reset CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 423 of 2438

² To set DAY of WEEK, press TIME button. An ar-

row will appear on the display and point to the Day.

Press and hold the SET button to move the day for-

ward or INFO button to move it backward.

² To set DAY of MONTH, press TIME button. The

arrow will point to Date. Press and hold the SET

button to advance the date or INFO button to move

it backwards.

² To set MONTH of YEAR, press TIME button. The

arrow will point to the Month. Press and hold the

SET button to advance the Month forward or INFO

button to move backward. TEMP button, pressing the Temp button will dis-

play:

² The temperature outside the vehicle

² Vehicle direction define by an eight point compass

If Compass has lost calibration or not receiving

good information from the engine compartment node,

an asterisk (*) will flash on the display and the word

calibrate will appear. Refer to Compass Calibration. FUEL BUTTON, WILL DISPLAY:

² Pressing FUEL button the first time will show, the

estimated number of miles that can be driven with

the remaining fuel. The destination to empty indica-

tion will vary every few seconds as the amount of

fuel and fuel efficiency is calculated. This function

can not be reset.

² Pressing the FUEL button second time; will dis-

play the fuel consumed.

²

Pressing the FUEL button third time; will display

the average fuel economy in miles per gallon since last

reset. The display will be updated every 16 seconds.

² Pressing the FUEL button forth time, the current

fuel economy will be displayed. The current fuel

economy will be up updated every two seconds.

² To reset Fuel consumed, press SET button until

the fuel consumed message is displayed and then

within five seconds press SET button.

² To reset AVERAGE FUEL ECONOMY, press the

FUEL button until average fuel economy is displayed

and within five seconds press SET button. TRIP RESET, press FUEL button and wait four

seconds press the SET button twice. This clears all

trip information and the message Trip Reset will be

displayed. This will occur only if a reset function is

currently being displayed. The reset functions:

² Fuel consumed

² Average fuel economy message

INFO button, will active a MONITORED SYS-

TEMS OK message on display if all monitored sys-

tems are operating properly. If a problem is detected,

the appropriate message will be displayed. SET button, will clear the various functions after

they have been displayed. It is used to enter the

clock set or compass variance modes. This button is

also used to reset certain trip computer functions and

the maintenance reminder message.

The EVIC display may be turned off by pressing the

TIME and SET buttons at the same time. Pressing the

buttons a second time will restore the display.

EVIC INFORMATION SOURCES

The EVIC monitors information provided by the

body controller, engine compartment node and pow-

ertrain control module. Refer to Body Diagnostic Test

Procedure Manual for test procedures. The Body Controller is a micro-controller unit

which, informs the EVIC overhead console via the

CCD bus of:

² Time of day

² Day of week

² Day of month

² Month of year

² Fuel range

² Fuel consumed

² Fuel efficiency

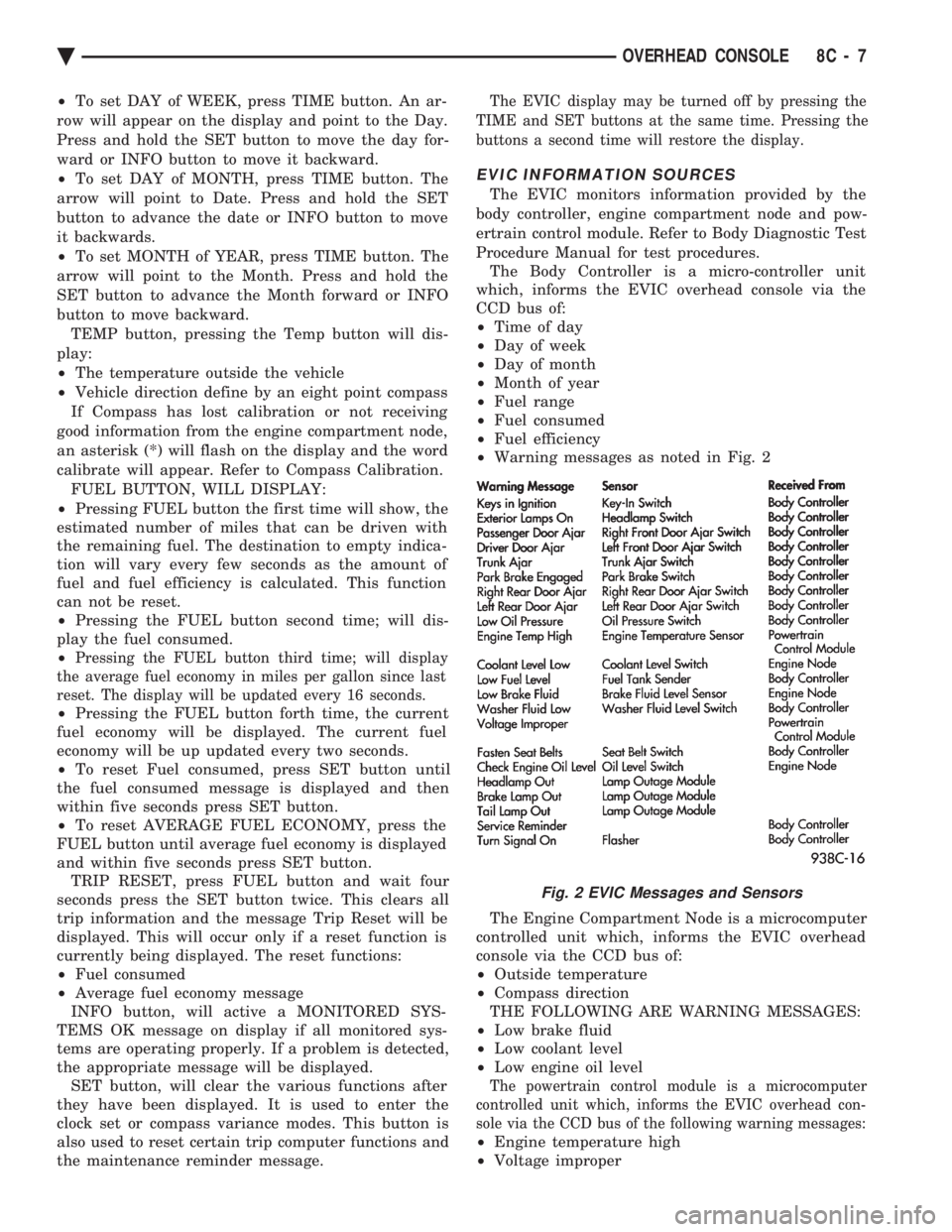

² Warning messages as noted in Fig. 2

The Engine Compartment Node is a microcomputer

controlled unit which, informs the EVIC overhead

console via the CCD bus of:

² Outside temperature

² Compass direction

THE FOLLOWING ARE WARNING MESSAGES:

² Low brake fluid

² Low coolant level

² Low engine oil level

The powertrain control module is a microcomputer

controlled unit which, informs the EVIC overhead con-

sole via the CCD bus of the following warning messages:

² Engine temperature high

² Voltage improper

Fig. 2 EVIC Messages and Sensors

Ä OVERHEAD CONSOLE 8C - 7

Page 426 of 2438

BUS ACCESSED DIAGNOSTICS

The following diagnostic test may be used to check

the integrity of the EVIC's internal connections and

operations. Refer to the Body Chassis Diagnostic Test

Procedure Manual for test procedures. MODULE RESET TEST, when the EVIC receives

this request from the DRB II, the EVIC will immedi-

ately enter into reset. DISPLAY TEST: The EVIC receives a request from

the DBR II, the EVIC will enter into a visual display

mode. Also checks the integrity of the display driver

to anode connections. The test shall consist of walk-

ing through the vertical and horizontal rows of an-

odes in the dot matrix display. SWITCH STATUS TEST, when the EVIC receives

this request from the DRB II, the EVIC will report

the open/closed status of each individual switch. FAULT BYTE TEST, when the EVIC receives this

request from the DRB II, the EVIC will report fault

status. Messages reported are:

² NO FAULT

² DISPLAY DRIVER FAULT

² EVIC MISSING MESSAGES

² POWER SUPPLY FAILURE

² FAULT IN RAM

² FAULT IN ROM

EVIC missing message implies that there may be a

system failure and/or the body controller is not pro-

viding EVIC with sufficient information. DISPLAY DRIVER FAULT, power supply failure

and fault in RAM/ROM implies that the EVIC is de-

fective.

