seat adjustment CHEVROLET DYNASTY 1993 Owner's Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 2101 of 2438

When rebuilding, reverse the above procedure.

Remove old sealant before applying new seal-

ant. Use MOPAR tAdhesive Sealant on retainer

to seal retainer to case.

BEARING ADJUSTMENT PROCEDURE

GENERAL RULES ON SERVICING BEARINGS

(1) Take extreme care when removing and in stalling

bearing cups and cones. Use only an arbor press for

installation, as a hammer may not properly align the

bearing cup or cone. Burrs or nicks on the bearing seat

will give a false end play reading, while gauging for

proper shims. Improperly seated bearing cup and cones

are subject to low-mileage failure. (2) Bearing cups and cones should be replaced if they

show signs of pitting or heat distress. If distress is seen on either the cup or bearing rollers,

both cup and cone must be replaced. Bearing end play and drag torque specifica-

tions must be maintained to avoid premature

bearing failures. Used (original) bearing may lose up to 50

of the original drag torque after break-in.

All bearing adjustments must be made with no

other component interference or gear inter-

mesh, except the transfer gear bearing. Oil all bearings before checking turning torque.OUTPUT GEAR BEARING

With output gear removed:

(1) Install a 4.50 mm (0.177 inch) gauging shim on

the rear carrier assembly hub, using grease to hold the

shim in place. (2) Install output gear and bearing assembly. Torque

to 271 N Im (200 ft. lbs.).

(3) To measure bearing end play:

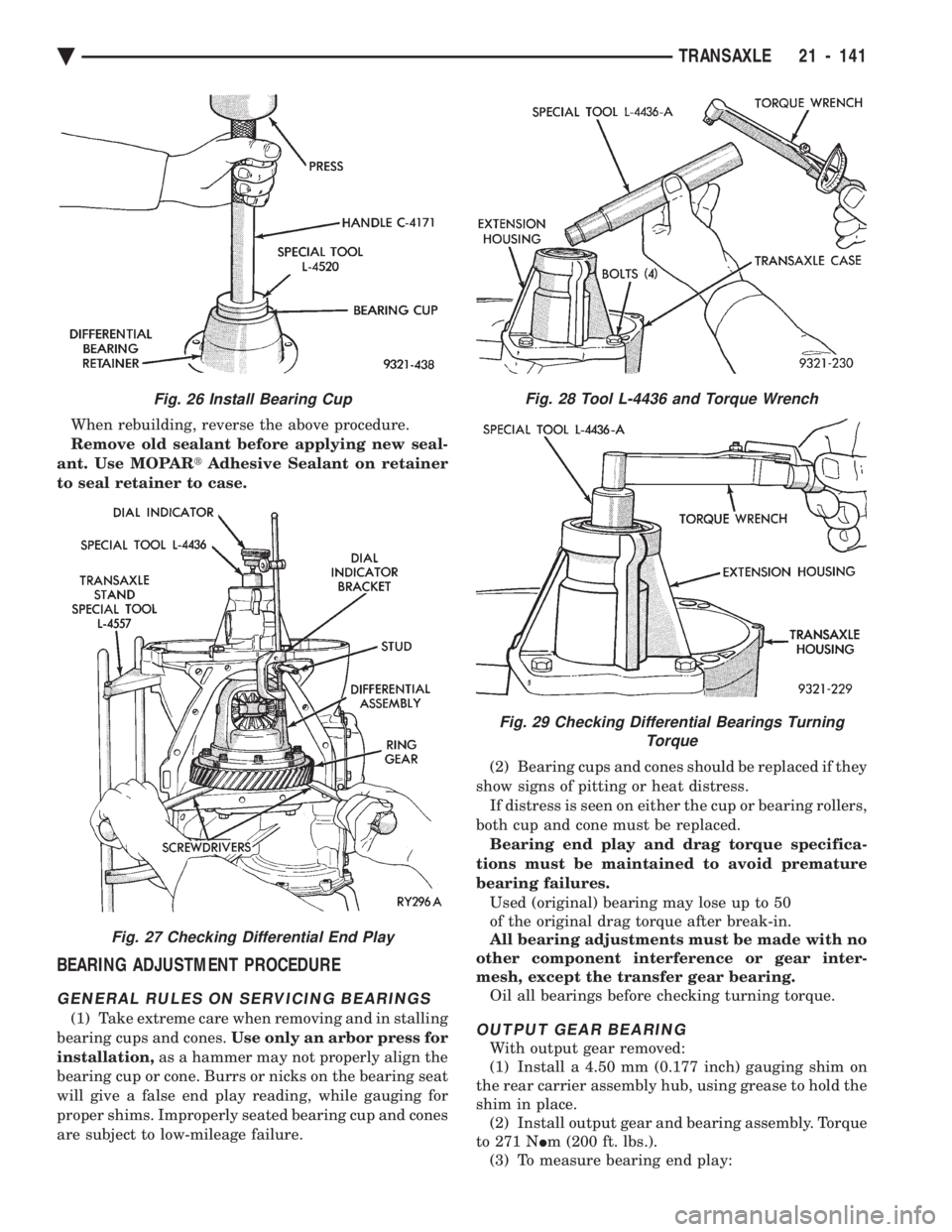

Fig. 26 Install Bearing Cup

Fig. 27 Checking Differential End Play

Fig. 28 Tool L-4436 and Torque Wrench

Fig. 29 Checking Differential Bearings Turning Torque

Ä TRANSAXLE 21 - 141

Page 2163 of 2438

(2) position wind deflector so 19 mm (0.75 in.)

above top surface of roof panel and 1 mm (0.040 in.)

rearward of roof panel forward edge. (3) Secure wind deflector to sunroof unit.

