relay CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 131 of 2438

AUTOMATIC AIR SUSPENSION INDEX

page page

Air Lines ............................... 75

Air Springs Rear ......................... 87

Compressor Performance Test .............. 77

Diagnosis .............................. 78

General Information ....................... 73

Recharge Air Spring ...................... 87 Right Shock Absorber (With Height Sensor)

.... 88

Safety Concerns ......................... 78

Service Procedures ....................... 85

Shipping Mode .......................... 78

Solenoids (Struts and Air Springs) ............ 86

System Operation ........................ 78

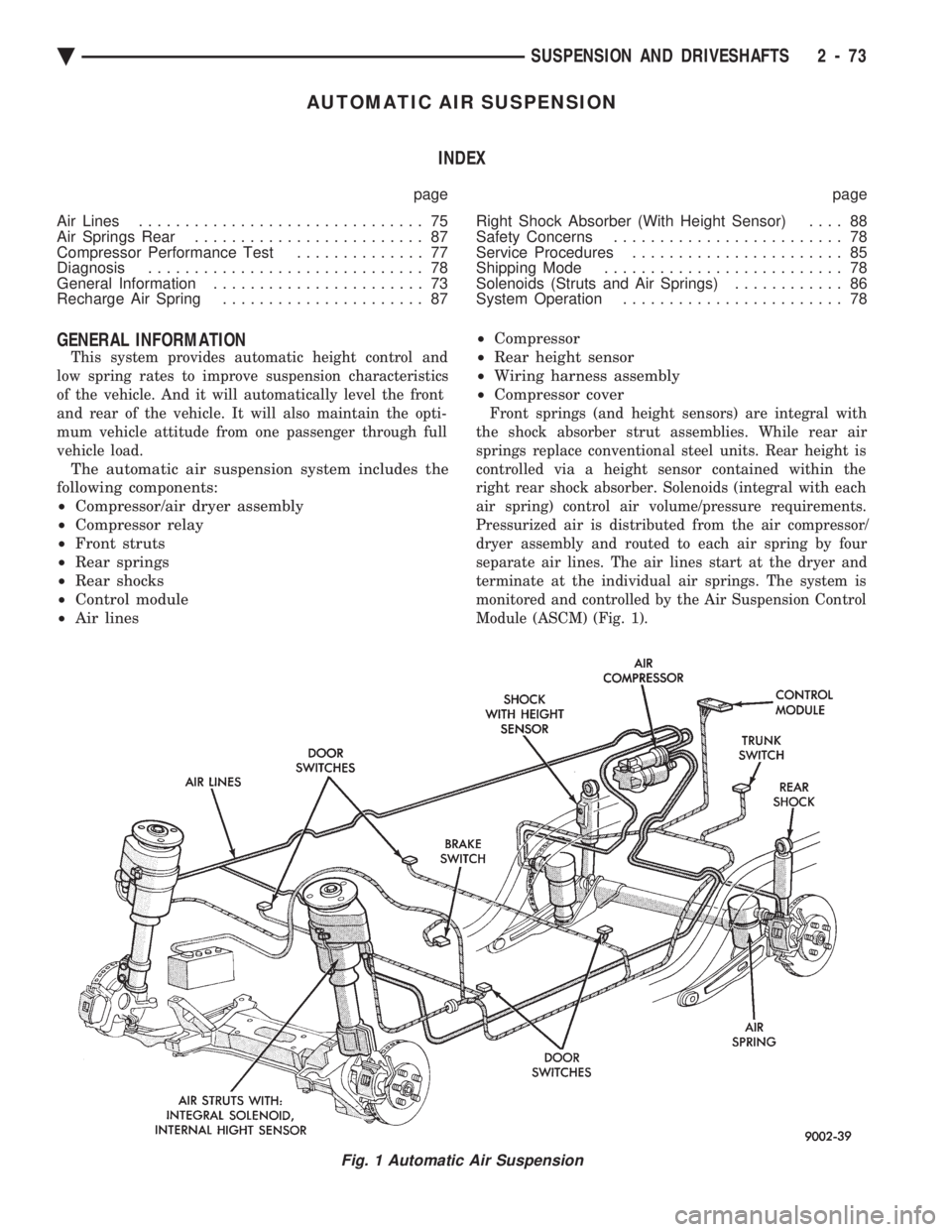

GENERAL INFORMATION

This system provides automatic height control and

low spring rates to improve suspension characteristics

of the vehicle. And it will automatically level the front

and rear of the vehicle. It will also maintain the opti-

mum vehicle attitude from one passenger through full

vehicle load.

The automatic air suspension system includes the

following components:

² Compressor/air dryer assembly

² Compressor relay

² Front struts

² Rear springs

² Rear shocks

² Control module

² Air lines ²

Compressor

² Rear height sensor

² Wiring harness assembly

² Compressor cover

Front springs (and height sensors) are integral with

the shock absorber strut assemblies. While rear air

springs replace conventional steel units. Rear height is

controlled via a height sensor contained within the

right rear shock absorber. Solenoids (integral with each

air spring) control air volume/pressure requirements.

Pressurized air is distributed from the air compressor/

dryer assembly and routed to each air spring by four

separate air lines. The air lines start at the dryer and

terminate at the individual air springs. The system is

monitored and controlled by the Air Suspension Control

Module (ASCM) (Fig. 1).

