fuel tank removal CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 33 of 2438

COMPONENT AND SYSTEM INDEX

Name Group-page Name Group-page

AUDIO SYSTEM ............................ 8F-1

ANTENNAS ............................ 8F-20

COMPACT DISC PLAYER ................... 8F-30

RADIOS ............................... 8F-1

SPEAKERS ............................. 8F-24

BATTERY/STARTER/GENERATOR SERVICE ..........8B-1

BATTERY REMOVAL, INSTALLATION AND SERVICE . . 8B-1

GENERATOR ............................ 8B-9

SPECIFICATIONS ........................ 8B-12

STARTER .............................. 8B-4

BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS ........................... 8A-1

BATTERY TEST PROCEDURES ON-VEHICLE .......8A-3

FAULT CODESÐON BOARD DIAGNOSTICS .......8A-23

GENERAL INFORMATION .................... 8A-1

GENERATOR TEST PROCEDURES ON VEHICLE ....8A-19

IGNITION OFF DRAW (IOD) ..................8A-9

SPECIFICATIONS ........................ 8A-28

STARTER TEST PROCEDURES ON VEHICLE ......8A-11

CHIME WARNING/REMINDER SYSTEM ............8U-1

EMISSION CONTROL SYSTEMS .................25-1

EVAPORATIVE EMISSION CONTROLS ...........25-1

EXHAUST EMISSION CONTROLS ..............25-17

FUEL SYSTEMS ............................ 14-1

2.2L TURBO III MULTI-PORT FUEL INJECTIONÐ GENERAL DIAGNOSIS ................... 14-95

2.2L TURBO III MULTI-PORT FUEL INJECTIONÐ ON-BOARD DIAGNOSTICS ................14-100

2.2L TURBO III MULTI-PORT FUEL INJECTIONÐ SERVICE PROCEDURES .................14-107

2.2L TURBO III MULTI-PORT FUEL INJECTIONÐ SYSTEM OPERATION .................... 14-83

2.2L/2.5L SINGLE POINT FUEL INJECTIONÐ GENERAL DIAGNOSIS ................... 14-35

2.2L/2.5L SINGLE POINT FUEL INJECTIONÐ ON-BOARD DIAGNOSTICS .................14-41

2.2L/2.5L SINGLE POINT FUEL INJECTIONÐ SERVICE PROCEDURES .................. 14-48

2.2L/2.5L SINGLE POINT FUEL INJECTIONÐ SYSTEM OPERATION .................... 14-24

2.5L FLEXIBLE FUEL MULTI-PORT FUEL INJECTIONÐGENERAL DIAGNOSIS ..........14-66

2.5L FLEXIBLE FUEL MULTI-PORT FUEL INJECTIONÐON-BOARD DIAGNOSTICS ........14-70

2.5L FLEXIBLE FUEL MULTI-PORT FUEL INJECTIONÐSERVICE PROCEDURES .........14-77

2.5L FLEXIBLE FUEL MULTI-PORT FUEL INJECTIONÐSYSTEM OPERATION ...........14-55

3.0L MULTI-PORT FUEL INJECTIONÐGENERAL DIAGNOSIS .......................... 14-125

3.0L MULTI-PORT FUEL INJECTIONÐON-BOARD DIAGNOSTICS ........................ 14-130

3.0L MULTI-PORT FUEL INJECTIONÐSERVICE PROCEDURES ........................ 14-138

3.0L MULTI-PORT FUEL INJECTIONÐSYSTEM OPERATION ......................... 14-113

3.3L AND 3.8L MULTI-PORT FUEL INJECTIONÐ GENERAL DIAGNOSIS ................... 14-157 3.3L AND 3.8L MULTI-PORT FUEL INJECTIONÐ

ON-BOARD DIAGNOSTICS ................14-162

3.3L AND 3.8L MULTI-PORT FUEL INJECTIONÐ SERVICE PROCEDURES .................14-169

3.3L AND 3.8L MULTI-PORT FUEL INJECTIONÐ SYSTEM OPERATION ................... 14-145

ACCELERATOR PEDAL AND THROTTLE CABLE ....14-21

FUEL DELIVERY SYSTEM .................... 14-3

FUEL TANKS ........................... 14-14

GENERAL INFORMATION .................... 14-1

SPECIFICATIONS ........................ 14-178

HORNS ................................. 8G-1

IGNITION SYSTEMS ......................... 8D-1

2.2L TBI, 2.5L TBI, 2.5L MPI AND 3.0L IGNITION SYSTEMSÐDIAGNOSTIC PROCEDURES .......8D-11

2.2L TBI, 2.5L TBI, 2.5L MPI AND 3.0L IGNITION SYSTEMSÐSERVICE PROCEDURES ..........8D-14

2.2L TBI, 2.5L TBI, 2.5L MPI AND 3.0L IGNITION SYSTEMSÐSYSTEM OPERATION ............8D-1

2.2L TURBO III, 3.3L AND 3.8L IGNITION SYSTEMÐDIAGNOSTIC PROCEDURES ........8D-35

2.2L TURBO III, 3.3L AND 3.8L IGNITION SYSTEMÐSYSTEM OPERATION ............8D-24

2.2L TURBO III, 3.3L AND 3.8L IGNITION SYSTEMSÐSERVICE PROCEDURES ..........8D-39

IGNITION SWITCH ....................... 8D-45

SPECIFICATIONS ........................ 8D-47

INSTRUMENT PANEL AND GAUGES ...............8E-1

AA BODY .............................. 8E-1

AC AND AY BODIES ...................... 8E-23

AG AND AJ BODIES ...................... 8E-42

AP BODY ............................. 8E-58

LAMPS .................................. 8L-1

BULB APPLICATION TABLE ..................8L-38

CONCEALED HEADLAMPS ..................8L-27

EXTERIOR LAMP SWITCHES AND HEADLAMP ALIGNMENT ........................... 8L-3

EXTERIOR LAMP SYSTEMS .................8L-25

EXTERIOR LAMPSÐAA BODY ................8L-7

EXTERIOR LAMPSÐAC BODY ...............8L-10

EXTERIOR LAMPSÐAG BODY ...............8L-14

EXTERIOR LAMPSÐAJ BODY ................8L-16

EXTERIOR LAMPSÐAP BODY ...............8L-19

EXTERIOR LAMPSÐAY-BODY ................8L-22

GENERAL INFORMATION .................... 8L-1

ILLUMINATED ENTRY SYSTEM ...............8L-33

OVERHEAD CONSOLE ........................ 8C-1

AA BODY .............................. 8C-1

AC AND AY BODY ........................ 8C-6

AG AND AJ BODIES ...................... 8C-13

AP BODY ............................. 8C-21

POWER LOCKS ............................ 8P-1

POWER MIRRORS ..........................8T-1

POWER SEATS ............................ 8R-1

POWER WINDOWS .......................... 8S-1

REAR WINDOW DEFOGGER .................... 8N-1

RESTRAINT SYSTEMS ....................... 8M-1

TURN SIGNALS AND HAZARD WARNING FLASHER ....8J-1

VEHICLE SPEED CONTROL .................... 8H-1

Page 522 of 2438

(b) Refer to sending unit removal Group 14, Fuel.

(c) Connect sending unit wire and jumper wire

as described in the test procedure.

(5) If fuel gauge now checks within specifications,

original sending unit is electrically okay, check fol-

lowing as a possible cause: (a) Ground wire from sending unit to left side

cowl for continuity. (b) Sending unit deformed. Make sure sending

unit float arm moves freely and pick up tube is not

bent upwards creating an interference with bottom

of tank and inspect float. (c) Sending unit improperly installed. Install

properly. (d) Mounting flange on fuel tank for sending

unit deformed. Feel for interference fit of sending

unit to bottom of tank. It is permissible to bend

pick up tube down a little near mounting flange to

gain interference fit. (e) Fuel tank bottom deformed, causing improper

positioning of sending unit pick up tube. Replace or

repair tank and recheck sending unit.

