wheel alignment CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 168 of 2438

REAR WHEEL DRUM BRAKES INDEX

page page

Brake Drum Refacing ..................... 21

Brake Shoe Assemblies ................... 19 Description

............................. 18

Service Procedures ....................... 18

DESCRIPTION

Rear wheel drum brakes (Fig .2&3)aretwoshoe,

internal expanding type with an automatic adjuster

screw assembly that is activated each time the

brakes are applied. The automatic adjuster screw is

located directly below the wheel cylinder as shown in

figure (Fig .2&3).

WARNING: DUST AND DIRT ON BRAKE PARTS

GENERATED DURING THE NORMAL USE AND

WEAR OF MOTOR VEHICLE BRAKE SYSTEMS MAY

CONTAIN ASBESTOS FIBERS. BREATHING EXCES-

SIVE CONCENTRATIONS OF ASBESTOS FIBERS

CAN CAUSE SERIOUS BODILY HARM, SUCH AS

ASBESTOSIS AND CANCER. EXTREME CARE

SHOULD BE EXERCISED WHILE SERVICING

BRAKE ASSEMBLIES OR COMPONENTS. DO NOT CLEAN BRAKE ASSEMBLIES OR COM-

PONENTS WITH COMPRESSED AIR OR BY DRY

BRUSHING; USE A VACUUM CLEANER SPECIFI-

CALLY RECOMMENDED FOR USE WITH ASBES-

TOS FIBERS. IF A SUITABLE VACUUM CLEANER IS

NOT AVAILABLE, CLEANING SHOULD BE DONE

WET USING A WATER DAMPENED CLOTH. DO NOT CREATE DUST BY SANDING, GRINDING,

AND/OR SHAVING BRAKE LININGS OR PADS UN-

LESS SUCH OPERATION IS DONE WHILE USING

PROPERLY EXHAUST VENTILATED EQUIPMENT. DISPOSE OF ALL DUST AND DIRT SUSPECTED

TO CONTAIN ANY ASBESTOS FIBERS IN SEALED

BAGS OR CONTAINERS TO MINIMIZE DUST EXPO-

SURE TO YOURSELF AND OTHERS. FOLLOW ALL RECOMMENDED PRACTICES PRE-

SCRIBED BY THE OCCUPATIONAL SAFETY AND

HEALTH ADMINISTRATION AND THE ENVIRON-

MENTAL PROTECTION AGENCY. FOR THE HAN-

DLING, PROCESSING, AND DISPOSITION OF DUST

OR DIRT WHICH MAY CONTAIN ASBESTOS FI-

BERS. IT IS RECOMMENDED NOT TO BREATH ANY

TYPE OF BRAKE LINING MATERIAL DUST EVEN

ASBESTOS FREE, DUE TO THE FIBROUS NATURE

OF THE MATERIALS BEING USED.

SERVICE PROCEDURES

REAR BRAKE DRUM REMOVAL

If the rear brake drum is difficult to remove, fur-

ther clearance can be obtained by backing off the

brake automatic adjuster screw. Remove rubber plug

from the top of the support plate and rotate the au-

tomatic adjuster screw assembly with an upward mo-

tion, using the Brake Adjuster, Special Tool C-3784. See adjusting rear service brakes in the Service

Adjustments section in this group of the service man-

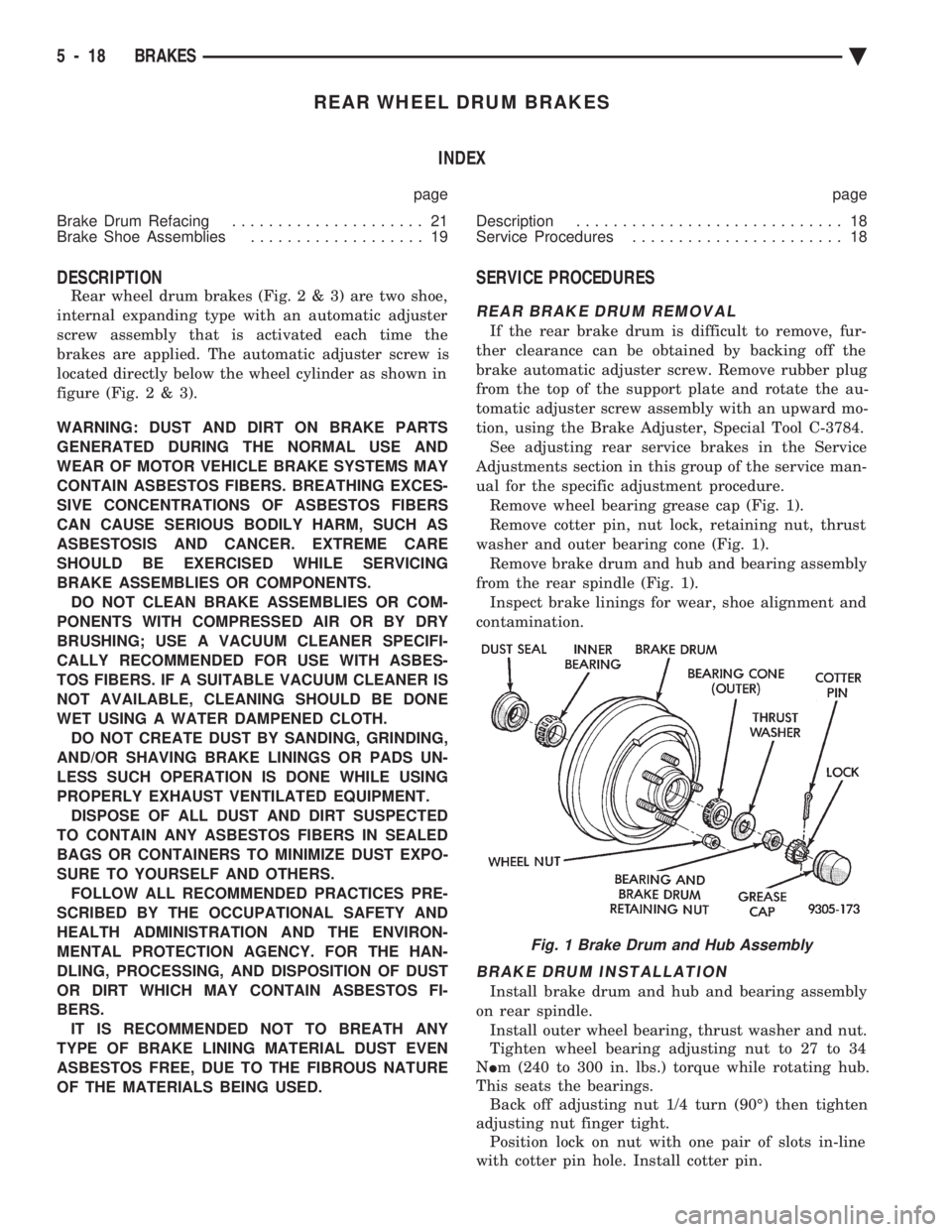

ual for the specific adjustment procedure. Remove wheel bearing grease cap (Fig. 1).

Remove cotter pin, nut lock, retaining nut, thrust

washer and outer bearing cone (Fig. 1). Remove brake drum and hub and bearing assembly

from the rear spindle (Fig. 1). Inspect brake linings for wear, shoe alignment and

contamination.

BRAKE DRUM INSTALLATION

Install brake drum and hub and bearing assembly

on rear spindle. Install outer wheel bearing, thrust washer and nut.

Tighten wheel bearing adjusting nut to 27 to 34

N Im (240 to 300 in. lbs.) torque while rotating hub.

This seats the bearings. Back off adjusting nut 1/4 turn (90É) then tighten

adjusting nut finger tight. Position lock on nut with one pair of slots in-line

with cotter pin hole. Install cotter pin.

