seat adjustment CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1673 of 2438

length of the spring to be tested is 33.34mm (1-5/16

inches). Turn table of Tool C-647 until surface is in line

with the 33.34mm (1-5/16 inch) mark on the threaded

stud and the zero mark on the front. Place spring over

stud on the table and lift compressing lever to set tone

device. Pull on torque wrench until ping is heard. Take

reading on torque wrench at this instant. Multiply this

reading by two. This will give the spring load at test

length. Fractional measurements are indicated on the

table for finer adjustments. Refer to specifications to

obtain specified height and allowable tensions. Discard

the springs that do not meet specifications.

VALVE INSTALLATION

(1) Coat valve stems with clean engine oil and insert

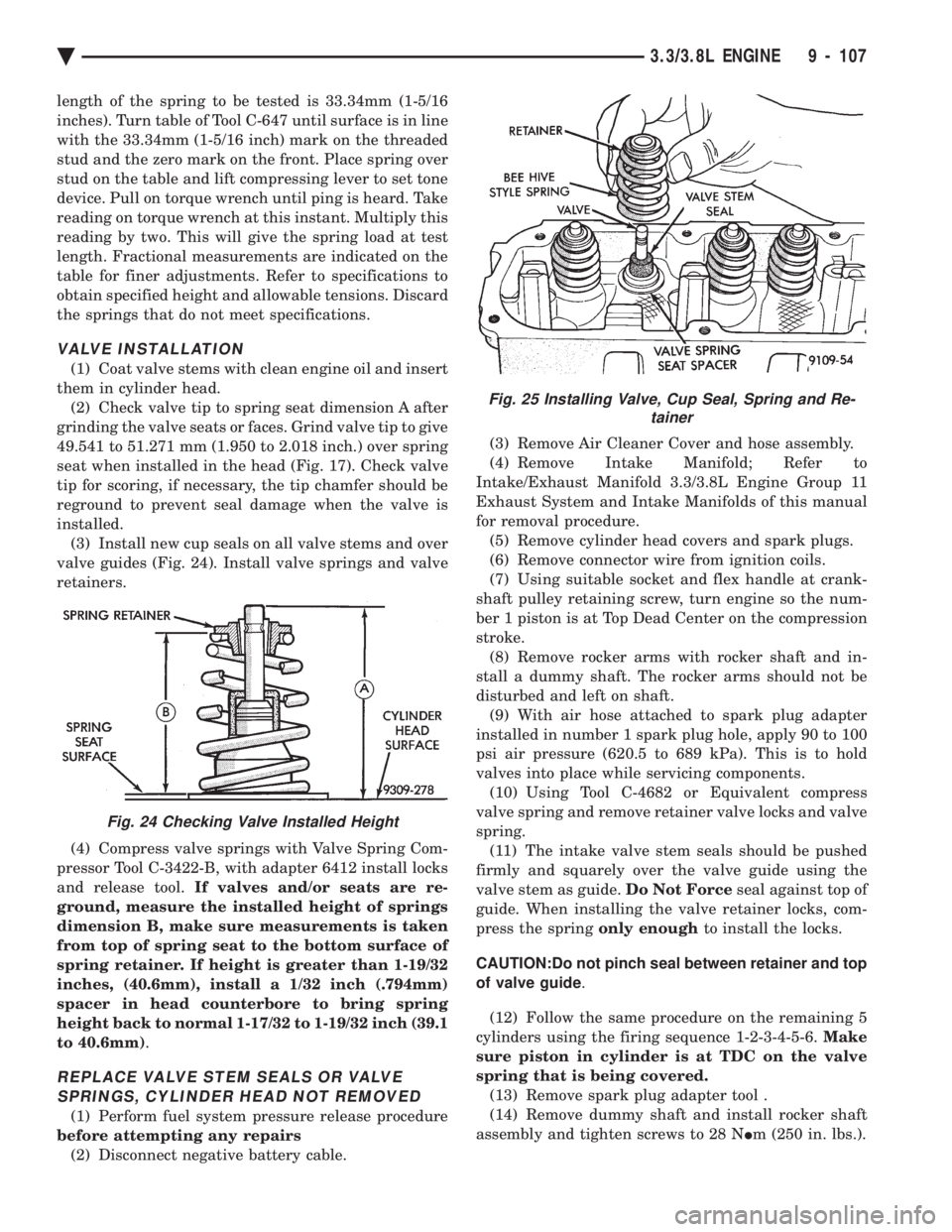

them in cylinder head. (2) Check valve tip to spring seat dimension A after

grinding the valve seats or faces. Grind valve tip to give

49.541 to 51.271 mm (1.950 to 2.018 inch.) over spring

seat when installed in the head (Fig. 17). Check valve

tip for scoring, if necessary, the tip chamfer should be

reground to prevent seal damage when the valve is

installed. (3) Install new cup seals on all valve stems and over

valve guides (Fig. 24). Install valve springs and valve

retainers.

(4) Compress valve springs with Valve Spring Com-

pressor Tool C-3422-B, with adapter 6412 install locks

and release tool. If valves and/or seats are re-

ground, measure the installed height of springs

dimension B, make sure measurements is taken

from top of spring seat to the bottom surface of

spring retainer. If height is greater than 1-19/32

inches, (40.6mm), install a 1/32 inch (.794mm)

spacer in head counterbore to bring spring

height back to normal 1-17/32 to 1-19/32 inch (39.1

to 40.6mm) .

REPLACE VALVE STEM SEALS OR VALVE

SPRINGS, CYLINDER HEAD NOT REMOVED

(1) Perform fuel system pressure release procedure

before attempting any repairs (2) Disconnect negative battery cable. (3) Remove Air Cleaner Cover and hose assembly.

(4) Remove Intake Manifold; Refer to

Intake/Exhaust Manifold 3.3/3.8L Engine Group 11

Exhaust System and Intake Manifolds of this manual

for removal procedure. (5) Remove cylinder head covers and spark plugs.

(6) Remove connector wire from ignition coils.

(7) Using suitable socket and flex handle at crank-

shaft pulley retaining screw, turn engine so the num-

ber 1 piston is at Top Dead Center on the compression

stroke. (8) Remove rocker arms with rocker shaft and in-

stall a dummy shaft. The rocker arms should not be

disturbed and left on shaft. (9) With air hose attached to spark plug adapter

installed in number 1 spark plug hole, apply 90 to 100

psi air pressure (620.5 to 689 kPa). This is to hold

valves into place while servicing components. (10) Using Tool C-4682 or Equivalent compress

valve spring and remove retainer valve locks and valve

spring. (11) The intake valve stem seals should be pushed

firmly and squarely over the valve guide using the

valve stem as guide. Do Not Forceseal against top of

guide. When installing the valve retainer locks, com-

press the spring only enoughto install the locks.

CAUTION:Do not pinch seal between retainer and top

of valve guide .

(12) Follow the same procedure on the remaining 5

cylinders using the firing sequence 1-2-3-4-5-6. Make

sure piston in cylinder is at TDC on the valve

spring that is being covered. (13) Remove spark plug adapter tool .

(14) Remove dummy shaft and install rocker shaft

assembly and tighten screws to 28 N Im (250 in. lbs.).

Fig. 24 Checking Valve Installed Height

Fig. 25 Installing Valve, Cup Seal, Spring and Re-

tainer

Ä 3.3/3.8L ENGINE 9 - 107

Page 1802 of 2438

ter mounting studs (Fig. 12). The top of the solenoid

has the word TOP on it. The solenoid will not oper-

ate unless it is installed correctly.

DATA LINK CONNECTORÐPCM OUTPUT

The data link connector provides the technician

with the means to connect the DRBII scan tool to di-

agnosis the vehicle.

