low oil pressure CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 243 of 2438

DRIVE-OFF CYCLE

The DRIVE-OFF CYCLE takes place when the ve-

hicle reaches about 3 miles per hour the first time af-

ter an ignition reset. During this test, the modulator

solenoid valves are activated briefly to test their

function. The DRIVE-OFF CYCLE will be bypassed

if you drive-off with the service brake pedal de-

pressed.

LATCHING VERSUS NON-LATCHING FAULTS

Some faults detected by the (CAB) are latching.

The fault is latched and (ABS) function is disabled

until the ignition switch is reset (turned OFF/ON).

Thus (ABS) function is disabled even if the original

fault has disappeared during the ignition cycle in

which it occurred. Other faults are non-latching; any

warning lights that are turned on are only on as long

as the fault condition exists. As soon as the condition

goes away. The Amber Anti-Lock Warning Light is

turned off. Although a fault code will be set in most

cases. (Example:low accumulator fault will not be

stored for a time of 2 minutes after the fault is de-

tected).

BENDIX ABS SYSTEMS DIAGNOSTICS

The Bendix Anti-Lock 10 Brake System diagnos-

tics. Beyond the basic mechanical diagnostics, sys-

tems and components covered earlier in this section,

is accomplished by using the DRB II diagnostic

tester. See testing procedures outlined in the Bendix

Anti-Lock 10 Diagnostics Manual for the 1993 M.Y. Please reference the above mentioned manual. For

any further diagnostic service procedures that are re-

quired on the Bendix Anti-Lock 10 Brake System, re-

quiring the use of the DRB II diagnostic tester.

ON CAR HYDRAULIC ABS COMPONENT SERVICE

WARNING: FAILURE TO FULLY DE-PRESSURIZE

THE HYDRAULIC ACCUMULATOR BEFORE PER-

FORMING HYDRAULIC SYSTEM SERVICE OPERA-

TIONS. COULD RESULT IN INJURY TO SERVICE

PERSONNEL AND OR DAMAGE TO PAINTED SUR-

FACES. SEE SECTION 2 FOR ADDITIONAL WARN-

INGS AND CAUTIONS.

GENERAL SERVICE PRECAUTIONS

The following are general precautions that should

be observed when servicing the Anti-Lock Brake Sys-

tem and/or other vehicle systems. Failure to observe

these precautions may result in Anti-Lock brake sys-

tem damage. If welding work is to be performed on the vehicle,

using an electric arc welder, the (CAB) connector

should be disconnected during the welding operation. The (CAB) or hydraulic assembly connector should

never be connected or disconnected with the ignition

switch in the ONposition.

Many components of the Anti-Lock brake system are

not serviceable and must be replaced as an assembly.

Do not attempt to disassemble any component

that is not designed to be a serviced component.

DE-PRESSURIZING HYDRAULIC ACCUMULA- TOR

The pump/motor assembly will keep the hydraulic

accumulator charged to approximately 11,032 and

13,790 kPa (1600 and 2000 psi) any time that the

ignition is in the ON position. The pump/motor assem-

bly cannot run if the ignition is off or if either battery

cable is disconnected. Unless otherwise specified, the hydraulic accumula-

tor should be de-pressurized before disassembling any

portion of the hydraulic system. The following proce-

dure should be used to relieve the pressure in the

hydraulic accumulator: (1) With ignition off, or either battery cable discon-

nected, pump the brake pedal a minimum of 40 times,

using approximately 222 N (50 lbs.) pedal force. A

noticeable change in pedal feel will occur, when the

accumulator is discharged. (2) When a definite increase in pedal effort is felt,

pump pedal a few additional times. This will insure

removal of all hydraulic pressure from the brake sys-

tem.

CHECKING BRAKE FLUID LEVEL

CAUTION: Use only brake fluid conforming to DOT 3

specifications such as Mopar Tor Equivalent. Do not

use any fluid in the brake hydraulic system, which

contains a petroleum base. Do not use a container

which has been used for petroleum based fluids or a

container that is wet with water. Petroleum based

fluids will cause swelling and distortion of rubber

parts in the hydraulic brake system and water will mix

with brake fluid, lowering the fluid boiling point. Keep

all brake fluid containers tightly capped to prevent

contamination.

The hydraulic assembly is equipped with a plastic

fluid reservoir, with a filter/strainer located in the filler

neck of each reservoir section. The Anti-Lock brake system requires that the hy-

draulic accumulator be de-pressurized when checking

the fluid level. To check the brake fluid level, the

following procedure should be used: (1) With the ignition off, de-pressurize the hydraulic

accumulator by applying the brake pedal approxi-

mately 40 times, using a pedal force of approximately

220 N (50 lbs.). A noticeable change in pedal feel will

occur when the accumulator is de-

Ä ANTI-LOCK 10 BRAKE SYSTEM 5 - 93

Page 252 of 2438

WARNING: FAILURE TO DE-PRESSURIZE HYDRAU-

LIC ASSEMBLY/ACCUMULATOR PRIOR PERFORM-

ING THIS OPERATION. MAY RESULT IN PERSONAL

INJURY AND/OR DAMAGE TO PAINTED SURFACES

OF THE VEHICLE.

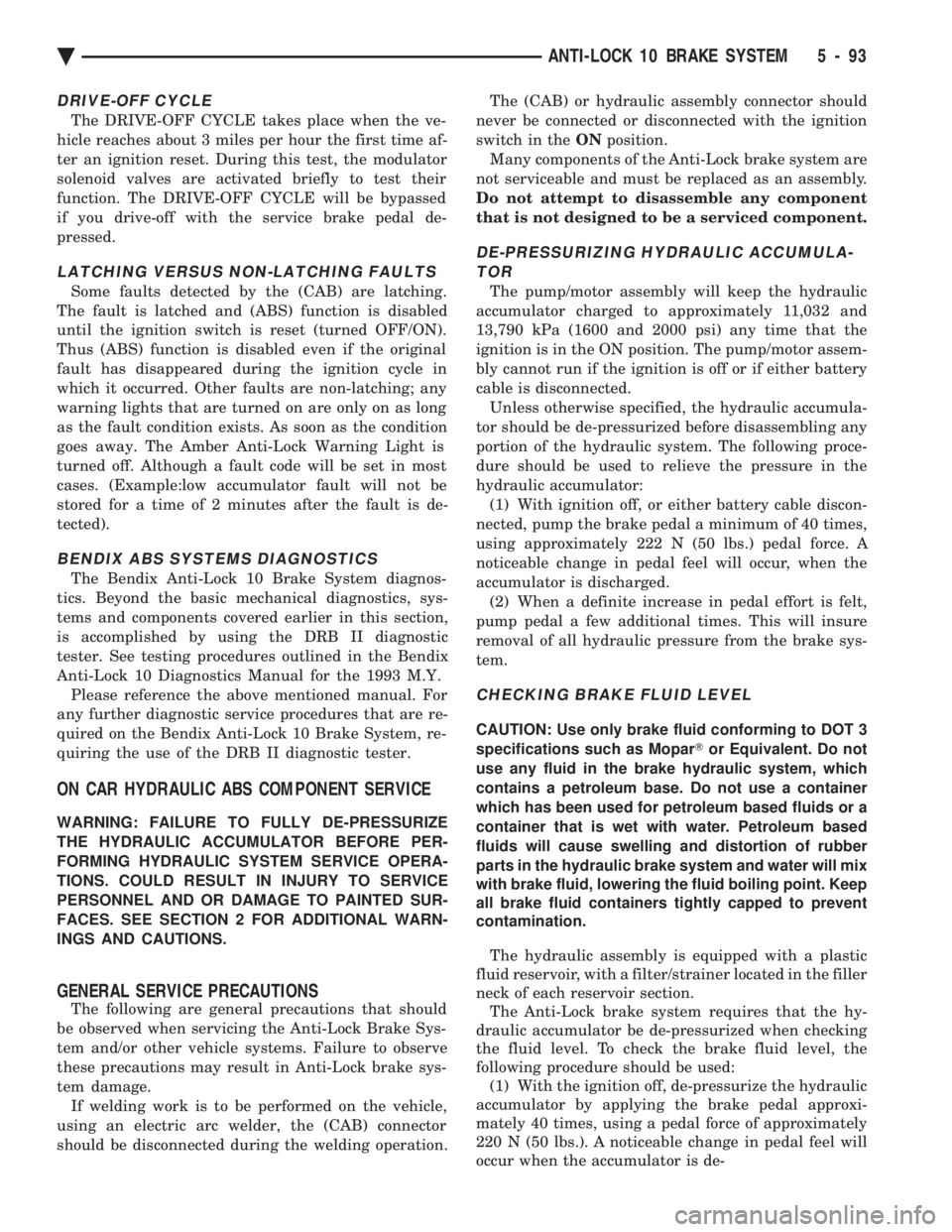

(2) Using Oil Filter Band Wrench, Special Tool

C-4065 or equivalent loosen bladder accumulator.