Fig. 1 Brake Drum and Hub Assembly

5 - 18 BRAKES Ä

Page 338 of 2438

(3) Clean the flywheel face with medium sandpa-

per (80-160 grade), then wipe the surface with min-

eral spirits. If the surface is severely scored, heat

checked, or warped, replace the flywheel.

CAUTION: Do not flat-machine the flywheel face.

The surface profile is tapered.

(4) The heavy side of the flywheel is indicated by a

daub of white paint near the outside diameter. To

minimize the effects of flywheel unbalance, perform

the following installation procedure: (a) Loose assemble the flywheel to the crank-

shaft. Use new flywheel attaching bolts which have

sealant on the threads. If new bolts are not avail-

able, apply Loctite sealant to the threads of the

original bolts. This sealant is required to prevent

engine oil leakage. (b) Rotate the flywheel and crankshaft until the

daub of white paint (heavy side) is at the 12 o'clock

position. (c) Torque flywheel attaching bolts to 95 N Im(70

ft. lbs.). Use a crisscross pattern when tightening

bolts.

(5) The disc assembly should be handled without

touching the facings. Replace disc if the facings show

evidence of grease or oil soakage, or wear to within

less than .38 mm (.015 inch) of the rivet heads. The

splines on the disc hub and transaxle input shaft

should be a snug fit without signs of excessive wear.

Metallic portions of disc assembly should be dry and

clean, and not been discolored from excessive heat.

Each of the arched springs between the facings

should not be broken and all rivets should be tight. (6) Wipe the friction surface of the pressure plate

with mineral spirits. (7) Using a straight edge, check clutch cover (pres-

sure plate) for flatness. The clutch cover (pressure

plate) friction area should be slightly concave, with

the inner diameter 0.02 mm to 0.1 mm (.0008 in. to

.0039 in.) below the outer diameter. It should also be

free from discoloration, burned areas, cracks,

grooves, or ridges. (8) Using a surface plate, test cover for flatness.

All sections around attaching bolt holes should be in

contact with surface plate within .015 inch. (9) The cover should be a snug fit on flywheel dow-

els. If the clutch assembly does not meet these re-

quirements, it should be replaced.

INSTALLATION

(1) Mount clutch assembly on flywheel,being care-

ful to properly align dowels and the alignment marks

made before removal. The flywheel side of the clutch

disc is marked for proper installation. If new clutch

or flywheel is installed, align cover balance spot as

close as possible to flywheel balance orange spot. Ap-

ply pressure to the alignment tool. Center the tip of the tool into the crankshaft and the sliding cone into

the clutch fingers. Tighten the clutch attaching bolts

sufficiently to hold the disc in position. (2) To avoid distortion of the clutch cover, bolts

should be tightened a few turns at a time, in a criss-

cross pattern, until they are all seated. Tighten bolts

to 28 N Im (250 in. lbs.) following a crisscross pattern

sequence. Remove clutch disc alignment tool. (3) Install transaxle. See group 21, Manual Tran-

saxle, for procedures.

RELEASE BEARING AND FORK

Remove the transaxle from the vehicle. See group

21 for removal and installation procedures.

REMOVAL AND INSTALLATION

(1) Remove clutch release shaft E-clip.

(2) Remove the clutch release shaft and then slide

the fork and bearing assembly off the bearing pilot. (3) Remove the fork from the bearing thrust plate.

(4) Examine the condition of the bearing. It is pre-

lubricated and sealed and should not be im-

mersed in oil or solvent. (5) The bearing should turn smoothly when held in

the hand under a light thrust load. A light drag

caused by the lubricant fill is normal. If the bearing

is noisy, rough, or dry, replace the complete bearing

assembly with a new bearing. (6) The bearing has a plastic sleeve pre-lubricated

at assembly. Wipe out the old grease. Refill the

sleeve cavities and coat the inner surface with mul-

tipurpose grease. If the liner is cracked or worn, re-

place the bearing assembly. (7) Check the condition of the spring clips. If the

clips are broken or distorted, replace the bearing as-

sembly. (8) Before assembling the fork, lubricate the

rounded thrust pads and the spring clip cavities with

multipurpose grease. (9) Assemble the fork to the bearing by sliding the

thrust pads under the spring clips. Be careful to

avoid distorting the spring clips. These clips prevent

the bearing thrust plate from rotating with the bear-

ing. (10) Slide the bearing and fork assembly onto the

input shaft bearing retainer. (11) Position the release shaft bushings in the

housing and install the release shaft. A small

amount of bearing grease between the release shaft

bushing and the shaft is beneficial but not required.

Install the retainer clip in the shaft groove near the

large bushing. (12) Install the release lever and retaining clip on

the outer end of the release shaft.

CLEANING PRECAUTIONS

Condensation from steam vapors tend to accumu-

late on the internal clutch mechanism when the ve-

6 - 6 MANUAL TRANSAXLE CLUTCH Ä

Page 672 of 2438

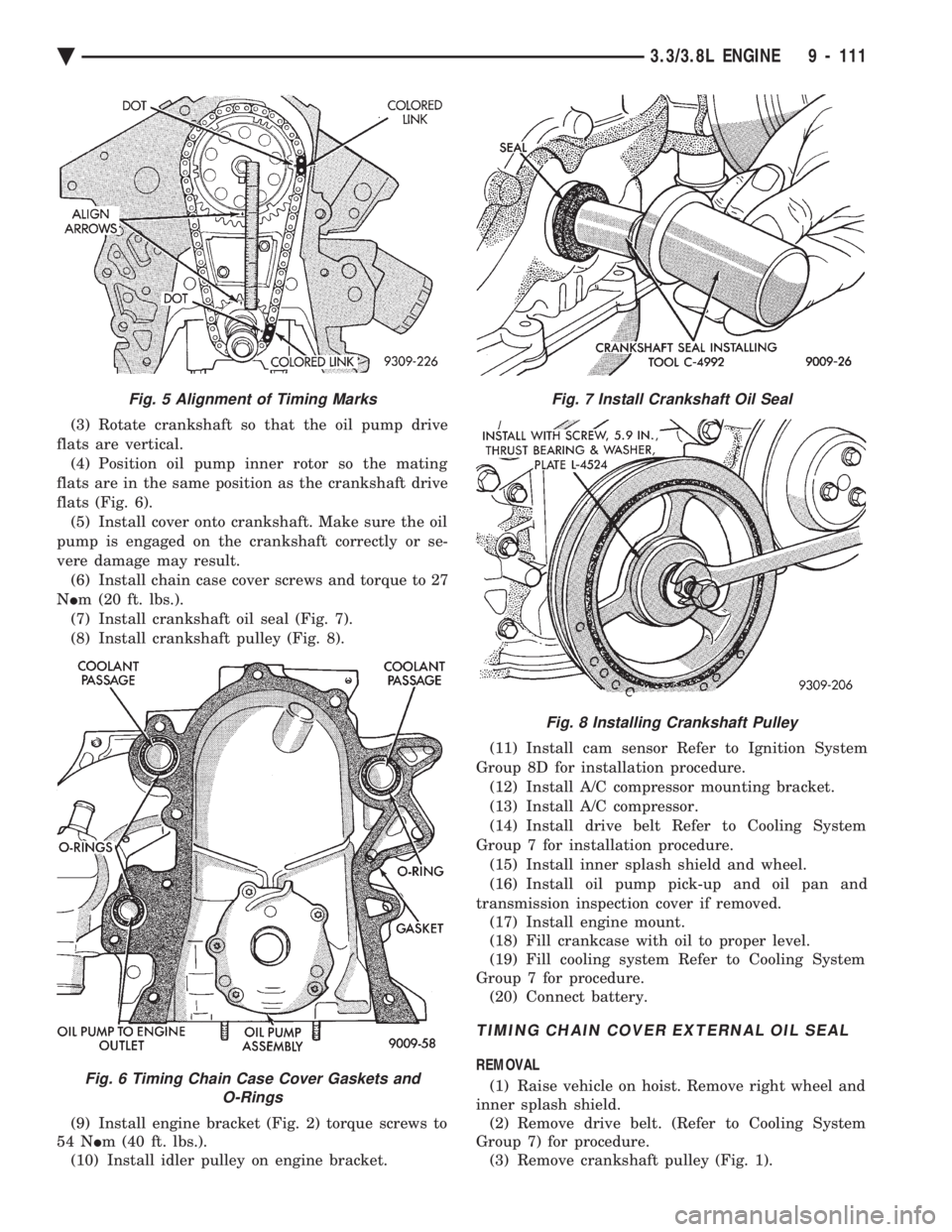

(2) Open hood and locate Power Distribution Cen-

ter forward of the left suspension tower (Fig. 3). (3) Remove cover from the center and pull the

