light CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1647 of 2438

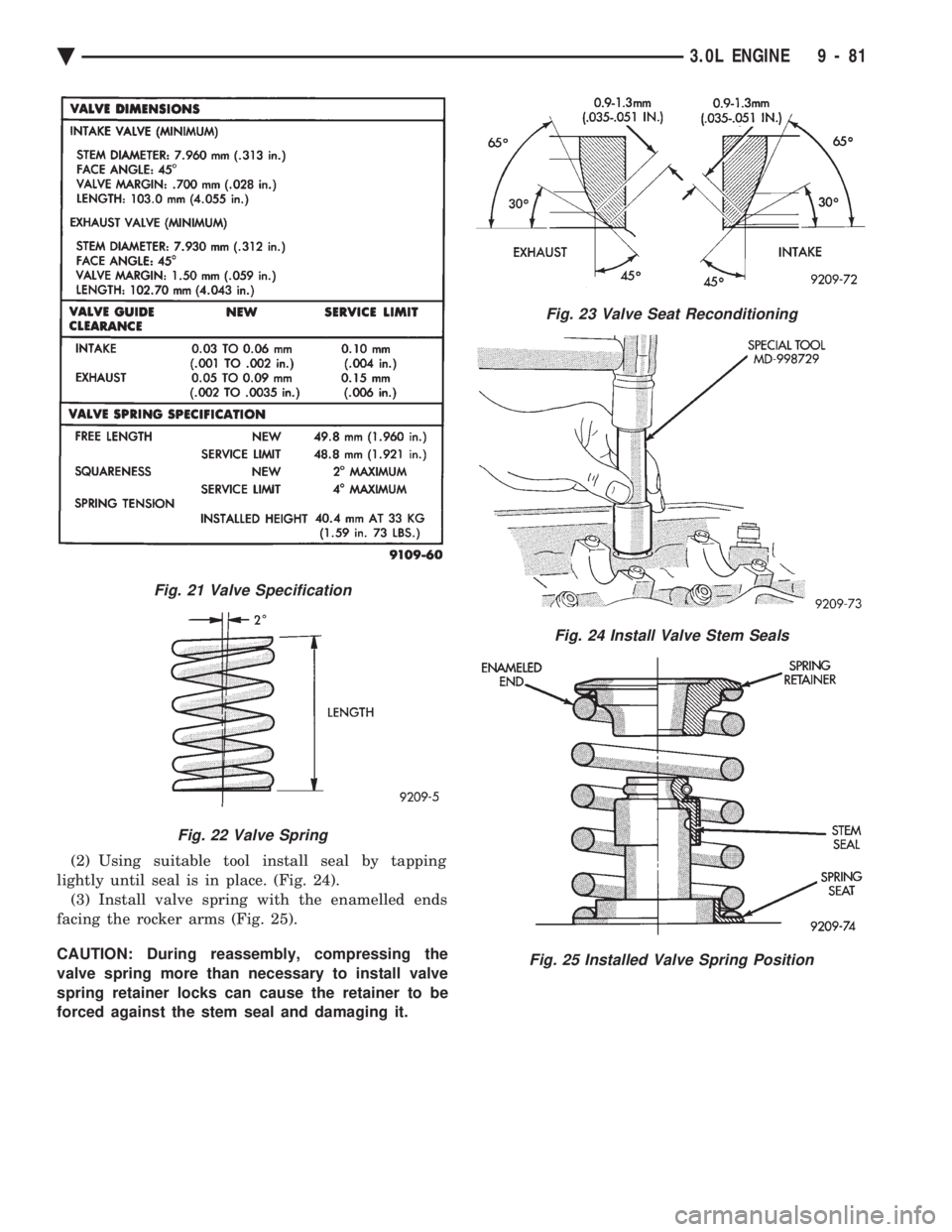

(2) Using suitable tool install seal by tapping

lightly until seal is in place. (Fig. 24). (3) Install valve spring with the enamelled ends

facing the rocker arms (Fig. 25).

CAUTION: During reassembly, compressing the

valve spring more than necessary to install valve

spring retainer locks can cause the retainer to be

forced against the stem seal and damaging it.

Fig. 21 Valve Specification

Fig. 22 Valve Spring

Fig. 23 Valve Seat Reconditioning

Fig. 24 Install Valve Stem Seals

Fig. 25 Installed Valve Spring Position

Ä 3.0L ENGINE 9 - 81

Page 1655 of 2438

(3) Apply light coating of engine oil to the entire

circumference of oil seal lip. (4) Install seal assembly on cylinder block and

tighten bolts to 12 N Im (104 in. lbs.)

FRONT CRANKSHAFT OIL PUMP AND OIL

SEAL

(1) Install oil pump gasket and oil pump case

(Figs. 1 and 14). CAUTION: Install bolts, depending on length in lo-

cations shown in (Fig. 14).

(2) Using front crankshaft oil seal installer Special

Tool MB998306 install oil seal in oil pump (Fig. 15).

CYLINDER BLOCK

Inspect cylinder block for scratches, cracks and rust

or corrosion, and repair or replace as required.

