wheel bolts CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 147 of 2438

REAR (STUB) AXLE ALIGNMENT ALL MODELS INDEX

page page

General Information ....................... 89 Rear Wheel Alignment..................... 89

GENERAL INFORMATION

Because front wheel drive vehicles are equipped with

rear suspension incorporating stub axles (or wheel

spindles). It is possible to align both the camber and toe

of the rear wheels.

REAR WHEEL ALIGNMENT

Alignment adjustment if required. Is made by adding

0.010 inch shims (from the service package kit) be-

tween the spindle mounting surface and axle mounting

plate. Each shim equals wheel change by .3É as shown

(for all car lines) in (Figs. 3 to 6). If rear wheel alignment is required, place vehicle on

alignment rack and check alignment specifications.

When recording rear toe-in (vehicle backed onto

alignment rack) REMEMBER to reverse sign

convention; a total toe-in on direct reading

charts is actually toe-out while driving. Maintain

rear alignment within Chrysler Motors recommenda-

tions, found in Specifications.

INSTALLATION OF REAR ALIGNMENT SHIMS

(1) Block front tires so vehicle will not move.

(2) Release parking brake.

(3) Hoist vehicle so that rear suspension is in full

rebound and tires are off the ground. See Hoisting in

Lubrication and Maintenance, Group 0. (4) Remove wheel and tire assembly.

(5) Pry off grease cap.

(6) Remove cotter pin and castle lock.

(7) Remove adjusting nut.

