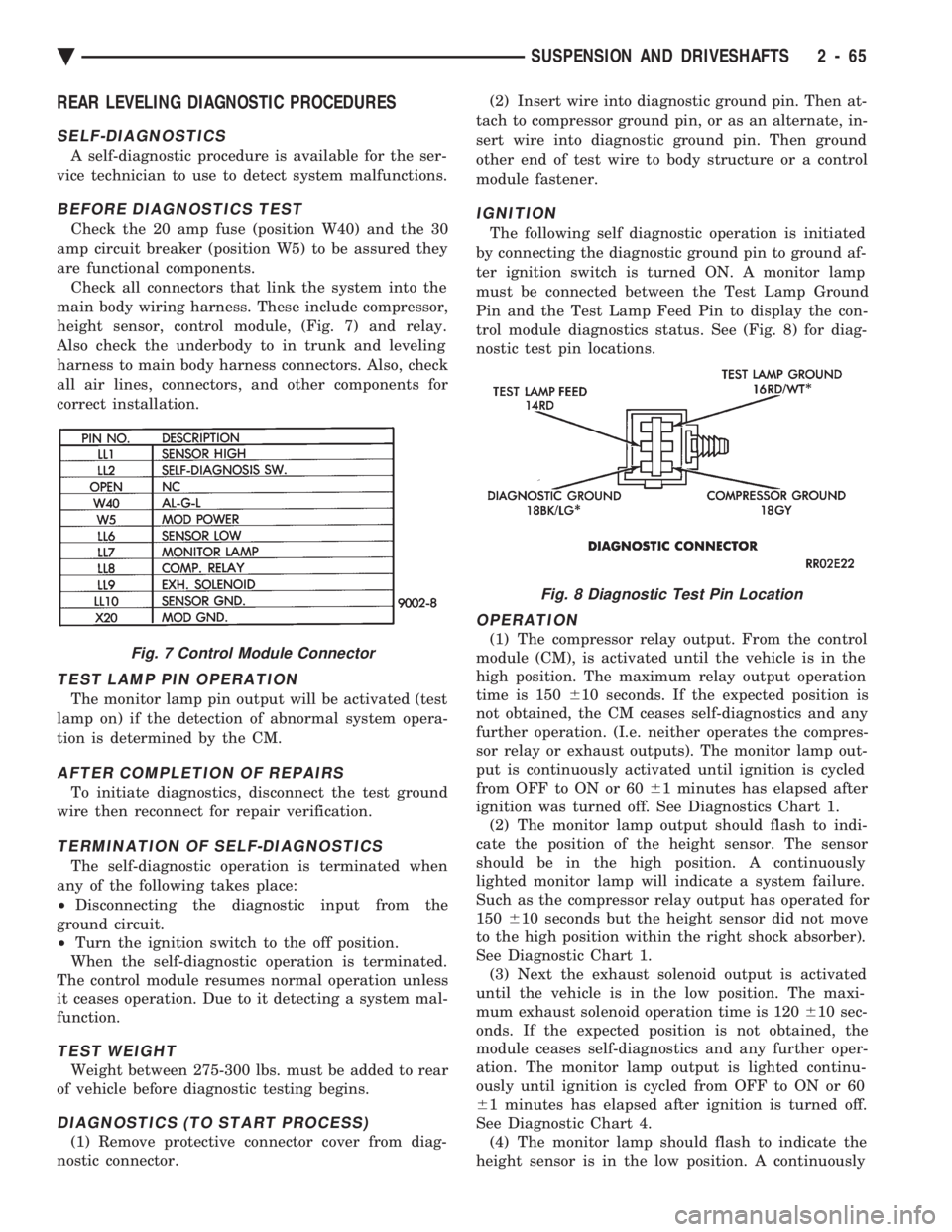

REAR LEVELING DIAGNOSTIC PROCEDURES

SELF-DIAGNOSTICS

A self-diagnostic procedure is available for the ser-

vice technician to use to detect system malfunctions.

BEFORE DIAGNOSTICS TEST

Check the 20 amp fuse (position W40) and the 30

amp circuit breaker (position W5) to be assured they

are functional components. Check all connectors that link the system into the

main body wiring harness. These include compressor,

height sensor, control module, (Fig. 7) and relay.

