oil reset CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1893 of 2438

the PCM determines crankshaft position, it begins

energizing the injectors in sequence.The auto shutdown (ASD) relay supplies battery

voltage to the injectors. The PCM provides the

ground path for the injectors. By switching the

ground path on and off, the PCM adjusts injector

pulse width. Pulse width is the amount of time the

injector is energized. The PCM adjusts injector pulse

width based on inputs it receives.

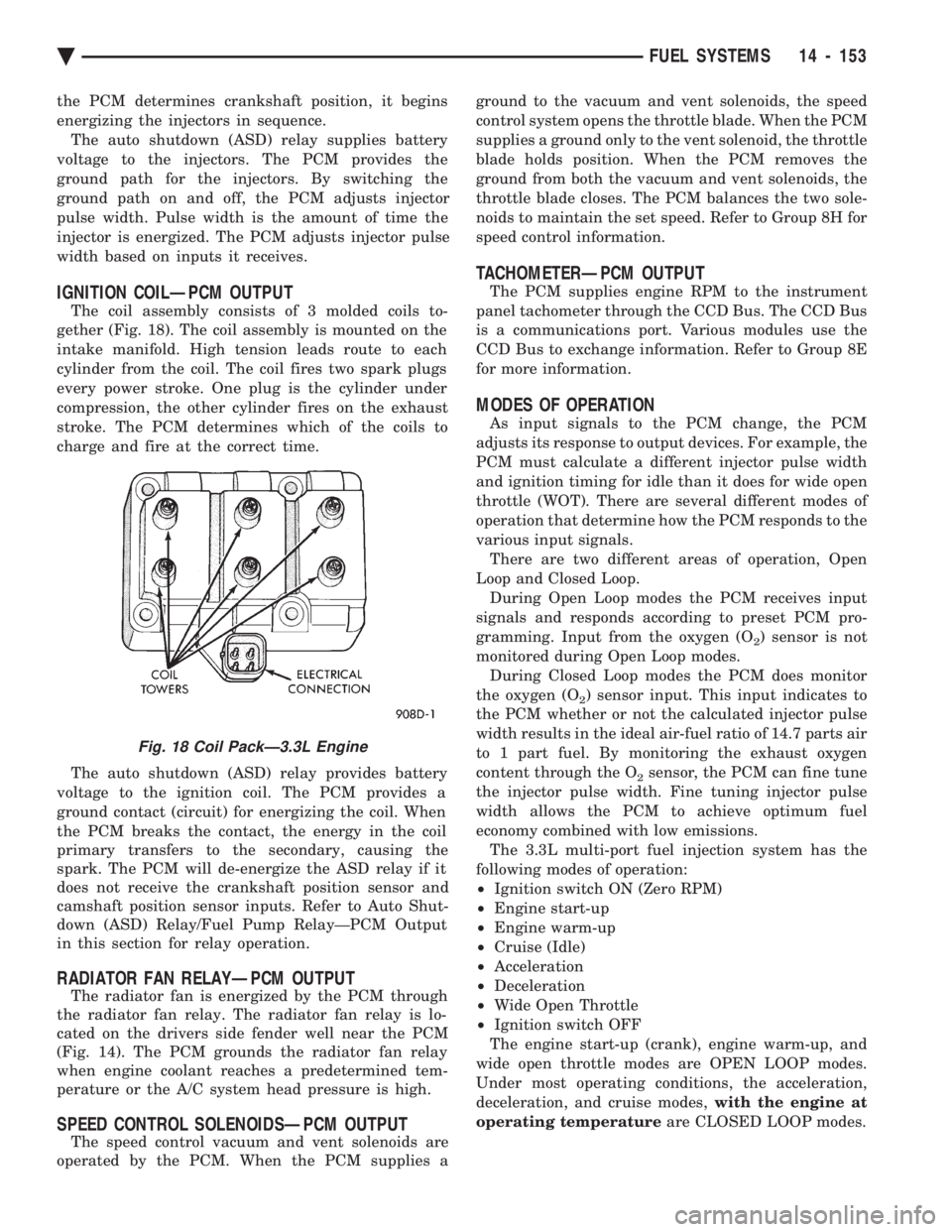

IGNITION COILÐPCM OUTPUT

The coil assembly consists of 3 molded coils to-

gether (Fig. 18). The coil assembly is mounted on the

intake manifold. High tension leads route to each

cylinder from the coil. The coil fires two spark plugs

every power stroke. One plug is the cylinder under

compression, the other cylinder fires on the exhaust

stroke. The PCM determines which of the coils to

charge and fire at the correct time.