Fig. 1 Automatic Air Suspension

Ä SUSPENSION AND DRIVESHAFTS 2 - 73

Page 132 of 2438

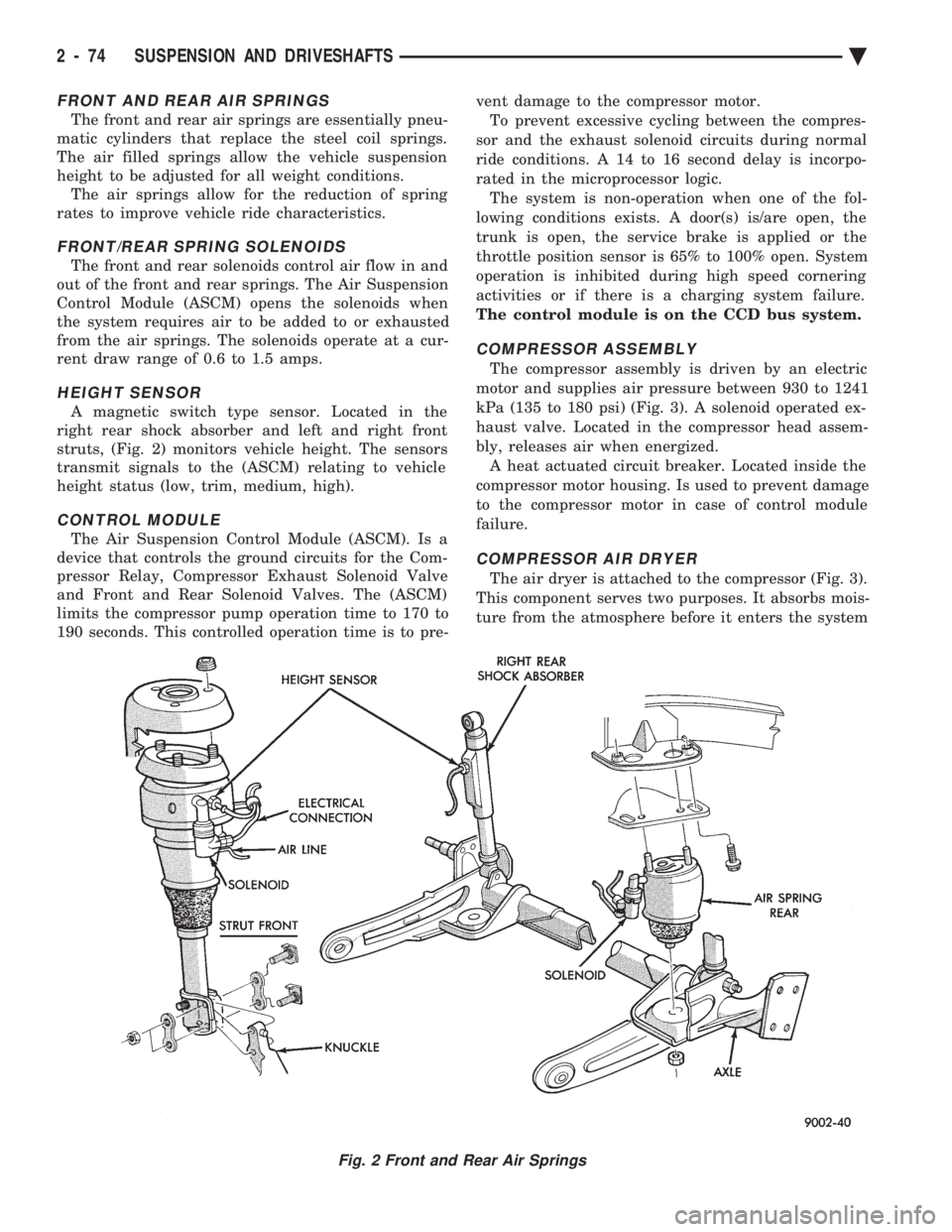

FRONT AND REAR AIR SPRINGS

The front and rear air springs are essentially pneu-

matic cylinders that replace the steel coil springs.

The air filled springs allow the vehicle suspension

height to be adjusted for all weight conditions. The air springs allow for the reduction of spring

rates to improve vehicle ride characteristics.

FRONT/REAR SPRING SOLENOIDS

The front and rear solenoids control air flow in and

out of the front and rear springs. The Air Suspension

Control Module (ASCM) opens the solenoids when

the system requires air to be added to or exhausted

from the air springs. The solenoids operate at a cur-

rent draw range of 0.6 to 1.5 amps.

HEIGHT SENSOR

A magnetic switch type sensor. Located in the

right rear shock absorber and left and right front

struts, (Fig. 2) monitors vehicle height. The sensors

transmit signals to the (ASCM) relating to vehicle

height status (low, trim, medium, high).

CONTROL MODULE

The Air Suspension Control Module (ASCM). Is a

device that controls the ground circuits for the Com-

pressor Relay, Compressor Exhaust Solenoid Valve

and Front and Rear Solenoid Valves. The (ASCM)

limits the compressor pump operation time to 170 to

190 seconds. This controlled operation time is to pre- vent damage to the compressor motor.

To prevent excessive cycling between the compres-

sor and the exhaust solenoid circuits during normal

ride conditions. A 14 to 16 second delay is incorpo-

rated in the microprocessor logic. The system is non-operation when one of the fol-

lowing conditions exists. A door(s) is/are open, the

trunk is open, the service brake is applied or the

throttle position sensor is 65% to 100% open. System

operation is inhibited during high speed cornering

activities or if there is a charging system failure.

The control module is on the CCD bus system.

COMPRESSOR ASSEMBLY

The compressor assembly is driven by an electric

motor and supplies air pressure between 930 to 1241

kPa (135 to 180 psi) (Fig. 3). A solenoid operated ex-

haust valve. Located in the compressor head assem-

bly, releases air when energized. A heat actuated circuit breaker. Located inside the

compressor motor housing. Is used to prevent damage

to the compressor motor in case of control module

failure.

COMPRESSOR AIR DRYER

The air dryer is attached to the compressor (Fig. 3).

This component serves two purposes. It absorbs mois-

ture from the atmosphere before it enters the system

Fig. 2 Front and Rear Air Springs

2 - 74 SUSPENSION AND DRIVESHAFTS Ä

Page 143 of 2438

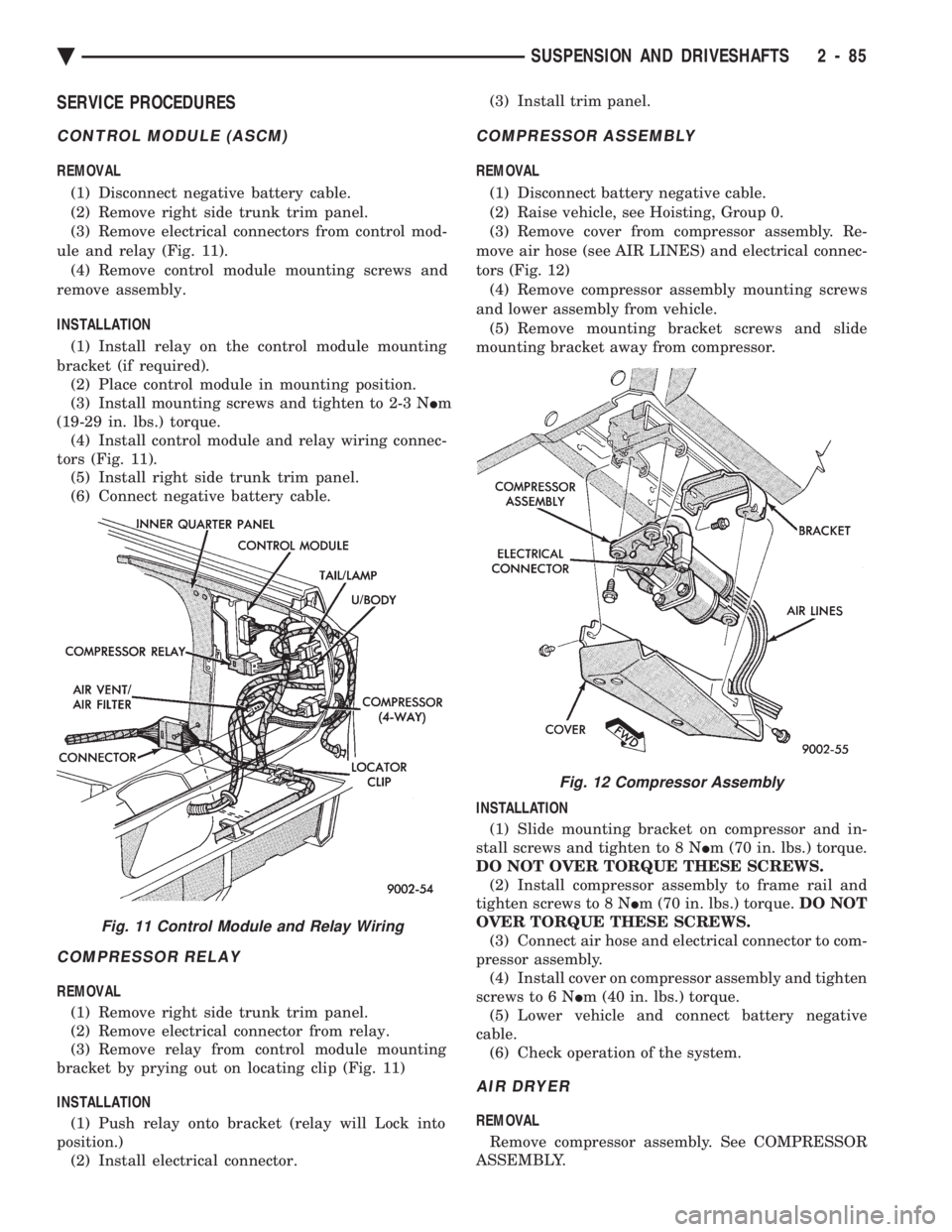

SERVICE PROCEDURES

CONTROL MODULE (ASCM)

REMOVAL (1) Disconnect negative battery cable.

(2) Remove right side trunk trim panel.

(3) Remove electrical connectors from control mod-

ule and relay (Fig. 11). (4) Remove control module mounting screws and

remove assembly.

INSTALLATION

(1) Install relay on the control module mounting

bracket (if required). (2) Place control module in mounting position.

(3) Install mounting screws and tighten to 2-3 N Im

(19-29 in. lbs.) torque. (4) Install control module and relay wiring connec-

tors (Fig. 11). (5) Install right side trunk trim panel.

(6) Connect negative battery cable.

COMPRESSOR RELAY

REMOVAL

(1) Remove right side trunk trim panel.

(2) Remove electrical connector from relay.