GLASS PANEL

GLASS PANEL REMOVAL

(1) Remove wind deflector mechanism covers (Fig.

1). (2) Position glass to vent position.

(3) Position sunshade full rearward.

(4) Loosen nuts holding glass panel to side adjust-

ment brackets. (5) Slide glass panel rearward 12 mm (0.5 in.) and

separate glass from sunroof unit.

GLASS PANEL INSTALLATION

(1) Position glass panel in opening with logo rear-

ward and slide panel forward 12 mm (0.5 in.). (2) Verify that attaching nuts are below top sur-

face of glass adjustment brackets. (3) Close sunroof to center glass panel in roof open-

ing. (4) Tighten center screws to hold adjustment.

(5) Open glass to vent position and tighten nuts to

8N Im (70.8 in-lbs.).

(6) Close glass and check alignment.

(7) Install the mechanism covers.

(8) Adjust wind deflector, if necessary.

ADJUSTMENT BRACKET

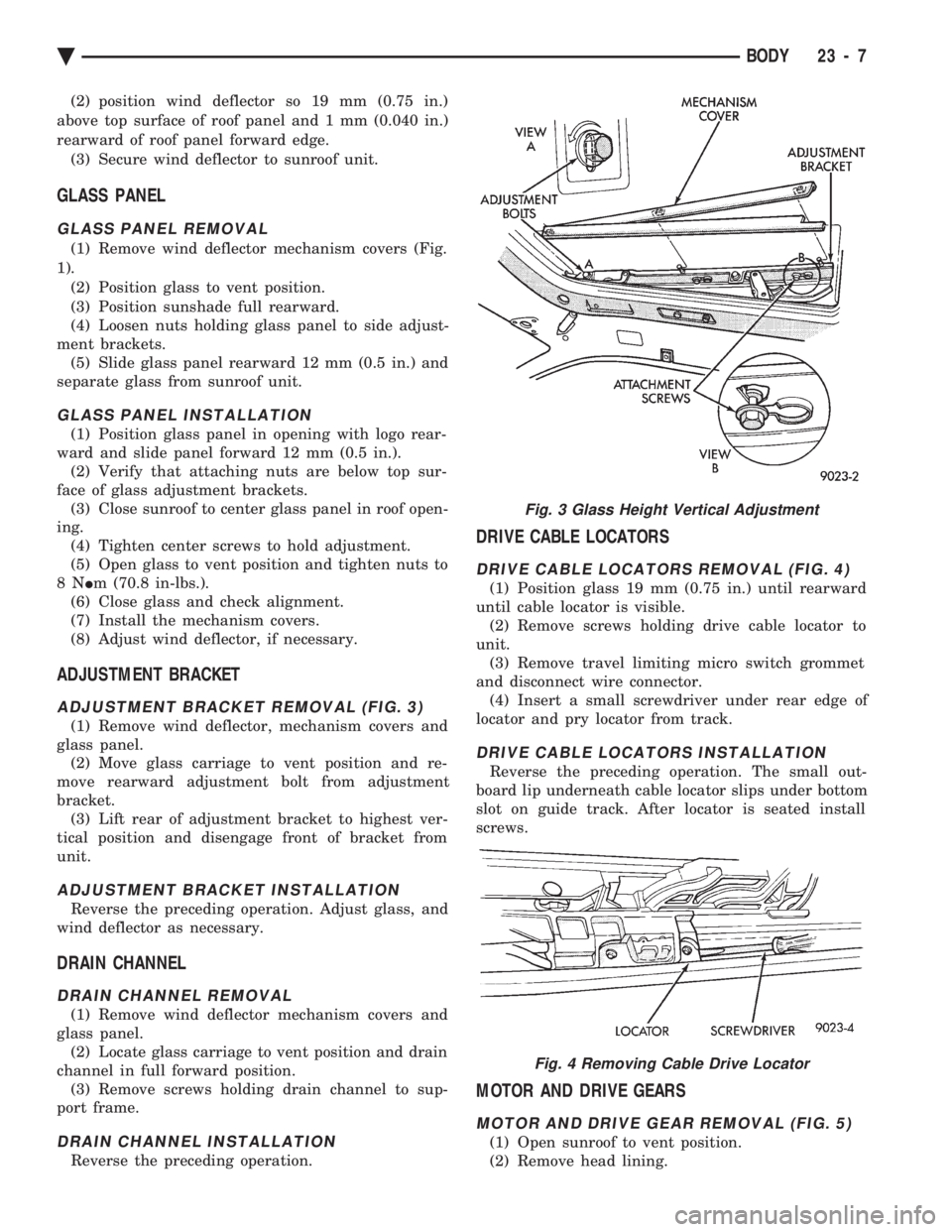

ADJUSTMENT BRACKET REMOVAL (FIG. 3)

(1) Remove wind deflector, mechanism covers and

glass panel. (2) Move glass carriage to vent position and re-

move rearward adjustment bolt from adjustment

bracket. (3) Lift rear of adjustment bracket to highest ver-

tical position and disengage front of bracket from

unit.