The auto shutdown (ASD) relay provides battery

voltage to the ignition coil. The PCM provides a

ground contact (circuit) for energizing the coil. When

the PCM breaks the contact, the energy in the coil

primary transfers to the secondary, causing the

spark. The PCM will de-energize the ASD relay if it

does not receive the crankshaft position sensor and

camshaft position sensor inputs. Refer to Auto Shut-

down (ASD) Relay/Fuel Pump RelayÐPCM Output

in this section for relay operation.

RADIATOR FAN RELAYÐPCM OUTPUT

The radiator fan is energized by the PCM through

the radiator fan relay. The radiator fan relay is lo-

cated on the drivers side fender well near the PCM

(Fig. 14). The PCM grounds the radiator fan relay

when engine coolant reaches a predetermined tem-

perature or the A/C system head pressure is high.

SPEED CONTROL SOLENOIDSÐPCM OUTPUT

The speed control vacuum and vent solenoids are

operated by the PCM. When the PCM supplies a ground to the vacuum and vent solenoids, the speed

control system opens the throttle blade. When the PCM

supplies a ground only to the vent solenoid, the throttle

blade holds position. When the PCM removes the

ground from both the vacuum and vent solenoids, the

throttle blade closes. The PCM balances the two sole-

noids to maintain the set speed. Refer to Group 8H for

speed control information.

TACHOMETERÐPCM OUTPUT

The PCM supplies engine RPM to the instrument

panel tachometer through the CCD Bus. The CCD Bus

is a communications port. Various modules use the

CCD Bus to exchange information. Refer to Group 8E

for more information.

MODES OF OPERATION

As input signals to the PCM change, the PCM

adjusts its response to output devices. For example, the

PCM must calculate a different injector pulse width

and ignition timing for idle than it does for wide open

throttle (WOT). There are several different modes of

operation that determine how the PCM responds to the

various input signals. There are two different areas of operation, Open

Loop and Closed Loop. During Open Loop modes the PCM receives input

signals and responds according to preset PCM pro-

gramming. Input from the oxygen (O

2) sensor is not

monitored during Open Loop modes. During Closed Loop modes the PCM does monitor

the oxygen (O

2) sensor input. This input indicates to

the PCM whether or not the calculated injector pulse

width results in the ideal air-fuel ratio of 14.7 parts air

to 1 part fuel. By monitoring the exhaust oxygen

content through the O

2sensor, the PCM can fine tune

the injector pulse width. Fine tuning injector pulse

width allows the PCM to achieve optimum fuel

economy combined with low emissions. The 3.3L multi-port fuel injection system has the

following modes of operation:

² Ignition switch ON (Zero RPM)

² Engine start-up

² Engine warm-up

² Cruise (Idle)

² Acceleration

² Deceleration

² Wide Open Throttle

² Ignition switch OFF

The engine start-up (crank), engine warm-up, and

wide open throttle modes are OPEN LOOP modes.

Under most operating conditions, the acceleration,

deceleration, and cruise modes, with the engine at

operating temperature are CLOSED LOOP modes.