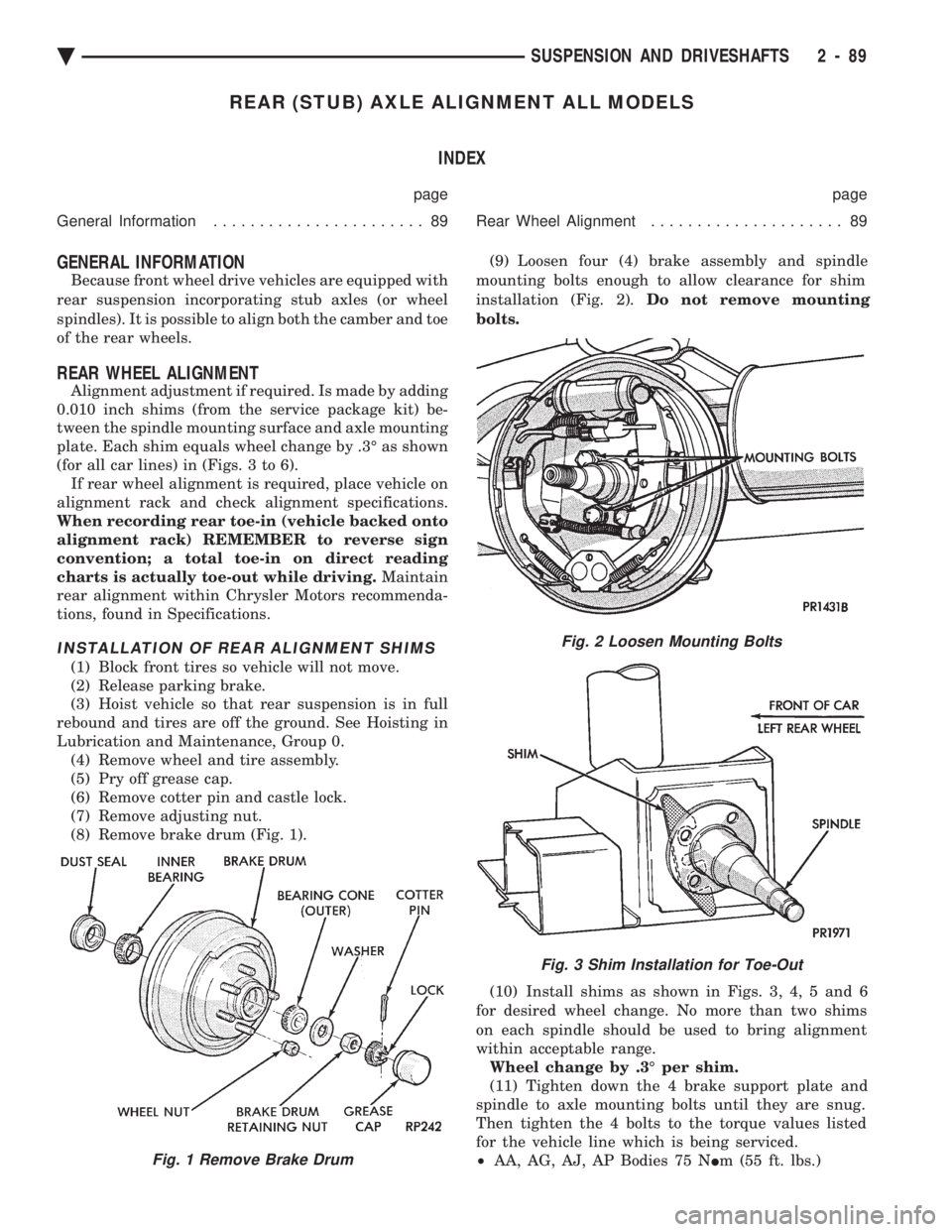

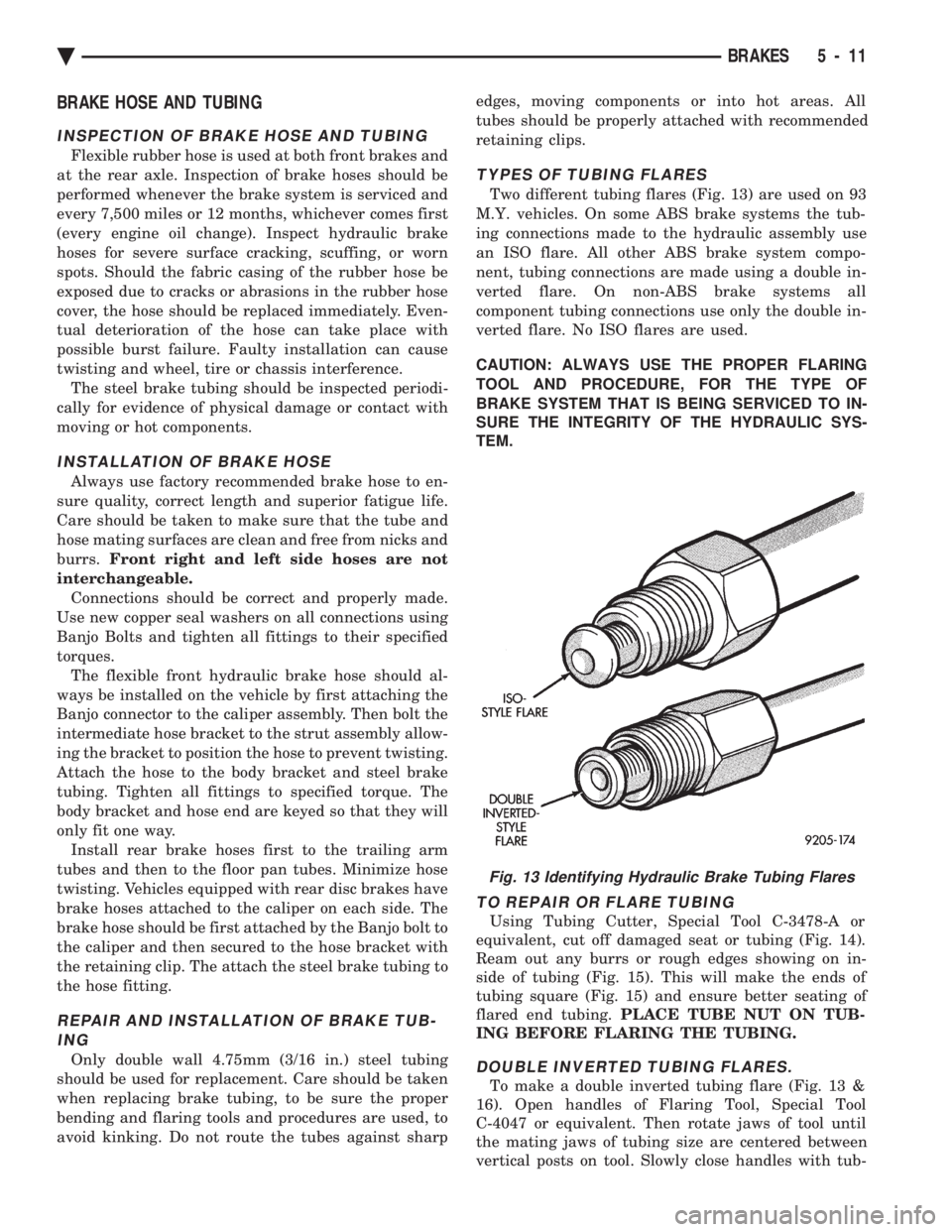

(8) Remove brake drum (Fig. 1). (9) Loosen four (4) brake assembly and spindle

mounting bolts enough to allow clearance for shim

installation (Fig. 2). Do not remove mounting

bolts.

(10) Install shims as shown in Figs. 3, 4, 5 and 6

for desired wheel change. No more than two shims

on each spindle should be used to bring alignment

within acceptable range. Wheel change by .3É per shim.

(11) Tighten down the 4 brake support plate and

spindle to axle mounting bolts until they are snug.

Then tighten the 4 bolts to the torque values listed

for the vehicle line which is being serviced.

² AA, AG, AJ, AP Bodies 75 N Im (55 ft. lbs.)

Fig. 2 Loosen Mounting Bolts

Fig. 3 Shim Installation for Toe-Out

Fig. 1 Remove Brake Drum

Ä SUSPENSION AND DRIVESHAFTS 2 - 89

Page 161 of 2438

BRAKE HOSE AND TUBING

INSPECTION OF BRAKE HOSE AND TUBING

Flexible rubber hose is used at both front brakes and

at the rear axle. Inspection of brake hoses should be

performed whenever the brake system is serviced and

every 7,500 miles or 12 months, whichever comes first

(every engine oil change). Inspect hydraulic brake

hoses for severe surface cracking, scuffing, or worn

spots. Should the fabric casing of the rubber hose be

exposed due to cracks or abrasions in the rubber hose

cover, the hose should be replaced immediately. Even-

tual deterioration of the hose can take place with

possible burst failure. Faulty installation can cause

twisting and wheel, tire or chassis interference. The steel brake tubing should be inspected periodi-

cally for evidence of physical damage or contact with

moving or hot components.

INSTALLATION OF BRAKE HOSE

Always use factory recommended brake hose to en-

sure quality, correct length and superior fatigue life.

Care should be taken to make sure that the tube and

hose mating surfaces are clean and free from nicks and

burrs. Front right and left side hoses are not

interchangeable. Connections should be correct and properly made.

Use new copper seal washers on all connections using

Banjo Bolts and tighten all fittings to their specified

torques. The flexible front hydraulic brake hose should al-

ways be installed on the vehicle by first attaching the

Banjo connector to the caliper assembly. Then bolt the

intermediate hose bracket to the strut assembly allow-

ing the bracket to position the hose to prevent twisting.

Attach the hose to the body bracket and steel brake

tubing. Tighten all fittings to specified torque. The

body bracket and hose end are keyed so that they will

only fit one way. Install rear brake hoses first to the trailing arm

tubes and then to the floor pan tubes. Minimize hose

twisting. Vehicles equipped with rear disc brakes have

brake hoses attached to the caliper on each side. The

brake hose should be first attached by the Banjo bolt to

the caliper and then secured to the hose bracket with

the retaining clip. The attach the steel brake tubing to

the hose fitting.

REPAIR AND INSTALLATION OF BRAKE TUB- ING

Only double wall 4.75mm (3/16 in.) steel tubing

should be used for replacement. Care should be taken

when replacing brake tubing, to be sure the proper

bending and flaring tools and procedures are used, to

avoid kinking. Do not route the tubes against sharp edges, moving components or into hot areas. All

tubes should be properly attached with recommended

retaining clips.

