reset CHEVROLET DYNASTY 1993 Owner's Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1803 of 2438

mode, the PCM compensates for the failure of certain

components that send incorrect signals. The PCM

substitutes for the incorrect signals with inputs from

other sensors and by using stored default values.Signals that can trigger the Malfunction Indi-

cator (Check Engine) Lamp.

² An emission system component

² Battery Voltage Input

² Charging system

² Engine Coolant Temperature Sensor

² Manifold Absolute Pressure Sensor

² Methanol Concentration Sensor

² Throttle Position Sensor

The malfunction indicator lamp can also display

diagnostic trouble codes. Cycle the ignition switch on,

off, on, off, on, within five seconds and the PCM

displays any diagnostic trouble codes stored in

memory. Refer to the 2.5L Flexible Fuel Multi-Port

Fuel InjectionÐOn Board Diagnostics section in this

group for diagnostic trouble code descriptions.

RADIATOR FAN RELAYÐPCM OUTPUT

The radiator fan is energized by the PCM through

the radiator fan relay. The PCM grounds the radiator

fan relay when engine coolant reaches a predetermined

temperature. For more information, refer to Group 7,

Cooling Systems. The radiator fan relay is mounted on the drivers side

fender well, next to the strut tower (Fig. 11).

SPEED CONTROL SOLENOIDSÐPCM OUTPUT

The speed control vacuum and vent solenoids are

operated by the PCM. When the PCM supplies a

ground to the vacuum and vent solenoids, the speed

control system opens the throttle blade. When the PCM

supplies a ground only to the vent solenoid, the throttle

blade holds position. When the PCM removes the

ground from both the vacuum and vent solenoids, the

throttle blade closes. The PCM balances the two sole-

noids to maintain the set speed. Refer to Group 8H for

speed control information.

TACHOMETERÐPCM OUTPUT

The PCM supplies engine RPM to the instrument

panel tachometer. Refer to Group 8 for tachometer

information.

TORQUE CONVERTER CLUTCH SOLENOIDÐPCM

OUTPUT

Three-speed automatic transaxles use a torque con-

verter clutch solenoid. The PCM controls the lock-up of

the torque convertor through the solenoid. The tran-

saxle is locked up only in direct drive mode. Refer to

Group 21 for transaxle information.

MODES OF OPERATION

As input signals to the PCM change, the PCM

adjusts its response to the output devices. For example, the PCM must calculate a different injector pulse

width and ignition timing for idle than it does for wide

open throttle (WOT). There are several different modes

of operation that determine how the PCM responds to

the various input signals. There are two different areas of operation, Open

Loop and Closed Loop. During Open Loop modes, the PCM receives input

signals and responds according to preset PCM pro-

gramming. Input from the oxygen (O

2) sensor is not

monitored during Open Loop modes. During CLOSED LOOP modes, the PCM does moni-

tor the oxygen (O

2) sensor input. The input indicates if

the calculated injector pulse width results in the ideal

air-fuel ratio for the current percentage of methanol in

the fuel. By monitoring the exhaust oxygen content

through the O

2sensor, the PCM can fine tune the

injector pulse width to achieve optimum fuel economy

combined with low emissions. The 2.5L flexible fuel multi-port fuel injection system

has the following modes of operation:

² Ignition switch ON - Zero RPM

² Engine start-up

² Engine warm-up

² Cruise (Idle)

² Acceleration

² Deceleration

² Wide Open Throttle

² Ignition switch OFF

The engine start-up (crank), engine warm-up, and

wide open throttle modes are OPEN LOOP modes. The

acceleration, deceleration, and cruise modes, with the

engine at operating temperature are CLOSED

LOOP modes (under most operating conditions).

IGNITION SWITCH ON (ZERO RPM) MODE

When the ignition switch cycles and past the On

position, the fuel injection system activates and the

following actions occur:

² For two seconds at key ON (and during cranking),

the methanol concentration sensor calibrates the PCM.

During the calibration period the sensor sends 4.45

volts to the PCM as a correction factor. After the

calibration period, the methanol concentration sensor

output represents the methanol percentage in the fuel.

² The PCM calculates basic fuel strategy by determin-

ing atmospheric air pressure from the MAP sensor

input.

² The PCM monitors the coolant temperature sensor

and throttle position sensor input. The PCM modifies

fuel strategy based on this input. When the key is in the ON position and the engine is

not running, the auto shutdown (ASD) relay and fuel

pump relay are not energized. Therefore battery volt-

age is not supplied to the fuel pump, ignition coil, fuel

injector or oxygen sensor heating element.

Ä FUEL SYSTEMS 14 - 63

Page 1832 of 2438

noid is energized. The solenoid mounts to the passen-

ger side inner fender panel, next to the strut tower

(Fig. 17).

MODES OF OPERATION

As input signals to the PCM change, the PCM

adjusts its response to the output devices. For example,

the PCM must calculate a different injector pulse

width and ignition timing for idle than it does for wide

open throttle (WOT). There are several different modes

of operation that determine how the PCM responds to

the various input signals. There are two different areas of operation, OPEN

LOOP and CLOSED LOOP. During OPEN LOOP modes, the PCM receives input

signals and responds according to preset PCM pro-

gramming. Input from the oxygen (O

2) sensor is not

monitored during OPEN LOOP modes. During CLOSED LOOP modes, the PCM does moni-

tor the oxygen (O

2) sensor input. This input indicates

to the PCM whether or not the calculated injector pulse

width results in the ideal air-fuel ratio of 14.7 parts air

to 1 part fuel. By monitoring the exhaust oxygen

content through the O

2sensor, the PCM can fine tune

the injector pulse width to achieve optimum fuel

economy combined with low emissions. The 2.2L Turbo III multi-port fuel injection system

has the following modes of operation:

² Ignition switch ON - Zero RPM

² Engine start-up

² Engine warm-up

² Cruise (Idle)

² Acceleration

² Deceleration

² Wide Open Throttle

² Ignition switch OFF

The engine start-up (crank), engine warm-up, and

wide open throttle modes are OPEN LOOP modes. The

acceleration, deceleration, and cruise modes, with the

engine at operating temperature are CLOSED

LOOP modes (under most operating conditions).

IGNITION SWITCH ON (ZERO RPM) MODE

When the ignition switch activates the fuel injection

system the following actions occur:

²

The PCM calculates basic fuel strategy by determining

atmospheric air pressure from the MAP sensor input.

² The PCM monitors the coolant temperature sensor

and throttle position sensor input. The PCM modifies

fuel strategy based on this input. When the key is in the ON position and the engine is

not running, the auto shutdown (ASD) relay and fuel

pump relay are not energized. Therefore battery volt-

age is not supplied to the fuel pump, ignition coil, fuel

injector or oxygen sensor heating element.

ENGINE START-UP MODE

This is an OPEN LOOP mode. The following actions

occur when the starter motor is engaged. If the PCM receives the camshaft position and crank-

shaft position sensor signals, it energizes the auto

shutdown (ASD) relay and fuel pump relay. These

relays supply battery voltage to the fuel pump, fuel

injectors, ignition coil, and oxygen sensor heating ele-

ment. If the PCM does not receive the camshaft posi-

tion sensor and crankshaft position sensor signals

within approximately one second, it de-energizes the

ASD relay and fuel pump relay. The PCM energizes all injectors until it determines

crankshaft position from the camshaft position sensor

and crankshaft position sensor signals. The PCM de-

termines crankshaft position within 1 engine revolu-

tion. After determining crankshaft position, the PCM be-

gins energizing the injectors in sequence. The PCM

adjusts injector pulse width and controls injector syn-

chronization by turning the individual ground paths to

the injectors On and Off. When the engine idles within 664 RPM of its target

RPM, the PCM compares current MAP sensor value

with the atmospheric pressure value received during

the Ignition Switch On (zero RPM) mode. If the PCM

does not detect a minimum difference between the two

values, it sets a MAP fault into memory. Once the ASD and fuel pump relays have been

energized, the PCM:

² Determines injector pulse width based on coolant

temperature, manifold absolute pressure (MAP) and

the number of engine revolutions since cranking was

initiated.

