wheel bolts CHEVROLET DYNASTY 1993 Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1937 of 2438

(18) Lower vehicle.

(19) Install the serpentine drive belt. Refer to (Fig.

10) for correct serpentine belt routing. See Cooling,

Group 7 for detailed installation procedure.

CAUTION: Do not use automatic transmission fluid

in power steering system. Only use Mopar T, Power

Steering Fluid, or equivalent.

(20) Fill power steering pump reservoir to correct

fluid level. (21) Connect the negative battery cable on the

negative battery post. (22) Start engine and turn steering wheel several

times from stop to stop to bleed air from fluid in sys-

tem. Stop engine, check fluid level, and inspect sys-

tem for leaks. See Checking Fluid Level.

TURBO III

REMOVE

(1) Disconnect the battery (-) negative cable from

the battery and isolate cable. (2) Raise vehicle See Hoisting, Group 0. Put oil

drain pan under vehicle to catch power steering

fluid. (3) Remove the right front underhood splash shield

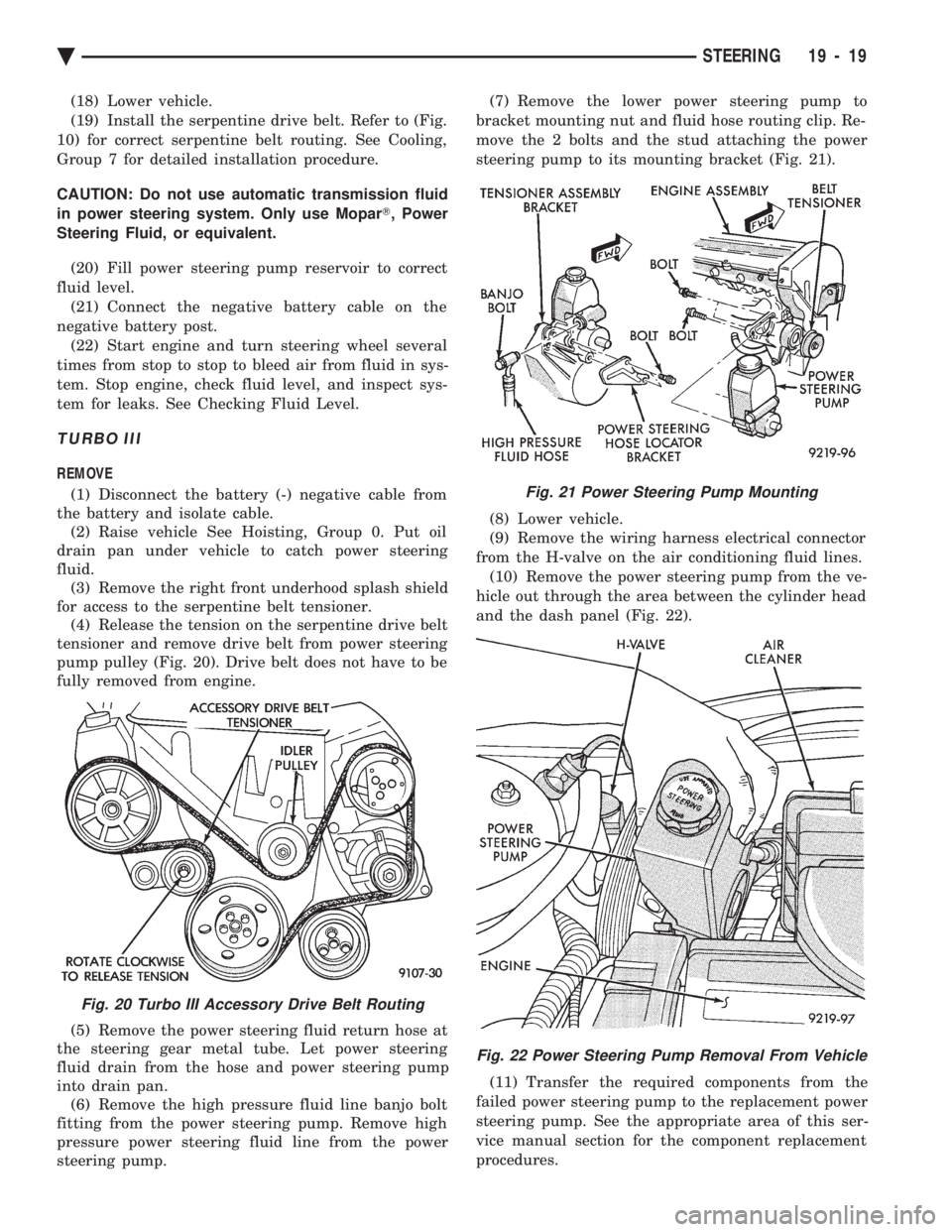

for access to the serpentine belt tensioner. (4) Release the tension on the serpentine drive belt

tensioner and remove drive belt from power steering

pump pulley (Fig. 20). Drive belt does not have to be

fully removed from engine.

