light CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1953 of 2438

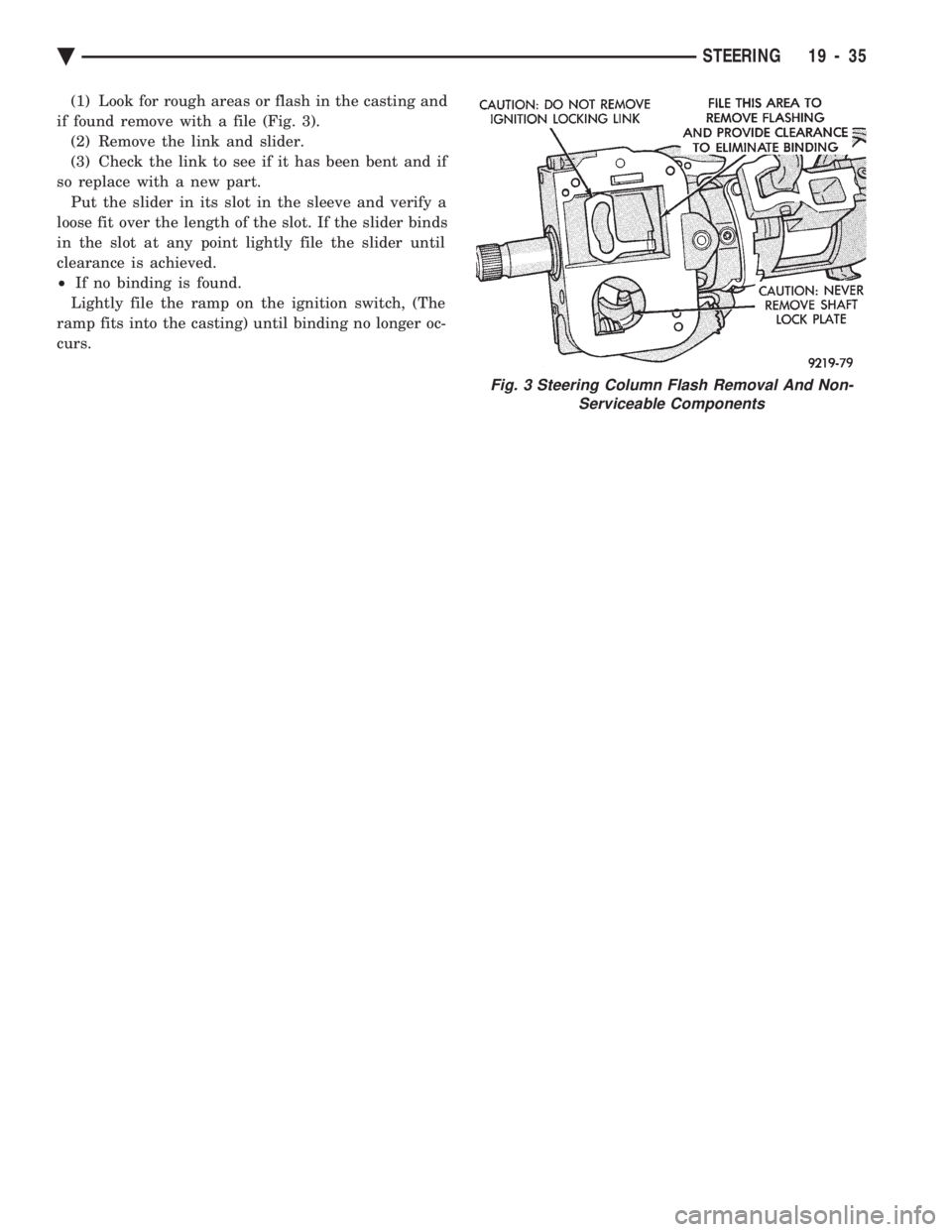

(1) Look for rough areas or flash in the casting and

if found remove with a file (Fig. 3). (2) Remove the link and slider.

