service schedule CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1697 of 2438

EXHAUST SYSTEM AND INTAKE MANIFOLD

CONTENTS

page page

GENERAL INFORMATION .................. 1

SERVICE PROCEDURES ................... 4 TORQUE SPECIFICATION

................. 25

GENERAL INFORMATION

Throughout this group, references may be made to

a particular vehicle by letter or number designation.

A chart showing the breakdown of these designations

is included in the Introduction Section at the front of

this service manual.

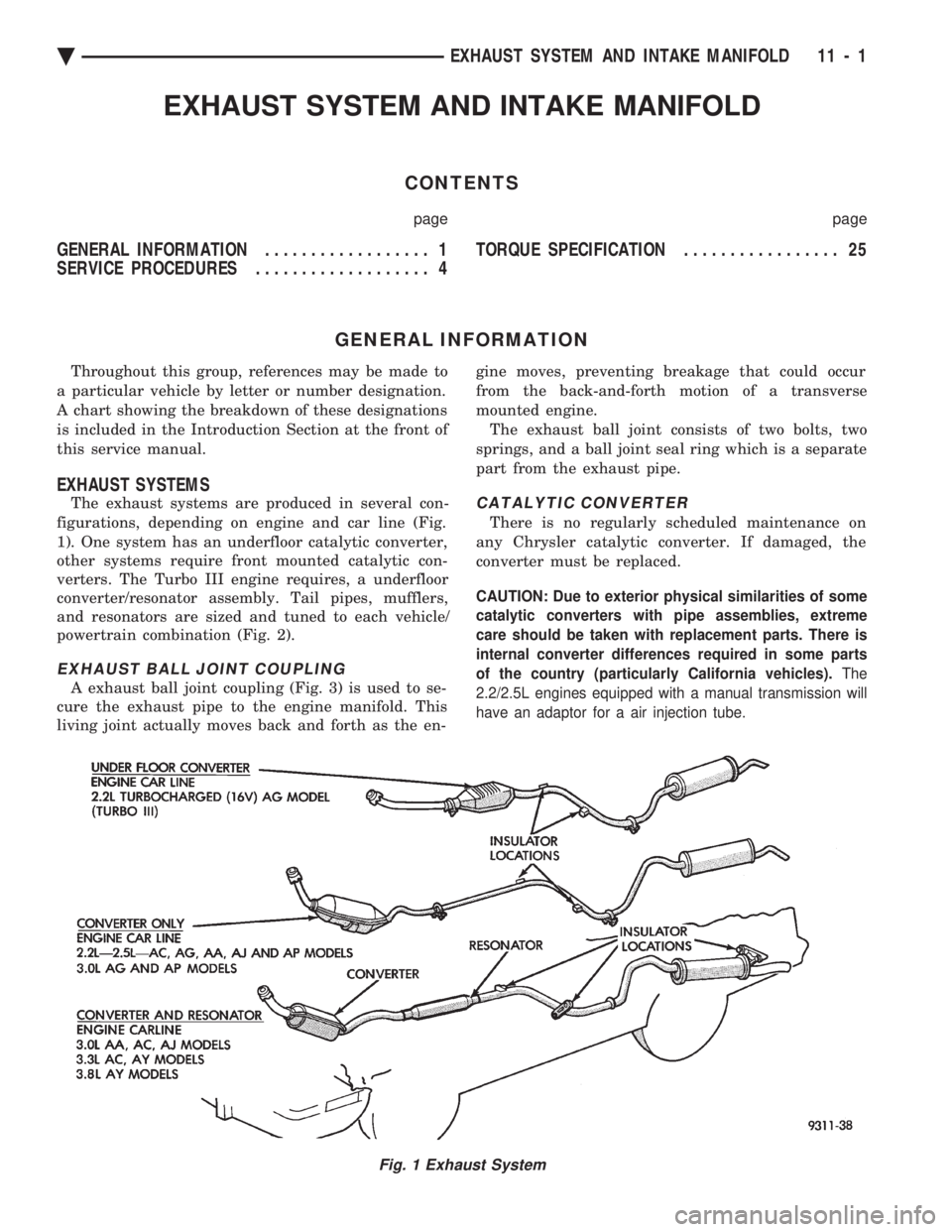

EXHAUST SYSTEMS

The exhaust systems are produced in several con-

figurations, depending on engine and car line (Fig.