(5) Remove the power steering fluid return hose at

the steering gear metal tube. Let power steering

fluid drain from the hose and power steering pump

into drain pan. (6) Remove the high pressure fluid line banjo bolt

fitting from the power steering pump. Remove high

pressure power steering fluid line from the power

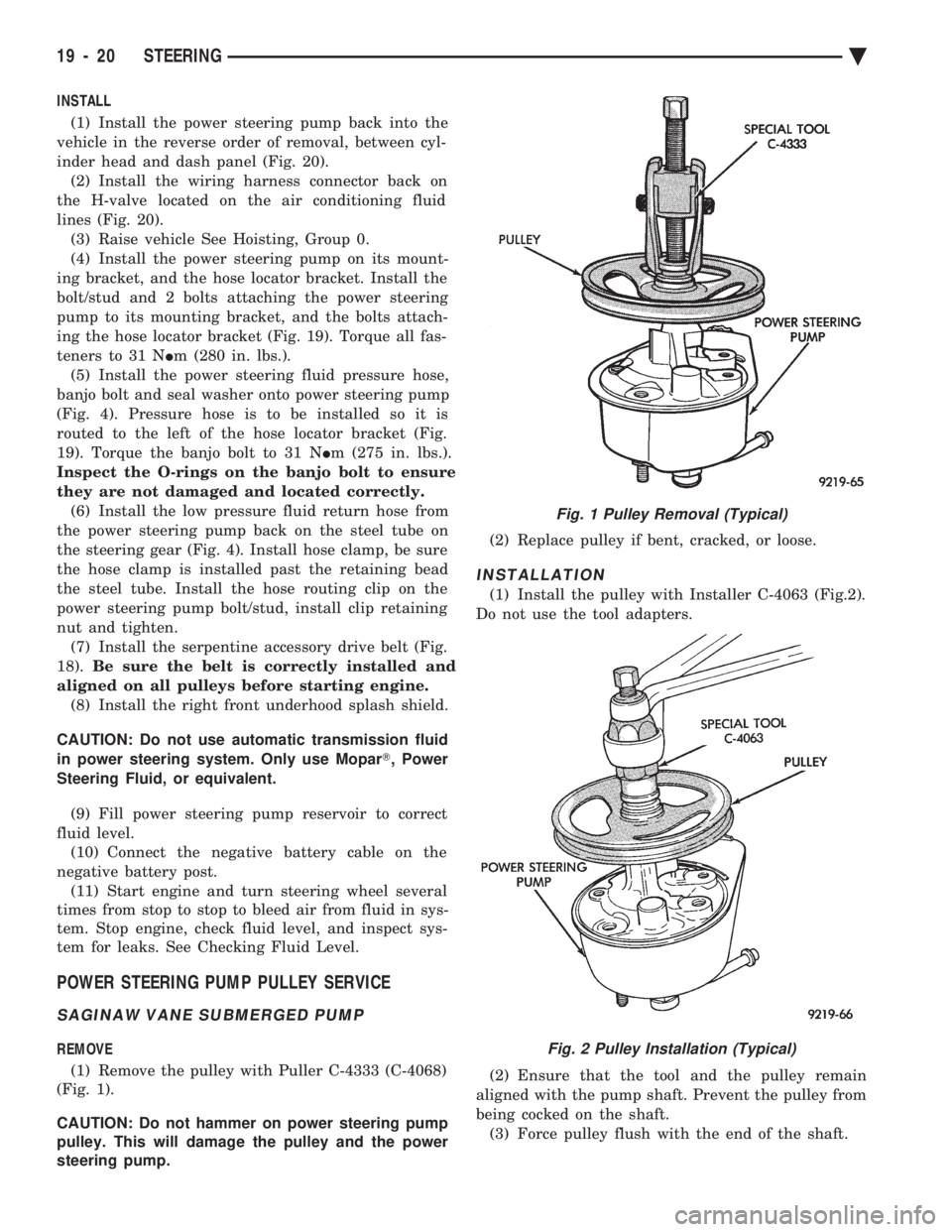

steering pump. (7) Remove the lower power steering pump to

bracket mounting nut and fluid hose routing clip. Re-

move the 2 bolts and the stud attaching the power

steering pump to its mounting bracket (Fig. 21).

(8) Lower vehicle.

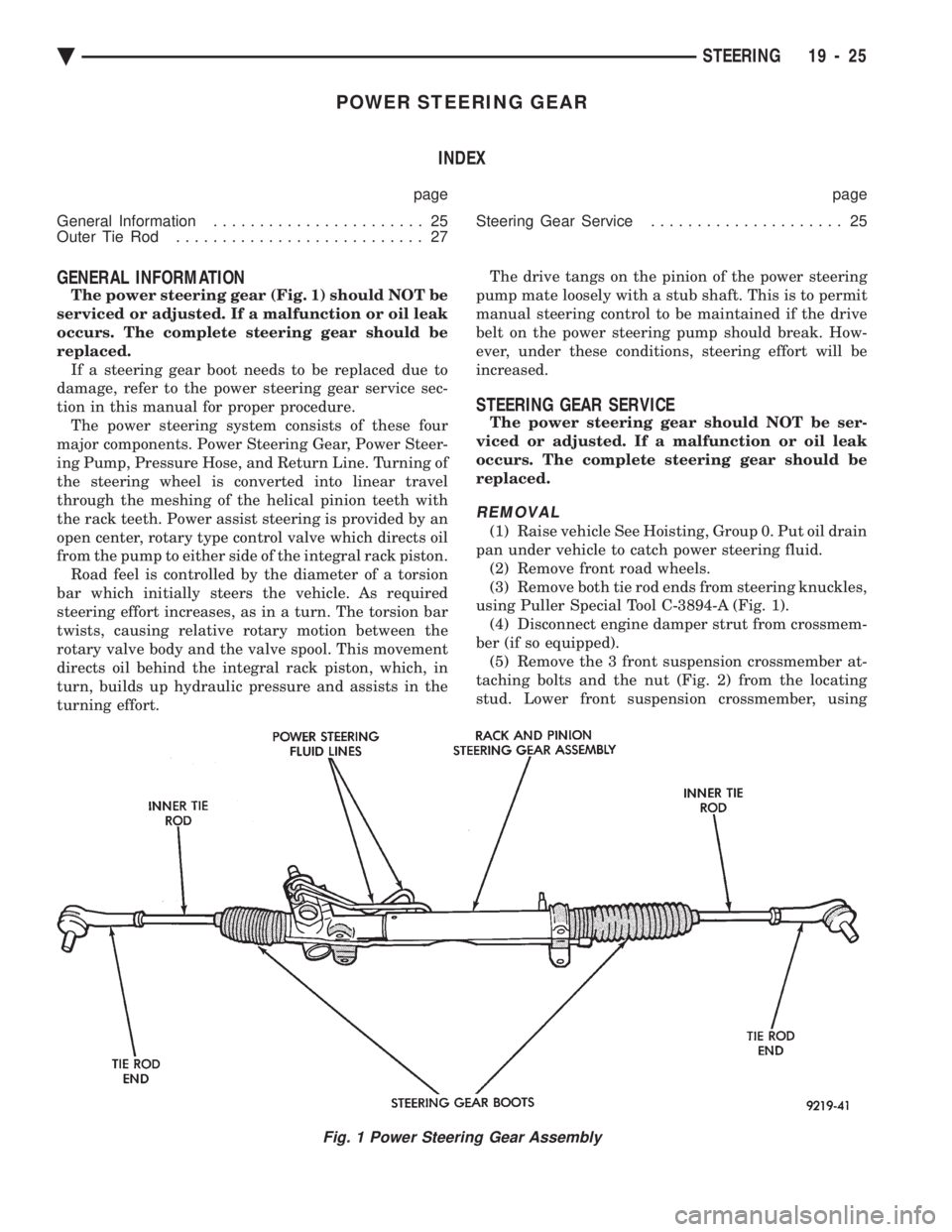

(9) Remove the wiring harness electrical connector

from the H-valve on the air conditioning fluid lines. (10) Remove the power steering pump from the ve-

hicle out through the area between the cylinder head

and the dash panel (Fig. 22).

(11) Transfer the required components from the

failed power steering pump to the replacement power

steering pump. See the appropriate area of this ser-

vice manual section for the component replacement

procedures.

Fig. 20 Turbo III Accessory Drive Belt Routing

Fig. 21 Power Steering Pump Mounting

Fig. 22 Power Steering Pump Removal From Vehicle

Ä STEERING 19 - 19

Page 1938 of 2438

INSTALL (1) Install the power steering pump back into the

vehicle in the reverse order of removal, between cyl-

inder head and dash panel (Fig. 20). (2) Install the wiring harness connector back on

the H-valve located on the air conditioning fluid

lines (Fig. 20). (3) Raise vehicle See Hoisting, Group 0.

(4) Install the power steering pump on its mount-

ing bracket, and the hose locator bracket. Install the

bolt/stud and 2 bolts attaching the power steering

pump to its mounting bracket, and the bolts attach-

ing the hose locator bracket (Fig. 19). Torque all fas-

teners to 31 N Im (280 in. lbs.).

(5) Install the power steering fluid pressure hose,

banjo bolt and seal washer onto power steering pump

(Fig. 4). Pressure hose is to be installed so it is

routed to the left of the hose locator bracket (Fig.

19). Torque the banjo bolt to 31 N Im (275 in. lbs.).

Inspect the O-rings on the banjo bolt to ensure

they are not damaged and located correctly. (6) Install the low pressure fluid return hose from

the power steering pump back on the steel tube on

the steering gear (Fig. 4). Install hose clamp, be sure

the hose clamp is installed past the retaining bead

the steel tube. Install the hose routing clip on the

power steering pump bolt/stud, install clip retaining

nut and tighten. (7) Install the serpentine accessory drive belt (Fig.

18). Be sure the belt is correctly installed and

aligned on all pulleys before starting engine. (8) Install the right front underhood splash shield.

CAUTION: Do not use automatic transmission fluid

in power steering system. Only use Mopar T, Power

Steering Fluid, or equivalent.

(9) Fill power steering pump reservoir to correct

fluid level. (10) Connect the negative battery cable on the

negative battery post. (11) Start engine and turn steering wheel several

times from stop to stop to bleed air from fluid in sys-

tem. Stop engine, check fluid level, and inspect sys-

tem for leaks. See Checking Fluid Level.