Fig. 10 Crankshaft Main Bearing Cap

Fig. 11 Checking Crankshaft End PlayFig. 12 Install Crankshaft Rear Oil Seal

Ä 3.0L ENGINE 9 - 89

Page 1665 of 2438

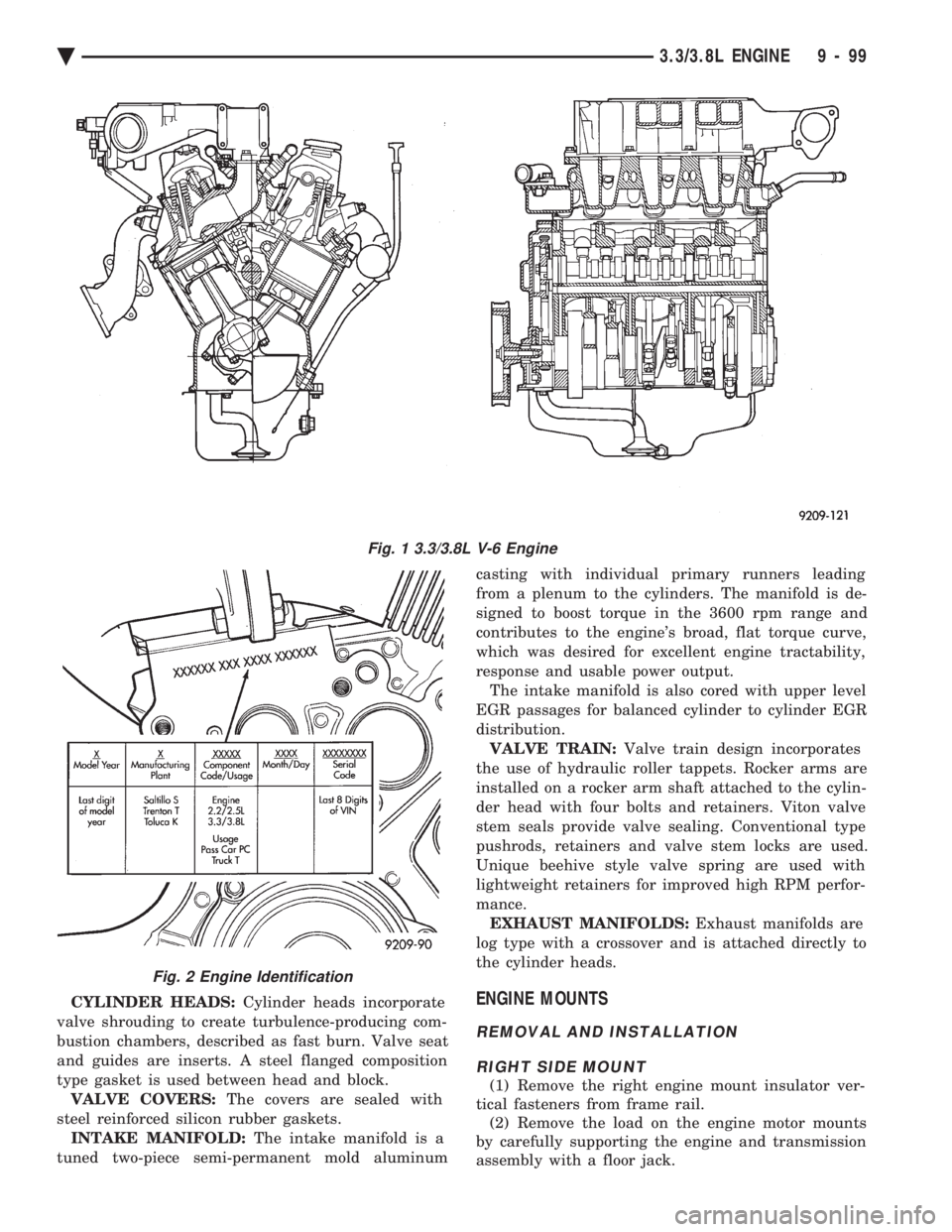

CYLINDER HEADS: Cylinder heads incorporate

valve shrouding to create turbulence-producing com-

bustion chambers, described as fast burn. Valve seat

and guides are inserts. A steel flanged composition

type gasket is used between head and block. VALVE COVERS: The covers are sealed with

steel reinforced silicon rubber gaskets. INTAKE MANIFOLD: The intake manifold is a

tuned two-piece semi-permanent mold aluminum casting with individual primary runners leading

from a plenum to the cylinders. The manifold is de-

signed to boost torque in the 3600 rpm range and

contributes to the engine's broad, flat torque curve,

which was desired for excellent engine tractability,

response and usable power output. The intake manifold is also cored with upper level

EGR passages for balanced cylinder to cylinder EGR

distribution. VALVE TRAIN: Valve train design incorporates

the use of hydraulic roller tappets. Rocker arms are

installed on a rocker arm shaft attached to the cylin-

der head with four bolts and retainers. Viton valve

stem seals provide valve sealing. Conventional type

pushrods, retainers and valve stem locks are used.

Unique beehive style valve spring are used with

lightweight retainers for improved high RPM perfor-

mance. EXHAUST MANIFOLDS: Exhaust manifolds are

log type with a crossover and is attached directly to

the cylinder heads.ENGINE MOUNTS

REMOVAL AND INSTALLATION

RIGHT SIDE MOUNT

(1) Remove the right engine mount insulator ver-

tical fasteners from frame rail. (2) Remove the load on the engine motor mounts

by carefully supporting the engine and transmission

assembly with a floor jack.

Fig. 1 3.3/3.8L V-6 Engine

Fig. 2 Engine Identification

Ä 3.3/3.8L ENGINE 9 - 99

Page 1669 of 2438

INSPECTION

(1) Before cleaning, check for leaks, damage and

cracks. (2) Clean cylinder head and oil passages.

(3) Check cylinder head for flatness (Fig. 8).

(4) Inspect all surfaces with a straightedge if there is

any reason to suspect leakage. If out of flatness exceeds

.019mm (.00075 inch). times the span length in inches

in any direction, either replace head or lightly machine

the head surface. As an example, if a 12 inch span is

1mm (.004 inch) out of flat, allowable is 12 x .019mm

(.00075 inch) equals .22mm (.009 in.) This amount of

out of flat is acceptable. *Maximum of 0.2 mm (.008 inch) for grinding is

permitted.

CAUTION: This is a combined total dimension of

stock removal from cylinder head and block top

surface.

INSTALLATION

(1) Clean all surfaces of cylinder block and cylinder

heads. (2) Install new gaskets on cylinder block (Fig. 9).