Then remove the bladder accumulator and brake

fluid shield from the hydraulic assembly (Fig. 17).

INSTALL

(1) Install the brake fluid spray shield onto the hy-

draulic accumulator (Fig. 1). (2) Install the bladder accumulator onto the hy-

draulic assembly by hand. Be sure that the O-Ring

on the bladder accumulator is fully seated into the

hydraulic assembly. (3) Using Oil Filter Band Wrench, Special Tool

C-4065 or equivalent, (Fig. 17) torque the bladder ac-

cumulator to 48 N Im (35 ft. lbs.)

(4) Turn ignition switch to the run position to en-

ergize the pump/motor assembly and pressurize hy-

draulic system. Check for leakage at the hydraulic

assembly to hydraulic bladder accumulator fitting. (5) Again de-pressurize accumulator by pumping

brake pedal a minimum of 40 times. Use procedure

described in De-Pressurizing Hydraulic Accumulator

in this section of the service manual. (6) Then check the brake fluid level in the hydrau-

lic assembly reservoir. If brake fluid level is low, fill

reservoir to proper level (Fig. 15) with Mopar tbrake

fluid or equivalent conforming to DOT 3 require-

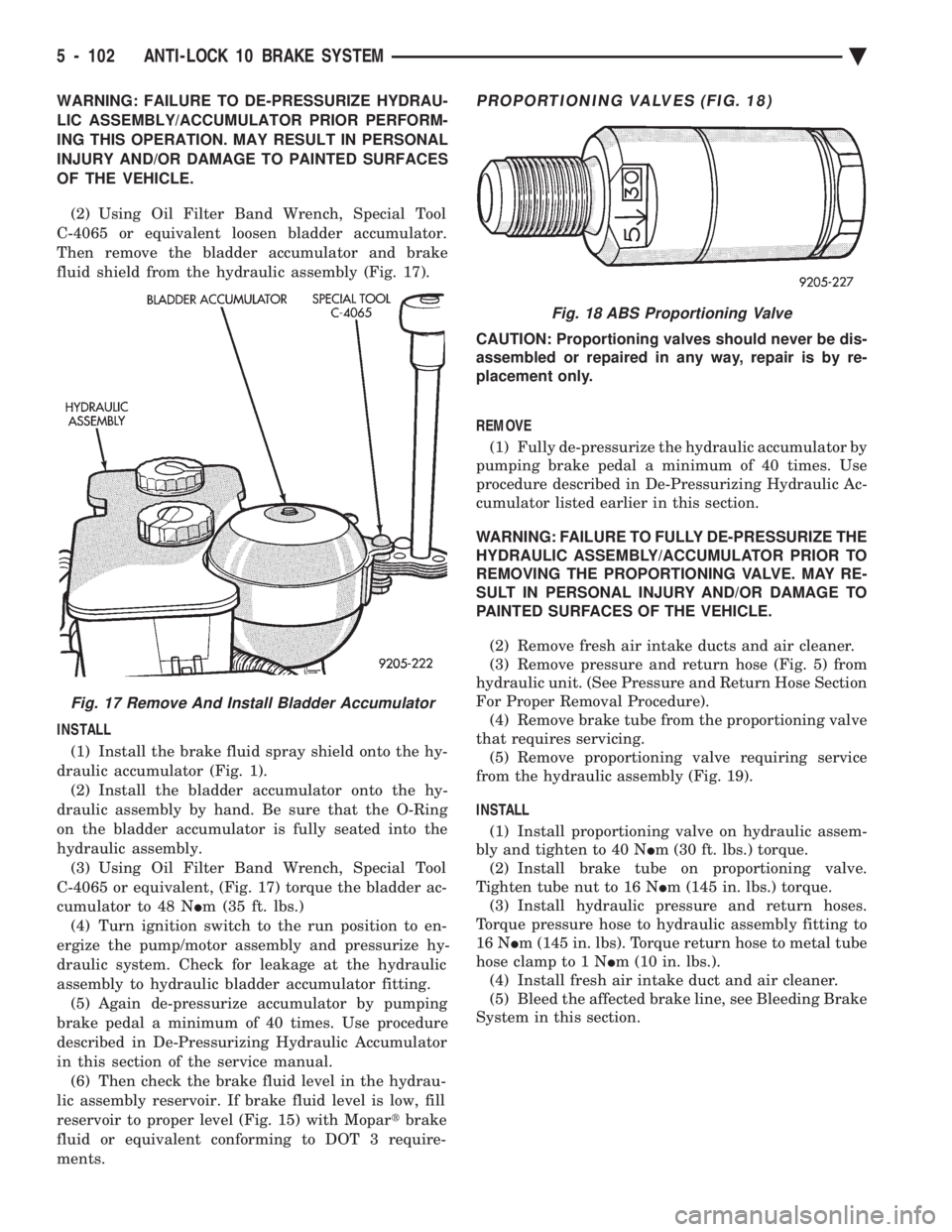

ments.PROPORTIONING VALVES (FIG. 18)

CAUTION: Proportioning valves should never be dis-

assembled or repaired in any way, repair is by re-

placement only.

REMOVE (1) Fully de-pressurize the hydraulic accumulator by

pumping brake pedal a minimum of 40 times. Use

procedure described in De-Pressurizing Hydraulic Ac-

cumulator listed earlier in this section.

WARNING: FAILURE TO FULLY DE-PRESSURIZE THE

HYDRAULIC ASSEMBLY/ACCUMULATOR PRIOR TO

REMOVING THE PROPORTIONING VALVE. MAY RE-

SULT IN PERSONAL INJURY AND/OR DAMAGE TO

PAINTED SURFACES OF THE VEHICLE.

(2) Remove fresh air intake ducts and air cleaner.

(3) Remove pressure and return hose (Fig. 5) from

hydraulic unit. (See Pressure and Return Hose Section

For Proper Removal Procedure). (4) Remove brake tube from the proportioning valve

that requires servicing. (5) Remove proportioning valve requiring service

from the hydraulic assembly (Fig. 19).

INSTALL (1) Install proportioning valve on hydraulic assem-

bly and tighten to 40 N Im (30 ft. lbs.) torque.

(2) Install brake tube on proportioning valve.

Tighten tube nut to 16 N Im (145 in. lbs.) torque.

(3) Install hydraulic pressure and return hoses.

Torque pressure hose to hydraulic assembly fitting to

16 N Im (145 in. lbs). Torque return hose to metal tube

hose clamp to 1 N Im (10 in. lbs.).

(4) Install fresh air intake duct and air cleaner.

(5) Bleed the affected brake line, see Bleeding Brake

System in this section.

Fig. 17 Remove And Install Bladder Accumulator

Fig. 18 ABS Proportioning Valve

5 - 102 ANTI-LOCK 10 BRAKE SYSTEM Ä

Page 258 of 2438

CAUTION: Do not insert dual function pressure

switch into hydraulic assembly using the socket

and ratchet. Cross threading of the switch may oc-

cur. (1) Install the dual function pressure switch into

the hydraulic assembly by hand until the O-ring

seals are seated. (2) Using Socket, Special Tool 6607, (Fig. 10)

torque the dual function pressure switch into the hy-

draulic assembly to 12 N Im (9 ft. lbs.).