(3) Remove relay from control module mounting

bracket by prying out on locating clip (Fig. 11)

INSTALLATION (1) Push relay onto bracket (relay will Lock into

position.) (2) Install electrical connector. (3) Install trim panel.

COMPRESSOR ASSEMBLY

REMOVAL

(1) Disconnect battery negative cable.

(2) Raise vehicle, see Hoisting, Group 0.

(3) Remove cover from compressor assembly. Re-

move air hose (see AIR LINES) and electrical connec-

tors (Fig. 12) (4) Remove compressor assembly mounting screws

and lower assembly from vehicle. (5) Remove mounting bracket screws and slide

mounting bracket away from compressor.

INSTALLATION (1) Slide mounting bracket on compressor and in-

stall screws and tighten to 8 N Im (70 in. lbs.) torque.

DO NOT OVER TORQUE THESE SCREWS. (2) Install compressor assembly to frame rail and

tighten screws to 8 N Im (70 in. lbs.) torque. DO NOT

OVER TORQUE THESE SCREWS. (3) Connect air hose and electrical connector to com-

pressor assembly. (4) Install cover on compressor assembly and tighten

screws to 6 N Im (40 in. lbs.) torque.

(5) Lower vehicle and connect battery negative

cable. (6) Check operation of the system.

AIR DRYER

REMOVAL

Remove compressor assembly. See COMPRESSOR

ASSEMBLY.

Fig. 11 Control Module and Relay Wiring

Fig. 12 Compressor Assembly

Ä SUSPENSION AND DRIVESHAFTS 2 - 85

Page 222 of 2438

ANTI-LOCK BRAKE SYSTEMÐBENDIX ANTI-LOCK 10 AC/Y BODY INDEX

page page

ABS Brake System Diagnostic Features ....... 92

ABS Braking System Diagnosis .............. 87

ABS Controller Anti-Lock Brake (CAB) Service Precautions ........................... 88

ABS Equipped Vehicle Performance .......... 75

ABS Hydraulic Circuits and Valve Operation .... 85

ABS System Diagnostic Connector ........... 82

ABS System General Service Precautions ...... 88

ABS System Self-Diagnostics ............... 75

ABS Warning Systems Operation ............ 75

Anti-Lock Brake System Components ......... 76 Anti-Lock Brake System Definitions

........... 72

Anti-Lock Operation and Performance ......... 73

Anti-Lock System Relays and Warning Lamps . . . 82

Controller Anti-Lock Brake (CAB) ............. 80

Electronic Components ................... 103

General Information ....................... 72

General Service Precautions ................ 93

Major ABS Components ................... 73

Mechanical Diagnostics and Service Procedures . 89

Normal Braking System Function ............. 72

On Car Hydraulic ABS Component Service ..... 93

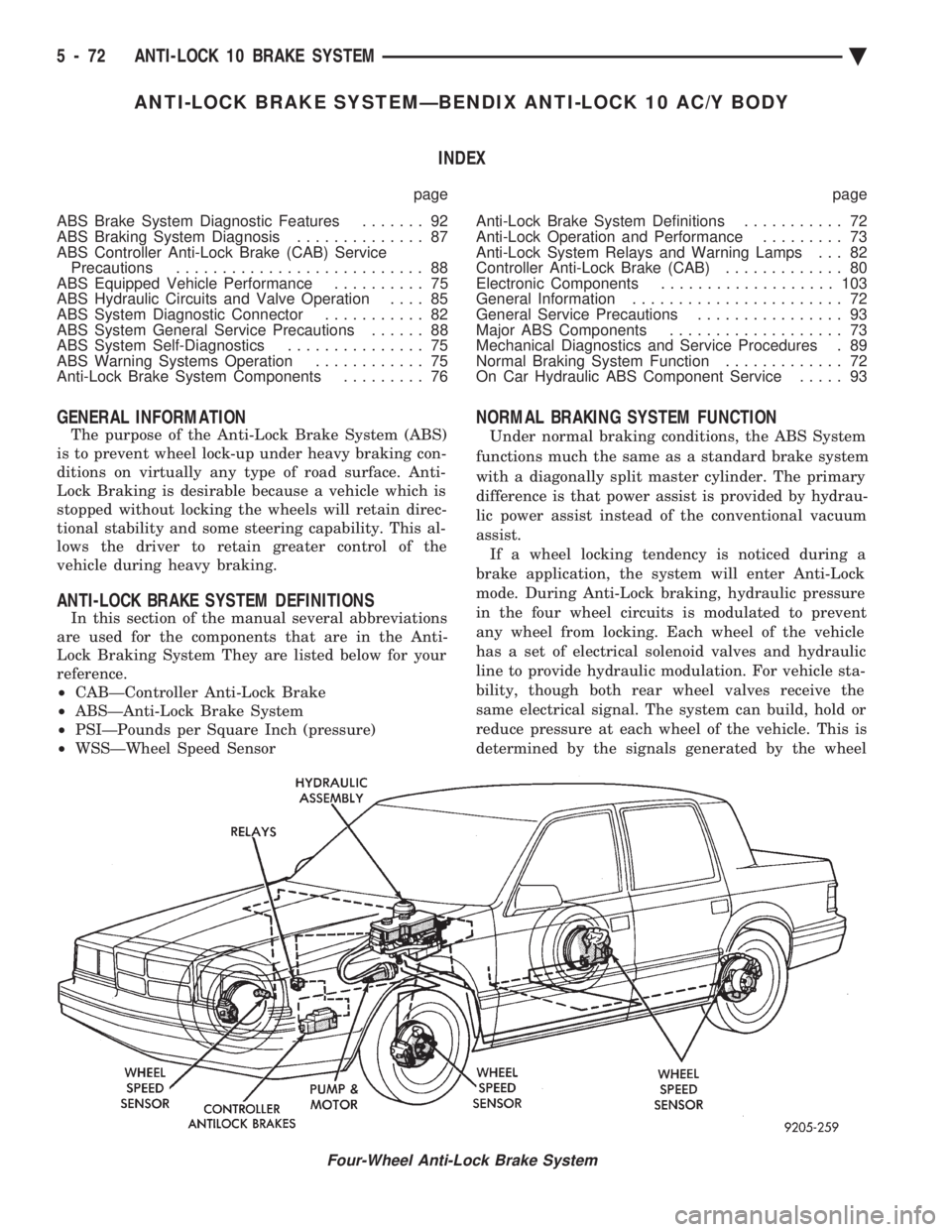

GENERAL INFORMATION

The purpose of the Anti-Lock Brake System (ABS)

is to prevent wheel lock-up under heavy braking con-

ditions on virtually any type of road surface. Anti-

Lock Braking is desirable because a vehicle which is

stopped without locking the wheels will retain direc-

tional stability and some steering capability. This al-

lows the driver to retain greater control of the

vehicle during heavy braking.

ANTI-LOCK BRAKE SYSTEM DEFINITIONS

In this section of the manual several abbreviations

are used for the components that are in the Anti-

Lock Braking System They are listed below for your

reference.

² CABÐController Anti-Lock Brake

² ABSÐAnti-Lock Brake System

² PSIÐPounds per Square Inch (pressure)

² WSSÐWheel Speed Sensor

NORMAL BRAKING SYSTEM FUNCTION

Under normal braking conditions, the ABS System

functions much the same as a standard brake system

with a diagonally split master cylinder. The primary

difference is that power assist is provided by hydrau-

lic power assist instead of the conventional vacuum

assist. If a wheel locking tendency is noticed during a

brake application, the system will enter Anti-Lock

mode. During Anti-Lock braking, hydraulic pressure

in the four wheel circuits is modulated to prevent

any wheel from locking. Each wheel of the vehicle

has a set of electrical solenoid valves and hydraulic

line to provide hydraulic modulation. For vehicle sta-

bility, though both rear wheel valves receive the

same electrical signal. The system can build, hold or

reduce pressure at each wheel of the vehicle. This is

determined by the signals generated by the wheel

Four-Wheel Anti-Lock Brake System

5 - 72 ANTI-LOCK 10 BRAKE SYSTEM Ä

Page 227 of 2438

circuits are hydraulically isolated so a leak or mal-

function in one circuit will allow continued braking

ability in the other.When force is applied to the brake pedal, the input

pushrod applies force to the boost control valve. As

the boost control valve is moved, it allows the pres-

surized fluid from the accumulator to flow into the

master cylinder booster chamber. The pressure gen-

erated in the booster chamber is directly propor-

tioned to the brake pedal force exerted by the driver.

