mirror CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 715 of 2438

above. When the control module has finished, it will

return to the normal operating mode after ten sec-

onds if no further switches are activated.The control module will also return to normal op-

erating mode if any manual seat or recliner move-

ment switch is actuated during the ten second

timeout. If the system has found a problem, refer to the ap-

propriate diagnosis condition.

POWER MEMORY SEAT, RECLINER AND

MIRRORS DIAGNOSIS

Before any diagnosis is done on the system, move

the seat switches and listen for relays clicking in the

control module under the seat. If relays can be heard,

the main battery and ground circuits to the control

module as well as the battery circuit to the switches

in the driver's door are good. When checking for voltage or continuity, always

use a volt/ohm meter to get accurate readings. The

seat and recliner switches must be activated to check

for voltage at the seat and recliner motors or at the

input to the control module from the switches. The control module creates a special voltage supply

for the position sensing functions. It also shuts down

after five seconds, in order to check this or any other

voltage being fed back to the control module. A

switch may have to be activated more than once to

verify a voltage reading. The voltage from the con-

trol module that feeds the seat and recliner position

sensing potentiometer, will be between 4.5 to 5 volts.

For simplicity in the diagnosis section, the feed volt-

age will be called 5 volts. On the position sensing

wires, these voltages will always be less than 5 volts

but more than 0 volts. Typically the high level is at

a maximum of about 4.25 volts and the low level can

be as little as 0.1 volts. If any seat or recliner potentiometer or mirror

rheostat position sense wires are crossed, the control

module will not move that part of the system. The

seat or mirror will be in a fault diagnostic mode.

CONDITION: SYSTEM WILL NOT OPERATE.