(3) Check the link to see if it has been bent and if

so replace with a new part. Put the slider in its slot in the sleeve and verify a

loose fit over the length of the slot. If the slider binds

in the slot at any point lightly file the slider until

clearance is achieved.

² If no binding is found.

Lightly file the ramp on the ignition switch, (The

ramp fits into the casting) until binding no longer oc-

curs.

Fig. 3 Steering Column Flash Removal And Non- Serviceable Components

Ä STEERING 19 - 35

Page 1992 of 2438

ing seat will give a false end play reading while

gauging for proper shims. Improperly seated bearing

cups and cones are subject to low mileage failure.(2) Bearing cups and cones should be replaced if they

show signs of pitting or heat distress. If distress is seen

on either the cup or bearing rollers, both cup and cone

must be replaced. (3) Bearing preload and drag torque specifications

must be maintained to avoid premature bearing

failures. Used (original) bearing may lose up to 50% of

the original drag torque after break in. All bearing

adjustments must be made with no other compo-

nent interference or gear intermesh. (4) Replace bearings as a pair. For example, if one

differential bearing is defective, replace both differen-

tial bearings. If one input shaft bearing is defective,

replace both input shaft bearings. (5) Bearing cones must notbe reused if removed.

(6) Turning torque readings should be obtained

while smoothly rotating in either direction (break-

away reading is not indicative of the true turning

torque). (7) Replace oil baffle, if damaged.

INPUT SHAFT BEARING END PLAY ADJUST-MENT

(1) Using Tool C-4656 with Handle C-4171, press

input shaft front bearing cup slightly forward in case.

Then, using Tool C-4655 with Handle C-4171, press

bearing cup back into case from the front. Properly

position bearing cup, before checking input shaft end

play (see input shaft front bearing cup replace in

Subassembly Recondition section).This step is

not necessary if Tool C-4655 was previously used

to install input shaft front bearing cup in the

case. Also no input shaft shim has been installed

since pressing cup into case. (2) Select a gauging shim which will give 0.025 to

0.254mm (.001 to .010 inch) end play. SUGGESTION:

Measure original shim from input shaft seal retainer and select a shim 0.254mm (.010

inch) thinner than original for the gauging shim.

(3) Install gauging shim on bearing cup and install

input shaft seal retainer.

CAUTION: The input shaft seal retainer is used to

draw the input shaft front bearing cup the proper

distance into the case bore during this step. Alter-

nately tighten input shaft seal retainer bolts until

input shaft seal retainer is bottomed against case.

Tighten bolts to 28 N Im (21 ft. lbs.).

(4) Oil input shaft bearings with SAE 5W-30 engine

oil and install input shaft in case. Install bearing

retainer plate with input shaft rear bearing cup

pressed in and bearing support plate installed. Tighten

all bolts and nuts to 28 N Im (21 ft. lbs.).