This pressure in the booster servo in turn applies

pressure to the primary master cylinder piston that

in turn applies pressure to the secondary master cyl-

inder piston. The pressure generated in the primary

and secondary circuits are used to apply the brakes

during normal braking.

WARNING: THE HYDRAULIC ACCUMULATORS

CONTAIN BRAKE FLUID AND NITROGEN GAS AT

HIGH PRESSURE. CERTAIN PORTIONS OF THE

BRAKE SYSTEM ALSO CONTAIN BRAKE FLUID AT

HIGH PRESSURE. REMOVAL OR DISASSEMBLY

MAY RESULT IN PERSONAL INJURY AND IM-

PROPER SYSTEM OPERATION. REFER TO THE AP-

PROPRIATE SERVICE MANUAL FOR PROPER

SERVICE PROCEDURES.

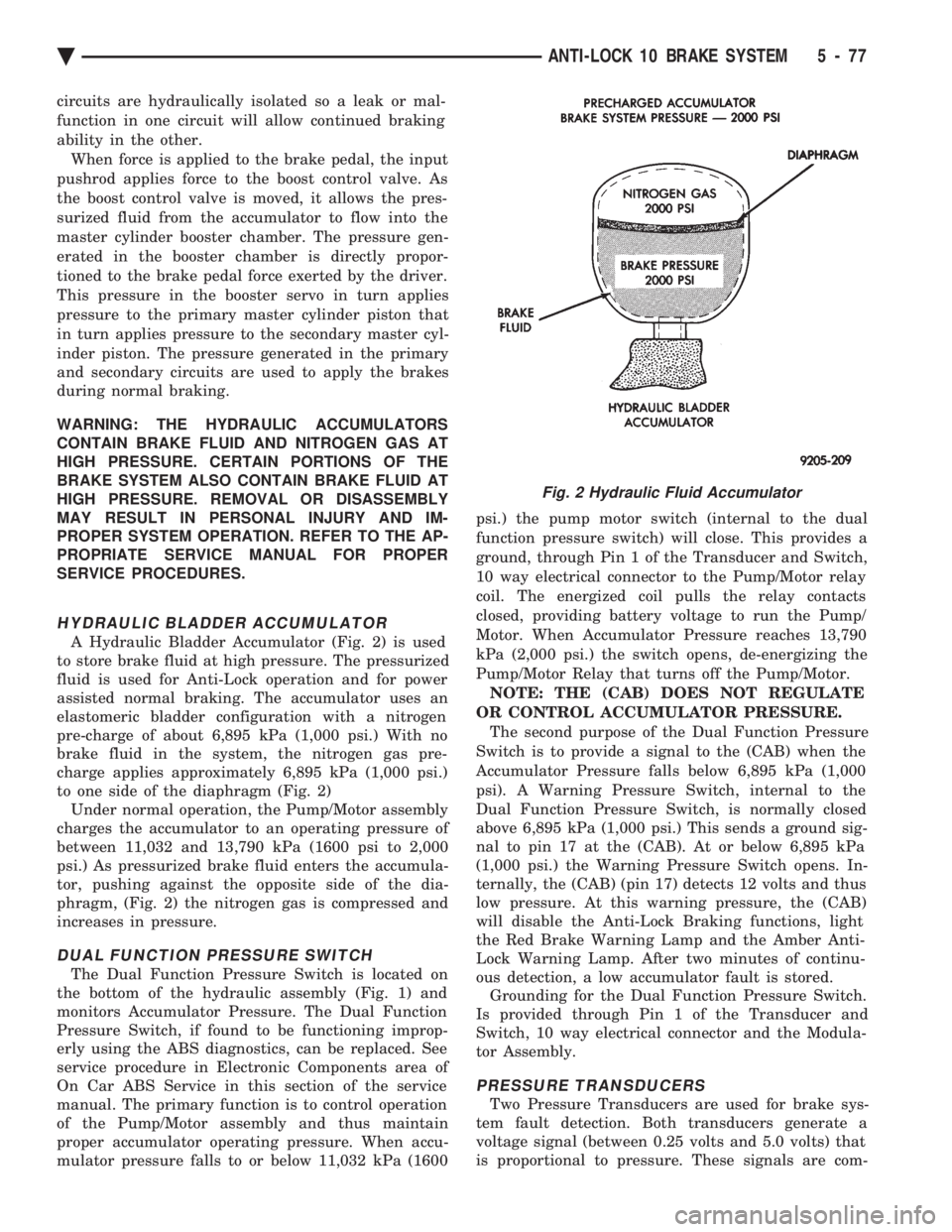

HYDRAULIC BLADDER ACCUMULATOR

A Hydraulic Bladder Accumulator (Fig. 2) is used

to store brake fluid at high pressure. The pressurized

fluid is used for Anti-Lock operation and for power

assisted normal braking. The accumulator uses an

elastomeric bladder configuration with a nitrogen

pre-charge of about 6,895 kPa (1,000 psi.) With no

brake fluid in the system, the nitrogen gas pre-

charge applies approximately 6,895 kPa (1,000 psi.)

to one side of the diaphragm (Fig. 2) Under normal operation, the Pump/Motor assembly

charges the accumulator to an operating pressure of

between 11,032 and 13,790 kPa (1600 psi to 2,000

psi.) As pressurized brake fluid enters the accumula-

tor, pushing against the opposite side of the dia-

phragm, (Fig. 2) the nitrogen gas is compressed and

increases in pressure.

DUAL FUNCTION PRESSURE SWITCH

The Dual Function Pressure Switch is located on

the bottom of the hydraulic assembly (Fig. 1) and

monitors Accumulator Pressure. The Dual Function

Pressure Switch, if found to be functioning improp-

erly using the ABS diagnostics, can be replaced. See

service procedure in Electronic Components area of

On Car ABS Service in this section of the service

manual. The primary function is to control operation

of the Pump/Motor assembly and thus maintain

proper accumulator operating pressure. When accu-

mulator pressure falls to or below 11,032 kPa (1600 psi.) the pump motor switch (internal to the dual

function pressure switch) will close. This provides a

ground, through Pin 1 of the Transducer and Switch,

10 way electrical connector to the Pump/Motor relay

coil. The energized coil pulls the relay contacts

closed, providing battery voltage to run the Pump/

Motor. When Accumulator Pressure reaches 13,790

kPa (2,000 psi.) the switch opens, de-energizing the

Pump/Motor Relay that turns off the Pump/Motor. NOTE: THE (CAB) DOES NOT REGULATE

OR CONTROL ACCUMULATOR PRESSURE. The second purpose of the Dual Function Pressure

Switch is to provide a signal to the (CAB) when the

Accumulator Pressure falls below 6,895 kPa (1,000

psi). A Warning Pressure Switch, internal to the

Dual Function Pressure Switch, is normally closed

above 6,895 kPa (1,000 psi.) This sends a ground sig-

nal to pin 17 at the (CAB). At or below 6,895 kPa

(1,000 psi.) the Warning Pressure Switch opens. In-

ternally, the (CAB) (pin 17) detects 12 volts and thus

low pressure. At this warning pressure, the (CAB)

will disable the Anti-Lock Braking functions, light

the Red Brake Warning Lamp and the Amber Anti-

Lock Warning Lamp. After two minutes of continu-

ous detection, a low accumulator fault is stored. Grounding for the Dual Function Pressure Switch.

Is provided through Pin 1 of the Transducer and

Switch, 10 way electrical connector and the Modula-

tor Assembly.