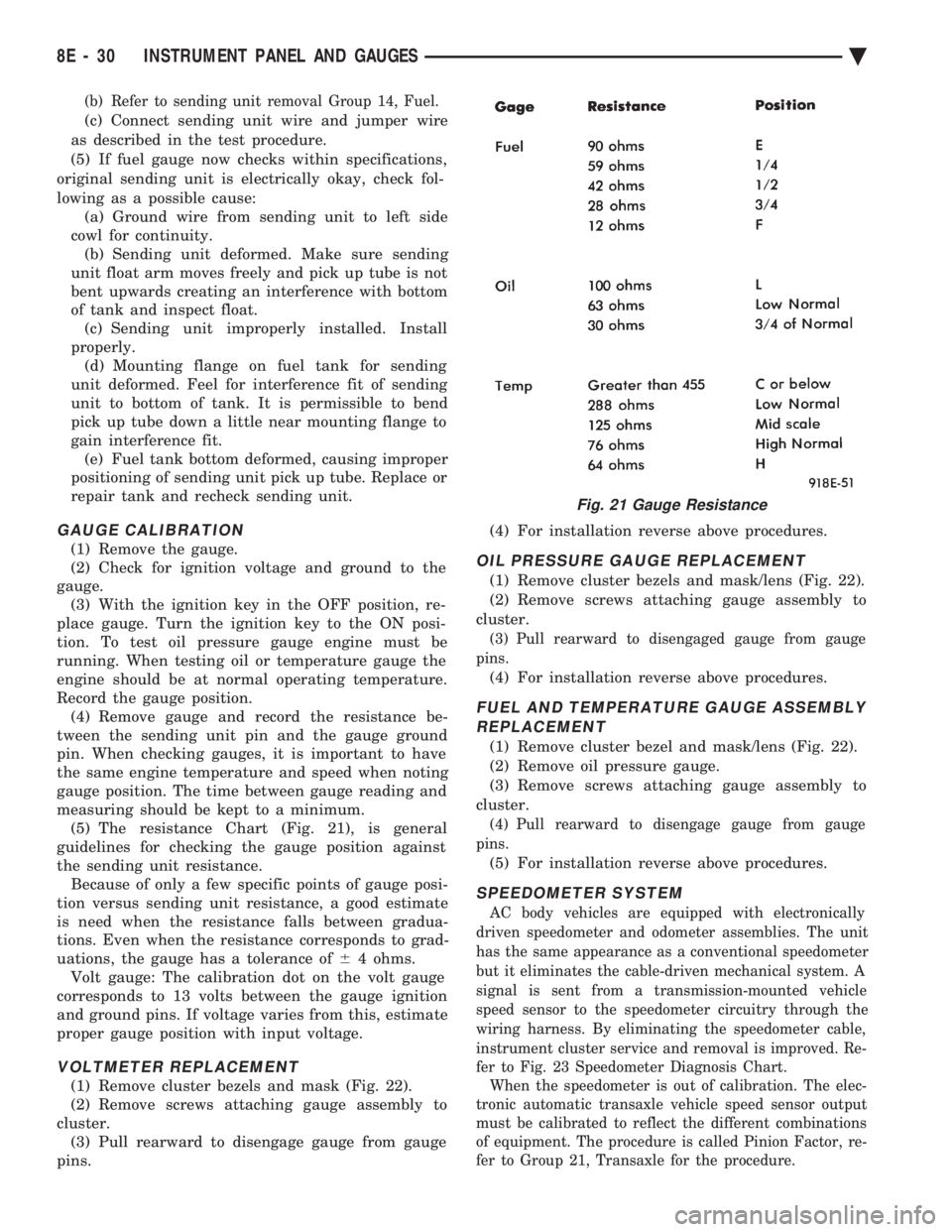

GAUGE CALIBRATION

(1) Remove the gauge.

(2) Check for ignition voltage and ground to the

gauge. (3) With the ignition key in the OFF position, re-

place gauge. Turn the ignition key to the ON posi-

tion. To test oil pressure gauge engine must be

running. When testing oil or temperature gauge the

engine should be at normal operating temperature.

Record the gauge position. (4) Remove gauge and record the resistance be-

tween the sending unit pin and the gauge ground

pin. When checking gauges, it is important to have

the same engine temperature and speed when noting

gauge position. The time between gauge reading and

measuring should be kept to a minimum. (5) The resistance Chart (Fig. 21), is general

guidelines for checking the gauge position against

the sending unit resistance. Because of only a few specific points of gauge posi-

tion versus sending unit resistance, a good estimate

is need when the resistance falls between gradua-

tions. Even when the resistance corresponds to grad-

uations, the gauge has a tolerance of 64 ohms.

Volt gauge: The calibration dot on the volt gauge

corresponds to 13 volts between the gauge ignition

and ground pins. If voltage varies from this, estimate

proper gauge position with input voltage.

VOLTMETER REPLACEMENT

(1) Remove cluster bezels and mask (Fig. 22).

(2) Remove screws attaching gauge assembly to

cluster. (3) Pull rearward to disengage gauge from gauge

pins. (4) For installation reverse above procedures.

OIL PRESSURE GAUGE REPLACEMENT

(1) Remove cluster bezels and mask/lens (Fig. 22).

(2) Remove screws attaching gauge assembly to

cluster.

(3) Pull rearward to disengaged gauge from gauge

pins.

(4) For installation reverse above procedures.

FUEL AND TEMPERATURE GAUGE ASSEMBLY REPLACEMENT

(1) Remove cluster bezel and mask/lens (Fig. 22).

(2) Remove oil pressure gauge.

(3) Remove screws attaching gauge assembly to

cluster.

(4) Pull rearward to disengage gauge from gauge

pins.

(5) For installation reverse above procedures.

SPEEDOMETER SYSTEM

AC body vehicles are equipped with electronically

driven speedometer and odometer assemblies. The unit

has the same appearance as a conventional speedometer

but it eliminates the cable-driven mechanical system. A

signal is sent from a transmission-mounted vehicle

speed sensor to the speedometer circuitry through the

wiring harness. By eliminating the speedometer cable,

instrument cluster service and removal is improved. Re-

fer to Fig. 23 Speedometer Diagnosis Chart. When the speedometer is out of calibration. The elec-

tronic automatic transaxle vehicle speed sensor output

must be calibrated to reflect the different combinations

of equipment. The procedure is called Pinion Factor, re-

fer to Group 21, Transaxle for the procedure.

Fig. 21 Gauge Resistance

8E - 30 INSTRUMENT PANEL AND GAUGES Ä

Page 555 of 2438

(f) If everything checks out OK, refer to Sending

Unit Test.

(4) With the ignition switch in the ON position,

check for battery voltage across the ignition pin and

the ground pin. (5) If fuel gauge meets specifications check fuel

tank and original fuel tank sending unit as follows: (a) Carefully remove fuel tank sending unit from

tank. (b) Refer to sending unit removal Group 14,

Fuel. (c) Connect sending unit wire and jumper wire

as described in the test procedure.