ADJUSTMENT BRACKET INSTALLATION

Reverse the preceding operation. Adjust glass, and

wind deflector as necessary.

DRAIN CHANNEL

DRAIN CHANNEL REMOVAL

(1) Remove wind deflector mechanism covers and

glass panel. (2) Locate glass carriage to vent position and drain

channel in full forward position. (3) Remove screws holding drain channel to sup-

port frame.

DRAIN CHANNEL INSTALLATION

Reverse the preceding operation.

DRIVE CABLE LOCATORS

DRIVE CABLE LOCATORS REMOVAL (FIG. 4)

(1) Position glass 19 mm (0.75 in.) until rearward

until cable locator is visible. (2) Remove screws holding drive cable locator to

unit. (3) Remove travel limiting micro switch grommet

and disconnect wire connector. (4) Insert a small screwdriver under rear edge of

locator and pry locator from track.

DRIVE CABLE LOCATORS INSTALLATION

Reverse the preceding operation. The small out-

board lip underneath cable locator slips under bottom

slot on guide track. After locator is seated install

screws.

MOTOR AND DRIVE GEARS

MOTOR AND DRIVE GEAR REMOVAL (FIG. 5)

(1) Open sunroof to vent position.

(2) Remove head lining.

Fig. 3 Glass Height Vertical Adjustment

Fig. 4 Removing Cable Drive Locator

Ä BODY 23 - 7

Page 2186 of 2438

INSTALLATION

Reverse the preceding operation. On vehicles with

automatic transaxle, verify gear selector indicator

adjustment before returning vehicle to use.

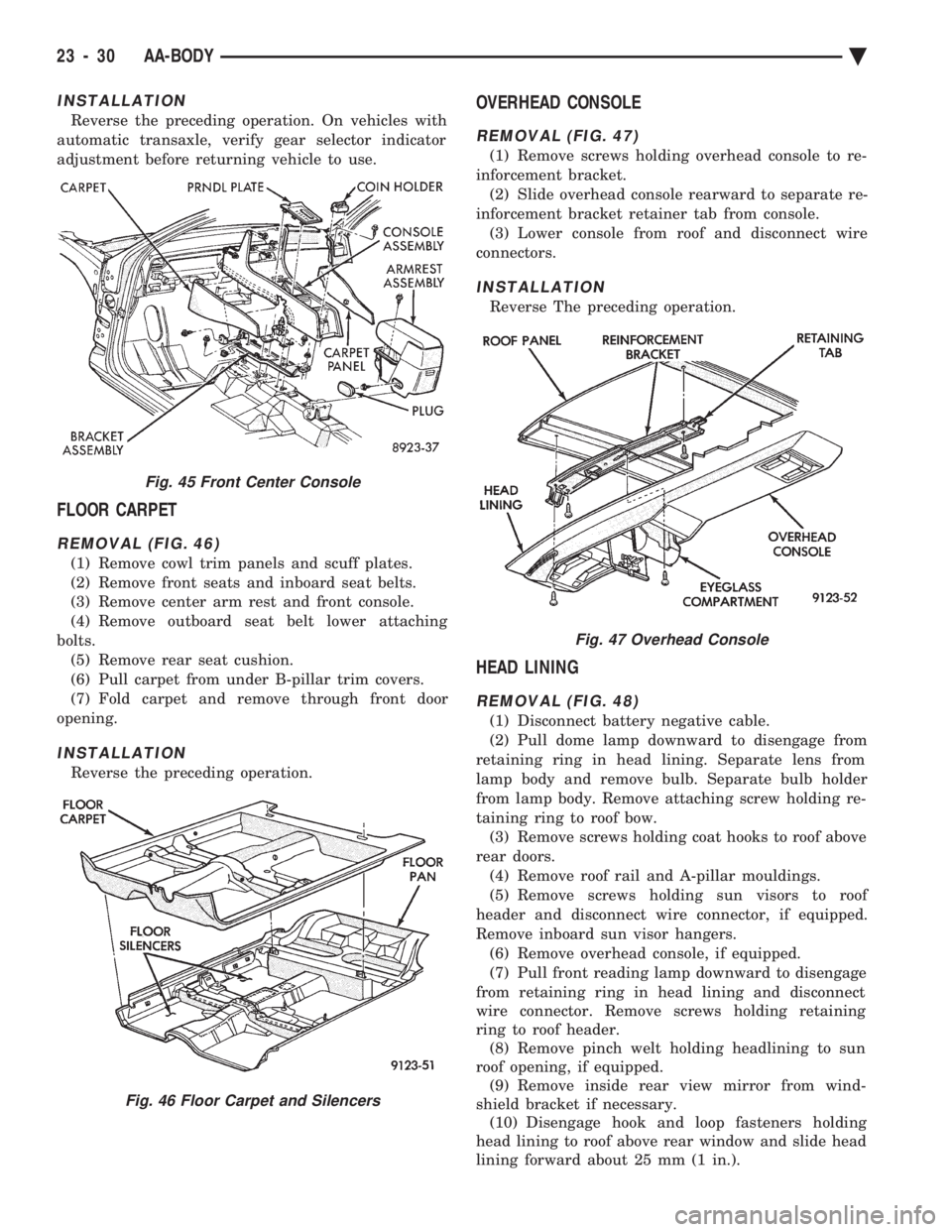

FLOOR CARPET

REMOVAL (FIG. 46)

(1) Remove cowl trim panels and scuff plates.