Headlamp Close Relay (Fig. 4) to keep the headlamp

doors from closing. (4) Turn headlight switch OFF.

(5) Remove two grill mounting screws and remove

grill assembly (Fig. 5). (6) Spring tension must be relieved from the head-

lamp doors before removing headlamp motor torsion

bar clips. Locate the thumb wheel on bottom of head-

lamp motor (Fig. 6). Rotate thumb wheel approxi-

mately six to seven turns clockwise to relieve all

tension. (7) Remove torsion bar anchor clip (Fig. 7).

(8) Slide torsion bar sleeve over the torsion bar

(Fig. 8). (9) Remove three clips retaining turn signal lamp

shield to body (Fig. 9), and remove shield. (10) Remove two screws retaining headlamp cover

to headlamp cover bracket (Fig. 10). (11) Remove outer headlamp.

(12) Remove outer pivot screw (Fig. 11).

(13) Remove E-clip and door crank screw (Fig. 12).

(14) Remove three bolts retaining cam pivot to

body and remove cam pivot (Fig. 11). (15) Remove Headlamp door assembly.

INSTALLATION

Reverse the preceding operation. Before installing

torsion bar clips, the holes in the torsion bars, tor-

sion bar sleeves and headlamp door cam pivots must

be in alignment. Refer to Aligning Headlamp Doors.

HEADLAMP DRIVE MOTORÐAY BODY

REMOVAL

(1) Open headlamp doors. Refer to Headlamp Door

paragraph for instructions. (2) Remove grill mounting screws and remove grill

assembly (Fig. 5). (3) Spring tension must be relieved from headlamp

doors before removing the headlamp motor torsion

bar clips. Locate the thumb wheel on bottom of the

headlamp motor (Fig. 6). Rotate thumb wheel ap-

proximately six to seven turns (clockwise) to relieve

all tension. (4) Remove both torsion bar anchor clips (Fig. 7).

(5) Slide torsion bar sleeves over the torsion bar

(Fig. 8).

Fig. 3 Power Distribution Center

Fig. 4 Headlamp Close Relay

Fig. 5 Grill

Fig. 6 Headlamp MotorÐBottom View

8L - 30 LAMPS Ä

Page 1677 of 2438

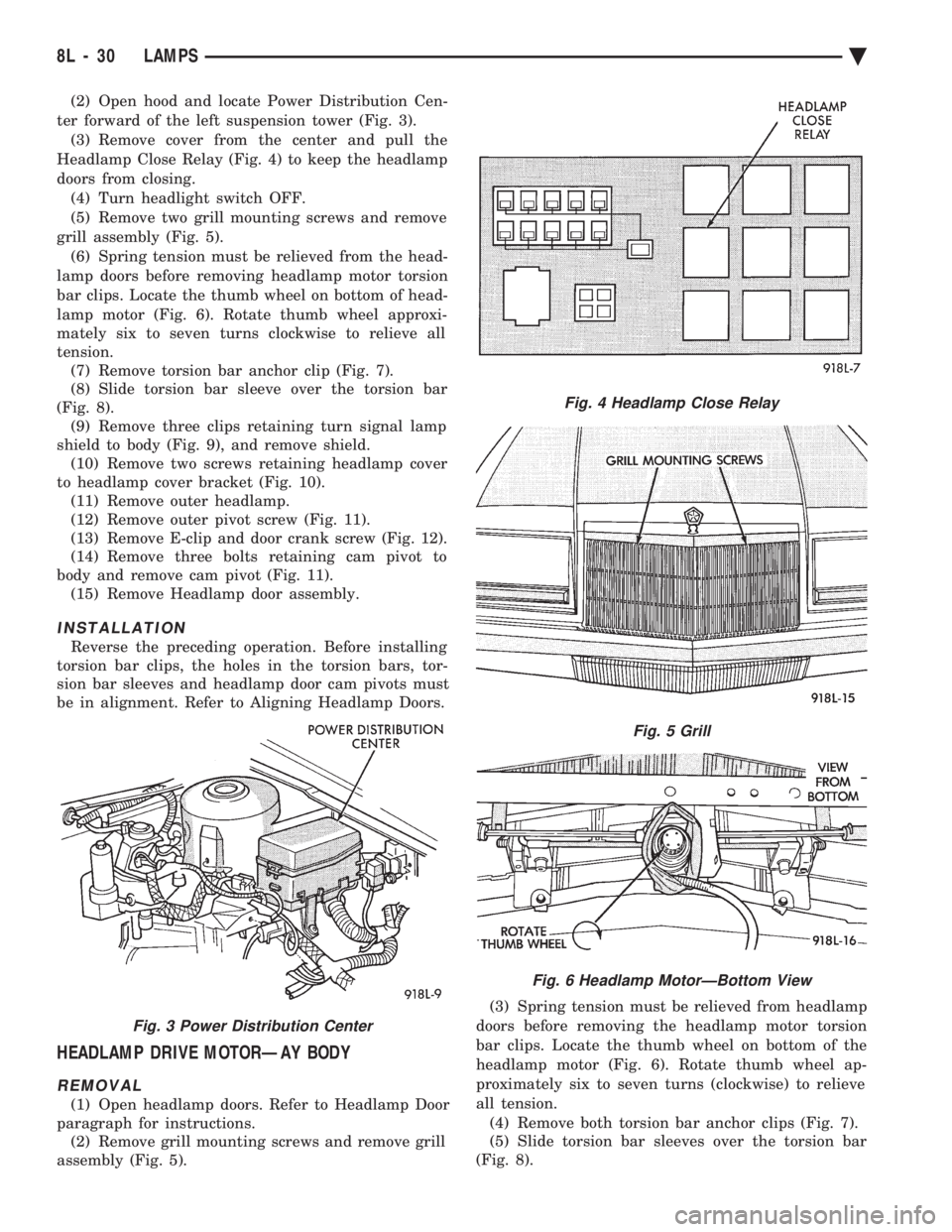

(3) Rotate crankshaft so that the oil pump drive

flats are vertical. (4) Position oil pump inner rotor so the mating

flats are in the same position as the crankshaft drive

flats (Fig. 6). (5) Install cover onto crankshaft. Make sure the oil

pump is engaged on the crankshaft correctly or se-

vere damage may result. (6) Install chain case cover screws and torque to 27

N Im (20 ft. lbs.).

(7) Install crankshaft oil seal (Fig. 7).

(8) Install crankshaft pulley (Fig. 8).

(9) Install engine bracket (Fig. 2) torque screws to

54 N Im (40 ft. lbs.).

(10) Install idler pulley on engine bracket. (11) Install cam sensor Refer to Ignition System

Group 8D for installation procedure. (12) Install A/C compressor mounting bracket.