1). One system has an underfloor catalytic converter,

other systems require front mounted catalytic con-

verters. The Turbo III engine requires, a underfloor

converter/resonator assembly. Tail pipes, mufflers,

and resonators are sized and tuned to each vehicle/

powertrain combination (Fig. 2).

EXHAUST BALL JOINT COUPLING

A exhaust ball joint coupling (Fig. 3) is used to se-

cure the exhaust pipe to the engine manifold. This

living joint actually moves back and forth as the en- gine moves, preventing breakage that could occur

from the back-and-forth motion of a transverse

mounted engine. The exhaust ball joint consists of two bolts, two

springs, and a ball joint seal ring which is a separate

part from the exhaust pipe.

CATALYTIC CONVERTER

There is no regularly scheduled maintenance on

any Chrysler catalytic converter. If damaged, the

converter must be replaced.

CAUTION: Due to exterior physical similarities of some

catalytic converters with pipe assemblies, extreme

care should be taken with replacement parts. There is

internal converter differences required in some parts

of the country (particularly California vehicles). The

2.2/2.5L engines equipped with a manual transmission will

have an adaptor for a air injection tube.

Fig. 1 Exhaust System

Ä EXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 1

Page 1826 of 2438

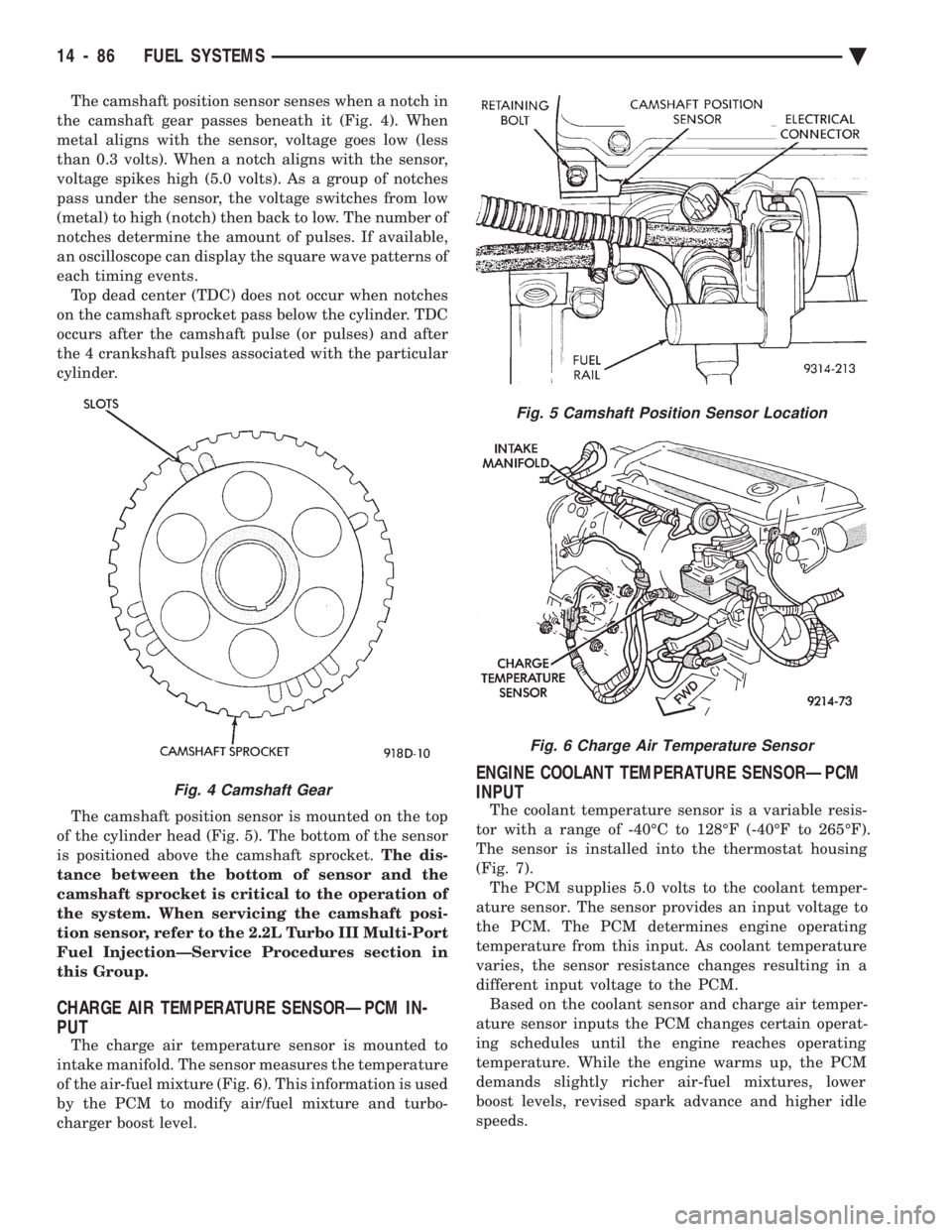

The camshaft position sensor senses when a notch in

the camshaft gear passes beneath it (Fig. 4). When

metal aligns with the sensor, voltage goes low (less

than 0.3 volts). When a notch aligns with the sensor,

voltage spikes high (5.0 volts). As a group of notches

pass under the sensor, the voltage switches from low

(metal) to high (notch) then back to low. The number of

notches determine the amount of pulses. If available,