(2) Remove front seats and inboard seat belts.

(3) Remove center arm rest and front console.

(4) Remove outboard seat belt lower attaching

bolts. (5) Remove rear seat cushion.

(6) Pull carpet from under B-pillar trim covers.

(7) Fold carpet and remove through front door

opening.

INSTALLATION

Reverse the preceding operation.

OVERHEAD CONSOLE

REMOVAL (FIG. 47)

(1) Remove screws holding overhead console to re-

inforcement bracket. (2) Slide overhead console rearward to separate re-

inforcement bracket retainer tab from console. (3) Lower console from roof and disconnect wire

connectors.

INSTALLATION

Reverse The preceding operation.

HEAD LINING

REMOVAL (FIG. 48)

(1) Disconnect battery negative cable.

(2) Pull dome lamp downward to disengage from

retaining ring in head lining. Separate lens from

lamp body and remove bulb. Separate bulb holder

from lamp body. Remove attaching screw holding re-

taining ring to roof bow. (3) Remove screws holding coat hooks to roof above

rear doors. (4) Remove roof rail and A-pillar mouldings.

(5) Remove screws holding sun visors to roof

header and disconnect wire connector, if equipped.

Remove inboard sun visor hangers. (6) Remove overhead console, if equipped.

(7) Pull front reading lamp downward to disengage

from retaining ring in head lining and disconnect

wire connector. Remove screws holding retaining

ring to roof header. (8) Remove pinch welt holding headlining to sun

roof opening, if equipped. (9) Remove inside rear view mirror from wind-

shield bracket if necessary. (10) Disengage hook and loop fasteners holding

head lining to roof above rear window and slide head

lining forward about 25 mm (1 in.).

Fig. 45 Front Center Console

Fig. 46 Floor Carpet and Silencers

Fig. 47 Overhead Console

23 - 30 AA-BODY Ä

Page 2212 of 2438

mm (0.240 in) gap to front door edge. All surfaces

across gaps should be flush.

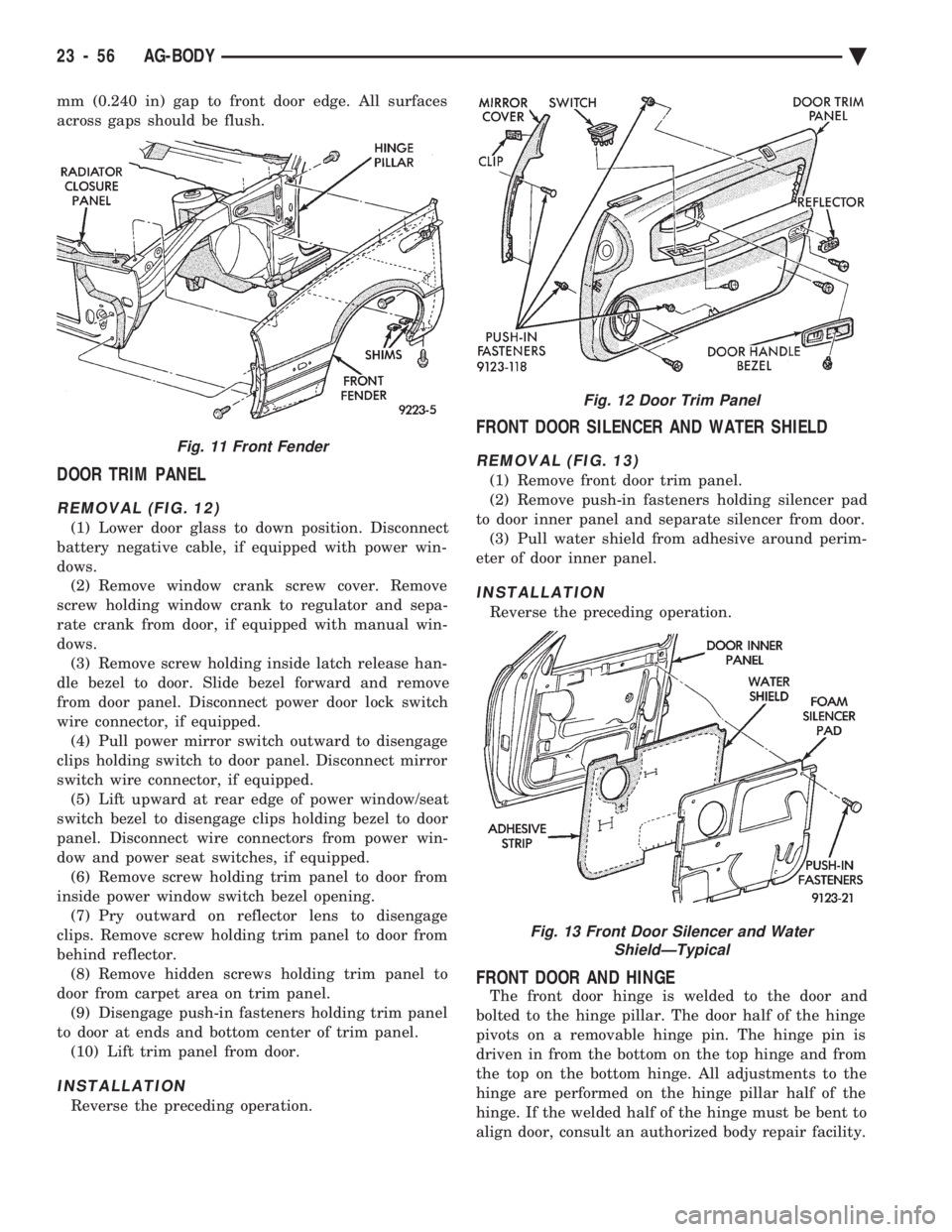

DOOR TRIM PANEL

REMOVAL (FIG. 12)