Fig. 18 Coil PackÐ3.3L Engine

Ä FUEL SYSTEMS 14 - 153

Page 1964 of 2438

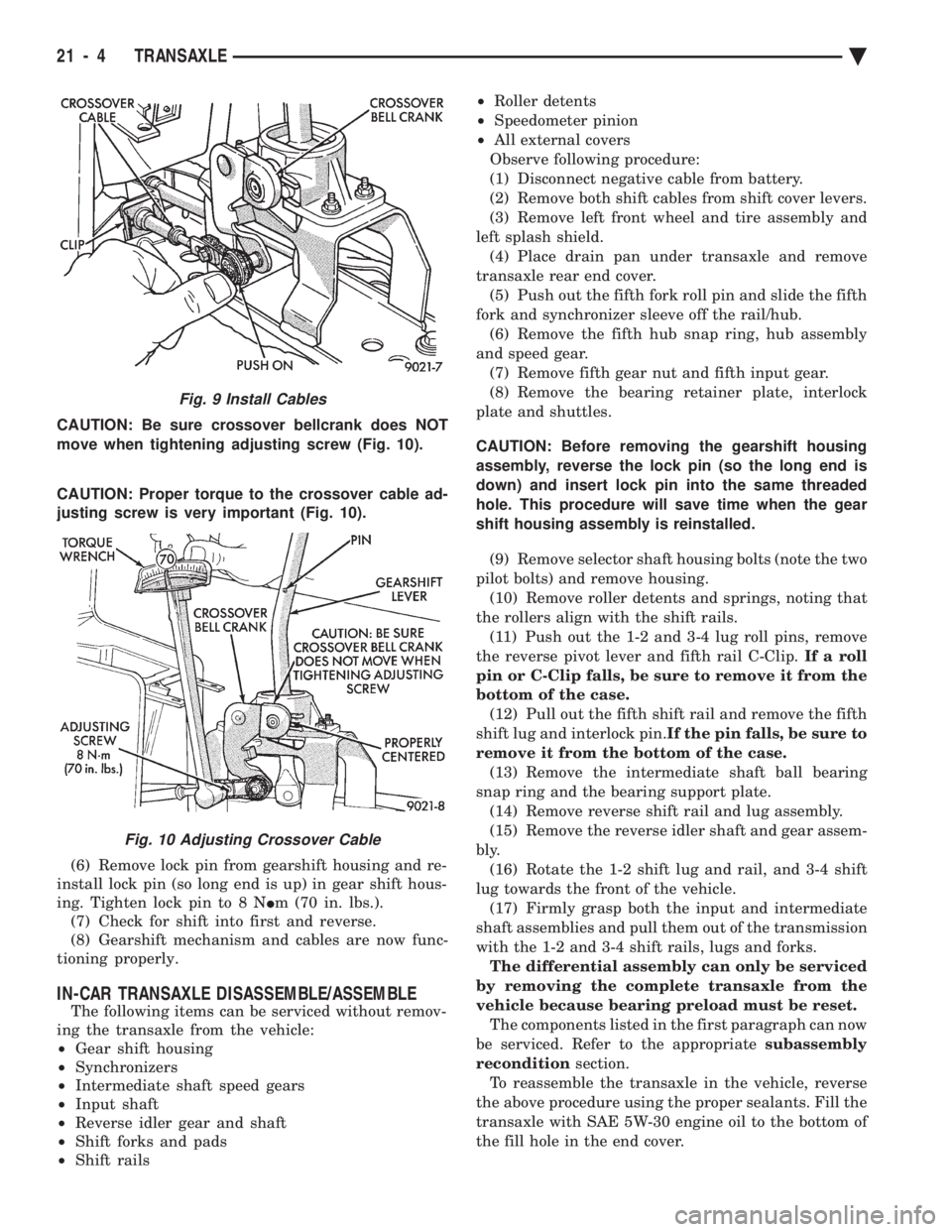

CAUTION: Be sure crossover bellcrank does NOT

move when tightening adjusting screw (Fig. 10).

CAUTION: Proper torque to the crossover cable ad-

justing screw is very important (Fig. 10).

(6) Remove lock pin from gearshift housing and re-

install lock pin (so long end is up) in gear shift hous-

ing. Tighten lock pin to 8 N Im (70 in. lbs.).

(7) Check for shift into first and reverse.

(8) Gearshift mechanism and cables are now func-

tioning properly.

IN-CAR TRANSAXLE DISASSEMBLE/ASSEMBLE

The following items can be serviced without remov-

ing the transaxle from the vehicle:

² Gear shift housing

² Synchronizers

² Intermediate shaft speed gears

² Input shaft

² Reverse idler gear and shaft

² Shift forks and pads

² Shift rails ²

Roller detents

² Speedometer pinion

² All external covers

Observe following procedure:

(1) Disconnect negative cable from battery.

(2) Remove both shift cables from shift cover levers.