(6) If fuel gauge now checks within specifications,

original sending unit is electrically okay, check fol-

lowing as a possible cause: (a) Ground wire from sending unit to left side

cowl for continuity. (b) Sending unit deformed. Make sure sending

unit float arm moves freely and pick up tube is not

bent upwards creating an interference with bottom

of tank and inspect float. (c) Sending unit improperly installed. Install

properly. (d) Mounting flange on fuel tank for sending

unit deformed. Feel for interference fit of sending

unit to bottom of tank. It is permissible to bend

pick up tube down a little near mounting flange to

gain interference fit. (e) Fuel tank bottom deformed, causing improper

positioning of sending unit pick up tube. Replace or

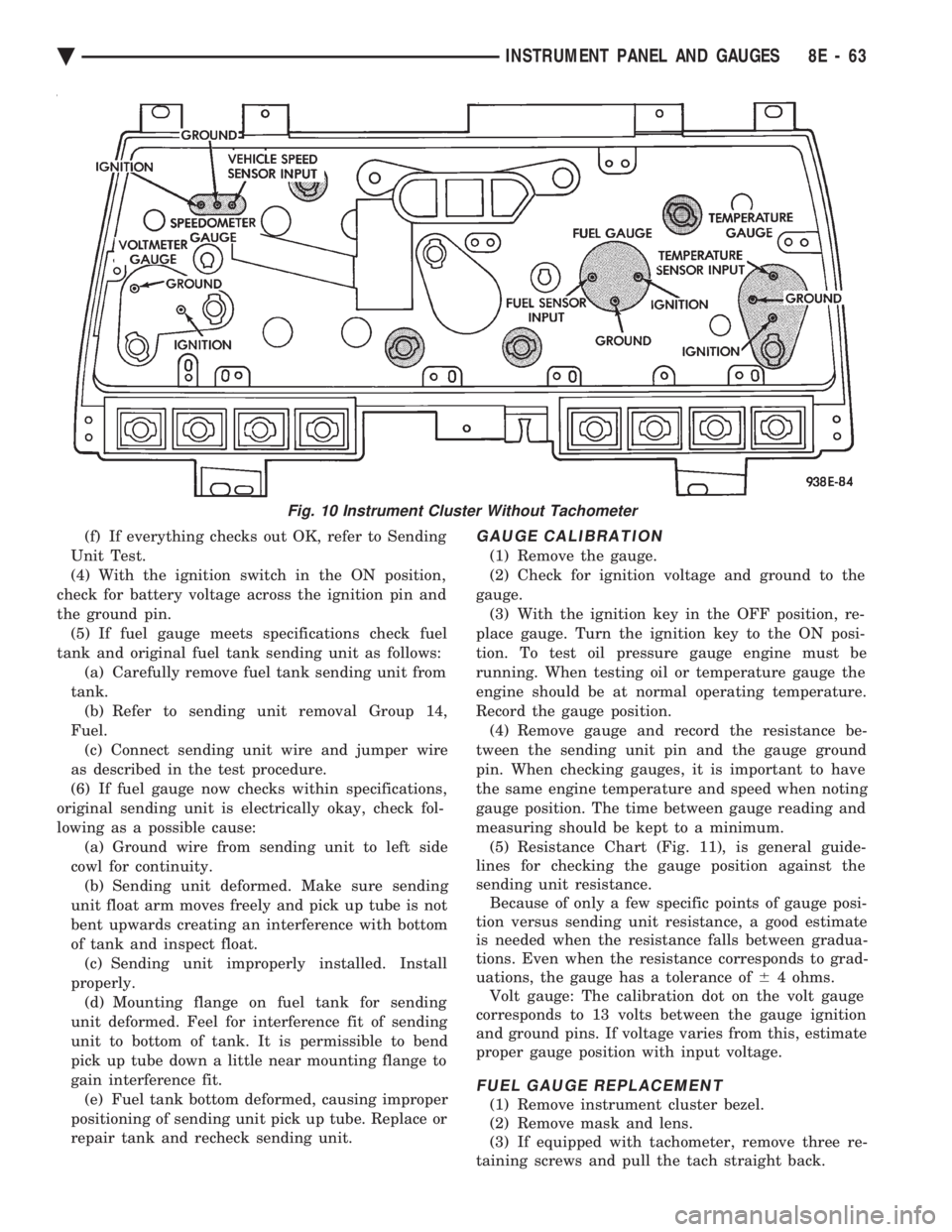

repair tank and recheck sending unit.GAUGE CALIBRATION

(1) Remove the gauge.

(2) Check for ignition voltage and ground to the

gauge. (3) With the ignition key in the OFF position, re-

place gauge. Turn the ignition key to the ON posi-

tion. To test oil pressure gauge engine must be

running. When testing oil or temperature gauge the

engine should be at normal operating temperature.

Record the gauge position. (4) Remove gauge and record the resistance be-

tween the sending unit pin and the gauge ground

pin. When checking gauges, it is important to have

the same engine temperature and speed when noting

gauge position. The time between gauge reading and

measuring should be kept to a minimum. (5) Resistance Chart (Fig. 11), is general guide-

lines for checking the gauge position against the

sending unit resistance. Because of only a few specific points of gauge posi-

tion versus sending unit resistance, a good estimate

is needed when the resistance falls between gradua-

tions. Even when the resistance corresponds to grad-

uations, the gauge has a tolerance of 64 ohms.

Volt gauge: The calibration dot on the volt gauge

corresponds to 13 volts between the gauge ignition

and ground pins. If voltage varies from this, estimate

proper gauge position with input voltage.

FUEL GAUGE REPLACEMENT

(1) Remove instrument cluster bezel.

(2) Remove mask and lens.

(3) If equipped with tachometer, remove three re-

taining screws and pull the tach straight back.

Fig. 10 Instrument Cluster Without Tachometer

Ä INSTRUMENT PANEL AND GAUGES 8E - 63

Page 1702 of 2438

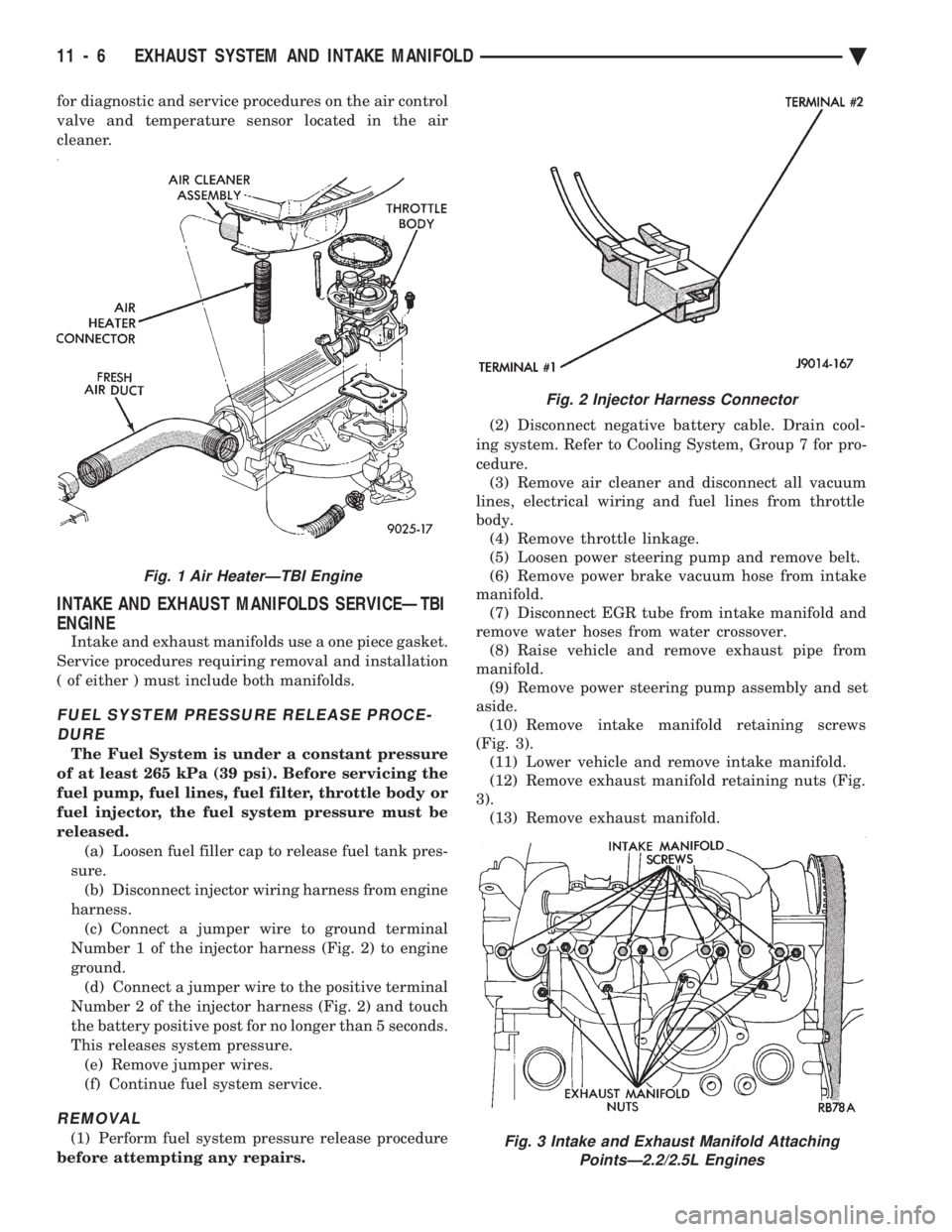

for diagnostic and service procedures on the air control

valve and temperature sensor located in the air

cleaner.

INTAKE AND EXHAUST MANIFOLDS SERVICEÐTBI

ENGINE

Intake and exhaust manifolds use a one piece gasket.

Service procedures requiring removal and installation

( of either ) must include both manifolds.

FUEL SYSTEM PRESSURE RELEASE PROCE- DURE

The Fuel System is under a constant pressure

of at least 265 kPa (39 psi). Before servicing the

fuel pump, fuel lines, fuel filter, throttle body or

fuel injector, the fuel system pressure must be

released. (a) Loosen fuel filler cap to release fuel tank pres-

sure. (b) Disconnect injector wiring harness from engine

harness. (c) Connect a jumper wire to ground terminal

Number 1 of the injector harness (Fig. 2) to engine

ground. (d) Connect a jumper wire to the positive terminal

Number 2 of the injector harness (Fig. 2) and touch

the battery positive post for no longer than 5 seconds.

This releases system pressure. (e) Remove jumper wires.

(f) Continue fuel system service.