(3) Connect the wiring harness connectors (Fig. 9)

onto the dual function pressure switch and the boost

pressure transducer. Be sure the locking tabs on the

connectors are fully engaged on the switches. (4) Lower the vehicle.

(5) Turn the ignition switch to the on position and

let the system pressurize. Check for any leaks at the

dual function pressure switch. (6) Fully de-pressurize the hydraulic assembly a

second time. This will purge any air out that may

have entered hydraulic assembly when the switch

was removed. Turn the ignition switch to the on po-

sition and let the system pressurize again. (7) Road test vehicle to insure that the brake sys-

tem is performing correctly.

PRIMARY PRESSURE TRANSDUCER

REMOVE

WARNING: FAILURE TO FULLY DE-PRESSURIZE

THE HYDRAULIC BLADDER ACCUMULATOR PRIOR

TO REMOVING PRIMARY PRESSURE TRANS-

DUCER. WILL RESULT IN PERSONAL INJURY

AND/OR DAMAGE TO PAINTED SURFACES OF THE

VEHICLE.

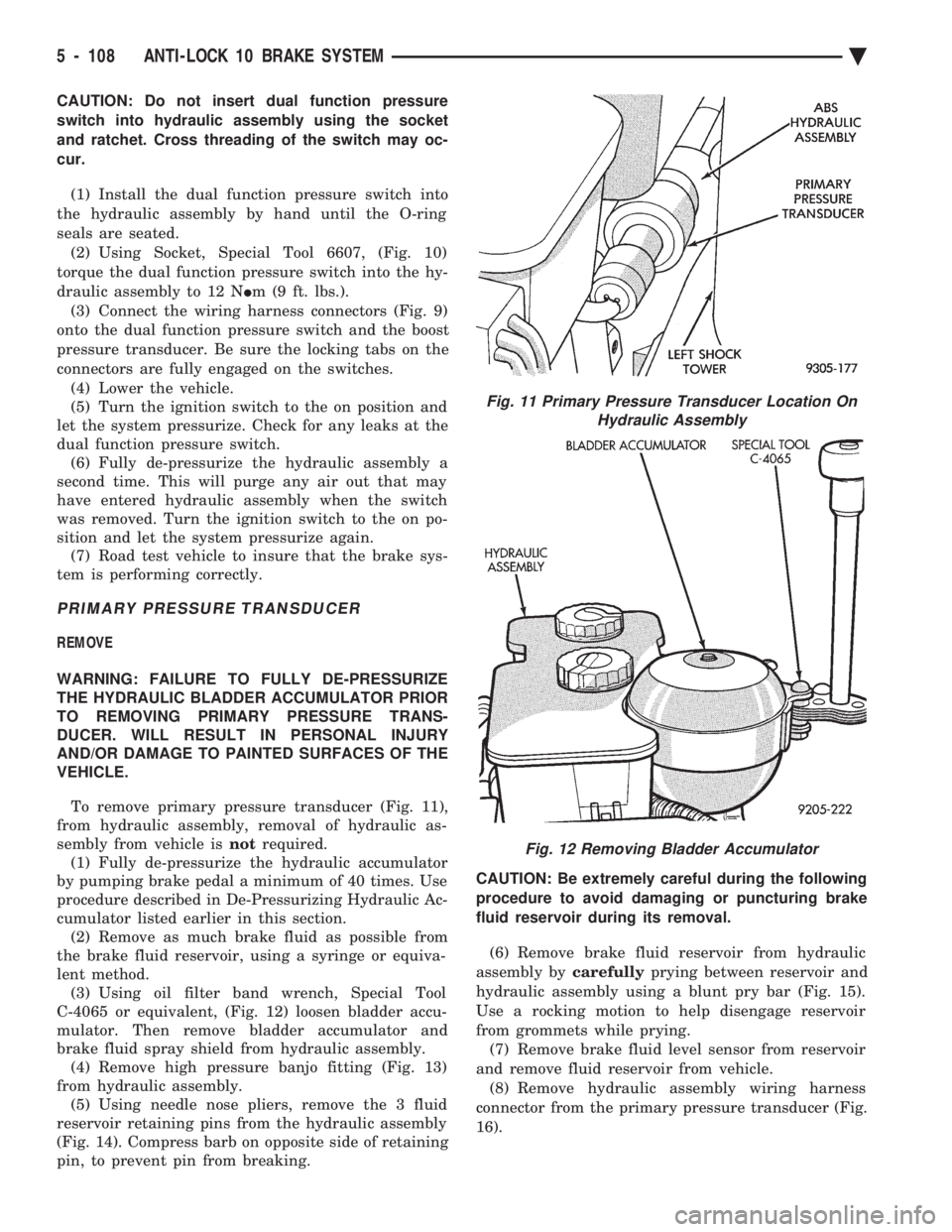

To remove primary pressure transducer (Fig. 11),

from hydraulic assembly, removal of hydraulic as-

sembly from vehicle is notrequired.

(1) Fully de-pressurize the hydraulic accumulator

by pumping brake pedal a minimum of 40 times. Use

procedure described in De-Pressurizing Hydraulic Ac-

cumulator listed earlier in this section. (2) Remove as much brake fluid as possible from

the brake fluid reservoir, using a syringe or equiva-

lent method. (3) Using oil filter band wrench, Special Tool

C-4065 or equivalent, (Fig. 12) loosen bladder accu-

mulator. Then remove bladder accumulator and

brake fluid spray shield from hydraulic assembly. (4) Remove high pressure banjo fitting (Fig. 13)

from hydraulic assembly. (5) Using needle nose pliers, remove the 3 fluid

reservoir retaining pins from the hydraulic assembly

(Fig. 14). Compress barb on opposite side of retaining

pin, to prevent pin from breaking. CAUTION: Be extremely careful during the following

procedure to avoid damaging or puncturing brake

fluid reservoir during its removal.

(6) Remove brake fluid reservoir from hydraulic

assembly by carefullyprying between reservoir and

hydraulic assembly using a blunt pry bar (Fig. 15).

Use a rocking motion to help disengage reservoir

from grommets while prying. (7) Remove brake fluid level sensor from reservoir

and remove fluid reservoir from vehicle. (8) Remove hydraulic assembly wiring harness

connector from the primary pressure transducer (Fig.

16).

Fig. 11 Primary Pressure Transducer Location On Hydraulic Assembly

Fig. 12 Removing Bladder Accumulator

5 - 108 ANTI-LOCK 10 BRAKE SYSTEM Ä

Page 271 of 2438

Lamp Relay opens the Anti-Lock Warning Lamp Re-

lay switch. This breaks the ground path to the Am-

ber Anti-Lock Warning Lamp and the light is turned

off. The (CAB) by itself, also has the ability to turn on

the Amber Anti-Lock Warning Lamp. The (CAB) can

turn on the Amber Anti-Lock Warning Lamp by pro-

viding a ground at pin 15.

ANTI-LOCK WARNING LAMP ON

System Relay and Anti-Lock Warning Lamp

Relay De-Energized. When the Amber Anti-Lock Warning Lamp is on,

there is no electrical current flow from the (CAB) at

pin 57. The System Relay coil is NOT energized. No

electrical current flows to pin 47 and 41 (modulator

valve power), or to the Anti-Lock Warning Lamp Re-

lay coil. Thus, the Amber Anti-Lock Warning Lamp

is not energized. The Amber Anti-Lock Warning Lamp is grounded through the Anti-Lock Warning

Lamp Relay contacts. The Amber Anti-Lock Warning

Lamp is turned on.

HYDRAULIC CIRCUITS AND VALVE OPERATION

Through the following operation descriptions and

diagrams. The function of the various hydraulic con-

trol valves in the ABS system will be described. The

fluid control valves mentioned below, control the flow

of pressurized brake fluid to the wheel brakes during

the different modes of Anti-Lock braking. For explanation purposes we will assume all speed

sensors are sending the same wheel speed informa-

tion, requiring the same hydraulic fluid modulation

at the same rate.