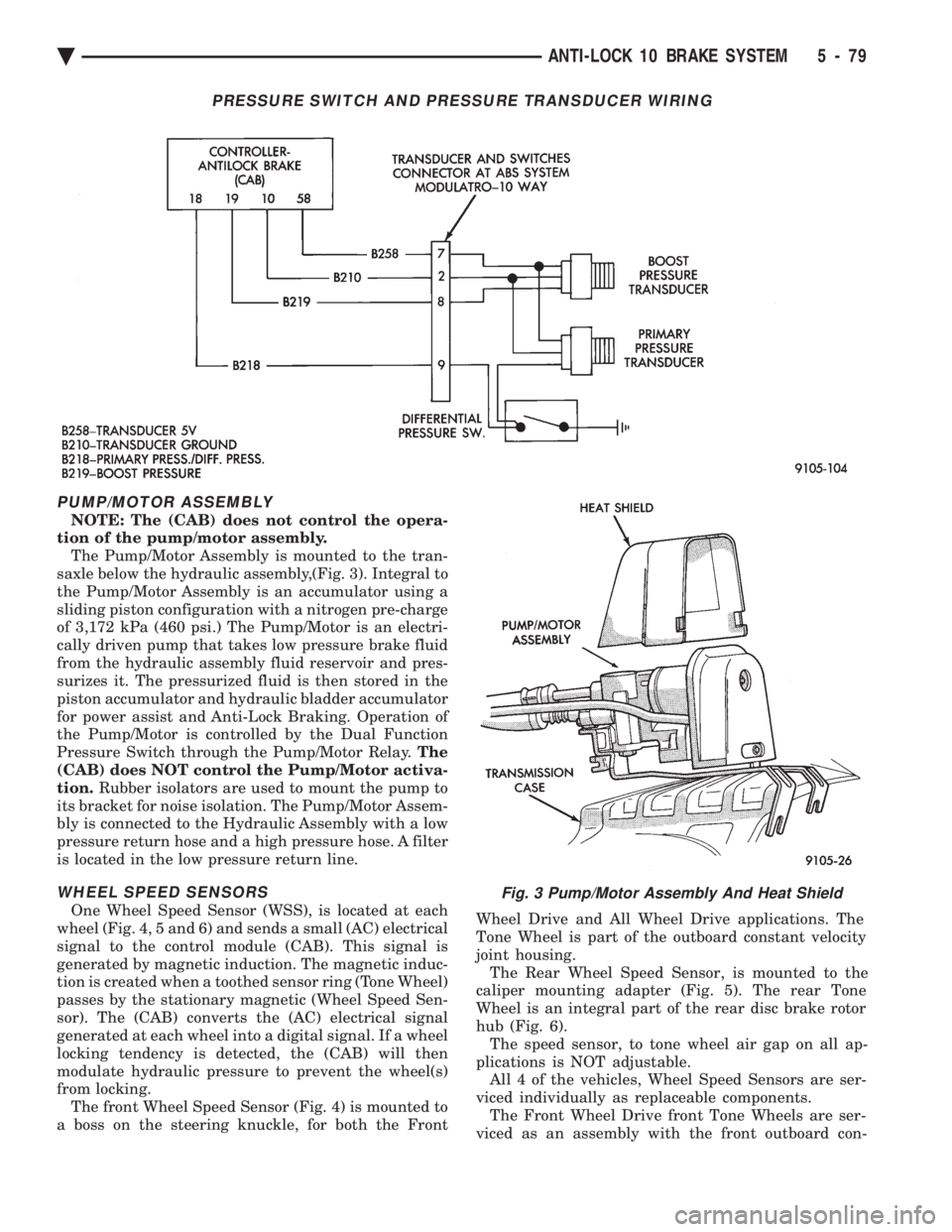

PRESSURE TRANSDUCERS

Two Pressure Transducers are used for brake sys-

tem fault detection. Both transducers generate a

voltage signal (between 0.25 volts and 5.0 volts) that

is proportional to pressure. These signals are com-

Fig. 2 Hydraulic Fluid Accumulator

Ä ANTI-LOCK 10 BRAKE SYSTEM 5 - 77

Page 229 of 2438

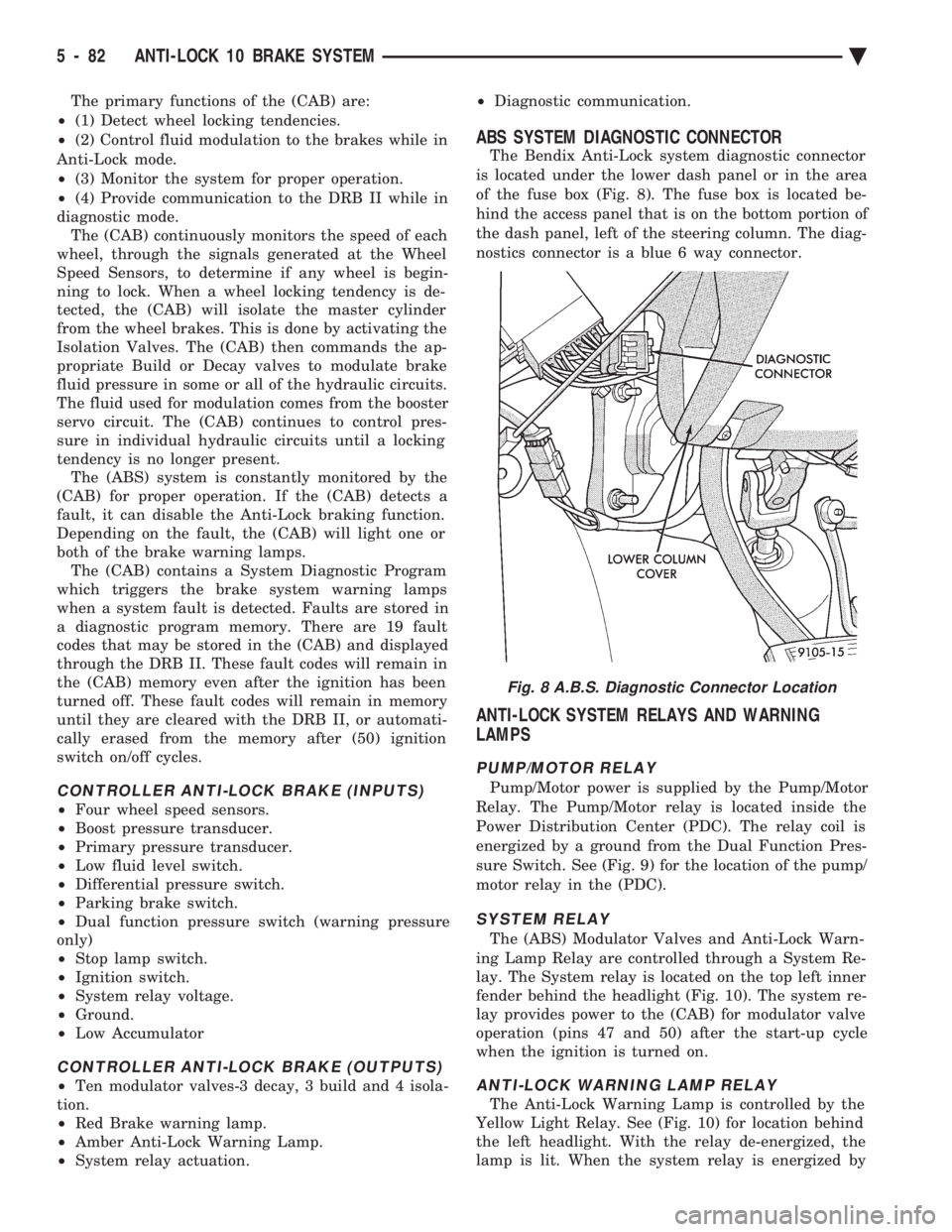

PUMP/MOTOR ASSEMBLY

NOTE: The (CAB) does not control the opera-

tion of the pump/motor assembly. The Pump/Motor Assembly is mounted to the tran-

saxle below the hydraulic assembly,(Fig. 3). Integral to

the Pump/Motor Assembly is an accumulator using a

sliding piston configuration with a nitrogen pre-charge

of 3,172 kPa (460 psi.) The Pump/Motor is an electri-

cally driven pump that takes low pressure brake fluid

from the hydraulic assembly fluid reservoir and pres-

surizes it. The pressurized fluid is then stored in the

piston accumulator and hydraulic bladder accumulator

for power assist and Anti-Lock Braking. Operation of

the Pump/Motor is controlled by the Dual Function

Pressure Switch through the Pump/Motor Relay. The

(CAB) does NOT control the Pump/Motor activa-

tion. Rubber isolators are used to mount the pump to

its bracket for noise isolation. The Pump/Motor Assem-

bly is connected to the Hydraulic Assembly with a low

pressure return hose and a high pressure hose. A filter

is located in the low pressure return line.