REMOVAL

(1) Perform fuel system pressure release procedure

before attempting any repairs. (2) Disconnect negative battery cable. Drain cool-

ing system. Refer to Cooling System, Group 7 for pro-

cedure. (3) Remove air cleaner and disconnect all vacuum

lines, electrical wiring and fuel lines from throttle

body. (4) Remove throttle linkage.

(5) Loosen power steering pump and remove belt.

(6) Remove power brake vacuum hose from intake

manifold. (7) Disconnect EGR tube from intake manifold and

remove water hoses from water crossover. (8) Raise vehicle and remove exhaust pipe from

manifold. (9) Remove power steering pump assembly and set

aside. (10) Remove intake manifold retaining screws

(Fig. 3). (11) Lower vehicle and remove intake manifold.

(12) Remove exhaust manifold retaining nuts (Fig.

3). (13) Remove exhaust manifold.

Fig. 2 Injector Harness Connector

Fig. 3 Intake and Exhaust Manifold Attaching PointsÐ2.2/2.5L Engines

Fig. 1 Air HeaterÐTBI Engine

11 - 6 EXHAUST SYSTEM AND INTAKE MANIFOLD Ä

Page 1710 of 2438

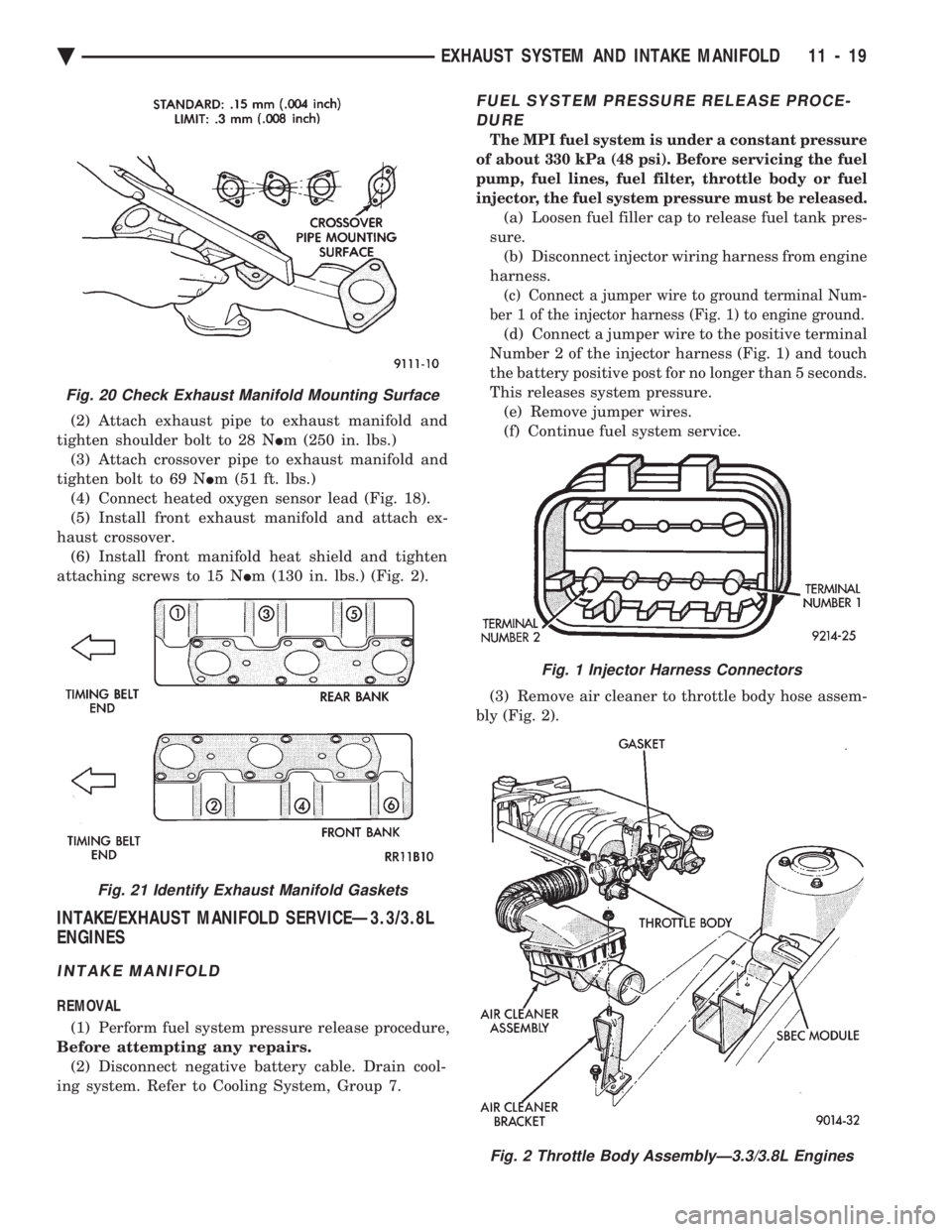

The exhaust manifolds are made of ductile cast

iron with the front bank and rear bank independent

of each other. The exhaust from the front bank ex-

haust manifold is led through on exhaust crossover

pipe to be combined with the rear bank exhaust at

the exhaust outlet to the exhaust pipe (Fig. 2).

INTAKE PLENUM/MANIFOLD

REMOVAL

(1) Perform fuel system pressure release procedure

(before attempting any repairs). (2) Disconnect negative battery cable. Drain cooling

system. See Cooling System, Group 7. (3) Remove air cleaner to throttle body hose (Fig. 3).

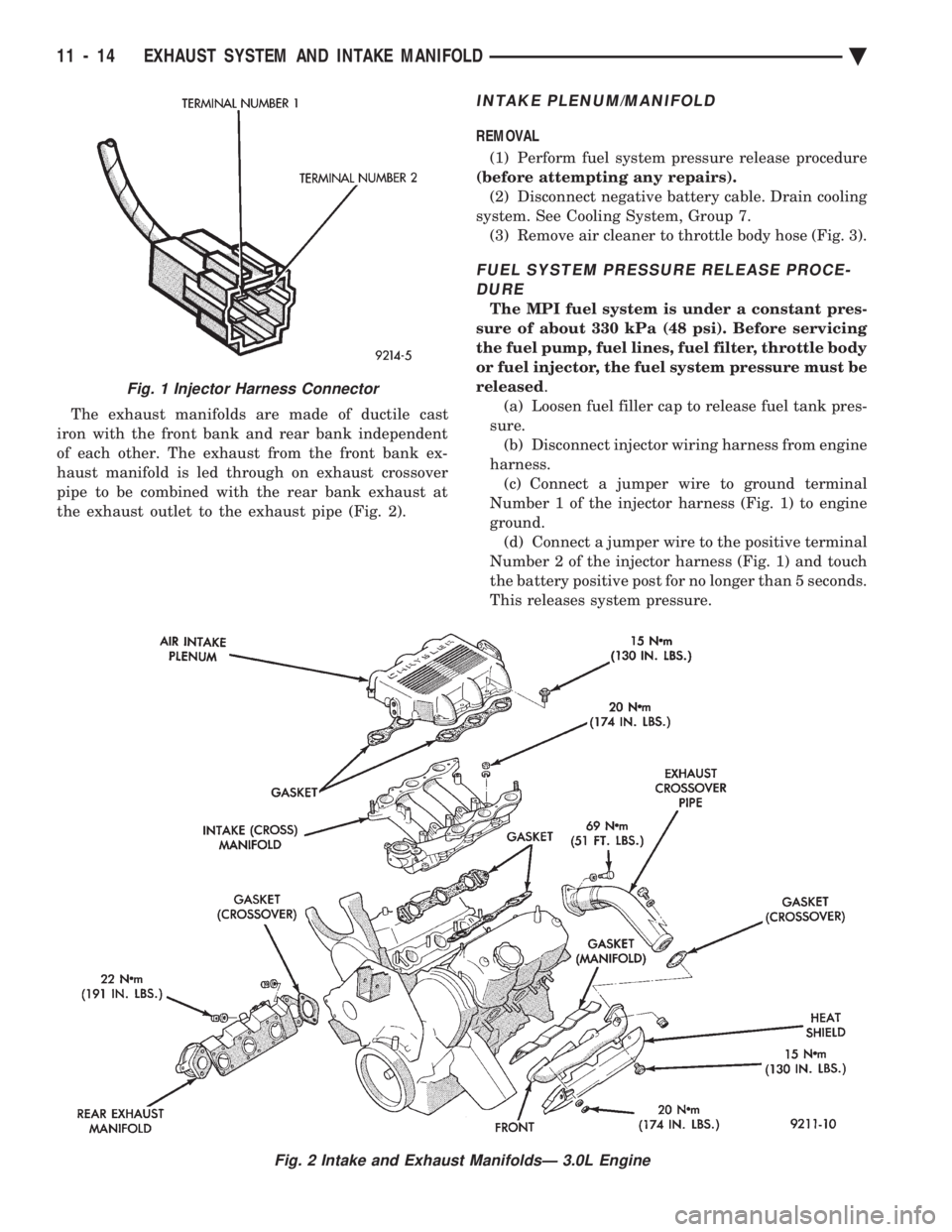

FUEL SYSTEM PRESSURE RELEASE PROCE-DURE

The MPI fuel system is under a constant pres-

sure of about 330 kPa (48 psi). Before servicing

the fuel pump, fuel lines, fuel filter, throttle body

or fuel injector, the fuel system pressure must be

released .