NORMAL BRAKING

ISOLATION VALVES

Open to primary and secondary master cylinder

fluid supply (Fig. 1)

BUILD/DECAY VALVES Closed (Fig. 1)

The brake pedal is applied. The travel of the brake

pedal closes primary and secondary circuits from the

master cylinder fluid supply. Brake fluid from the

primary and secondary circuits flows through the

open isolation valves, through the build/decay valves

to the wheel brakes.

ABS BRAKING-BUILD PRESSURE

ISOLATION VALVES

Closed, isolating wheel brakes from master cylin-

der primary and secondary fluid supply. Through

open build valves (Fig. 2).

BUILD/DECAY VALVES Open (Fig. 2)

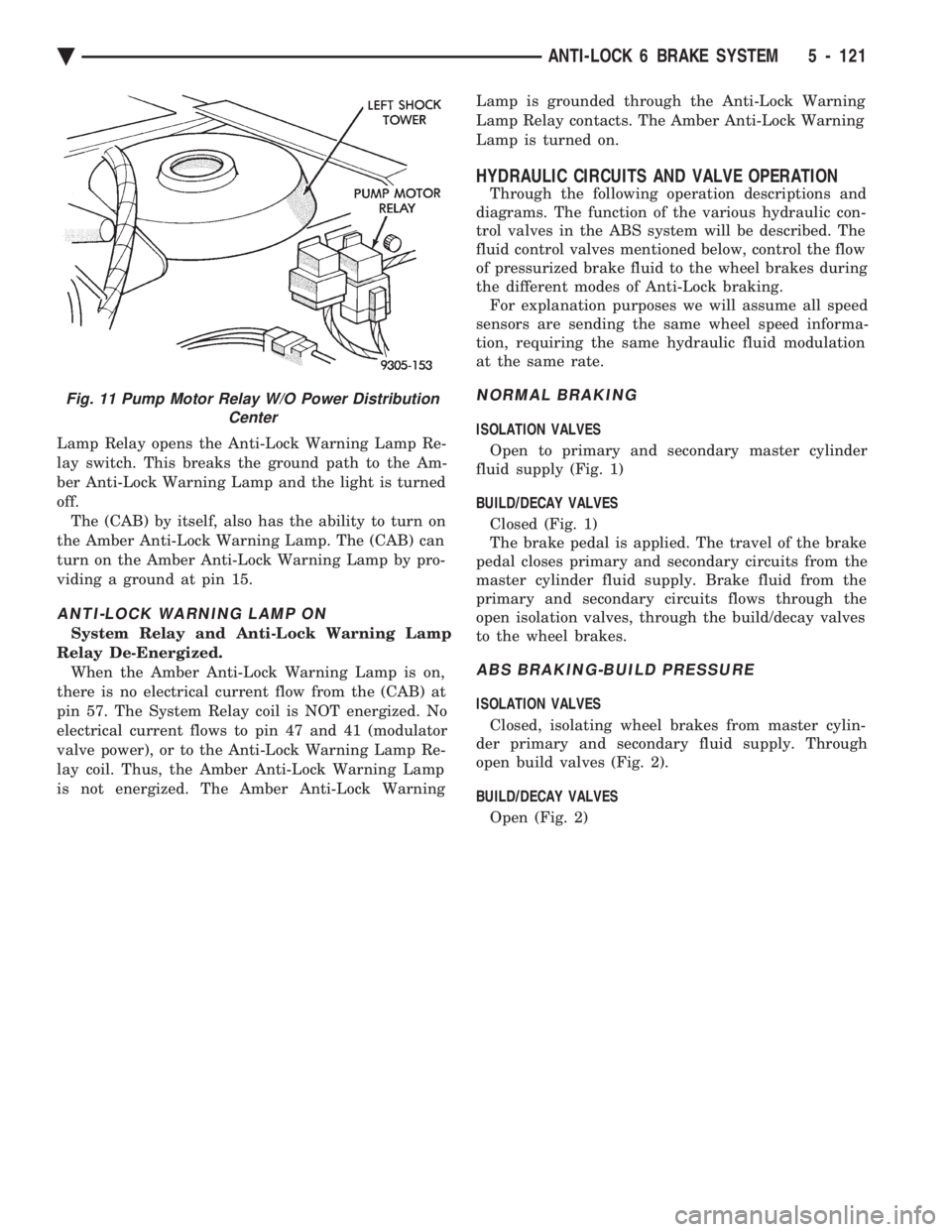

Fig. 11 Pump Motor Relay W/O Power Distribution Center

Ä ANTI-LOCK 6 BRAKE SYSTEM 5 - 121

Page 276 of 2438

As soon as the condition goes away, the Anti-Lock

Warning Light is turned off. Although a fault code

will be set in most cases.

BENDIX ABS SYSTEMS DIAGNOSTICS

Bendix Anti-Lock 6 Brake System Diagnostics, be-

yond basic mechanical diagnostics, covered earlier in

this section. Are accomplished by using the DRB II

scan tool. See testing procedures outlined in the Ben-

dix Anti-Lock 6 Diagnostics Manual for the 1992

M.Y. vehicles. Please refer to the above mentioned manual for

any further electronic diagnostics and service proce-

dures that are required on the Bendix Anti-Lock 6

Brake System.

ON-CAR ABS BRAKE SYSTEM SERVICE

GENERAL SERVICE PRECAUTIONS

The following are general cautions which should be

observed when servicing the Anti-Lock brake system

and/or other vehicle systems. Failure to observe

these precautions may result in Anti-Lock Brake

System component damage. If welding work is to be performed on the vehicle,

using an electric arc welder, the (CAB) connector

should be disconnected during the welding operation. The (CAB) connector should never be connected or

disconnected with the ignition switch in the ON po-

sition. Many components of the Anti-Lock Brake System

are not serviceable and must be replaced as an as-

sembly. Do not disassemble any component which is

not designed to be serviced.

CHECKING BRAKE FLUID LEVEL

CAUTION: Only use brake fluid conforming to DOT

3 specifications, such as Mopar or Equivalent. Do

not use any fluid which contains a petroleum base.

Do not use a container which has been used for pe-

troleum based fluids or a container which is wet

with water. Petroleum based fluids will cause swell-

ing and distortion of rubber parts in the hydraulic

brake system. Water will mix with brake fluid, low-

ering the fluid boiling point. Keep all brake fluid

containers capped to prevent contamination. Re-

move the front cap of the master cylinder reservoir

and fill to the bottom of the split ring.

For the specific procedure for the inspection of

brake fluid level and adding of brake to the reser-

voir. Refer to the Service Adjustments Section in this

group of the service manual.

BLEEDING BENDIX ANTI-LOCK 6 BRAKE SYSTEM

The Anti-Lock Brake System must be bled anytime

air is permitted to enter the hydraulic system, due to

disconnection of brake lines, hoses of components. If the Modulator Assembly is removed from the ve-

hicle, both the Base Brake System and the Anti-Lock

Brake System must be bled using the appropriate

procedures. It is important to note that excessive air

in the brake system will cause a soft or spongy feel-

ing brake pedal. During bleeding operations, be sure that the brake

fluid level remains close to the FULL level in the

reservoir. Check the fluid level periodically during

the bleeding procedure and add DOT 3 brake fluid as

required. The Bendix Anti-Lock 6 Brake System must be

bled as two independent braking systems. The non

ABS portion of the brake system is to be bled the

same as any non ABS system. Refer to the Service

Adjustments section in this manual for the proper

bleeding procedure to be used. This brake system can

be either pressure bled or manually bled. The Anti-Lock portion of brake system MUST be

bled separately. This bleeding procedure requires the

use of the DRB II Diagnostic tester and the bleeding

sequence procedure outlined below.