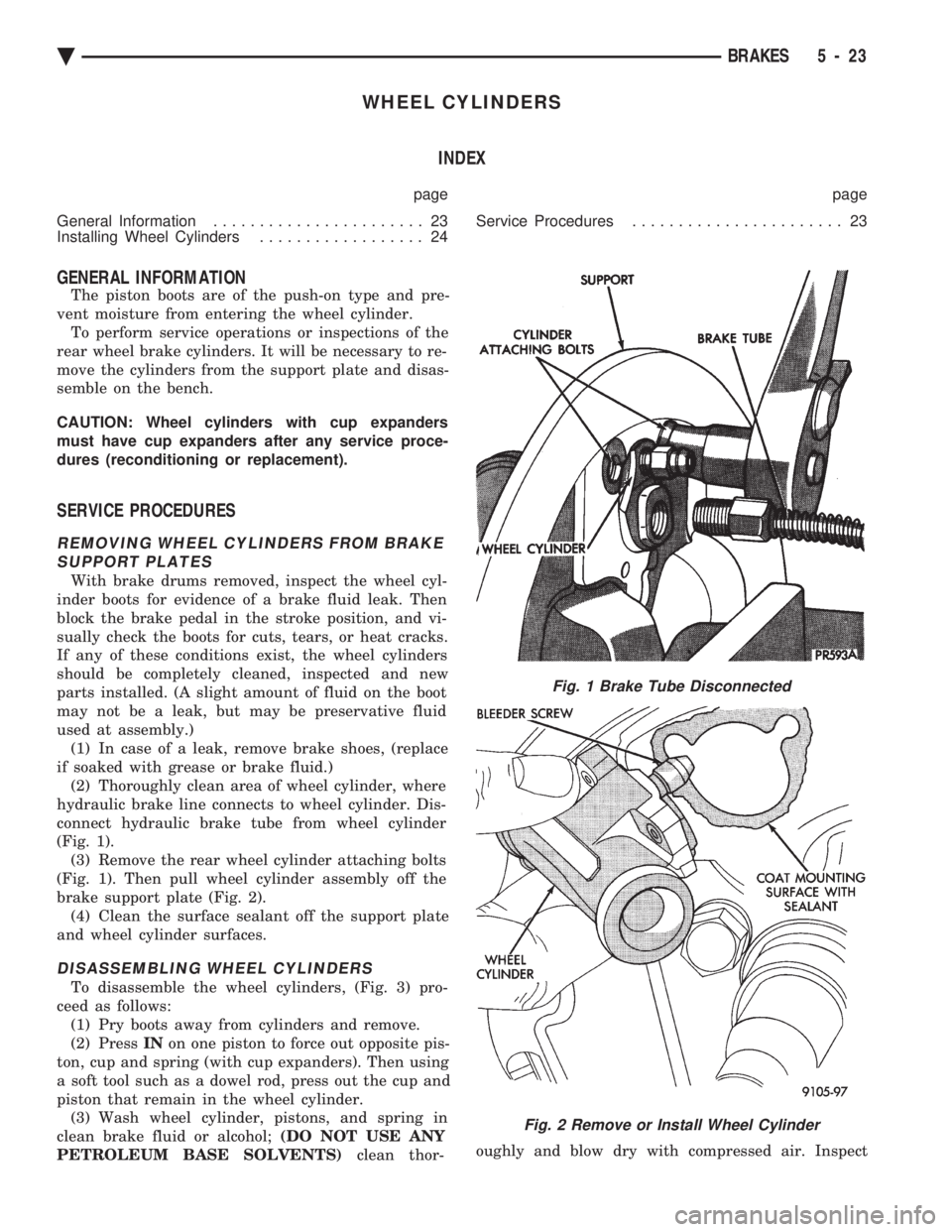

TYPES OF TUBING FLARES

Two different tubing flares (Fig. 13) are used on 93

M.Y. vehicles. On some ABS brake systems the tub-

ing connections made to the hydraulic assembly use

an ISO flare. All other ABS brake system compo-

nent, tubing connections are made using a double in-

verted flare. On non-ABS brake systems all

component tubing connections use only the double in-

verted flare. No ISO flares are used.

CAUTION: ALWAYS USE THE PROPER FLARING

TOOL AND PROCEDURE, FOR THE TYPE OF

BRAKE SYSTEM THAT IS BEING SERVICED TO IN-

SURE THE INTEGRITY OF THE HYDRAULIC SYS-

TEM.

TO REPAIR OR FLARE TUBING

Using Tubing Cutter, Special Tool C-3478-A or

equivalent, cut off damaged seat or tubing (Fig. 14).

Ream out any burrs or rough edges showing on in-

side of tubing (Fig. 15). This will make the ends of

tubing square (Fig. 15) and ensure better seating of

flared end tubing. PLACE TUBE NUT ON TUB-

ING BEFORE FLARING THE TUBING.

DOUBLE INVERTED TUBING FLARES.

To make a double inverted tubing flare (Fig. 13 &

16). Open handles of Flaring Tool, Special Tool

C-4047 or equivalent. Then rotate jaws of tool until

the mating jaws of tubing size are centered between

vertical posts on tool. Slowly close handles with tub-

Fig. 13 Identifying Hydraulic Brake Tubing Flares

Ä BRAKES 5 - 11

Page 173 of 2438

WHEEL CYLINDERS INDEX

page page

General Information ....................... 23

Installing Wheel Cylinders .................. 24 Service Procedures

....................... 23

GENERAL INFORMATION

The piston boots are of the push-on type and pre-

vent moisture from entering the wheel cylinder. To perform service operations or inspections of the

rear wheel brake cylinders. It will be necessary to re-

move the cylinders from the support plate and disas-

semble on the bench.

CAUTION: Wheel cylinders with cup expanders

must have cup expanders after any service proce-

dures (reconditioning or replacement).

SERVICE PROCEDURES

REMOVING WHEEL CYLINDERS FROM BRAKE SUPPORT PLATES

With brake drums removed, inspect the wheel cyl-

inder boots for evidence of a brake fluid leak. Then

block the brake pedal in the stroke position, and vi-

sually check the boots for cuts, tears, or heat cracks.

If any of these conditions exist, the wheel cylinders

should be completely cleaned, inspected and new

parts installed. (A slight amount of fluid on the boot

may not be a leak, but may be preservative fluid

used at assembly.) (1) In case of a leak, remove brake shoes, (replace

if soaked with grease or brake fluid.) (2) Thoroughly clean area of wheel cylinder, where

hydraulic brake line connects to wheel cylinder. Dis-

connect hydraulic brake tube from wheel cylinder

(Fig. 1). (3) Remove the rear wheel cylinder attaching bolts

(Fig. 1). Then pull wheel cylinder assembly off the

brake support plate (Fig. 2). (4) Clean the surface sealant off the support plate

and wheel cylinder surfaces.

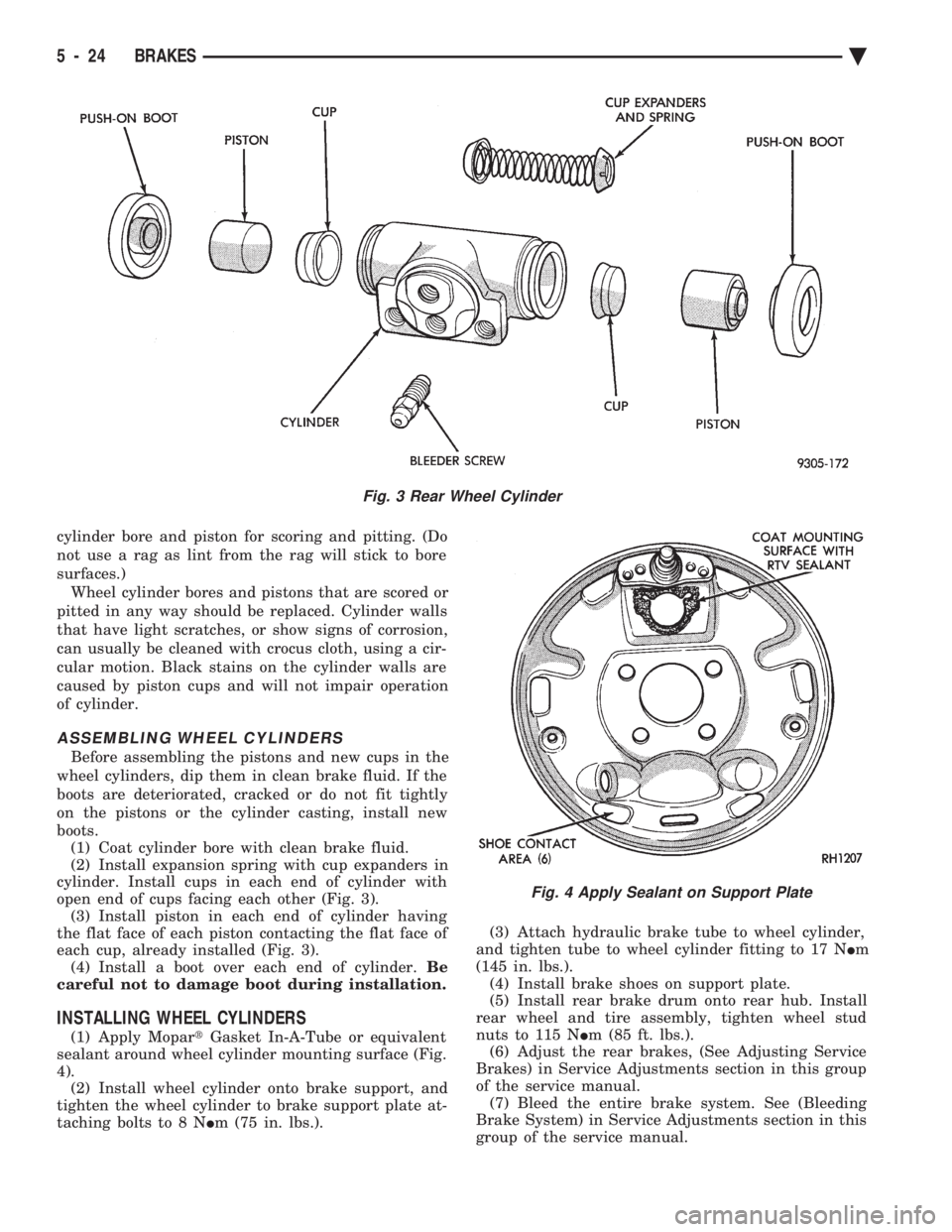

DISASSEMBLING WHEEL CYLINDERS

To disassemble the wheel cylinders, (Fig. 3) pro-

ceed as follows: (1) Pry boots away from cylinders and remove.