PROCEDURE

(1) Check for forward/rearward operation of re-

cliner. If not operable, check for an open or loose cir-

cuit breaker mounted in board on the relay bank in

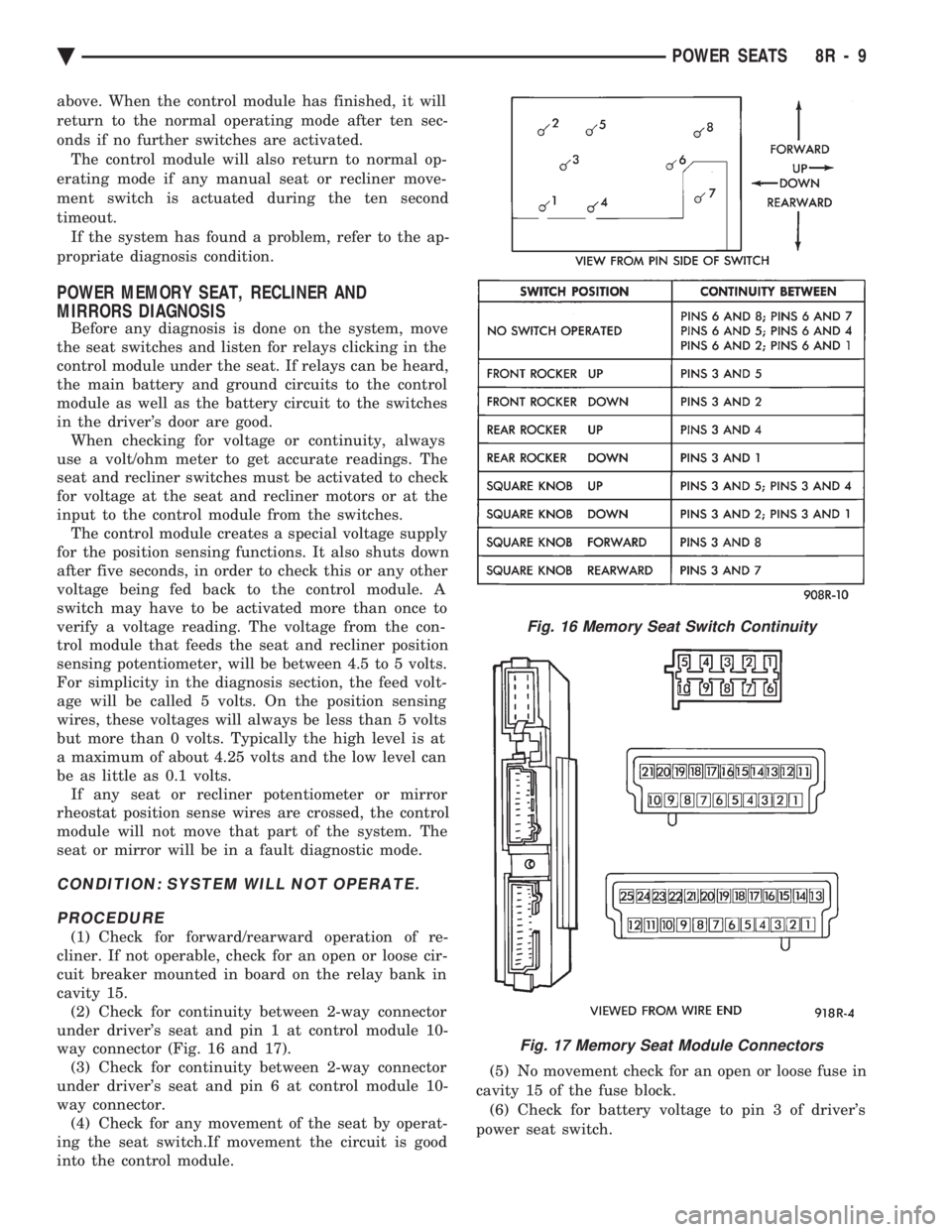

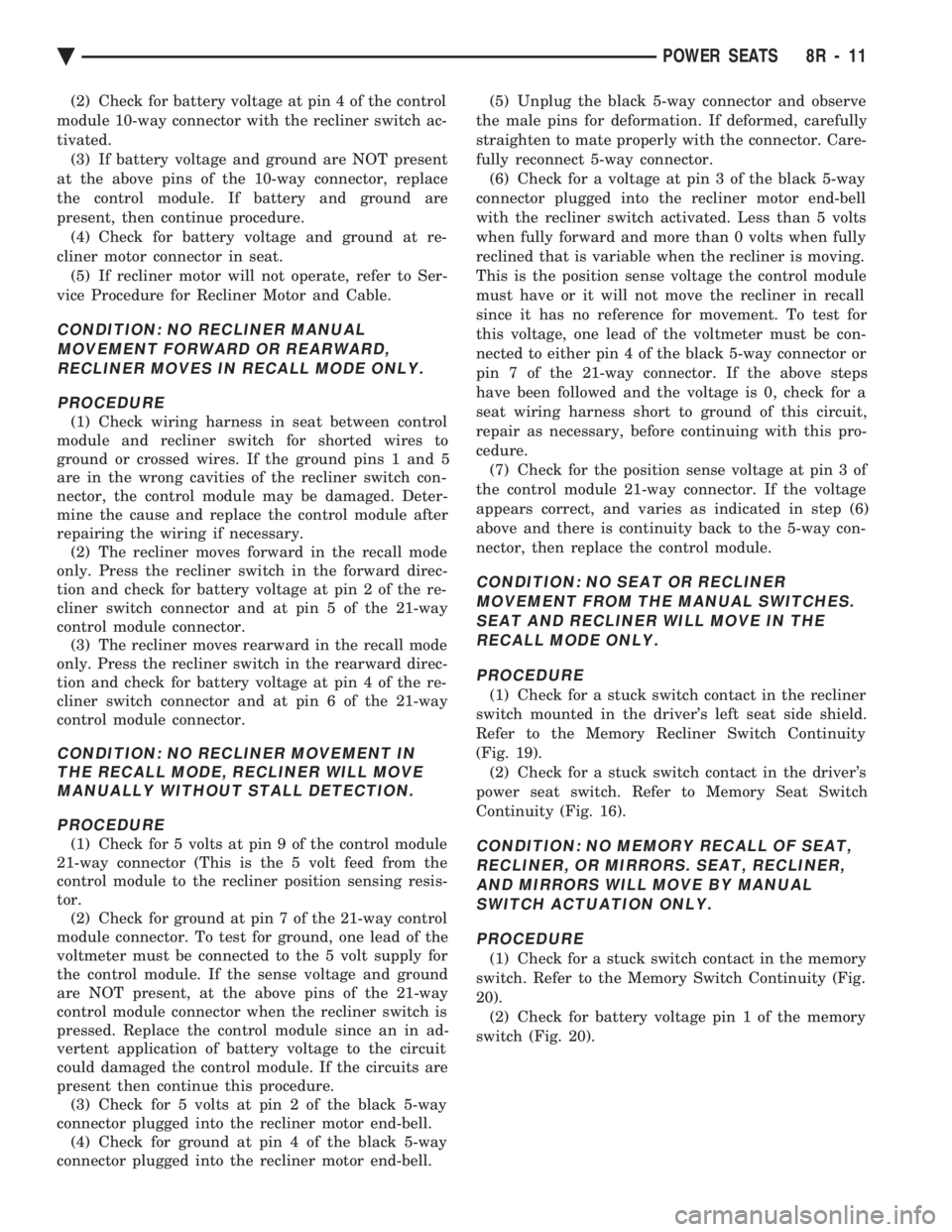

cavity 15. (2) Check for continuity between 2-way connector

under driver's seat and pin 1 at control module 10-

way connector (Fig. 16 and 17). (3) Check for continuity between 2-way connector

under driver's seat and pin 6 at control module 10-

way connector. (4) Check for any movement of the seat by operat-

ing the seat switch.If movement the circuit is good

into the control module. (5) No movement check for an open or loose fuse in

cavity 15 of the fuse block. (6) Check for battery voltage to pin 3 of driver's

power seat switch.

Fig. 16 Memory Seat Switch Continuity

Fig. 17 Memory Seat Module Connectors

Ä POWER SEATS 8R - 9

Page 717 of 2438

(2) Check for battery voltage at pin 4 of the control

module 10-way connector with the recliner switch ac-

tivated. (3) If battery voltage and ground are NOT present

at the above pins of the 10-way connector, replace

the control module. If battery and ground are

present, then continue procedure. (4) Check for battery voltage and ground at re-

cliner motor connector in seat. (5) If recliner motor will not operate, refer to Ser-

vice Procedure for Recliner Motor and Cable.

CONDITION: NO RECLINER MANUAL MOVEMENT FORWARD OR REARWARD,RECLINER MOVES IN RECALL MODE ONLY.

PROCEDURE

(1) Check wiring harness in seat between control

module and recliner switch for shorted wires to

ground or crossed wires. If the ground pins 1 and 5

are in the wrong cavities of the recliner switch con-

nector, the control module may be damaged. Deter-

mine the cause and replace the control module after

repairing the wiring if necessary. (2) The recliner moves forward in the recall mode

only. Press the recliner switch in the forward direc-

tion and check for battery voltage at pin 2 of the re-

cliner switch connector and at pin 5 of the 21-way

control module connector. (3) The recliner moves rearward in the recall mode

only. Press the recliner switch in the rearward direc-

tion and check for battery voltage at pin 4 of the re-

cliner switch connector and at pin 6 of the 21-way

control module connector.

CONDITION: NO RECLINER MOVEMENT IN THE RECALL MODE, RECLINER WILL MOVEMANUALLY WITHOUT STALL DETECTION.

PROCEDURE

(1) Check for 5 volts at pin 9 of the control module

21-way connector (This is the 5 volt feed from the

control module to the recliner position sensing resis-

tor. (2) Check for ground at pin 7 of the 21-way control

module connector. To test for ground, one lead of the

voltmeter must be connected to the 5 volt supply for

the control module. If the sense voltage and ground

are NOT present, at the above pins of the 21-way

control module connector when the recliner switch is

pressed. Replace the control module since an in ad-

vertent application of battery voltage to the circuit

could damaged the control module. If the circuits are

present then continue this procedure. (3) Check for 5 volts at pin 2 of the black 5-way

connector plugged into the recliner motor end-bell. (4) Check for ground at pin 4 of the black 5-way

connector plugged into the recliner motor end-bell. (5) Unplug the black 5-way connector and observe

the male pins for deformation. If deformed, carefully

straighten to mate properly with the connector. Care-

fully reconnect 5-way connector. (6) Check for a voltage at pin 3 of the black 5-way

connector plugged into the recliner motor end-bell

with the recliner switch activated. Less than 5 volts

when fully forward and more than 0 volts when fully

reclined that is variable when the recliner is moving.

This is the position sense voltage the control module

must have or it will not move the recliner in recall

since it has no reference for movement. To test for

this voltage, one lead of the voltmeter must be con-

nected to either pin 4 of the black 5-way connector or

pin 7 of the 21-way connector. If the above steps

have been followed and the voltage is 0, check for a

seat wiring harness short to ground of this circuit,

repair as necessary, before continuing with this pro-

cedure. (7) Check for the position sense voltage at pin 3 of

the control module 21-way connector. If the voltage

appears correct, and varies as indicated in step (6)

above and there is continuity back to the 5-way con-

nector, then replace the control module.

CONDITION: NO SEAT OR RECLINER MOVEMENT FROM THE MANUAL SWITCHES.SEAT AND RECLINER WILL MOVE IN THERECALL MODE ONLY.

PROCEDURE

(1) Check for a stuck switch contact in the recliner

switch mounted in the driver's left seat side shield.

Refer to the Memory Recliner Switch Continuity

(Fig. 19). (2) Check for a stuck switch contact in the driver's

power seat switch. Refer to Memory Seat Switch

Continuity (Fig. 16).

CONDITION: NO MEMORY RECALL OF SEAT, RECLINER, OR MIRRORS. SEAT, RECLINER,AND MIRRORS WILL MOVE BY MANUALSWITCH ACTUATION ONLY.