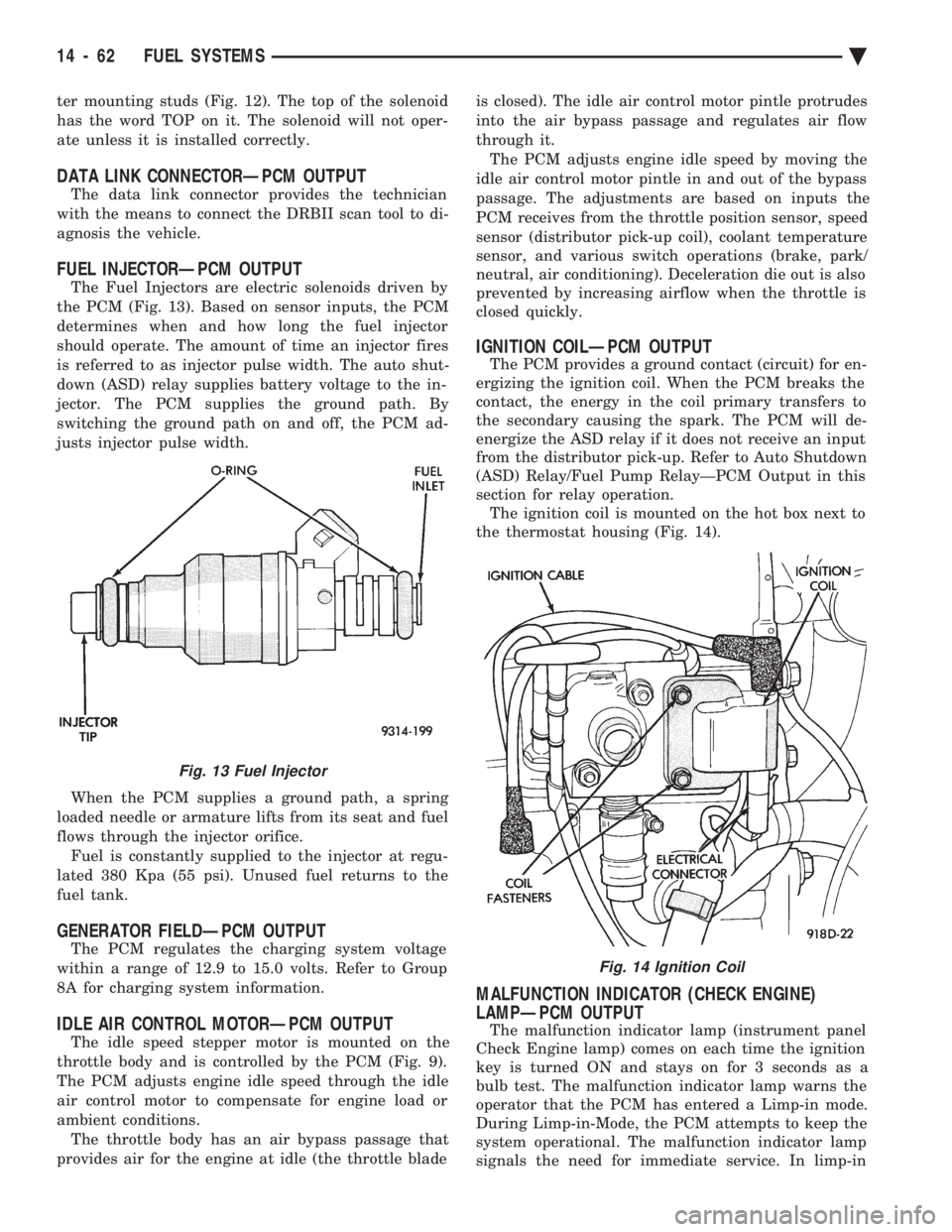

FUEL INJECTORÐPCM OUTPUT

The Fuel Injectors are electric solenoids driven by

the PCM (Fig. 13). Based on sensor inputs, the PCM

determines when and how long the fuel injector

should operate. The amount of time an injector fires

is referred to as injector pulse width. The auto shut-

down (ASD) relay supplies battery voltage to the in-

jector. The PCM supplies the ground path. By

switching the ground path on and off, the PCM ad-

justs injector pulse width.

When the PCM supplies a ground path, a spring

loaded needle or armature lifts from its seat and fuel

flows through the injector orifice. Fuel is constantly supplied to the injector at regu-

lated 380 Kpa (55 psi). Unused fuel returns to the

fuel tank.

GENERATOR FIELDÐPCM OUTPUT

The PCM regulates the charging system voltage

within a range of 12.9 to 15.0 volts. Refer to Group

8A for charging system information.

IDLE AIR CONTROL MOTORÐPCM OUTPUT

The idle speed stepper motor is mounted on the

throttle body and is controlled by the PCM (Fig. 9).

The PCM adjusts engine idle speed through the idle

air control motor to compensate for engine load or

ambient conditions. The throttle body has an air bypass passage that

provides air for the engine at idle (the throttle blade is closed). The idle air control motor pintle protrudes

into the air bypass passage and regulates air flow

through it. The PCM adjusts engine idle speed by moving the

idle air control motor pintle in and out of the bypass

passage. The adjustments are based on inputs the

PCM receives from the throttle position sensor, speed

sensor (distributor pick-up coil), coolant temperature

sensor, and various switch operations (brake, park/

neutral, air conditioning). Deceleration die out is also

prevented by increasing airflow when the throttle is

closed quickly.

IGNITION COILÐPCM OUTPUT

The PCM provides a ground contact (circuit) for en-

ergizing the ignition coil. When the PCM breaks the

contact, the energy in the coil primary transfers to

the secondary causing the spark. The PCM will de-

energize the ASD relay if it does not receive an input

from the distributor pick-up. Refer to Auto Shutdown

(ASD) Relay/Fuel Pump RelayÐPCM Output in this

section for relay operation. The ignition coil is mounted on the hot box next to

the thermostat housing (Fig. 14).

MALFUNCTION INDICATOR (CHECK ENGINE)

LAMPÐPCM OUTPUT

The malfunction indicator lamp (instrument panel

Check Engine lamp) comes on each time the ignition

key is turned ON and stays on for 3 seconds as a

bulb test. The malfunction indicator lamp warns the

operator that the PCM has entered a Limp-in mode.