² Monitors the coolant temperature sensor, camshaft

position sensor, crankshaft position sensor, MAP sen-

sor, and throttle position sensor to determine correct

ignition timing.

ENGINE WARM-UP MODE

This is a OPEN LOOP mode. The following inputs

are received by the PCM:

² engine coolant temperature

² knock sensor

² manifold absolute pressure (MAP)

² engine speed (crankshaft position sensor)

² throttle position

² A/C switch

² battery voltage

The PCM provides a ground path for the injectors to

precisely control injector pulse width (by switching the

ground on and off). The PCM adjusts engine idle speed

through the idle air control motor. Also, the PCM

regulates ignition timing.

14 - 92 FUEL SYSTEMS Ä

Page 1834 of 2438

THROTTLE BODY

The throttle body assembly is located on the left

end of the intake manifold plenum (Fig. 20). The

throttle body houses the throttle position sensor and

the idle air control motor. Air flow through the throt-

tle body is controlled by a cable operated throttle

blade located in the base of the throttle body.

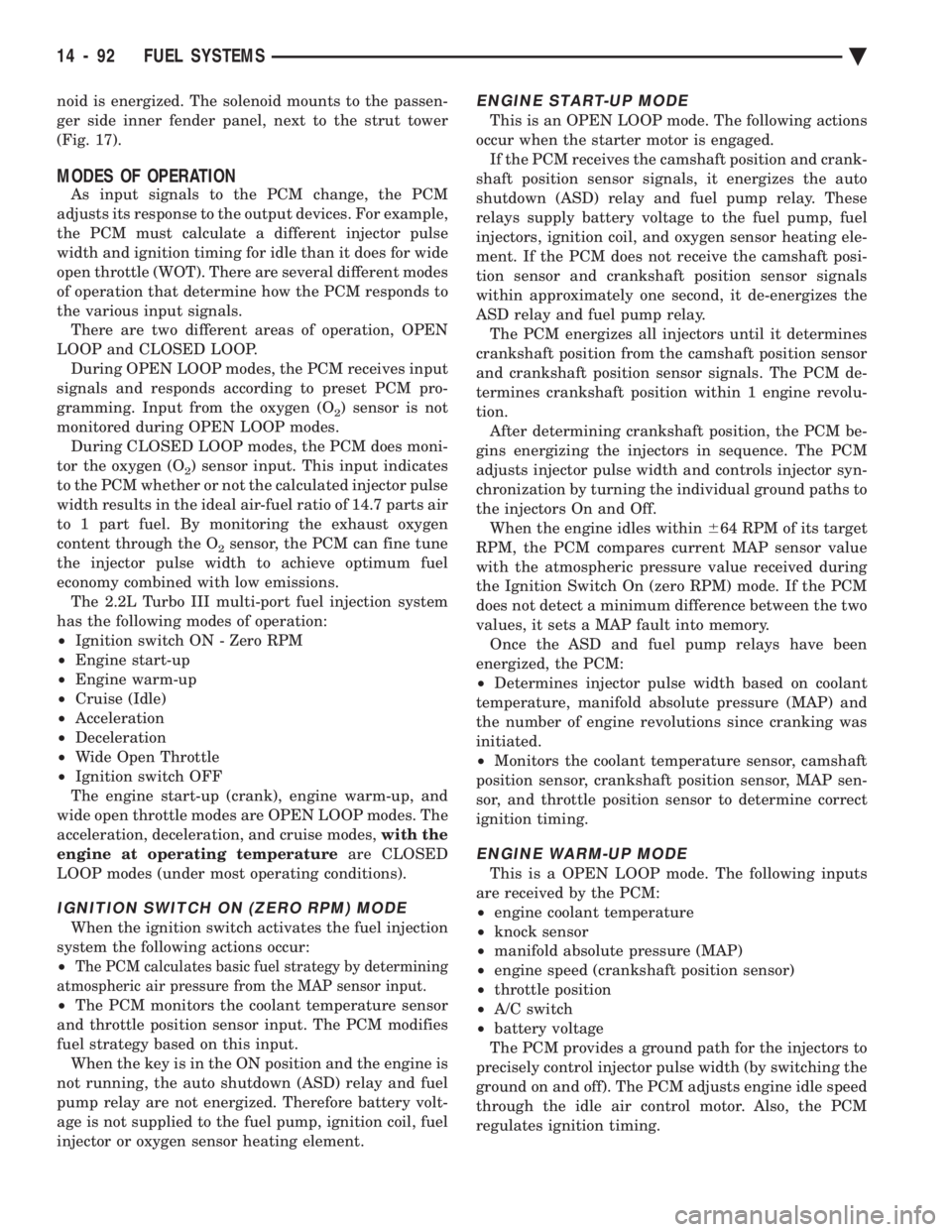

FUEL SUPPLY CIRCUIT

Fuel is pumped to the fuel rail by an electrical

pump in the fuel tank. The pump inlet is fitted with

a strainer to prevent water and other contaminants

from entering the fuel supply circuit. Fuel pressure is controlled to a preset level above

intake manifold pressure by a pressure regulator.

The regulator is mounted on the fuel rail (Fig. 21).

The regulator uses intake manifold pressure as a ref-

erence.

FUEL INJECTORS AND FUEL RAIL ASSEMBLY

Four fuel injectors are retained in the fuel rail by

lock rings. The rail and injector assembly are in-

stalled with the injectors inserted into recessed holes

in the intake manifold.