ABS BLEEDING PROCEDURE (FIG. 1)

(1) Assemble and install all brake system compo-

nents on vehicle making sure all hydraulic fluid

lines are installed and properly torqued. (2) Bleed the base brake system. Using the stan-

dard pressure or manual bleeding procedure as out-

lined in the Service Adjustments section of this

service manual. To perform the bleeding procedure on the ABS

unit. The battery and acid shield must be removed

from the vehicle. Reconnect the vehicles battery, to

the vehicles positive and negative battery cables us-

ing jumper cables. This is necessary to allow access

to the 4 bleeder screws located on the top of the Mod-

ulator assembly. (3) Connect the DRB II Diagnostics Tester to the

diagnostics connector. Located behind the Fuse Panel

access cover on the lower section of the dash panel to

the left of the steering column. (It is a blue 6 way

connector). (4) Using the DRB II check to make sure the

(CAB) does not have any fault codes stored. If it does

remove them using the DRB II.

5 - 126 ANTI-LOCK 6 BRAKE SYSTEM Ä

Page 289 of 2438

SERVICE ADJUSTMENTS INDEX

page page

Bleeding Bendix Antilock 4 Brake System ....... 3

Master Cylinder Fluid Level .................. 3 Testing for Fluid Contamination

............... 4

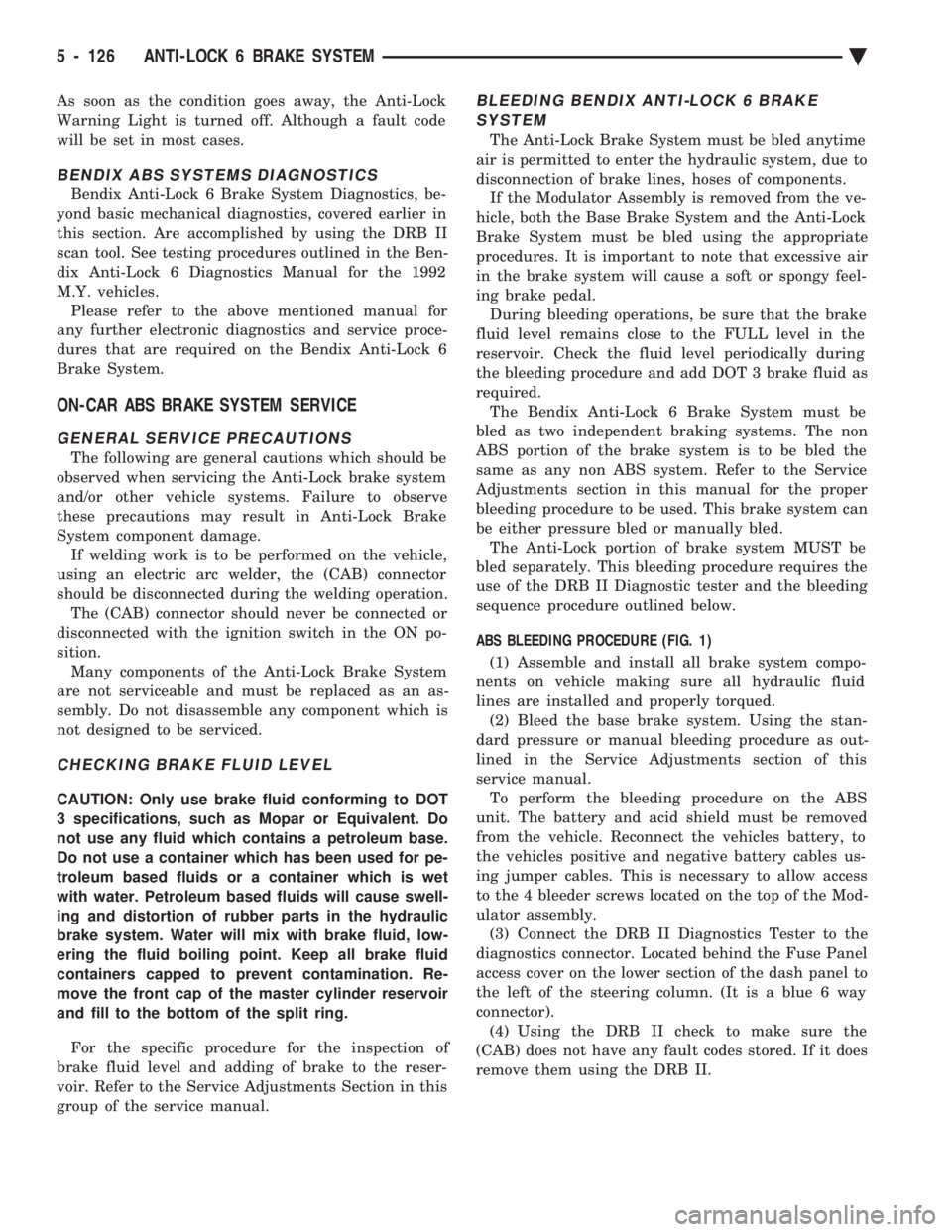

MASTER CYLINDER FLUID LEVEL

Check master cylinder reservoir brake fluid level a

minimum of two times a year. Master cylinder reservoirs are marked with the

words fill to bottom of rings indicating proper fluid

level (Fig. 4). Use only Mopar tbrake fluid or an equivalent from

a sealed container. Brake fluid must conform to DOT

3, specifications. Use only brake fluid that was stored in a tightly-

sealed container.

CAUTION: DO NOT use petroleum-based fluid be-

cause seal damage in the brake system will result.

CAUTION: DO NOT use brake fluid with a lower

boiling point, as brake failure could result during

prolonged hard braking.

If necessary add only an approved brake fluid to

master cylinder fluid reservoir until filled to the

proper level. Correct master cylinder fluid reservoir

fill level is to the bottom of the primary reservoir

split ring.

BLEEDING BENDIX ANTILOCK 4 BRAKE SYSTEM

CAUTION: When bleeding the Bendix Antilock 4

Brake System hydraulic circuits, refer to the Bendix

Antilock 4 Brake System bleeding procedure in this

service manual supplement.

BASE BRAKE SYSTEM BLEEDING PROCEDURE

CAUTION: The base brakes hydraulic system, on a

vehicle equipped with a Bendix Antilock 4 Brake

System, can NOT be bled using a brake hydraulic

system pressure bleeder. This type of pressure

bleeding equipment, does not develop the pressure

required in the brake hydraulic system, to ade-

quately bleed all trapped air. The only approved

method of bleeding the base brakes hydraulic sys-

tem, on vehicles equipped with a Bendix Antilock 4

Brake System, is the manual procedure of pressur-

izing the hydraulic system using constant moderate

to heavy foot pressure on the brake pedal.