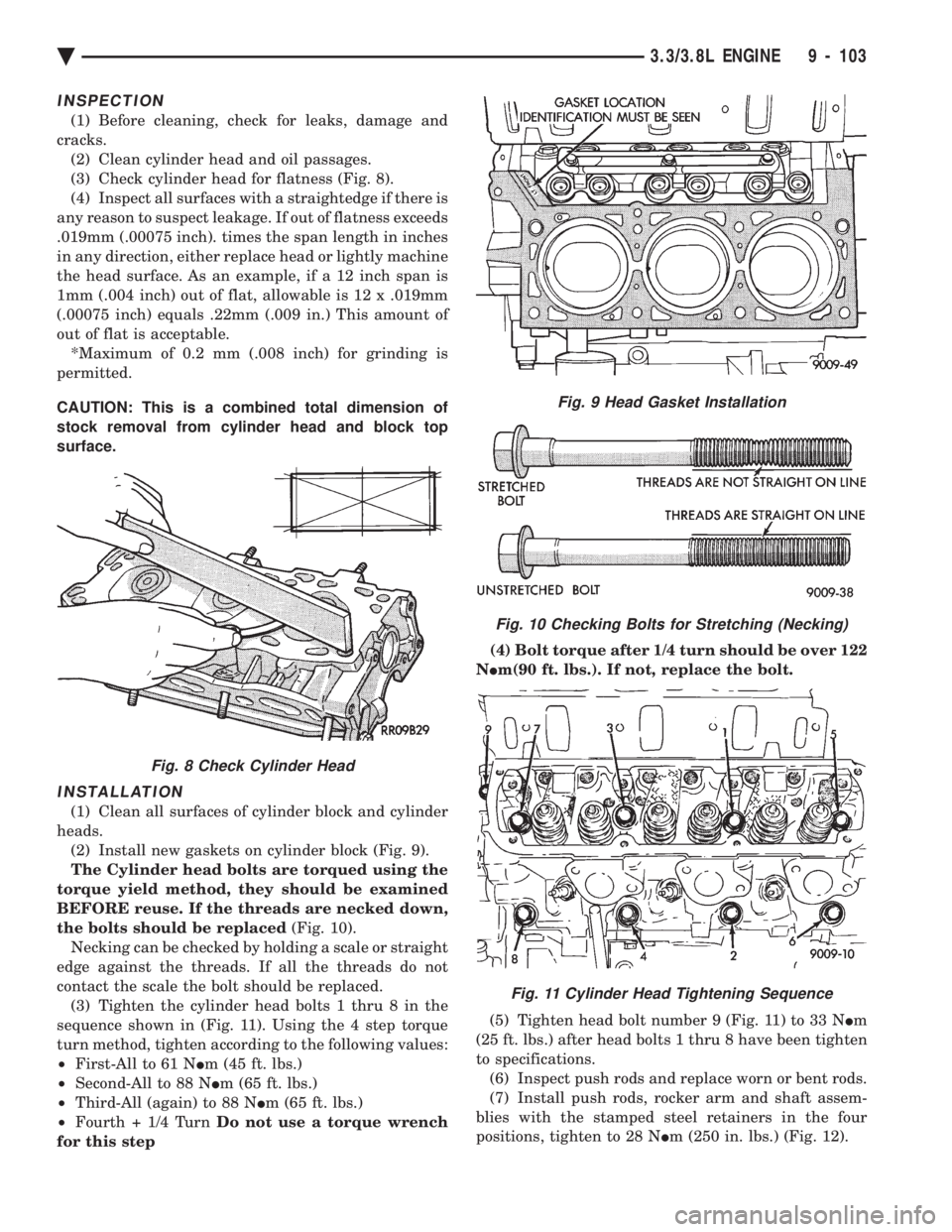

The Cylinder head bolts are torqued using the

torque yield method, they should be examined

BEFORE reuse. If the threads are necked down,

the bolts should be replaced (Fig. 10).

Necking can be checked by holding a scale or straight

edge against the threads. If all the threads do not

contact the scale the bolt should be replaced. (3) Tighten the cylinder head bolts 1 thru 8 in the

sequence shown in (Fig. 11). Using the 4 step torque

turn method, tighten according to the following values:

² First-All to 61 N Im (45 ft. lbs.)

² Second-All to 88 N Im (65 ft. lbs.)

² Third-All (again) to 88 N Im (65 ft. lbs.)

² Fourth + 1/4 Turn Do not use a torque wrench

for this step (4) Bolt torque after 1/4 turn should be over 122

N Im(90 ft. lbs.). If not, replace the bolt.

(5) Tighten head bolt number 9 (Fig. 11) to 33 N Im

(25 ft. lbs.) after head bolts 1 thru 8 have been tighten

to specifications. (6) Inspect push rods and replace worn or bent rods.

(7) Install push rods, rocker arm and shaft assem-

blies with the stamped steel retainers in the four

positions, tighten to 28 N Im (250 in. lbs.) (Fig. 12).

Fig. 8 Check Cylinder Head

Fig. 9 Head Gasket Installation

Fig. 10 Checking Bolts for Stretching (Necking)

Fig. 11 Cylinder Head Tightening Sequence

Ä 3.3/3.8L ENGINE 9 - 103

Page 1672 of 2438

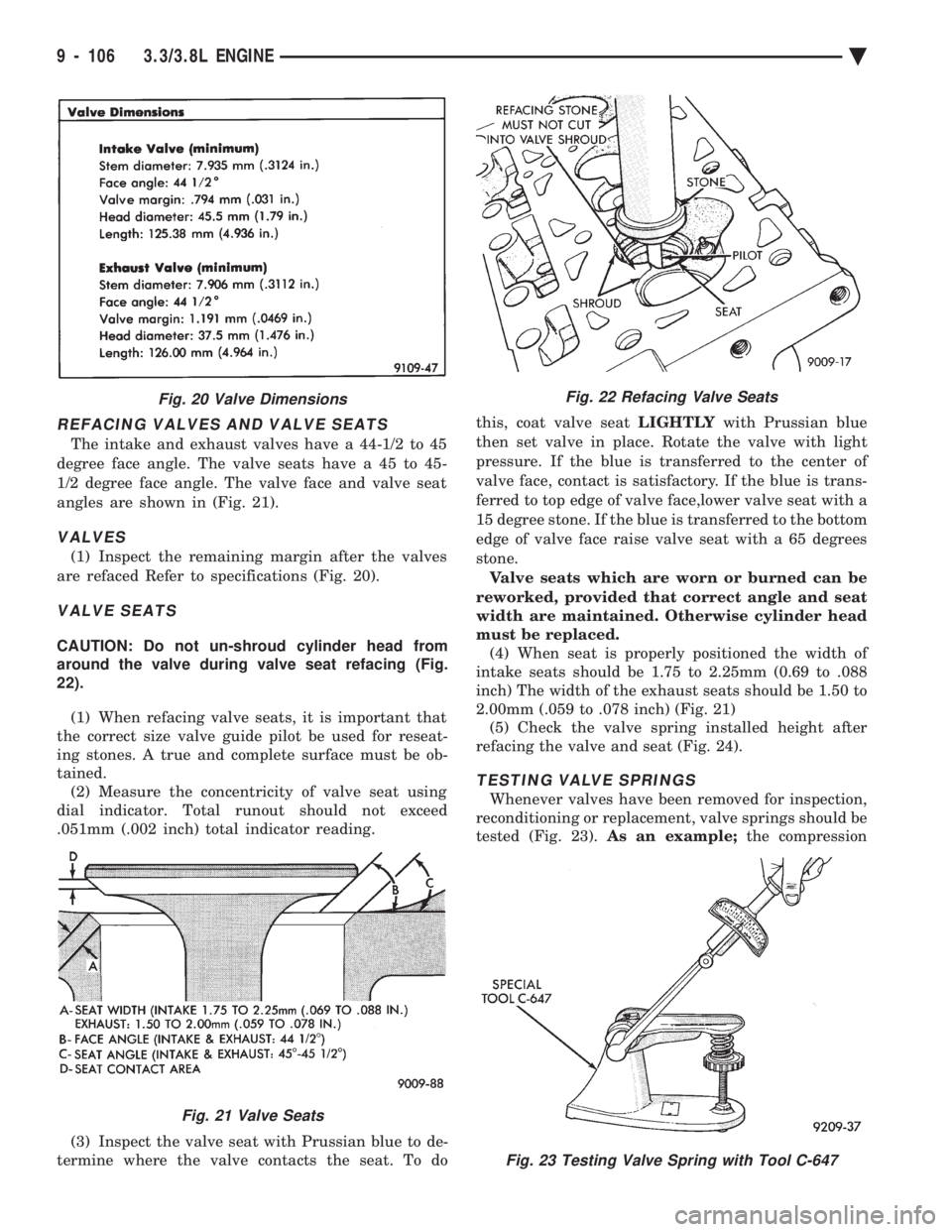

REFACING VALVES AND VALVE SEATS

The intake and exhaust valves have a 44-1/2 to 45

degree face angle. The valve seats have a 45 to 45-

1/2 degree face angle. The valve face and valve seat

angles are shown in (Fig. 21).