POWER STEERING PUMP PULLEY SERVICE

SAGINAW VANE SUBMERGED PUMP

REMOVE

(1) Remove the pulley with Puller C-4333 (C-4068)

(Fig. 1).

CAUTION: Do not hammer on power steering pump

pulley. This will damage the pulley and the power

steering pump. (2) Replace pulley if bent, cracked, or loose.

INSTALLATION

(1) Install the pulley with Installer C-4063 (Fig.2).

Do not use the tool adapters.

(2) Ensure that the tool and the pulley remain

aligned with the pump shaft. Prevent the pulley from

being cocked on the shaft. (3) Force pulley flush with the end of the shaft.

Fig. 1 Pulley Removal (Typical)

Fig. 2 Pulley Installation (Typical)

19 - 20 STEERING Ä

Page 1943 of 2438

POWER STEERING GEAR INDEX

page page

General Information ....................... 25

Outer Tie Rod ........................... 27 Steering Gear Service

..................... 25

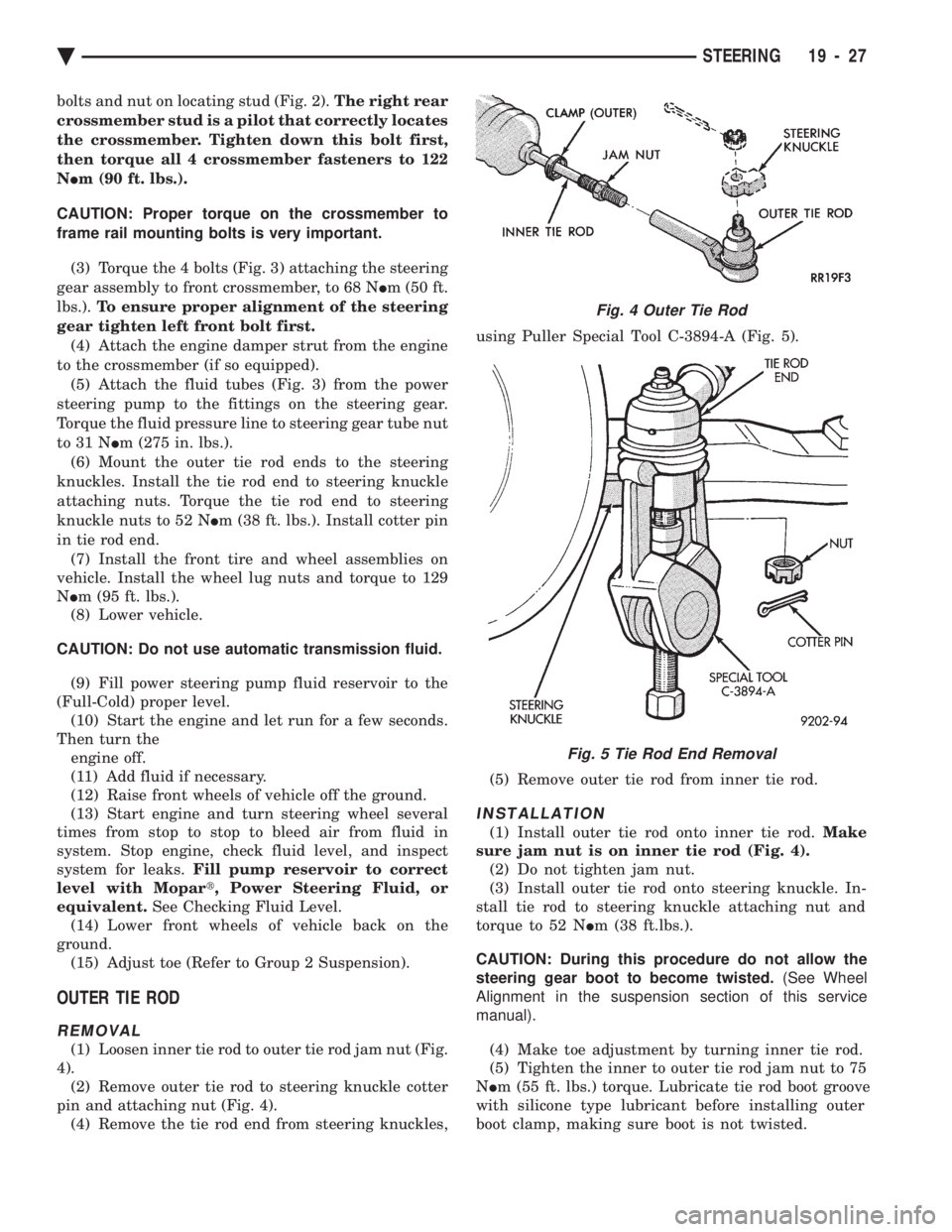

GENERAL INFORMATION

The power steering gear (Fig. 1) should NOT be

serviced or adjusted. If a malfunction or oil leak

occurs. The complete steering gear should be

replaced. If a steering gear boot needs to be replaced due to

damage, refer to the power steering gear service sec-

tion in this manual for proper procedure. The power steering system consists of these four

major components. Power Steering Gear, Power Steer-

ing Pump, Pressure Hose, and Return Line. Turning of

the steering wheel is converted into linear travel

through the meshing of the helical pinion teeth with

the rack teeth. Power assist steering is provided by an

open center, rotary type control valve which directs oil

from the pump to either side of the integral rack piston. Road feel is controlled by the diameter of a torsion

bar which initially steers the vehicle. As required

steering effort increases, as in a turn. The torsion bar

twists, causing relative rotary motion between the

rotary valve body and the valve spool. This movement

directs oil behind the integral rack piston, which, in

turn, builds up hydraulic pressure and assists in the

turning effort. The drive tangs on the pinion of the power steering

pump mate loosely with a stub shaft. This is to permit

manual steering control to be maintained if the drive

belt on the power steering pump should break. How-

ever, under these conditions, steering effort will be

increased.

STEERING GEAR SERVICE

The power steering gear should NOT be ser-

viced or adjusted. If a malfunction or oil leak

occurs. The complete steering gear should be

replaced.

REMOVAL

(1) Raise vehicle See Hoisting, Group 0. Put oil drain

pan under vehicle to catch power steering fluid. (2) Remove front road wheels.

(3) Remove both tie rod ends from steering knuckles,

using Puller Special Tool C-3894-A (Fig. 1). (4) Disconnect engine damper strut from crossmem-

ber (if so equipped). (5) Remove the 3 front suspension crossmember at-

taching bolts and the nut (Fig. 2) from the locating

stud. Lower front suspension crossmember, using

Fig. 1 Power Steering Gear Assembly

Ä STEERING 19 - 25

Page 1945 of 2438

bolts and nut on locating stud (Fig. 2). The right rear

crossmember stud is a pilot that correctly locates

the crossmember. Tighten down this bolt first,

then torque all 4 crossmember fasteners to 122

N Im (90 ft. lbs.).

CAUTION: Proper torque on the crossmember to

frame rail mounting bolts is very important.

(3) Torque the 4 bolts (Fig. 3) attaching the steering

gear assembly to front crossmember, to 68 N Im (50 ft.

lbs.). To ensure proper alignment of the steering

gear tighten left front bolt first. (4) Attach the engine damper strut from the engine

to the crossmember (if so equipped). (5) Attach the fluid tubes (Fig. 3) from the power

steering pump to the fittings on the steering gear.

Torque the fluid pressure line to steering gear tube nut

to 31 N Im (275 in. lbs.).

(6) Mount the outer tie rod ends to the steering

knuckles. Install the tie rod end to steering knuckle

attaching nuts. Torque the tie rod end to steering

knuckle nuts to 52 N Im (38 ft. lbs.). Install cotter pin

in tie rod end. (7) Install the front tire and wheel assemblies on

vehicle. Install the wheel lug nuts and torque to 129

N Im (95 ft. lbs.).