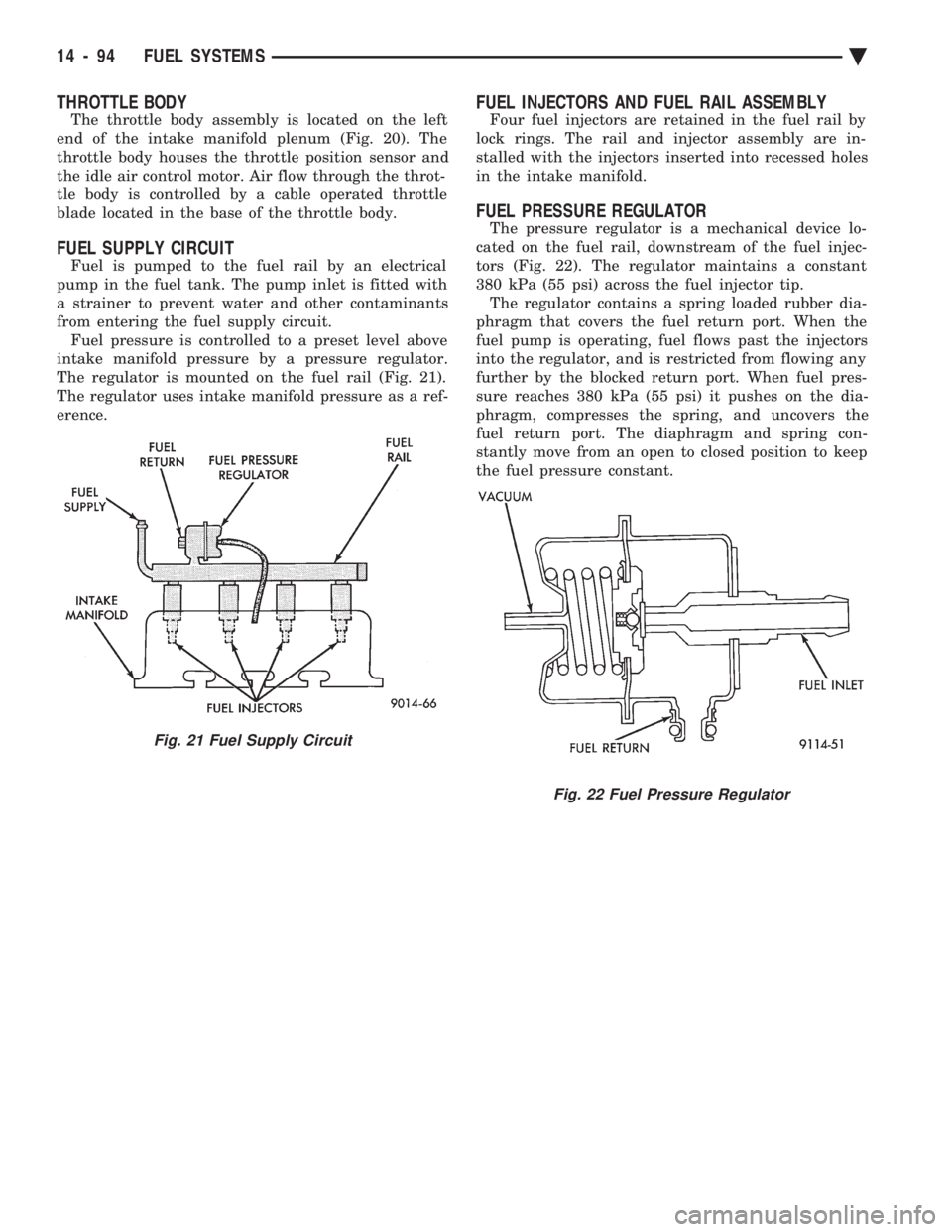

FUEL PRESSURE REGULATOR

The pressure regulator is a mechanical device lo-

cated on the fuel rail, downstream of the fuel injec-

tors (Fig. 22). The regulator maintains a constant

380 kPa (55 psi) across the fuel injector tip. The regulator contains a spring loaded rubber dia-

phragm that covers the fuel return port. When the

fuel pump is operating, fuel flows past the injectors

into the regulator, and is restricted from flowing any

further by the blocked return port. When fuel pres-

sure reaches 380 kPa (55 psi) it pushes on the dia-

phragm, compresses the spring, and uncovers the

fuel return port. The diaphragm and spring con-

stantly move from an open to closed position to keep

the fuel pressure constant.

Fig. 21 Fuel Supply Circuit

Fig. 22 Fuel Pressure Regulator

14 - 94 FUEL SYSTEMS Ä

Page 1861 of 2438

tially energizes all injectors at the same time. Once

the PCM determines crankshaft position, it begins

energizing the injectors in sequence.Battery voltage is supplied to the injectors through

the ASD relay. The PCM provides the ground path

for the injectors. By switching the ground path on

and off, the PCM adjusts injector pulse width. Pulse

width is the amount of time the injector is energized.

The PCM adjusts injector pulse width based on in-

puts it receives.

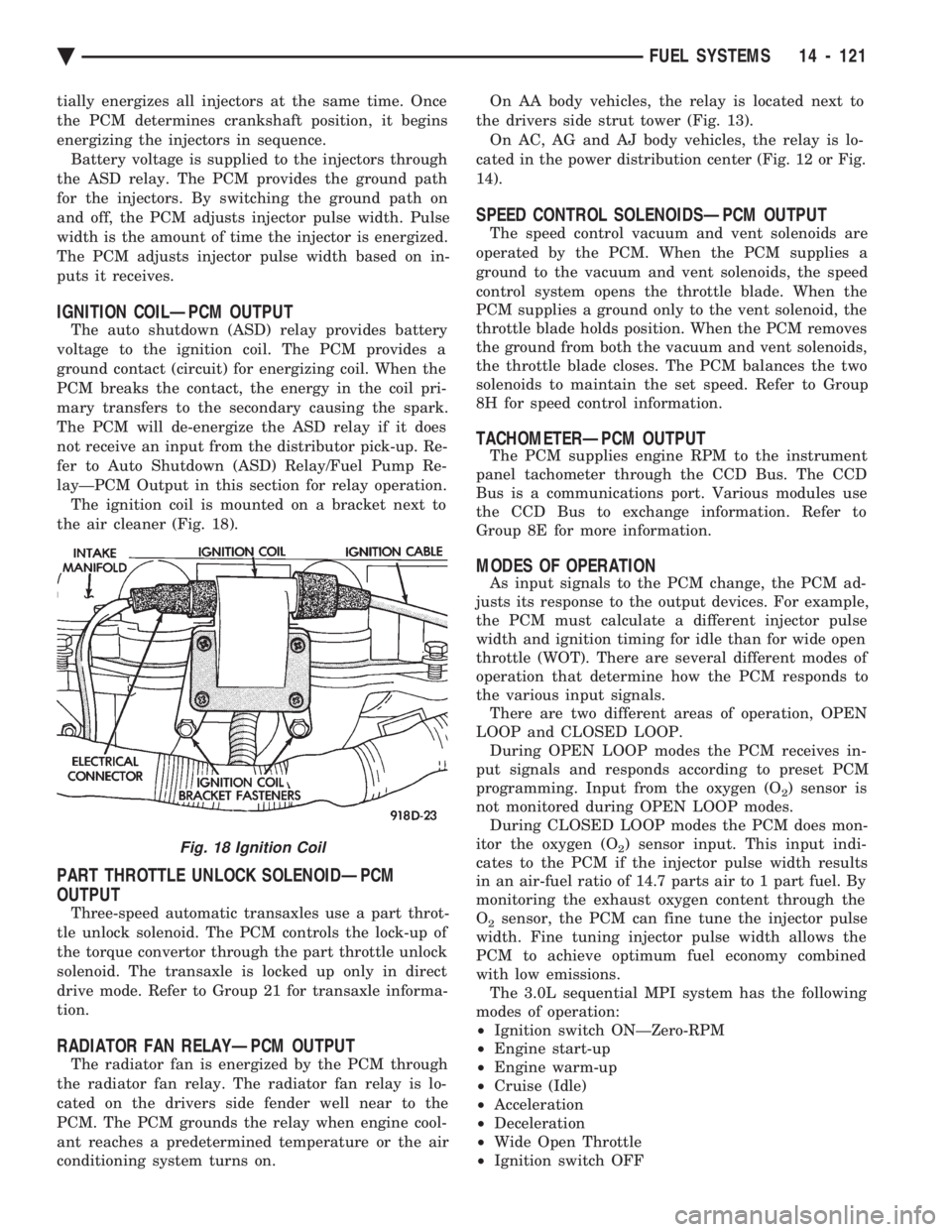

IGNITION COILÐPCM OUTPUT

The auto shutdown (ASD) relay provides battery

voltage to the ignition coil. The PCM provides a

ground contact (circuit) for energizing coil. When the

PCM breaks the contact, the energy in the coil pri-

mary transfers to the secondary causing the spark.

The PCM will de-energize the ASD relay if it does

not receive an input from the distributor pick-up. Re-

fer to Auto Shutdown (ASD) Relay/Fuel Pump Re-

layÐPCM Output in this section for relay operation. The ignition coil is mounted on a bracket next to

the air cleaner (Fig. 18).

PART THROTTLE UNLOCK SOLENOIDÐPCM

OUTPUT

Three-speed automatic transaxles use a part throt-

tle unlock solenoid. The PCM controls the lock-up of

the torque convertor through the part throttle unlock

solenoid. The transaxle is locked up only in direct

drive mode. Refer to Group 21 for transaxle informa-

tion.