VALVES

(1) Inspect the remaining margin after the valves

are refaced Refer to specifications (Fig. 20).

VALVE SEATS

CAUTION: Do not un-shroud cylinder head from

around the valve during valve seat refacing (Fig.

22).

(1) When refacing valve seats, it is important that

the correct size valve guide pilot be used for reseat-

ing stones. A true and complete surface must be ob-

tained. (2) Measure the concentricity of valve seat using

dial indicator. Total runout should not exceed

.051mm (.002 inch) total indicator reading.

(3) Inspect the valve seat with Prussian blue to de-

termine where the valve contacts the seat. To do this, coat valve seat

LIGHTLYwith Prussian blue

then set valve in place. Rotate the valve with light

pressure. If the blue is transferred to the center of

valve face, contact is satisfactory. If the blue is trans-

ferred to top edge of valve face,lower valve seat with a

15 degree stone. If the blue is transferred to the bottom

edge of valve face raise valve seat with a 65 degrees

stone. Valve seats which are worn or burned can be

reworked, provided that correct angle and seat

width are maintained. Otherwise cylinder head

must be replaced. (4) When seat is properly positioned the width of

intake seats should be 1.75 to 2.25mm (0.69 to .088

inch) The width of the exhaust seats should be 1.50 to

2.00mm (.059 to .078 inch) (Fig. 21) (5) Check the valve spring installed height after

refacing the valve and seat (Fig. 24).

TESTING VALVE SPRINGS

Whenever valves have been removed for inspection,

reconditioning or replacement, valve springs should be

tested (Fig. 23). As an example; the compression

Fig. 23 Testing Valve Spring with Tool C-647

Fig. 20 Valve Dimensions

Fig. 21 Valve Seats

Fig. 22 Refacing Valve Seats

9 - 106 3.3/3.8L ENGINE Ä

Page 1674 of 2438

(15) Install rocker arm covers tighten screws to 14

N Im (120 in. lbs.) and connector to ignition coils.

(16) Install Intake Manifold; Refer to Intake Mani-

fold Installation 3.3/3.8L Engine, Group 11 Exhaust

System and Intake Manifold.

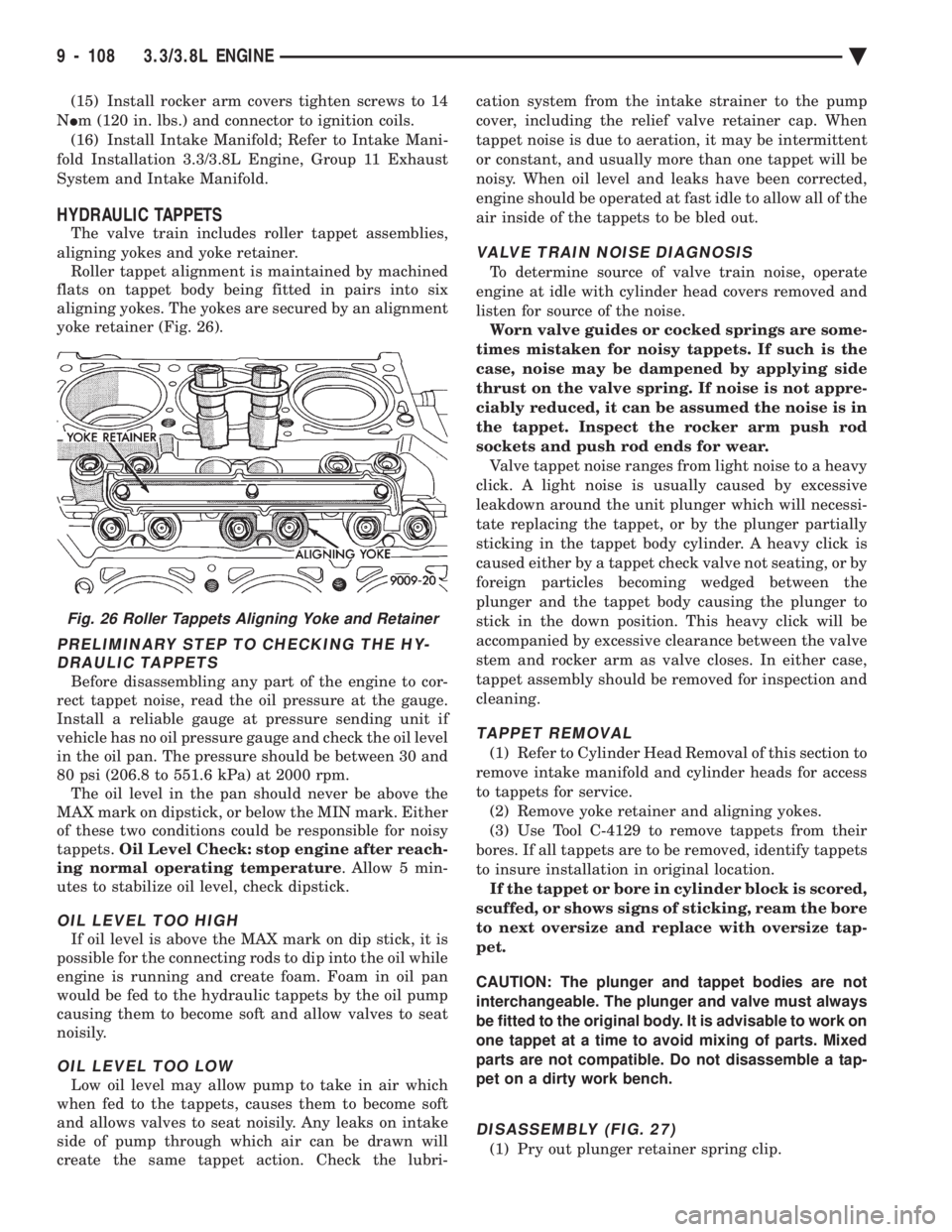

HYDRAULIC TAPPETS

The valve train includes roller tappet assemblies,

aligning yokes and yoke retainer. Roller tappet alignment is maintained by machined

flats on tappet body being fitted in pairs into six

aligning yokes. The yokes are secured by an alignment

yoke retainer (Fig. 26).