PROCEDURE

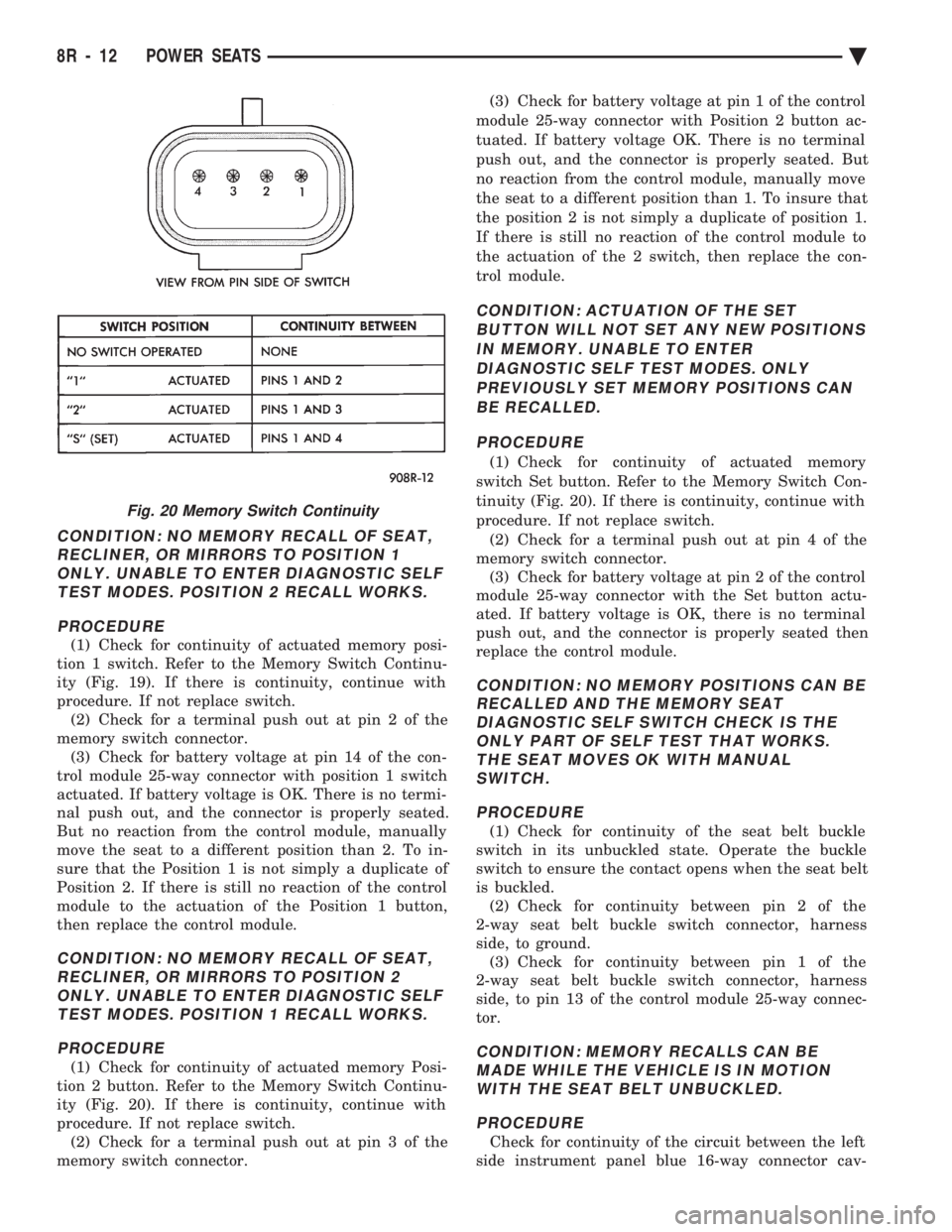

(1) Check for a stuck switch contact in the memory

switch. Refer to the Memory Switch Continuity (Fig.

20). (2) Check for battery voltage pin 1 of the memory

switch (Fig. 20).

Ä POWER SEATS 8R - 11

Page 718 of 2438

CONDITION: NO MEMORY RECALL OF SEAT, RECLINER, OR MIRRORS TO POSITION 1ONLY. UNABLE TO ENTER DIAGNOSTIC SELFTEST MODES. POSITION 2 RECALL WORKS.

PROCEDURE

(1) Check for continuity of actuated memory posi-

tion 1 switch. Refer to the Memory Switch Continu-

ity (Fig. 19). If there is continuity, continue with

procedure. If not replace switch. (2) Check for a terminal push out at pin 2 of the

memory switch connector. (3) Check for battery voltage at pin 14 of the con-

trol module 25-way connector with position 1 switch

actuated. If battery voltage is OK. There is no termi-

nal push out, and the connector is properly seated.

But no reaction from the control module, manually

move the seat to a different position than 2. To in-

sure that the Position 1 is not simply a duplicate of

Position 2. If there is still no reaction of the control

module to the actuation of the Position 1 button,

then replace the control module.

CONDITION: NO MEMORY RECALL OF SEAT, RECLINER, OR MIRRORS TO POSITION 2ONLY. UNABLE TO ENTER DIAGNOSTIC SELFTEST MODES. POSITION 1 RECALL WORKS.

PROCEDURE

(1) Check for continuity of actuated memory Posi-

tion 2 button. Refer to the Memory Switch Continu-

ity (Fig. 20). If there is continuity, continue with

procedure. If not replace switch. (2) Check for a terminal push out at pin 3 of the

memory switch connector. (3) Check for battery voltage at pin 1 of the control

module 25-way connector with Position 2 button ac-

tuated. If battery voltage OK. There is no terminal

push out, and the connector is properly seated. But

no reaction from the control module, manually move

the seat to a different position than 1. To insure that

the position 2 is not simply a duplicate of position 1.

If there is still no reaction of the control module to

the actuation of the 2 switch, then replace the con-

trol module.

CONDITION: ACTUATION OF THE SET BUTTON WILL NOT SET ANY NEW POSITIONSIN MEMORY. UNABLE TO ENTERDIAGNOSTIC SELF TEST MODES. ONLYPREVIOUSLY SET MEMORY POSITIONS CANBE RECALLED.

PROCEDURE

(1) Check for continuity of actuated memory

switch Set button. Refer to the Memory Switch Con-

tinuity (Fig. 20). If there is continuity, continue with

procedure. If not replace switch. (2) Check for a terminal push out at pin 4 of the

memory switch connector. (3) Check for battery voltage at pin 2 of the control

module 25-way connector with the Set button actu-

ated. If battery voltage is OK, there is no terminal

push out, and the connector is properly seated then

replace the control module.

CONDITION: NO MEMORY POSITIONS CAN BE RECALLED AND THE MEMORY SEATDIAGNOSTIC SELF SWITCH CHECK IS THEONLY PART OF SELF TEST THAT WORKS.THE SEAT MOVES OK WITH MANUALSWITCH.

PROCEDURE

(1) Check for continuity of the seat belt buckle

switch in its unbuckled state. Operate the buckle

switch to ensure the contact opens when the seat belt

is buckled. (2) Check for continuity between pin 2 of the

2-way seat belt buckle switch connector, harness

side, to ground. (3) Check for continuity between pin 1 of the

2-way seat belt buckle switch connector, harness

side, to pin 13 of the control module 25-way connec-

tor.

CONDITION: MEMORY RECALLS CAN BE MADE WHILE THE VEHICLE IS IN MOTIONWITH THE SEAT BELT UNBUCKLED.

PROCEDURE

Check for continuity of the circuit between the left

side instrument panel blue 16-way connector cav-

Fig. 20 Memory Switch Continuity

8R - 12 POWER SEATS Ä

Page 721 of 2438

(3) Use an ohmmeter to test the wiring between

the door switch and the control module in the driv-

er's seat. The circuits should be disconnected from

their components at each end. Repair the wiring as

required for open circuits, terminal push outs, or bad

crimps. If the circuits are good to the control module

but the function is still missing, replace the control

module.

CONDITION: NO MOVEMENT OF THE SEAT, RELAYS CAN BE HEARD CLICKING WHENTHE SEAT SWITCH IS ACTIVATED.