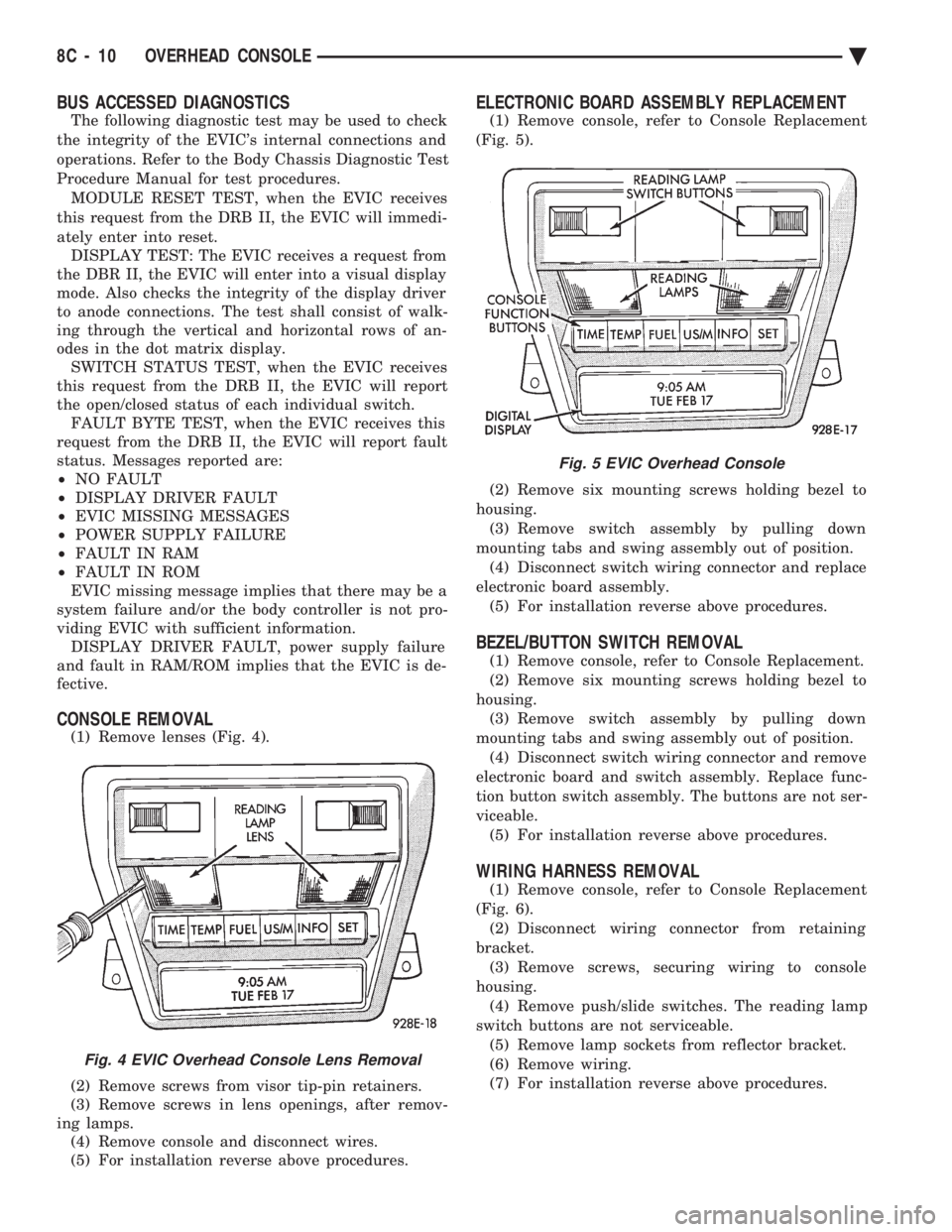

CONSOLE REMOVAL

(1) Remove lenses (Fig. 4).

(2) Remove screws from visor tip-pin retainers.

(3) Remove screws in lens openings, after remov-

ing lamps. (4) Remove console and disconnect wires.

(5) For installation reverse above procedures.

ELECTRONIC BOARD ASSEMBLY REPLACEMENT

(1) Remove console, refer to Console Replacement

(Fig. 5).

(2) Remove six mounting screws holding bezel to

housing. (3) Remove switch assembly by pulling down

mounting tabs and swing assembly out of position. (4) Disconnect switch wiring connector and replace

electronic board assembly. (5) For installation reverse above procedures.

BEZEL/BUTTON SWITCH REMOVAL

(1) Remove console, refer to Console Replacement.

(2) Remove six mounting screws holding bezel to

housing. (3) Remove switch assembly by pulling down

mounting tabs and swing assembly out of position. (4) Disconnect switch wiring connector and remove

electronic board and switch assembly. Replace func-

tion button switch assembly. The buttons are not ser-

viceable. (5) For installation reverse above procedures.

WIRING HARNESS REMOVAL

(1) Remove console, refer to Console Replacement

(Fig. 6). (2) Disconnect wiring connector from retaining

bracket. (3) Remove screws, securing wiring to console

housing. (4) Remove push/slide switches. The reading lamp

switch buttons are not serviceable. (5) Remove lamp sockets from reflector bracket.

(6) Remove wiring.

(7) For installation reverse above procedures.

Fig. 4 EVIC Overhead Console Lens Removal

Fig. 5 EVIC Overhead Console

8C - 10 OVERHEAD CONSOLE Ä

Page 430 of 2438

dition exists. These messages are displayed on the

center of the instrument panel.For complete EVIC operating instructions, refer to

the Owners Manual provided with the vehicle.

EVIC BUTTON FUNCTIONS

TIME button will display:

² Time of day

² Day of week

² Day of month

² Month of year

² To set HOURS, press TIME button and within four

seconds press the SET button. An arrow will appear

on the display and point to the hours. Press and hold

the SET button to advance the hours or INFO button

to set back the hours.

² To set MINUTES, press TIME button. The arrow

will point to the minutes. Press and hold the SET

button to advance the minutes or INFO button to set

back the minutes.

² To set DAY of WEEK, press TIME button. An ar-

row will appear on the display and point to the Day.

Press and hold the SET button to move the day for-

ward or INFO button to move it backward.

² To set DAY of MONTH, press TIME button. The

arrow will point to Date. Press and hold the SET

button to advance the date or INFO button to move

it backwards.