PRELIMINARY STEP TO CHECKING THE HY- DRAULIC TAPPETS

Before disassembling any part of the engine to cor-

rect tappet noise, read the oil pressure at the gauge.

Install a reliable gauge at pressure sending unit if

vehicle has no oil pressure gauge and check the oil level

in the oil pan. The pressure should be between 30 and

80 psi (206.8 to 551.6 kPa) at 2000 rpm. The oil level in the pan should never be above the

MAX mark on dipstick, or below the MIN mark. Either

of these two conditions could be responsible for noisy

tappets. Oil Level Check: stop engine after reach-

ing normal operating temperature . Allow 5 min-

utes to stabilize oil level, check dipstick.

OIL LEVEL TOO HIGH

If oil level is above the MAX mark on dip stick, it is

possible for the connecting rods to dip into the oil while

engine is running and create foam. Foam in oil pan

would be fed to the hydraulic tappets by the oil pump

causing them to become soft and allow valves to seat

noisily.

OIL LEVEL TOO LOW

Low oil level may allow pump to take in air which

when fed to the tappets, causes them to become soft

and allows valves to seat noisily. Any leaks on intake

side of pump through which air can be drawn will

create the same tappet action. Check the lubri- cation system from the intake strainer to the pump

cover, including the relief valve retainer cap. When

tappet noise is due to aeration, it may be intermittent

or constant, and usually more than one tappet will be

noisy. When oil level and leaks have been corrected,

engine should be operated at fast idle to allow all of the

air inside of the tappets to be bled out.

VALVE TRAIN NOISE DIAGNOSIS

To determine source of valve train noise, operate

engine at idle with cylinder head covers removed and

listen for source of the noise. Worn valve guides or cocked springs are some-

times mistaken for noisy tappets. If such is the

case, noise may be dampened by applying side

thrust on the valve spring. If noise is not appre-

ciably reduced, it can be assumed the noise is in

the tappet. Inspect the rocker arm push rod

sockets and push rod ends for wear. Valve tappet noise ranges from light noise to a heavy

click. A light noise is usually caused by excessive

leakdown around the unit plunger which will necessi-

tate replacing the tappet, or by the plunger partially

sticking in the tappet body cylinder. A heavy click is

caused either by a tappet check valve not seating, or by

foreign particles becoming wedged between the

plunger and the tappet body causing the plunger to

stick in the down position. This heavy click will be

accompanied by excessive clearance between the valve

stem and rocker arm as valve closes. In either case,

tappet assembly should be removed for inspection and

cleaning.

TAPPET REMOVAL

(1) Refer to Cylinder Head Removal of this section to

remove intake manifold and cylinder heads for access

to tappets for service. (2) Remove yoke retainer and aligning yokes.

(3) Use Tool C-4129 to remove tappets from their

bores. If all tappets are to be removed, identify tappets

to insure installation in original location. If the tappet or bore in cylinder block is scored,

scuffed, or shows signs of sticking, ream the bore

to next oversize and replace with oversize tap-

pet.

CAUTION: The plunger and tappet bodies are not

interchangeable. The plunger and valve must always

be fitted to the original body. It is advisable to work on

one tappet at a time to avoid mixing of parts. Mixed

parts are not compatible. Do not disassemble a tap-

pet on a dirty work bench.

DISASSEMBLY (FIG. 27)

(1) Pry out plunger retainer spring clip.