PROCEDURE

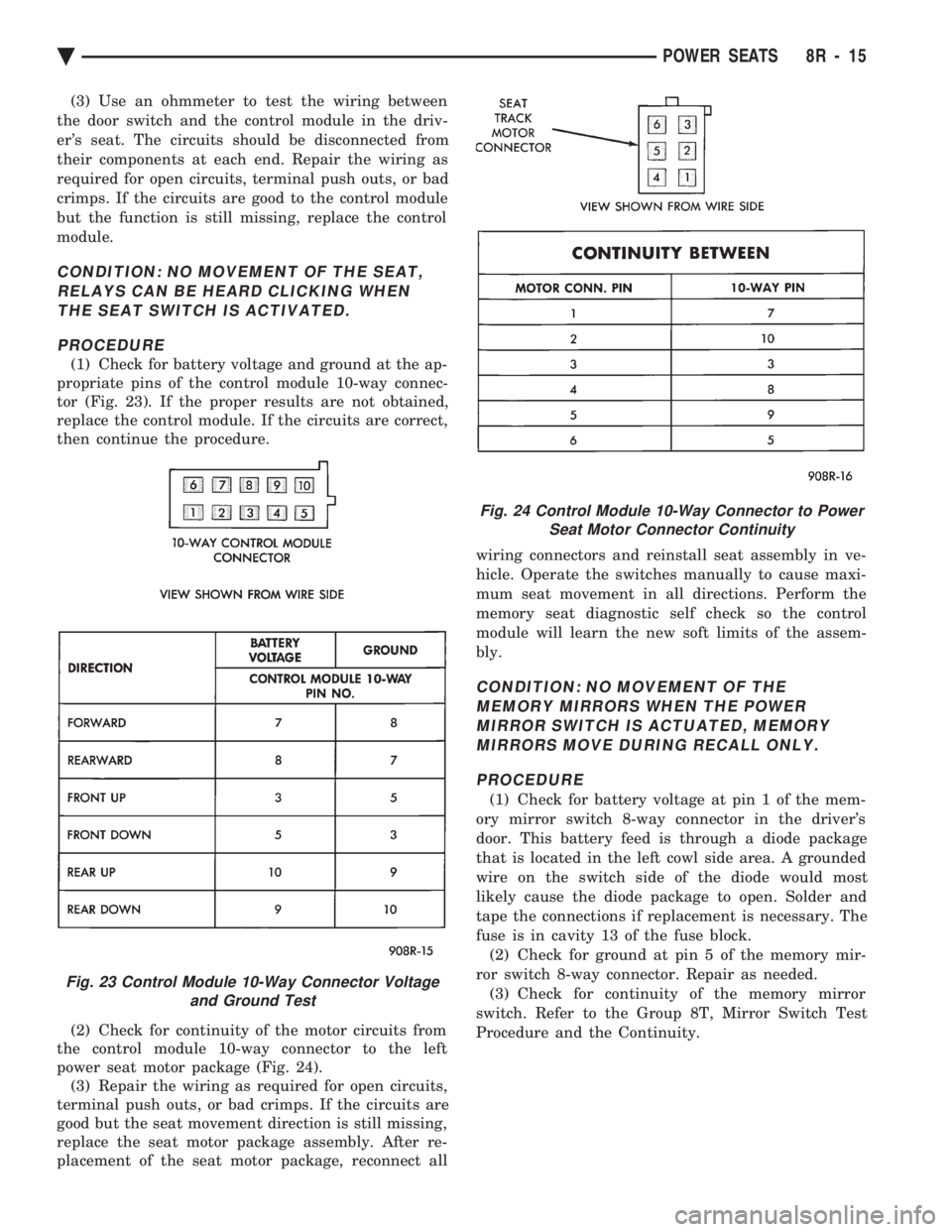

(1) Check for battery voltage and ground at the ap-

propriate pins of the control module 10-way connec-

tor (Fig. 23). If the proper results are not obtained,

replace the control module. If the circuits are correct,

then continue the procedure.

(2) Check for continuity of the motor circuits from

the control module 10-way connector to the left

power seat motor package (Fig. 24). (3) Repair the wiring as required for open circuits,

terminal push outs, or bad crimps. If the circuits are

good but the seat movement direction is still missing,

replace the seat motor package assembly. After re-

placement of the seat motor package, reconnect all wiring connectors and reinstall seat assembly in ve-

hicle. Operate the switches manually to cause maxi-

mum seat movement in all directions. Perform the

memory seat diagnostic self check so the control

module will learn the new soft limits of the assem-

bly.

CONDITION: NO MOVEMENT OF THE MEMORY MIRRORS WHEN THE POWERMIRROR SWITCH IS ACTUATED, MEMORYMIRRORS MOVE DURING RECALL ONLY.

PROCEDURE

(1) Check for battery voltage at pin 1 of the mem-

ory mirror switch 8-way connector in the driver's

door. This battery feed is through a diode package

that is located in the left cowl side area. A grounded

wire on the switch side of the diode would most

likely cause the diode package to open. Solder and

tape the connections if replacement is necessary. The

fuse is in cavity 13 of the fuse block. (2) Check for ground at pin 5 of the memory mir-

ror switch 8-way connector. Repair as needed. (3) Check for continuity of the memory mirror

switch. Refer to the Group 8T, Mirror Switch Test

Procedure and the Continuity.

Fig. 23 Control Module 10-Way Connector Voltage and Ground Test

Fig. 24 Control Module 10-Way Connector to PowerSeat Motor Connector Continuity

Ä POWER SEATS 8R - 15

Page 722 of 2438

CONDITION: NO MOVEMENT OF BOTH MEMORY MIRRORS OR ONLY ONE MEMORY MIRROR DURING THE RECALL MODE,MEMORY MIRRORS WILL MOVE ONLY WHENTHE POWER MIRROR SWITCH IS ACTUATED.MEMORY SEAT AND RECLINER MOVE INRECALL.

PROCEDURE

(1) Determine the fault precisely. If all memory

mirror recall movements appear to be missing, first

set the mirrors to two different vertical and horizon-

tal positions for both mirrors. Refer to the General

Information paragraph at the beginning of this sec-

tion for position setting instructions. Try to recall

these set positions that were just placed in memory. (2) Observe for no movement in a specific direction

for a specific mirror. If there is still no movement of

either mirror in any direction, re place the control

module. Perform the memory seat diagnostic self

check so the control module will learn the new soft

limits of the assembly. If the non-movement is in a

specific direction or a specific mirror, continue with

the procedure. (3) Perform the diagnostic self tests, mirror check

mode, to determine if the fault is with a motor or

with a position sensing rheostat circuit. Refer to

Memory Seat and Mirror Diagnostic Self-Tests expla-

nation for further information and understanding of

the diagnostic process and identifying of the fault. If

the fault is with a motor, continue this procedure as

follows in step (4) below. If the fault is with a rheo-

stat, as indicated by the mirror nod in the vertical or

horizontal plane, continue the procedure with step (5)