(3) Remove left front wheel and tire assembly and

left splash shield. (4) Place drain pan under transaxle and remove

transaxle rear end cover. (5) Push out the fifth fork roll pin and slide the fifth

fork and synchronizer sleeve off the rail/hub. (6) Remove the fifth hub snap ring, hub assembly

and speed gear. (7) Remove fifth gear nut and fifth input gear.

(8) Remove the bearing retainer plate, interlock

plate and shuttles.

CAUTION: Before removing the gearshift housing

assembly, reverse the lock pin (so the long end is

down) and insert lock pin into the same threaded

hole. This procedure will save time when the gear

shift housing assembly is reinstalled. (9) Remove selector shaft housing bolts (note the two

pilot bolts) and remove housing. (10) Remove roller detents and springs, noting that

the rollers align with the shift rails. (11) Push out the 1-2 and 3-4 lug roll pins, remove

the reverse pivot lever and fifth rail C-Clip. If a roll

pin or C-Clip falls, be sure to remove it from the

bottom of the case. (12) Pull out the fifth shift rail and remove the fifth

shift lug and interlock pin. If the pin falls, be sure to

remove it from the bottom of the case. (13) Remove the intermediate shaft ball bearing

snap ring and the bearing support plate. (14) Remove reverse shift rail and lug assembly.

(15) Remove the reverse idler shaft and gear assem-

bly. (16) Rotate the 1-2 shift lug and rail, and 3-4 shift

lug towards the front of the vehicle. (17) Firmly grasp both the input and intermediate

shaft assemblies and pull them out of the transmission

with the 1-2 and 3-4 shift rails, lugs and forks. The differential assembly can only be serviced

by removing the complete transaxle from the

vehicle because bearing preload must be reset. The components listed in the first paragraph can now

be serviced. Refer to the appropriate subassembly

recondition section.

To reassemble the transaxle in the vehicle, reverse

the above procedure using the proper sealants. Fill the

transaxle with SAE 5W-30 engine oil to the bottom of

the fill hole in the end cover.

Fig. 9 Install Cables

Fig. 10 Adjusting Crossover Cable

21 - 4 TRANSAXLE Ä

Page 2057 of 2438

first separator plate and watch carefully for the pis-

ton to move forward. The piston should return to its

original position after the air pressure is removed.

UNDERDRIVE CLUTCH

Because this clutch piston cannot be seen, its oper-

ation is checked by function. Air pressure is applied

to the low/reverse and the 2/4 clutches. This locks

the output shaft. Use a piece of rubber hose wrapped

around the input shaft and a pair of clamp-on pliers

to turn the input shaft. Next apply air pressure to

the underdrive clutch. The input shaft should not ro-

tate with hand torque. Release the air pressure and

confirm that the input shaft will rotate.

FLUID LEAKAGE-TORQUE CONVERTER HOUSING

AREA

(1) Check for source of leakage.

Since fluid leakage at or around the torque con-

verter area may originate from an engine oil leak,

the area should be examined closely. Factory fill

fluid is dyed red and, therefore, can be distinguished

from engine oil. (2) Prior to removing the transaxle, perform the

following checks: When leakage is determined to originate from the

transaxle, check fluid level prior to removal of the

transaxle and torque converter. High oil level can result in oil leakage out the vent

in the manual shaft. If the fluid level is high, adjust

to proper level. After performing this operation, inspect for leak-

age. If a leak persists, perform the following opera-

tion on the vehicle to determine if it is the torque

converter or transaxle that is leaking.