(a) Loosen fuel filler cap to release fuel tank pres-

sure. (b) Disconnect injector wiring harness from engine

harness. (c) Connect a jumper wire to ground terminal

Number 1 of the injector harness (Fig. 1) to engine

ground. (d) Connect a jumper wire to the positive terminal

Number 2 of the injector harness (Fig. 1) and touch

the battery positive post for no longer than 5 seconds.

This releases system pressure.

Fig. 1 Injector Harness Connector

Fig. 2 Intake and Exhaust ManifoldsÐ 3.0L Engine

11 - 14 EXHAUST SYSTEM AND INTAKE MANIFOLD Ä

Page 1715 of 2438

(2) Attach exhaust pipe to exhaust manifold and

tighten shoulder bolt to 28 N Im (250 in. lbs.)

(3) Attach crossover pipe to exhaust manifold and

tighten bolt to 69 N Im (51 ft. lbs.)

(4) Connect heated oxygen sensor lead (Fig. 18).

(5) Install front exhaust manifold and attach ex-

haust crossover. (6) Install front manifold heat shield and tighten

attaching screws to 15 N Im (130 in. lbs.) (Fig. 2).

INTAKE/EXHAUST MANIFOLD SERVICEÐ3.3/3.8L

ENGINES

INTAKE MANIFOLD

REMOVAL

(1) Perform fuel system pressure release procedure,

Before attempting any repairs. (2) Disconnect negative battery cable. Drain cool-

ing system. Refer to Cooling System, Group 7.

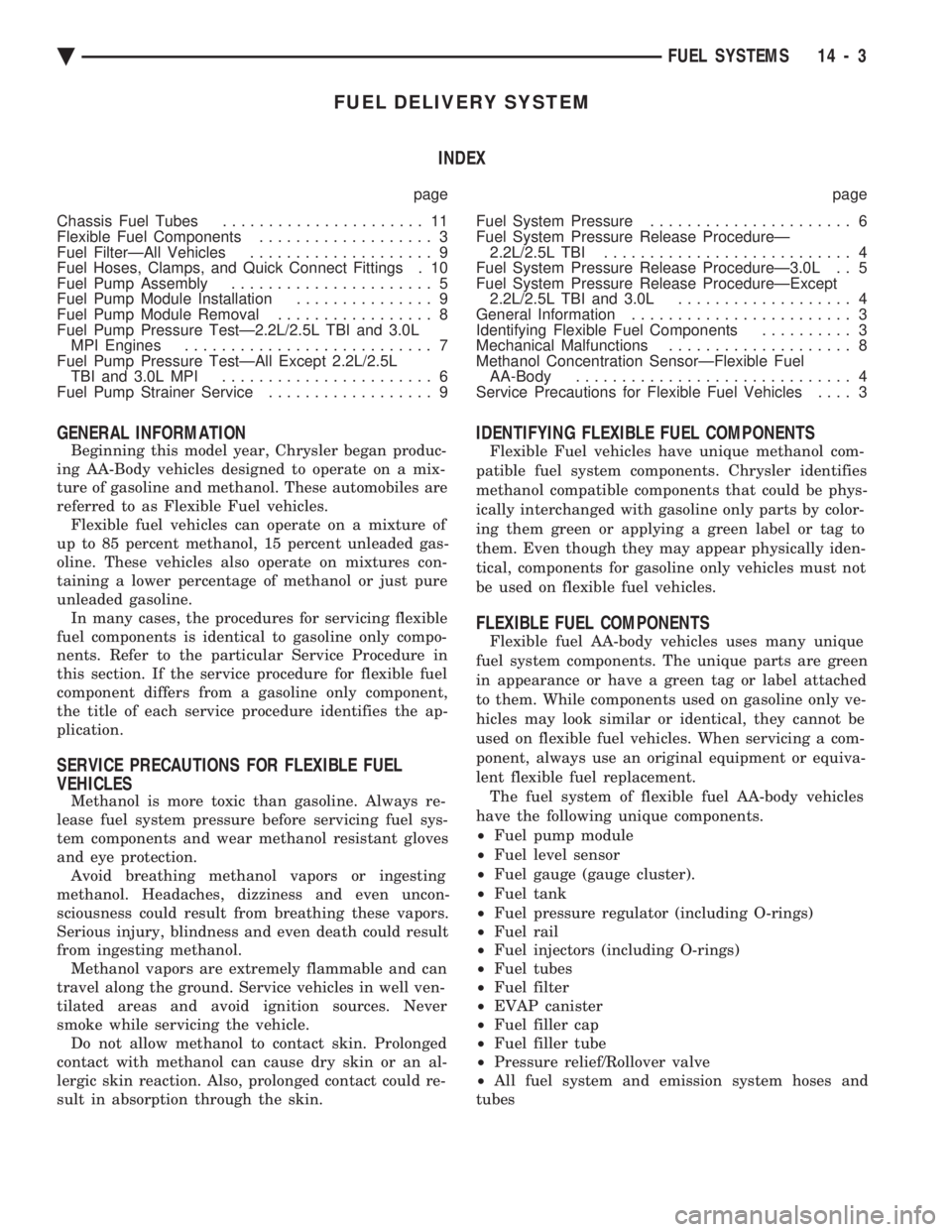

FUEL SYSTEM PRESSURE RELEASE PROCE- DURE

The MPI fuel system is under a constant pressure

of about 330 kPa (48 psi). Before servicing the fuel

pump, fuel lines, fuel filter, throttle body or fuel

injector, the fuel system pressure must be released.

(a) Loosen fuel filler cap to release fuel tank pres-

sure. (b) Disconnect injector wiring harness from engine

harness.

(c) Connect a jumper wire to ground terminal Num-

ber 1 of the injector harness (Fig. 1) to engine ground.

(d) Connect a jumper wire to the positive terminal

Number 2 of the injector harness (Fig. 1) and touch

the battery positive post for no longer than 5 seconds.

This releases system pressure. (e) Remove jumper wires.

(f) Continue fuel system service.

(3) Remove air cleaner to throttle body hose assem-

bly (Fig. 2).

Fig. 20 Check Exhaust Manifold Mounting Surface

Fig. 21 Identify Exhaust Manifold Gaskets

Fig. 1 Injector Harness Connectors

Fig. 2 Throttle Body AssemblyÐ3.3/3.8L Engines

Ä EXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 19

Page 1743 of 2438

FUEL DELIVERY SYSTEM INDEX

page page

Chassis Fuel Tubes ...................... 11

Flexible Fuel Components ................... 3

Fuel FilterÐAll Vehicles .................... 9

Fuel Hoses, Clamps, and Quick Connect Fittings . 10

Fuel Pump Assembly ...................... 5

Fuel Pump Module Installation ............... 9

Fuel Pump Module Removal ................. 8

Fuel Pump Pressure TestÐ2.2L/2.5L TBI and 3.0L MPI Engines ........................... 7

Fuel Pump Pressure TestÐAll Except 2.2L/2.5L TBI and 3.0L MPI ....................... 6

Fuel Pump Strainer Service .................. 9 Fuel System Pressure

...................... 6

Fuel System Pressure Release ProcedureÐ 2.2L/2.5L TBI ........................... 4

Fuel System Pressure Release ProcedureÐ3.0L . . 5

Fuel System Pressure Release ProcedureÐExcept 2.2L/2.5L TBI and 3.0L ................... 4

General Information ........................ 3

Identifying Flexible Fuel Components .......... 3

Mechanical Malfunctions .................... 8

Methanol Concentration SensorÐFlexible Fuel AA-Body .............................. 4

Service Precautions for Flexible Fuel Vehicles .... 3

GENERAL INFORMATION

Beginning this model year, Chrysler began produc-

ing AA-Body vehicles designed to operate on a mix-

ture of gasoline and methanol. These automobiles are

referred to as Flexible Fuel vehicles. Flexible fuel vehicles can operate on a mixture of

up to 85 percent methanol, 15 percent unleaded gas-

oline. These vehicles also operate on mixtures con-

taining a lower percentage of methanol or just pure

unleaded gasoline. In many cases, the procedures for servicing flexible

fuel components is identical to gasoline only compo-

nents. Refer to the particular Service Procedure in

this section. If the service procedure for flexible fuel

component differs from a gasoline only component,

the title of each service procedure identifies the ap-

plication.