Fig. 26 Roller Tappets Aligning Yoke and Retainer

9 - 108 3.3/3.8L ENGINE Ä

Page 1679 of 2438

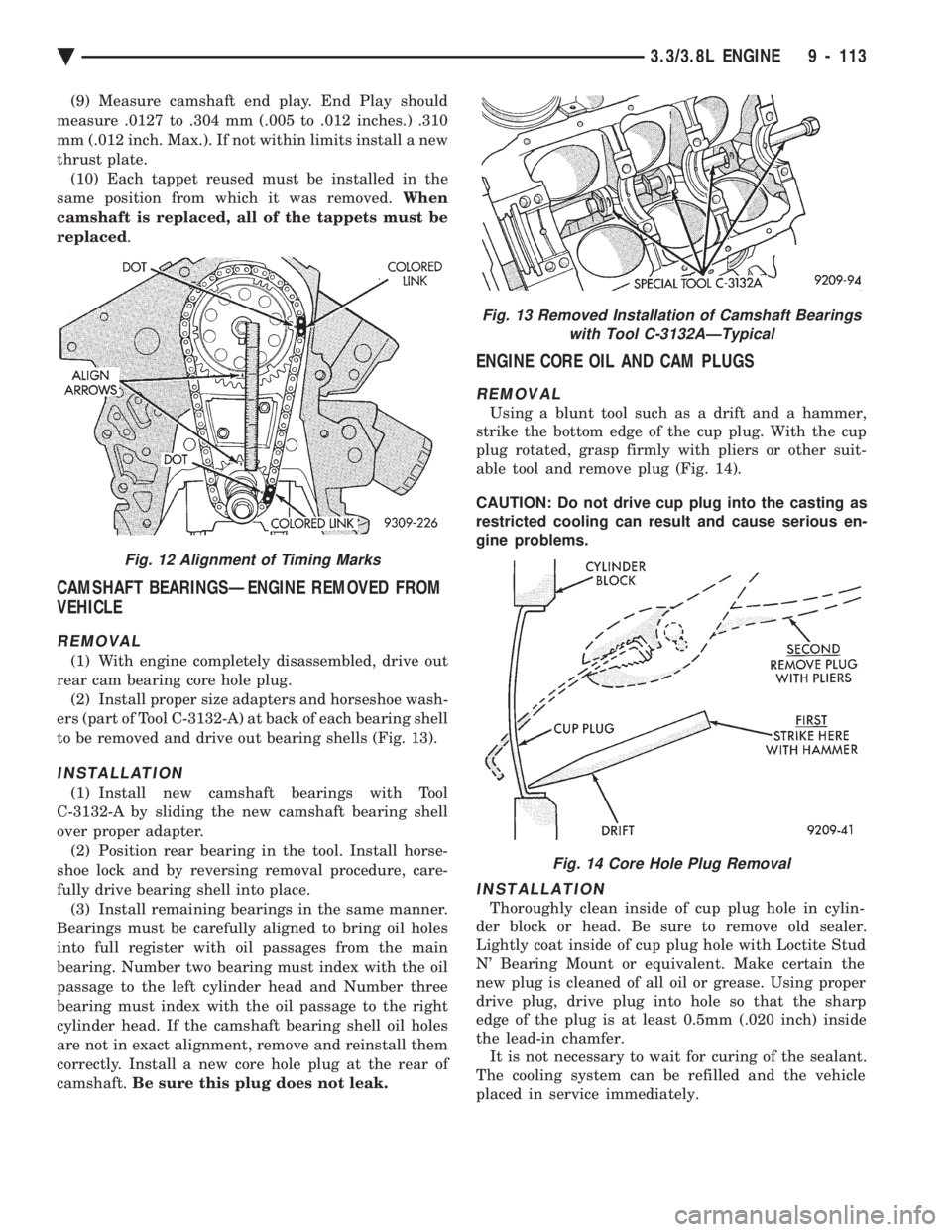

(9) Measure camshaft end play. End Play should

measure .0127 to .304 mm (.005 to .012 inches.) .310

mm (.012 inch. Max.). If not within limits install a new

thrust plate. (10) Each tappet reused must be installed in the

same position from which it was removed. When

camshaft is replaced, all of the tappets must be

replaced .

CAMSHAFT BEARINGSÐENGINE REMOVED FROM

VEHICLE

REMOVAL

(1) With engine completely disassembled, drive out

rear cam bearing core hole plug. (2) Install proper size adapters and horseshoe wash-

ers (part of Tool C-3132-A) at back of each bearing shell

to be removed and drive out bearing shells (Fig. 13).

INSTALLATION

(1) Install new camshaft bearings with Tool

C-3132-A by sliding the new camshaft bearing shell

over proper adapter. (2) Position rear bearing in the tool. Install horse-

shoe lock and by reversing removal procedure, care-

fully drive bearing shell into place. (3) Install remaining bearings in the same manner.

Bearings must be carefully aligned to bring oil holes

into full register with oil passages from the main

bearing. Number two bearing must index with the oil

passage to the left cylinder head and Number three

bearing must index with the oil passage to the right

cylinder head. If the camshaft bearing shell oil holes

are not in exact alignment, remove and reinstall them

correctly. Install a new core hole plug at the rear of

camshaft. Be sure this plug does not leak.

ENGINE CORE OIL AND CAM PLUGS

REMOVAL

Using a blunt tool such as a drift and a hammer,

strike the bottom edge of the cup plug. With the cup

plug rotated, grasp firmly with pliers or other suit-

able tool and remove plug (Fig. 14).

CAUTION: Do not drive cup plug into the casting as

restricted cooling can result and cause serious en-

gine problems.

INSTALLATION

Thoroughly clean inside of cup plug hole in cylin-

der block or head. Be sure to remove old sealer.

Lightly coat inside of cup plug hole with Loctite Stud

N' Bearing Mount or equivalent. Make certain the

new plug is cleaned of all oil or grease. Using proper

drive plug, drive plug into hole so that the sharp

edge of the plug is at least 0.5mm (.020 inch) inside

the lead-in chamfer. It is not necessary to wait for curing of the sealant.

The cooling system can be refilled and the vehicle

placed in service immediately.

Fig. 13 Removed Installation of Camshaft Bearings with Tool C-3132AÐTypical

Fig. 14 Core Hole Plug Removal

Fig. 12 Alignment of Timing Marks

Ä 3.3/3.8L ENGINE 9 - 113

Page 1685 of 2438

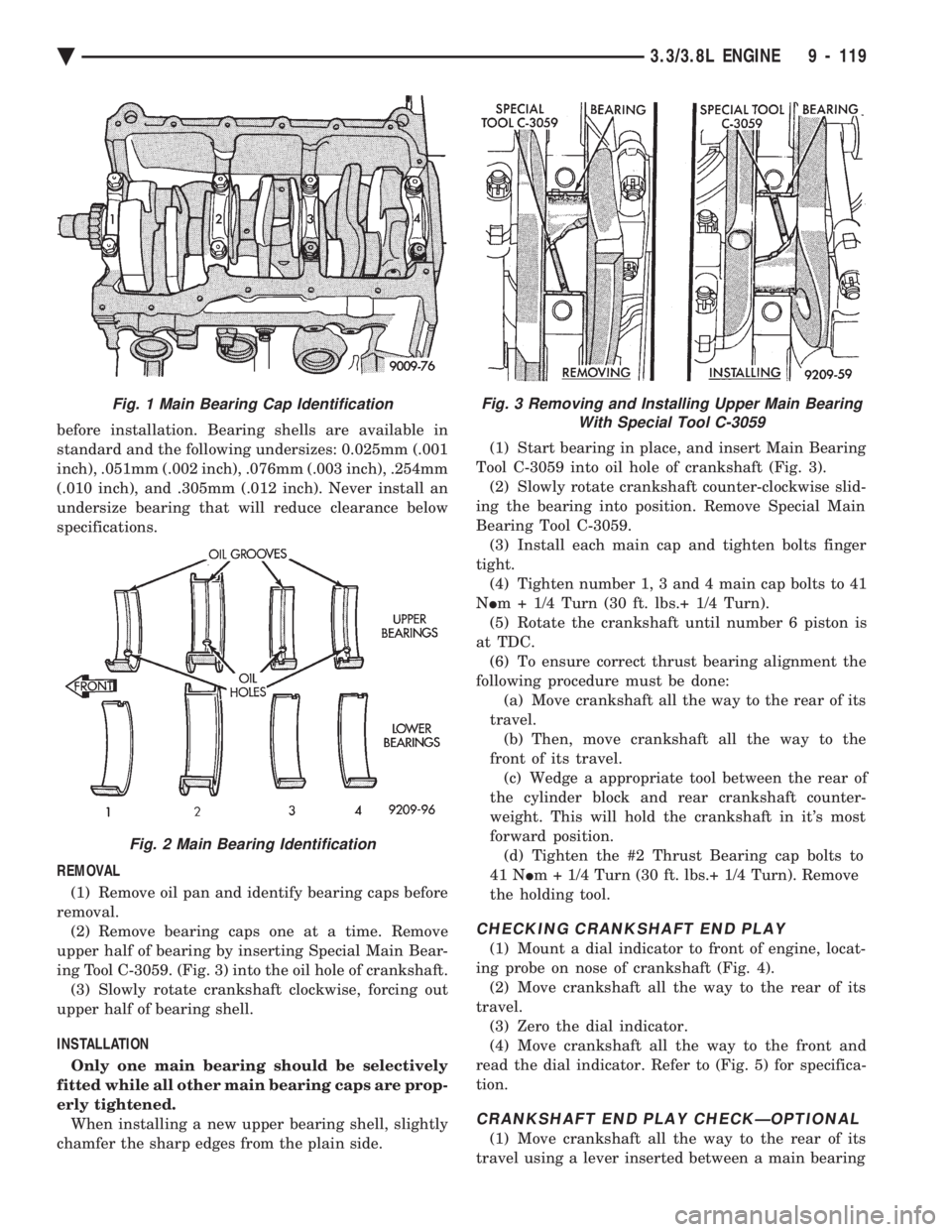

before installation. Bearing shells are available in

standard and the following undersizes: 0.025mm (.001

inch), .051mm (.002 inch), .076mm (.003 inch), .254mm

(.010 inch), and .305mm (.012 inch). Never install an

undersize bearing that will reduce clearance below

specifications.