(2) Press INon one piston to force out opposite pis-

ton, cup and spring (with cup expanders). Then using

a soft tool such as a dowel rod, press out the cup and

piston that remain in the wheel cylinder. (3) Wash wheel cylinder, pistons, and spring in

clean brake fluid or alcohol; (DO NOT USE ANY

PETROLEUM BASE SOLVENTS) clean thor- oughly and blow dry with compressed air. Inspect

Fig. 1 Brake Tube Disconnected

Fig. 2 Remove or Install Wheel Cylinder

Ä

BRAKES 5 - 23

Page 174 of 2438

cylinder bore and piston for scoring and pitting. (Do

not use a rag as lint from the rag will stick to bore

surfaces.) Wheel cylinder bores and pistons that are scored or

pitted in any way should be replaced. Cylinder walls

that have light scratches, or show signs of corrosion,

can usually be cleaned with crocus cloth, using a cir-

cular motion. Black stains on the cylinder walls are

caused by piston cups and will not impair operation

of cylinder.

ASSEMBLING WHEEL CYLINDERS

Before assembling the pistons and new cups in the

wheel cylinders, dip them in clean brake fluid. If the

boots are deteriorated, cracked or do not fit tightly

on the pistons or the cylinder casting, install new

boots. (1) Coat cylinder bore with clean brake fluid.

(2) Install expansion spring with cup expanders in

cylinder. Install cups in each end of cylinder with

open end of cups facing each other (Fig. 3). (3) Install piston in each end of cylinder having

the flat face of each piston contacting the flat face of

each cup, already installed (Fig. 3). (4) Install a boot over each end of cylinder. Be

careful not to damage boot during installation.

INSTALLING WHEEL CYLINDERS

(1) Apply Mopar tGasket In-A-Tube or equivalent

sealant around wheel cylinder mounting surface (Fig.

4). (2) Install wheel cylinder onto brake support, and

tighten the wheel cylinder to brake support plate at-

taching bolts to 8 N Im (75 in. lbs.). (3) Attach hydraulic brake tube to wheel cylinder,

and tighten tube to wheel cylinder fitting to 17 N Im

(145 in. lbs.). (4) Install brake shoes on support plate.

(5) Install rear brake drum onto rear hub. Install

rear wheel and tire assembly, tighten wheel stud

nuts to 115 N Im (85 ft. lbs.).

(6) Adjust the rear brakes, (See Adjusting Service

Brakes) in Service Adjustments section in this group

of the service manual. (7) Bleed the entire brake system. See (Bleeding

Brake System) in Service Adjustments section in this

group of the service manual.

Fig. 3 Rear Wheel Cylinder

Fig. 4 Apply Sealant on Support Plate

5 - 24 BRAKES Ä

Page 175 of 2438

BRAKE SUPPORT ASSEMBLY

REMOVAL

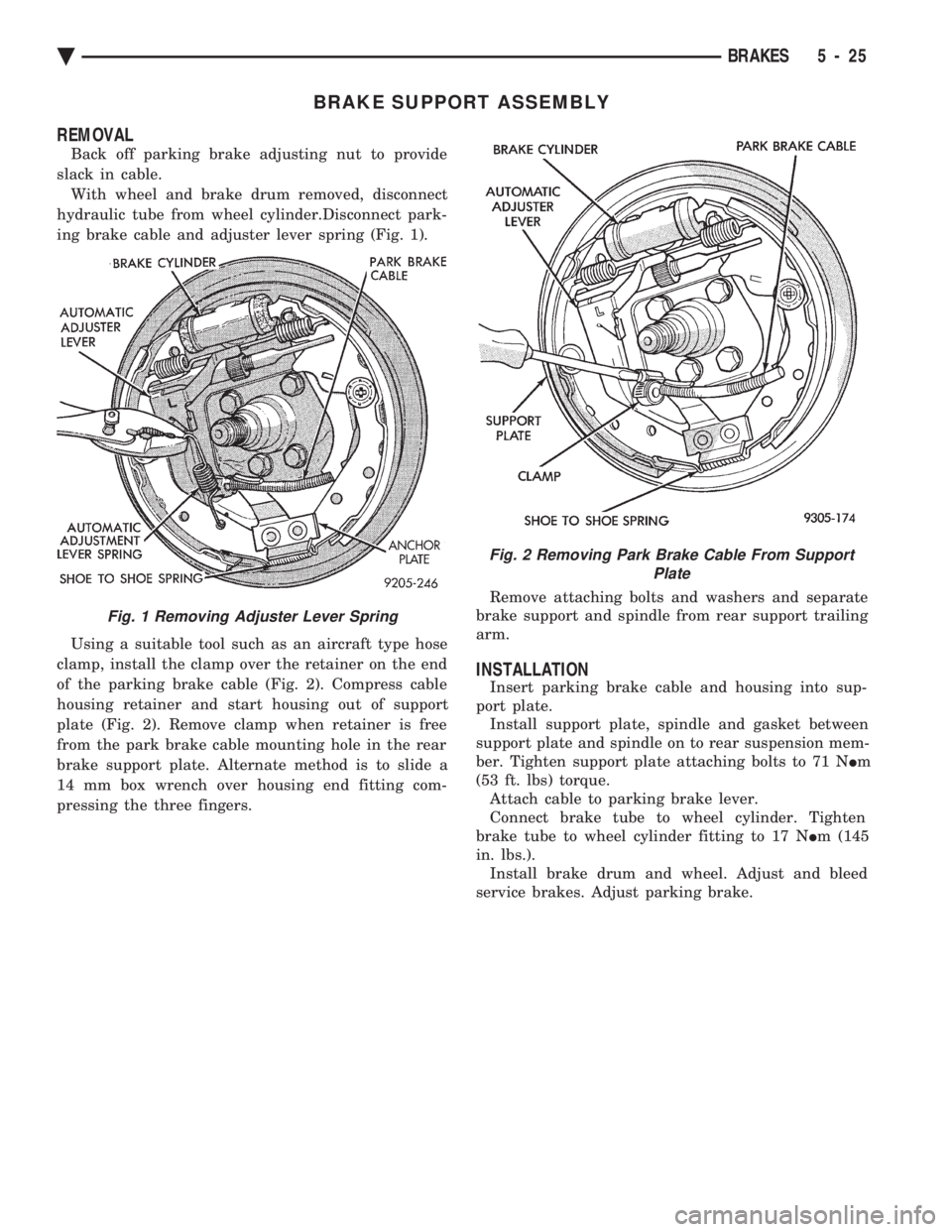

Back off parking brake adjusting nut to provide

slack in cable. With wheel and brake drum removed, disconnect

hydraulic tube from wheel cylinder.Disconnect park-

ing brake cable and adjuster lever spring (Fig. 1).