(13) Install A/C compressor.

(14) Install drive belt Refer to Cooling System

Group 7 for installation procedure. (15) Install inner splash shield and wheel.

(16) Install oil pump pick-up and oil pan and

transmission inspection cover if removed. (17) Install engine mount.

(18) Fill crankcase with oil to proper level.

(19) Fill cooling system Refer to Cooling System

Group 7 for procedure. (20) Connect battery.

TIMING CHAIN COVER EXTERNAL OIL SEAL

REMOVAL

(1) Raise vehicle on hoist. Remove right wheel and

inner splash shield. (2) Remove drive belt. (Refer to Cooling System

Group 7) for procedure. (3) Remove crankshaft pulley (Fig. 1).

Fig. 5 Alignment of Timing Marks

Fig. 6 Timing Chain Case Cover Gaskets and O-Rings

Fig. 7 Install Crankshaft Oil Seal

Fig. 8 Installing Crankshaft Pulley

Ä 3.3/3.8L ENGINE 9 - 111

Page 1678 of 2438

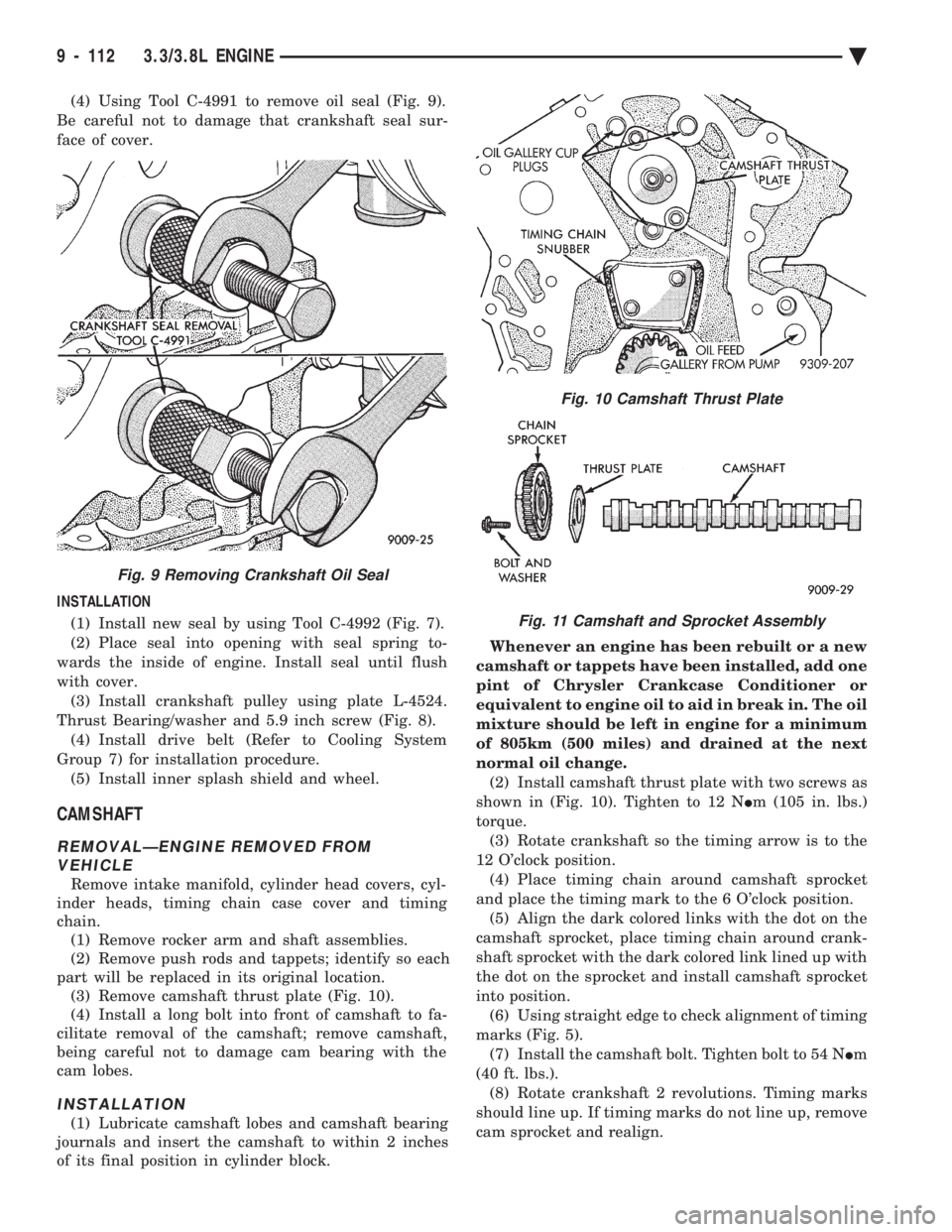

(4) Using Tool C-4991 to remove oil seal (Fig. 9).

Be careful not to damage that crankshaft seal sur-

face of cover.

INSTALLATION (1) Install new seal by using Tool C-4992 (Fig. 7).

(2) Place seal into opening with seal spring to-

wards the inside of engine. Install seal until flush

with cover. (3) Install crankshaft pulley using plate L-4524.

Thrust Bearing/washer and 5.9 inch screw (Fig. 8). (4) Install drive belt (Refer to Cooling System

Group 7) for installation procedure. (5) Install inner splash shield and wheel.

CAMSHAFT

REMOVALÐENGINE REMOVED FROM VEHICLE

Remove intake manifold, cylinder head covers, cyl-

inder heads, timing chain case cover and timing

chain. (1) Remove rocker arm and shaft assemblies.