(8) Lower vehicle.

CAUTION: Do not use automatic transmission fluid. (9) Fill power steering pump fluid reservoir to the

(Full-Cold) proper level. (10) Start the engine and let run for a few seconds.

Then turn the engine off.

(11) Add fluid if necessary.

(12) Raise front wheels of vehicle off the ground.

(13) Start engine and turn steering wheel several

times from stop to stop to bleed air from fluid in

system. Stop engine, check fluid level, and inspect

system for leaks. Fill pump reservoir to correct

level with Mopar t, Power Steering Fluid, or

equivalent. See Checking Fluid Level.

(14) Lower front wheels of vehicle back on the

ground. (15) Adjust toe (Refer to Group 2 Suspension).

OUTER TIE ROD

REMOVAL

(1) Loosen inner tie rod to outer tie rod jam nut (Fig.

4). (2) Remove outer tie rod to steering knuckle cotter

pin and attaching nut (Fig. 4). (4) Remove the tie rod end from steering knuckles, using Puller Special Tool C-3894-A (Fig. 5).

(5) Remove outer tie rod from inner tie rod.

INSTALLATION

(1) Install outer tie rod onto inner tie rod. Make

sure jam nut is on inner tie rod (Fig. 4). (2) Do not tighten jam nut.

(3) Install outer tie rod onto steering knuckle. In-

stall tie rod to steering knuckle attaching nut and

torque to 52 N Im (38 ft.lbs.).

CAUTION: During this procedure do not allow the

steering gear boot to become twisted. (See Wheel

Alignment in the suspension section of this service

manual).

(4) Make toe adjustment by turning inner tie rod.

(5) Tighten the inner to outer tie rod jam nut to 75

N Im (55 ft. lbs.) torque. Lubricate tie rod boot groove

with silicone type lubricant before installing outer

boot clamp, making sure boot is not twisted.

Fig. 4 Outer Tie Rod

Fig. 5 Tie Rod End Removal

Ä STEERING 19 - 27

Page 1964 of 2438

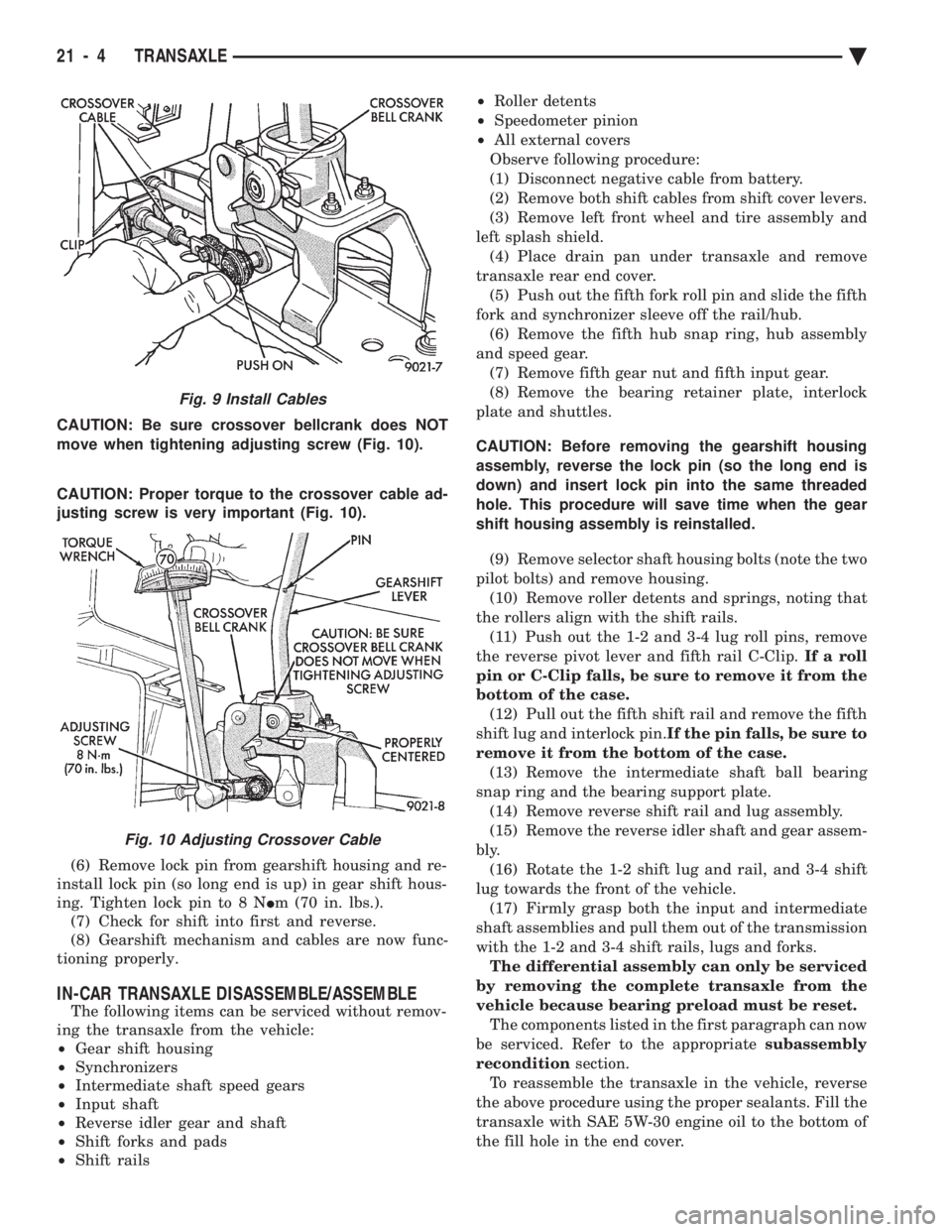

CAUTION: Be sure crossover bellcrank does NOT

move when tightening adjusting screw (Fig. 10).

CAUTION: Proper torque to the crossover cable ad-

justing screw is very important (Fig. 10).

(6) Remove lock pin from gearshift housing and re-

install lock pin (so long end is up) in gear shift hous-

ing. Tighten lock pin to 8 N Im (70 in. lbs.).

(7) Check for shift into first and reverse.

(8) Gearshift mechanism and cables are now func-

tioning properly.

IN-CAR TRANSAXLE DISASSEMBLE/ASSEMBLE

The following items can be serviced without remov-

ing the transaxle from the vehicle:

² Gear shift housing

² Synchronizers

² Intermediate shaft speed gears

² Input shaft

² Reverse idler gear and shaft

² Shift forks and pads

² Shift rails ²

Roller detents

² Speedometer pinion

² All external covers

Observe following procedure:

(1) Disconnect negative cable from battery.

(2) Remove both shift cables from shift cover levers.

(3) Remove left front wheel and tire assembly and

left splash shield. (4) Place drain pan under transaxle and remove

transaxle rear end cover. (5) Push out the fifth fork roll pin and slide the fifth

fork and synchronizer sleeve off the rail/hub. (6) Remove the fifth hub snap ring, hub assembly

and speed gear. (7) Remove fifth gear nut and fifth input gear.

(8) Remove the bearing retainer plate, interlock

plate and shuttles.

CAUTION: Before removing the gearshift housing

assembly, reverse the lock pin (so the long end is

down) and insert lock pin into the same threaded

hole. This procedure will save time when the gear

shift housing assembly is reinstalled. (9) Remove selector shaft housing bolts (note the two

pilot bolts) and remove housing. (10) Remove roller detents and springs, noting that

the rollers align with the shift rails. (11) Push out the 1-2 and 3-4 lug roll pins, remove

the reverse pivot lever and fifth rail C-Clip. If a roll

pin or C-Clip falls, be sure to remove it from the

bottom of the case. (12) Pull out the fifth shift rail and remove the fifth

shift lug and interlock pin. If the pin falls, be sure to

remove it from the bottom of the case. (13) Remove the intermediate shaft ball bearing

snap ring and the bearing support plate. (14) Remove reverse shift rail and lug assembly.