² To set MONTH of YEAR, press TIME button. The

arrow will point to the Month. Press and hold the

SET button to advance the Month forward or INFO

button to move backward. TEMP button, pressing the Temp button will dis-

play:

² The temperature outside the vehicle

² Vehicle direction define by an eight point compass

If Compass has lost calibration or not receiving

good information from the engine compartment node,

an asterisk (*) will flash on the display and the word

calibrate will appear. Refer to Compass Calibration. FUEL BUTTON, WILL DISPLAY:

² Pressing FUEL button the first time will show, the

estimated number of miles that can be driven with

the remaining fuel. The destination to empty indica-

tion will vary every few seconds as the amount of

fuel and fuel efficiency is calculated. This function

can not be reset.

² Pressing the FUEL button second time; will dis-

play the fuel consumed.

² Pressing the FUEL button third time; will display

the average fuel economy in miles per gallon since

last reset. The display will be updated every 16 sec-

onds.

² Pressing the FUEL button forth time, the current

fuel economy will be displayed. The current fuel

economy will be up updated every two seconds. ²

To reset Fuel consumed, press SET button until

the fuel consumed message is displayed and then

within five seconds press SET button.

² To reset AVERAGE FUEL ECONOMY, press the

FUEL button until average fuel economy is displayed

and within five seconds press SET button. TRIP RESET, press FUEL button and wait four

seconds press the SET button twice. This clears all

trip information and the message Trip Reset will be

displayed. This will occur only if a reset function is

currently being displayed. The reset functions:

² Fuel consumed

² Average fuel economy message

INFO button, will active a MONITORED SYS-

TEMS OK message on display if all monitored sys-

tems are operating properly. If a problem is detected,

the appropriate message will be displayed. SET button, will clear the various functions after

they have been displayed. It is used to enter the

clock set or compass variance modes. This button is

also used to reset certain trip computer functions and

the maintenance reminder message. The EVIC display may be turned off by pressing

the TIME and SET buttons at the same time. Press-

ing the buttons a second time will restore the dis-

play.

EVIC INFORMATION SOURCES

The EVIC monitors information provided by the

body controller, engine compartment node and pow-

ertrain control module. Refer to Body Diagnostic Test

Procedure Manual for test procedures. The Body Controller is a micro-controller unit

which, informs the EVIC via the CCD bus of:

² Time of day

² Day of week

² Day of month

² Month of year

² Fuel range

² Fuel consumed

² Fuel efficiency

² Warning messages as noted in Fig. 3.

The Engine Compartment Node is a microcomputer

controlled unit which, informs the EVIC via the CCD

bus of:

² Outside temperature

² Compass direction

THE FOLLOWING ARE WARNING MESSAGES:

² Low brake fluid

² Low coolant level

² Low engine oil level

The powertrain control module is a microcomputer

controlled unit which, informs the EVIC via the CCD

bus of the following warning messages:

² Engine temperature high

² Voltage improper

8C - 14 OVERHEAD CONSOLE Ä

Page 517 of 2438

off, there should be continuity in the system. Start

the engine. With the engine running, the ohmmeter

should show no continuity. If the above results are

not obtained, replace the switch.

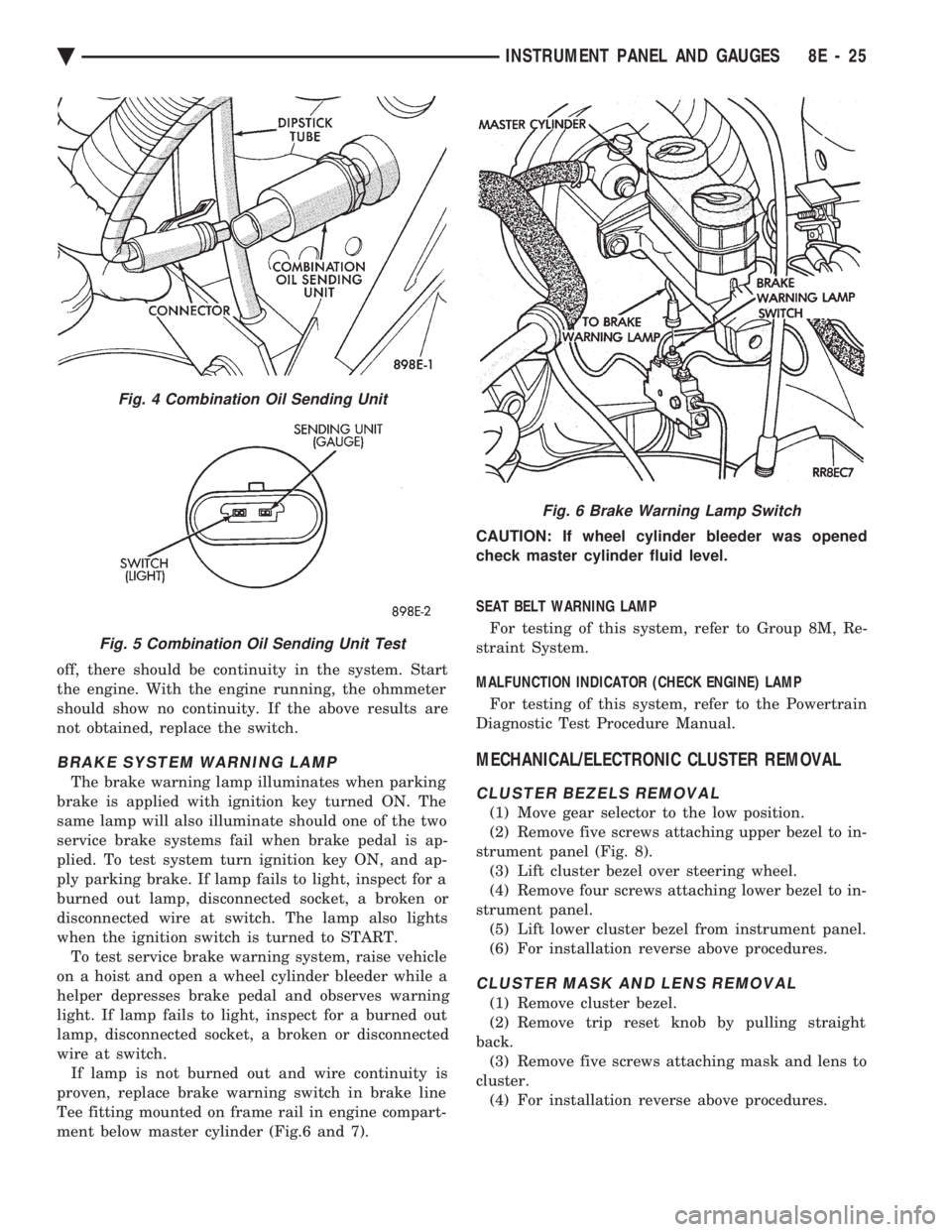

BRAKE SYSTEM WARNING LAMP

The brake warning lamp illuminates when parking

brake is applied with ignition key turned ON. The

same lamp will also illuminate should one of the two

service brake systems fail when brake pedal is ap-

plied. To test system turn ignition key ON, and ap-

ply parking brake. If lamp fails to light, inspect for a

burned out lamp, disconnected socket, a broken or

disconnected wire at switch. The lamp also lights

when the ignition switch is turned to START. To test service brake warning system, raise vehicle

on a hoist and open a wheel cylinder bleeder while a

helper depresses brake pedal and observes warning

light. If lamp fails to light, inspect for a burned out

lamp, disconnected socket, a broken or disconnected

wire at switch. If lamp is not burned out and wire continuity is

proven, replace brake warning switch in brake line

Tee fitting mounted on frame rail in engine compart-

ment below master cylinder (Fig.6 and 7). CAUTION: If wheel cylinder bleeder was opened

check master cylinder fluid level.