REMOVAL (1) Remove oil pan and identify bearing caps before

removal. (2) Remove bearing caps one at a time. Remove

upper half of bearing by inserting Special Main Bear-

ing Tool C-3059. (Fig. 3) into the oil hole of crankshaft. (3) Slowly rotate crankshaft clockwise, forcing out

upper half of bearing shell.

INSTALLATION Only one main bearing should be selectively

fitted while all other main bearing caps are prop-

erly tightened. When installing a new upper bearing shell, slightly

chamfer the sharp edges from the plain side. (1) Start bearing in place, and insert Main Bearing

Tool C-3059 into oil hole of crankshaft (Fig. 3). (2) Slowly rotate crankshaft counter-clockwise slid-

ing the bearing into position. Remove Special Main

Bearing Tool C-3059. (3) Install each main cap and tighten bolts finger

tight. (4) Tighten number 1, 3 and 4 main cap bolts to 41

N Im + 1/4 Turn (30 ft. lbs.+ 1/4 Turn).

(5) Rotate the crankshaft until number 6 piston is

at TDC. (6) To ensure correct thrust bearing alignment the

following procedure must be done: (a) Move crankshaft all the way to the rear of its

travel. (b) Then, move crankshaft all the way to the

front of its travel. (c) Wedge a appropriate tool between the rear of

the cylinder block and rear crankshaft counter-

weight. This will hold the crankshaft in it's most

forward position. (d) Tighten the #2 Thrust Bearing cap bolts to

41 N Im + 1/4 Turn (30 ft. lbs.+ 1/4 Turn). Remove

the holding tool.

CHECKING CRANKSHAFT END PLAY

(1) Mount a dial indicator to front of engine, locat-

ing probe on nose of crankshaft (Fig. 4). (2) Move crankshaft all the way to the rear of its

travel. (3) Zero the dial indicator.

(4) Move crankshaft all the way to the front and

read the dial indicator. Refer to (Fig. 5) for specifica-

tion.

CRANKSHAFT END PLAY CHECKÐOPTIONAL

(1) Move crankshaft all the way to the rear of its

travel using a lever inserted between a main bearing

Fig. 3 Removing and Installing Upper Main Bearing With Special Tool C-3059Fig. 1 Main Bearing Cap Identification

Fig. 2 Main Bearing Identification

Ä 3.3/3.8L ENGINE 9 - 119

Page 1687 of 2438

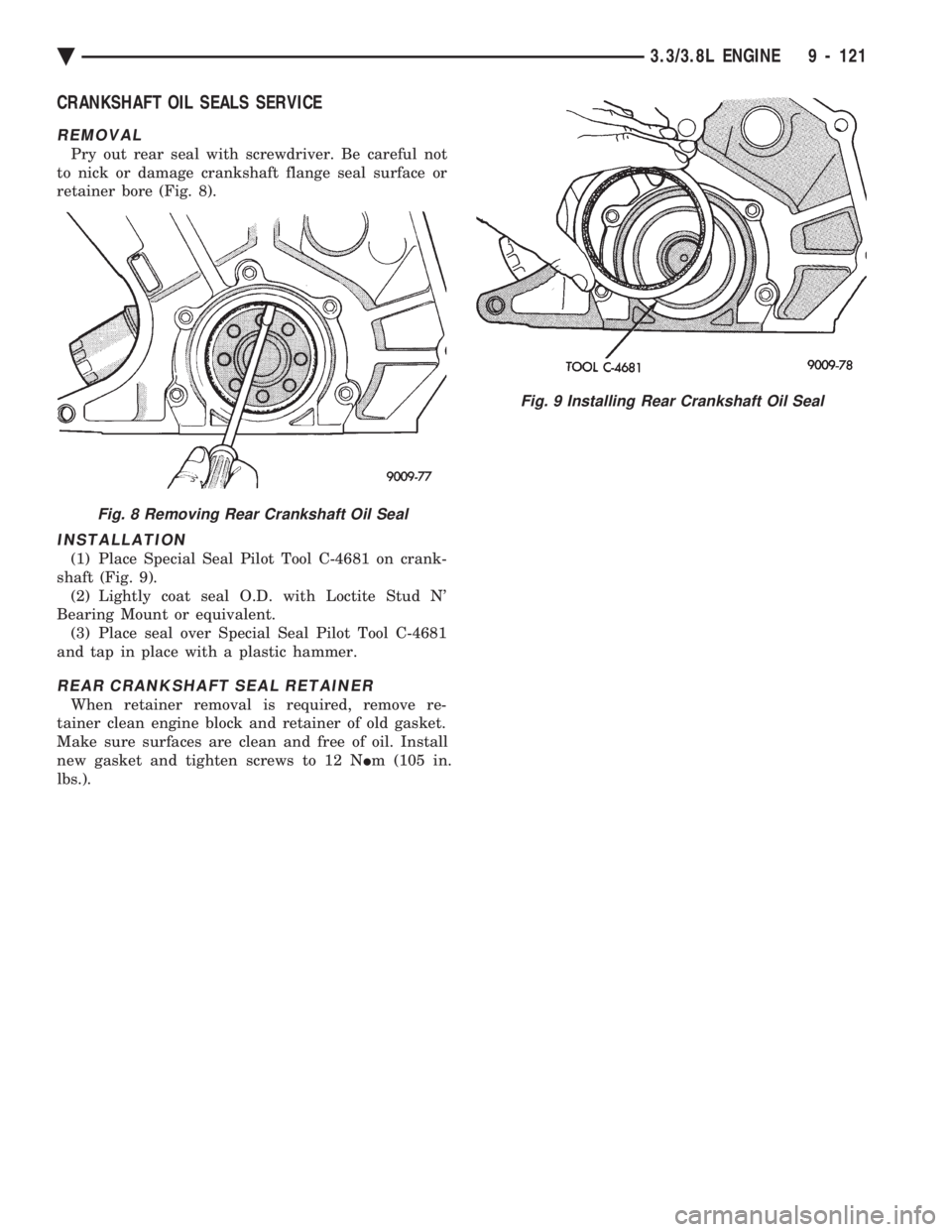

CRANKSHAFT OIL SEALS SERVICE

REMOVAL

Pry out rear seal with screwdriver. Be careful not

to nick or damage crankshaft flange seal surface or

retainer bore (Fig. 8).