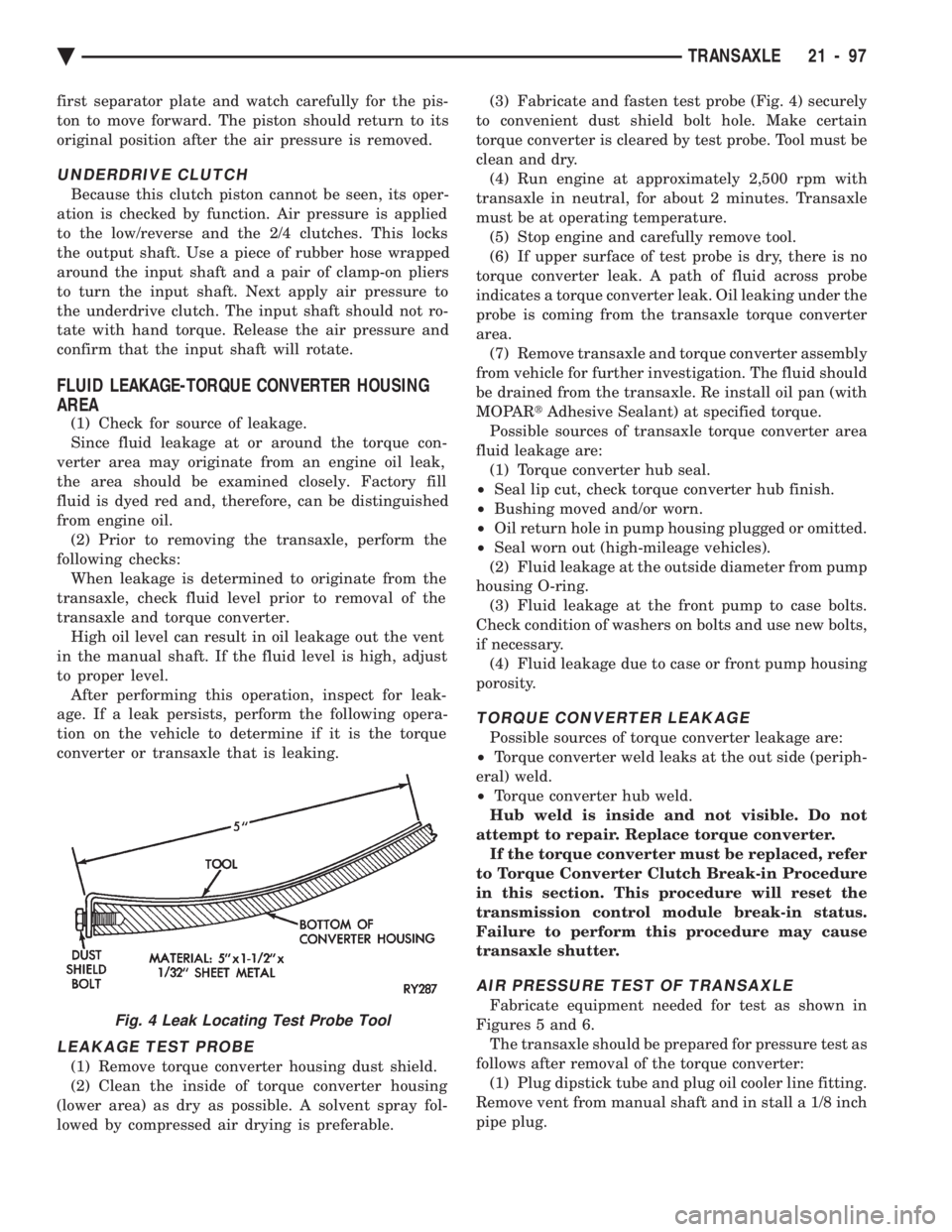

LEAKAGE TEST PROBE

(1) Remove torque converter housing dust shield.

(2) Clean the inside of torque converter housing

(lower area) as dry as possible. A solvent spray fol-

lowed by compressed air drying is preferable. (3) Fabricate and fasten test probe (Fig. 4) securely

to convenient dust shield bolt hole. Make certain

torque converter is cleared by test probe. Tool must be

clean and dry. (4) Run engine at approximately 2,500 rpm with

transaxle in neutral, for about 2 minutes. Transaxle

must be at operating temperature. (5) Stop engine and carefully remove tool.

(6) If upper surface of test probe is dry, there is no

torque converter leak. A path of fluid across probe

indicates a torque converter leak. Oil leaking under the

probe is coming from the transaxle torque converter

area. (7) Remove transaxle and torque converter assembly

from vehicle for further investigation. The fluid should

be drained from the transaxle. Re install oil pan (with

MOPAR tAdhesive Sealant) at specified torque.

Possible sources of transaxle torque converter area

fluid leakage are: (1) Torque converter hub seal.

² Seal lip cut, check torque converter hub finish.

² Bushing moved and/or worn.

² Oil return hole in pump housing plugged or omitted.

² Seal worn out (high-mileage vehicles).

(2) Fluid leakage at the outside diameter from pump

housing O-ring. (3) Fluid leakage at the front pump to case bolts.