SEAT BELT WARNING LAMP

For testing of this system, refer to Group 8M, Re-

straint System.

MALFUNCTION INDICATOR (CHECK ENGINE) LAMP

For testing of this system, refer to the Powertrain

Diagnostic Test Procedure Manual.

MECHANICAL/ELECTRONIC CLUSTER REMOVAL

CLUSTER BEZELS REMOVAL

(1) Move gear selector to the low position.

(2) Remove five screws attaching upper bezel to in-

strument panel (Fig. 8). (3) Lift cluster bezel over steering wheel.

(4) Remove four screws attaching lower bezel to in-

strument panel. (5) Lift lower cluster bezel from instrument panel.

(6) For installation reverse above procedures.

CLUSTER MASK AND LENS REMOVAL

(1) Remove cluster bezel.

(2) Remove trip reset knob by pulling straight

back. (3) Remove five screws attaching mask and lens to

cluster. (4) For installation reverse above procedures.

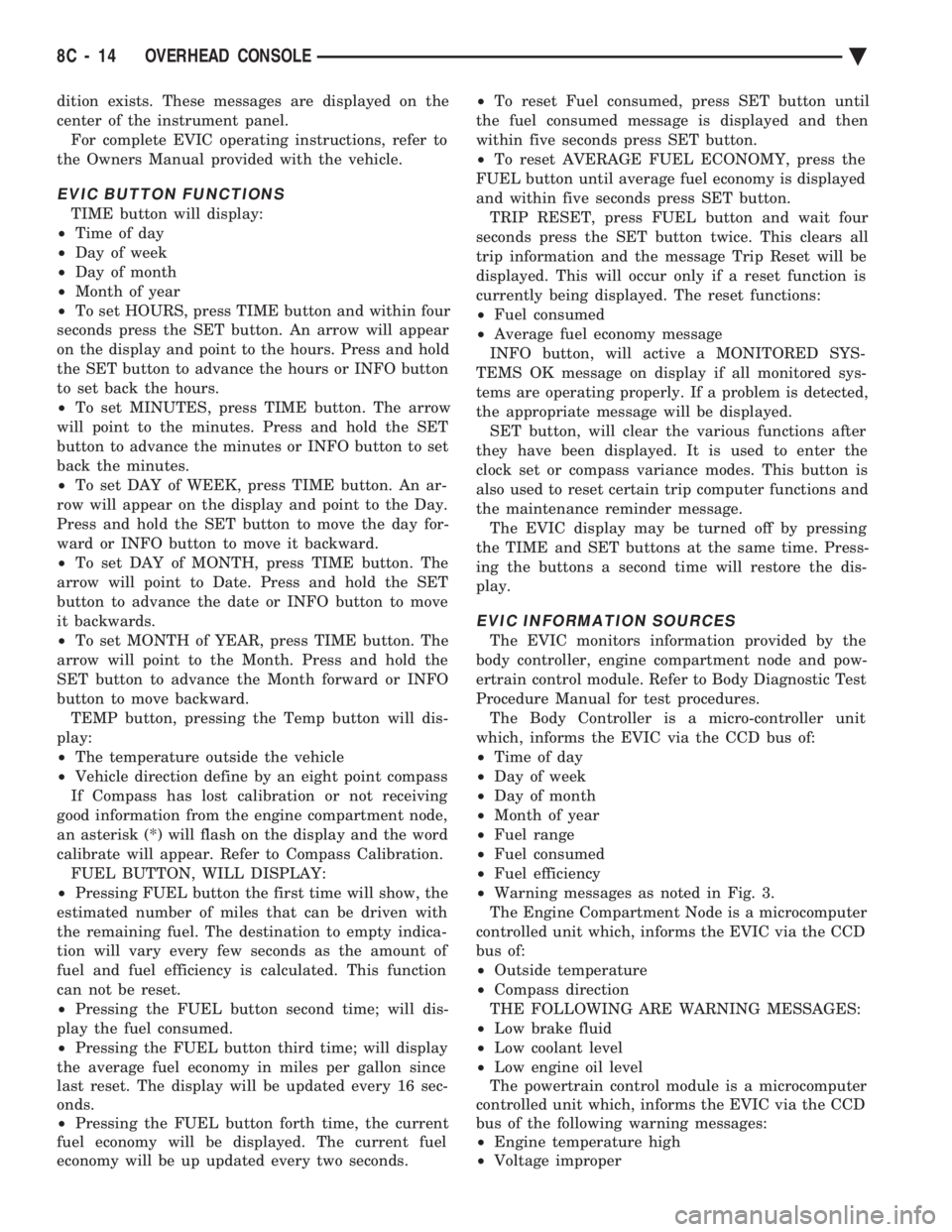

Fig. 4 Combination Oil Sending Unit

Fig. 5 Combination Oil Sending Unit Test

Fig. 6 Brake Warning Lamp Switch

Ä INSTRUMENT PANEL AND GAUGES 8E - 25

Page 529 of 2438

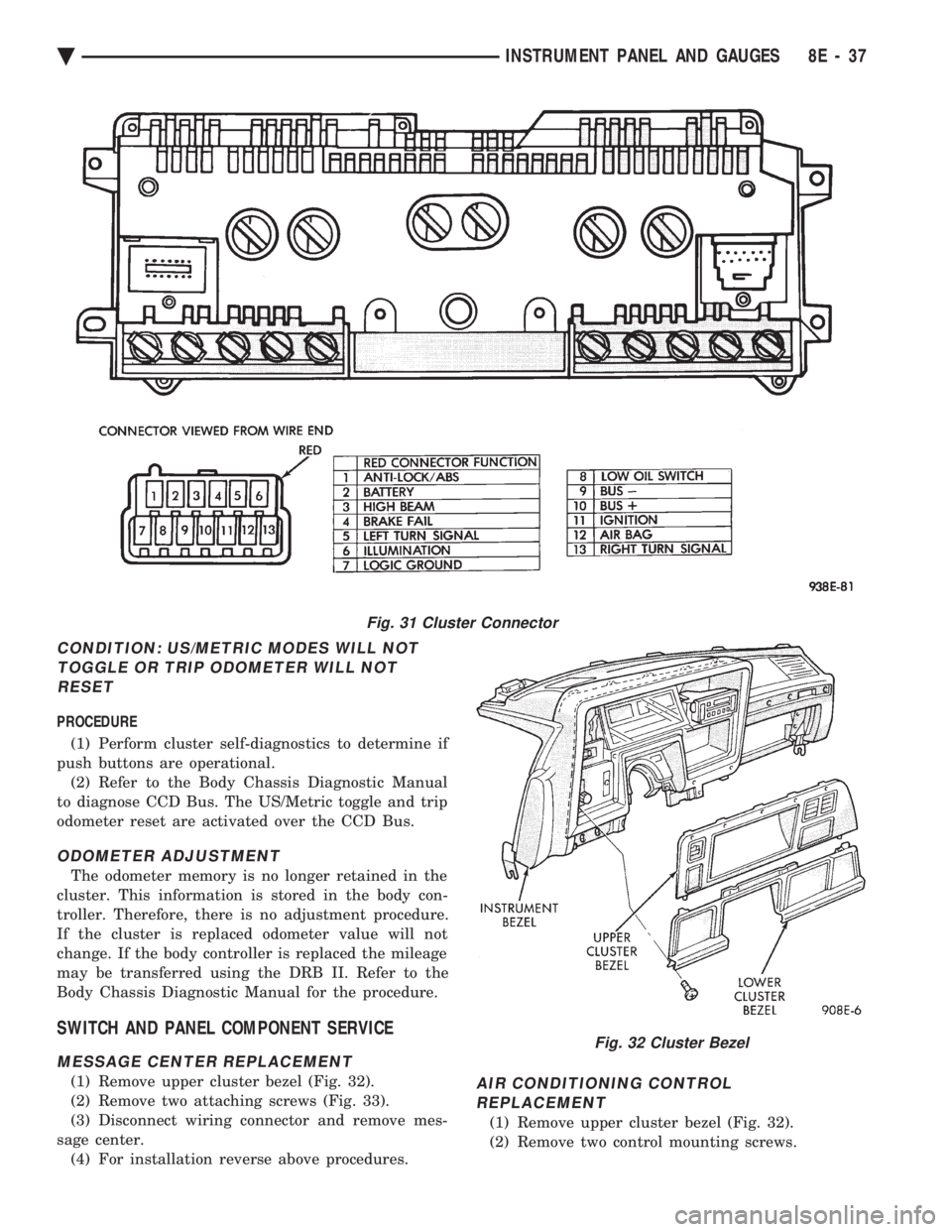

CONDITION: US/METRIC MODES WILL NOT TOGGLE OR TRIP ODOMETER WILL NOTRESET

PROCEDURE

(1) Perform cluster self-diagnostics to determine if

push buttons are operational. (2) Refer to the Body Chassis Diagnostic Manual

to diagnose CCD Bus. The US/Metric toggle and trip

odometer reset are activated over the CCD Bus.

ODOMETER ADJUSTMENT

The odometer memory is no longer retained in the

cluster. This information is stored in the body con-

troller. Therefore, there is no adjustment procedure.

If the cluster is replaced odometer value will not

change. If the body controller is replaced the mileage