RADIATOR FAN RELAYÐPCM OUTPUT

The radiator fan is energized by the PCM through

the radiator fan relay. The radiator fan relay is lo-

cated on the drivers side fender well near to the

PCM. The PCM grounds the relay when engine cool-

ant reaches a predetermined temperature or the air

conditioning system turns on. On AA body vehicles, the relay is located next to

the drivers side strut tower (Fig. 13). On AC, AG and AJ body vehicles, the relay is lo-

cated in the power distribution center (Fig. 12 or Fig.

14).

SPEED CONTROL SOLENOIDSÐPCM OUTPUT

The speed control vacuum and vent solenoids are

operated by the PCM. When the PCM supplies a

ground to the vacuum and vent solenoids, the speed

control system opens the throttle blade. When the

PCM supplies a ground only to the vent solenoid, the

throttle blade holds position. When the PCM removes

the ground from both the vacuum and vent solenoids,

the throttle blade closes. The PCM balances the two

solenoids to maintain the set speed. Refer to Group

8H for speed control information.

TACHOMETERÐPCM OUTPUT

The PCM supplies engine RPM to the instrument

panel tachometer through the CCD Bus. The CCD

Bus is a communications port. Various modules use

the CCD Bus to exchange information. Refer to

Group 8E for more information.

MODES OF OPERATION

As input signals to the PCM change, the PCM ad-

justs its response to the output devices. For example,

the PCM must calculate a different injector pulse

width and ignition timing for idle than for wide open

throttle (WOT). There are several different modes of

operation that determine how the PCM responds to

the various input signals. There are two different areas of operation, OPEN

LOOP and CLOSED LOOP. During OPEN LOOP modes the PCM receives in-

put signals and responds according to preset PCM

programming. Input from the oxygen (O

2) sensor is

not monitored during OPEN LOOP modes. During CLOSED LOOP modes the PCM does mon-

itor the oxygen (O

2) sensor input. This input indi-

cates to the PCM if the injector pulse width results

in an air-fuel ratio of 14.7 parts air to 1 part fuel. By

monitoring the exhaust oxygen content through the

O

2sensor, the PCM can fine tune the injector pulse

width. Fine tuning injector pulse width allows the

PCM to achieve optimum fuel economy combined

with low emissions. The 3.0L sequential MPI system has the following

modes of operation:

² Ignition switch ONÐZero-RPM

² Engine start-up

² Engine warm-up

² Cruise (Idle)

² Acceleration

² Deceleration

² Wide Open Throttle

² Ignition switch OFF

Fig. 18 Ignition Coil

Ä FUEL SYSTEMS 14 - 121

Page 1863 of 2438

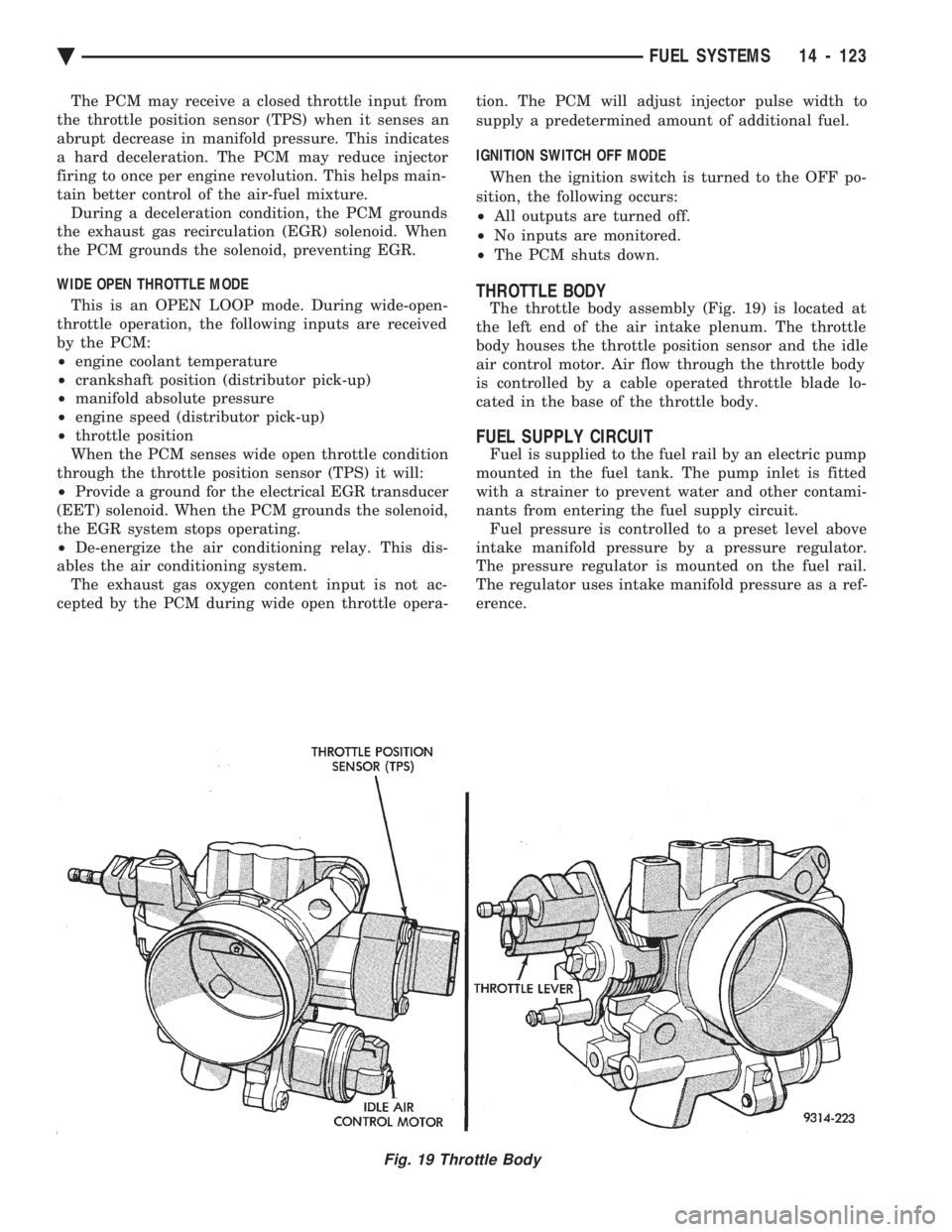

The PCM may receive a closed throttle input from

the throttle position sensor (TPS) when it senses an

abrupt decrease in manifold pressure. This indicates

a hard deceleration. The PCM may reduce injector

firing to once per engine revolution. This helps main-

tain better control of the air-fuel mixture. During a deceleration condition, the PCM grounds

the exhaust gas recirculation (EGR) solenoid. When

the PCM grounds the solenoid, preventing EGR.

WIDE OPEN THROTTLE MODE This is an OPEN LOOP mode. During wide-open-

throttle operation, the following inputs are received

by the PCM:

² engine coolant temperature

² crankshaft position (distributor pick-up)

² manifold absolute pressure

² engine speed (distributor pick-up)

² throttle position

When the PCM senses wide open throttle condition

through the throttle position sensor (TPS) it will:

² Provide a ground for the electrical EGR transducer

(EET) solenoid. When the PCM grounds the solenoid,

the EGR system stops operating.

² De-energize the air conditioning relay. This dis-

ables the air conditioning system. The exhaust gas oxygen content input is not ac-

cepted by the PCM during wide open throttle opera- tion. The PCM will adjust injector pulse width to

supply a predetermined amount of additional fuel.