(1) Lower door glass to down position. Disconnect

battery negative cable, if equipped with power win-

dows. (2) Remove window crank screw cover. Remove

screw holding window crank to regulator and sepa-

rate crank from door, if equipped with manual win-

dows. (3) Remove screw holding inside latch release han-

dle bezel to door. Slide bezel forward and remove

from door panel. Disconnect power door lock switch

wire connector, if equipped. (4) Pull power mirror switch outward to disengage

clips holding switch to door panel. Disconnect mirror

switch wire connector, if equipped. (5) Lift upward at rear edge of power window/seat

switch bezel to disengage clips holding bezel to door

panel. Disconnect wire connectors from power win-

dow and power seat switches, if equipped. (6) Remove screw holding trim panel to door from

inside power window switch bezel opening. (7) Pry outward on reflector lens to disengage

clips. Remove screw holding trim panel to door from

behind reflector. (8) Remove hidden screws holding trim panel to

door from carpet area on trim panel. (9) Disengage push-in fasteners holding trim panel

to door at ends and bottom center of trim panel. (10) Lift trim panel from door.

INSTALLATION

Reverse the preceding operation.

FRONT DOOR SILENCER AND WATER SHIELD

REMOVAL (FIG. 13)

(1) Remove front door trim panel.

(2) Remove push-in fasteners holding silencer pad

to door inner panel and separate silencer from door. (3) Pull water shield from adhesive around perim-

eter of door inner panel.

INSTALLATION

Reverse the preceding operation.

FRONT DOOR AND HINGE

The front door hinge is welded to the door and

bolted to the hinge pillar. The door half of the hinge

pivots on a removable hinge pin. The hinge pin is

driven in from the bottom on the top hinge and from

the top on the bottom hinge. All adjustments to the

hinge are performed on the hinge pillar half of the

hinge. If the welded half of the hinge must be bent to

align door, consult an authorized body repair facility.