During Limp-in-Mode, the PCM attempts to keep the

system operational. The malfunction indicator lamp

signals the need for immediate service. In limp-in

Fig. 13 Fuel Injector

Fig. 14 Ignition Coil

14 - 62 FUEL SYSTEMS Ä

Page 1951 of 2438

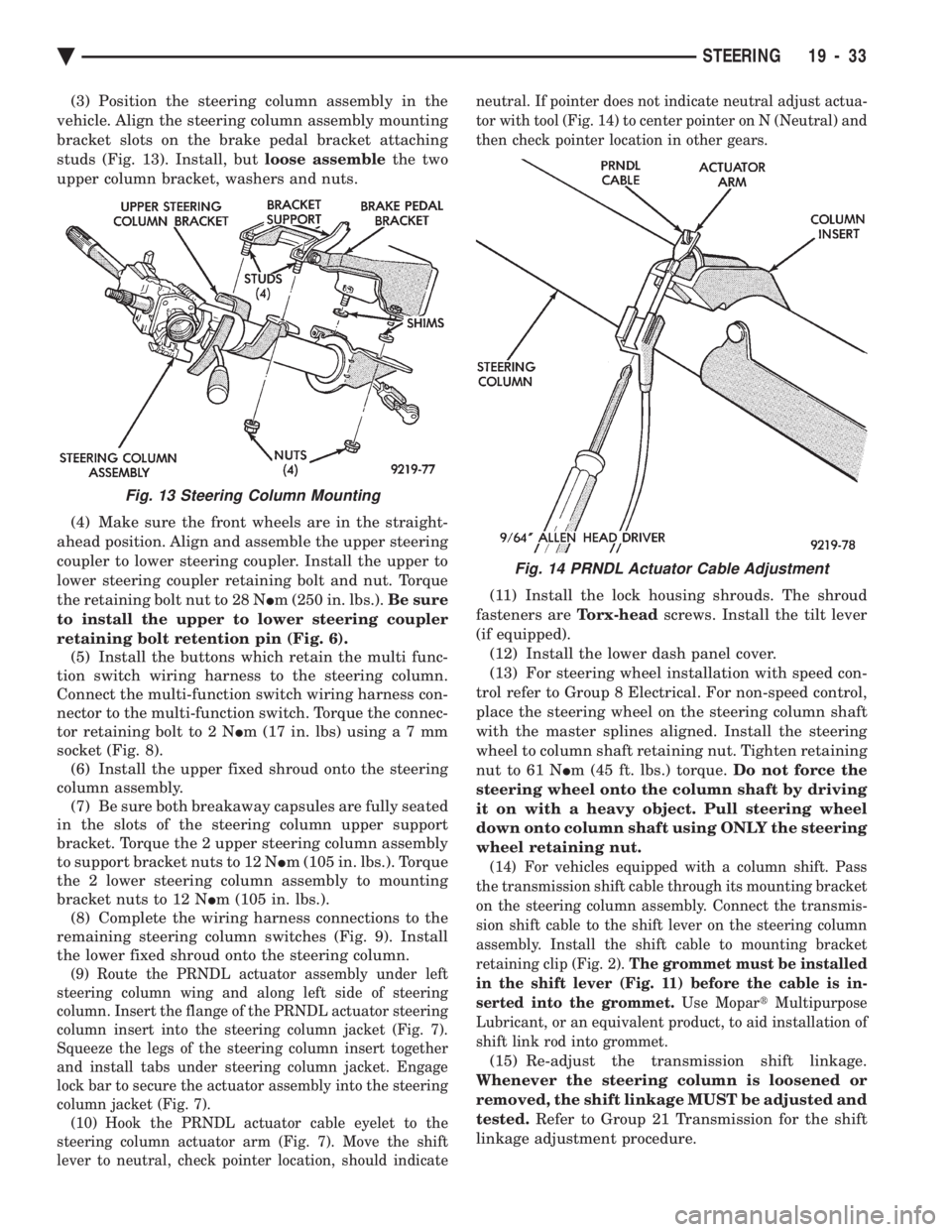

(3) Position the steering column assembly in the

vehicle. Align the steering column assembly mounting

bracket slots on the brake pedal bracket attaching

studs (Fig. 13). Install, but loose assemblethe two

upper column bracket, washers and nuts.

(4) Make sure the front wheels are in the straight-

ahead position. Align and assemble the upper steering

coupler to lower steering coupler. Install the upper to

lower steering coupler retaining bolt and nut. Torque

the retaining bolt nut to 28 N Im (250 in. lbs.). Be sure

to install the upper to lower steering coupler

retaining bolt retention pin (Fig. 6). (5) Install the buttons which retain the multi func-

tion switch wiring harness to the steering column.

Connect the multi-function switch wiring harness con-

nector to the multi-function switch. Torque the connec-

tor retaining bolt to 2 N Im (17 in. lbs) usin ga7mm

socket (Fig. 8). (6) Install the upper fixed shroud onto the steering

column assembly. (7) Be sure both breakaway capsules are fully seated

in the slots of the steering column upper support

bracket. Torque the 2 upper steering column assembly

to support bracket nuts to 12 N Im (105 in. lbs.). Torque

the 2 lower steering column assembly to mounting

bracket nuts to 12 N Im (105 in. lbs.).

(8) Complete the wiring harness connections to the

remaining steering column switches (Fig. 9). Install

the lower fixed shroud onto the steering column.

(9) Route the PRNDL actuator assembly under left

steering column wing and along left side of steering

column. Insert the flange of the PRNDL actuator steering

column insert into the steering column jacket (Fig. 7).

Squeeze the legs of the steering column insert together

and install tabs under steering column jacket. Engage

lock bar to secure the actuator assembly into the steering

column jacket (Fig. 7). (10) Hook the PRNDL actuator cable eyelet to the

steering column actuator arm (Fig. 7). Move the shift

lever to neutral, check pointer location, should indicate neutral. If pointer does not indicate neutral adjust actua-

tor with tool (Fig. 14) to center pointer on N (Neutral) and

then check pointer location in other gears.

(11) Install the lock housing shrouds. The shroud

fasteners are Torx-headscrews. Install the tilt lever

(if equipped). (12) Install the lower dash panel cover.

(13) For steering wheel installation with speed con-

trol refer to Group 8 Electrical. For non-speed control,

place the steering wheel on the steering column shaft

with the master splines aligned. Install the steering

wheel to column shaft retaining nut. Tighten retaining

nut to 61 N Im (45 ft. lbs.) torque. Do not force the

steering wheel onto the column shaft by driving

it on with a heavy object. Pull steering wheel

down onto column shaft using ONLY the steering

wheel retaining nut.

(14) For vehicles equipped with a column shift. Pass

the transmission shift cable through its mounting bracket

on the steering column assembly. Connect the transmis-

sion shift cable to the shift lever on the steering column

assembly. Install the shift cable to mounting bracket

retaining clip (Fig. 2). The grommet must be installed

in the shift lever (Fig. 11) before the cable is in-

serted into the grommet. Use MopartMultipurpose

Lubricant, or an equivalent product, to aid installation of

shift link rod into grommet.

(15) Re-adjust the transmission shift linkage.

Whenever the steering column is loosened or

removed, the shift linkage MUST be adjusted and

tested. Refer to Group 21 Transmission for the shift

linkage adjustment procedure.