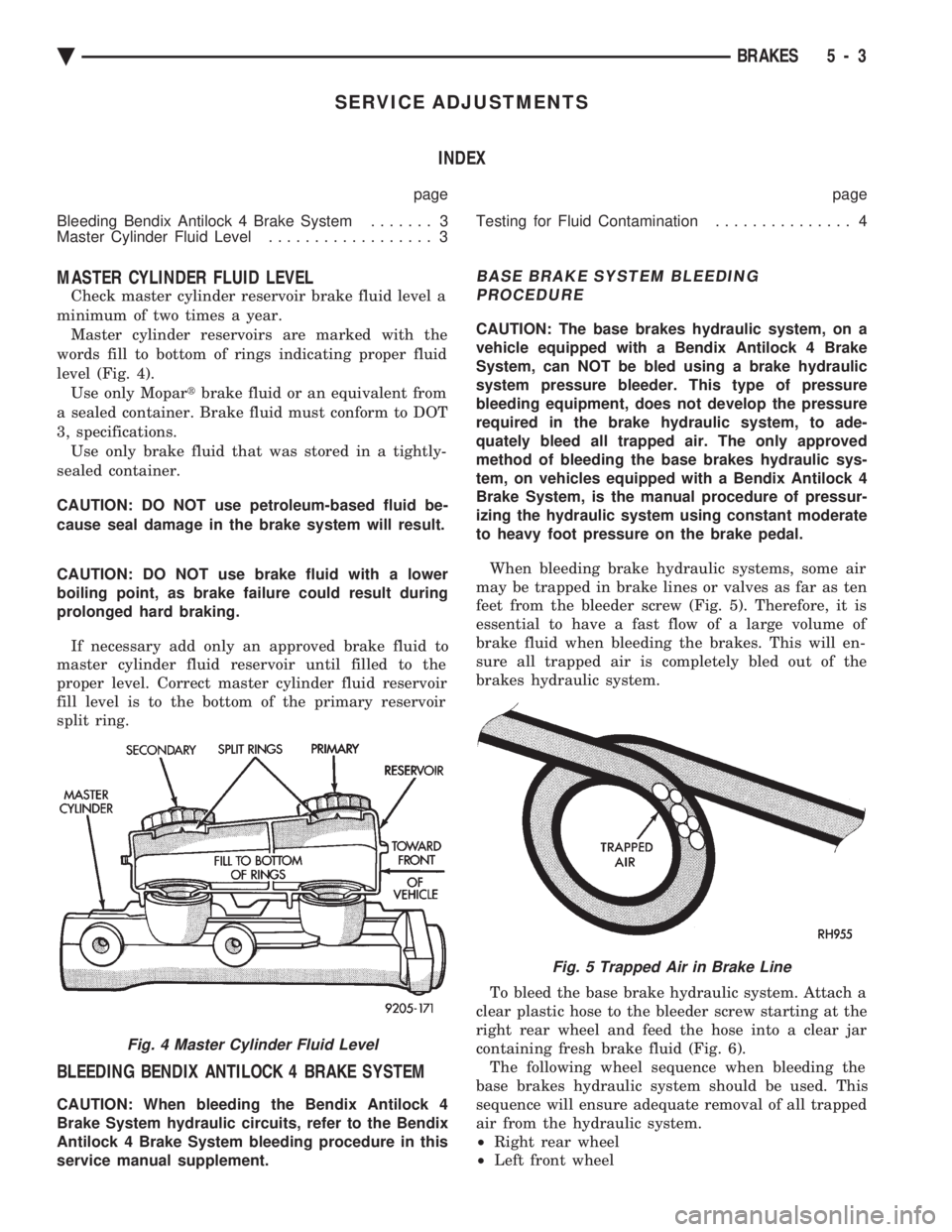

When bleeding brake hydraulic systems, some air

may be trapped in brake lines or valves as far as ten

feet from the bleeder screw (Fig. 5). Therefore, it is

essential to have a fast flow of a large volume of

brake fluid when bleeding the brakes. This will en-

sure all trapped air is completely bled out of the

brakes hydraulic system.

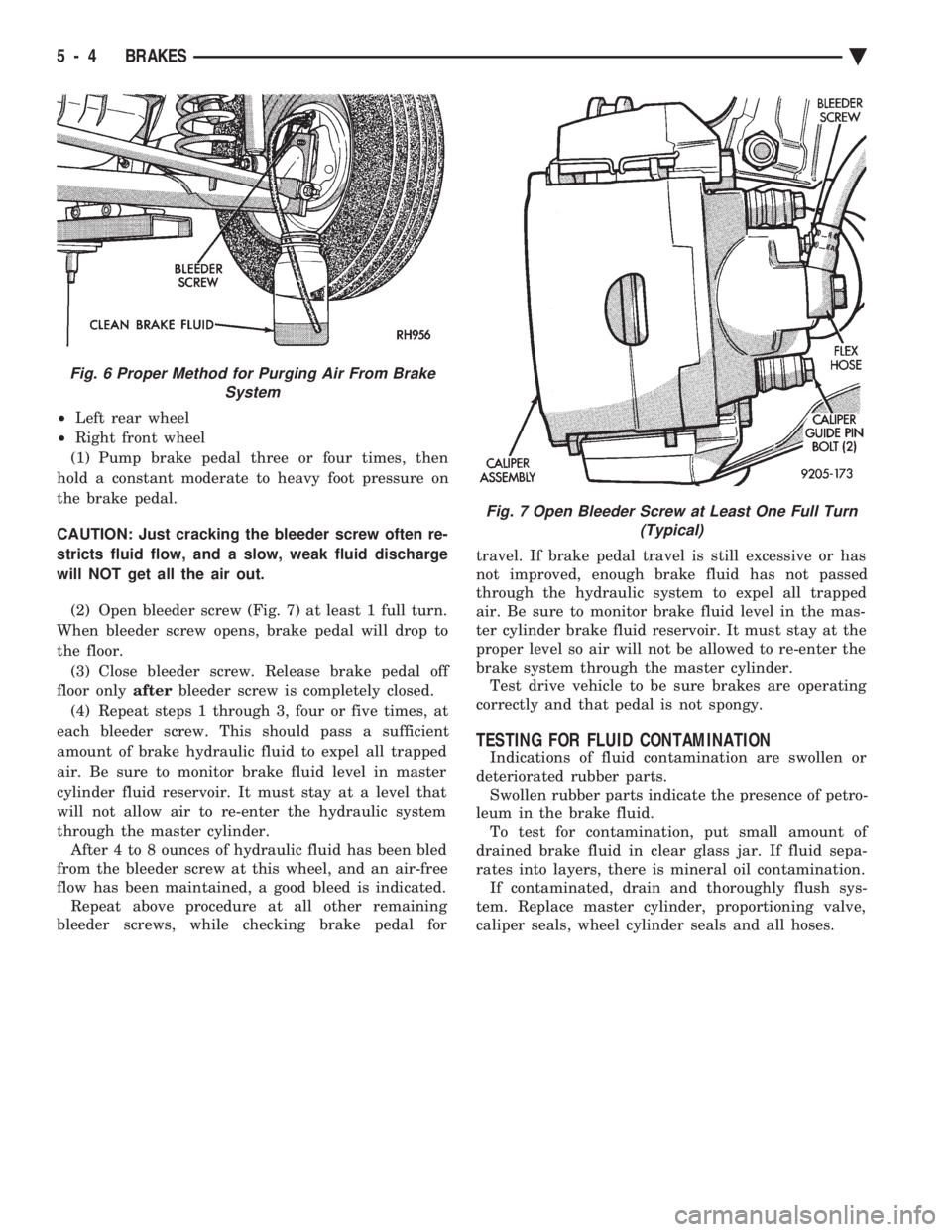

To bleed the base brake hydraulic system. Attach a

clear plastic hose to the bleeder screw starting at the

right rear wheel and feed the hose into a clear jar

containing fresh brake fluid (Fig. 6). The following wheel sequence when bleeding the

base brakes hydraulic system should be used. This

sequence will ensure adequate removal of all trapped

air from the hydraulic system.

² Right rear wheel

² Left front wheel

Fig. 4 Master Cylinder Fluid Level

Fig. 5 Trapped Air in Brake Line

Ä BRAKES 5 - 3

Page 290 of 2438

² Left rear wheel

² Right front wheel

(1) Pump brake pedal three or four times, then

hold a constant moderate to heavy foot pressure on

the brake pedal.

CAUTION: Just cracking the bleeder screw often re-

stricts fluid flow, and a slow, weak fluid discharge

will NOT get all the air out.