Fig. 11 Front Fender

Fig. 12 Door Trim Panel

Fig. 13 Front Door Silencer and Water ShieldÐTypical

23 - 56 AG-BODY Ä

Page 2242 of 2438

AJ/27-VEHICLE CONVERTIBLE BODY COMPONENT SERVICE INDEX

page page

Adjustment Procedures .................... 92

Folding Top Cover ....................... 90

Folding Top Headlining .................... 87

Folding Top Storage Sling Well .............. 87

Hydraulic Cylinder ........................ 95

Hydraulic Cylinder Line Seals ............... 95

Hydraulic Pump Assembly .................. 95

Hydraulic Pump Line Seals ................. 95 Hydraulic System Tests

.................... 95

Hydraulic Systems ........................ 95

Quarter Window ......................... 87

Rear Seat Back .......................... 86

Rear Seat Belt Retractors .................. 86

Rear Seat Cushion ....................... 86

Rear Window and Zipper ................... 88

Rear WindowÐWithout Zipper ............... 88

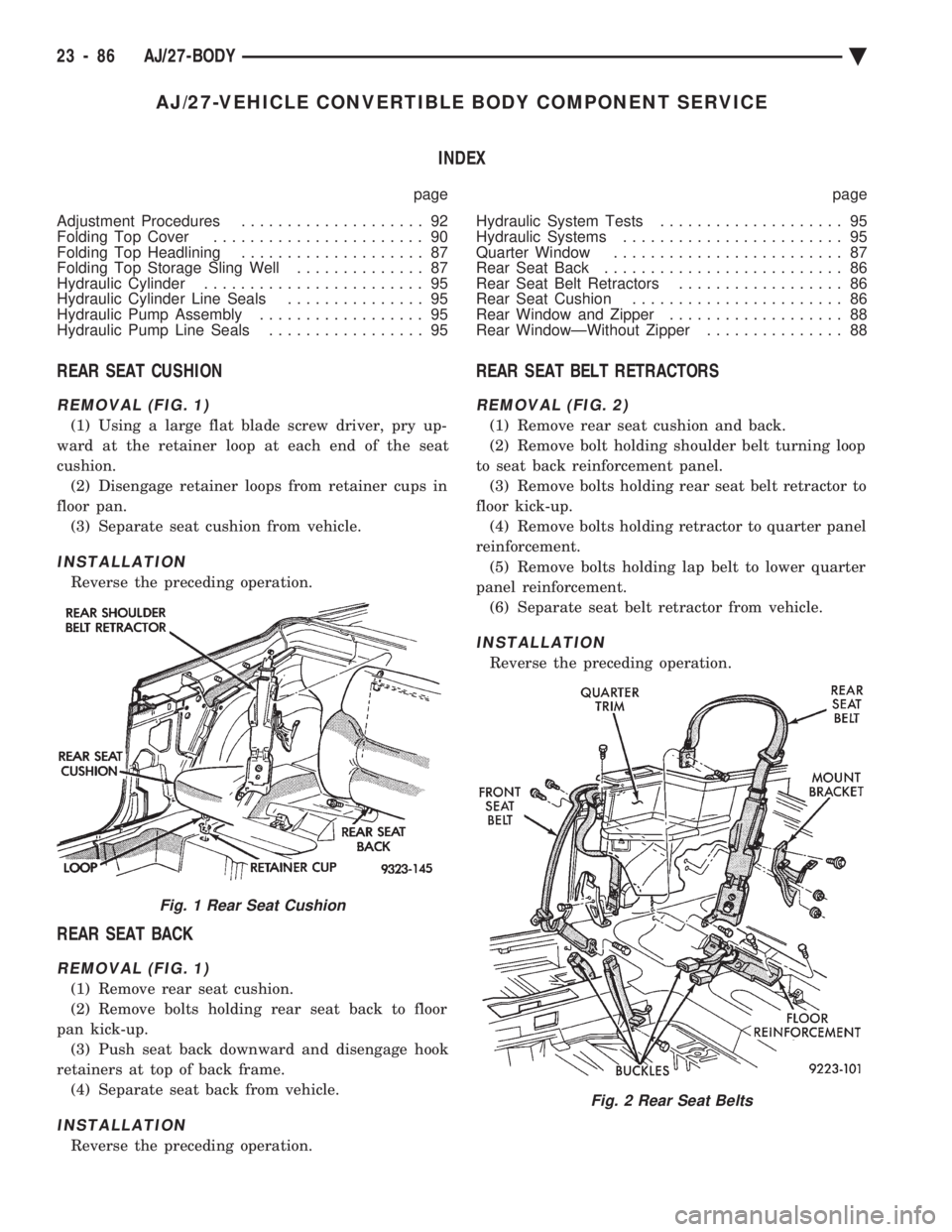

REAR SEAT CUSHION

REMOVAL (FIG. 1)

(1) Using a large flat blade screw driver, pry up-

ward at the retainer loop at each end of the seat

cushion. (2) Disengage retainer loops from retainer cups in

floor pan. (3) Separate seat cushion from vehicle.

INSTALLATION

Reverse the preceding operation.

REAR SEAT BACK

REMOVAL (FIG. 1)

(1) Remove rear seat cushion.

(2) Remove bolts holding rear seat back to floor

pan kick-up. (3) Push seat back downward and disengage hook

retainers at top of back frame. (4) Separate seat back from vehicle.

INSTALLATION

Reverse the preceding operation.

REAR SEAT BELT RETRACTORS

REMOVAL (FIG. 2)

(1) Remove rear seat cushion and back.

(2) Remove bolt holding shoulder belt turning loop

to seat back reinforcement panel. (3) Remove bolts holding rear seat belt retractor to

floor kick-up. (4) Remove bolts holding retractor to quarter panel

reinforcement. (5) Remove bolts holding lap belt to lower quarter

panel reinforcement. (6) Separate seat belt retractor from vehicle.

INSTALLATION

Reverse the preceding operation.

Fig. 1 Rear Seat Cushion

Fig. 2 Rear Seat Belts

23 - 86 AJ/27-BODY Ä

Page 2269 of 2438

REAR SEAT BACK INSTALLATION

Reverse the preceding operation.