may be transferred using the DRB II. Refer to the

Body Chassis Diagnostic Manual for the procedure.

SWITCH AND PANEL COMPONENT SERVICE

MESSAGE CENTER REPLACEMENT

(1) Remove upper cluster bezel (Fig. 32).

(2) Remove two attaching screws (Fig. 33).

(3) Disconnect wiring connector and remove mes-

sage center. (4) For installation reverse above procedures.AIR CONDITIONING CONTROLREPLACEMENT

(1) Remove upper cluster bezel (Fig. 32).

(2) Remove two control mounting screws.

Fig. 31 Cluster Connector

Fig. 32 Cluster Bezel

Ä INSTRUMENT PANEL AND GAUGES 8E - 37

Page 744 of 2438

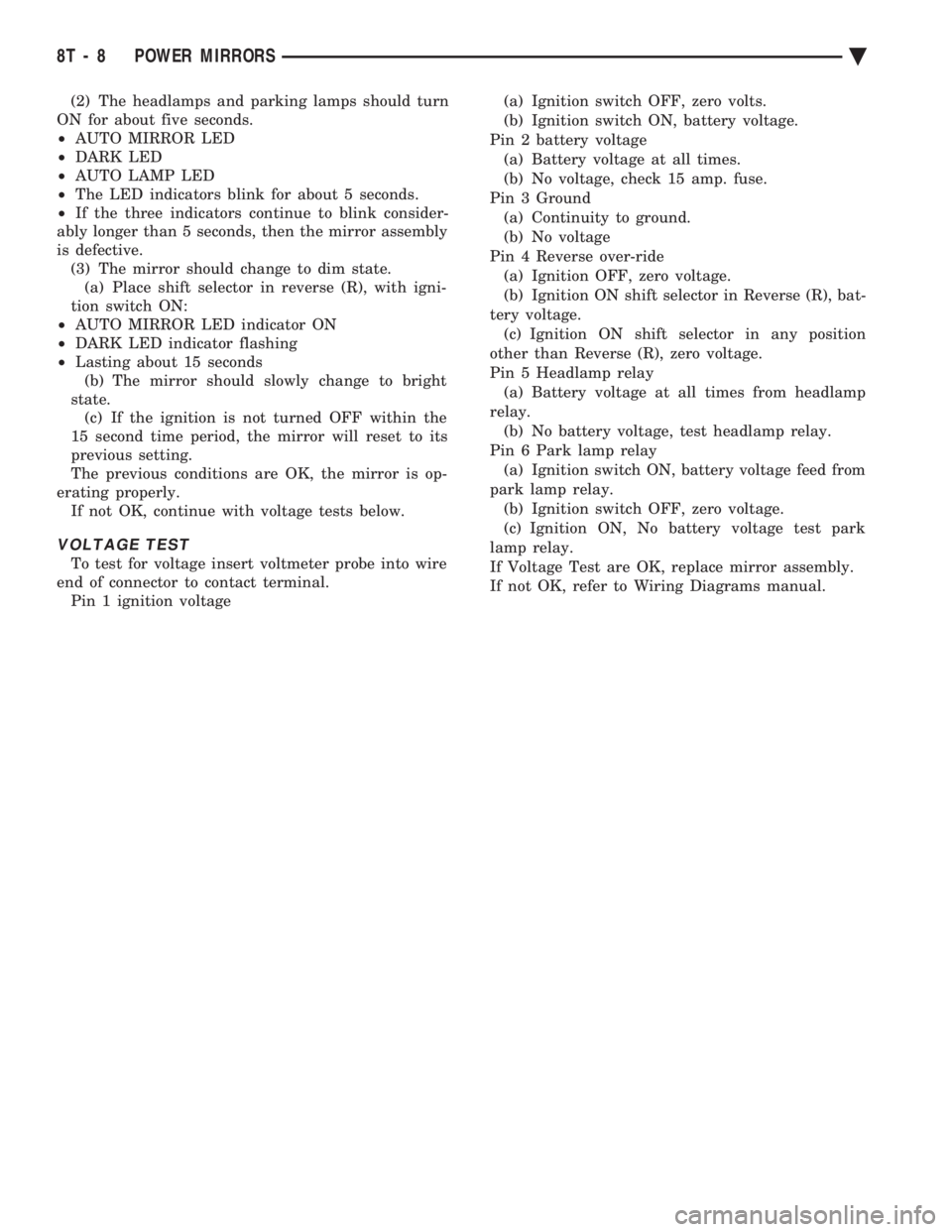

(2) The headlamps and parking lamps should turn

ON for about five seconds.

² AUTO MIRROR LED

² DARK LED

² AUTO LAMP LED

² The LED indicators blink for about 5 seconds.

² If the three indicators continue to blink consider-

ably longer than 5 seconds, then the mirror assembly

is defective. (3) The mirror should change to dim state.(a) Place shift selector in reverse (R), with igni-

tion switch ON:

² AUTO MIRROR LED indicator ON

² DARK LED indicator flashing

² Lasting about 15 seconds

(b) The mirror should slowly change to bright

state. (c) If the ignition is not turned OFF within the

15 second time period, the mirror will reset to its

previous setting.

The previous conditions are OK, the mirror is op-

erating properly. If not OK, continue with voltage tests below.

VOLTAGE TEST

To test for voltage insert voltmeter probe into wire

end of connector to contact terminal. Pin 1 ignition voltage (a) Ignition switch OFF, zero volts.

(b) Ignition switch ON, battery voltage.

Pin 2 battery voltage (a) Battery voltage at all times.