Using a suitable tool such as an aircraft type hose

clamp, install the clamp over the retainer on the end

of the parking brake cable (Fig. 2). Compress cable

housing retainer and start housing out of support

plate (Fig. 2). Remove clamp when retainer is free

from the park brake cable mounting hole in the rear

brake support plate. Alternate method is to slide a

14 mm box wrench over housing end fitting com-

pressing the three fingers. Remove attaching bolts and washers and separate

brake support and spindle from rear support trailing

arm.

INSTALLATION

Insert parking brake cable and housing into sup-

port plate. Install support plate, spindle and gasket between

support plate and spindle on to rear suspension mem-

ber. Tighten support plate attaching bolts to 71 N Im

(53 ft. lbs) torque. Attach cable to parking brake lever.

Connect brake tube to wheel cylinder. Tighten

brake tube to wheel cylinder fitting to 17 N Im (145

in. lbs.). Install brake drum and wheel. Adjust and bleed

service brakes. Adjust parking brake.

Fig. 1 Removing Adjuster Lever Spring

Fig. 2 Removing Park Brake Cable From Support Plate

Ä BRAKES 5 - 25

Page 185 of 2438

KELSEY HAYES DOUBLE PIN FAMILY CALIPER

BRAKE SHOE SERVICE PROCEDURES

BRAKE SHOE REMOVAL

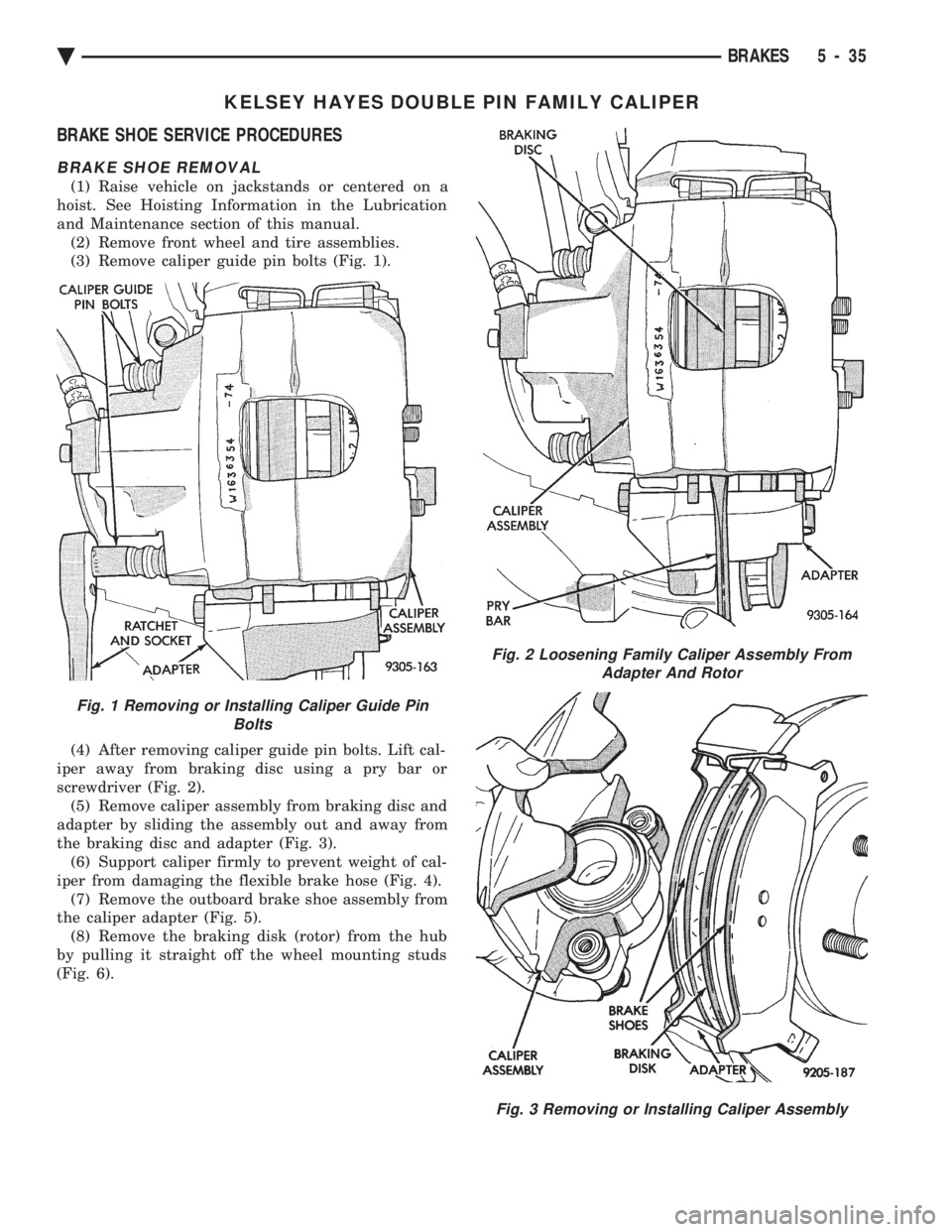

(1) Raise vehicle on jackstands or centered on a

hoist. See Hoisting Information in the Lubrication

and Maintenance section of this manual. (2) Remove front wheel and tire assemblies.

(3) Remove caliper guide pin bolts (Fig. 1).

(4) After removing caliper guide pin bolts. Lift cal-

iper away from braking disc using a pry bar or

screwdriver (Fig. 2). (5) Remove caliper assembly from braking disc and

adapter by sliding the assembly out and away from

the braking disc and adapter (Fig. 3). (6) Support caliper firmly to prevent weight of cal-

iper from damaging the flexible brake hose (Fig. 4). (7) Remove the outboard brake shoe assembly from

the caliper adapter (Fig. 5). (8) Remove the braking disk (rotor) from the hub

by pulling it straight off the wheel mounting studs

(Fig. 6).