IGNITION SWITCH OFF MODE

When the ignition switch is turned to the OFF po-

sition, the following occurs:

² All outputs are turned off.

² No inputs are monitored.

² The PCM shuts down.

THROTTLE BODY

The throttle body assembly (Fig. 19) is located at

the left end of the air intake plenum. The throttle

body houses the throttle position sensor and the idle

air control motor. Air flow through the throttle body

is controlled by a cable operated throttle blade lo-

cated in the base of the throttle body.

FUEL SUPPLY CIRCUIT

Fuel is supplied to the fuel rail by an electric pump

mounted in the fuel tank. The pump inlet is fitted

with a strainer to prevent water and other contami-

nants from entering the fuel supply circuit. Fuel pressure is controlled to a preset level above

intake manifold pressure by a pressure regulator.

The pressure regulator is mounted on the fuel rail.

The regulator uses intake manifold pressure as a ref-

erence.

Fig. 19 Throttle Body

Ä FUEL SYSTEMS 14 - 123

Page 1893 of 2438

the PCM determines crankshaft position, it begins

energizing the injectors in sequence.The auto shutdown (ASD) relay supplies battery

voltage to the injectors. The PCM provides the

ground path for the injectors. By switching the

ground path on and off, the PCM adjusts injector

pulse width. Pulse width is the amount of time the

injector is energized. The PCM adjusts injector pulse

width based on inputs it receives.

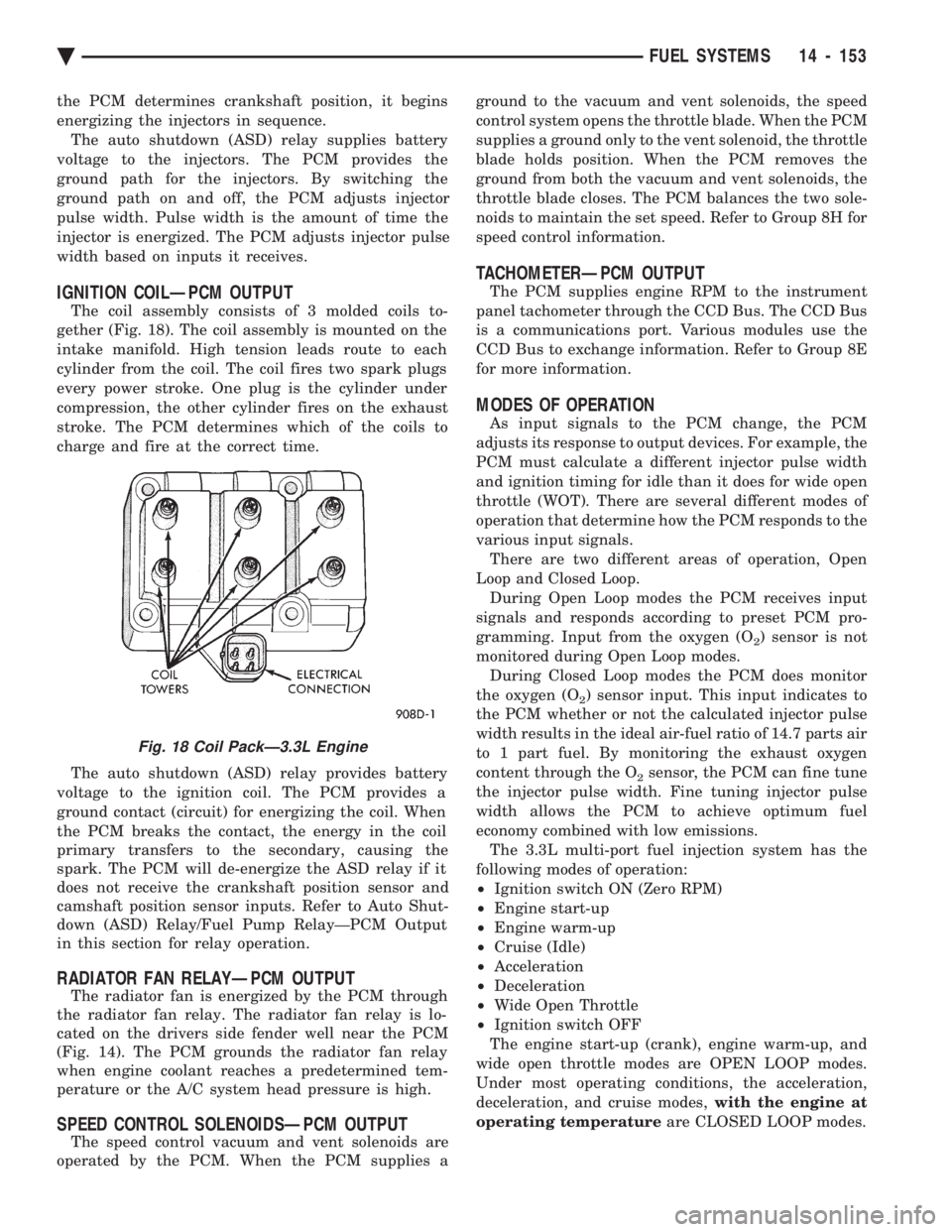

IGNITION COILÐPCM OUTPUT

The coil assembly consists of 3 molded coils to-

gether (Fig. 18). The coil assembly is mounted on the

intake manifold. High tension leads route to each

cylinder from the coil. The coil fires two spark plugs

every power stroke. One plug is the cylinder under

compression, the other cylinder fires on the exhaust

stroke. The PCM determines which of the coils to

charge and fire at the correct time.

The auto shutdown (ASD) relay provides battery

voltage to the ignition coil. The PCM provides a

ground contact (circuit) for energizing the coil. When

the PCM breaks the contact, the energy in the coil

primary transfers to the secondary, causing the

spark. The PCM will de-energize the ASD relay if it

does not receive the crankshaft position sensor and

camshaft position sensor inputs. Refer to Auto Shut-

down (ASD) Relay/Fuel Pump RelayÐPCM Output

in this section for relay operation.

RADIATOR FAN RELAYÐPCM OUTPUT

The radiator fan is energized by the PCM through

the radiator fan relay. The radiator fan relay is lo-

cated on the drivers side fender well near the PCM

(Fig. 14). The PCM grounds the radiator fan relay

when engine coolant reaches a predetermined tem-

perature or the A/C system head pressure is high.

SPEED CONTROL SOLENOIDSÐPCM OUTPUT

The speed control vacuum and vent solenoids are

operated by the PCM. When the PCM supplies a ground to the vacuum and vent solenoids, the speed

control system opens the throttle blade. When the PCM

supplies a ground only to the vent solenoid, the throttle

blade holds position. When the PCM removes the

ground from both the vacuum and vent solenoids, the

throttle blade closes. The PCM balances the two sole-

noids to maintain the set speed. Refer to Group 8H for

speed control information.

TACHOMETERÐPCM OUTPUT

The PCM supplies engine RPM to the instrument

panel tachometer through the CCD Bus. The CCD Bus

is a communications port. Various modules use the

CCD Bus to exchange information. Refer to Group 8E

for more information.