(2) Remove push rods and tappets; identify so each

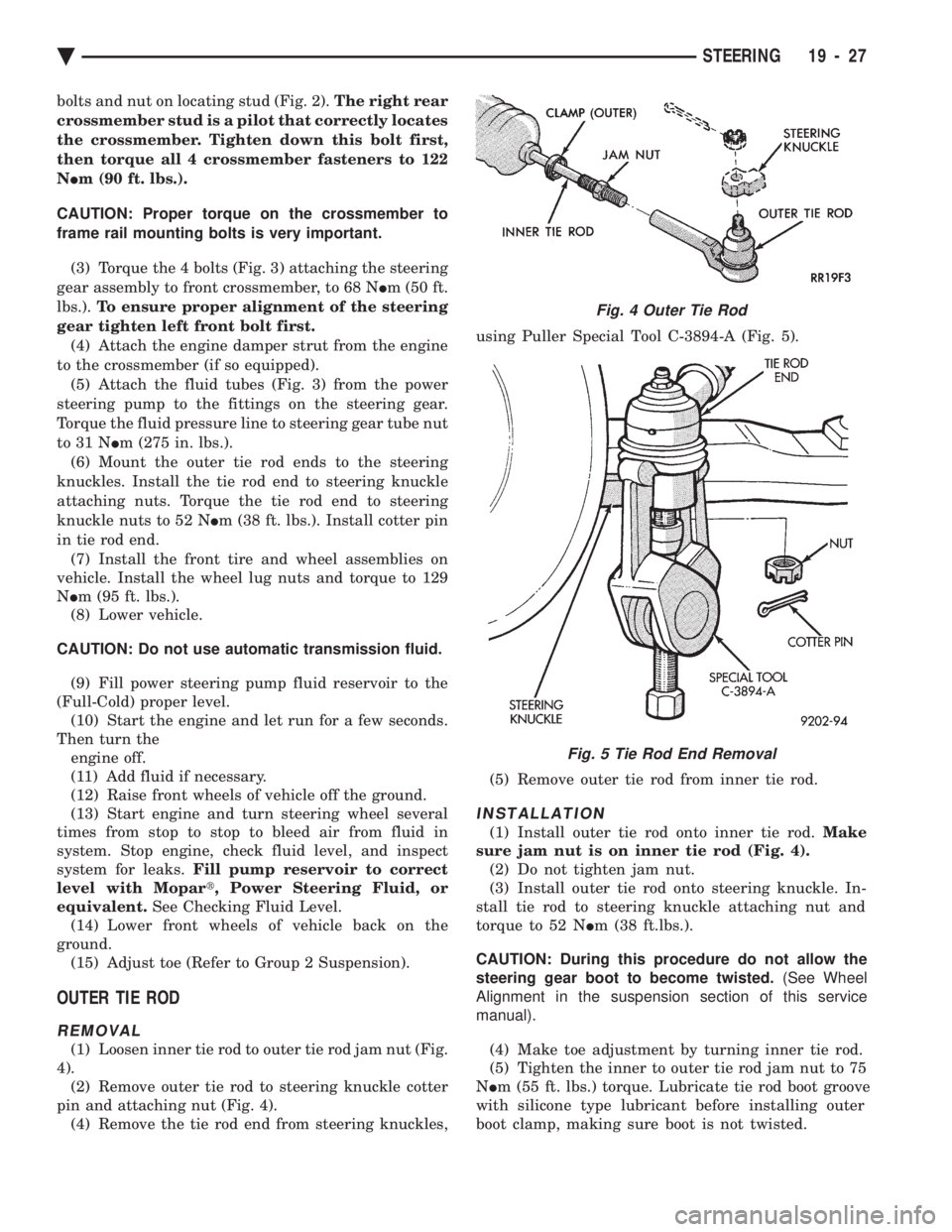

part will be replaced in its original location. (3) Remove camshaft thrust plate (Fig. 10).

(4) Install a long bolt into front of camshaft to fa-

cilitate removal of the camshaft; remove camshaft,

being careful not to damage cam bearing with the

cam lobes.

INSTALLATION

(1) Lubricate camshaft lobes and camshaft bearing

journals and insert the camshaft to within 2 inches

of its final position in cylinder block. Whenever an engine has been rebuilt or a new

camshaft or tappets have been installed, add one

pint of Chrysler Crankcase Conditioner or

equivalent to engine oil to aid in break in. The oil

mixture should be left in engine for a minimum

of 805km (500 miles) and drained at the next

normal oil change. (2) Install camshaft thrust plate with two screws as

shown in (Fig. 10). Tighten to 12 N Im (105 in. lbs.)

torque. (3) Rotate crankshaft so the timing arrow is to the

12 O'clock position. (4) Place timing chain around camshaft sprocket

and place the timing mark to the 6 O'clock position. (5) Align the dark colored links with the dot on the

camshaft sprocket, place timing chain around crank-

shaft sprocket with the dark colored link lined up with

the dot on the sprocket and install camshaft sprocket

into position. (6) Using straight edge to check alignment of timing

marks (Fig. 5). (7) Install the camshaft bolt. Tighten bolt to 54 N Im

(40 ft. lbs.). (8) Rotate crankshaft 2 revolutions. Timing marks

should line up. If timing marks do not line up, remove

cam sprocket and realign.

Fig. 9 Removing Crankshaft Oil Seal

Fig. 10 Camshaft Thrust Plate

Fig. 11 Camshaft and Sprocket Assembly

9 - 112 3.3/3.8L ENGINE Ä

Page 1945 of 2438

bolts and nut on locating stud (Fig. 2). The right rear

crossmember stud is a pilot that correctly locates

the crossmember. Tighten down this bolt first,

then torque all 4 crossmember fasteners to 122

N Im (90 ft. lbs.).

CAUTION: Proper torque on the crossmember to

frame rail mounting bolts is very important.

(3) Torque the 4 bolts (Fig. 3) attaching the steering

gear assembly to front crossmember, to 68 N Im (50 ft.

lbs.). To ensure proper alignment of the steering

gear tighten left front bolt first. (4) Attach the engine damper strut from the engine

to the crossmember (if so equipped). (5) Attach the fluid tubes (Fig. 3) from the power

steering pump to the fittings on the steering gear.

Torque the fluid pressure line to steering gear tube nut

to 31 N Im (275 in. lbs.).

(6) Mount the outer tie rod ends to the steering

knuckles. Install the tie rod end to steering knuckle

attaching nuts. Torque the tie rod end to steering

knuckle nuts to 52 N Im (38 ft. lbs.). Install cotter pin

in tie rod end. (7) Install the front tire and wheel assemblies on

vehicle. Install the wheel lug nuts and torque to 129

N Im (95 ft. lbs.).

(8) Lower vehicle.

CAUTION: Do not use automatic transmission fluid. (9) Fill power steering pump fluid reservoir to the

(Full-Cold) proper level. (10) Start the engine and let run for a few seconds.

Then turn the engine off.

(11) Add fluid if necessary.

(12) Raise front wheels of vehicle off the ground.

(13) Start engine and turn steering wheel several

times from stop to stop to bleed air from fluid in

system. Stop engine, check fluid level, and inspect

system for leaks. Fill pump reservoir to correct

level with Mopar t, Power Steering Fluid, or

equivalent. See Checking Fluid Level.

(14) Lower front wheels of vehicle back on the

ground. (15) Adjust toe (Refer to Group 2 Suspension).