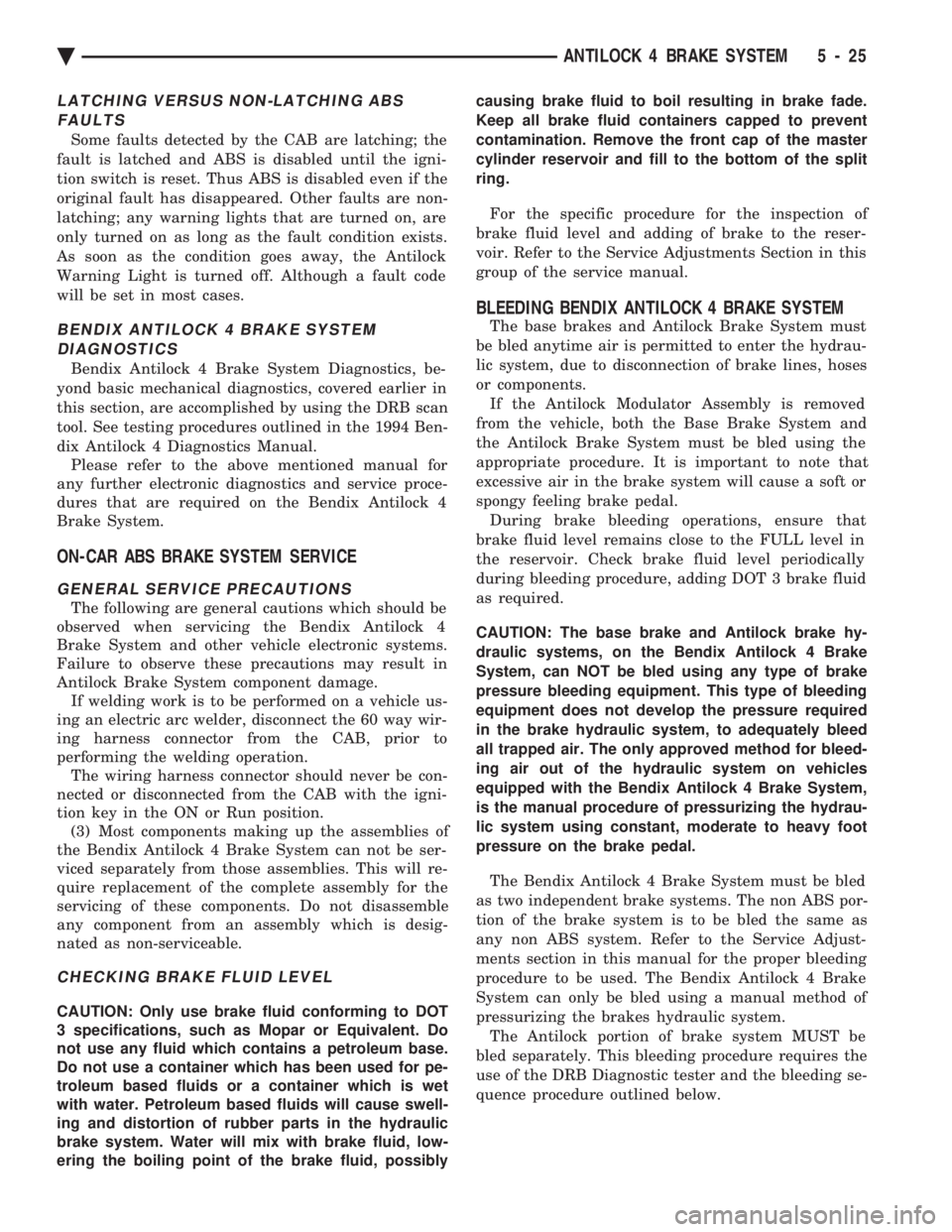

(2) Open bleeder screw (Fig. 7) at least 1 full turn.

When bleeder screw opens, brake pedal will drop to

the floor. (3) Close bleeder screw. Release brake pedal off

floor only afterbleeder screw is completely closed.

(4) Repeat steps 1 through 3, four or five times, at

each bleeder screw. This should pass a sufficient

amount of brake hydraulic fluid to expel all trapped

air. Be sure to monitor brake fluid level in master

cylinder fluid reservoir. It must stay at a level that

will not allow air to re-enter the hydraulic system

through the master cylinder. After 4 to 8 ounces of hydraulic fluid has been bled

from the bleeder screw at this wheel, and an air-free

flow has been maintained, a good bleed is indicated. Repeat above procedure at all other remaining

bleeder screws, while checking brake pedal for travel. If brake pedal travel is still excessive or has

not improved, enough brake fluid has not passed

through the hydraulic system to expel all trapped

air. Be sure to monitor brake fluid level in the mas-

ter cylinder brake fluid reservoir. It must stay at the

proper level so air will not be allowed to re-enter the

brake system through the master cylinder. Test drive vehicle to be sure brakes are operating

correctly and that pedal is not spongy.

TESTING FOR FLUID CONTAMINATION

Indications of fluid contamination are swollen or

deteriorated rubber parts. Swollen rubber parts indicate the presence of petro-

leum in the brake fluid. To test for contamination, put small amount of

drained brake fluid in clear glass jar. If fluid sepa-

rates into layers, there is mineral oil contamination. If contaminated, drain and thoroughly flush sys-

tem. Replace master cylinder, proportioning valve,

caliper seals, wheel cylinder seals and all hoses.

Fig. 6 Proper Method for Purging Air From Brake System

Fig. 7 Open Bleeder Screw at Least One Full Turn(Typical)

5 - 4 BRAKES Ä

Page 306 of 2438

ANTILOCK WARNING LAMP DIODE

The Warning Lamp Relay on the Bendix Antilock

4 Brake System has been replaced with a diode. The

diode is used to control the function of the warning

lamp and is located inside the CAB module wiring

harness. The diode is a replaceable component of the

wiring harness, and will not require replacement of

the entire wiring harness if only the diode is diag-

nosed to have failed. When the system relay is de-energized, the Anti-

lock warning lamp will be lit. This will occur because

a ground path exists for the Antilock warning lamp

through the Antilock warning lamp diode and the

system relay armature. When the system relay is en-

ergized by the CAB, the system relay armature will

no longer provide a ground and the lamp will turn

off. Thus, the lamp will be lit if either the CAB is

disconnected or a system fault causes the Antilock to

be turned off.

PUMP/MOTOR RELAY

Pump/Motor power is supplied by the Pump/Motor

Relay. The Pump/Motor Relay is either mounted on

the left front inner fender shield, or the front of the

left shock tower. The mounting location is dependent

on whether the vehicle is or is not equipped with a

power distribution center. See (Fig. 11 and 12) for

specific mounting locations.

ANTILOCK WARNING LAMP OFF

System Relay Energized

From pin 57, the CAB energizes the Antilock sys-

tem relay coil, thus the electrical current flow in the

coil closes the system relay. Then electrical current

is provided to pins 47 and 41 of the CAB to provide

power to the modulator valves. The CAB turns off the Amber Antilock Warning

Lamp by breaking the ground path through pin 15 of

the CAB.

ANTILOCK WARNING LAMP ON

System Relay De-Energized.

When the Amber Antilock Warning Lamp is on,

there is no electrical current flow from the CAB at

pin 57 and the System Relay coil is NOT energized.

No electrical current flows to pin 47 and 41 (modula-

tor valve power), or to the Antilock Warning Lamp

diode. Thus, the Amber Antilock Warning Lamp is

not energized. The Amber Antilock Warning Lamp is

now grounded through the Antilock Warning Lamp

diode and pin 15 of the CAB turning on the Amber

Antilock Warning Lamp.

HYDRAULIC CIRCUITS AND VALVE OPERATION

Through the following operation descriptions and

diagrams. The function of the various hydraulic con-

trol valves in the ABS system will be described. The

fluid control valves mentioned below, control the flow

of pressurized brake fluid to the wheel brakes during

the different modes of Antilock braking. For explanation purposes we will assume all speed

sensors are sending the same wheel speed informa-

tion, requiring the same hydraulic fluid modulation

at the same rate.

NORMAL BRAKING

BUILD/DECAY VALVES

Closed (Fig. 1)

The brake pedal is applied. The travel of the brake

pedal closes primary and secondary circuits from the

master cylinder fluid supply. Brake fluid from the

master cylinder primary and secondary circuits flows

through the build/decay valves to the wheel brakes.

ABS BRAKING-BUILD PRESSURE

BUILD/DECAY VALVES

Open (Fig. 2)

Fig. 11 Pump Motor Relay Location On AA Body W/O Power Distribution Center

Fig. 12 Pump Motor Relay Location On AJ BodyWith Power Distribution Center

5 - 20 ANTILOCK 4 BRAKE SYSTEM Ä

Page 311 of 2438

LATCHING VERSUS NON-LATCHING ABS FAULTS

Some faults detected by the CAB are latching; the

fault is latched and ABS is disabled until the igni-

tion switch is reset. Thus ABS is disabled even if the

original fault has disappeared. Other faults are non-

latching; any warning lights that are turned on, are

only turned on as long as the fault condition exists.