Fig. 13 Steering Column Mounting

Fig. 14 PRNDL Actuator Cable Adjustment

Ä STEERING 19 - 33

Page 1955 of 2438

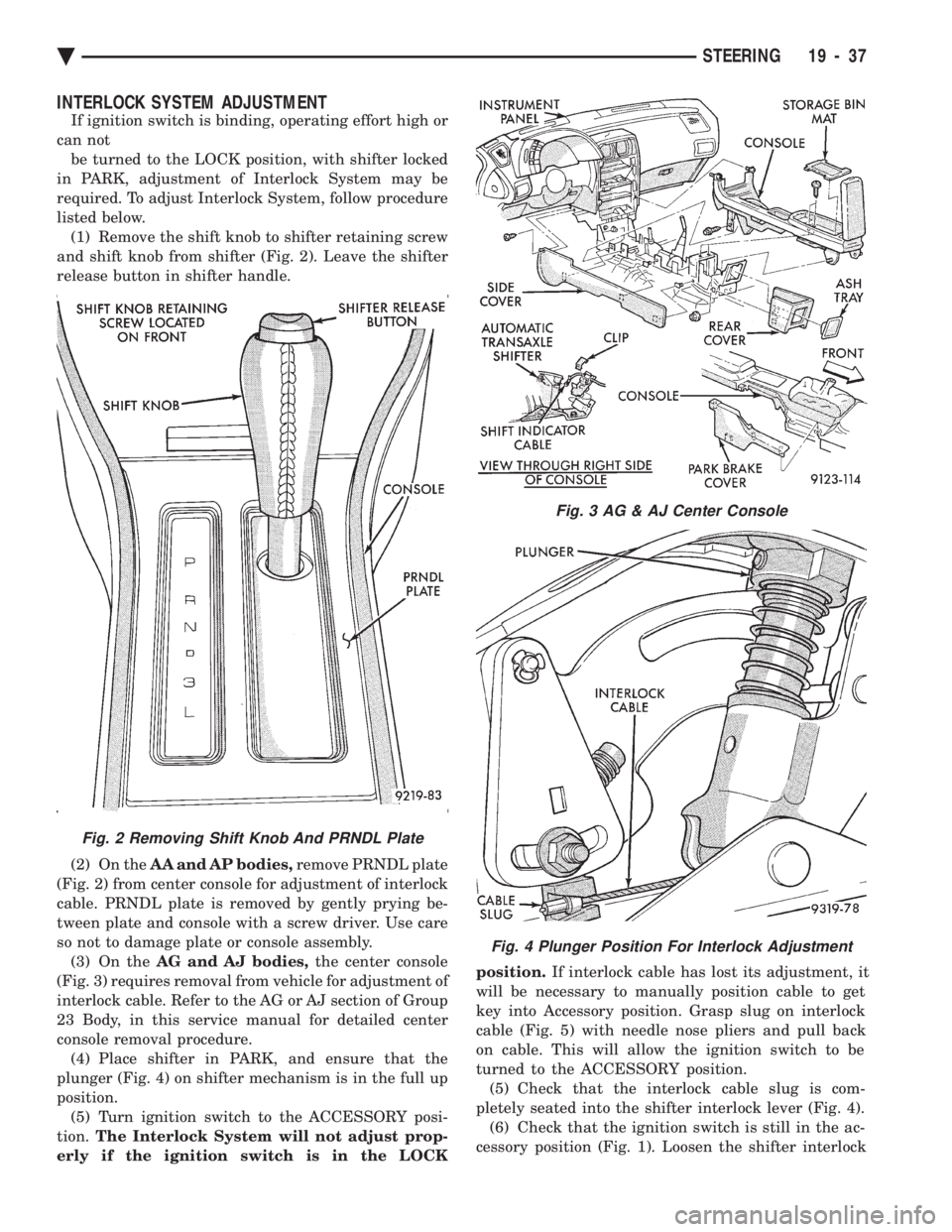

INTERLOCK SYSTEM ADJUSTMENT

If ignition switch is binding, operating effort high or

can not be turned to the LOCK position, with shifter locked

in PARK, adjustment of Interlock System may be

required. To adjust Interlock System, follow procedure

listed below. (1) Remove the shift knob to shifter retaining screw

and shift knob from shifter (Fig. 2). Leave the shifter

release button in shifter handle.

(2) On the AA and AP bodies, remove PRNDL plate

(Fig. 2) from center console for adjustment of interlock

cable. PRNDL plate is removed by gently prying be-

tween plate and console with a screw driver. Use care

so not to damage plate or console assembly. (3) On the AG and AJ bodies, the center console

(Fig. 3) requires removal from vehicle for adjustment of

interlock cable. Refer to the AG or AJ section of Group

23 Body, in this service manual for detailed center

console removal procedure. (4) Place shifter in PARK, and ensure that the

plunger (Fig. 4) on shifter mechanism is in the full up

position. (5) Turn ignition switch to the ACCESSORY posi-

tion. The Interlock System will not adjust prop-

erly if the ignition switch is in the LOCK position.

If interlock cable has lost its adjustment, it

will be necessary to manually position cable to get

key into Accessory position. Grasp slug on interlock

cable (Fig. 5) with needle nose pliers and pull back

on cable. This will allow the ignition switch to be

turned to the ACCESSORY position. (5) Check that the interlock cable slug is com-

pletely seated into the shifter interlock lever (Fig. 4). (6) Check that the ignition switch is still in the ac-

cessory position (Fig. 1). Loosen the shifter interlock

Fig. 3 AG & AJ Center Console

Fig. 4 Plunger Position For Interlock Adjustment

Fig. 2 Removing Shift Knob And PRNDL Plate

Ä STEERING 19 - 37

Page 1959 of 2438

CAUTION: Interlock cable must by completely

clipped to the throttle pedal bracket with both barbs

of clip fully installed through mounting holes. This

is to prevent interference with throttle pedal.

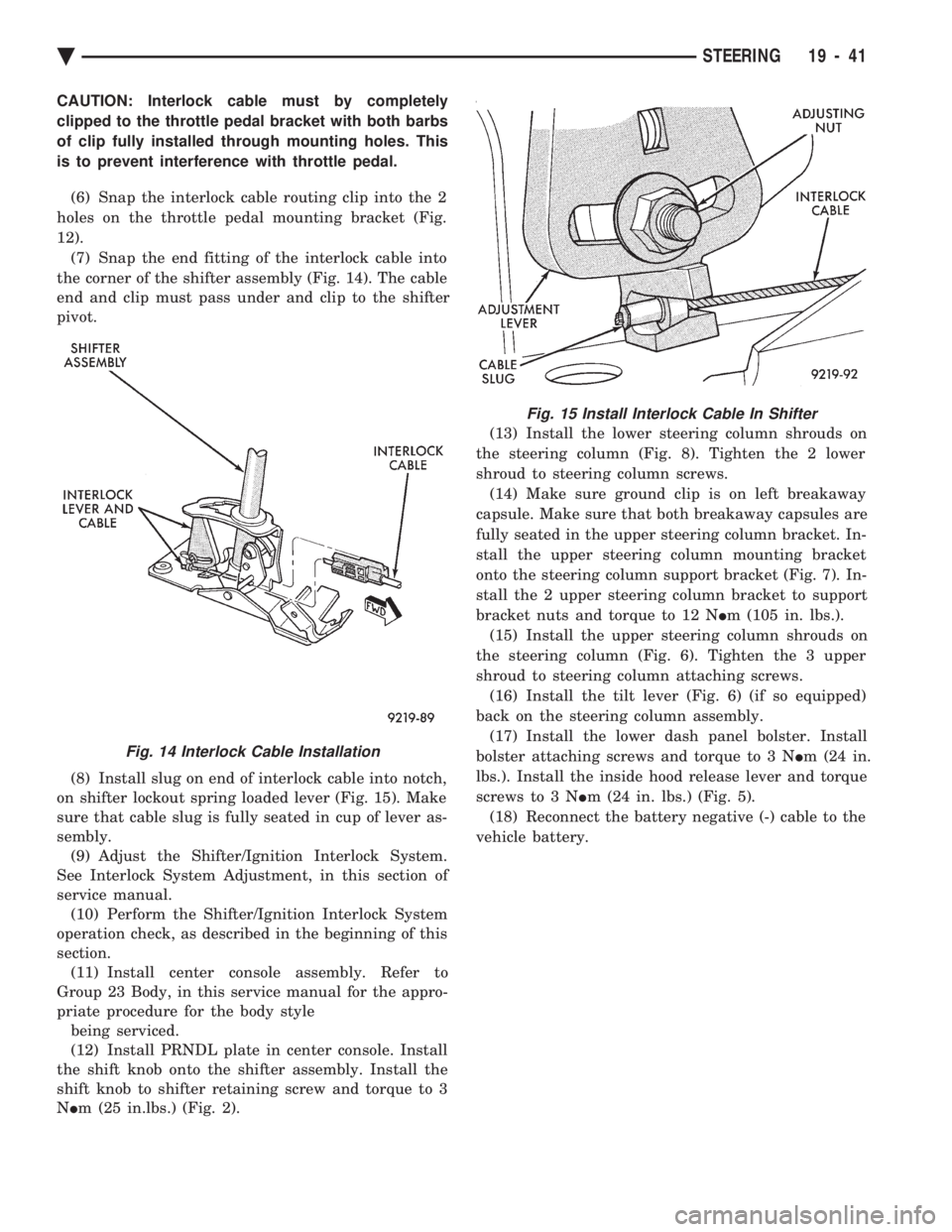

(6) Snap the interlock cable routing clip into the 2

holes on the throttle pedal mounting bracket (Fig.