an oscilloscope can display the square wave patterns of

each timing events. Top dead center (TDC) does not occur when notches

on the camshaft sprocket pass below the cylinder. TDC

occurs after the camshaft pulse (or pulses) and after

the 4 crankshaft pulses associated with the particular

cylinder.

The camshaft position sensor is mounted on the top

of the cylinder head (Fig. 5). The bottom of the sensor

is positioned above the camshaft sprocket. The dis-

tance between the bottom of sensor and the

camshaft sprocket is critical to the operation of

the system. When servicing the camshaft posi-

tion sensor, refer to the 2.2L Turbo III Multi-Port

Fuel InjectionÐService Procedures section in

this Group.

CHARGE AIR TEMPERATURE SENSORÐPCM IN-

PUT

The charge air temperature sensor is mounted to

intake manifold. The sensor measures the temperature

of the air-fuel mixture (Fig. 6). This information is used

by the PCM to modify air/fuel mixture and turbo-

charger boost level.

ENGINE COOLANT TEMPERATURE SENSORÐPCM

INPUT

The coolant temperature sensor is a variable resis-

tor with a range of -40ÉC to 128ÉF (-40ÉF to 265ÉF).

The sensor is installed into the thermostat housing

(Fig. 7). The PCM supplies 5.0 volts to the coolant temper-

ature sensor. The sensor provides an input voltage to

the PCM. The PCM determines engine operating

temperature from this input. As coolant temperature

varies, the sensor resistance changes resulting in a

different input voltage to the PCM. Based on the coolant sensor and charge air temper-

ature sensor inputs the PCM changes certain operat-

ing schedules until the engine reaches operating

temperature. While the engine warms up, the PCM

demands slightly richer air-fuel mixtures, lower

boost levels, revised spark advance and higher idle

speeds.