(b) No voltage, check 15 amp. fuse.

Pin 3 Ground (a) Continuity to ground.

(b) No voltage

Pin 4 Reverse over-ride (a) Ignition OFF, zero voltage.

(b) Ignition ON shift selector in Reverse (R), bat-

tery voltage. (c) Ignition ON shift selector in any position

other than Reverse (R), zero voltage.

Pin 5 Headlamp relay (a) Battery voltage at all times from headlamp

relay. (b) No battery voltage, test headlamp relay.

Pin 6 Park lamp relay (a) Ignition switch ON, battery voltage feed from

park lamp relay. (b) Ignition switch OFF, zero voltage.

(c) Ignition ON, No battery voltage test park

lamp relay.

If Voltage Test are OK, replace mirror assembly.

If not OK, refer to Wiring Diagrams manual.

8T - 8 POWER MIRRORS Ä

Page 756 of 2438

(5) Reset the terminal locking tang, if it has one.

(6) Insert the removed wire in the same cavity on

the repair connector. (7) Repeat steps four thru six for each wire in the

connector. Check that all wires are inserted into the

proper cavities. For connector pin out identification

refer to the wiring diagrams. (8) Insert the connector locking wedge into the re-

paired connector. (9) Connect connector to its mating half.

(10) Connect battery and test all affected systems.

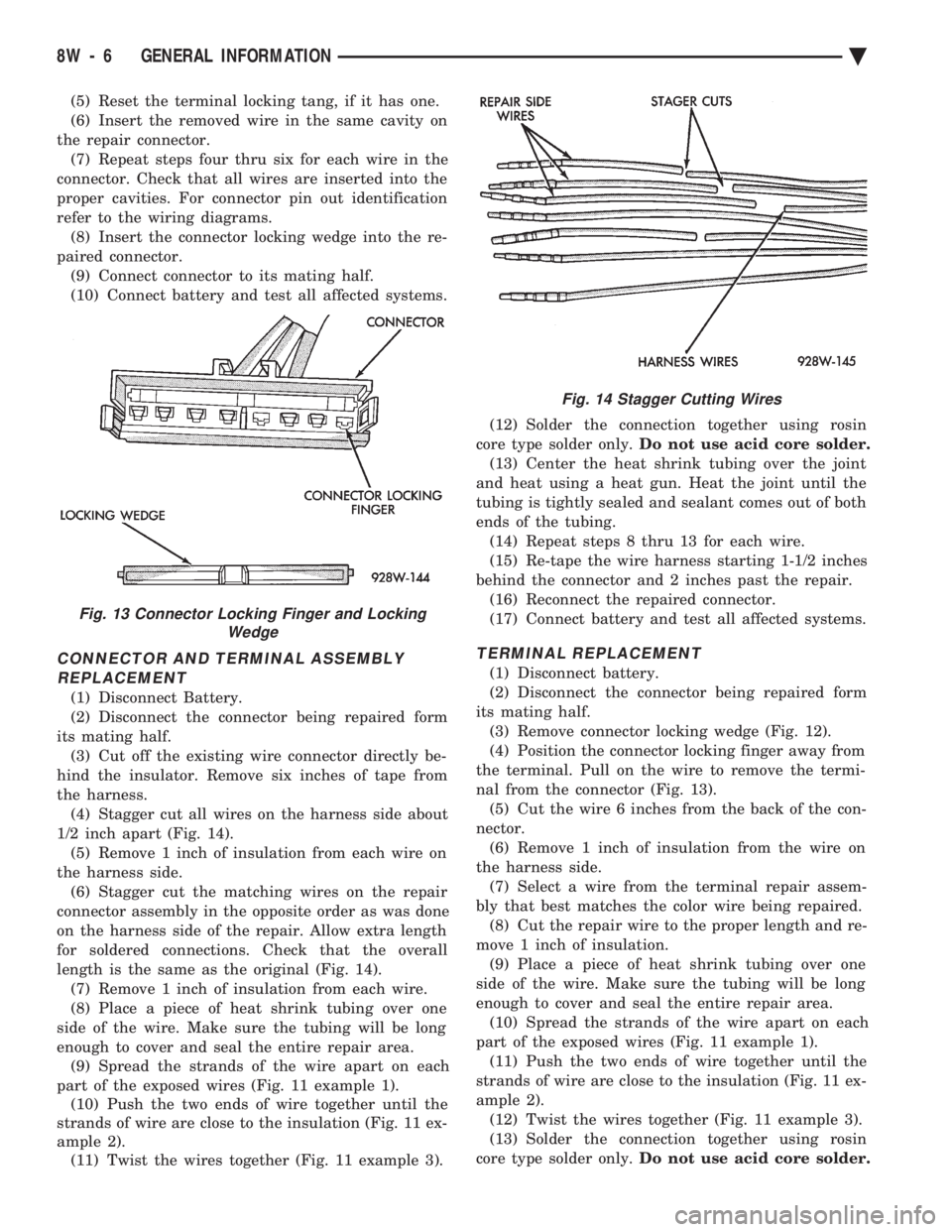

CONNECTOR AND TERMINAL ASSEMBLY REPLACEMENT

(1) Disconnect Battery.

(2) Disconnect the connector being repaired form

its mating half. (3) Cut off the existing wire connector directly be-

hind the insulator. Remove six inches of tape from

the harness. (4) Stagger cut all wires on the harness side about

1/2 inch apart (Fig. 14). (5) Remove 1 inch of insulation from each wire on

the harness side. (6) Stagger cut the matching wires on the repair

connector assembly in the opposite order as was done

on the harness side of the repair. Allow extra length

for soldered connections. Check that the overall

length is the same as the original (Fig. 14). (7) Remove 1 inch of insulation from each wire.

(8) Place a piece of heat shrink tubing over one

side of the wire. Make sure the tubing will be long

enough to cover and seal the entire repair area. (9) Spread the strands of the wire apart on each

part of the exposed wires (Fig. 11 example 1). (10) Push the two ends of wire together until the

strands of wire are close to the insulation (Fig. 11 ex-

ample 2). (11) Twist the wires together (Fig. 11 example 3). (12) Solder the connection together using rosin

core type solder only. Do not use acid core solder.

(13) Center the heat shrink tubing over the joint

and heat using a heat gun. Heat the joint until the

tubing is tightly sealed and sealant comes out of both

ends of the tubing. (14) Repeat steps 8 thru 13 for each wire.

(15) Re-tape the wire harness starting 1-1/2 inches

behind the connector and 2 inches past the repair. (16) Reconnect the repaired connector.

(17) Connect battery and test all affected systems.

TERMINAL REPLACEMENT

(1) Disconnect battery.

(2) Disconnect the connector being repaired form

its mating half. (3) Remove connector locking wedge (Fig. 12).

(4) Position the connector locking finger away from

the terminal. Pull on the wire to remove the termi-

nal from the connector (Fig. 13). (5) Cut the wire 6 inches from the back of the con-

nector. (6) Remove 1 inch of insulation from the wire on

the harness side. (7) Select a wire from the terminal repair assem-

bly that best matches the color wire being repaired. (8) Cut the repair wire to the proper length and re-

move 1 inch of insulation. (9) Place a piece of heat shrink tubing over one

side of the wire. Make sure the tubing will be long

enough to cover and seal the entire repair area. (10) Spread the strands of the wire apart on each

part of the exposed wires (Fig. 11 example 1). (11) Push the two ends of wire together until the

strands of wire are close to the insulation (Fig. 11 ex-

ample 2). (12) Twist the wires together (Fig. 11 example 3).