12). (7) Snap the end fitting of the interlock cable into

the corner of the shifter assembly (Fig. 14). The cable

end and clip must pass under and clip to the shifter

pivot.

(8) Install slug on end of interlock cable into notch,

on shifter lockout spring loaded lever (Fig. 15). Make

sure that cable slug is fully seated in cup of lever as-

sembly. (9) Adjust the Shifter/Ignition Interlock System.

See Interlock System Adjustment, in this section of

service manual. (10) Perform the Shifter/Ignition Interlock System

operation check, as described in the beginning of this

section. (11) Install center console assembly. Refer to

Group 23 Body, in this service manual for the appro-

priate procedure for the body style being serviced.

(12) Install PRNDL plate in center console. Install

the shift knob onto the shifter assembly. Install the

shift knob to shifter retaining screw and torque to 3

N Im (25 in.lbs.) (Fig. 2). (13) Install the lower steering column shrouds on

the steering column (Fig. 8). Tighten the 2 lower

shroud to steering column screws. (14) Make sure ground clip is on left breakaway

capsule. Make sure that both breakaway capsules are

fully seated in the upper steering column bracket. In-

stall the upper steering column mounting bracket

onto the steering column support bracket (Fig. 7). In-

stall the 2 upper steering column bracket to support

bracket nuts and torque to 12 N Im (105 in. lbs.).

(15) Install the upper steering column shrouds on

the steering column (Fig. 6). Tighten the 3 upper

shroud to steering column attaching screws. (16) Install the tilt lever (Fig. 6) (if so equipped)

back on the steering column assembly. (17) Install the lower dash panel bolster. Install

bolster attaching screws and torque to 3 N Im (24 in.

lbs.). Install the inside hood release lever and torque

screws to 3 N Im (24 in. lbs.) (Fig. 5).

(18) Reconnect the battery negative (-) cable to the

vehicle battery.

Fig. 14 Interlock Cable Installation

Fig. 15 Install Interlock Cable In Shifter

Ä STEERING 19 - 41

Page 1962 of 2438

A-568 HEAVYÐDUTY MANUAL TRANSAXLE

The greater torque of the high output turbo engines

require a stronger transmission. It includes a die-cast

aluminum case and a stronger, coarse-pitch gear set. It

has five forward speed ratios and reverse. Gear ratios

are as follows: 1stÐ3.31, 2ndÐ1.89, 3rdÐ1.28,

4thÐ0.94, 5thÐ0.71, ReverseÐ3.14. Final drive ratio

of 3.85 was selected for maximum performance. All

forward gears are synchronized. To reduce wear, this transaxle, in common with other

manual transaxles, uses SAE 5W-30 engine oil as the

lubricant.

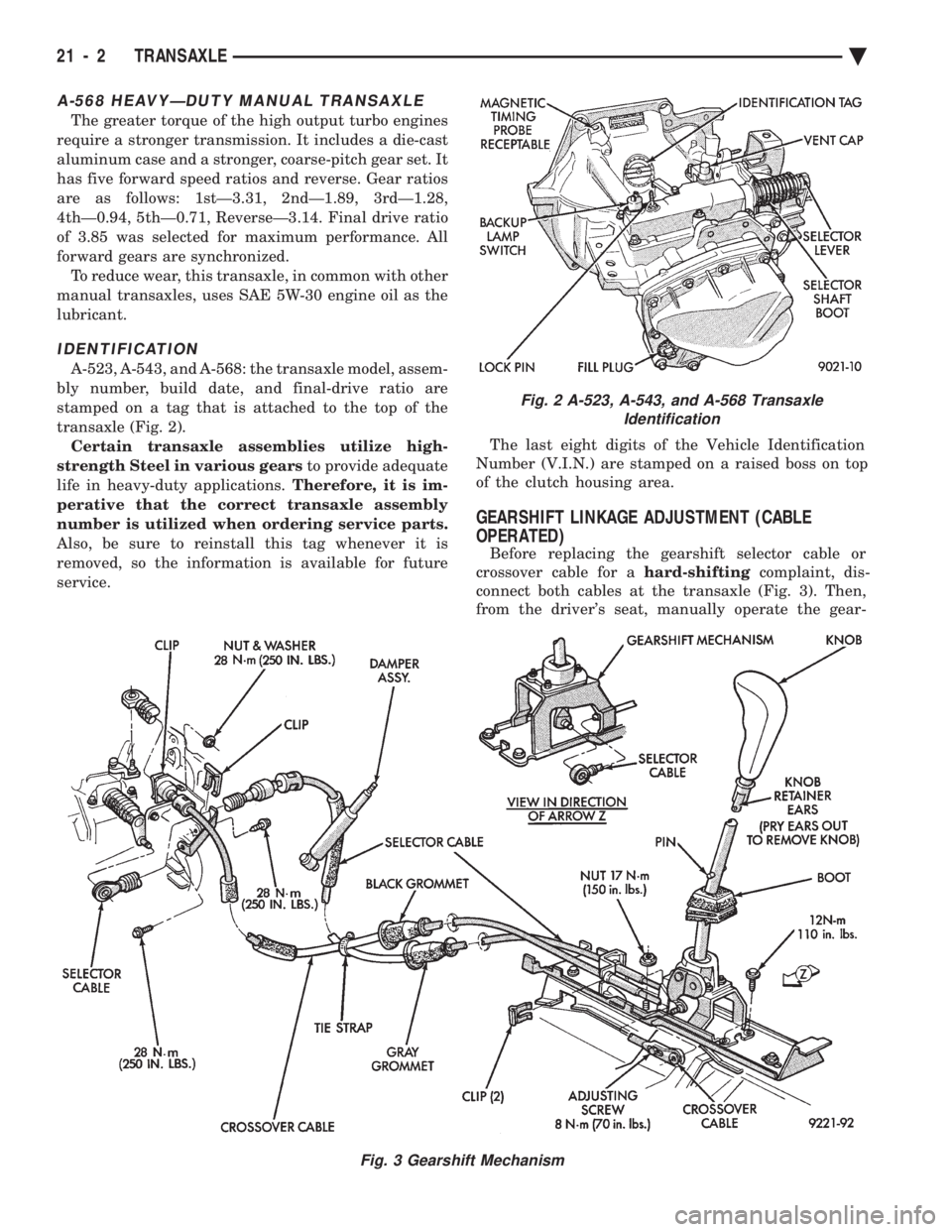

IDENTIFICATION

A-523, A-543, and A-568: the transaxle model, assem-

bly number, build date, and final-drive ratio are

stamped on a tag that is attached to the top of the

transaxle (Fig. 2). Certain transaxle assemblies utilize high-

strength Steel in various gears to provide adequate

life in heavy-duty applications. Therefore, it is im-

perative that the correct transaxle assembly

number is utilized when ordering service parts.

Also, be sure to reinstall this tag whenever it is

removed, so the information is available for future

service. The last eight digits of the Vehicle Identification

Number (V.I.N.) are stamped on a raised boss on top

of the clutch housing area.