Fig. 1 Removing or Installing Caliper Guide Pin Bolts

Fig. 2 Loosening Family Caliper Assembly FromAdapter And Rotor

Fig. 3 Removing or Installing Caliper Assembly

Ä BRAKES 5 - 35

Page 187 of 2438

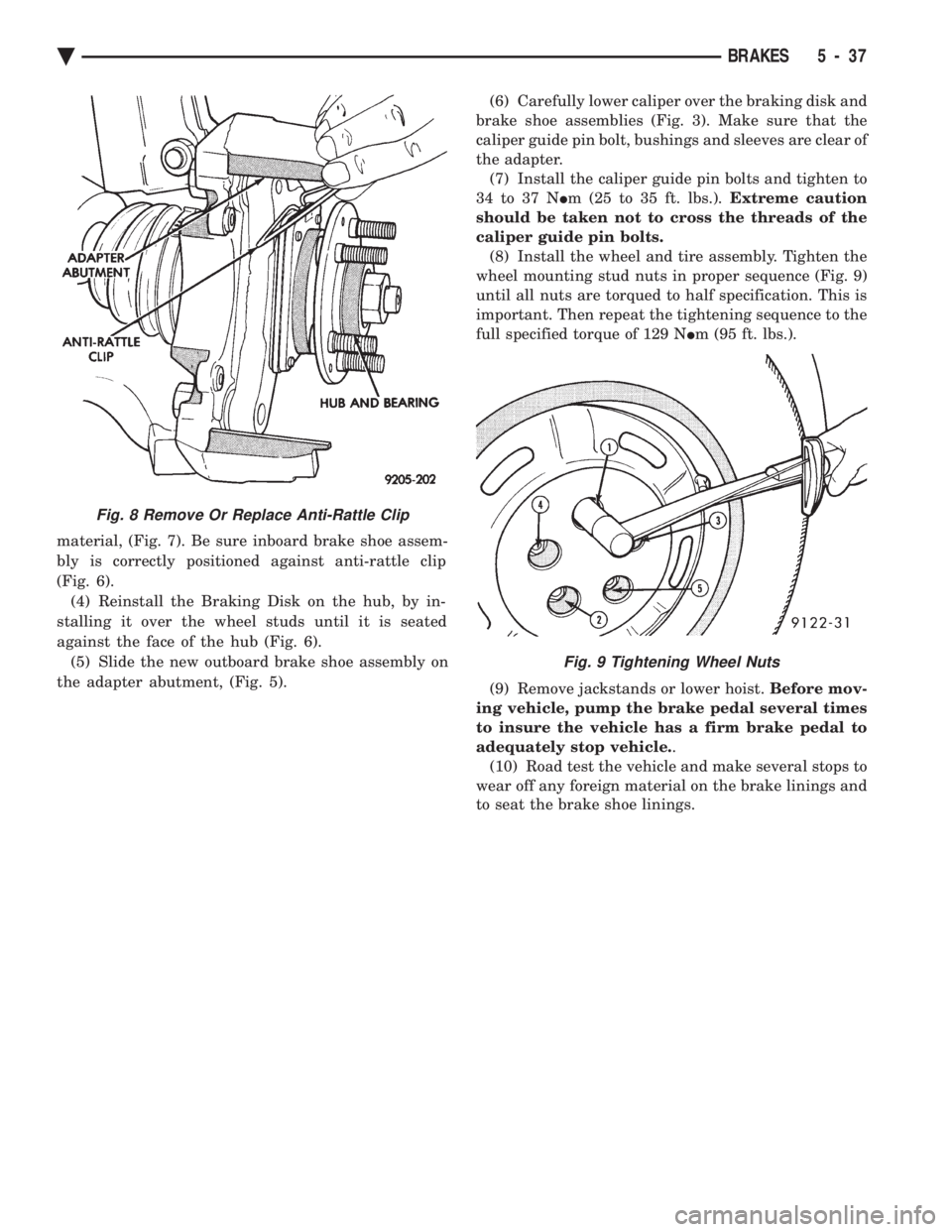

material, (Fig. 7). Be sure inboard brake shoe assem-

bly is correctly positioned against anti-rattle clip

(Fig. 6). (4) Reinstall the Braking Disk on the hub, by in-

stalling it over the wheel studs until it is seated

against the face of the hub (Fig. 6). (5) Slide the new outboard brake shoe assembly on

the adapter abutment, (Fig. 5). (6) Carefully lower caliper over the braking disk and

brake shoe assemblies (Fig. 3). Make sure that the

caliper guide pin bolt, bushings and sleeves are clear of

the adapter. (7) Install the caliper guide pin bolts and tighten to

34 to 37 N Im (25 to 35 ft. lbs.). Extreme caution

should be taken not to cross the threads of the

caliper guide pin bolts. (8) Install the wheel and tire assembly. Tighten the

wheel mounting stud nuts in proper sequence (Fig. 9)

until all nuts are torqued to half specification. This is

important. Then repeat the tightening sequence to the

full specified torque of 129 N Im (95 ft. lbs.).

(9) Remove jackstands or lower hoist. Before mov-

ing vehicle, pump the brake pedal several times

to insure the vehicle has a firm brake pedal to

adequately stop vehicle. .

(10) Road test the vehicle and make several stops to

wear off any foreign material on the brake linings and

to seat the brake shoe linings.

Fig. 8 Remove Or Replace Anti-Rattle Clip

Fig. 9 Tightening Wheel Nuts

Ä BRAKES 5 - 37

Page 188 of 2438

KELSEY HAYES DOUBLE PIN NON-FAMILY CALIPER INDEX

page page

Assembling Disc Brake Caliper .............. 42

Cleaning and Inspection of Brake Caliper ...... 41 Disc Brake Caliper Disassembly