(15) Remove the reverse idler shaft and gear assem-

bly. (16) Rotate the 1-2 shift lug and rail, and 3-4 shift

lug towards the front of the vehicle. (17) Firmly grasp both the input and intermediate

shaft assemblies and pull them out of the transmission

with the 1-2 and 3-4 shift rails, lugs and forks. The differential assembly can only be serviced

by removing the complete transaxle from the

vehicle because bearing preload must be reset. The components listed in the first paragraph can now

be serviced. Refer to the appropriate subassembly

recondition section.

To reassemble the transaxle in the vehicle, reverse

the above procedure using the proper sealants. Fill the

transaxle with SAE 5W-30 engine oil to the bottom of

the fill hole in the end cover.

Fig. 9 Install Cables

Fig. 10 Adjusting Crossover Cable

21 - 4 TRANSAXLE Ä

Page 1965 of 2438

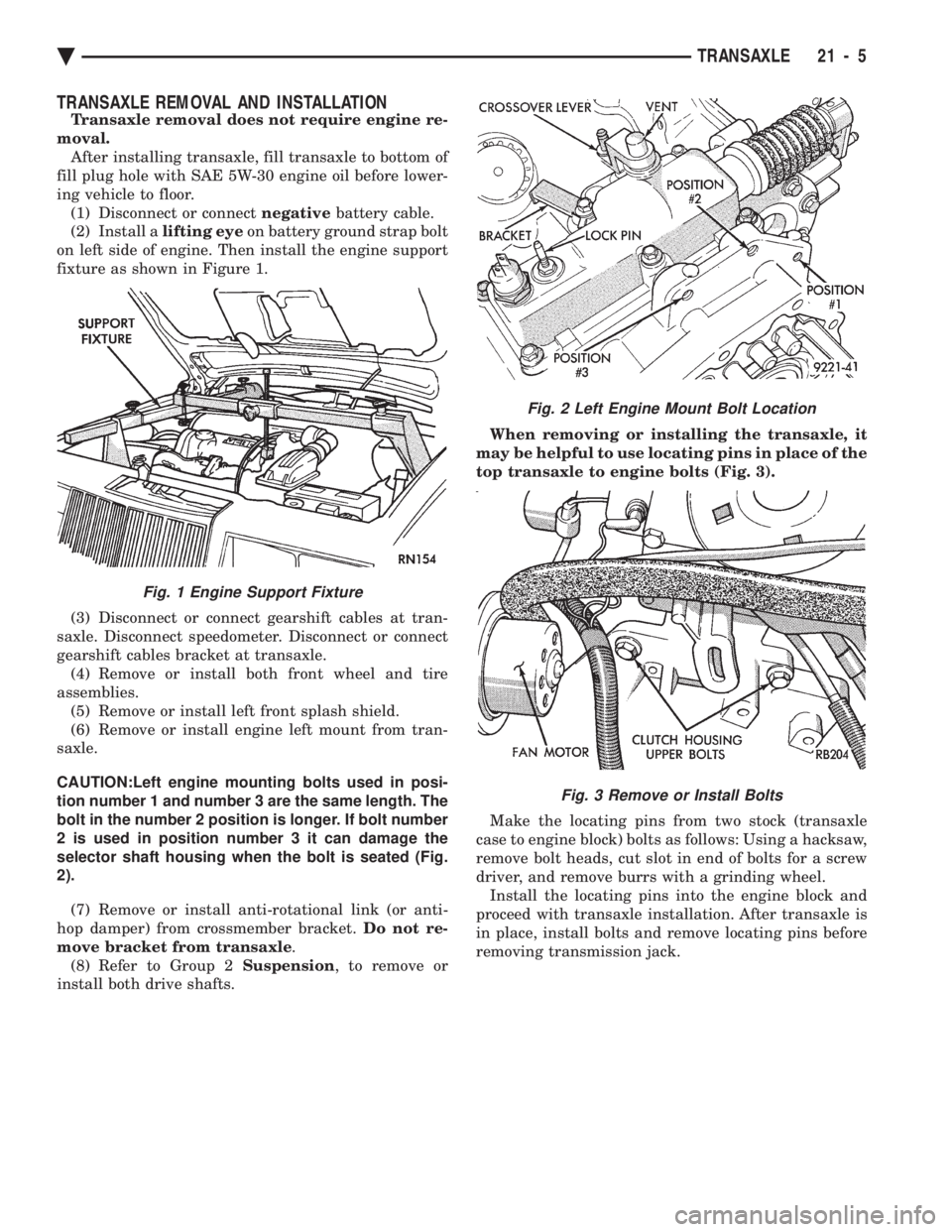

TRANSAXLE REMOVAL AND INSTALLATION

Transaxle removal does not require engine re-

moval. After installing transaxle, fill transaxle to bottom of

fill plug hole with SAE 5W-30 engine oil before lower-

ing vehicle to floor. (1) Disconnect or connect negativebattery cable.

(2) Install a lifting eyeon battery ground strap bolt

on left side of engine. Then install the engine support

fixture as shown in Figure 1.

(3) Disconnect or connect gearshift cables at tran-

saxle. Disconnect speedometer. Disconnect or connect

gearshift cables bracket at transaxle. (4) Remove or install both front wheel and tire

assemblies. (5) Remove or install left front splash shield.

(6) Remove or install engine left mount from tran-

saxle.

CAUTION:Left engine mounting bolts used in posi-

tion number 1 and number 3 are the same length. The

bolt in the number 2 position is longer. If bolt number

2 is used in position number 3 it can damage the

selector shaft housing when the bolt is seated (Fig.

2).

(7) Remove or install anti-rotational link (or anti-

hop damper) from crossmember bracket. Do not re-

move bracket from transaxle .

(8) Refer to Group 2 Suspension, to remove or

install both drive shafts. When removing or installing the transaxle, it

may be helpful to use locating pins in place of the

top transaxle to engine bolts (Fig. 3).

Make the locating pins from two stock (transaxle

case to engine block) bolts as follows: Using a hacksaw,

remove bolt heads, cut slot in end of bolts for a screw

driver, and remove burrs with a grinding wheel. Install the locating pins into the engine block and

proceed with transaxle installation. After transaxle is

in place, install bolts and remove locating pins before

removing transmission jack.