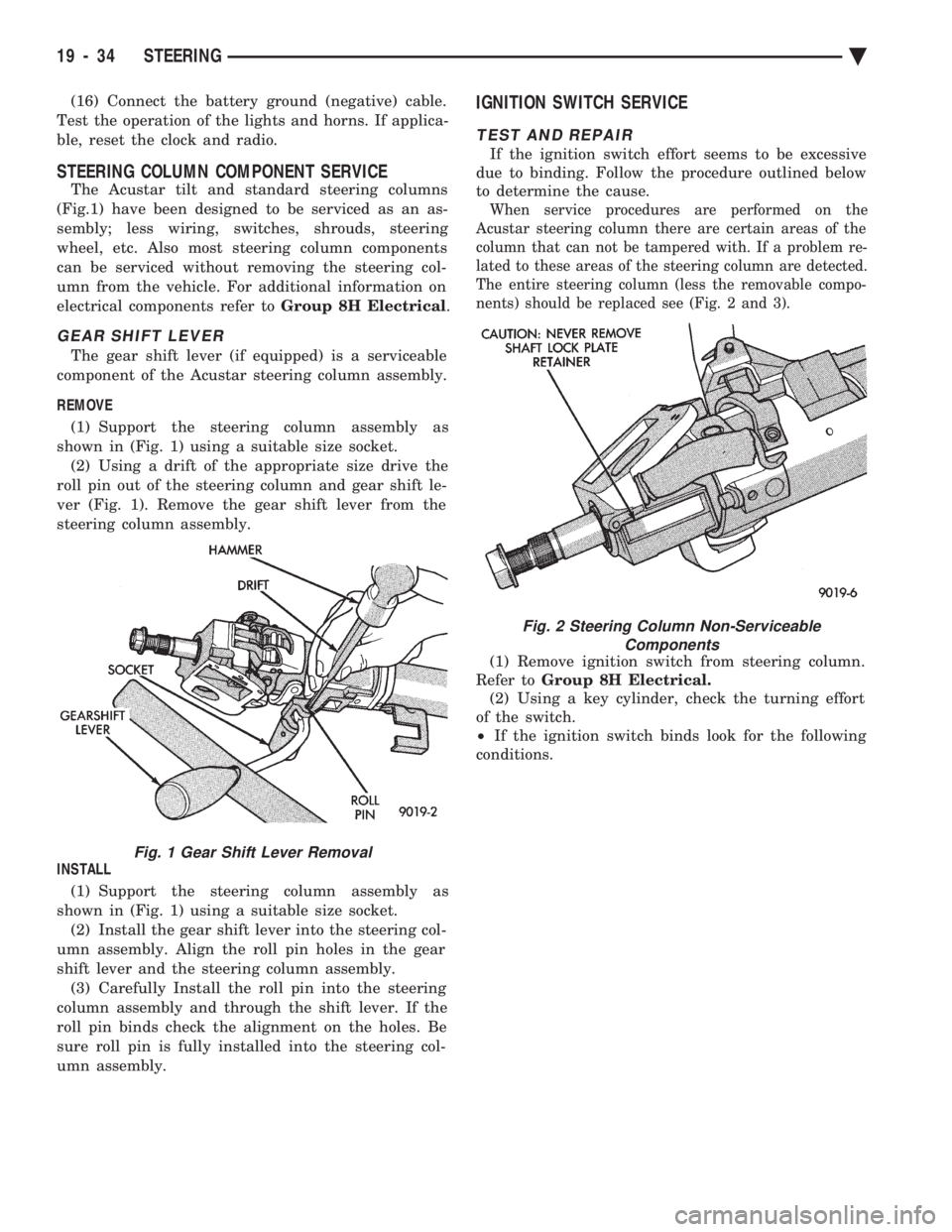

OUTER TIE ROD

REMOVAL

(1) Loosen inner tie rod to outer tie rod jam nut (Fig.

4). (2) Remove outer tie rod to steering knuckle cotter

pin and attaching nut (Fig. 4). (4) Remove the tie rod end from steering knuckles, using Puller Special Tool C-3894-A (Fig. 5).

(5) Remove outer tie rod from inner tie rod.

INSTALLATION

(1) Install outer tie rod onto inner tie rod. Make

sure jam nut is on inner tie rod (Fig. 4). (2) Do not tighten jam nut.

(3) Install outer tie rod onto steering knuckle. In-

stall tie rod to steering knuckle attaching nut and

torque to 52 N Im (38 ft.lbs.).

CAUTION: During this procedure do not allow the

steering gear boot to become twisted. (See Wheel

Alignment in the suspension section of this service

manual).

(4) Make toe adjustment by turning inner tie rod.

(5) Tighten the inner to outer tie rod jam nut to 75

N Im (55 ft. lbs.) torque. Lubricate tie rod boot groove

with silicone type lubricant before installing outer

boot clamp, making sure boot is not twisted.

Fig. 4 Outer Tie Rod

Fig. 5 Tie Rod End Removal

Ä STEERING 19 - 27

Page 1952 of 2438

(16) Connect the battery ground (negative) cable.

Test the operation of the lights and horns. If applica-

ble, reset the clock and radio.

STEERING COLUMN COMPONENT SERVICE

The Acustar tilt and standard steering columns

(Fig.1) have been designed to be serviced as an as-

sembly; less wiring, switches, shrouds, steering

wheel, etc. Also most steering column components

can be serviced without removing the steering col-

umn from the vehicle. For additional information on

electrical components refer to Group 8H Electrical.

GEAR SHIFT LEVER

The gear shift lever (if equipped) is a serviceable

component of the Acustar steering column assembly.

REMOVE (1) Support the steering column assembly as

shown in (Fig. 1) using a suitable size socket. (2) Using a drift of the appropriate size drive the

roll pin out of the steering column and gear shift le-

ver (Fig. 1). Remove the gear shift lever from the

steering column assembly.

INSTALL (1) Support the steering column assembly as

shown in (Fig. 1) using a suitable size socket. (2) Install the gear shift lever into the steering col-

umn assembly. Align the roll pin holes in the gear

shift lever and the steering column assembly. (3) Carefully Install the roll pin into the steering

column assembly and through the shift lever. If the

roll pin binds check the alignment on the holes. Be

sure roll pin is fully installed into the steering col-

umn assembly.

IGNITION SWITCH SERVICE

TEST AND REPAIR

If the ignition switch effort seems to be excessive

due to binding. Follow the procedure outlined below

to determine the cause.

When service procedures are performed on the

Acustar steering column there are certain areas of the

column that can not be tampered with. If a problem re-

lated to these areas of the steering column are detected.

The entire steering column (less the removable compo-

nents) should be replaced see (Fig. 2 and 3).

(1) Remove ignition switch from steering column.

Refer to Group 8H Electrical.

(2) Using a key cylinder, check the turning effort

of the switch.

² If the ignition switch binds look for the following

conditions.

Fig. 1 Gear Shift Lever Removal

Fig. 2 Steering Column Non-Serviceable Components

19 - 34 STEERING Ä

Page 2154 of 2438

WHEELS SERVICE PROCEDURES INDEX

page page

General Information ........................ 6

Tire and Wheel Balance .................... 6

Tire and Wheel Run Out .................... 7 Wheel Installation

......................... 6

Wheel Replacement ....................... 6

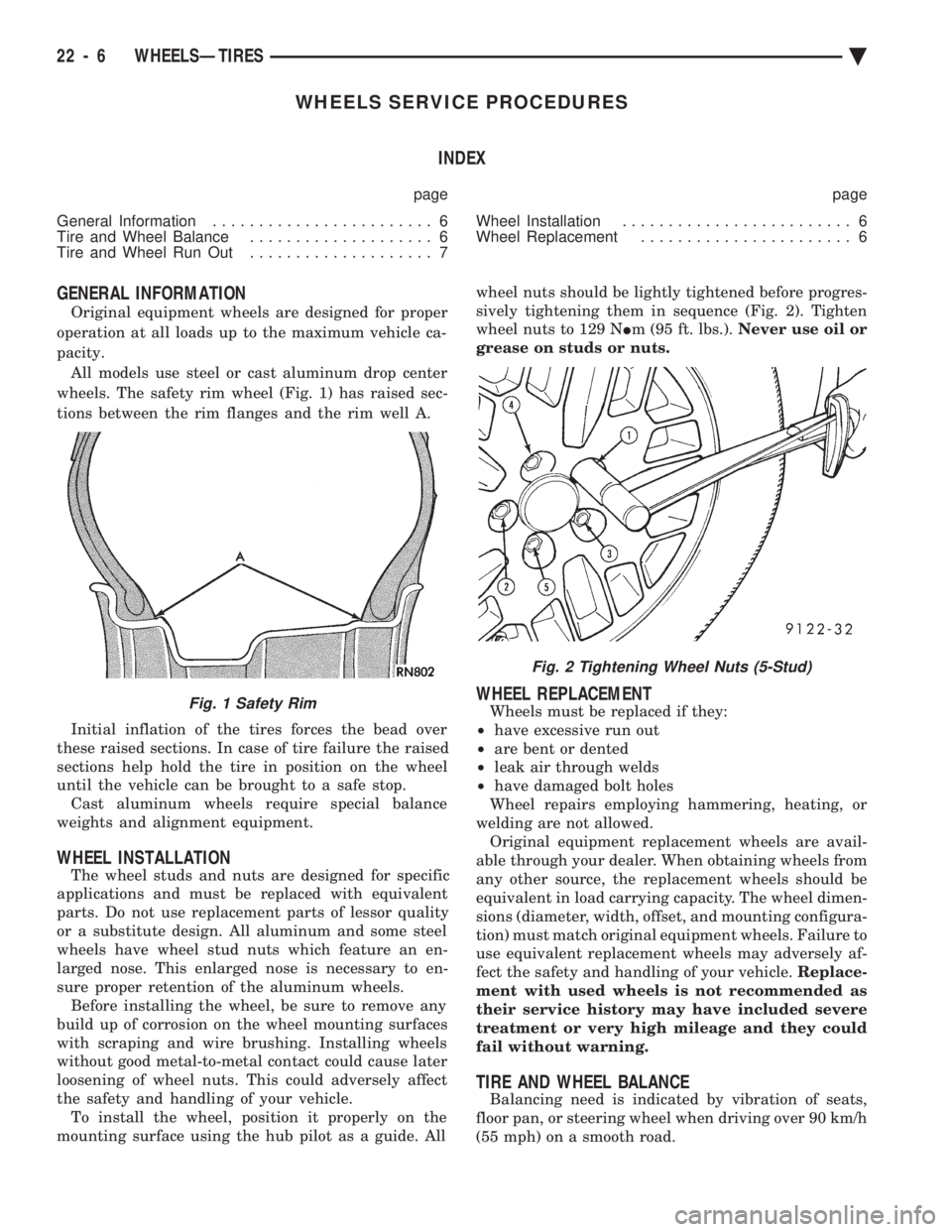

GENERAL INFORMATION

Original equipment wheels are designed for proper

operation at all loads up to the maximum vehicle ca-

pacity. All models use steel or cast aluminum drop center

wheels. The safety rim wheel (Fig. 1) has raised sec-

tions between the rim flanges and the rim well A.