WHEEL SPEED SENSORS

One Wheel Speed Sensor (WSS), is located at each

wheel (Fig. 4, 5 and 6) and sends a small (AC) electrical

signal to the control module (CAB). This signal is

generated by magnetic induction. The magnetic induc-

tion is created when a toothed sensor ring (Tone Wheel)

passes by the stationary magnetic (Wheel Speed Sen-

sor). The (CAB) converts the (AC) electrical signal

generated at each wheel into a digital signal. If a wheel

locking tendency is detected, the (CAB) will then

modulate hydraulic pressure to prevent the wheel(s)

from locking. The front Wheel Speed Sensor (Fig. 4) is mounted to

a boss on the steering knuckle, for both the Front Wheel Drive and All Wheel Drive applications. The

Tone Wheel is part of the outboard constant velocity

joint housing. The Rear Wheel Speed Sensor, is mounted to the

caliper mounting adapter (Fig. 5). The rear Tone

Wheel is an integral part of the rear disc brake rotor

hub (Fig. 6). The speed sensor, to tone wheel air gap on all ap-

plications is NOT adjustable. All 4 of the vehicles, Wheel Speed Sensors are ser-

viced individually as replaceable components. The Front Wheel Drive front Tone Wheels are ser-

viced as an assembly with the front outboard con-

Fig. 3 Pump/Motor Assembly And Heat Shield

PRESSURE SWITCH AND PRESSURE TRANSDUCER WIRING

Ä ANTI-LOCK 10 BRAKE SYSTEM 5 - 79

Page 232 of 2438

The primary functions of the (CAB) are:

² (1) Detect wheel locking tendencies.

² (2) Control fluid modulation to the brakes while in

Anti-Lock mode.

² (3) Monitor the system for proper operation.

² (4) Provide communication to the DRB II while in

diagnostic mode. The (CAB) continuously monitors the speed of each

wheel, through the signals generated at the Wheel

Speed Sensors, to determine if any wheel is begin-

ning to lock. When a wheel locking tendency is de-

tected, the (CAB) will isolate the master cylinder

from the wheel brakes. This is done by activating the

Isolation Valves. The (CAB) then commands the ap-

propriate Build or Decay valves to modulate brake

fluid pressure in some or all of the hydraulic circuits.

The fluid used for modulation comes from the booster

servo circuit. The (CAB) continues to control pres-

sure in individual hydraulic circuits until a locking

tendency is no longer present. The (ABS) system is constantly monitored by the

(CAB) for proper operation. If the (CAB) detects a

fault, it can disable the Anti-Lock braking function.

Depending on the fault, the (CAB) will light one or

both of the brake warning lamps. The (CAB) contains a System Diagnostic Program

which triggers the brake system warning lamps

when a system fault is detected. Faults are stored in

a diagnostic program memory. There are 19 fault

codes that may be stored in the (CAB) and displayed

through the DRB II. These fault codes will remain in

the (CAB) memory even after the ignition has been

turned off. These fault codes will remain in memory

until they are cleared with the DRB II, or automati-

cally erased from the memory after (50) ignition

switch on/off cycles.

CONTROLLER ANTI-LOCK BRAKE (INPUTS)

² Four wheel speed sensors.

² Boost pressure transducer.

² Primary pressure transducer.

² Low fluid level switch.

² Differential pressure switch.

² Parking brake switch.

² Dual function pressure switch (warning pressure

only)

² Stop lamp switch.

² Ignition switch.

² System relay voltage.

² Ground.

² Low Accumulator

CONTROLLER ANTI-LOCK BRAKE (OUTPUTS)

²Ten modulator valves-3 decay, 3 build and 4 isola-

tion.

² Red Brake warning lamp.

² Amber Anti-Lock Warning Lamp.

² System relay actuation. ²

Diagnostic communication.

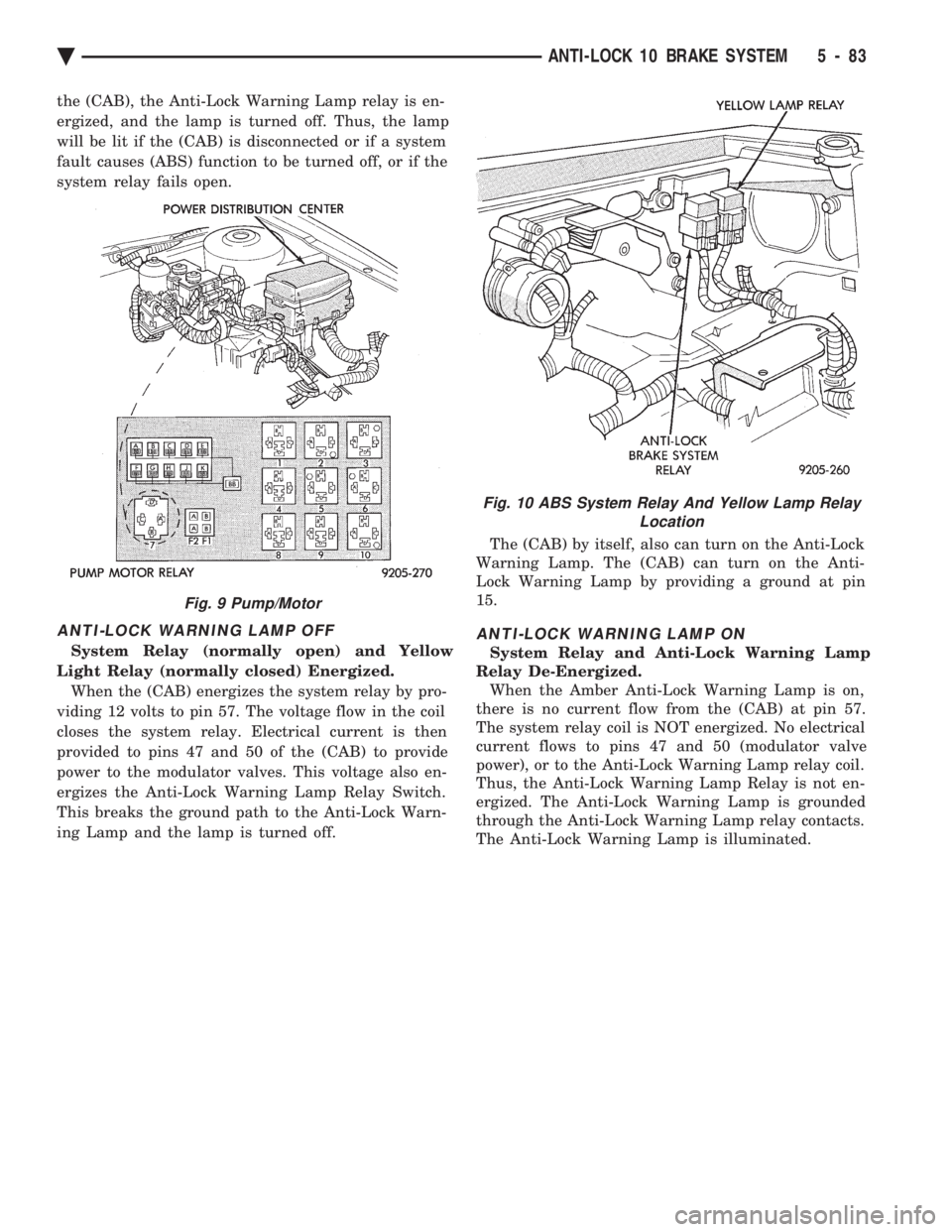

ABS SYSTEM DIAGNOSTIC CONNECTOR

The Bendix Anti-Lock system diagnostic connector

is located under the lower dash panel or in the area

of the fuse box (Fig. 8). The fuse box is located be-

hind the access panel that is on the bottom portion of

the dash panel, left of the steering column. The diag-

nostics connector is a blue 6 way connector.