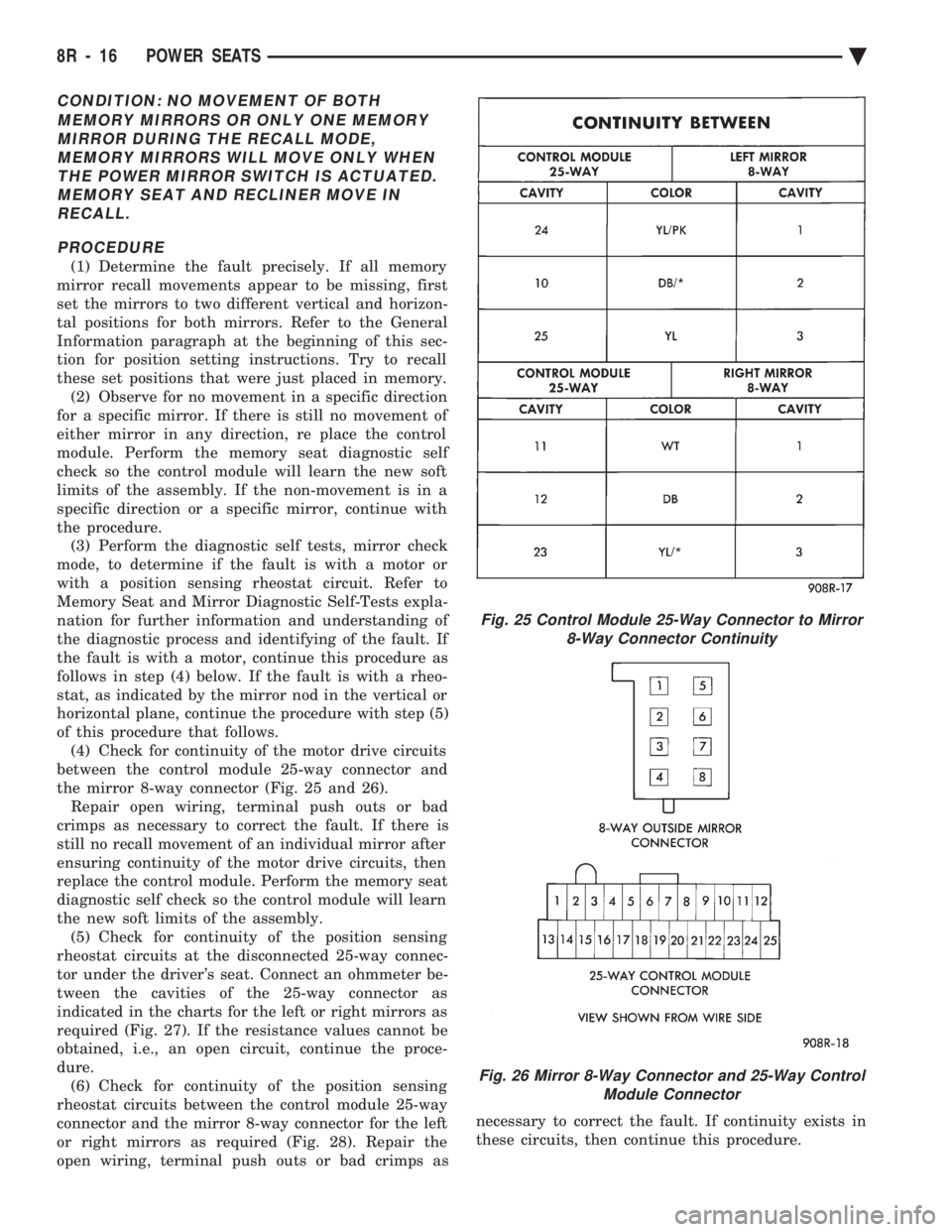

of this procedure that follows. (4) Check for continuity of the motor drive circuits

between the control module 25-way connector and

the mirror 8-way connector (Fig. 25 and 26). Repair open wiring, terminal push outs or bad

crimps as necessary to correct the fault. If there is

still no recall movement of an individual mirror after

ensuring continuity of the motor drive circuits, then

replace the control module. Perform the memory seat

diagnostic self check so the control module will learn

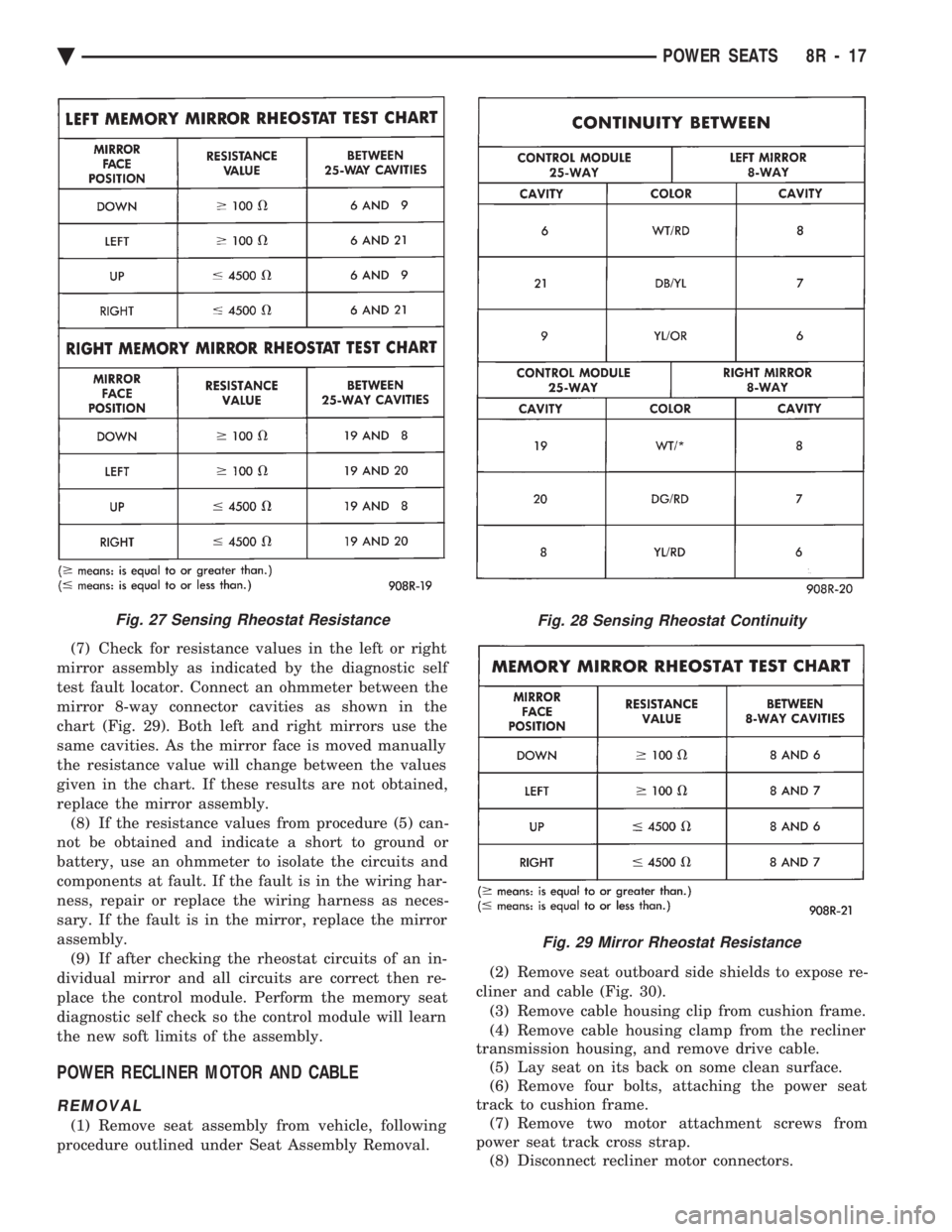

the new soft limits of the assembly. (5) Check for continuity of the position sensing

rheostat circuits at the disconnected 25-way connec-

tor under the driver's seat. Connect an ohmmeter be-

tween the cavities of the 25-way connector as

indicated in the charts for the left or right mirrors as

required (Fig. 27). If the resistance values cannot be

obtained, i.e., an open circuit, continue the proce-

dure. (6) Check for continuity of the position sensing

rheostat circuits between the control module 25-way

connector and the mirror 8-way connector for the left

or right mirrors as required (Fig. 28). Repair the

open wiring, terminal push outs or bad crimps as necessary to correct the fault. If continuity exists in

these circuits, then continue this procedure.

Fig. 25 Control Module 25-Way Connector to Mirror 8-Way Connector Continuity

Fig. 26 Mirror 8-Way Connector and 25-Way Control Module Connector

8R - 16 POWER SEATS Ä

Page 723 of 2438

(7) Check for resistance values in the left or right

mirror assembly as indicated by the diagnostic self

test fault locator. Connect an ohmmeter between the

mirror 8-way connector cavities as shown in the

chart (Fig. 29). Both left and right mirrors use the

same cavities. As the mirror face is moved manually

the resistance value will change between the values

given in the chart. If these results are not obtained,

replace the mirror assembly. (8) If the resistance values from procedure (5) can-

not be obtained and indicate a short to ground or

battery, use an ohmmeter to isolate the circuits and

components at fault. If the fault is in the wiring har-

ness, repair or replace the wiring harness as neces-

sary. If the fault is in the mirror, replace the mirror

assembly. (9) If after checking the rheostat circuits of an in-

dividual mirror and all circuits are correct then re-

place the control module. Perform the memory seat

diagnostic self check so the control module will learn

the new soft limits of the assembly.