MODES OF OPERATION

As input signals to the PCM change, the PCM

adjusts its response to output devices. For example, the

PCM must calculate a different injector pulse width

and ignition timing for idle than it does for wide open

throttle (WOT). There are several different modes of

operation that determine how the PCM responds to the

various input signals. There are two different areas of operation, Open

Loop and Closed Loop. During Open Loop modes the PCM receives input

signals and responds according to preset PCM pro-

gramming. Input from the oxygen (O

2) sensor is not

monitored during Open Loop modes. During Closed Loop modes the PCM does monitor

the oxygen (O

2) sensor input. This input indicates to

the PCM whether or not the calculated injector pulse

width results in the ideal air-fuel ratio of 14.7 parts air

to 1 part fuel. By monitoring the exhaust oxygen

content through the O

2sensor, the PCM can fine tune

the injector pulse width. Fine tuning injector pulse

width allows the PCM to achieve optimum fuel

economy combined with low emissions. The 3.3L multi-port fuel injection system has the

following modes of operation:

² Ignition switch ON (Zero RPM)

² Engine start-up

² Engine warm-up

² Cruise (Idle)

² Acceleration

² Deceleration

² Wide Open Throttle

² Ignition switch OFF

The engine start-up (crank), engine warm-up, and

wide open throttle modes are OPEN LOOP modes.

Under most operating conditions, the acceleration,

deceleration, and cruise modes, with the engine at

operating temperature are CLOSED LOOP modes.

Fig. 18 Coil PackÐ3.3L Engine

Ä FUEL SYSTEMS 14 - 153

Page 1895 of 2438

WIDE OPEN THROTTLE MODE This is an OPEN LOOP mode. During wide-open-

throttle operation, the following inputs are received

by the PCM:

² battery voltage

² engine coolant temperature

² manifold absolute pressure

² engine speed

² throttle position

When the PCM senses wide open throttle condition

through the throttle position sensor (TPS) it will:

² De-energize the air conditioning relay. This dis-

ables the air conditioning system.

² Provide a ground for the electrical EGR transducer

(EET) solenoid. When the PCM grounds the solenoid,

the EGR system stops operating. The exhaust gas oxygen content input is not ac-

cepted by the PCM during wide open throttle opera-

tion. The PCM will adjust injector pulse width to

supply a predetermined amount of additional fuel.

IGNITION SWITCH OFF MODE When the ignition switch is turned to the OFF po-

sition, the following occurs:

² All outputs are turned off.

² No inputs are monitored.

² The PCM shuts down.

THROTTLE BODY

The throttle body assembly is located on the left

side of the intake manifold plenum (Fig. 19). The

throttle body houses the throttle position sensor and

the idle air control motor. Air flow through the throt- tle body is controlled by a cable operated throttle

blade located in the base of the throttle body.

FUEL SUPPLY CIRCUIT

Fuel is pumped to the fuel rail by an electrical

pump in the fuel tank. The pump inlet is fitted with

a strainer to prevent water and other contaminants

from entering the fuel supply circuit. Fuel pressure is controlled to a preset level above

intake manifold pressure by a pressure regulator.

The regulator is mounted on the fuel rail. The regu-

lator uses intake manifold pressure as a reference.

FUEL INJECTORS AND FUEL RAIL ASSEMBLY

Six fuel injectors are retained in the fuel rail by

lock rings (Fig. 20). The rail and injector assembly is

installed in position with the injectors inserted in re-

cessed holes in the intake manifold.

Fig. 19 Throttle Body

Fig. 20 Fuel Rail Assembly

Ä FUEL SYSTEMS 14 - 155

Page 1952 of 2438

(16) Connect the battery ground (negative) cable.

Test the operation of the lights and horns. If applica-

ble, reset the clock and radio.

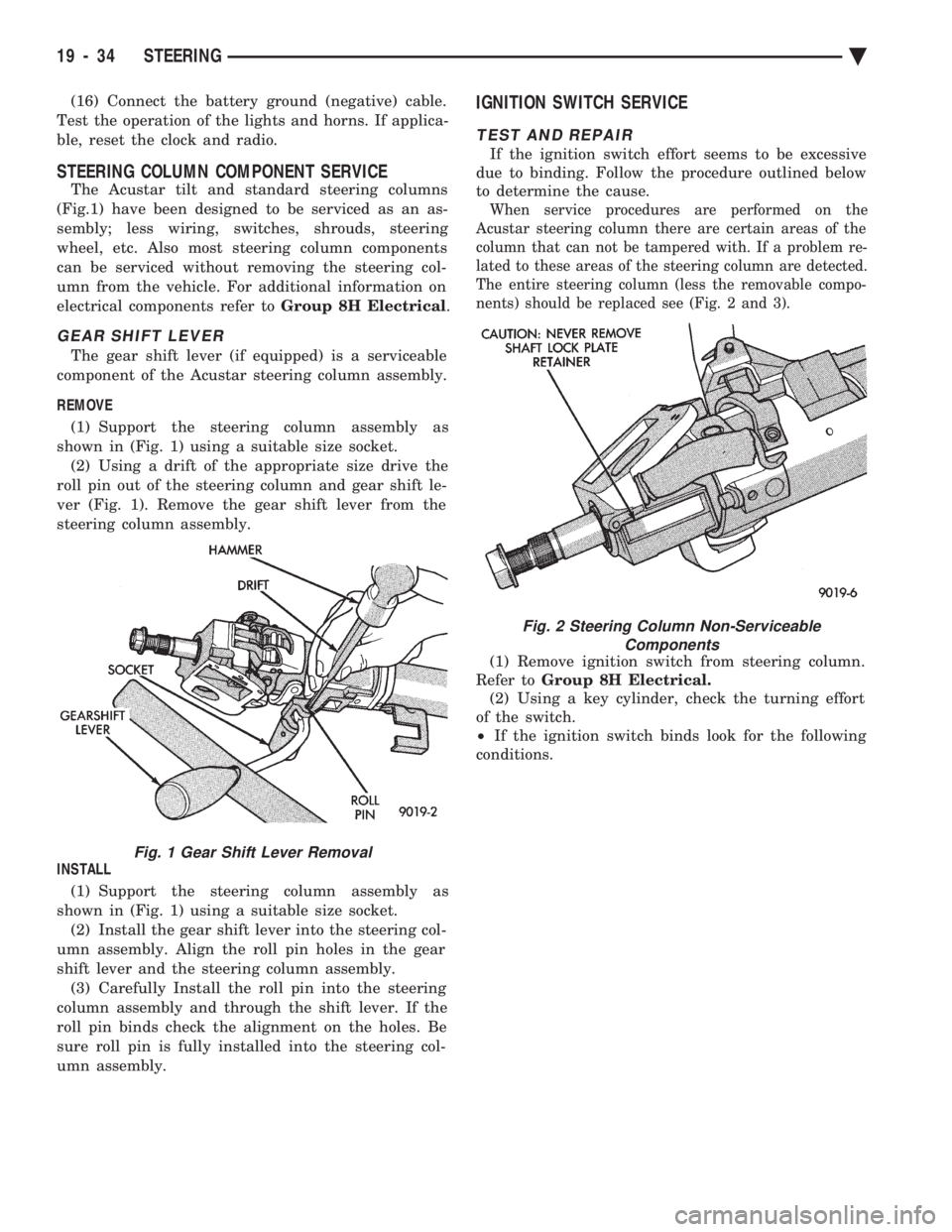

STEERING COLUMN COMPONENT SERVICE

The Acustar tilt and standard steering columns

(Fig.1) have been designed to be serviced as an as-

sembly; less wiring, switches, shrouds, steering

wheel, etc. Also most steering column components

can be serviced without removing the steering col-

umn from the vehicle. For additional information on

electrical components refer to Group 8H Electrical.

GEAR SHIFT LEVER

The gear shift lever (if equipped) is a serviceable

component of the Acustar steering column assembly.

REMOVE (1) Support the steering column assembly as

shown in (Fig. 1) using a suitable size socket. (2) Using a drift of the appropriate size drive the

roll pin out of the steering column and gear shift le-

ver (Fig. 1). Remove the gear shift lever from the

steering column assembly.