(13) Solder the connection together using rosin

core type solder only. Do not use acid core solder.

Fig. 13 Connector Locking Finger and Locking

Wedge

Fig. 14 Stagger Cutting Wires

8W - 6 GENERAL INFORMATION Ä

Page 1582 of 2438

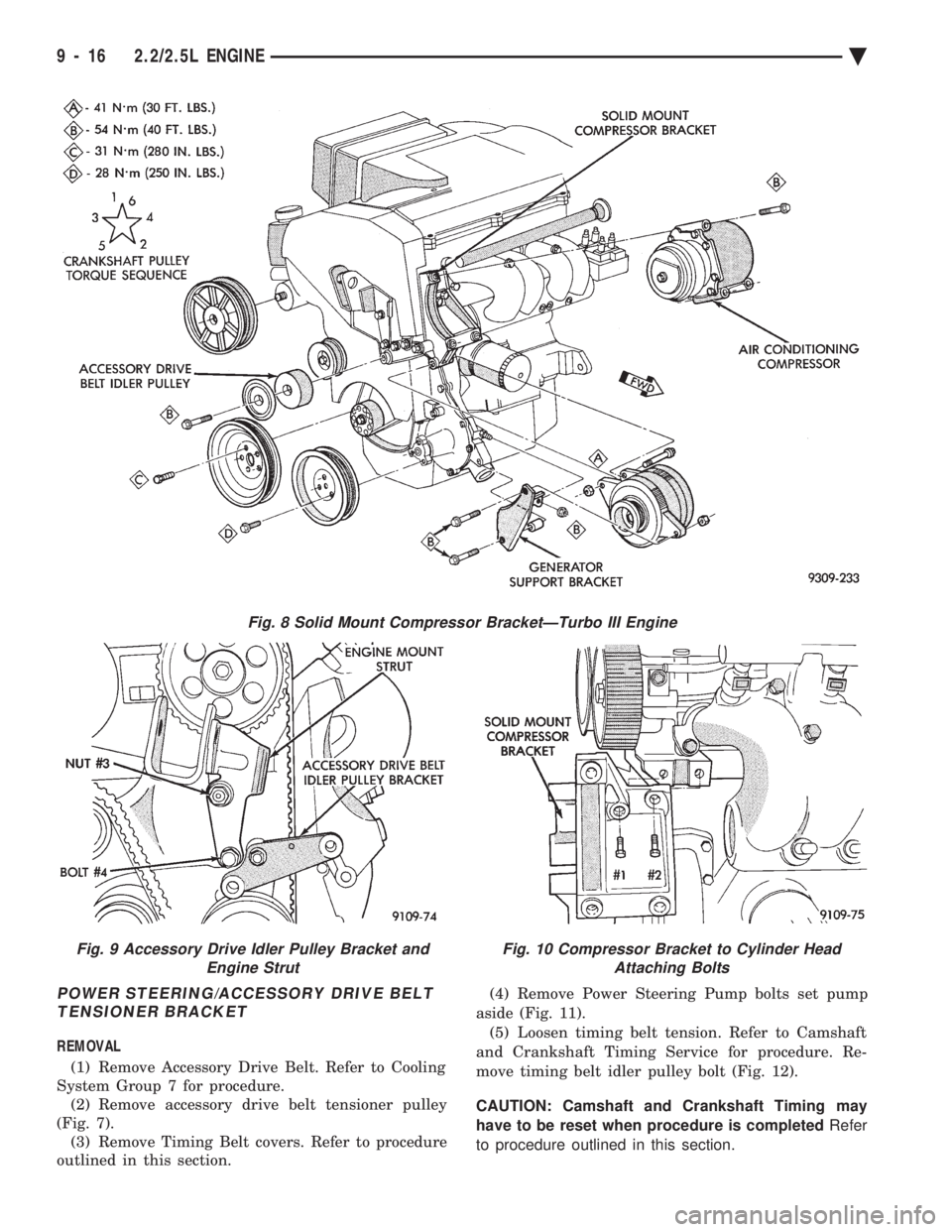

POWER STEERING/ACCESSORY DRIVE BELT TENSIONER BRACKET

REMOVAL

(1) Remove Accessory Drive Belt. Refer to Cooling

System Group 7 for procedure. (2) Remove accessory drive belt tensioner pulley

(Fig. 7). (3) Remove Timing Belt covers. Refer to procedure

outlined in this section. (4) Remove Power Steering Pump bolts set pump

aside (Fig. 11). (5) Loosen timing belt tension. Refer to Camshaft

and Crankshaft Timing Service for procedure. Re-

move timing belt idler pulley bolt (Fig. 12).

CAUTION: Camshaft and Crankshaft Timing may

have to be reset when procedure is completed Refer

to procedure outlined in this section.

Fig. 8 Solid Mount Compressor BracketÐTurbo III Engine

Fig. 9 Accessory Drive Idler Pulley Bracket and Engine StrutFig. 10 Compressor Bracket to Cylinder HeadAttaching Bolts