SERVICE PRECAUTIONS FOR FLEXIBLE FUEL

VEHICLES

Methanol is more toxic than gasoline. Always re-

lease fuel system pressure before servicing fuel sys-

tem components and wear methanol resistant gloves

and eye protection. Avoid breathing methanol vapors or ingesting

methanol. Headaches, dizziness and even uncon-

sciousness could result from breathing these vapors.

Serious injury, blindness and even death could result

from ingesting methanol. Methanol vapors are extremely flammable and can

travel along the ground. Service vehicles in well ven-

tilated areas and avoid ignition sources. Never

smoke while servicing the vehicle. Do not allow methanol to contact skin. Prolonged

contact with methanol can cause dry skin or an al-

lergic skin reaction. Also, prolonged contact could re-

sult in absorption through the skin.

IDENTIFYING FLEXIBLE FUEL COMPONENTS

Flexible Fuel vehicles have unique methanol com-

patible fuel system components. Chrysler identifies

methanol compatible components that could be phys-

ically interchanged with gasoline only parts by color-

ing them green or applying a green label or tag to

them. Even though they may appear physically iden-

tical, components for gasoline only vehicles must not

be used on flexible fuel vehicles.

FLEXIBLE FUEL COMPONENTS

Flexible fuel AA-body vehicles uses many unique

fuel system components. The unique parts are green

in appearance or have a green tag or label attached

to them. While components used on gasoline only ve-

hicles may look similar or identical, they cannot be

used on flexible fuel vehicles. When servicing a com-

ponent, always use an original equipment or equiva-

lent flexible fuel replacement. The fuel system of flexible fuel AA-body vehicles

have the following unique components.

² Fuel pump module

² Fuel level sensor

² Fuel gauge (gauge cluster).

² Fuel tank

² Fuel pressure regulator (including O-rings)

² Fuel rail

² Fuel injectors (including O-rings)

² Fuel tubes

² Fuel filter

² EVAP canister

² Fuel filler cap

² Fuel filler tube

² Pressure relief/Rollover valve

² All fuel system and emission system hoses and

tubes

Ä FUEL SYSTEMS 14 - 3

Page 1744 of 2438

INSTRUMENT PANEL CLUSTER IDENTIFICATIONÐFLEXIBLE FUEL AA-BODY

Flexible fuel A-Body vehicles use a unique gauge

cluster. To identify the cluster, remove it from the

instrument panel and check the number on the tag

on the top. If the part number matches the number

in the parts book for flexible fuel A-bodies, the vehi-

cle was built with the correct cluster. Refer to Group

8E, Instrument Panel and Gauges, for cluster re-

moval and installation.

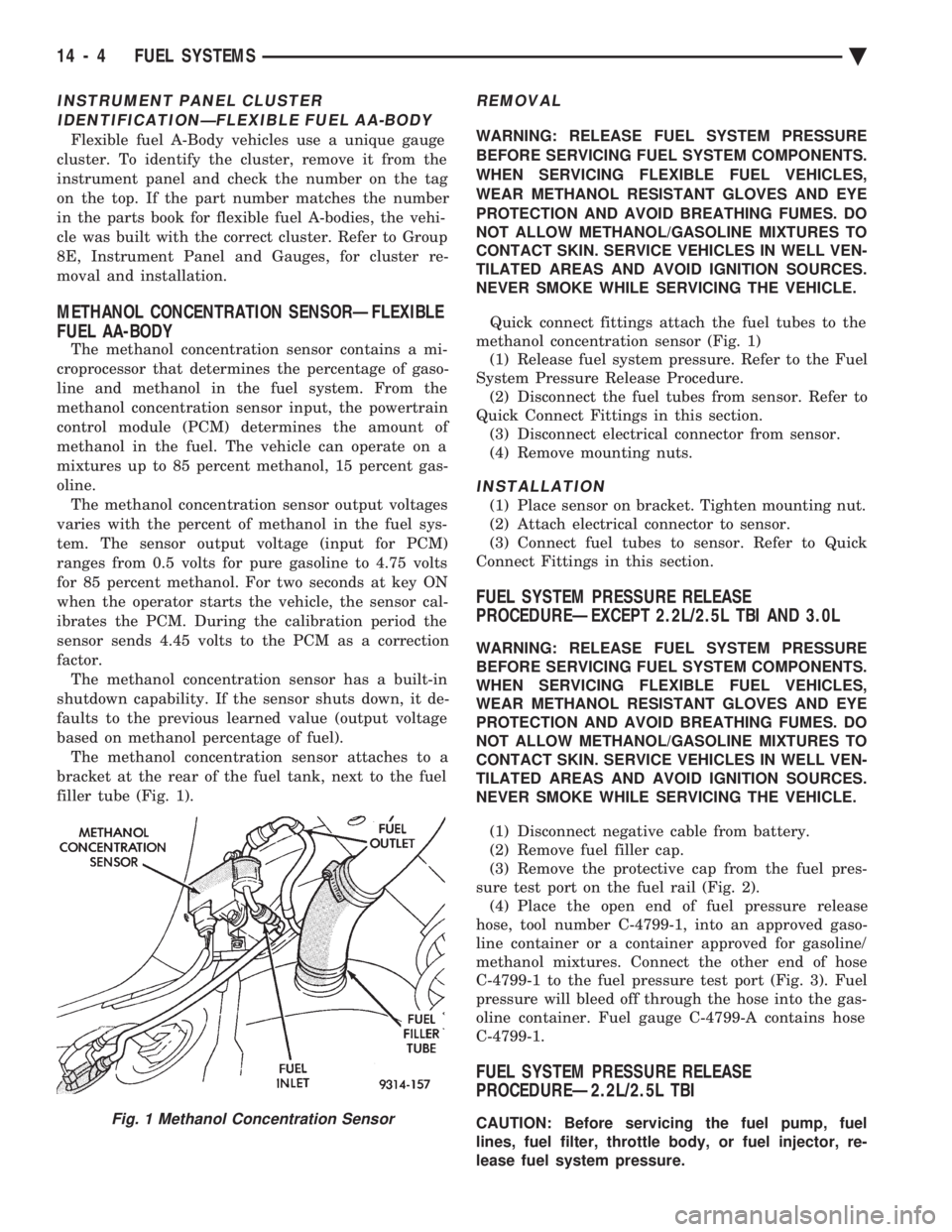

METHANOL CONCENTRATION SENSORÐFLEXIBLE

FUEL AA-BODY

The methanol concentration sensor contains a mi-

croprocessor that determines the percentage of gaso-

line and methanol in the fuel system. From the

methanol concentration sensor input, the powertrain

control module (PCM) determines the amount of

methanol in the fuel. The vehicle can operate on a

mixtures up to 85 percent methanol, 15 percent gas-

oline. The methanol concentration sensor output voltages

varies with the percent of methanol in the fuel sys-

tem. The sensor output voltage (input for PCM)

ranges from 0.5 volts for pure gasoline to 4.75 volts

for 85 percent methanol. For two seconds at key ON

when the operator starts the vehicle, the sensor cal-

ibrates the PCM. During the calibration period the

sensor sends 4.45 volts to the PCM as a correction

factor. The methanol concentration sensor has a built-in

shutdown capability. If the sensor shuts down, it de-

faults to the previous learned value (output voltage

based on methanol percentage of fuel). The methanol concentration sensor attaches to a

bracket at the rear of the fuel tank, next to the fuel

filler tube (Fig. 1).

REMOVAL

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

WHEN SERVICING FLEXIBLE FUEL VEHICLES,

WEAR METHANOL RESISTANT GLOVES AND EYE

PROTECTION AND AVOID BREATHING FUMES. DO

NOT ALLOW METHANOL/GASOLINE MIXTURES TO

CONTACT SKIN. SERVICE VEHICLES IN WELL VEN-

TILATED AREAS AND AVOID IGNITION SOURCES.

NEVER SMOKE WHILE SERVICING THE VEHICLE.