GEARSHIFT LINKAGE ADJUSTMENT (CABLE

OPERATED)

Before replacing the gearshift selector cable or

crossover cable for a hard-shiftingcomplaint, dis-

connect both cables at the transaxle (Fig. 3). Then,

from the driver's seat, manually operate the gear-

Fig. 2 A-523, A-543, and A-568 Transaxle Identification

Fig. 3 Gearshift Mechanism

21 - 2 TRANSAXLE Ä

Page 1992 of 2438

ing seat will give a false end play reading while

gauging for proper shims. Improperly seated bearing

cups and cones are subject to low mileage failure.(2) Bearing cups and cones should be replaced if they

show signs of pitting or heat distress. If distress is seen

on either the cup or bearing rollers, both cup and cone

must be replaced. (3) Bearing preload and drag torque specifications

must be maintained to avoid premature bearing

failures. Used (original) bearing may lose up to 50% of

the original drag torque after break in. All bearing

adjustments must be made with no other compo-

nent interference or gear intermesh. (4) Replace bearings as a pair. For example, if one

differential bearing is defective, replace both differen-

tial bearings. If one input shaft bearing is defective,

replace both input shaft bearings. (5) Bearing cones must notbe reused if removed.

(6) Turning torque readings should be obtained

while smoothly rotating in either direction (break-

away reading is not indicative of the true turning

torque). (7) Replace oil baffle, if damaged.

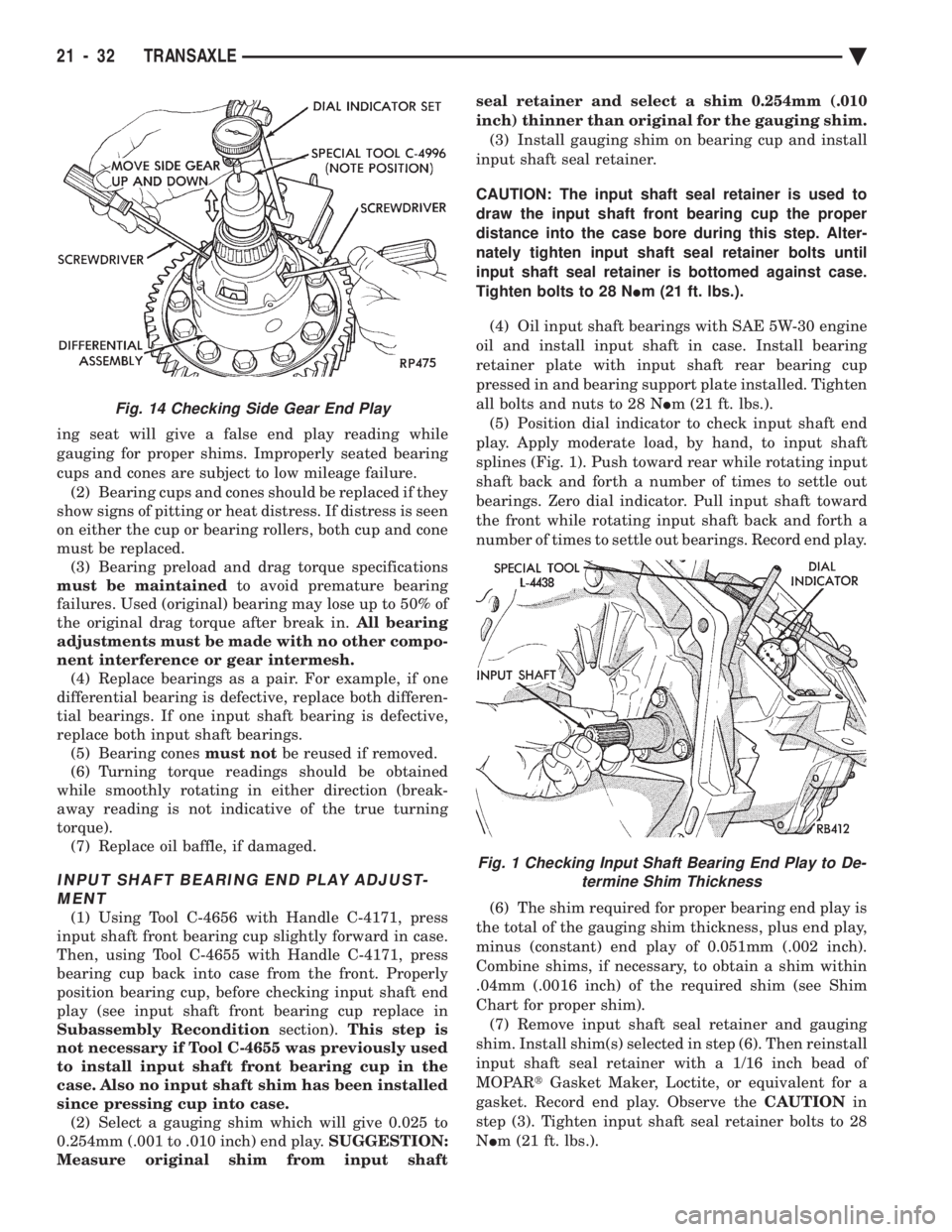

INPUT SHAFT BEARING END PLAY ADJUST-MENT

(1) Using Tool C-4656 with Handle C-4171, press

input shaft front bearing cup slightly forward in case.

Then, using Tool C-4655 with Handle C-4171, press

bearing cup back into case from the front. Properly

position bearing cup, before checking input shaft end

play (see input shaft front bearing cup replace in

Subassembly Recondition section).This step is

not necessary if Tool C-4655 was previously used

to install input shaft front bearing cup in the

case. Also no input shaft shim has been installed

since pressing cup into case. (2) Select a gauging shim which will give 0.025 to

0.254mm (.001 to .010 inch) end play. SUGGESTION:

Measure original shim from input shaft seal retainer and select a shim 0.254mm (.010

inch) thinner than original for the gauging shim.

(3) Install gauging shim on bearing cup and install

input shaft seal retainer.

CAUTION: The input shaft seal retainer is used to

draw the input shaft front bearing cup the proper

distance into the case bore during this step. Alter-

nately tighten input shaft seal retainer bolts until

input shaft seal retainer is bottomed against case.

Tighten bolts to 28 N Im (21 ft. lbs.).

(4) Oil input shaft bearings with SAE 5W-30 engine

oil and install input shaft in case. Install bearing

retainer plate with input shaft rear bearing cup

pressed in and bearing support plate installed. Tighten

all bolts and nuts to 28 N Im (21 ft. lbs.).

(5) Position dial indicator to check input shaft end

play. Apply moderate load, by hand, to input shaft

splines (Fig. 1). Push toward rear while rotating input

shaft back and forth a number of times to settle out

bearings. Zero dial indicator. Pull input shaft toward

the front while rotating input shaft back and forth a

number of times to settle out bearings. Record end play.

(6) The shim required for proper bearing end play is

the total of the gauging shim thickness, plus end play,

minus (constant) end play of 0.051mm (.002 inch).

Combine shims, if necessary, to obtain a shim within

.04mm (.0016 inch) of the required shim (see Shim

Chart for proper shim). (7) Remove input shaft seal retainer and gauging

shim. Install shim(s) selected in step (6). Then reinstall

input shaft seal retainer with a 1/16 inch bead of

MOPAR tGasket Maker, Loctite, or equivalent for a

gasket. Record end play. Observe the CAUTIONin

step (3). Tighten input shaft seal retainer bolts to 28

N Im (21 ft. lbs.).

Fig. 14 Checking Side Gear End Play

Fig. 1 Checking Input Shaft Bearing End Play to De-

termine Shim Thickness

21 - 32 TRANSAXLE Ä

Page 2000 of 2438

FLUID LEVEL AND CONDITION

The transmission and differential sump have a

common oil sump with a communicating opening

between the two. Before removing the dipstick, wipe all dirt off of the

protective disc and the dipstick handle. The torque converter will fill in both the PPark or N

Neutral positions. Place the selector lever in PPark to

check fluid level. Inspect fluid level on dipstick every six months.