9 - 16 2.2/2.5L ENGINE Ä

Page 1587 of 2438

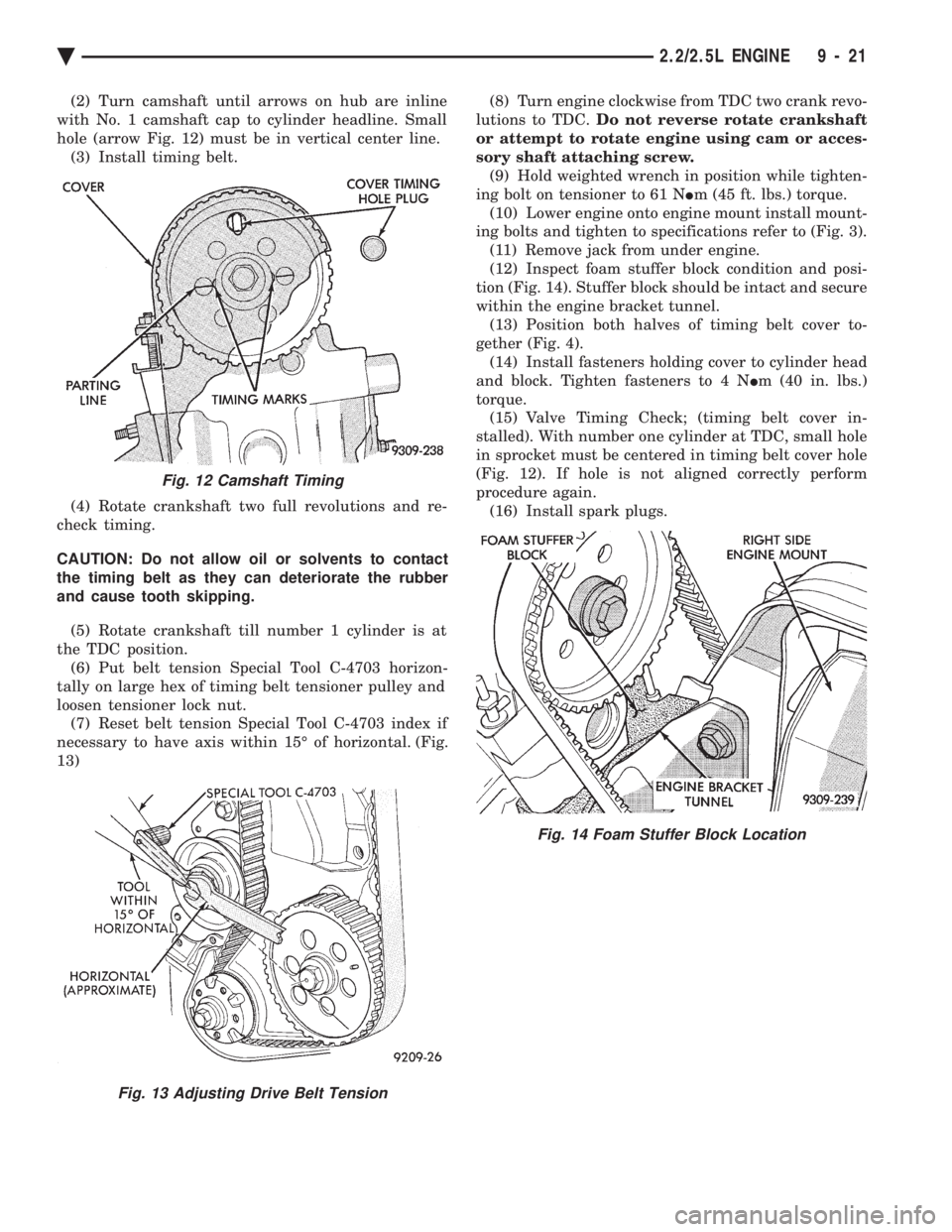

(2) Turn camshaft until arrows on hub are inline

with No. 1 camshaft cap to cylinder headline. Small

hole (arrow Fig. 12) must be in vertical center line. (3) Install timing belt.

(4) Rotate crankshaft two full revolutions and re-

check timing.

CAUTION: Do not allow oil or solvents to contact

the timing belt as they can deteriorate the rubber

and cause tooth skipping.

(5) Rotate crankshaft till number 1 cylinder is at

the TDC position. (6) Put belt tension Special Tool C-4703 horizon-

tally on large hex of timing belt tensioner pulley and

loosen tensioner lock nut. (7) Reset belt tension Special Tool C-4703 index if

necessary to have axis within 15É of horizontal. (Fig.

13) (8) Turn engine clockwise from TDC two crank revo-

lutions to TDC. Do not reverse rotate crankshaft

or attempt to rotate engine using cam or acces-

sory shaft attaching screw. (9) Hold weighted wrench in position while tighten-

ing bolt on tensioner to 61 N Im (45 ft. lbs.) torque.

(10) Lower engine onto engine mount install mount-

ing bolts and tighten to specifications refer to (Fig. 3). (11) Remove jack from under engine.

(12) Inspect foam stuffer block condition and posi-

tion (Fig. 14). Stuffer block should be intact and secure

within the engine bracket tunnel. (13) Position both halves of timing belt cover to-

gether (Fig. 4). (14) Install fasteners holding cover to cylinder head

and block. Tighten fasteners to 4 N Im (40 in. lbs.)

torque. (15) Valve Timing Check; (timing belt cover in-

stalled). With number one cylinder at TDC, small hole

in sprocket must be centered in timing belt cover hole

(Fig. 12). If hole is not aligned correctly perform

procedure again. (16) Install spark plugs.

Fig. 12 Camshaft Timing

Fig. 13 Adjusting Drive Belt Tension

Fig. 14 Foam Stuffer Block Location

Ä 2.2/2.5L ENGINE 9 - 21

Page 1772 of 2438

TACHOMETERÐPCM OUTPUT

The PCM supplies engine RPM to the instrument

panel tachometer. Refer to Group 8 for tachometer

information.

MODES OF OPERATION

As input signals to the PCM change, the PCM

adjusts its response to the output devices. For example,

the PCM must calculate a different injector pulse

width and ignition timing for idle than it does for wide

open throttle (WOT). There are several different modes

of operation that determine how the PCM responds to

the various input signals. There are two different areas of operation, OPEN

LOOP and CLOSED LOOP. During OPEN LOOP modes, the PCM receives input

signals and responds according to preset PCM pro-

gramming. Input from the oxygen (O

2) sensor is not

monitored during OPEN LOOP modes. During CLOSED LOOP modes, the PCM does moni-

tor the oxygen (O

2) sensor input. This input tells the

PCM if the calculated injector pulse width results in an

air-fuel ratio of 14.7 to 1. By monitoring the exhaust

oxygen content, the can PCM fine tune injector pulse

width for optimum fuel economy and low emissions. The single point fuel injection system has the follow-

ing modes of operation:

² Ignition switch ON - Zero RPM

² Engine start-up

² Engine warm-up

² Cruise (Idle)

² Acceleration

² Deceleration

² Wide Open Throttle

² Ignition switch OFF

The engine start-up (cranking), engine warm-up, and

wide open throttle modes are OPEN LOOP modes. The

acceleration, deceleration, and cruise modes, with the

engine at operating temperature are CLOSED

LOOP modes (under most operating conditions).

IGNITION SWITCH ON (ZERO RPM) MODE

When the single point fuel injection system is acti-

vated by the ignition switch, the following actions

occur:

² The PCM determines atmospheric air pressure from

the MAP sensor input to calculate basic fuel strategy.

² The PCM monitors the coolant temperature sensor

and throttle position sensor inputs. The PCM modifies

fuel strategy based on these inputs. When the key is in the ON position and the engine is

not running, the (ASD) and fuel pump relays are not

energized. Therefore, battery voltage is not supplied to

the fuel pump, ignition coil, fuel injector or oxygen

sensor heating element. ENGINE START-UP MODE

This is an OPEN LOOP mode. The following actions

occur when the starter motor is engaged. If the PCM receives a distributor signal it energizes

the auto shutdown (ASD) relay and fuel pump relay to

supply battery voltage to the fuel injector, ignition coil

and oxygen sensor heating element. If the PCM does

not receive a distributor input, it de-energizes the ASD

and fuel pump relays after approximately one second. When the engine idles within 664 RPM of the target

RPM, the PCM compares the current MAP value with

the atmospheric pressure value it received during the

Ignition Switch On (Zero RPM) Mode. If a minimum

difference between the two is not detected, a MAP

sensor fault is set into memory. Once the ASD relay and fuel pump relay have ener-

gized, the PCM:

² Supplies a ground path to the injector. The injector

is pulsed four times per engine revolution instead of

the normal two pulses per revolution.

² Determines injector pulse width based on coolant

temperature, MAP sensor input, throttle position, and

the number of engine revolutions since cranking was

initiated.

² Monitors the coolant temperature sensor, distribu-

tor pick-up, MAP sensor, and throttle position sensor to

determine correct ignition timing.

ENGINE WARM-UP MODE

This is a OPEN LOOP mode. The following inputs

are received by the PCM:

² coolant temperature

² manifold absolute pressure (MAP)

² engine speed (distributor pick-up)

² throttle position

² A/C switch

² battery voltage

The PCM provides a ground path for the injector to

precisely control injector pulse width (by switching the

ground on and off) and fires the injector twice per

engine revolution. The PCM regulates ignition timing.

It also adjusts engine idle speed through the idle air

control motor.

CRUISE OR IDLE MODE

When the engine is at operating temperature this is

a CLOSED LOOP mode. During cruising speed and at

idle the following inputs are received by the PCM:

² coolant temperature

² manifold absolute pressure

² engine speed

² throttle position

² exhaust gas oxygen content

² A/C control positions

² battery voltage

14 - 32 FUEL SYSTEMS Ä