INSTALL (1) Support the steering column assembly as

shown in (Fig. 1) using a suitable size socket. (2) Install the gear shift lever into the steering col-

umn assembly. Align the roll pin holes in the gear

shift lever and the steering column assembly. (3) Carefully Install the roll pin into the steering

column assembly and through the shift lever. If the

roll pin binds check the alignment on the holes. Be

sure roll pin is fully installed into the steering col-

umn assembly.

IGNITION SWITCH SERVICE

TEST AND REPAIR

If the ignition switch effort seems to be excessive

due to binding. Follow the procedure outlined below

to determine the cause.

When service procedures are performed on the

Acustar steering column there are certain areas of the

column that can not be tampered with. If a problem re-

lated to these areas of the steering column are detected.

The entire steering column (less the removable compo-

nents) should be replaced see (Fig. 2 and 3).

(1) Remove ignition switch from steering column.

Refer to Group 8H Electrical.

(2) Using a key cylinder, check the turning effort

of the switch.

² If the ignition switch binds look for the following

conditions.

Fig. 1 Gear Shift Lever Removal

Fig. 2 Steering Column Non-Serviceable Components

19 - 34 STEERING Ä

Page 1964 of 2438

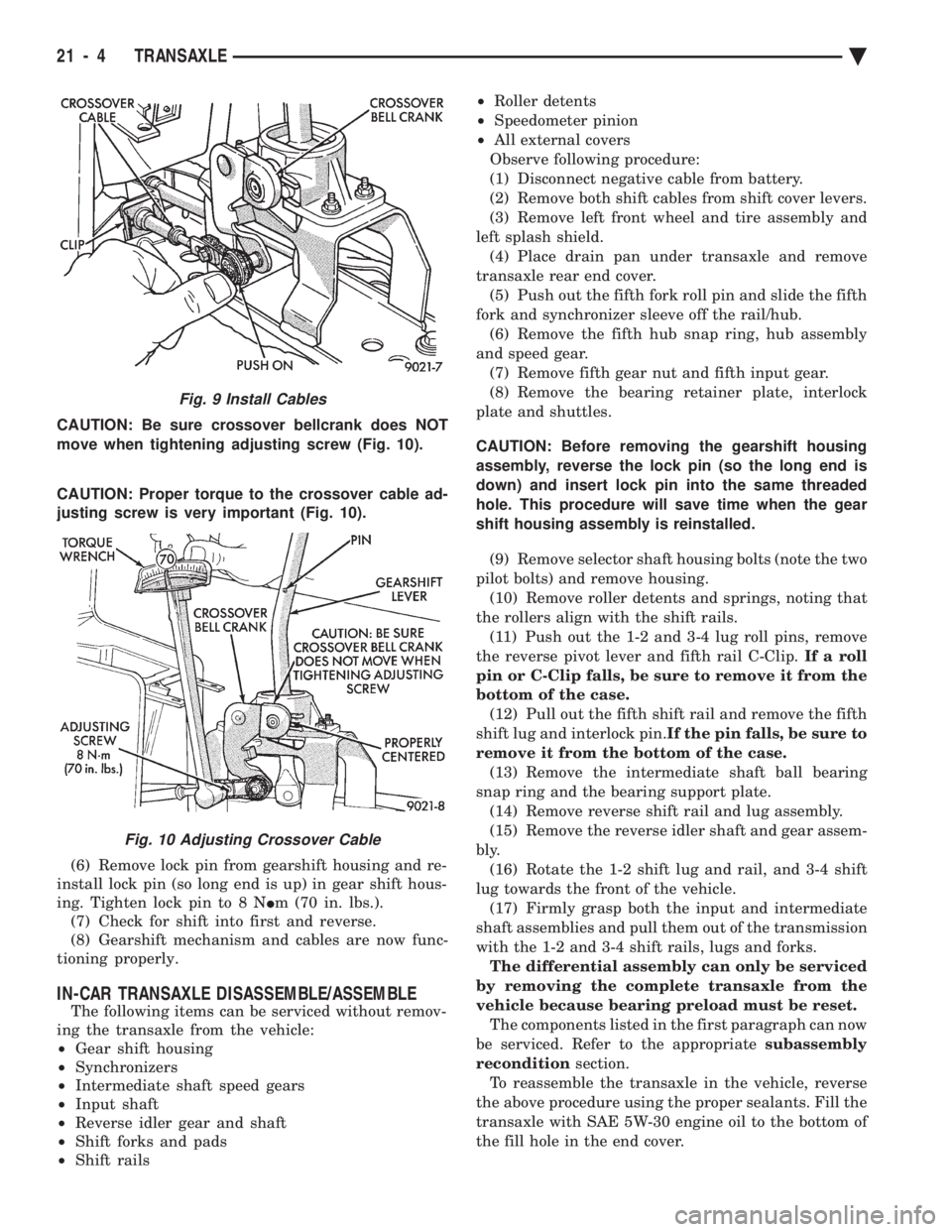

CAUTION: Be sure crossover bellcrank does NOT

move when tightening adjusting screw (Fig. 10).

CAUTION: Proper torque to the crossover cable ad-

justing screw is very important (Fig. 10).

(6) Remove lock pin from gearshift housing and re-

install lock pin (so long end is up) in gear shift hous-

ing. Tighten lock pin to 8 N Im (70 in. lbs.).

(7) Check for shift into first and reverse.

(8) Gearshift mechanism and cables are now func-

tioning properly.

IN-CAR TRANSAXLE DISASSEMBLE/ASSEMBLE

The following items can be serviced without remov-

ing the transaxle from the vehicle:

² Gear shift housing

² Synchronizers

² Intermediate shaft speed gears

² Input shaft

² Reverse idler gear and shaft

² Shift forks and pads

² Shift rails ²

Roller detents

² Speedometer pinion

² All external covers

Observe following procedure:

(1) Disconnect negative cable from battery.

(2) Remove both shift cables from shift cover levers.

(3) Remove left front wheel and tire assembly and

left splash shield. (4) Place drain pan under transaxle and remove

transaxle rear end cover. (5) Push out the fifth fork roll pin and slide the fifth

fork and synchronizer sleeve off the rail/hub. (6) Remove the fifth hub snap ring, hub assembly

and speed gear. (7) Remove fifth gear nut and fifth input gear.

(8) Remove the bearing retainer plate, interlock

plate and shuttles.

CAUTION: Before removing the gearshift housing

assembly, reverse the lock pin (so the long end is

down) and insert lock pin into the same threaded

hole. This procedure will save time when the gear

shift housing assembly is reinstalled. (9) Remove selector shaft housing bolts (note the two

pilot bolts) and remove housing. (10) Remove roller detents and springs, noting that

the rollers align with the shift rails. (11) Push out the 1-2 and 3-4 lug roll pins, remove

the reverse pivot lever and fifth rail C-Clip. If a roll

pin or C-Clip falls, be sure to remove it from the

bottom of the case. (12) Pull out the fifth shift rail and remove the fifth

shift lug and interlock pin. If the pin falls, be sure to

remove it from the bottom of the case. (13) Remove the intermediate shaft ball bearing

snap ring and the bearing support plate. (14) Remove reverse shift rail and lug assembly.

(15) Remove the reverse idler shaft and gear assem-

bly. (16) Rotate the 1-2 shift lug and rail, and 3-4 shift

lug towards the front of the vehicle. (17) Firmly grasp both the input and intermediate

shaft assemblies and pull them out of the transmission

with the 1-2 and 3-4 shift rails, lugs and forks. The differential assembly can only be serviced

by removing the complete transaxle from the

vehicle because bearing preload must be reset. The components listed in the first paragraph can now

be serviced. Refer to the appropriate subassembly

recondition section.