Fig. 1 Engine Support Fixture

Fig. 2 Left Engine Mount Bolt Location

Fig. 3 Remove or Install Bolts

Ä TRANSAXLE 21 - 5

Page 2009 of 2438

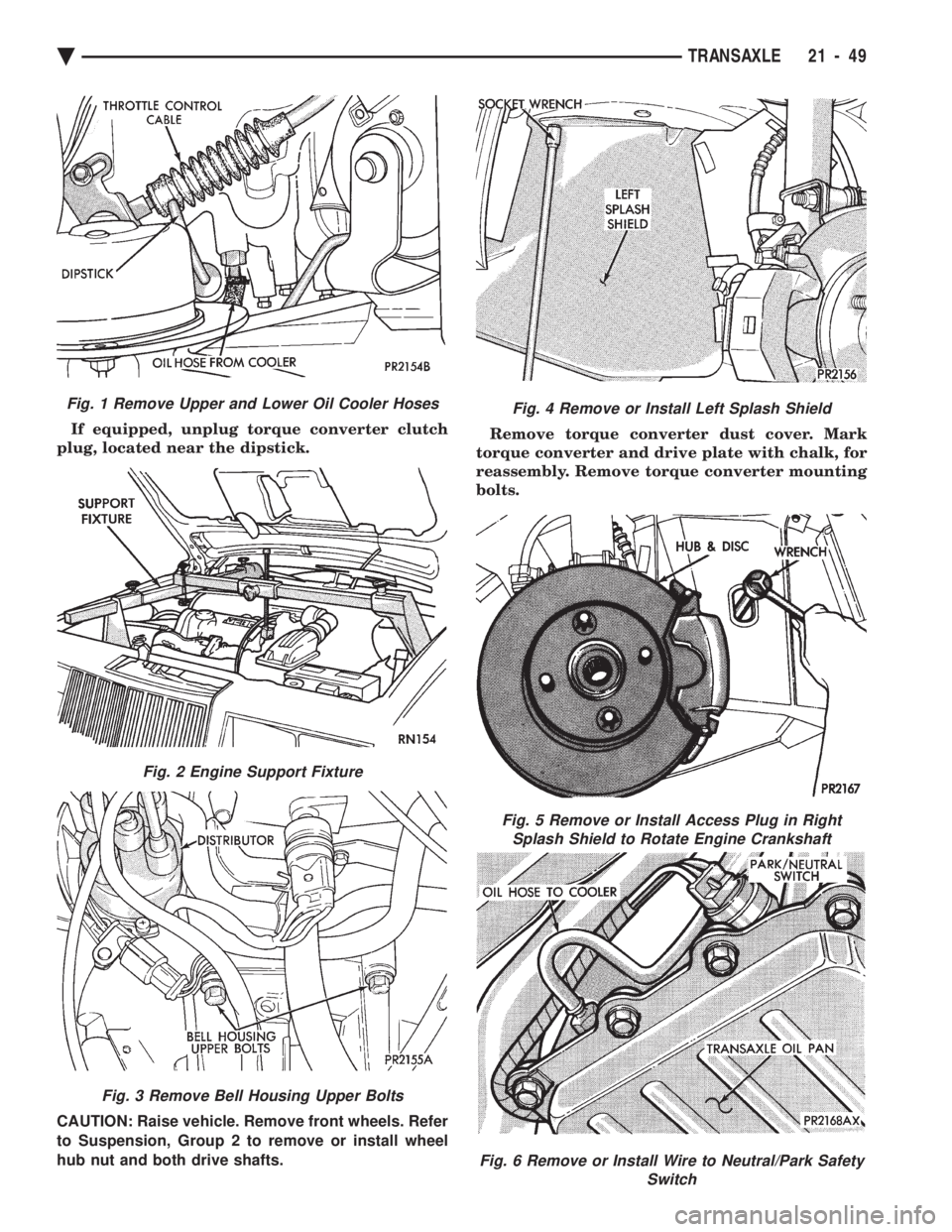

If equipped, unplug torque converter clutch

plug, located near the dipstick.

CAUTION: Raise vehicle. Remove front wheels. Refer

to Suspension, Group 2 to remove or install wheel

hub nut and both drive shafts. Remove torque converter dust cover. Mark

torque converter and drive plate with chalk, for

reassembly. Remove torque converter mounting

bolts.

Fig. 1 Remove Upper and Lower Oil Cooler Hoses

Fig. 2 Engine Support Fixture

Fig. 3 Remove Bell Housing Upper Bolts

Fig. 4 Remove or Install Left Splash Shield

Fig. 5 Remove or Install Access Plug in Right Splash Shield to Rotate Engine Crankshaft

Fig. 6 Remove or Install Wire to Neutral/Park Safety Switch

Ä TRANSAXLE 21 - 49

Page 2059 of 2438

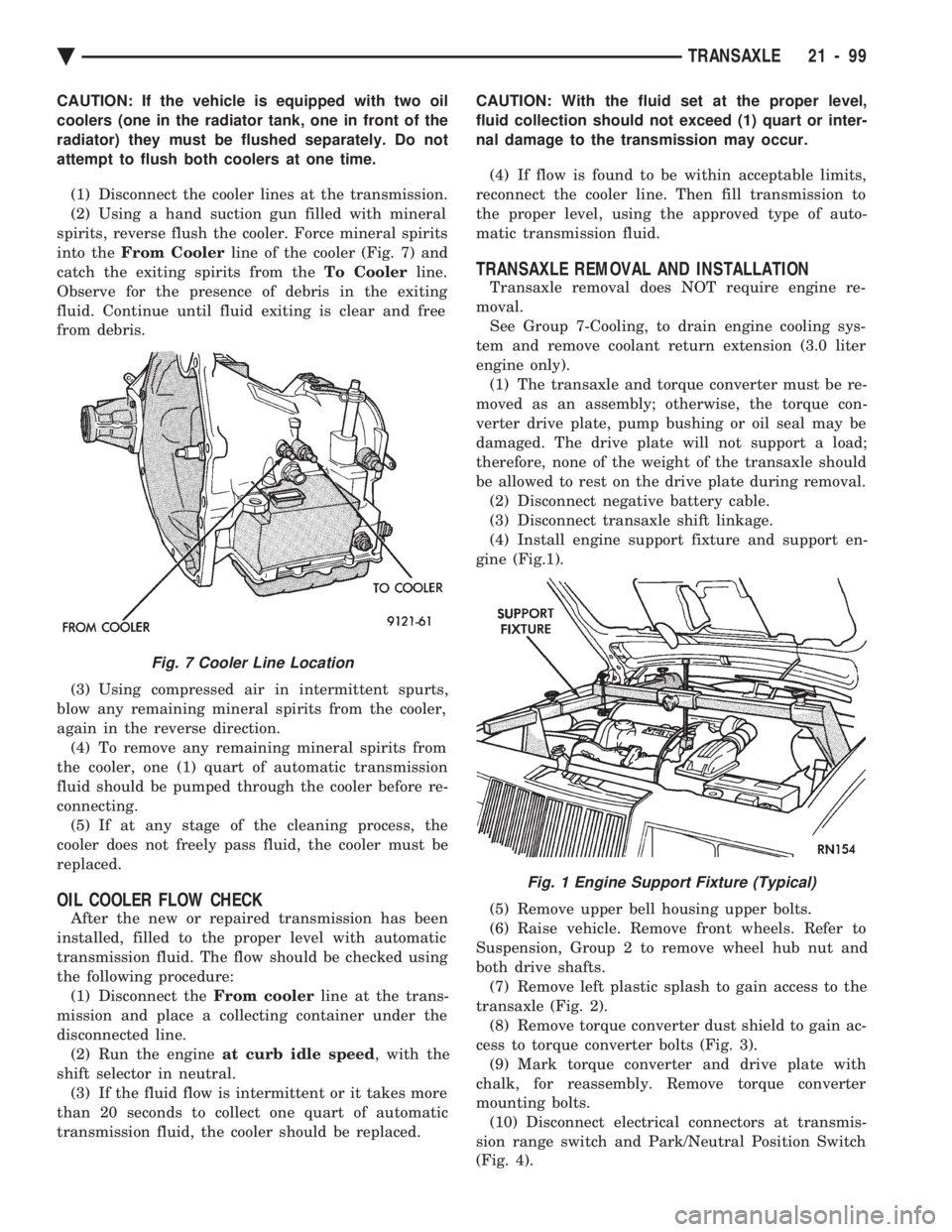

CAUTION: If the vehicle is equipped with two oil

coolers (one in the radiator tank, one in front of the

radiator) they must be flushed separately. Do not

attempt to flush both coolers at one time. (1) Disconnect the cooler lines at the transmission.

(2) Using a hand suction gun filled with mineral

spirits, reverse flush the cooler. Force mineral spirits

into the From Cooler line of the cooler (Fig. 7) and

catch the exiting spirits from the To Coolerline.