Initial inflation of the tires forces the bead over

these raised sections. In case of tire failure the raised

sections help hold the tire in position on the wheel

until the vehicle can be brought to a safe stop. Cast aluminum wheels require special balance

weights and alignment equipment.

WHEEL INSTALLATION

The wheel studs and nuts are designed for specific

applications and must be replaced with equivalent

parts. Do not use replacement parts of lessor quality

or a substitute design. All aluminum and some steel

wheels have wheel stud nuts which feature an en-

larged nose. This enlarged nose is necessary to en-

sure proper retention of the aluminum wheels. Before installing the wheel, be sure to remove any

build up of corrosion on the wheel mounting surfaces

with scraping and wire brushing. Installing wheels

without good metal-to-metal contact could cause later

loosening of wheel nuts. This could adversely affect

the safety and handling of your vehicle. To install the wheel, position it properly on the

mounting surface using the hub pilot as a guide. All wheel nuts should be lightly tightened before progres-

sively tightening them in sequence (Fig. 2). Tighten

wheel nuts to 129 N Im (95 ft. lbs.). Never use oil or

grease on studs or nuts.

WHEEL REPLACEMENT

Wheels must be replaced if they:

² have excessive run out

² are bent or dented

² leak air through welds

² have damaged bolt holes

Wheel repairs employing hammering, heating, or

welding are not allowed. Original equipment replacement wheels are avail-

able through your dealer. When obtaining wheels from

any other source, the replacement wheels should be

equivalent in load carrying capacity. The wheel dimen-

sions (diameter, width, offset, and mounting configura-

tion) must match original equipment wheels. Failure to

use equivalent replacement wheels may adversely af-

fect the safety and handling of your vehicle. Replace-

ment with used wheels is not recommended as

their service history may have included severe

treatment or very high mileage and they could

fail without warning.

TIRE AND WHEEL BALANCE

Balancing need is indicated by vibration of seats,

floor pan, or steering wheel when driving over 90 km/h

(55 mph) on a smooth road.

Fig. 1 Safety Rim

Fig. 2 Tightening Wheel Nuts (5-Stud)

22 - 6 WHEELSÐTIRES Ä

Page 2172 of 2438

(6) Separate door from vehicle.

FRONT DOOR INSTALLATION

Reverse the preceding operation. The door should

not require re-alignment. If door does need align-

ment, refer to Front Door Hinge Installation para-

graph in this section.

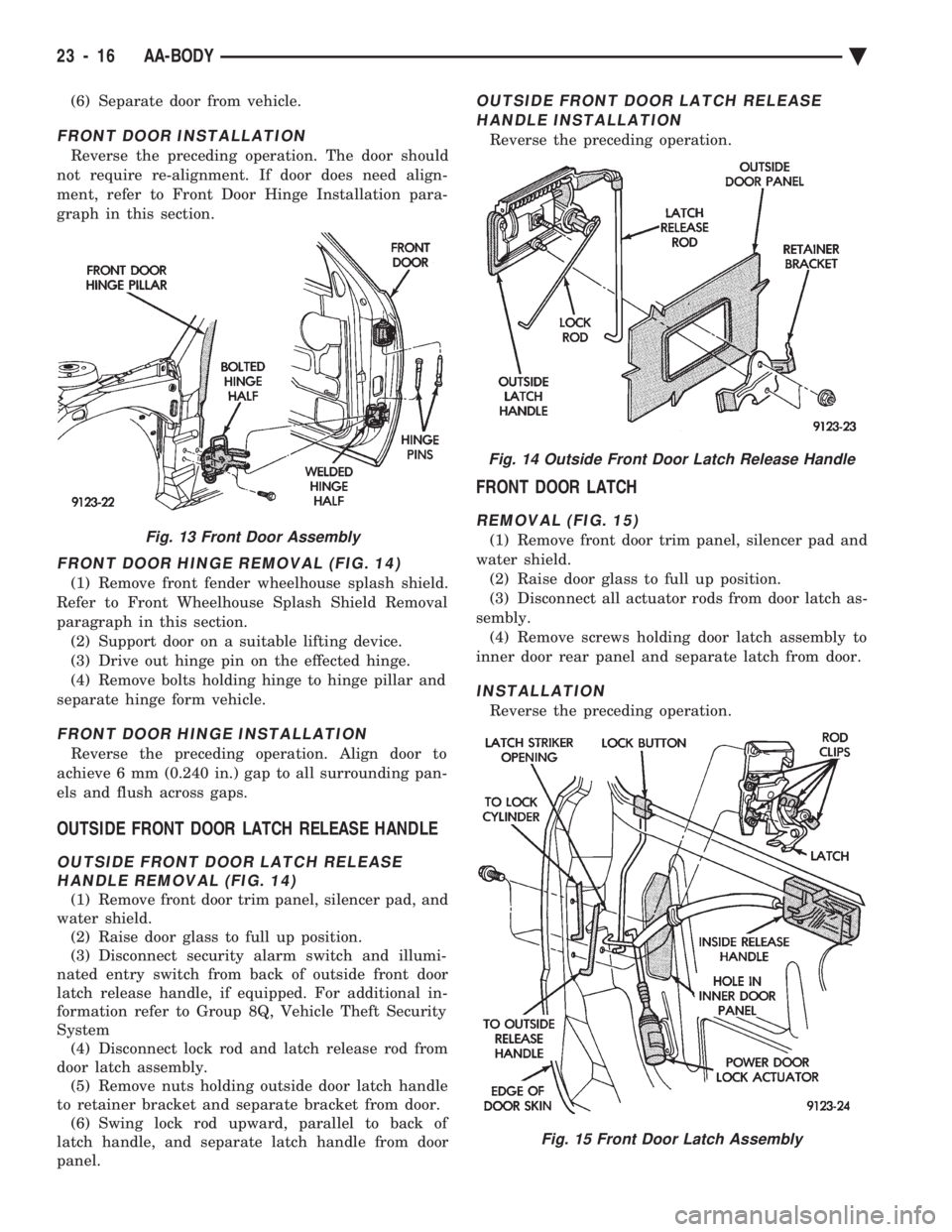

FRONT DOOR HINGE REMOVAL (FIG. 14)

(1) Remove front fender wheelhouse splash shield.

Refer to Front Wheelhouse Splash Shield Removal

paragraph in this section. (2) Support door on a suitable lifting device.

(3) Drive out hinge pin on the effected hinge.

(4) Remove bolts holding hinge to hinge pillar and

separate hinge form vehicle.

FRONT DOOR HINGE INSTALLATION

Reverse the preceding operation. Align door to

achieve 6 mm (0.240 in.) gap to all surrounding pan-

els and flush across gaps.