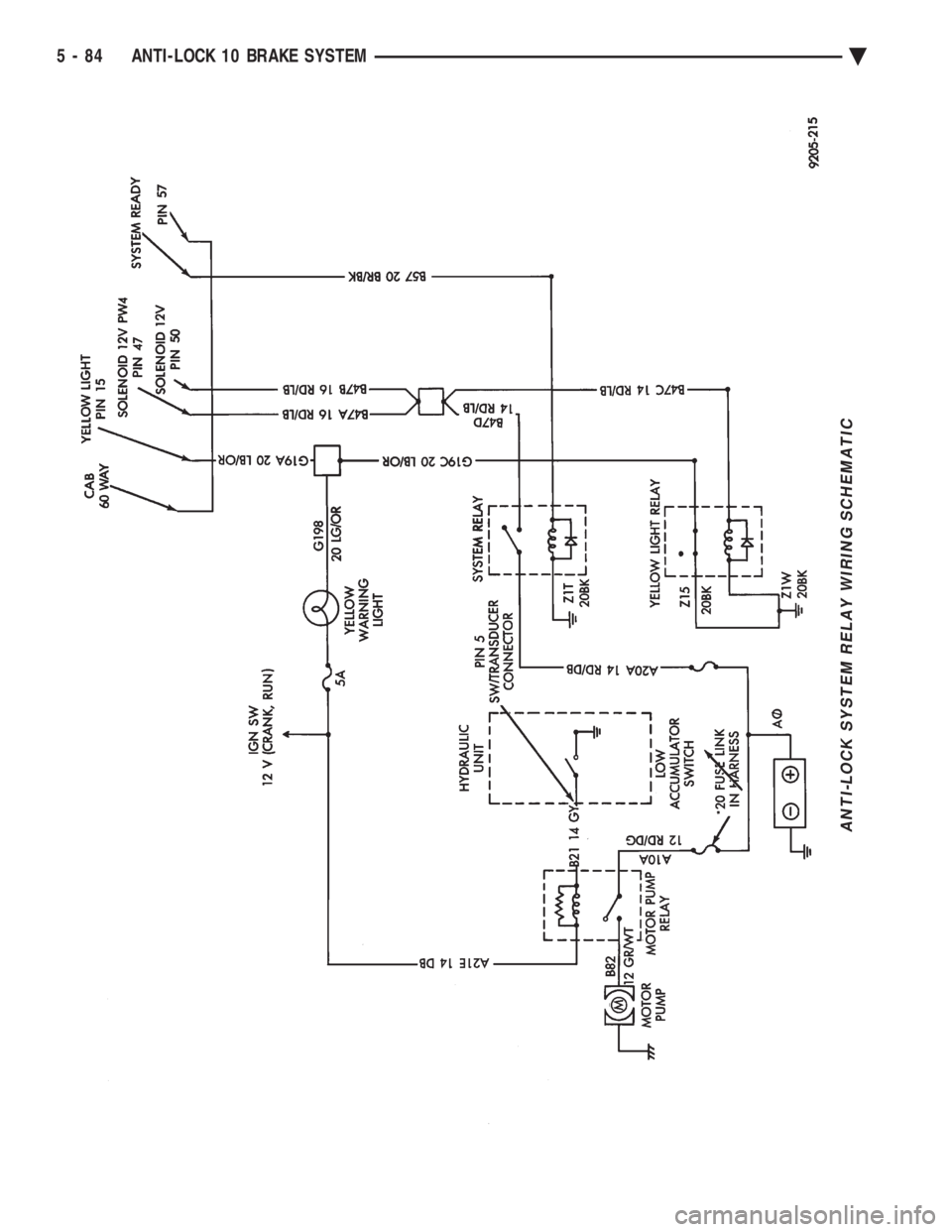

ANTI-LOCK SYSTEM RELAYS AND WARNING

LAMPS

PUMP/MOTOR RELAY

Pump/Motor power is supplied by the Pump/Motor

Relay. The Pump/Motor relay is located inside the

Power Distribution Center (PDC). The relay coil is

energized by a ground from the Dual Function Pres-

sure Switch. See (Fig. 9) for the location of the pump/

motor relay in the (PDC).

SYSTEM RELAY

The (ABS) Modulator Valves and Anti-Lock Warn-

ing Lamp Relay are controlled through a System Re-

lay. The System relay is located on the top left inner

fender behind the headlight (Fig. 10). The system re-

lay provides power to the (CAB) for modulator valve

operation (pins 47 and 50) after the start-up cycle

when the ignition is turned on.

ANTI-LOCK WARNING LAMP RELAY

The Anti-Lock Warning Lamp is controlled by the

Yellow Light Relay. See (Fig. 10) for location behind

the left headlight. With the relay de-energized, the

lamp is lit. When the system relay is energized by

Fig. 8 A.B.S. Diagnostic Connector Location

5 - 82 ANTI-LOCK 10 BRAKE SYSTEM Ä

Page 233 of 2438

the (CAB), the Anti-Lock Warning Lamp relay is en-

ergized, and the lamp is turned off. Thus, the lamp

will be lit if the (CAB) is disconnected or if a system

fault causes (ABS) function to be turned off, or if the

system relay fails open.

ANTI-LOCK WARNING LAMP OFF

System Relay (normally open) and Yellow

Light Relay (normally closed) Energized. When the (CAB) energizes the system relay by pro-

viding 12 volts to pin 57. The voltage flow in the coil

closes the system relay. Electrical current is then

provided to pins 47 and 50 of the (CAB) to provide

power to the modulator valves. This voltage also en-

ergizes the Anti-Lock Warning Lamp Relay Switch.

This breaks the ground path to the Anti-Lock Warn-

ing Lamp and the lamp is turned off. The (CAB) by itself, also can turn on the Anti-Lock

Warning Lamp. The (CAB) can turn on the Anti-

Lock Warning Lamp by providing a ground at pin

15.

ANTI-LOCK WARNING LAMP ON

System Relay and Anti-Lock Warning Lamp

Relay De-Energized. When the Amber Anti-Lock Warning Lamp is on,

there is no current flow from the (CAB) at pin 57.

The system relay coil is NOT energized. No electrical

current flows to pins 47 and 50 (modulator valve

power), or to the Anti-Lock Warning Lamp relay coil.

Thus, the Anti-Lock Warning Lamp Relay is not en-

ergized. The Anti-Lock Warning Lamp is grounded

through the Anti-Lock Warning Lamp relay contacts.

The Anti-Lock Warning Lamp is illuminated.

Fig. 9 Pump/Motor

Fig. 10 ABS System Relay And Yellow Lamp Relay Location

Ä ANTI-LOCK 10 BRAKE SYSTEM 5 - 83

Page 234 of 2438

ANTI-LOCK SYSTEM RELAY WIRING SCHEMATIC

5 - 84 ANTI-LOCK 10 BRAKE SYSTEM Ä

Page 242 of 2438

(11) Remove all special tools previously installed,

from the ABS hydraulic assembly. (12) Install accumulator port plug into hydraulic

assembly. Torque accumulator port plug to 12 N Im(9

ft. lbs.). (13) Install high pressure brake hose from the

pump motor assembly into hydraulic fitting on ABS

hydraulic assembly. Torque high pressure brake hose

tube nut to 16 N Im (145 in. lbs.).