As soon as the condition goes away, the Antilock

Warning Light is turned off. Although a fault code

will be set in most cases.

BENDIX ANTILOCK 4 BRAKE SYSTEM DIAGNOSTICS

Bendix Antilock 4 Brake System Diagnostics, be-

yond basic mechanical diagnostics, covered earlier in

this section, are accomplished by using the DRB scan

tool. See testing procedures outlined in the 1994 Ben-

dix Antilock 4 Diagnostics Manual. Please refer to the above mentioned manual for

any further electronic diagnostics and service proce-

dures that are required on the Bendix Antilock 4

Brake System.

ON-CAR ABS BRAKE SYSTEM SERVICE

GENERAL SERVICE PRECAUTIONS

The following are general cautions which should be

observed when servicing the Bendix Antilock 4

Brake System and other vehicle electronic systems.

Failure to observe these precautions may result in

Antilock Brake System component damage. If welding work is to be performed on a vehicle us-

ing an electric arc welder, disconnect the 60 way wir-

ing harness connector from the CAB, prior to

performing the welding operation. The wiring harness connector should never be con-

nected or disconnected from the CAB with the igni-

tion key in the ON or Run position. (3) Most components making up the assemblies of

the Bendix Antilock 4 Brake System can not be ser-

viced separately from those assemblies. This will re-

quire replacement of the complete assembly for the

servicing of these components. Do not disassemble

any component from an assembly which is desig-

nated as non-serviceable.

CHECKING BRAKE FLUID LEVEL

CAUTION: Only use brake fluid conforming to DOT

3 specifications, such as Mopar or Equivalent. Do

not use any fluid which contains a petroleum base.

Do not use a container which has been used for pe-

troleum based fluids or a container which is wet

with water. Petroleum based fluids will cause swell-

ing and distortion of rubber parts in the hydraulic

brake system. Water will mix with brake fluid, low-

ering the boiling point of the brake fluid, possibly causing brake fluid to boil resulting in brake fade.

Keep all brake fluid containers capped to prevent

contamination. Remove the front cap of the master

cylinder reservoir and fill to the bottom of the split

ring.

For the specific procedure for the inspection of

brake fluid level and adding of brake to the reser-

voir. Refer to the Service Adjustments Section in this

group of the service manual.

BLEEDING BENDIX ANTILOCK 4 BRAKE SYSTEM

The base brakes and Antilock Brake System must

be bled anytime air is permitted to enter the hydrau-

lic system, due to disconnection of brake lines, hoses

or components. If the Antilock Modulator Assembly is removed

from the vehicle, both the Base Brake System and

the Antilock Brake System must be bled using the

appropriate procedure. It is important to note that

excessive air in the brake system will cause a soft or

spongy feeling brake pedal. During brake bleeding operations, ensure that

brake fluid level remains close to the FULL level in

the reservoir. Check brake fluid level periodically

during bleeding procedure, adding DOT 3 brake fluid

as required.

CAUTION: The base brake and Antilock brake hy-

draulic systems, on the Bendix Antilock 4 Brake

System, can NOT be bled using any type of brake

pressure bleeding equipment. This type of bleeding

equipment does not develop the pressure required

in the brake hydraulic system, to adequately bleed

all trapped air. The only approved method for bleed-

ing air out of the hydraulic system on vehicles

equipped with the Bendix Antilock 4 Brake System,

is the manual procedure of pressurizing the hydrau-

lic system using constant, moderate to heavy foot

pressure on the brake pedal.

The Bendix Antilock 4 Brake System must be bled

as two independent brake systems. The non ABS por-

tion of the brake system is to be bled the same as

any non ABS system. Refer to the Service Adjust-

ments section in this manual for the proper bleeding

procedure to be used. The Bendix Antilock 4 Brake

System can only be bled using a manual method of

pressurizing the brakes hydraulic system. The Antilock portion of brake system MUST be

bled separately. This bleeding procedure requires the

use of the DRB Diagnostic tester and the bleeding se-

quence procedure outlined below.

Ä ANTILOCK 4 BRAKE SYSTEM 5 - 25

Page 333 of 2438

MANUAL TRANSAXLE CLUTCH

CONTENTS

page page

CLEANING PRECAUTIONS ................. 6

CLUTCH CABLE MECHANISM .............. 1

CLUTCH CABLE REPLACEMENT ............ 2

CLUTCH CHATTER COMPLAINTS ........... 1

CLUTCH DISC REPLACEMENT ............. 5

CLUTCH PEDAL NOISE/POP ............... 2 CLUTCH PEDAL POSITION SWITCH

......... 4

EXCESSIVE CLUTCH SPIN TIME/CLASH INTO REVERSE COMPLAINTS ............ 1

GENERAL INFORMATION .................. 1

RELEASE BEARING AND FORK ............. 6

GENERAL INFORMATION

Throughout this group, references may be made to

a particular vehicle by letter or number designation.

A chart showing the breakdown of these designations

is included in the Introduction Section at the front of

this service manual. The clutch used in all models are a single, dry disc

type with no adjustment for wear being provided in

the clutch itself. The clutch pedal is connected to the release shaft

through a cable and lever. The upper end of the clutch pedal pivots in the

pedal bracket on two nylon bushings. These bushings

do not require periodic lubrication.

CLUTCH CHATTER COMPLAINTS

For all clutch chatter complaints, do the following:

(1) Check for loose, misaligned, or broken engine

and transmission mounts. If present, they should be

corrected at this time. Test vehicle for chatter. If

chatter is gone, there is no need to go any further. If

chatter persists: (2) Check to see if clutch cable routing is correct

and operates smoothly. (3) Check for loose connections in drive train. Cor-

rect any problems and determine if clutch chatter

complaints has been satisfied. If not, (4) Remove transaxle. See Group 21, Manual Tran-

saxle, for procedure. (5) Check to see if the release bearing is sticky or

binding. Replace bearing, if needed. (6) Check linkage for excessive wear on bushings.

Replace all worn parts. A small amount of bearing

grease between the release shaft bushings and the

shaft is beneficial, but not required. (7) Check flywheel and clutch pressure plate for

contamination (dirt, oil) or scored. Replace flywheel

and/or pressure plate, if required. (8) Check to see if the clutch disc hub splines are

damaged. Replace with new disc. (9) Check input shaft splines for damage. Replace

if necessary. (10) Check for uneven wear on clutch fingers.

EXCESSIVE CLUTCH SPIN TIME/CLASH INTO

REVERSE COMPLAINTS

For all excessive clutch spin time/clash into reverse

complaints, do the following: (1) Depress clutch pedal to floor and hold. After

three seconds, shift to reverse. If clash is present,

clutch has excessive spin time. (2) Remove transaxle. See Group 21, Manual Tran-

saxle, for procedure. (3) Check the input shaft spline, clutch disc splines

and release bearing for dry rust. If present, clean

rust off and apply a light coat of bearing grease to

the input shaft splines. Apply grease on the input

shaft splines only where the clutch disc slides. (4) Check to see if the clutch disc hub splines are

damaged, replace with new disc if required. (5) Check the input shaft for damaged splines. Re-

place as necessary. (6) Check for excessive clutch disc runout or

warpage. (7) Install clutch assembly and transaxle.

CLUTCH CABLE MECHANISM

The manual transaxle clutch release system has a

unique self-adjusting mechanism to compensate for

clutch disc wear. This adjuster mechanism is located

within the clutch pedal. The preload spring main-

tains tension on the cable. This tension keeps the

clutch release bearing continuously loaded against

the fingers of the clutch cover assembly. When the pedal is depressed, teeth on the adjuster

and the positioner engage and pull the release cable.

A spring located behind the adjuster ensures proper

tooth engagement. When the pedal is released, the adjuster contacts

the bumper. This separates the adjuster and posi-

tioner teeth, allowing the preload spring to function.

Ä MANUAL TRANSAXLE CLUTCH 6 - 1