Allow the engine to idle for at least one minute

with vehicle on level ground. This will assure

complete oil level stabilization between differen-

tial and transmission. A properly filled transaxle

will read near the addmark when fluid temperature is

21 degrees Celsius (70 degrees Fahrenheit). When the

transaxle reaches operating temperature the fluid

should be in the HOTregion.

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with the

fluid. As in any hydraulic system, air bubbles make the

fluid spongy, therefore, pressures will be low and build

up slowly. Improper filling can also raise the fluid level too

high. When the transaxle has too much fluid, the gears

churn up foam and cause the same conditions which

occur with a low fluid level. In either case, the air bubbles can cause overheating,

fluid oxidation, and varnishing, which can interfere

with normal valve, clutch, and servo operation. Foam-

ing can also result in fluid escaping from the transaxle

vent (dipstick handle) where it may be mistaken for a

leak. Along with fluid level, it is important to check the

condition of the fluid. When the fluid smells burned,

and is contaminated with metal or friction material

particles, a complete transaxle overhaul is needed. Be

sure to examine the fluid on the dipstick closely. If

there is any doubt about its condition, drain out a

sample for a double check. After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

SELECTION OF LUBRICANT

It is important that the proper lubricant be used in

these transmissions. MOPAR tATF PLUS (Automatic

Transmission Fluid-Type 7176) should be used to aid in

assuring optimum transmission performance. Fluids of

the type labeled DEXRON II Automatic Transmission

Fluid should be used only if the recommended fluid is

not available. It is important that the transmission

fluid be maintained at the prescribed level using the

recommended fluids.

SPECIAL ADDITIVES

Chrysler Corporation does not recommend the addi-

tion of any fluids to the transmission, other than the

automatic transmission fluid listed above. An ex- ception to this policy is the use of special dyes to aid in

detecting fluid leaks. The use of transmission sealers

should be avoided, since they may adversely affect

seals.

FLUID AND FILTER CHANGE

When the factory fill fluid is changed, only

fluids of the type labeled MOPAR tATF PLUS

(Automatic Transmission fluid) Type 7176 should

be used. A band adjustment and filter change

should be made at the time of the oil change. The

magnet (on the inside of the oil pan) should also

be cleaned with a clean, dry cloth. If the transaxle is disassembled for any reason,

the fluid and filter should be changed, and the

band(s) adjusted.

FLUID DRAIN AND REFILL

(1) Raise vehicle on a hoist (See Lubrication, Group

0). Place a drain container with a large opening, under

transaxle oil pan. (2) Loosen pan bolts and tap the pan at one corner to

break it loose allowing fluid to drain, then remove the

oil pan. (3) Install a new filter and gasket on bottom of the

valve body and tighten retaining screws to 5 N Im (40

in. lbs.). (4) Clean the oil pan and magnet. Reinstall pan

using new MOPAR tAdhesive sealant. Tighten oil pan

bolts to 19 N Im (165 in. lbs.).

(5) Pour four quarts of MOPAR tATF PLUS (Auto-

matic Transmission Fluid) Type 7176 through the

dipstick opening. (6) Start engine and allow to idle for at least one

minute. Then, with parking and service brakes ap-

plied, move selector lever momentarily to each posi-

tion, ending in the park or neutral position. (7) Add sufficient fluid to bring level to 1/8 inch

below the ADD mark. Recheck fluid level after transaxle is at normal

operating temperature. The level should be in the HOT

region (Fig. 1). To prevent dirt from entering transaxle, make cer-

tain that dipstick is full seated into the dipstick open-

ing.

TORQUE CONVERTER CLUTCH SOLENOID WIRING

CONNECTOR

If wiring connector is unplugged, the torque con-

verter clutch will not operate (Fig. 2).

ROAD TEST

Prior to performing a road test, be certain that the

fluid level and condition, and control cable adjustments

have been checked and approved. During the road test, the transaxle should be oper-

ated in each position to check for slipping and any

variation in shifting.

21 - 40 TRANSAXLE Ä

Page 2041 of 2438

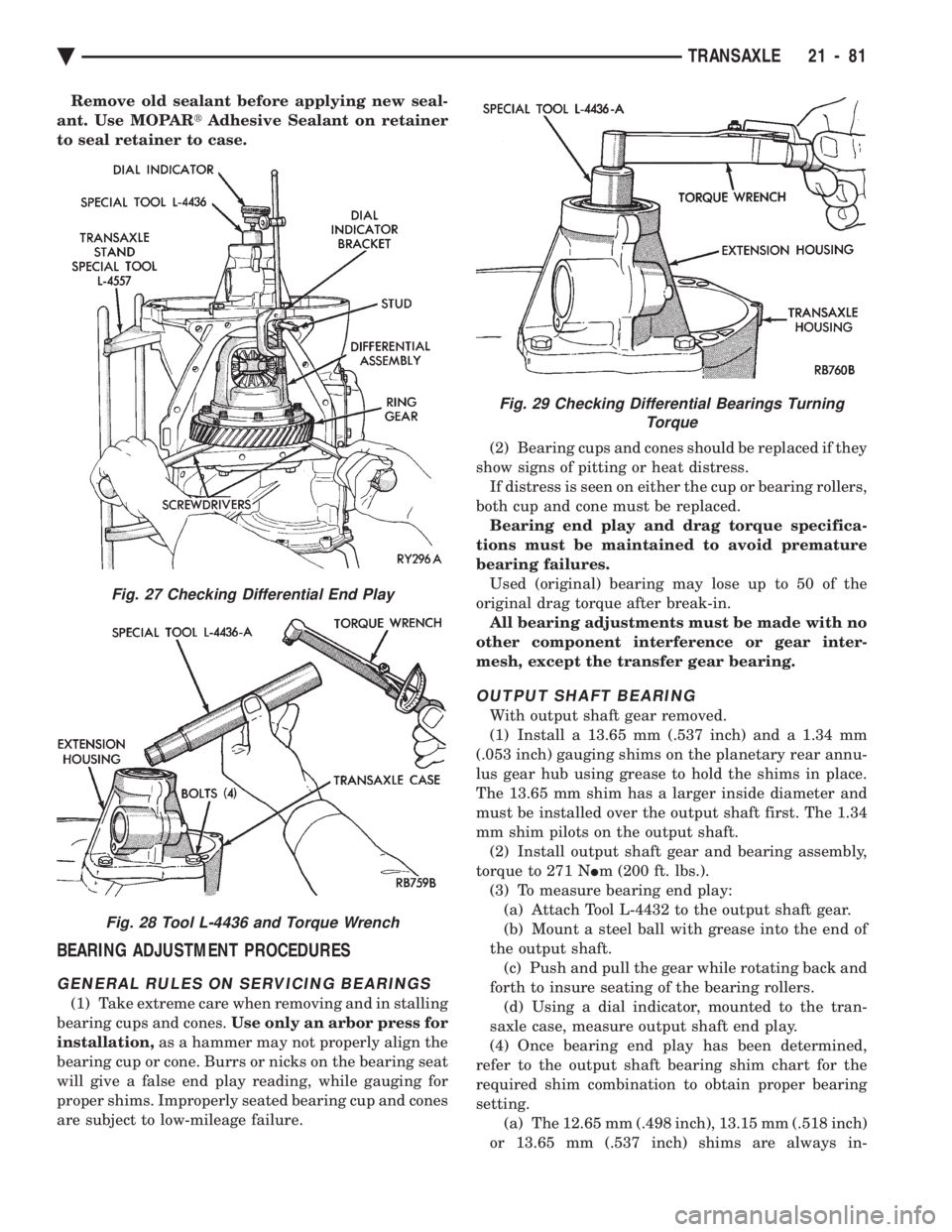

Remove old sealant before applying new seal-

ant. Use MOPAR tAdhesive Sealant on retainer

to seal retainer to case.