Check condition of washers on bolts and use new bolts,

if necessary. (4) Fluid leakage due to case or front pump housing

porosity.

TORQUE CONVERTER LEAKAGE

Possible sources of torque converter leakage are:

² Torque converter weld leaks at the out side (periph-

eral) weld.

² Torque converter hub weld.

Hub weld is inside and not visible. Do not

attempt to repair. Replace torque converter. If the torque converter must be replaced, refer

to Torque Converter Clutch Break-in Procedure

in this section. This procedure will reset the

transmission control module break-in status.

Failure to perform this procedure may cause

transaxle shutter.

AIR PRESSURE TEST OF TRANSAXLE

Fabricate equipment needed for test as shown in

Figures 5 and 6. The transaxle should be prepared for pressure test as

follows after removal of the torque converter: (1) Plug dipstick tube and plug oil cooler line fitting.

Remove vent from manual shaft and in stall a 1/8 inch

pipe plug.Fig. 4 Leak Locating Test Probe Tool

Ä TRANSAXLE 21 - 97

Page 2065 of 2438

If screen (c) appears, the transmission control mod-

ule has completed its break-in status program. Press

the enter key on the DRB II scan tool key pad to return

the status to the start of break-in. (9) After pressing the enter key a second time in step

8 a screen will appear that says ``RESET LU CLUTCH

ARE YOU SURE ?''. Press the enter key on the DRB II

scan tool key pad. The DRB II scan tool will then carry

out the reset command. (10) After the DRB II scan tool completes the reset

command, a screen will appear saying ``LU Clutch

Break-in Status has been RESET to Start''. This screen

will indicate that the reset procedure has been success-

fully completed. (11) Disconnect the DRB II scan tool from the blue

CCD Bus connector.