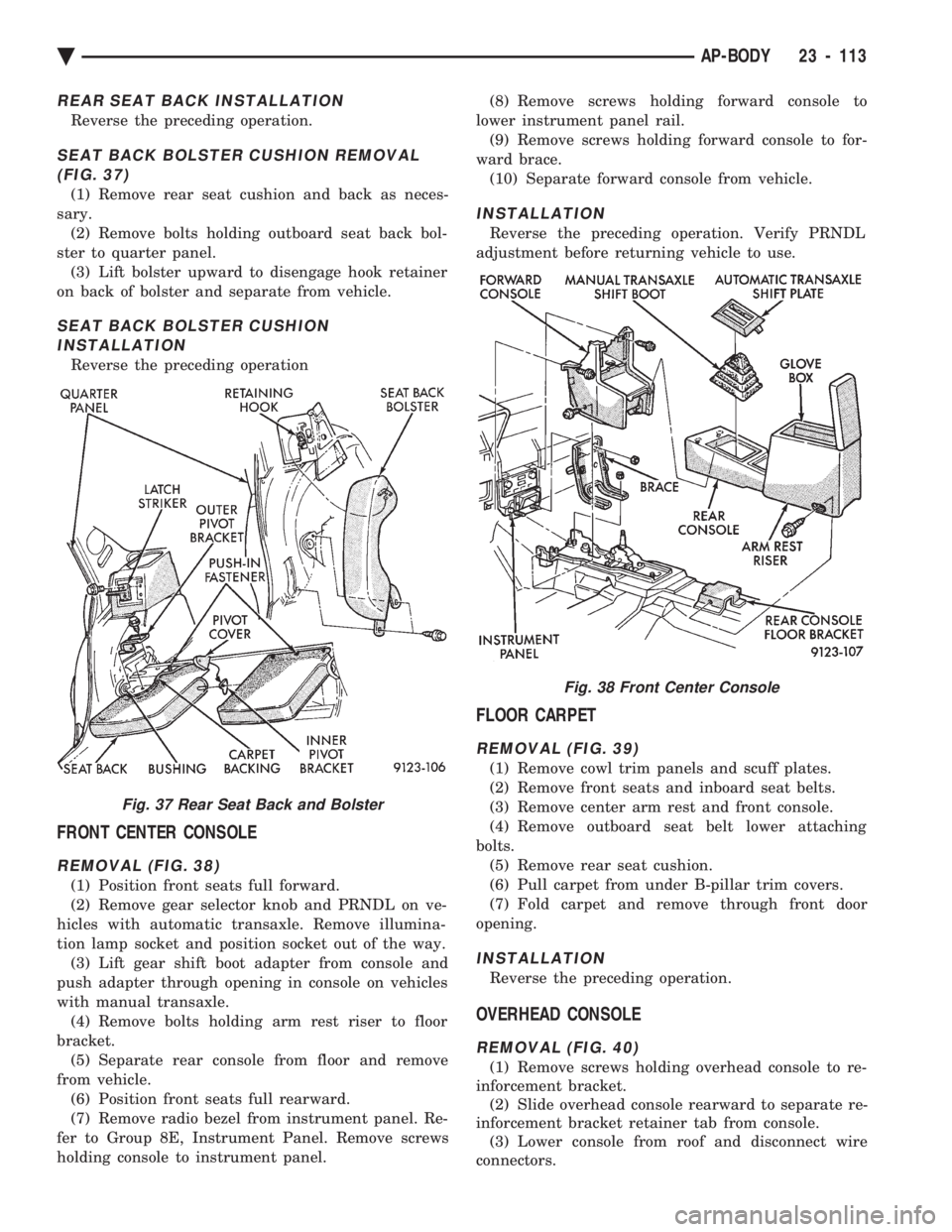

SEAT BACK BOLSTER CUSHION REMOVAL (FIG. 37)

(1) Remove rear seat cushion and back as neces-

sary. (2) Remove bolts holding outboard seat back bol-

ster to quarter panel. (3) Lift bolster upward to disengage hook retainer

on back of bolster and separate from vehicle.

SEAT BACK BOLSTER CUSHION INSTALLATION

Reverse the preceding operation

FRONT CENTER CONSOLE

REMOVAL (FIG. 38)

(1) Position front seats full forward.

(2) Remove gear selector knob and PRNDL on ve-

hicles with automatic transaxle. Remove illumina-

tion lamp socket and position socket out of the way. (3) Lift gear shift boot adapter from console and

push adapter through opening in console on vehicles

with manual transaxle. (4) Remove bolts holding arm rest riser to floor

bracket. (5) Separate rear console from floor and remove

from vehicle. (6) Position front seats full rearward.

(7) Remove radio bezel from instrument panel. Re-

fer to Group 8E, Instrument Panel. Remove screws

holding console to instrument panel. (8) Remove screws holding forward console to

lower instrument panel rail. (9) Remove screws holding forward console to for-

ward brace. (10) Separate forward console from vehicle.

INSTALLATION

Reverse the preceding operation. Verify PRNDL

adjustment before returning vehicle to use.

FLOOR CARPET

REMOVAL (FIG. 39)

(1) Remove cowl trim panels and scuff plates.

(2) Remove front seats and inboard seat belts.

(3) Remove center arm rest and front console.

(4) Remove outboard seat belt lower attaching

bolts. (5) Remove rear seat cushion.

(6) Pull carpet from under B-pillar trim covers.

(7) Fold carpet and remove through front door

opening.

INSTALLATION

Reverse the preceding operation.

OVERHEAD CONSOLE

REMOVAL (FIG. 40)

(1) Remove screws holding overhead console to re-

inforcement bracket. (2) Slide overhead console rearward to separate re-

inforcement bracket retainer tab from console. (3) Lower console from roof and disconnect wire

connectors.

Fig. 37 Rear Seat Back and Bolster

Fig. 38 Front Center Console

Ä AP-BODY 23 - 113

Page 2273 of 2438

AP/27-VEHICLE CONVERTIBLE BODY COMPONENT SERVICE INDEX

page page

A-Pillar and Windshield Header Weatherstrip . . . 117

Convertible Top Adjustments ............... 131

Convertible Top Header ................... 118

Convertible Top Latch Hooks ............... 131

Door Glass Alignment .................... 131

Door Glass Rear Channel ................. 127

Door Striker Guide ...................... 128

Forward Roof Rail ....................... 121

Fourth Roof Bow and Slat ................. 120

Fourth Roof Bow Slat .................... 132

Front Door Belt Moulding and Weatherstrip .... 127

Front Door Glass ........................ 125

Front Door Stationary Glass and Division Channel ............................. 126

Front Door Stationary Glass Channel Weatherstrip .......................... 126

Front Door Striker Guide Socket ............ 127

Front Seat Belt Retractor .................. 128

General Information ...................... 117

Quarter Glass and Roller Bracket ........... 132

Quarter Panel Belt Moulding ............... 129

Quarter Trim Panel ...................... 128

Rear Roof Rail ......................... 121

Rear Seat Back ......................... 128 Rear Seat Belt Retractor

.................. 129

Rear Tensioner Plate ..................... 132

Rear Window .......................... 122

Roof Linkage ........................... 121

Roof Rail Weatherstrip ................... 118

Roof Rail Weatherstrip Retainer ............. 131

Second Roof Bow and Linkage ............. 119

Sling-Well ............................. 124

Stationary Quarter Glass and Weatherstrip .... 121

Third Roof Bow ......................... 120

Top Cover ............................. 124

Top Frame ............................ 125

Top Header Trim Cover ................... 118

Top Latch ............................. 118

Top Lift Assist Cylinder ................... 122

Top Stack Down-Stop .................... 132

Top Stack Up-Stop ...................... 132

Trunk Hinge Lid ........................ 130

Trunk Lid .............................. 130

Trunk Lid Applique ...................... 130

Trunk Lid Lining ........................ 129

Trunk Opening Weatherstrip ............... 130

Windshield Header Lining ................. 117

Windshield Header Moulding ............... 117

GENERAL INFORMATION

This section will cover components that are unique

to the AP-vehicle convertible. All components that

are common to the AP-vehicle two door hardtop are

covered in the AP-Vehicle Body Components section.