Quick connect fittings attach the fuel tubes to the

methanol concentration sensor (Fig. 1) (1) Release fuel system pressure. Refer to the Fuel

System Pressure Release Procedure. (2) Disconnect the fuel tubes from sensor. Refer to

Quick Connect Fittings in this section. (3) Disconnect electrical connector from sensor.

(4) Remove mounting nuts.

INSTALLATION

(1) Place sensor on bracket. Tighten mounting nut.

(2) Attach electrical connector to sensor.

(3) Connect fuel tubes to sensor. Refer to Quick

Connect Fittings in this section.

FUEL SYSTEM PRESSURE RELEASE

PROCEDUREÐEXCEPT 2.2L/2.5L TBI AND 3.0L

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

WHEN SERVICING FLEXIBLE FUEL VEHICLES,

WEAR METHANOL RESISTANT GLOVES AND EYE

PROTECTION AND AVOID BREATHING FUMES. DO

NOT ALLOW METHANOL/GASOLINE MIXTURES TO

CONTACT SKIN. SERVICE VEHICLES IN WELL VEN-

TILATED AREAS AND AVOID IGNITION SOURCES.

NEVER SMOKE WHILE SERVICING THE VEHICLE.

(1) Disconnect negative cable from battery.

(2) Remove fuel filler cap.

(3) Remove the protective cap from the fuel pres-

sure test port on the fuel rail (Fig. 2). (4) Place the open end of fuel pressure release

hose, tool number C-4799-1, into an approved gaso-

line container or a container approved for gasoline/

methanol mixtures. Connect the other end of hose

C-4799-1 to the fuel pressure test port (Fig. 3). Fuel

pressure will bleed off through the hose into the gas-

oline container. Fuel gauge C-4799-A contains hose

C-4799-1.

FUEL SYSTEM PRESSURE RELEASE

PROCEDUREÐ2.2L/2.5L TBI

CAUTION: Before servicing the fuel pump, fuel

lines, fuel filter, throttle body, or fuel injector, re-

lease fuel system pressure.Fig. 1 Methanol Concentration Sensor

14 - 4 FUEL SYSTEMS Ä

Page 1748 of 2438

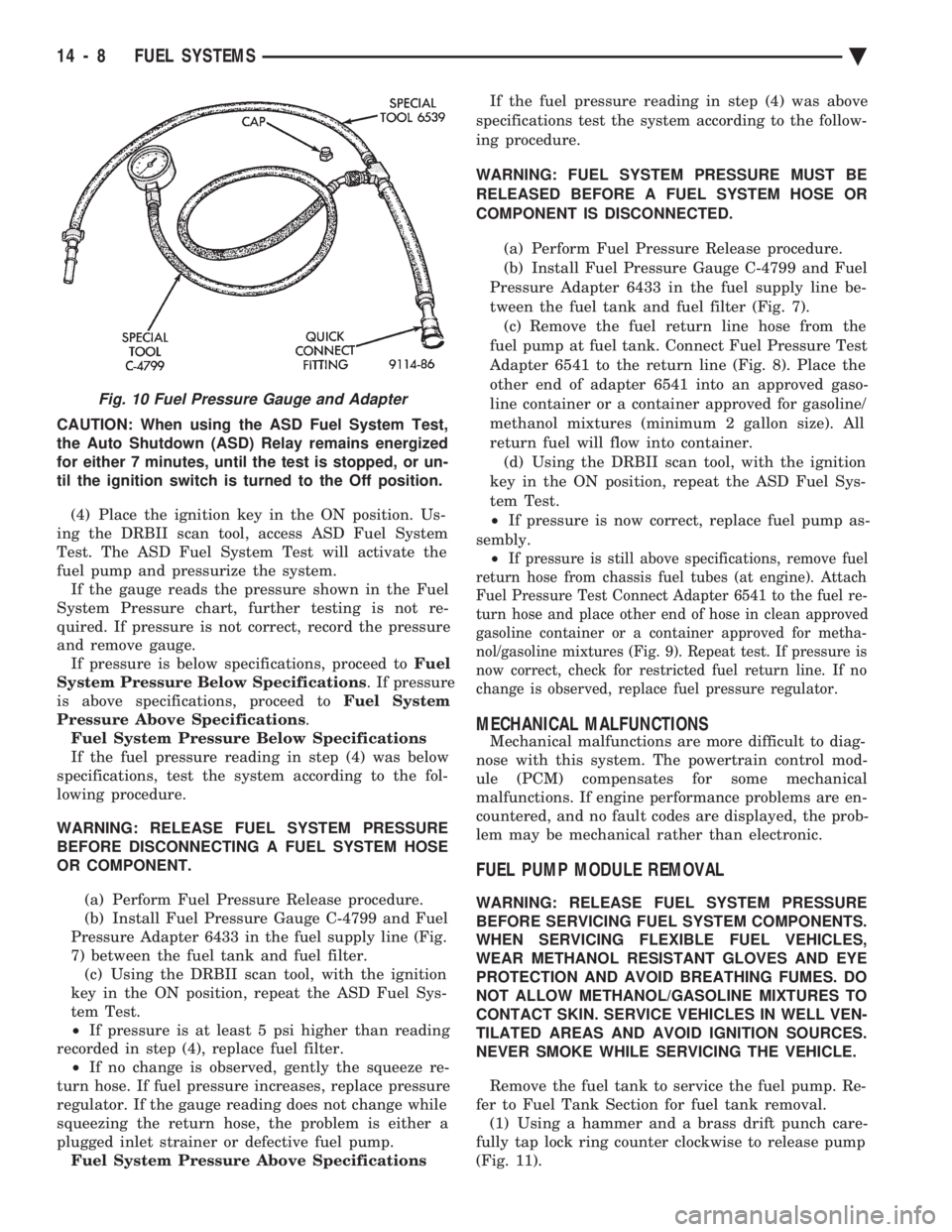

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or un-

til the ignition switch is turned to the Off position.

(4) Place the ignition key in the ON position. Us-

ing the DRBII scan tool, access ASD Fuel System

Test. The ASD Fuel System Test will activate the

fuel pump and pressurize the system. If the gauge reads the pressure shown in the Fuel

System Pressure chart, further testing is not re-

quired. If pressure is not correct, record the pressure

and remove gauge. If pressure is below specifications, proceed to Fuel

System Pressure Below Specifications . If pressure

is above specifications, proceed to Fuel System

Pressure Above Specifications .

Fuel System Pressure Below Specifications

If the fuel pressure reading in step (4) was below

specifications, test the system according to the fol-

lowing procedure.

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE DISCONNECTING A FUEL SYSTEM HOSE

OR COMPONENT.

(a) Perform Fuel Pressure Release procedure.

(b) Install Fuel Pressure Gauge C-4799 and Fuel

Pressure Adapter 6433 in the fuel supply line (Fig.

7) between the fuel tank and fuel filter. (c) Using the DRBII scan tool, with the ignition

key in the ON position, repeat the ASD Fuel Sys-

tem Test.

² If pressure is at least 5 psi higher than reading

recorded in step (4), replace fuel filter. ² If no change is observed, gently the squeeze re-

turn hose. If fuel pressure increases, replace pressure

regulator. If the gauge reading does not change while

squeezing the return hose, the problem is either a

plugged inlet strainer or defective fuel pump. Fuel System Pressure Above Specifications If the fuel pressure reading in step (4) was above

specifications test the system according to the follow-

ing procedure.

WARNING: FUEL SYSTEM PRESSURE MUST BE

RELEASED BEFORE A FUEL SYSTEM HOSE OR

COMPONENT IS DISCONNECTED.

(a) Perform Fuel Pressure Release procedure.

(b) Install Fuel Pressure Gauge C-4799 and Fuel

Pressure Adapter 6433 in the fuel supply line be-

tween the fuel tank and fuel filter (Fig. 7). (c) Remove the fuel return line hose from the

fuel pump at fuel tank. Connect Fuel Pressure Test

Adapter 6541 to the return line (Fig. 8). Place the

other end of adapter 6541 into an approved gaso-

line container or a container approved for gasoline/

methanol mixtures (minimum 2 gallon size). All

return fuel will flow into container. (d) Using the DRBII scan tool, with the ignition

key in the ON position, repeat the ASD Fuel Sys-

tem Test.

² If pressure is now correct, replace fuel pump as-

sembly. ²

If pressure is still above specifications, remove fuel

return hose from chassis fuel tubes (at engine). Attach

Fuel Pressure Test Connect Adapter 6541 to the fuel re-

turn hose and place other end of hose in clean approved

gasoline container or a container approved for metha-

nol/gasoline mixtures (Fig. 9). Repeat test. If pressure is

now correct, check for restricted fuel return line. If no

change is observed, replace fuel pressure regulator.