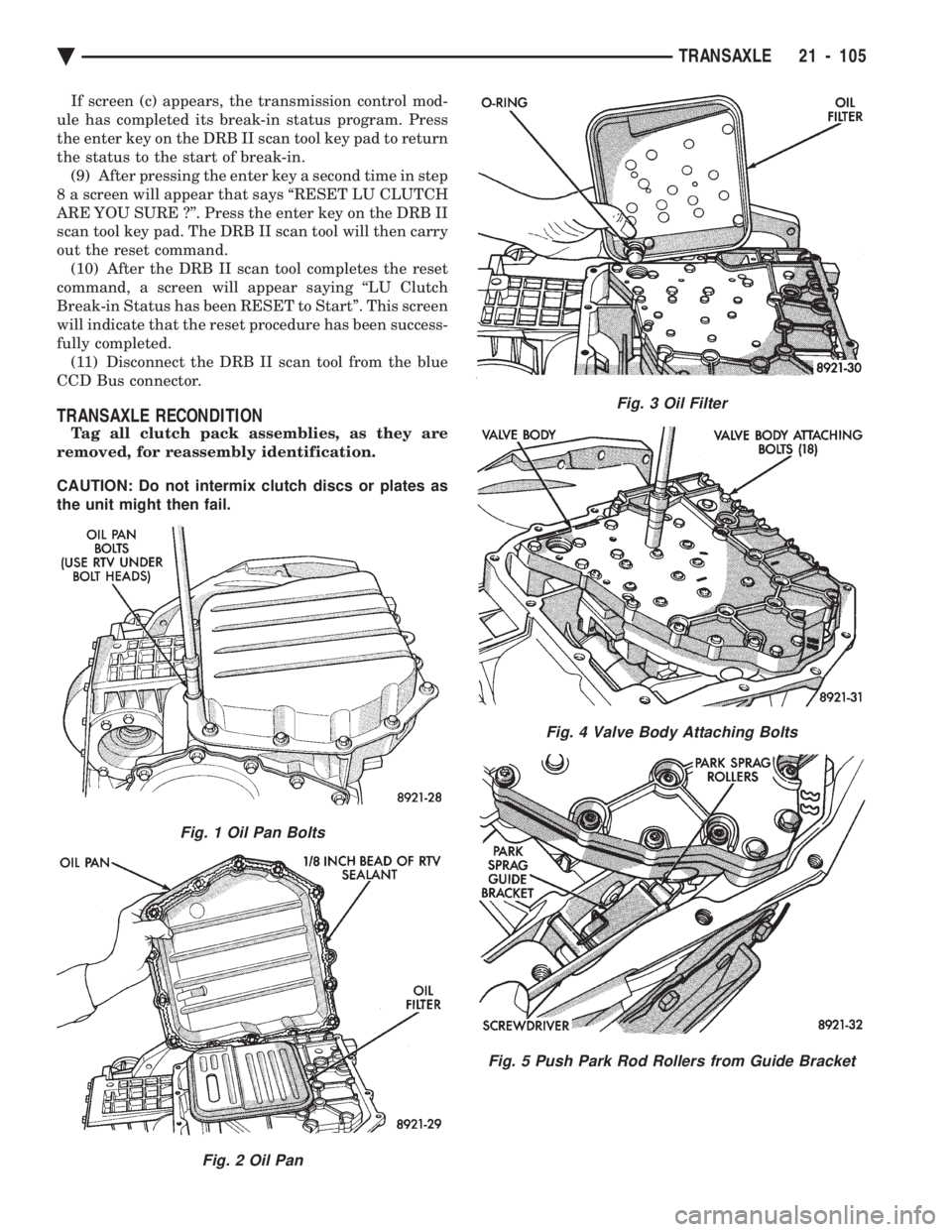

TRANSAXLE RECONDITION

Tag all clutch pack assemblies, as they are

removed, for reassembly identification.

CAUTION: Do not intermix clutch discs or plates as

the unit might then fail.

Fig. 1 Oil Pan Bolts

Fig. 2 Oil Pan

Fig. 3 Oil Filter

Fig. 4 Valve Body Attaching Bolts

Fig. 5 Push Park Rod Rollers from Guide Bracket

Ä TRANSAXLE 21 - 105

Page 2338 of 2438

(8) With the front clutch plate assembly tight

against the shims, measure the air gap between ar-

mature plate and rotor-pulley face with feeler gauges

(Fig. 4). The air gap should be between 0.35 and 0.65

mm (0.013 and 0.025 inch). If proper air gap is not

obtained, add or subtract shims until desired air gap

is obtained.

(9) Install compressor shaft nut. Tighten nut to

17.5 N Im (155 in. lbs.) torque.

Shims may compress after tightening shaft bolt.

Check air gap in four or more places to verify if air

gap is still correct. Spin pulley for final check. (10) Install the compressor onto the mount.

CLUTCH/COIL BREAK-IN

After a new clutch/coil has been installed, cycle the

A/C clutch 20 times (5 sec. on and 5 sec. off). During

this procedure, run engine at 1500-2000 rpm and set

the A/C on the HIGH mode. This procedure (burnish-

ing) will seat the opposing friction surfaces and pro-

vide a higher clutch torque capability.