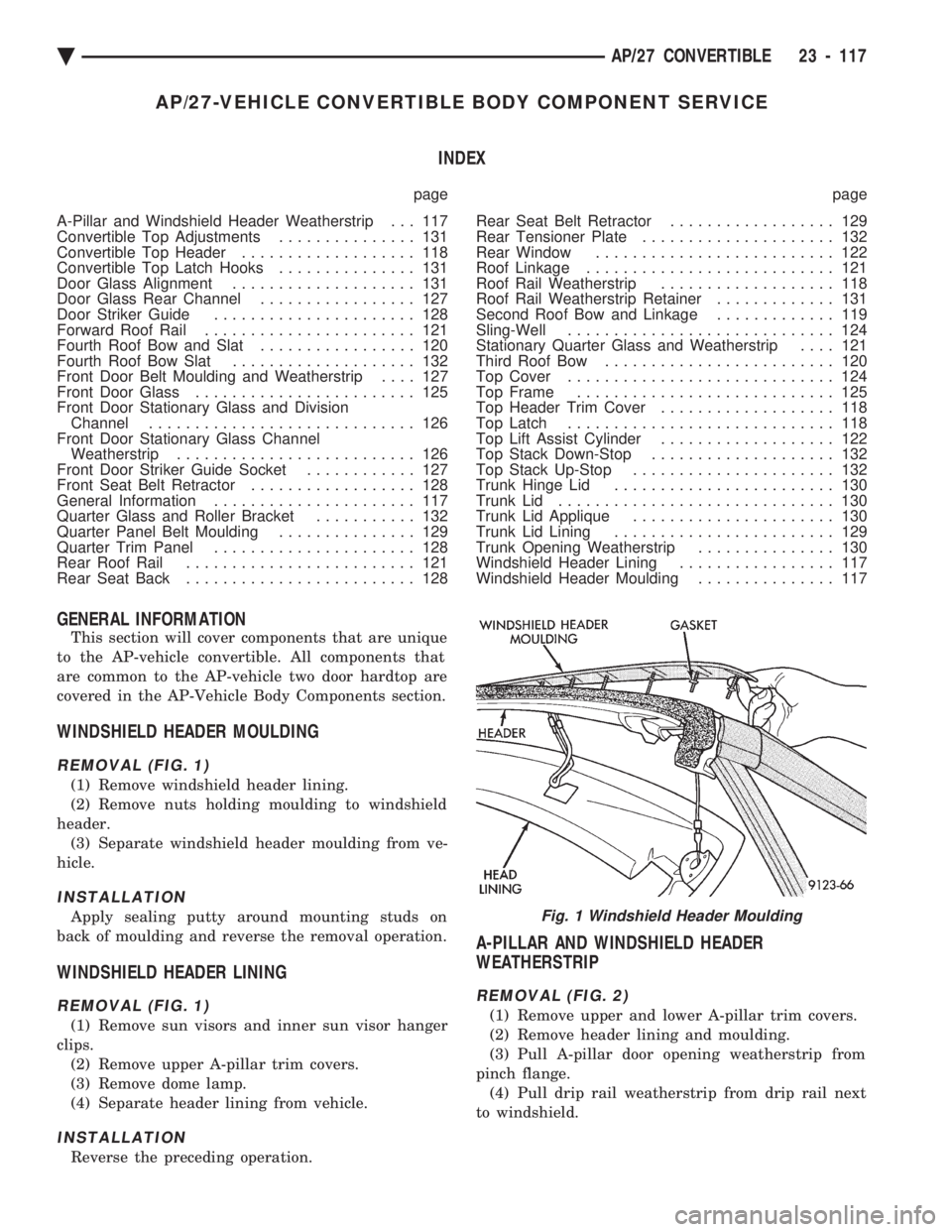

WINDSHIELD HEADER MOULDING

REMOVAL (FIG. 1)

(1) Remove windshield header lining.

(2) Remove nuts holding moulding to windshield

header. (3) Separate windshield header moulding from ve-

hicle.

INSTALLATION

Apply sealing putty around mounting studs on

back of moulding and reverse the removal operation.

WINDSHIELD HEADER LINING

REMOVAL (FIG. 1)

(1) Remove sun visors and inner sun visor hanger

clips. (2) Remove upper A-pillar trim covers.

(3) Remove dome lamp.

(4) Separate header lining from vehicle.

INSTALLATION

Reverse the preceding operation.

A-PILLAR AND WINDSHIELD HEADER

WEATHERSTRIP

REMOVAL (FIG. 2)

(1) Remove upper and lower A-pillar trim covers.

(2) Remove header lining and moulding.

(3) Pull A-pillar door opening weatherstrip from

pinch flange. (4) Pull drip rail weatherstrip from drip rail next

to windshield.

Fig. 1 Windshield Header Moulding

Ä AP/27 CONVERTIBLE 23 - 117