To reassemble the transaxle in the vehicle, reverse

the above procedure using the proper sealants. Fill the

transaxle with SAE 5W-30 engine oil to the bottom of

the fill hole in the end cover.

Fig. 9 Install Cables

Fig. 10 Adjusting Crossover Cable

21 - 4 TRANSAXLE Ä

Page 2057 of 2438

first separator plate and watch carefully for the pis-

ton to move forward. The piston should return to its

original position after the air pressure is removed.

UNDERDRIVE CLUTCH

Because this clutch piston cannot be seen, its oper-

ation is checked by function. Air pressure is applied

to the low/reverse and the 2/4 clutches. This locks

the output shaft. Use a piece of rubber hose wrapped

around the input shaft and a pair of clamp-on pliers

to turn the input shaft. Next apply air pressure to

the underdrive clutch. The input shaft should not ro-

tate with hand torque. Release the air pressure and

confirm that the input shaft will rotate.

FLUID LEAKAGE-TORQUE CONVERTER HOUSING

AREA

(1) Check for source of leakage.

Since fluid leakage at or around the torque con-

verter area may originate from an engine oil leak,

the area should be examined closely. Factory fill

fluid is dyed red and, therefore, can be distinguished

from engine oil. (2) Prior to removing the transaxle, perform the

following checks: When leakage is determined to originate from the

transaxle, check fluid level prior to removal of the

transaxle and torque converter. High oil level can result in oil leakage out the vent

in the manual shaft. If the fluid level is high, adjust

to proper level. After performing this operation, inspect for leak-

age. If a leak persists, perform the following opera-

tion on the vehicle to determine if it is the torque

converter or transaxle that is leaking.

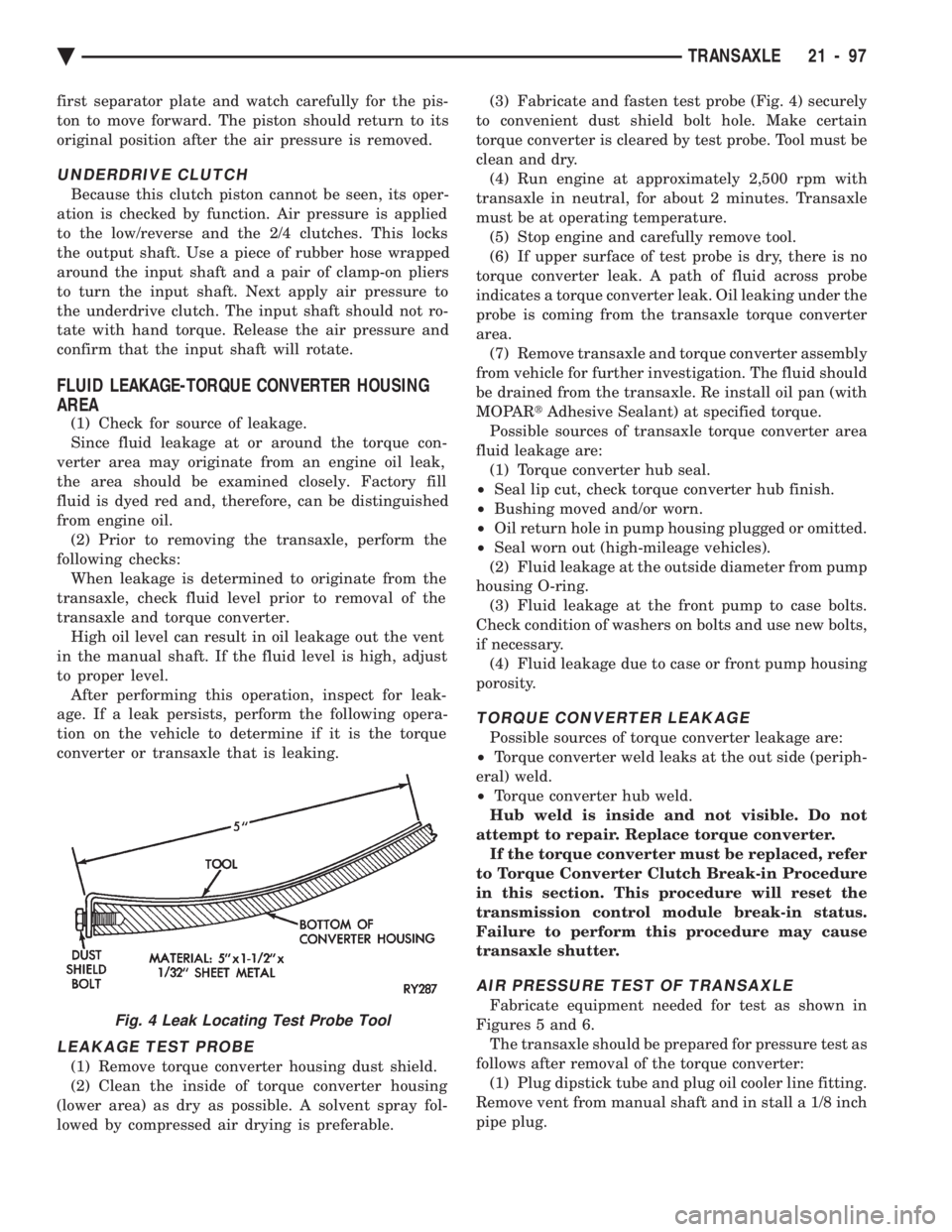

LEAKAGE TEST PROBE

(1) Remove torque converter housing dust shield.

(2) Clean the inside of torque converter housing

(lower area) as dry as possible. A solvent spray fol-

lowed by compressed air drying is preferable. (3) Fabricate and fasten test probe (Fig. 4) securely

to convenient dust shield bolt hole. Make certain

torque converter is cleared by test probe. Tool must be

clean and dry. (4) Run engine at approximately 2,500 rpm with

transaxle in neutral, for about 2 minutes. Transaxle

must be at operating temperature. (5) Stop engine and carefully remove tool.

(6) If upper surface of test probe is dry, there is no

torque converter leak. A path of fluid across probe

indicates a torque converter leak. Oil leaking under the

probe is coming from the transaxle torque converter

area. (7) Remove transaxle and torque converter assembly

from vehicle for further investigation. The fluid should

be drained from the transaxle. Re install oil pan (with

MOPAR tAdhesive Sealant) at specified torque.

Possible sources of transaxle torque converter area

fluid leakage are: (1) Torque converter hub seal.

² Seal lip cut, check torque converter hub finish.

² Bushing moved and/or worn.

² Oil return hole in pump housing plugged or omitted.

² Seal worn out (high-mileage vehicles).

(2) Fluid leakage at the outside diameter from pump

housing O-ring. (3) Fluid leakage at the front pump to case bolts.

Check condition of washers on bolts and use new bolts,

if necessary. (4) Fluid leakage due to case or front pump housing

porosity.

TORQUE CONVERTER LEAKAGE

Possible sources of torque converter leakage are:

² Torque converter weld leaks at the out side (periph-

eral) weld.

² Torque converter hub weld.

Hub weld is inside and not visible. Do not

attempt to repair. Replace torque converter. If the torque converter must be replaced, refer

to Torque Converter Clutch Break-in Procedure

in this section. This procedure will reset the

transmission control module break-in status.

Failure to perform this procedure may cause

transaxle shutter.

AIR PRESSURE TEST OF TRANSAXLE

Fabricate equipment needed for test as shown in

Figures 5 and 6. The transaxle should be prepared for pressure test as

follows after removal of the torque converter: (1) Plug dipstick tube and plug oil cooler line fitting.

Remove vent from manual shaft and in stall a 1/8 inch

pipe plug.Fig. 4 Leak Locating Test Probe Tool

Ä TRANSAXLE 21 - 97