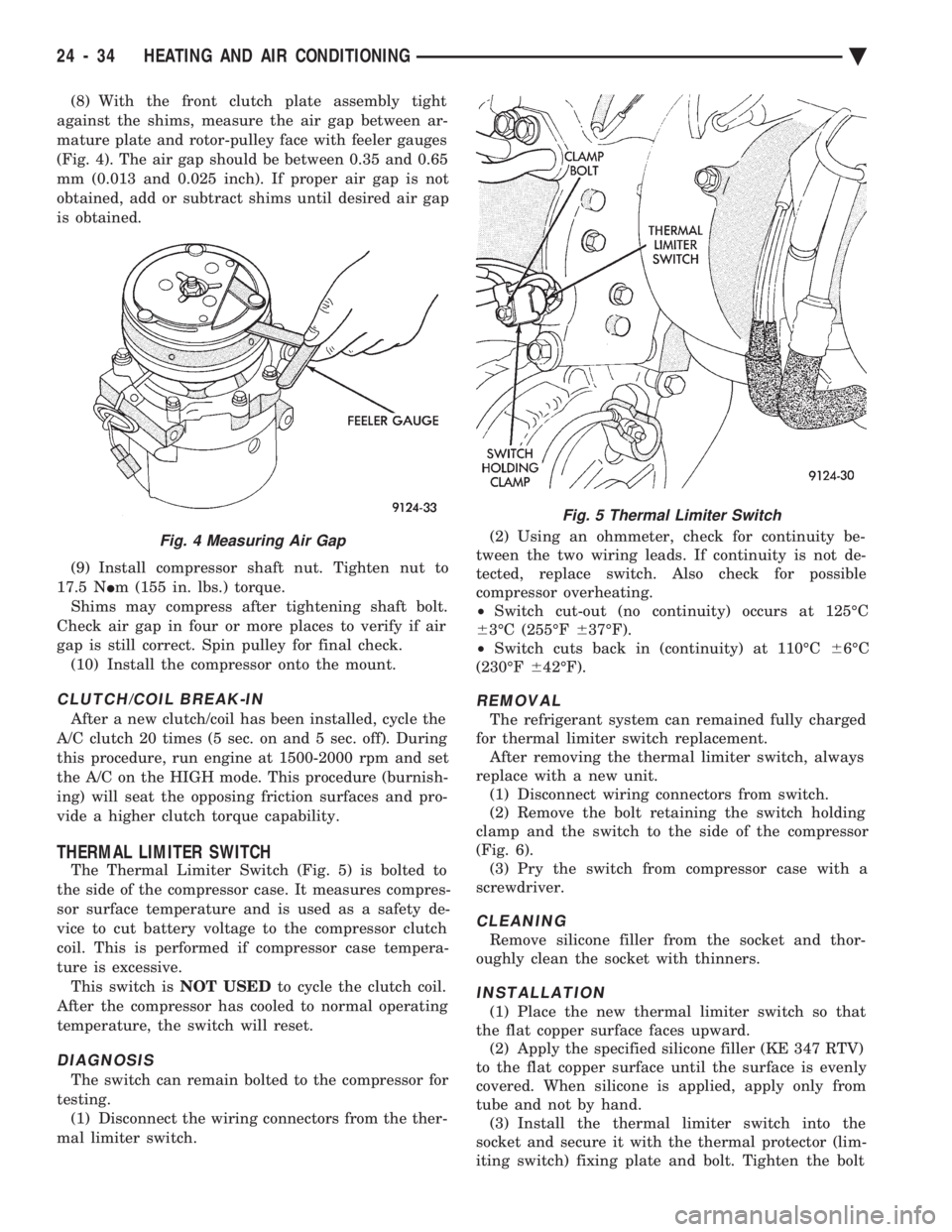

THERMAL LIMITER SWITCH

The Thermal Limiter Switch (Fig. 5) is bolted to

the side of the compressor case. It measures compres-

sor surface temperature and is used as a safety de-

vice to cut battery voltage to the compressor clutch

coil. This is performed if compressor case tempera-

ture is excessive. This switch is NOT USEDto cycle the clutch coil.

After the compressor has cooled to normal operating

temperature, the switch will reset.

DIAGNOSIS

The switch can remain bolted to the compressor for

testing. (1) Disconnect the wiring connectors from the ther-

mal limiter switch. (2) Using an ohmmeter, check for continuity be-

tween the two wiring leads. If continuity is not de-

tected, replace switch. Also check for possible

compressor overheating.

² Switch cut-out (no continuity) occurs at 125ÉC

6 3ÉC (255ÉF 637ÉF).

² Switch cuts back in (continuity) at 110ÉC 66ÉC

(230ÉF 642ÉF).

REMOVAL

The refrigerant system can remained fully charged

for thermal limiter switch replacement. After removing the thermal limiter switch, always

replace with a new unit. (1) Disconnect wiring connectors from switch.

(2) Remove the bolt retaining the switch holding

clamp and the switch to the side of the compressor

(Fig. 6). (3) Pry the switch from compressor case with a

screwdriver.

CLEANING

Remove silicone filler from the socket and thor-

oughly clean the socket with thinners.

INSTALLATION

(1) Place the new thermal limiter switch so that

the flat copper surface faces upward. (2) Apply the specified silicone filler (KE 347 RTV)

to the flat copper surface until the surface is evenly

covered. When silicone is applied, apply only from

tube and not by hand. (3) Install the thermal limiter switch into the

socket and secure it with the thermal protector (lim-

iting switch) fixing plate and bolt. Tighten the bolt

Fig. 4 Measuring Air Gap

Fig. 5 Thermal Limiter Switch

24 - 34 HEATING AND AIR CONDITIONING Ä