Observe for the presence of debris in the exiting

fluid. Continue until fluid exiting is clear and free

from debris.

(3) Using compressed air in intermittent spurts,

blow any remaining mineral spirits from the cooler,

again in the reverse direction. (4) To remove any remaining mineral spirits from

the cooler, one (1) quart of automatic transmission

fluid should be pumped through the cooler before re-

connecting. (5) If at any stage of the cleaning process, the

cooler does not freely pass fluid, the cooler must be

replaced.

OIL COOLER FLOW CHECK

After the new or repaired transmission has been

installed, filled to the proper level with automatic

transmission fluid. The flow should be checked using

the following procedure: (1) Disconnect the From coolerline at the trans-

mission and place a collecting container under the

disconnected line. (2) Run the engine at curb idle speed , with the

shift selector in neutral. (3) If the fluid flow is intermittent or it takes more

than 20 seconds to collect one quart of automatic

transmission fluid, the cooler should be replaced. CAUTION: With the fluid set at the proper level,

fluid collection should not exceed (1) quart or inter-

nal damage to the transmission may occur.

(4) If flow is found to be within acceptable limits,

reconnect the cooler line. Then fill transmission to

the proper level, using the approved type of auto-

matic transmission fluid.

TRANSAXLE REMOVAL AND INSTALLATION

Transaxle removal does NOT require engine re-

moval. See Group 7-Cooling, to drain engine cooling sys-

tem and remove coolant return extension (3.0 liter

engine only). (1) The transaxle and torque converter must be re-

moved as an assembly; otherwise, the torque con-

verter drive plate, pump bushing or oil seal may be

damaged. The drive plate will not support a load;

therefore, none of the weight of the transaxle should

be allowed to rest on the drive plate during removal. (2) Disconnect negative battery cable.

(3) Disconnect transaxle shift linkage.

(4) Install engine support fixture and support en-

gine (Fig.1).

(5) Remove upper bell housing upper bolts.

(6) Raise vehicle. Remove front wheels. Refer to

Suspension, Group 2 to remove wheel hub nut and

both drive shafts. (7) Remove left plastic splash to gain access to the

transaxle (Fig. 2). (8) Remove torque converter dust shield to gain ac-

cess to torque converter bolts (Fig. 3). (9) Mark torque converter and drive plate with

chalk, for reassembly. Remove torque converter

mounting bolts. (10) Disconnect electrical connectors at transmis-

sion range switch and Park/Neutral Position Switch

(Fig. 4).

Fig. 7 Cooler Line Location

Fig. 1 Engine Support Fixture (Typical)

Ä TRANSAXLE 21 - 99

Page 2169 of 2438

(2) Remove push-in fasteners holding hood latch

cover to radiator closure panel and separate cover

from vehicle. (3) Disconnect hood release cable casing and cable

end from hood latch assembly. Refer to Hood Latch

Removal procedure in this section. (4) Remove hood latch release cable handle attach-

ing bolts from under left lower edge of instrument

panel. (5) Disengage release cable rubber grommet from

engine compartment dash panel behind instrument

panel. (6) Rout cable assembly through engine compart-

ment around battery, under fender lip, under relay

bank, and under wiring harnesses, toward dash

panel. Push cable through access hole in dash panel

under the brake master cylinder, into passenger com-

partment.

HOOD LATCH RELEASE CABLE INSTALLATION

Reverse the preceding operation.

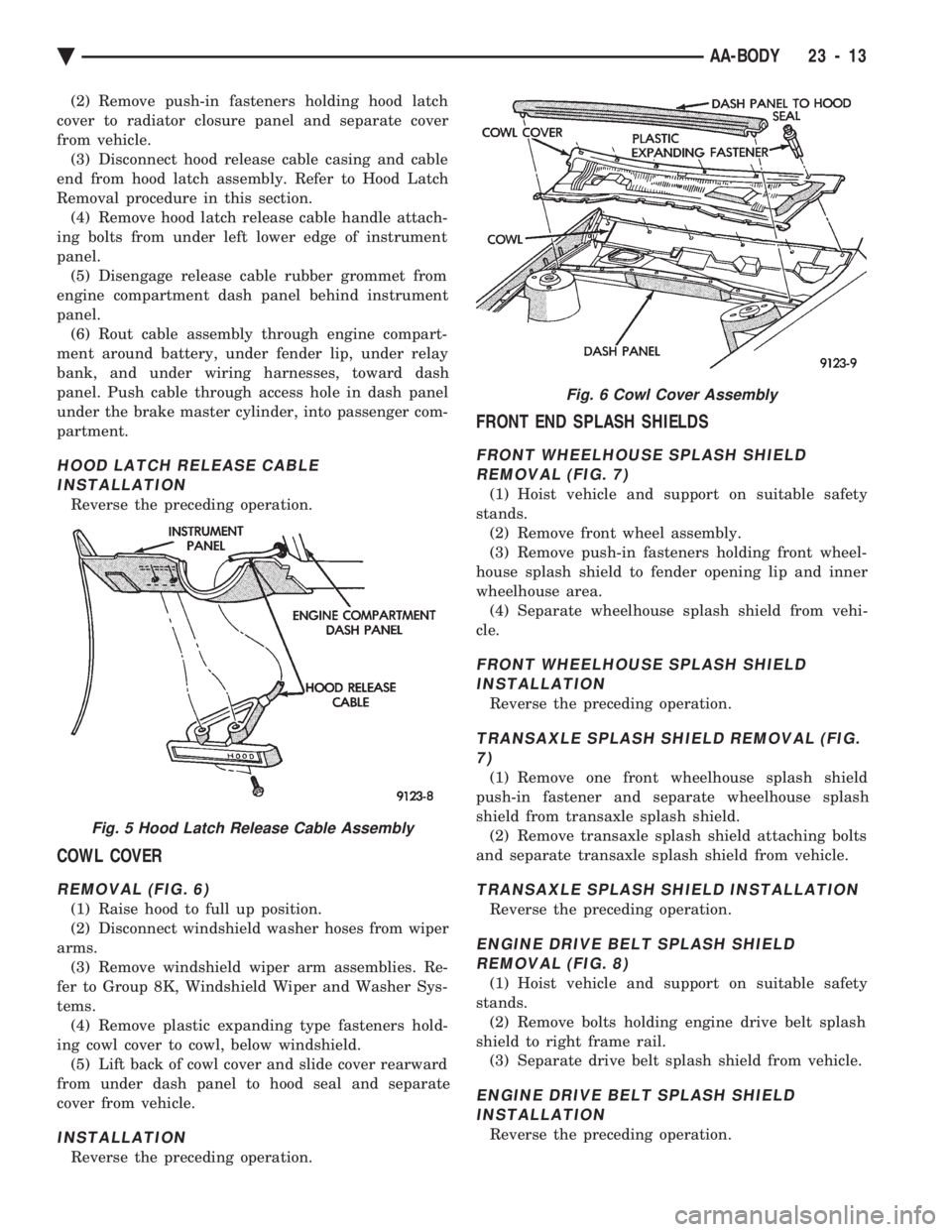

COWL COVER

REMOVAL (FIG. 6)

(1) Raise hood to full up position.

(2) Disconnect windshield washer hoses from wiper

arms. (3) Remove windshield wiper arm assemblies. Re-

fer to Group 8K, Windshield Wiper and Washer Sys-

tems. (4) Remove plastic expanding type fasteners hold-

ing cowl cover to cowl, below windshield. (5) Lift back of cowl cover and slide cover rearward

from under dash panel to hood seal and separate

cover from vehicle.

INSTALLATION

Reverse the preceding operation.