............. 40

Service Procedures ....................... 38

SERVICE PROCEDURES

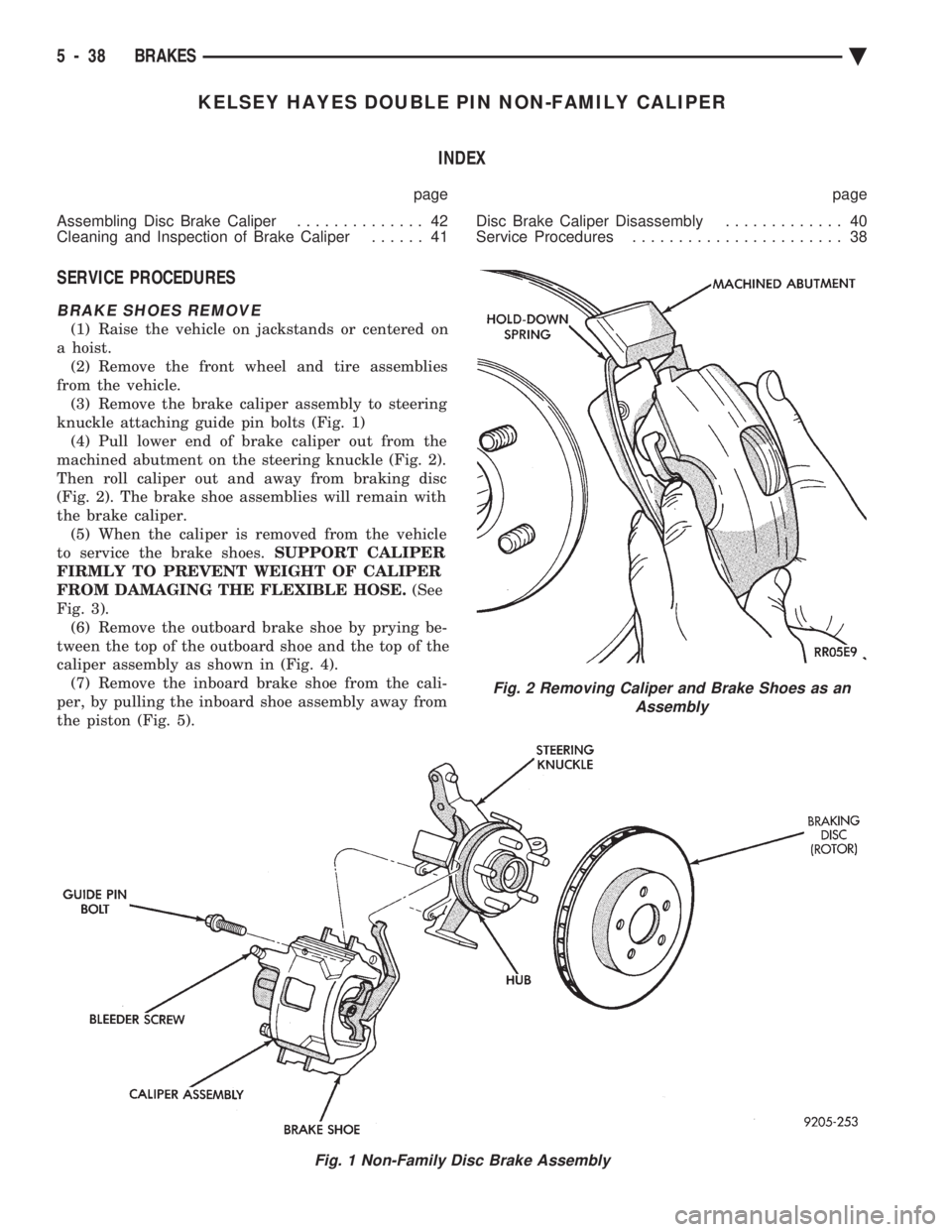

BRAKE SHOES REMOVE

(1) Raise the vehicle on jackstands or centered on

a hoist. (2) Remove the front wheel and tire assemblies

from the vehicle. (3) Remove the brake caliper assembly to steering

knuckle attaching guide pin bolts (Fig. 1) (4) Pull lower end of brake caliper out from the

machined abutment on the steering knuckle (Fig. 2).

Then roll caliper out and away from braking disc

(Fig. 2). The brake shoe assemblies will remain with

the brake caliper. (5) When the caliper is removed from the vehicle

to service the brake shoes. SUPPORT CALIPER

FIRMLY TO PREVENT WEIGHT OF CALIPER

FROM DAMAGING THE FLEXIBLE HOSE. (See

Fig. 3). (6) Remove the outboard brake shoe by prying be-

tween the top of the outboard shoe and the top of the

caliper assembly as shown in (Fig. 4). (7) Remove the inboard brake shoe from the cali-

per, by pulling the inboard shoe assembly away from

the piston (Fig. 5).

Fig. 1 Non-Family Disc Brake Assembly

Fig. 2 Removing Caliper and Brake Shoes as an Assembly

5 - 38 BRAKES Ä

Page 190 of 2438

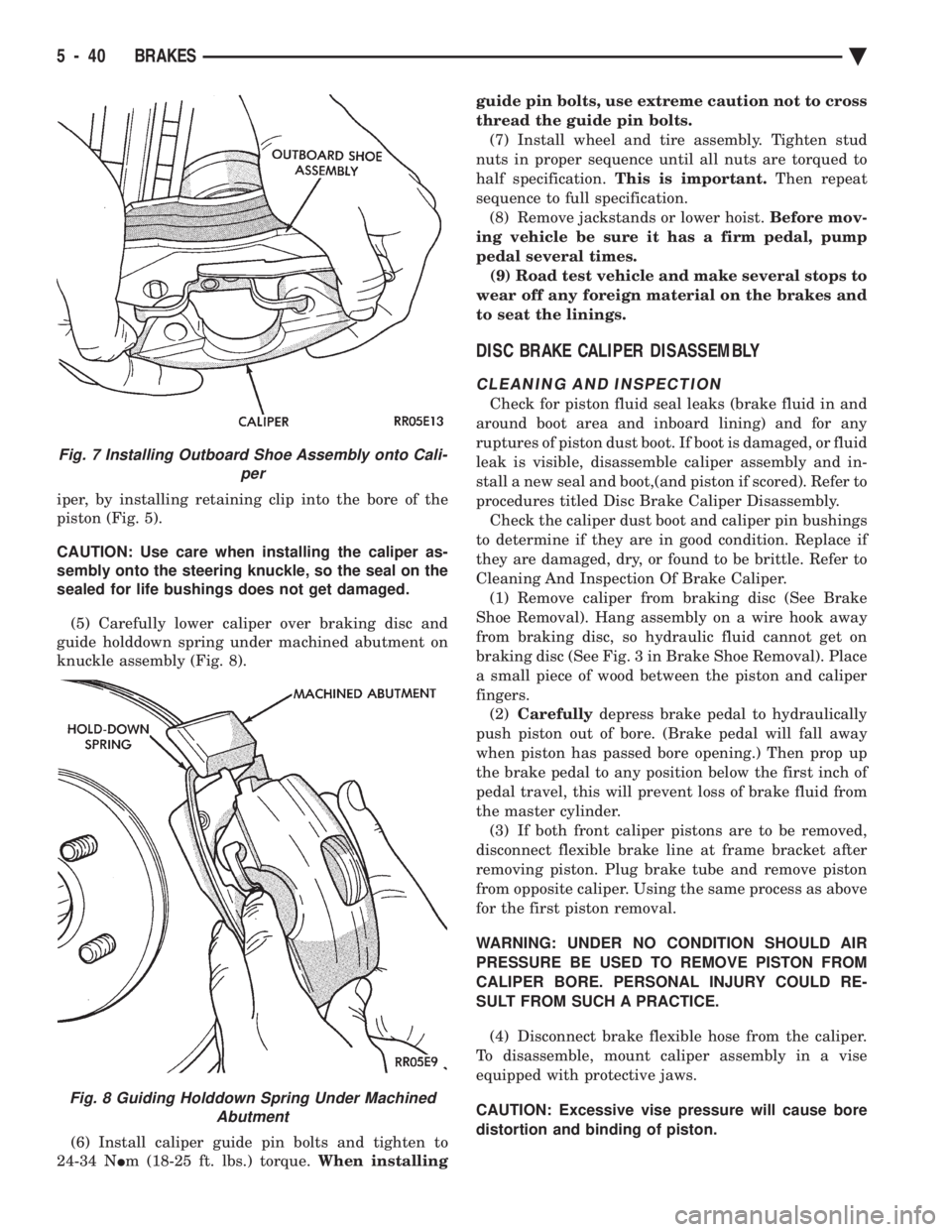

iper, by installing retaining clip into the bore of the

piston (Fig. 5).

CAUTION: Use care when installing the caliper as-

sembly onto the steering knuckle, so the seal on the

sealed for life bushings does not get damaged.

(5) Carefully lower caliper over braking disc and

guide holddown spring under machined abutment on

knuckle assembly (Fig. 8).

(6) Install caliper guide pin bolts and tighten to

24-34 N Im (18-25 ft. lbs.) torque. When installing guide pin bolts, use extreme caution not to cross

thread the guide pin bolts.

(7) Install wheel and tire assembly. Tighten stud

nuts in proper sequence until all nuts are torqued to

half specification. This is important. Then repeat

sequence to full specification. (8) Remove jackstands or lower hoist. Before mov-

ing vehicle be sure it has a firm pedal, pump

pedal several times. (9) Road test vehicle and make several stops to

wear off any foreign material on the brakes and

to seat the linings.

DISC BRAKE CALIPER DISASSEMBLY

CLEANING AND INSPECTION

Check for piston fluid seal leaks (brake fluid in and

around boot area and inboard lining) and for any

ruptures of piston dust boot. If boot is damaged, or fluid

leak is visible, disassemble caliper assembly and in-

stall a new seal and boot,(and piston if scored). Refer to

procedures titled Disc Brake Caliper Disassembly. Check the caliper dust boot and caliper pin bushings

to determine if they are in good condition. Replace if

they are damaged, dry, or found to be brittle. Refer to

Cleaning And Inspection Of Brake Caliper. (1) Remove caliper from braking disc (See Brake

Shoe Removal). Hang assembly on a wire hook away

from braking disc, so hydraulic fluid cannot get on

braking disc (See Fig. 3 in Brake Shoe Removal). Place

a small piece of wood between the piston and caliper

fingers. (2) Carefully depress brake pedal to hydraulically

push piston out of bore. (Brake pedal will fall away

when piston has passed bore opening.) Then prop up

the brake pedal to any position below the first inch of

pedal travel, this will prevent loss of brake fluid from

the master cylinder. (3) If both front caliper pistons are to be removed,

disconnect flexible brake line at frame bracket after

removing piston. Plug brake tube and remove piston

from opposite caliper. Using the same process as above

for the first piston removal.