POWER RECLINER MOTOR AND CABLE

REMOVAL

(1) Remove seat assembly from vehicle, following

procedure outlined under Seat Assembly Removal. (2) Remove seat outboard side shields to expose re-

cliner and cable (Fig. 30). (3) Remove cable housing clip from cushion frame.

(4) Remove cable housing clamp from the recliner

transmission housing, and remove drive cable. (5) Lay seat on its back on some clean surface.

(6) Remove four bolts, attaching the power seat

track to cushion frame. (7) Remove two motor attachment screws from

power seat track cross strap. (8) Disconnect recliner motor connectors.

Fig. 27 Sensing Rheostat ResistanceFig. 28 Sensing Rheostat Continuity

Fig. 29 Mirror Rheostat Resistance

Ä POWER SEATS 8R - 17

Page 737 of 2438

POWER MIRRORS

CONTENTS

page page

AUTOMATIC DAY/NIGHT INSIDE MIRROR .... 7

AUTOMATIC DAY/NIGHT INSIDE MIRROR WITH ULTRALIGHT HEADLAMP CONTROL ....... 7

GENERAL INFORMATION .................. 1

HEATED MIRROR ........................ 2

INSIDE MIRROR/READING LAMPS BULB/LENS REPLACEMENT ........................ 6

INSIDE MIRROR/READING LAMPS REPLACEMENT ........................ 6

MIRROR ASSEMBLY REPLACEMENTÐAA BODY.5

MIRROR ASSEMBLY REPLACEMENTÐ AC AND AY BODIES .................... 5

MIRROR ASSEMBLY REPLACEMENTÐAG BODY.5

MIRROR ASSEMBLY REPLACEMENTÐAJ BODY.5

MIRROR ASSEMBLY REPLACEMENTÐAP BODY.5

MIRROR MOTOR TEST PROCEDURE ........ 2

MIRROR SWITCH REPLACEMENTÐAA BODY . 3

MIRROR SWITCH REPLACEMENTÐAC AND AY BODIES .............................. 4

MIRROR SWITCH REPLACEMENTÐAG AND AJ BODIES .............................. 3

MIRROR SWITCH REPLACEMENTÐAP BODY . 4

MIRROR SWITCH TEST PROCEDURE ....... 2

TEST PROCEDURES ...................... 2

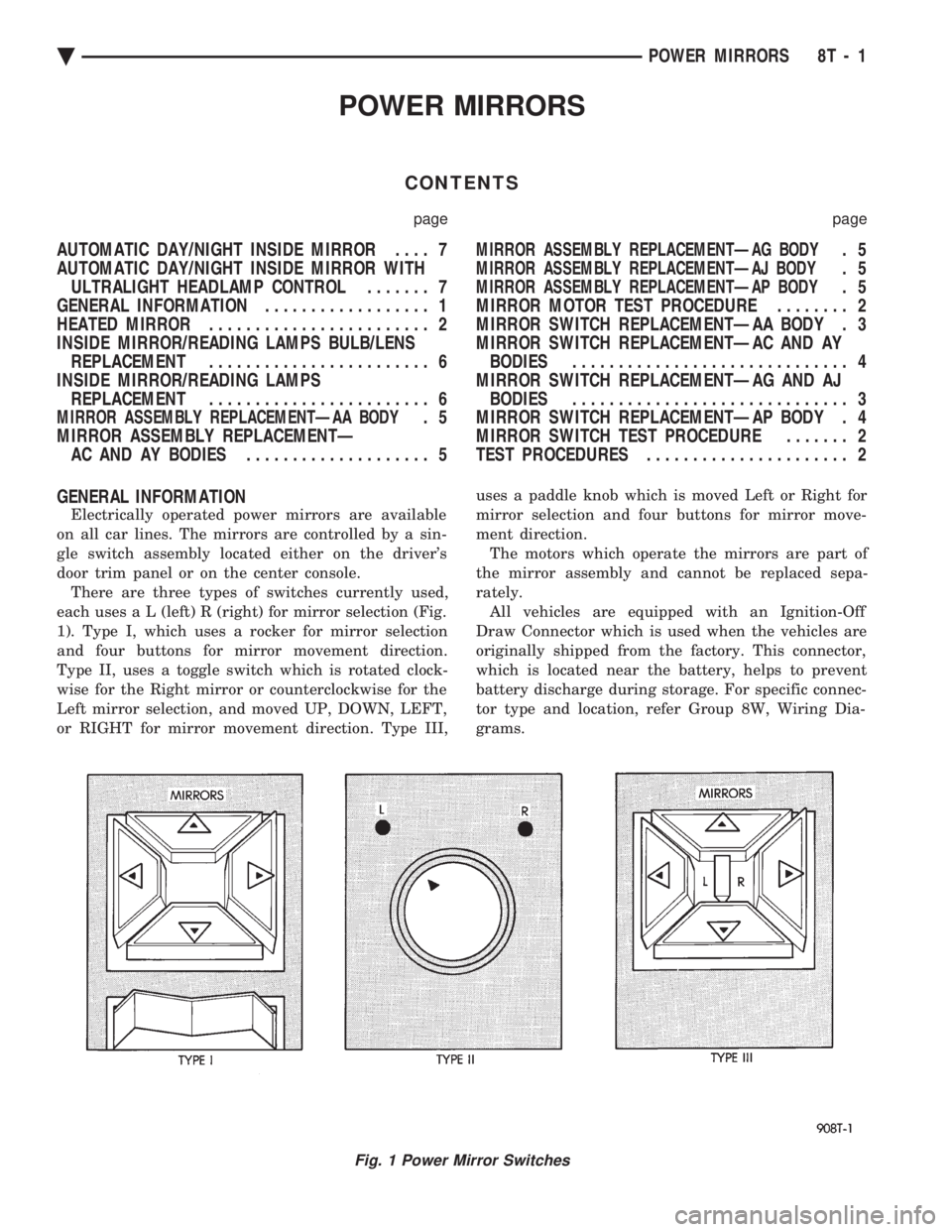

GENERAL INFORMATION

Electrically operated power mirrors are available

on all car lines. The mirrors are controlled by a sin-

gle switch assembly located either on the driver's

door trim panel or on the center console. There are three types of switches currently used,

each use s a L (left) R (right) for mirror selection (Fig.

1). Type I, which uses a rocker for mirror selection

and four buttons for mirror movement direction.

Type II, uses a toggle switch which is rotated clock-

wise for the Right mirror or counterclockwise for the

Left mirror selection, and moved UP, DOWN, LEFT,

or RIGHT for mirror movement direction. Type III, uses a paddle knob which is moved Left or Right for

mirror selection and four buttons for mirror move-

ment direction.

The motors which operate the mirrors are part of

the mirror assembly and cannot be replaced sepa-

rately. All vehicles are equipped with an Ignition-Off

Draw Connector which is used when the vehicles are

originally shipped from the factory. This connector,

which is located near the battery, helps to prevent

battery discharge during storage. For specific connec-

tor type and location, refer Group 8W, Wiring Dia-

grams.