(14) Turn ignition switch to the run position to en-

ergize the pump/motor assembly and pressurize hy-

draulic system. Check for leakage at the hydraulic

assembly to hydraulic bladder accumulator fitting. (15) Again de-pressurize accumulator by pumping

brake pedal a minimum of 40 times. Use procedure

described in De-Pressurizing Hydraulic Accumulator

in this section of the service manual. (16) Then check the brake fluid level in the hy-

draulic assembly reservoir. If brake fluid level is low,

fill reservoir to proper level with Mopar tbrake fluid

or equivalent conforming to DOT 3 requirements.

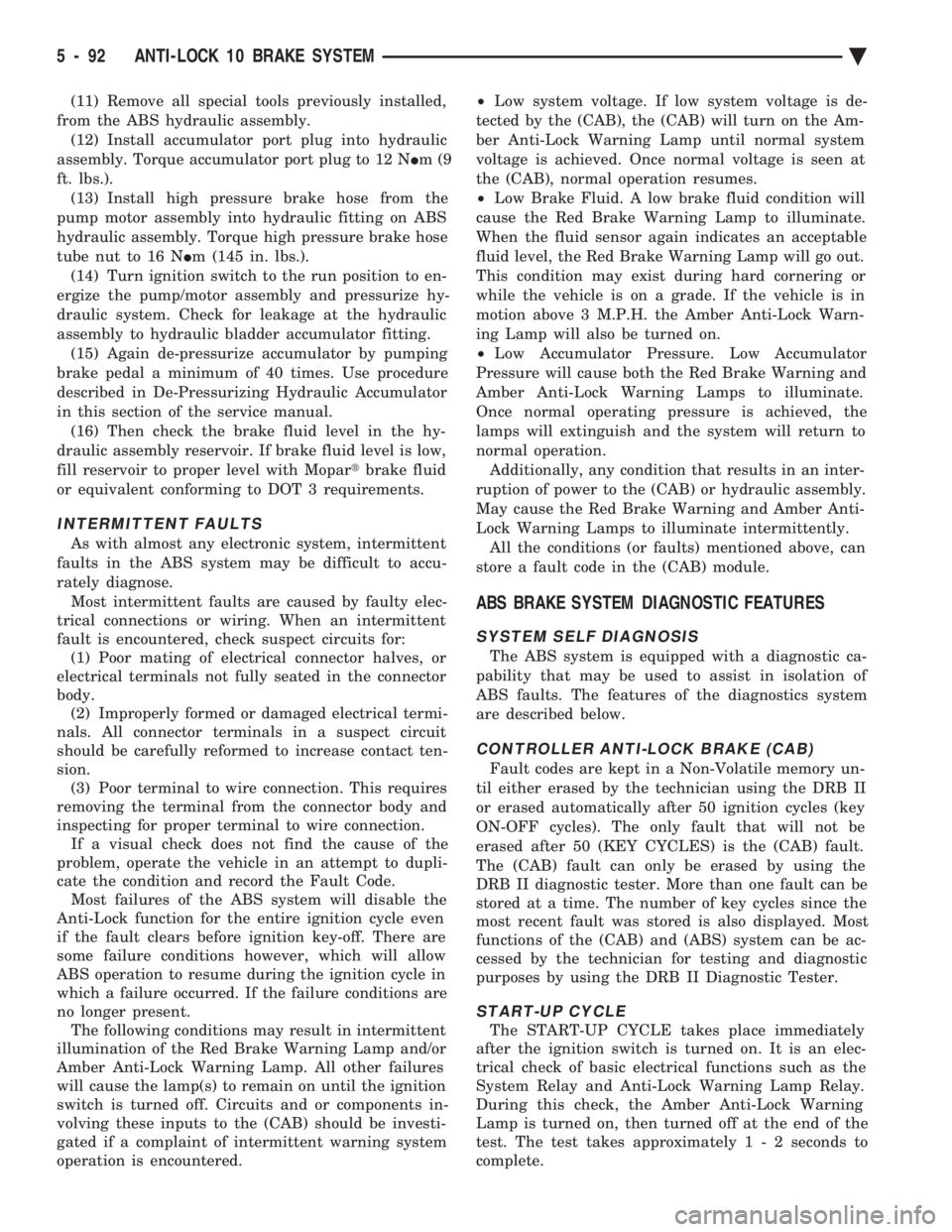

INTERMITTENT FAULTS

As with almost any electronic system, intermittent

faults in the ABS system may be difficult to accu-

rately diagnose. Most intermittent faults are caused by faulty elec-

trical connections or wiring. When an intermittent

fault is encountered, check suspect circuits for: (1) Poor mating of electrical connector halves, or

electrical terminals not fully seated in the connector

body. (2) Improperly formed or damaged electrical termi-

nals. All connector terminals in a suspect circuit

should be carefully reformed to increase contact ten-

sion. (3) Poor terminal to wire connection. This requires

removing the terminal from the connector body and

inspecting for proper terminal to wire connection. If a visual check does not find the cause of the

problem, operate the vehicle in an attempt to dupli-

cate the condition and record the Fault Code. Most failures of the ABS system will disable the

Anti-Lock function for the entire ignition cycle even

if the fault clears before ignition key-off. There are

some failure conditions however, which will allow

ABS operation to resume during the ignition cycle in

which a failure occurred. If the failure conditions are

no longer present. The following conditions may result in intermittent

illumination of the Red Brake Warning Lamp and/or

Amber Anti-Lock Warning Lamp. All other failures

will cause the lamp(s) to remain on until the ignition

switch is turned off. Circuits and or components in-

volving these inputs to the (CAB) should be investi-

gated if a complaint of intermittent warning system

operation is encountered. ²

Low system voltage. If low system voltage is de-

tected by the (CAB), the (CAB) will turn on the Am-

ber Anti-Lock Warning Lamp until normal system

voltage is achieved. Once normal voltage is seen at

the (CAB), normal operation resumes.

² Low Brake Fluid. A low brake fluid condition will

cause the Red Brake Warning Lamp to illuminate.

When the fluid sensor again indicates an acceptable

fluid level, the Red Brake Warning Lamp will go out.

This condition may exist during hard cornering or

while the vehicle is on a grade. If the vehicle is in

motion above 3 M.P.H. the Amber Anti-Lock Warn-

ing Lamp will also be turned on.

² Low Accumulator Pressure. Low Accumulator

Pressure will cause both the Red Brake Warning and

Amber Anti-Lock Warning Lamps to illuminate.

Once normal operating pressure is achieved, the

lamps will extinguish and the system will return to

normal operation. Additionally, any condition that results in an inter-

ruption of power to the (CAB) or hydraulic assembly.

May cause the Red Brake Warning and Amber Anti-

Lock Warning Lamps to illuminate intermittently. All the conditions (or faults) mentioned above, can

store a fault code in the (CAB) module.

ABS BRAKE SYSTEM DIAGNOSTIC FEATURES

SYSTEM SELF DIAGNOSIS

The ABS system is equipped with a diagnostic ca-

pability that may be used to assist in isolation of

ABS faults. The features of the diagnostics system

are described below.

CONTROLLER ANTI-LOCK BRAKE (CAB)

Fault codes are kept in a Non-Volatile memory un-

til either erased by the technician using the DRB II

or erased automatically after 50 ignition cycles (key

ON-OFF cycles). The only fault that will not be

erased after 50 (KEY CYCLES) is the (CAB) fault.

The (CAB) fault can only be erased by using the

DRB II diagnostic tester. More than one fault can be

stored at a time. The number of key cycles since the

most recent fault was stored is also displayed. Most

functions of the (CAB) and (ABS) system can be ac-

cessed by the technician for testing and diagnostic

purposes by using the DRB II Diagnostic Tester.

START-UP CYCLE

The START-UP CYCLE takes place immediately

after the ignition switch is turned on. It is an elec-

trical check of basic electrical functions such as the

System Relay and Anti-Lock Warning Lamp Relay.

During this check, the Amber Anti-Lock Warning

Lamp is turned on, then turned off at the end of the

test. The test takes approximatel y1-2seconds to

complete.

5 - 92 ANTI-LOCK 10 BRAKE SYSTEM Ä