WARNING: UNDER NO CONDITION SHOULD AIR

PRESSURE BE USED TO REMOVE PISTON FROM

CALIPER BORE. PERSONAL INJURY COULD RE-

SULT FROM SUCH A PRACTICE.

(4) Disconnect brake flexible hose from the caliper.

To disassemble, mount caliper assembly in a vise

equipped with protective jaws.

CAUTION: Excessive vise pressure will cause bore

distortion and binding of piston.

Fig. 7 Installing Outboard Shoe Assembly onto Cali- per

Fig. 8 Guiding Holddown Spring Under MachinedAbutment

5 - 40 BRAKES Ä

Page 195 of 2438

REAR DISC BRAKES INDEX

page page

Assembling Rear Disc Brake Caliper .......... 49

Brake Shoe Removal ..................... 46

Cleaning and Inspection ................... 49

Disassembling Rear Caliper Assembly ......... 48 General Information

....................... 45

Lining Wear ............................. 45

Service Precautions ....................... 46

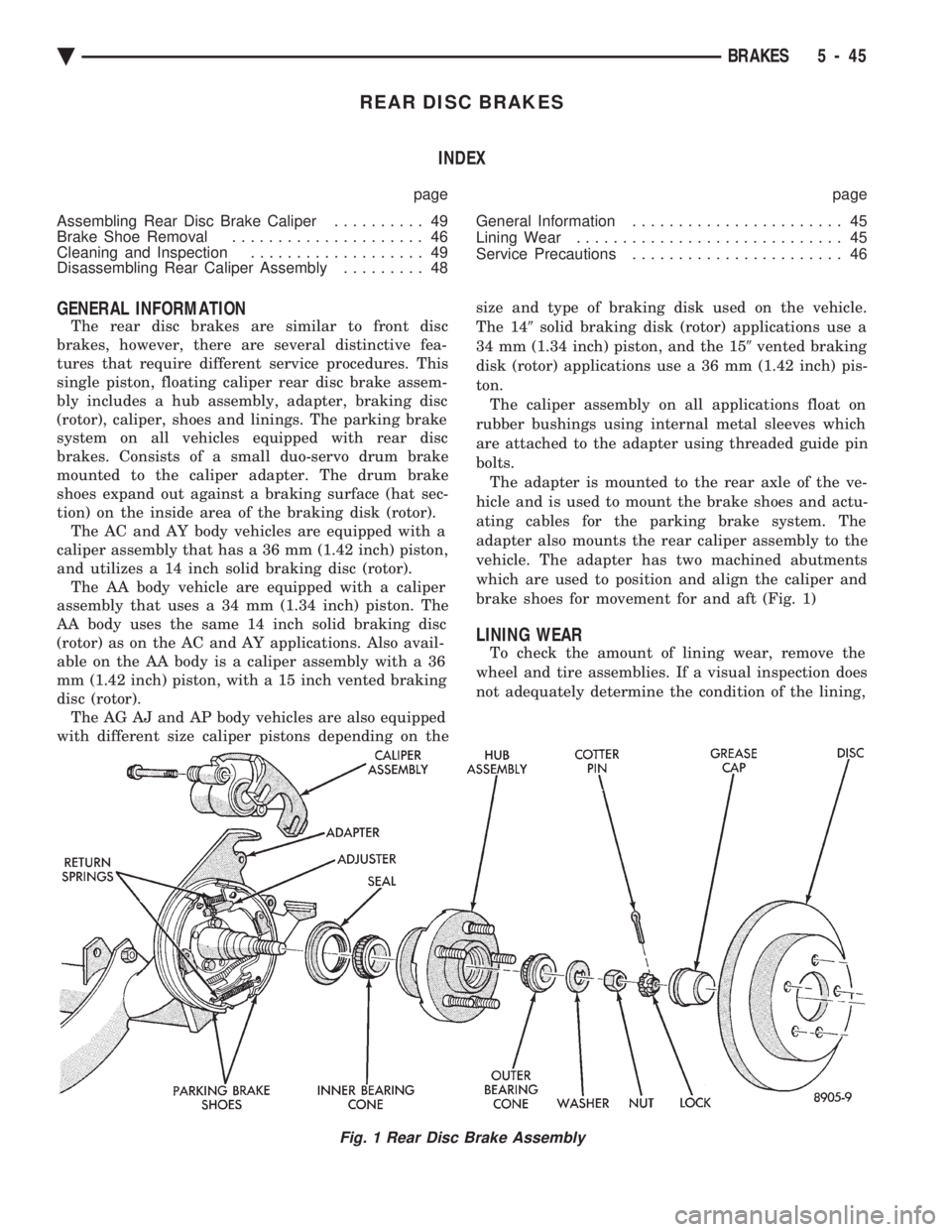

GENERAL INFORMATION

The rear disc brakes are similar to front disc

brakes, however, there are several distinctive fea-

tures that require different service procedures. This

single piston, floating caliper rear disc brake assem-

bly includes a hub assembly, adapter, braking disc

(rotor), caliper, shoes and linings. The parking brake

system on all vehicles equipped with rear disc

brakes. Consists of a small duo-servo drum brake

mounted to the caliper adapter. The drum brake

shoes expand out against a braking surface (hat sec-

tion) on the inside area of the braking disk (rotor). The AC and AY body vehicles are equipped with a

caliper assembly that has a 36 mm (1.42 inch) piston,

and utilizes a 14 inch solid braking disc (rotor). The AA body vehicle are equipped with a caliper

assembly that uses a 34 mm (1.34 inch) piston. The

AA body uses the same 14 inch solid braking disc

(rotor) as on the AC and AY applications. Also avail-

able on the AA body is a caliper assembly with a 36

mm (1.42 inch) piston, with a 15 inch vented braking

disc (rotor). The AG AJ and AP body vehicles are also equipped

with different size caliper pistons depending on the size and type of braking disk used on the vehicle.

The 14 9solid braking disk (rotor) applications use a

34 mm (1.34 inch) piston, and the 15 9vented braking

disk (rotor) applications use a 36 mm (1.42 inch) pis-

ton. The caliper assembly on all applications float on

rubber bushings using internal metal sleeves which

are attached to the adapter using threaded guide pin

bolts. The adapter is mounted to the rear axle of the ve-

hicle and is used to mount the brake shoes and actu-

ating cables for the parking brake system. The

adapter also mounts the rear caliper assembly to the

vehicle. The adapter has two machined abutments

which are used to position and align the caliper and

brake shoes for movement for and aft (Fig. 1)

LINING WEAR

To check the amount of lining wear, remove the

wheel and tire assemblies. If a visual inspection does

not adequately determine the condition of the lining,

Fig. 1 Rear Disc Brake Assembly

Ä BRAKES 5 - 45