MECHANICAL MALFUNCTIONS

Mechanical malfunctions are more difficult to diag-

nose with this system. The powertrain control mod-

ule (PCM) compensates for some mechanical

malfunctions. If engine performance problems are en-

countered, and no fault codes are displayed, the prob-

lem may be mechanical rather than electronic.

FUEL PUMP MODULE REMOVAL

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

WHEN SERVICING FLEXIBLE FUEL VEHICLES,

WEAR METHANOL RESISTANT GLOVES AND EYE

PROTECTION AND AVOID BREATHING FUMES. DO

NOT ALLOW METHANOL/GASOLINE MIXTURES TO

CONTACT SKIN. SERVICE VEHICLES IN WELL VEN-

TILATED AREAS AND AVOID IGNITION SOURCES.

NEVER SMOKE WHILE SERVICING THE VEHICLE.

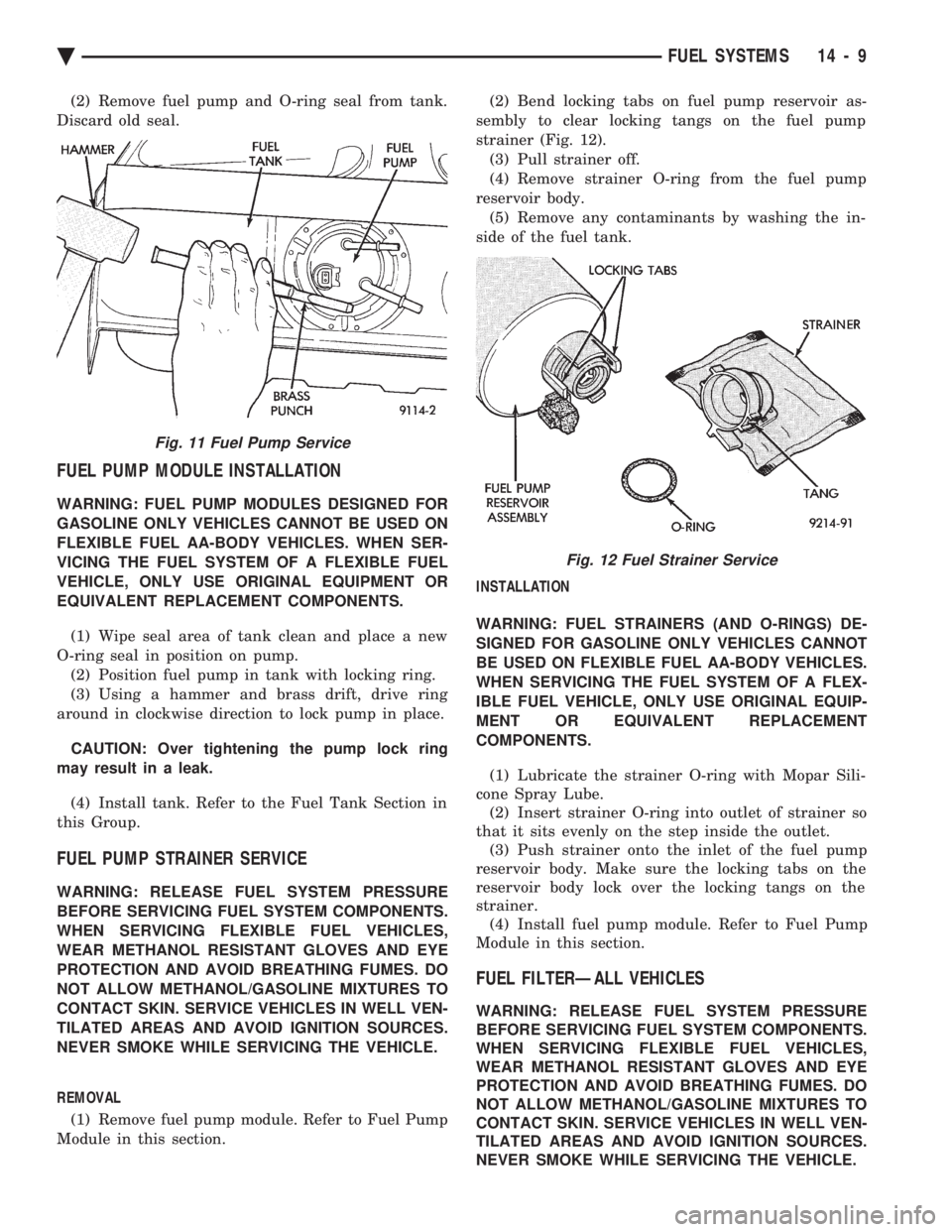

Remove the fuel tank to service the fuel pump. Re-

fer to Fuel Tank Section for fuel tank removal. (1) Using a hammer and a brass drift punch care-

fully tap lock ring counter clockwise to release pump

(Fig. 11).

Fig. 10 Fuel Pressure Gauge and Adapter

14 - 8 FUEL SYSTEMS Ä

Page 1749 of 2438

(2) Remove fuel pump and O-ring seal from tank.

Discard old seal.

FUEL PUMP MODULE INSTALLATION

WARNING: FUEL PUMP MODULES DESIGNED FOR

GASOLINE ONLY VEHICLES CANNOT BE USED ON

FLEXIBLE FUEL AA-BODY VEHICLES. WHEN SER-

VICING THE FUEL SYSTEM OF A FLEXIBLE FUEL

VEHICLE, ONLY USE ORIGINAL EQUIPMENT OR

EQUIVALENT REPLACEMENT COMPONENTS.

(1) Wipe seal area of tank clean and place a new

O-ring seal in position on pump. (2) Position fuel pump in tank with locking ring.

(3) Using a hammer and brass drift, drive ring

around in clockwise direction to lock pump in place.

CAUTION: Over tightening the pump lock ring

may result in a leak.

(4) Install tank. Refer to the Fuel Tank Section in

this Group.

FUEL PUMP STRAINER SERVICE

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

WHEN SERVICING FLEXIBLE FUEL VEHICLES,

WEAR METHANOL RESISTANT GLOVES AND EYE

PROTECTION AND AVOID BREATHING FUMES. DO

NOT ALLOW METHANOL/GASOLINE MIXTURES TO

CONTACT SKIN. SERVICE VEHICLES IN WELL VEN-

TILATED AREAS AND AVOID IGNITION SOURCES.

NEVER SMOKE WHILE SERVICING THE VEHICLE.

REMOVAL

(1) Remove fuel pump module. Refer to Fuel Pump

Module in this section. (2) Bend locking tabs on fuel pump reservoir as-

sembly to clear locking tangs on the fuel pump

strainer (Fig. 12). (3) Pull strainer off.

(4) Remove strainer O-ring from the fuel pump

reservoir body. (5) Remove any contaminants by washing the in-

side of the fuel tank.

INSTALLATION

WARNING: FUEL STRAINERS (AND O-RINGS) DE-

SIGNED FOR GASOLINE ONLY VEHICLES CANNOT

BE USED ON FLEXIBLE FUEL AA-BODY VEHICLES.

WHEN SERVICING THE FUEL SYSTEM OF A FLEX-

IBLE FUEL VEHICLE, ONLY USE ORIGINAL EQUIP-

MENT OR EQUIVALENT REPLACEMENT

COMPONENTS.

(1) Lubricate the strainer O-ring with Mopar Sili-

cone Spray Lube. (2) Insert strainer O-ring into outlet of strainer so

that it sits evenly on the step inside the outlet. (3) Push strainer onto the inlet of the fuel pump

reservoir body. Make sure the locking tabs on the

reservoir body lock over the locking tangs on the

strainer. (4) Install fuel pump module. Refer to Fuel Pump

Module in this section.

FUEL FILTERÐALL VEHICLES

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

WHEN SERVICING FLEXIBLE FUEL VEHICLES,

WEAR METHANOL RESISTANT GLOVES AND EYE

PROTECTION AND AVOID BREATHING FUMES. DO

NOT ALLOW METHANOL/GASOLINE MIXTURES TO

CONTACT SKIN. SERVICE VEHICLES IN WELL VEN-

TILATED AREAS AND AVOID IGNITION SOURCES.

NEVER SMOKE WHILE SERVICING THE VEHICLE.

Fig. 11 Fuel Pump Service

Fig. 12 Fuel Strainer Service

Ä FUEL SYSTEMS 14 - 9