Also check the underbody to in trunk and leveling

harness to main body harness connectors. Also, check

all air lines, connectors, and other components for

correct installation.

TEST LAMP PIN OPERATION

The monitor lamp pin output will be activated (test

lamp on) if the detection of abnormal system opera-

tion is determined by the CM.

AFTER COMPLETION OF REPAIRS

To initiate diagnostics, disconnect the test ground

wire then reconnect for repair verification.

TERMINATION OF SELF-DIAGNOSTICS

The self-diagnostic operation is terminated when

any of the following takes place:

² Disconnecting the diagnostic input from the

ground circuit.

² Turn the ignition switch to the off position.

When the self-diagnostic operation is terminated.

The control module resumes normal operation unless

it ceases operation. Due to it detecting a system mal-

function.

TEST WEIGHT

Weight between 275-300 lbs. must be added to rear

of vehicle before diagnostic testing begins.

DIAGNOSTICS (TO START PROCESS)

(1) Remove protective connector cover from diag-

nostic connector. (2) Insert wire into diagnostic ground pin. Then at-

tach to compressor ground pin, or as an alternate, in-

sert wire into diagnostic ground pin. Then ground

other end of test wire to body structure or a control

module fastener.

IGNITION

The following self diagnostic operation is initiated

by connecting the diagnostic ground pin to ground af-

ter ignition switch is turned ON. A monitor lamp

must be connected between the Test Lamp Ground

Pin and the Test Lamp Feed Pin to display the con-

trol module diagnostics status. See (Fig. 8) for diag-

nostic test pin locations.

OPERATION

(1) The compressor relay output. From the control

module (CM), is activated until the vehicle is in the

high position. The maximum relay output operation

time is 150 610 seconds. If the expected position is

not obtained, the CM ceases self-diagnostics and any

further operation. (I.e. neither operates the compres-

sor relay or exhaust outputs). The monitor lamp out-

put is continuously activated until ignition is cycled

from OFF to ON or 60 61 minutes has elapsed after

ignition was turned off. See Diagnostics Chart 1. (2) The monitor lamp output should flash to indi-

cate the position of the height sensor. The sensor

should be in the high position. A continuously

lighted monitor lamp will indicate a system failure.

Such as the compressor relay output has operated for

150 610 seconds but the height sensor did not move

to the high position within the right shock absorber).

See Diagnostic Chart 1. (3) Next the exhaust solenoid output is activated

until the vehicle is in the low position. The maxi-

mum exhaust solenoid operation time is 120 610 sec-

onds. If the expected position is not obtained, the

module ceases self-diagnostics and any further oper-

ation. The monitor lamp output is lighted continu-

ously until ignition is cycled from OFF to ON or 60

6 1 minutes has elapsed after ignition is turned off.

See Diagnostic Chart 4. (4) The monitor lamp should flash to indicate the

height sensor is in the low position. A continuouslyFig. 7 Control Module Connector

Fig. 8 Diagnostic Test Pin Location

Ä SUSPENSION AND DRIVESHAFTS 2 - 65

Page 124 of 2438

lighted monitor lamp will indicate a system failure.

Such as the exhaust solenoid operated for 120 610

seconds but the height sensor did not move to the

low position. See Diagnostic Chart 4. (5) The compressor relay output is activated to re-

turn the vehicle to the neutral (leveled) position. The

maximum operation time of the relay output is 150

6 10 seconds. If the expected position is not obtained.

The control module ceases self-diagnostics and any

further operation. The monitor lamp is continuously

lighted until the ignition is cycled from OFF to ON

or 60 61 minutes has elapsed after ignition is turned

off. The sensor will move to the neutral position. If not,

a continuously lighted monitor lamp will indicate a system failure. Such as the compressor relay output

operated for 150 610 seconds but the sensor did not

move to or sense the neutral position. See Diagnostic

Chart 1. (6) Completion of diagnostics, is when self diagnostic

procedure is successfully completed and control module

resumes normal operation. The diagnostic test is now

complete. Throughout the testing the vehicle load must

be maintained at a specific level. No loads are allowed

to be added/removed to/from the vehicle once the self

diagnosis tests have been initiated. The Diagnostic connector cover must be in-

stalled after completion of the test.