OUTSIDE FRONT DOOR LATCH RELEASE HANDLE

OUTSIDE FRONT DOOR LATCH RELEASE HANDLE REMOVAL (FIG. 14)

(1) Remove front door trim panel, silencer pad, and

water shield. (2) Raise door glass to full up position.

(3) Disconnect security alarm switch and illumi-

nated entry switch from back of outside front door

latch release handle, if equipped. For additional in-

formation refer to Group 8Q, Vehicle Theft Security

System (4) Disconnect lock rod and latch release rod from

door latch assembly. (5) Remove nuts holding outside door latch handle

to retainer bracket and separate bracket from door. (6) Swing lock rod upward, parallel to back of

latch handle, and separate latch handle from door

panel.

OUTSIDE FRONT DOOR LATCH RELEASE

HANDLE INSTALLATION

Reverse the preceding operation.

FRONT DOOR LATCH

REMOVAL (FIG. 15)

(1) Remove front door trim panel, silencer pad and

water shield. (2) Raise door glass to full up position.

(3) Disconnect all actuator rods from door latch as-

sembly. (4) Remove screws holding door latch assembly to

inner door rear panel and separate latch from door.

INSTALLATION

Reverse the preceding operation.

Fig. 13 Front Door Assembly

Fig. 14 Outside Front Door Latch Release Handle

Fig. 15 Front Door Latch Assembly

23 - 16 AA-BODY Ä

Page 2197 of 2438

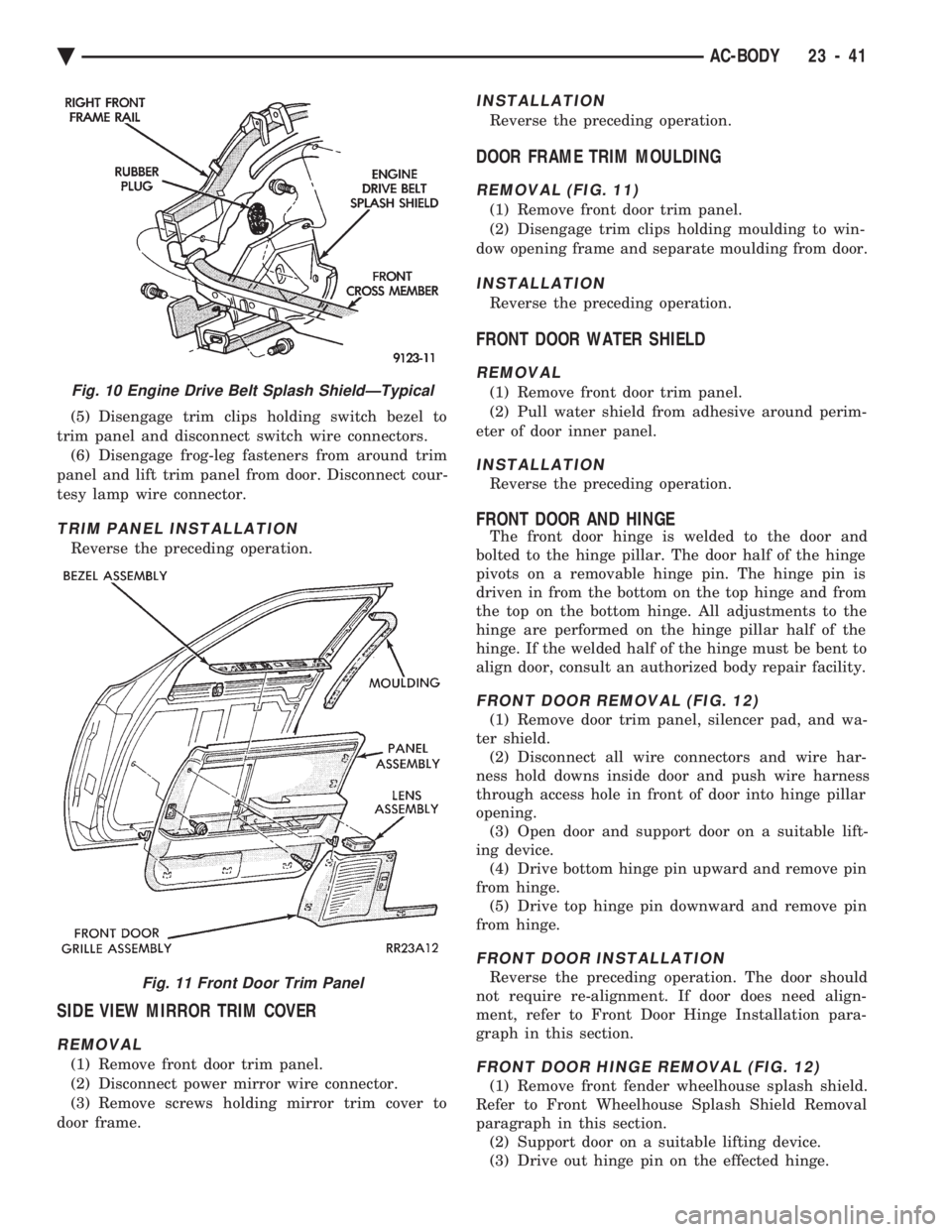

(5) Disengage trim clips holding switch bezel to

trim panel and disconnect switch wire connectors. (6) Disengage frog-leg fasteners from around trim

panel and lift trim panel from door. Disconnect cour-

tesy lamp wire connector.

TRIM PANEL INSTALLATION

Reverse the preceding operation.

SIDE VIEW MIRROR TRIM COVER

REMOVAL

(1) Remove front door trim panel.

(2) Disconnect power mirror wire connector.

(3) Remove screws holding mirror trim cover to

door frame.

INSTALLATION

Reverse the preceding operation.

DOOR FRAME TRIM MOULDING

REMOVAL (FIG. 11)

(1) Remove front door trim panel.

(2) Disengage trim clips holding moulding to win-

dow opening frame and separate moulding from door.

INSTALLATION

Reverse the preceding operation.

FRONT DOOR WATER SHIELD

REMOVAL

(1) Remove front door trim panel.

(2) Pull water shield from adhesive around perim-

eter of door inner panel.

INSTALLATION

Reverse the preceding operation.

FRONT DOOR AND HINGE

The front door hinge is welded to the door and

bolted to the hinge pillar. The door half of the hinge

pivots on a removable hinge pin. The hinge pin is

driven in from the bottom on the top hinge and from

the top on the bottom hinge. All adjustments to the

hinge are performed on the hinge pillar half of the

hinge. If the welded half of the hinge must be bent to

align door, consult an authorized body repair facility.

FRONT DOOR REMOVAL (FIG. 12)

(1) Remove door trim panel, silencer pad, and wa-

ter shield. (2) Disconnect all wire connectors and wire har-

ness hold downs inside door and push wire harness

through access hole in front of door into hinge pillar

opening. (3) Open door and support door on a suitable lift-

ing device. (4) Drive bottom hinge pin upward and remove pin

from hinge. (5) Drive top hinge pin downward and remove pin

from hinge.

FRONT DOOR INSTALLATION

Reverse the preceding operation. The door should

not require re-alignment. If door does need align-

ment, refer to Front Door Hinge Installation para-

graph in this section.

FRONT DOOR HINGE REMOVAL (FIG. 12)

(1) Remove front fender wheelhouse splash shield.

Refer to Front Wheelhouse Splash Shield Removal

paragraph in this section. (2) Support door on a suitable lifting device.

(3) Drive out hinge pin on the effected hinge.

Fig. 10 Engine Drive Belt Splash ShieldÐTypical

Fig. 11 Front Door Trim Panel

Ä AC-BODY 23 - 41