INSTALLATION

(1) Place Special Seal Pilot Tool C-4681 on crank-

shaft (Fig. 9). (2) Lightly coat seal O.D. with Loctite Stud N'

Bearing Mount or equivalent. (3) Place seal over Special Seal Pilot Tool C-4681

and tap in place with a plastic hammer.

REAR CRANKSHAFT SEAL RETAINER

When retainer removal is required, remove re-

tainer clean engine block and retainer of old gasket.

Make sure surfaces are clean and free of oil. Install

new gasket and tighten screws to 12 N Im (105 in.

lbs.).

Fig. 9 Installing Rear Crankshaft Oil Seal

Fig. 8 Removing Rear Crankshaft Oil Seal

Ä 3.3/3.8L ENGINE 9 - 121

Page 1699 of 2438

CAUTION: Avoid application of rust prevention

compounds or undercoating materials to exhaust

system floor pan heat shields on cars if equipped.

Light overspray near the edges is permitted. Appli-

cation of coating will greatly reduce the efficiency

of the heat shields resulting in excessive floor pan

temperatures and objectionable fumes.

The combustion reaction caused by the catalyst re-

leases additional heat in the exhaust system. Caus-

ing temperature increases in the area of the reactor

under severe operating conditions. Such conditions

can exist when the engine misfires or otherwise does

not operate at peak efficiency. Do notremove spark

plug wires from plugs or by any other means short

out cylinders if exhaust system is equipped with cat-

alytic converter. Failure of the catalytic converter

can occur due to temperature increases caused by un-

burned fuel passing through the converter. The use of the catalysts also involves some non-au-

tomotive problems. Unleaded gasoline must be used

to avoid poisoning the catalyst core. Do not allow en- gine to operate above 1200 RPM in neutral for ex-

tended periods over 5 minutes. This condition may

result in excessive exhaust system/floor pan temper-

atures because of no air movement under the vehicle.

EXHAUST GAS RECIRCULATION (EGR) SYSTEM

To assist in the control of oxides of nitrogen (NOx)

in engine exhaust, some engines are equipped with

an exhaust gas recirculation system. The use of ex-

haust gas to dilute incoming air/fuel mixtures lowers

peak flame temperatures during combustion, thus

limiting the formation of NOx. Exhaust gases are taken from openings in the ex-

haust gas crossover passage in the intake manifold.

REFER TO SECTION 25 EMISSION SYSTEMS

FOR A COMPLETE DESCRIPTION, DIAGNOSIS

AND SERVICE PROCEDURES ON THE EXHAUST

GAS RECIRCULATION SYSTEM AND COMPO-

NENTS.

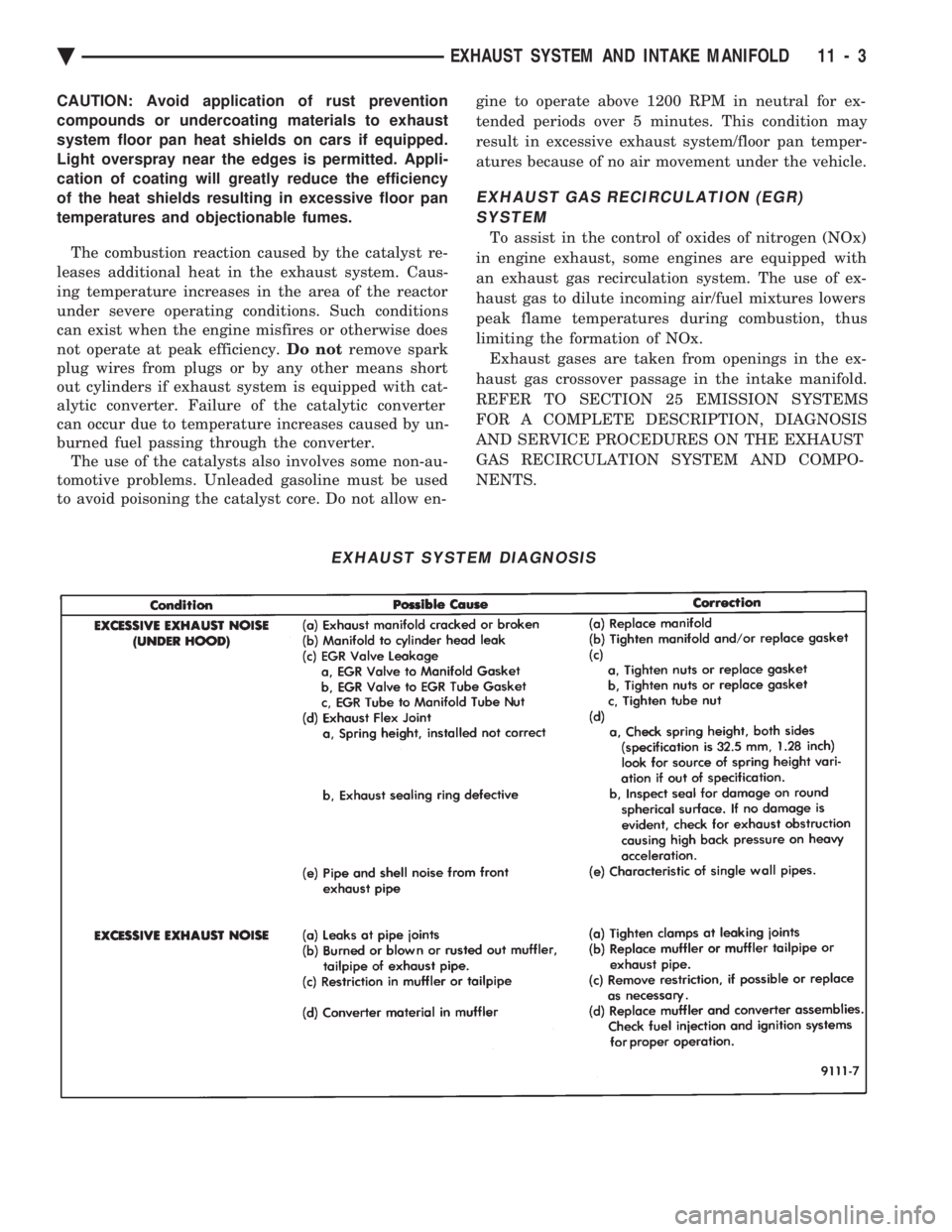

EXHAUST SYSTEM DIAGNOSIS

Ä EXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 3