2 - 66 SUSPENSION AND DRIVESHAFTS Ä

Page 151 of 2438

BRAKES

CONTENTS

page page

ANTI-LOCK BRAKE SYSTEMÐBENDIX ANTI-LOCK 10 AC/Y BODY ............. 72

ANTI-LOCK BRAKE SYSTEMÐBENDIX ANTI-LOCK 6 AA,AG,AJ,AP BODY ....... 113

BRAKE DISC (ROTOR) ................... 53

BRAKE SUPPORT ASSEMBLY ............. 25

FRONT DISC BRAKES ................... 31

GENERAL INFORMATION .................. 1

HYDRAULIC SYSTEM CONTROL VALVES . . . 26

KELSEY HAYES DOUBLE PIN FAMILY CALIPER ............................ 35 KELSEY HAYES DOUBLE PIN NON-FAMILY

CALIPER ............................ 38

MASTER CYLINDER ..................... 66

PARKING BRAKES ...................... 57

POWER BRAKES ....................... 68

REAR DISC BRAKES .................... 45

REAR WHEEL DRUM BRAKES ............ 18

SERVICE ADJUSTMENTS .................. 4

WHEEL BEARINGS ...................... 70

WHEEL CYLINDERS ..................... 23

GENERAL INFORMATION

Throughout this group, references may be made to

a particular vehicle by letter or number designation.

A chart showing the break down of these designa-

tions is included in the Introduction Section at the

front of this service manual. Standard brake equipment consists of:

² Double pin floating caliper disc front brakes.

² Rear automatic adjusting drum brakes.

² Differential valve with a brake warning switch.

² Master cylinder.

² Vacuum power booster.

² Double pin floating caliper rear disc brakes are

available on some models. The Bendix Anti-Lock 10 braking system, uses the

standard power brake system caliper assemblies,

braking discs, pedal assembly, brake lines and hoses.

The unique parts of the Bendix Anti-Lock 10 braking

system consists of the following components. Propor-

tioning valves, wheel speed sensors, tone wheels,

electronic control unit, modulator assembly and hy-

draulic assembly. These components replace the con-

ventional master cylinder and power booster. The

components will be described in detail in the Bendix

Anti-Lock 10 brake section in this group of the ser-

vice manual. The Bendix Anti-Lock 6 braking system, uses the

following standard brake system components. Master

cylinder, power booster, caliper assemblies, braking

discs, pedal assembly, brake lines and hoses. The

unique parts of the Bendix Anti-Lock 6 braking sys-

tem consists of the following components. Modulator

assembly, unique proportioning valves, wheel speed

sensors, tone wheels, and electronic control unit.

These components will be described in detail in the

Bendix Anti-Lock 6 brake section in this group of the

service manual. The front disc brake shoes have semi-metallic lin-

ings. The hydraulic brake system (Fig .123and4)is

diagonally split on both the Non-ABS and ABS brak-

ing system. With the left front and right rear brakes

on one hydraulic system and the right front and left

rear on the other. The Non-ABS and ABS brake system may use dif-

ferent types of brake line fittings and tubing flares.

The Non-ABS brake system uses double wall tubing

flares and fittings at all tubing joint locations. Some

ABS brake systems use both ISO style tubing flares

and double wall tubing flares and corresponding fit-

tings at different joint locations. See (Figs . 2 3 and 4)

for specific joint locations and type of tubing flare. The front disc brakes consist of two different types

of caliper assemblies. A double pin Kelsey-Hayes cal-

iper (family caliper) with a bolt-on adapter attached

to the steering knuckle. Or a double pin Kelsey-

Hayes caliper (non-family caliper) which mounts di-

rectly to rails on the steering knuckle. The non-

family caliper is only used on the AY Body

(Imperials).

CAUTION: Caliper pistons, boots and seals for the

different caliper assemblies used on the front and

rear disc brake assemblies are not interchangeable.

Misusage could result in a complete brake system

failure. Be sure that the parts are replaced with the

correct replacement parts, refer to the parts book

for the type and model year of the vehicle being

worked on.

The master cylinder is anodized, lightweight alu-

minum, with a bore size of 24.0mm, 21.0mm or 7/8

inch.

Ä BRAKES 5 - 1