Fig. 1 Power Mirror Switches

Ä POWER MIRRORS 8T - 1

Page 738 of 2438

This connector is included in the power mirror cir-

cuity except, for AC and AY body and should be

checked if the mirrors are inoperative.

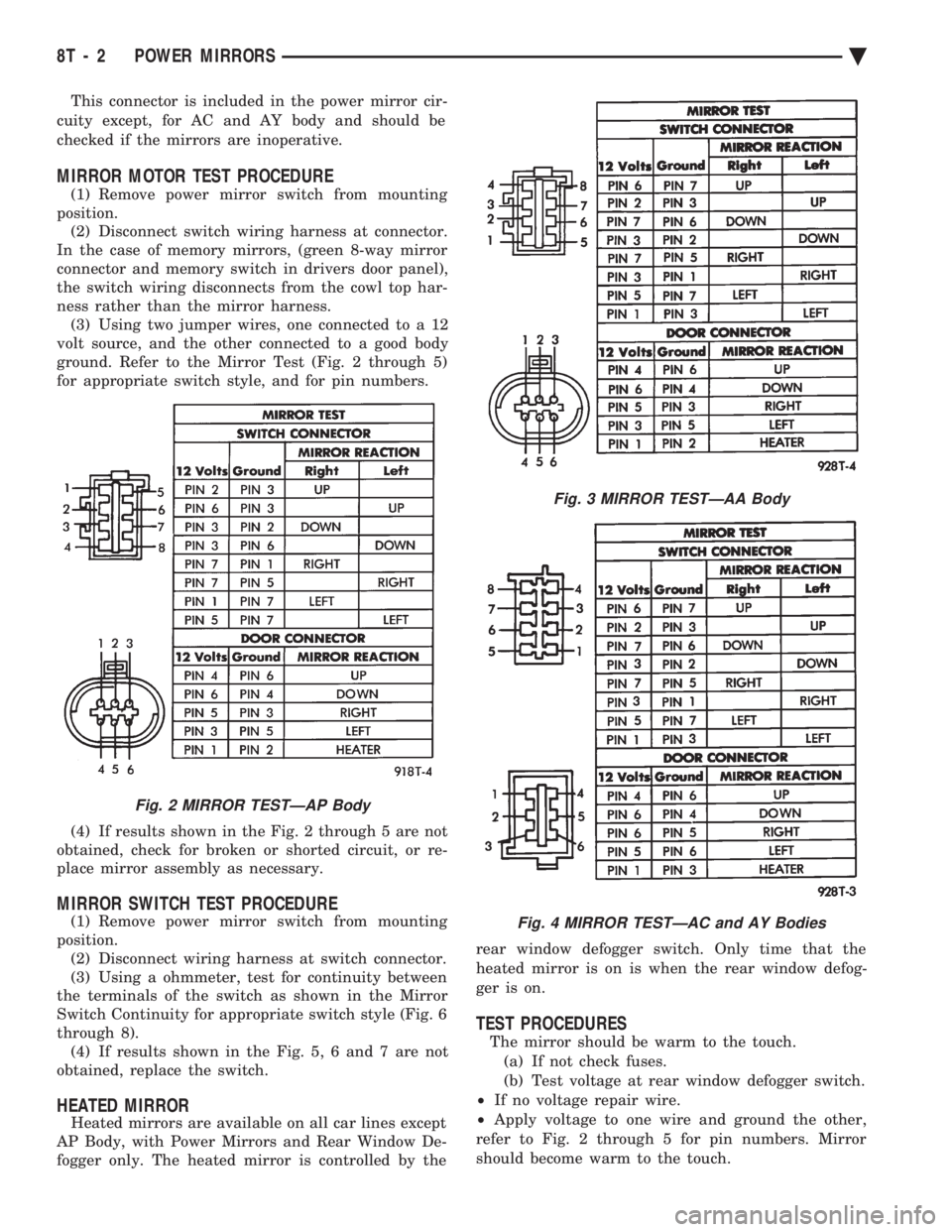

MIRROR MOTOR TEST PROCEDURE

(1) Remove power mirror switch from mounting

position. (2) Disconnect switch wiring harness at connector.

In the case of memory mirrors, (green 8-way mirror

connector and memory switch in drivers door panel),

the switch wiring disconnects from the cowl top har-

ness rather than the mirror harness. (3) Using two jumper wires, one connected to a 12

volt source, and the other connected to a good body

ground. Refer to the Mirror Test (Fig. 2 through 5)

for appropriate switch style, and for pin numbers.

(4) If results shown in the Fig. 2 through 5 are not

obtained, check for broken or shorted circuit, or re-

place mirror assembly as necessary.

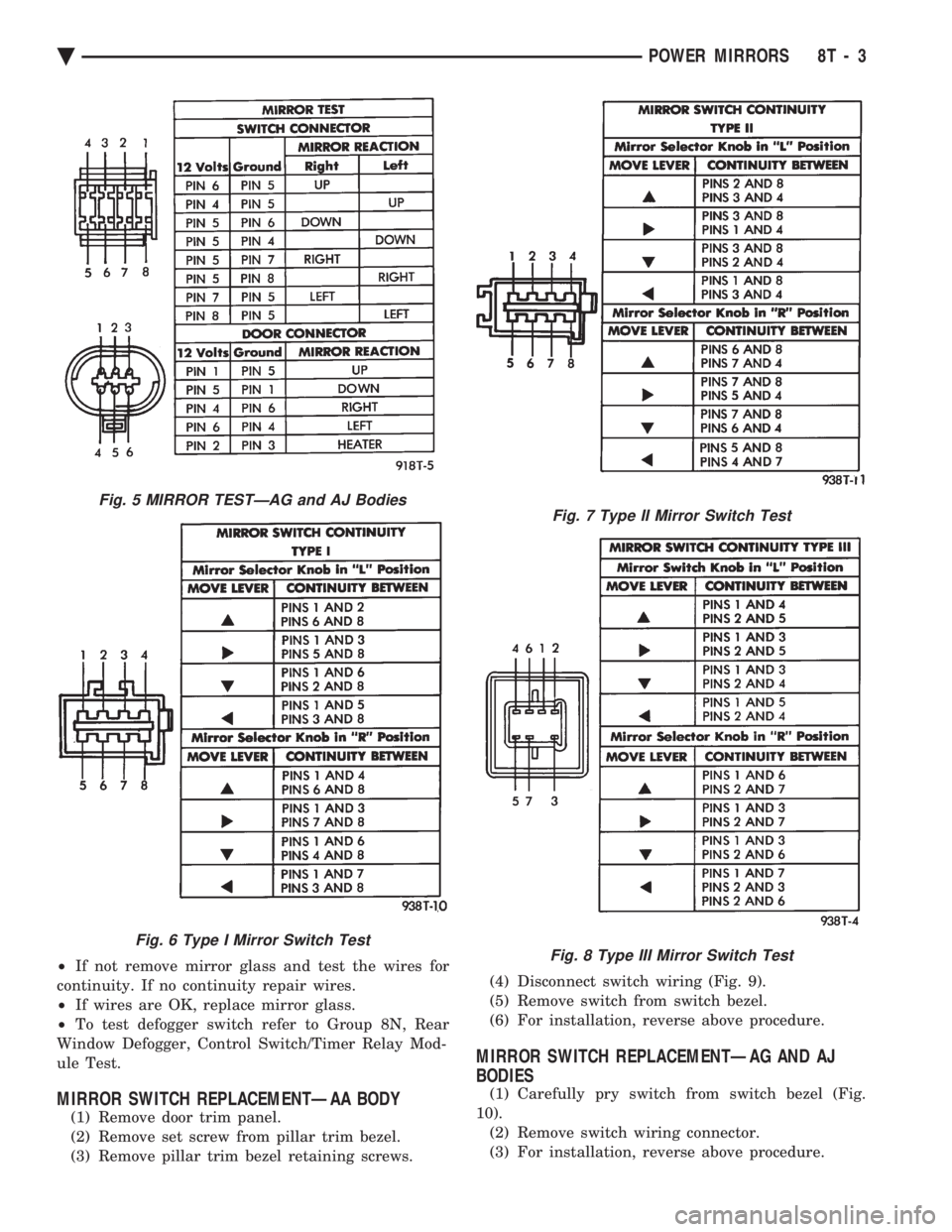

MIRROR SWITCH TEST PROCEDURE

(1) Remove power mirror switch from mounting

position. (2) Disconnect wiring harness at switch connector.