Fig. 5 Camshaft Position Sensor Location

Fig. 6 Charge Air Temperature Sensor

Fig. 4 Camshaft Gear

14 - 86 FUEL SYSTEMS Ä

Page 1827 of 2438

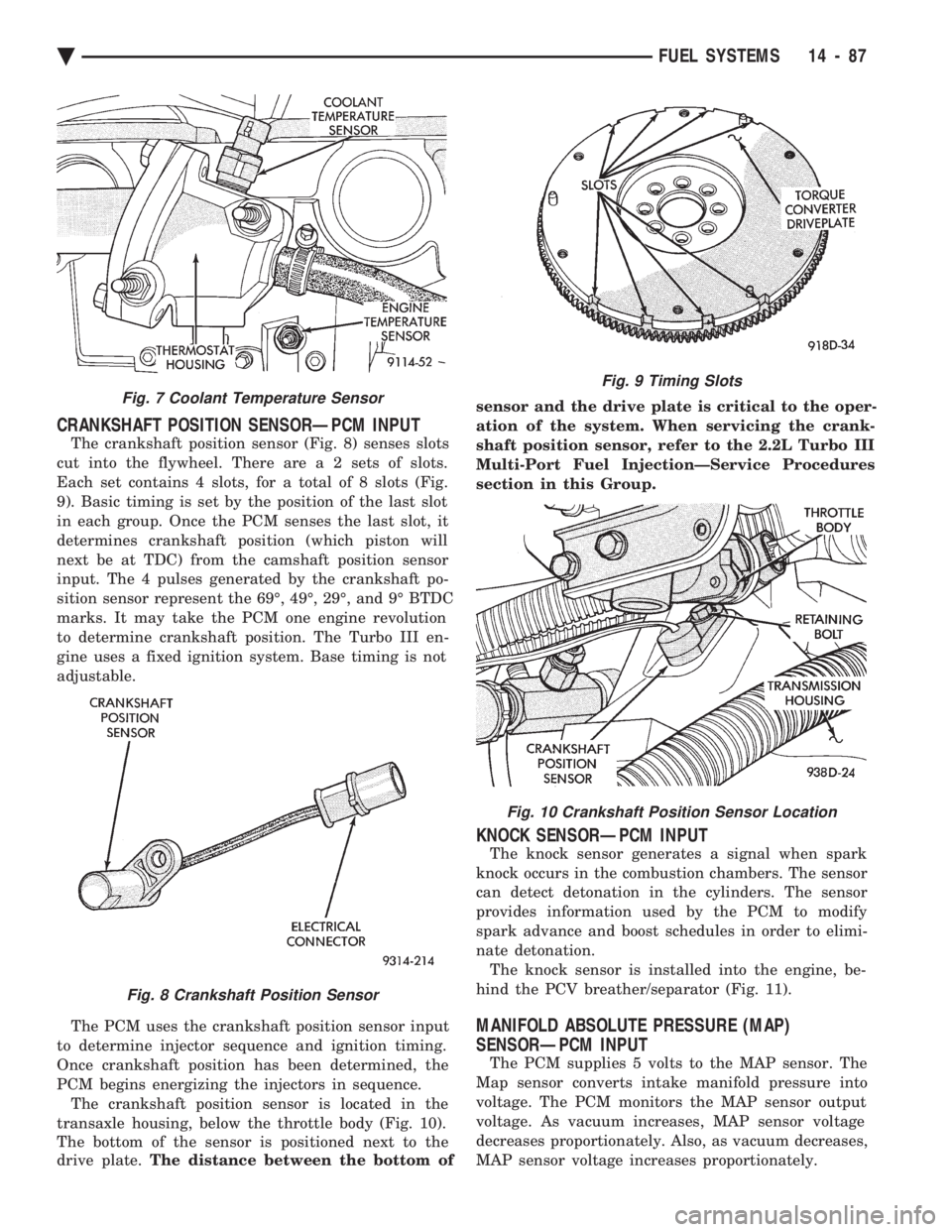

CRANKSHAFT POSITION SENSORÐPCM INPUT

The crankshaft position sensor (Fig. 8) senses slots

cut into the flywheel. There ar e a 2 sets of slots.

Each set contains 4 slots, for a total of 8 slots (Fig.

9). Basic timing is set by the position of the last slot

in each group. Once the PCM senses the last slot, it

determines crankshaft position (which piston will

next be at TDC) from the camshaft position sensor

input. The 4 pulses generated by the crankshaft po-

sition sensor represent the 69É, 49É, 29É, and 9É BTDC

marks. It may take the PCM one engine revolution

to determine crankshaft position. The Turbo III en-

gine uses a fixed ignition system. Base timing is not

adjustable.

The PCM uses the crankshaft position sensor input

to determine injector sequence and ignition timing.

Once crankshaft position has been determined, the

PCM begins energizing the injectors in sequence. The crankshaft position sensor is located in the

transaxle housing, below the throttle body (Fig. 10).

The bottom of the sensor is positioned next to the

drive plate. The distance between the bottom of sensor and the drive plate is critical to the oper-

ation of the system. When servicing the crank-

shaft position sensor, refer to the 2.2L Turbo III

Multi-Port Fuel InjectionÐService Procedures

section in this Group.

KNOCK SENSORÐPCM INPUT

The knock sensor generates a signal when spark

knock occurs in the combustion chambers. The sensor

can detect detonation in the cylinders. The sensor

provides information used by the PCM to modify

spark advance and boost schedules in order to elimi-

nate detonation. The knock sensor is installed into the engine, be-

hind the PCV breather/separator (Fig. 11).

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSORÐPCM INPUT

The PCM supplies 5 volts to the MAP sensor. The

Map sensor converts intake manifold pressure into

voltage. The PCM monitors the MAP sensor output

voltage. As vacuum increases, MAP sensor voltage

decreases proportionately. Also, as vacuum decreases,

MAP sensor voltage increases proportionately.

Fig. 7 Coolant Temperature Sensor

Fig. 8 Crankshaft Position Sensor

Fig. 9 Timing Slots

Fig. 10 Crankshaft Position Sensor Location

Ä FUEL SYSTEMS 14 - 87