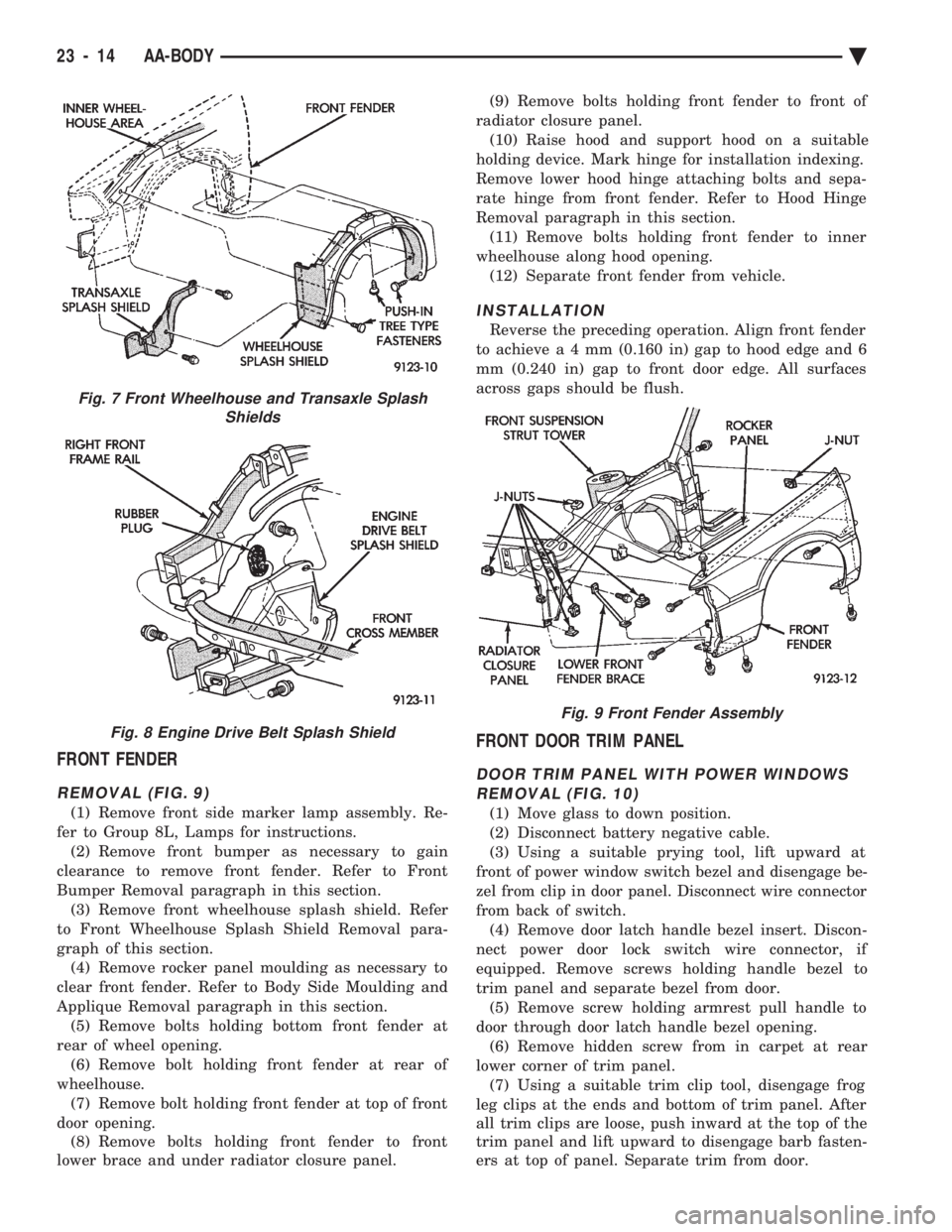

FRONT END SPLASH SHIELDS

FRONT WHEELHOUSE SPLASH SHIELD REMOVAL (FIG. 7)

(1) Hoist vehicle and support on suitable safety

stands. (2) Remove front wheel assembly.

(3) Remove push-in fasteners holding front wheel-

house splash shield to fender opening lip and inner

wheelhouse area. (4) Separate wheelhouse splash shield from vehi-

cle.

FRONT WHEELHOUSE SPLASH SHIELD INSTALLATION

Reverse the preceding operation.

TRANSAXLE SPLASH SHIELD REMOVAL (FIG.7)

(1) Remove one front wheelhouse splash shield

push-in fastener and separate wheelhouse splash

shield from transaxle splash shield. (2) Remove transaxle splash shield attaching bolts

and separate transaxle splash shield from vehicle.

TRANSAXLE SPLASH SHIELD INSTALLATION

Reverse the preceding operation.

ENGINE DRIVE BELT SPLASH SHIELD REMOVAL (FIG. 8)

(1) Hoist vehicle and support on suitable safety

stands. (2) Remove bolts holding engine drive belt splash

shield to right frame rail. (3) Separate drive belt splash shield from vehicle.

ENGINE DRIVE BELT SPLASH SHIELDINSTALLATION

Reverse the preceding operation.

Fig. 5 Hood Latch Release Cable Assembly

Fig. 6 Cowl Cover Assembly

Ä AA-BODY 23 - 13

Page 2170 of 2438

FRONT FENDER

REMOVAL (FIG. 9)

(1) Remove front side marker lamp assembly. Re-

fer to Group 8L, Lamps for instructions. (2) Remove front bumper as necessary to gain

clearance to remove front fender. Refer to Front

Bumper Removal paragraph in this section. (3) Remove front wheelhouse splash shield. Refer

to Front Wheelhouse Splash Shield Removal para-

graph of this section. (4) Remove rocker panel moulding as necessary to

clear front fender. Refer to Body Side Moulding and

Applique Removal paragraph in this section. (5) Remove bolts holding bottom front fender at

rear of wheel opening. (6) Remove bolt holding front fender at rear of

wheelhouse. (7) Remove bolt holding front fender at top of front

door opening. (8) Remove bolts holding front fender to front

lower brace and under radiator closure panel. (9) Remove bolts holding front fender to front of

radiator closure panel. (10) Raise hood and support hood on a suitable

holding device. Mark hinge for installation indexing.

Remove lower hood hinge attaching bolts and sepa-

rate hinge from front fender. Refer to Hood Hinge

Removal paragraph in this section. (11) Remove bolts holding front fender to inner

wheelhouse along hood opening. (12) Separate front fender from vehicle.

INSTALLATION

Reverse the preceding operation. Align front fender

to achiev ea4mm (0.160 in) gap to hood edge and 6

mm (0.240 in) gap to front door edge. All surfaces

across gaps should be flush.

FRONT DOOR TRIM PANEL

DOOR TRIM PANEL WITH POWER WINDOWS REMOVAL (FIG. 10)

(1) Move glass to down position.

(2) Disconnect battery negative cable.

(3) Using a suitable prying tool, lift upward at

front of power window switch bezel and disengage be-

zel from clip in door panel. Disconnect wire connector

from back of switch. (4) Remove door latch handle bezel insert. Discon-

nect power door lock switch wire connector, if

equipped. Remove screws holding handle bezel to

trim panel and separate bezel from door. (5) Remove screw holding armrest pull handle to

door through door latch handle bezel opening. (6) Remove hidden screw from in carpet at rear

lower corner of trim panel. (7) Using a suitable trim clip tool, disengage frog

leg clips at the ends and bottom of trim panel. After

all trim clips are loose, push inward at the top of the

trim panel and lift upward to disengage barb fasten-

ers at top of panel. Separate trim from door.

Fig. 7 Front Wheelhouse and Transaxle Splash Shields

Fig. 8 Engine Drive Belt Splash Shield

Fig. 9 Front Fender Assembly

23 - 14 AA-BODY Ä