BEARING ADJUSTMENT PROCEDURES

GENERAL RULES ON SERVICING BEARINGS

(1) Take extreme care when removing and in stalling

bearing cups and cones. Use only an arbor press for

installation, as a hammer may not properly align the

bearing cup or cone. Burrs or nicks on the bearing seat

will give a false end play reading, while gauging for

proper shims. Improperly seated bearing cup and cones

are subject to low-mileage failure. (2) Bearing cups and cones should be replaced if they

show signs of pitting or heat distress. If distress is seen on either the cup or bearing rollers,

both cup and cone must be replaced. Bearing end play and drag torque specifica-

tions must be maintained to avoid premature

bearing failures. Used (original) bearing may lose up to 50 of the

original drag torque after break-in. All bearing adjustments must be made with no

other component interference or gear inter-

mesh, except the transfer gear bearing.

OUTPUT SHAFT BEARING

With output shaft gear removed.

(1) Install a 13.65 mm (.537 inch) and a 1.34 mm

(.053 inch) gauging shims on the planetary rear annu-

lus gear hub using grease to hold the shims in place.

The 13.65 mm shim has a larger inside diameter and

must be installed over the output shaft first. The 1.34

mm shim pilots on the output shaft. (2) Install output shaft gear and bearing assembly,

torque to 271 N Im (200 ft. lbs.).

(3) To measure bearing end play: (a) Attach Tool L-4432 to the output shaft gear.

(b) Mount a steel ball with grease into the end of

the output shaft. (c) Push and pull the gear while rotating back and

forth to insure seating of the bearing rollers. (d) Using a dial indicator, mounted to the tran-

saxle case, measure output shaft end play.

(4) Once bearing end play has been determined,

refer to the output shaft bearing shim chart for the

required shim combination to obtain proper bearing

setting. (a) The 12.65 mm (.498 inch), 13.15 mm (.518 inch)

or 13.65 mm (.537 inch) shims are always in-

Fig. 27 Checking Differential End Play

Fig. 28 Tool L-4436 and Torque Wrench

Fig. 29 Checking Differential Bearings Turning Torque

Ä TRANSAXLE 21 - 81

Page 2080 of 2438

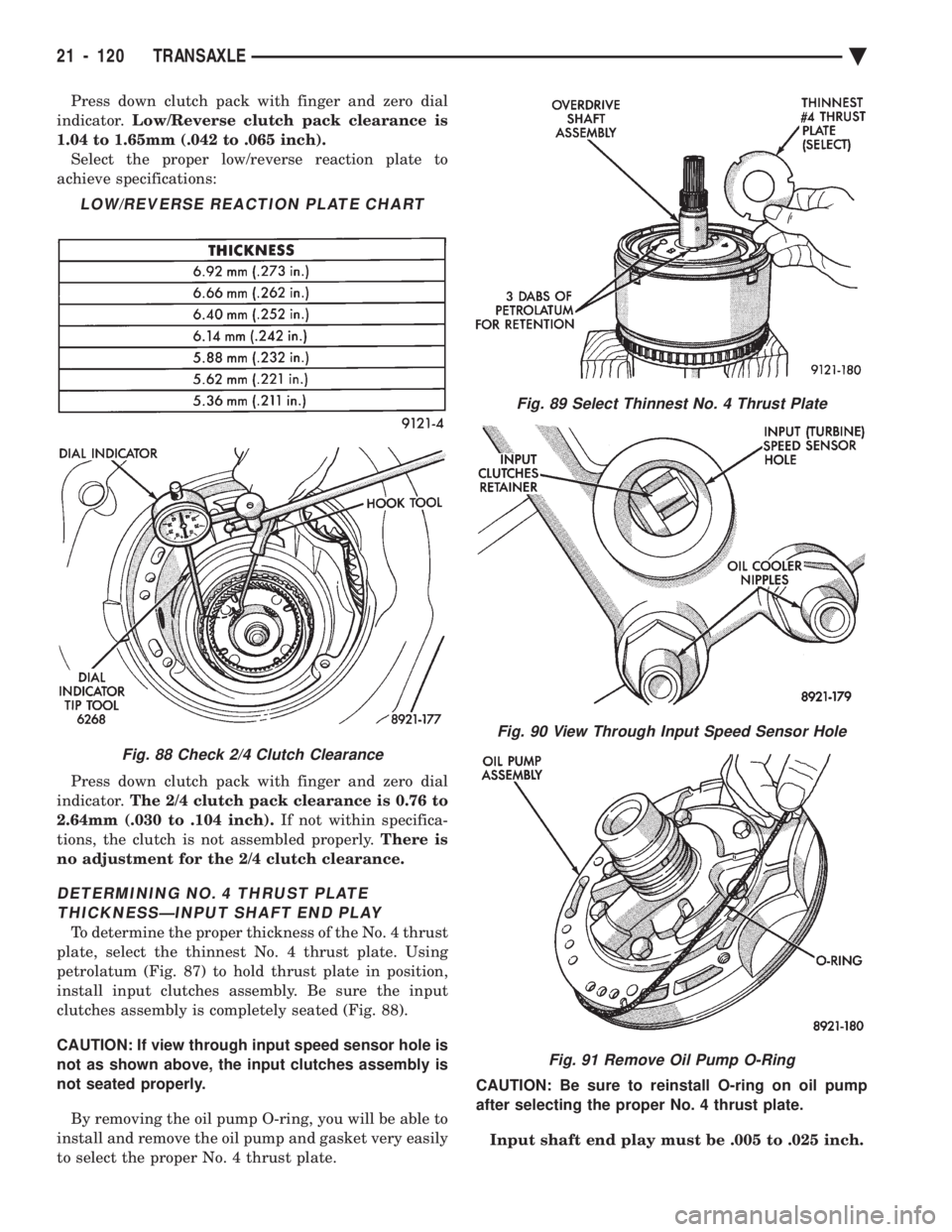

Press down clutch pack with finger and zero dial

indicator. Low/Reverse clutch pack clearance is

1.04 to 1.65mm (.042 to .065 inch). Select the proper low/reverse reaction plate to

achieve specifications:

Press down clutch pack with finger and zero dial

indicator. The 2/4 clutch pack clearance is 0.76 to

2.64mm (.030 to .104 inch). If not within specifica-

tions, the clutch is not assembled properly. There is

no adjustment for the 2/4 clutch clearance.

DETERMINING NO. 4 THRUST PLATE THICKNESSÐINPUT SHAFT END PLAY

To determine the proper thickness of the No. 4 thrust

plate, select the thinnest No. 4 thrust plate. Using

petrolatum (Fig. 87) to hold thrust plate in position,

install input clutches assembly. Be sure the input

clutches assembly is completely seated (Fig. 88).

CAUTION: If view through input speed sensor hole is

not as shown above, the input clutches assembly is

not seated properly.

By removing the oil pump O-ring, you will be able to

install and remove the oil pump and gasket very easily

to select the proper No. 4 thrust plate. CAUTION: Be sure to reinstall O-ring on oil pump

after selecting the proper No. 4 thrust plate.

Input shaft end play must be .005 to .025 inch.

LOW/REVERSE REACTION PLATE CHART

Fig. 88 Check 2/4 Clutch Clearance

Fig. 89 Select Thinnest No. 4 Thrust Plate

Fig. 90 View Through Input Speed Sensor Hole

Fig. 91 Remove Oil Pump O-Ring

21 - 120 TRANSAXLE Ä