(3) Using a ohmmeter, test for continuity between

the terminals of the switch as shown in the Mirror

Switch Continuity for appropriate switch style (Fig. 6

through 8). (4) If results shown in the Fig. 5, 6 and 7 are not

obtained, replace the switch.

HEATED MIRROR

Heated mirrors are available on all car lines except

AP Body, with Power Mirrors and Rear Window De-

fogger only. The heated mirror is controlled by the rear window defogger switch. Only time that the

heated mirror is on is when the rear window defog-

ger is on.

TEST PROCEDURES

The mirror should be warm to the touch. (a) If not check fuses.

(b) Test voltage at rear window defogger switch.

² If no voltage repair wire.

² Apply voltage to one wire and ground the other,

refer to Fig. 2 through 5 for pin numbers. Mirror

should become warm to the touch.

Fig. 2 MIRROR TESTÐAP Body

Fig. 3 MIRROR TESTÐAA Body

Fig. 4 MIRROR TESTÐAC and AY Bodies

8T - 2 POWER MIRRORS Ä

Page 739 of 2438

² If not remove mirror glass and test the wires for

continuity. If no continuity repair wires.

² If wires are OK, replace mirror glass.

² To test defogger switch refer to Group 8N, Rear

Window Defogger, Control Switch/Timer Relay Mod-

ule Test.

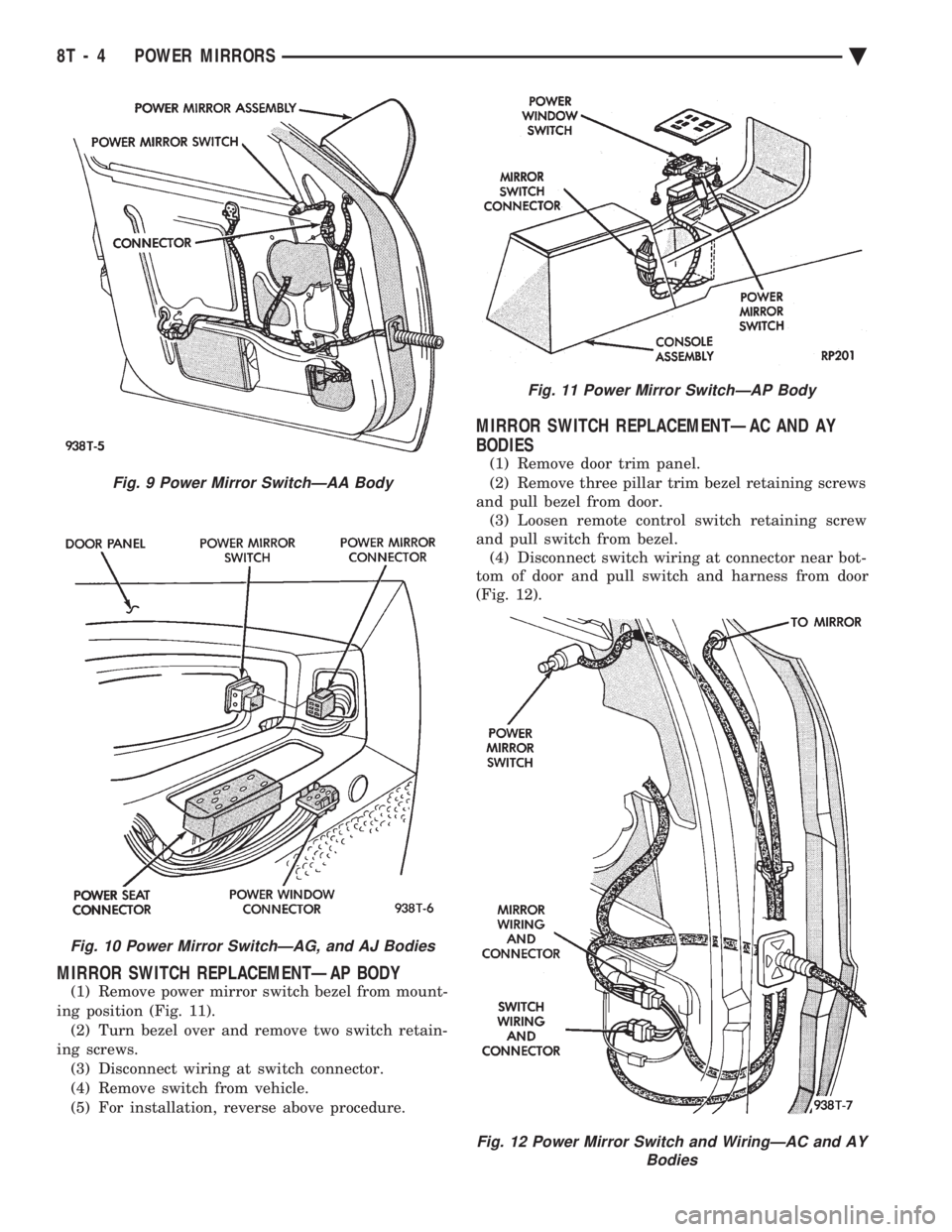

MIRROR SWITCH REPLACEMENTÐAA BODY

(1) Remove door trim panel.

(2) Remove set screw from pillar trim bezel.

(3) Remove pillar trim bezel retaining screws. (4) Disconnect switch wiring (Fig. 9).

(5) Remove switch from switch bezel.

(6) For installation, reverse above procedure.

MIRROR SWITCH REPLACEMENTÐAG AND AJ

BODIES

(1) Carefully pry switch from switch bezel (Fig.

10). (2) Remove switch wiring connector.

(3) For installation, reverse above procedure.

Fig. 5 MIRROR TESTÐAG and AJ Bodies

Fig. 6 Type I Mirror Switch Test

Fig. 7 Type II Mirror Switch Test

Fig. 8 Type III Mirror Switch Test

Ä POWER MIRRORS 8T - 3

Page 740 of 2438

MIRROR SWITCH REPLACEMENTÐAP BODY

(1) Remove power mirror switch bezel from mount-

ing position (Fig. 11). (2) Turn bezel over and remove two switch retain-

ing screws. (3) Disconnect wiring at switch connector.

(4) Remove switch from vehicle.

(5) For installation, reverse above procedure.

MIRROR SWITCH REPLACEMENTÐAC AND AY

BODIES

(1) Remove door trim panel.

(2) Remove three pillar trim bezel retaining screws

and pull bezel from door. (3) Loosen remote control switch retaining screw

and pull switch from bezel. (4) Disconnect switch wiring at connector near bot-

tom of door and pull switch and harness from door

(Fig. 12).

Fig. 9 Power Mirror SwitchÐAA Body

Fig. 10 Power Mirror SwitchÐAG, and AJ Bodies

Fig. 11 Power Mirror SwitchÐAP Body

Fig. 12 Power Mirror Switch and WiringÐAC and AY Bodies

8T - 4 POWER MIRRORS Ä