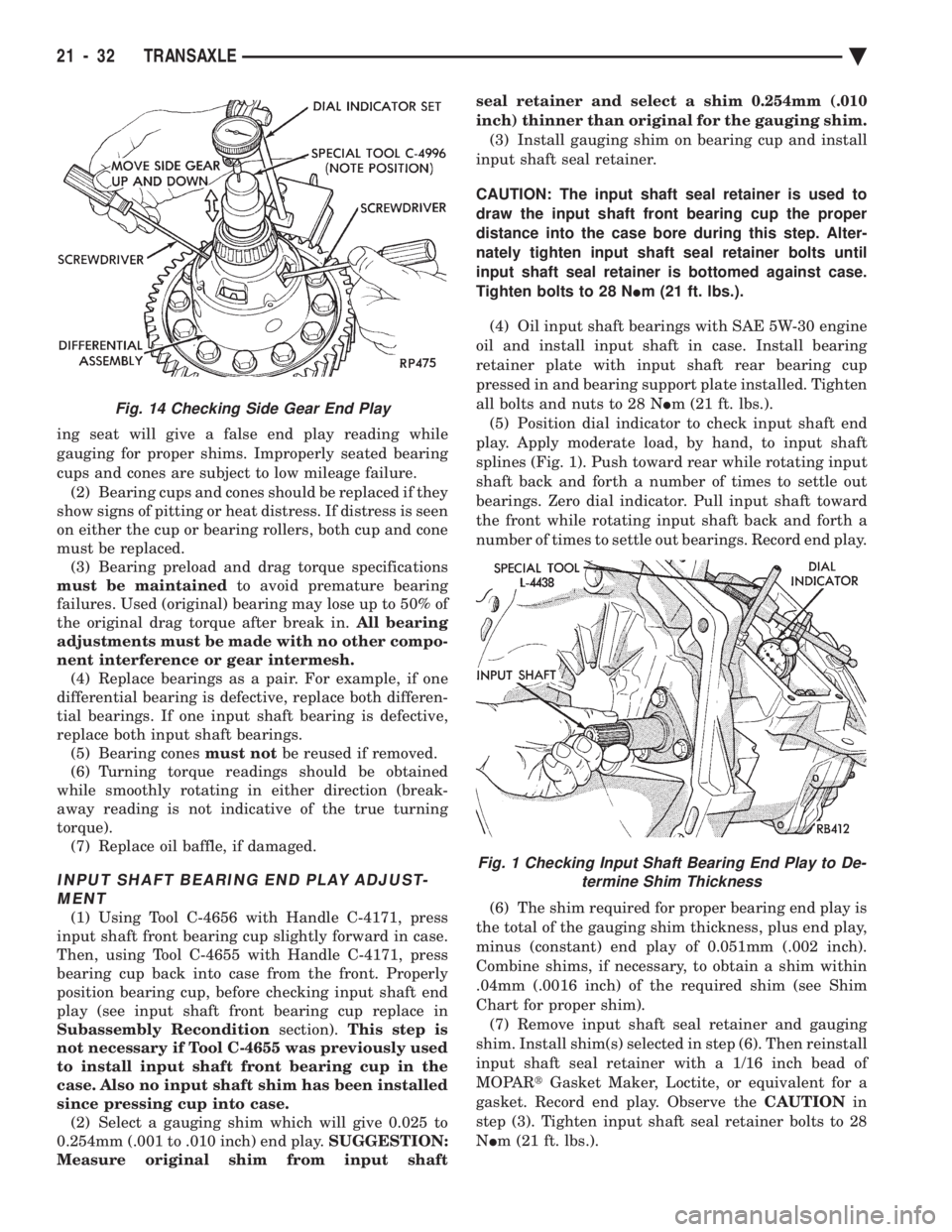

(5) Position dial indicator to check input shaft end

play. Apply moderate load, by hand, to input shaft

splines (Fig. 1). Push toward rear while rotating input

shaft back and forth a number of times to settle out

bearings. Zero dial indicator. Pull input shaft toward

the front while rotating input shaft back and forth a

number of times to settle out bearings. Record end play.

(6) The shim required for proper bearing end play is

the total of the gauging shim thickness, plus end play,

minus (constant) end play of 0.051mm (.002 inch).

Combine shims, if necessary, to obtain a shim within

.04mm (.0016 inch) of the required shim (see Shim

Chart for proper shim). (7) Remove input shaft seal retainer and gauging

shim. Install shim(s) selected in step (6). Then reinstall

input shaft seal retainer with a 1/16 inch bead of

MOPAR tGasket Maker, Loctite, or equivalent for a

gasket. Record end play. Observe the CAUTIONin

step (3). Tighten input shaft seal retainer bolts to 28

N Im (21 ft. lbs.).

Fig. 14 Checking Side Gear End Play

Fig. 1 Checking Input Shaft Bearing End Play to De-

termine Shim Thickness

21 - 32 TRANSAXLE Ä

Page 2017 of 2438

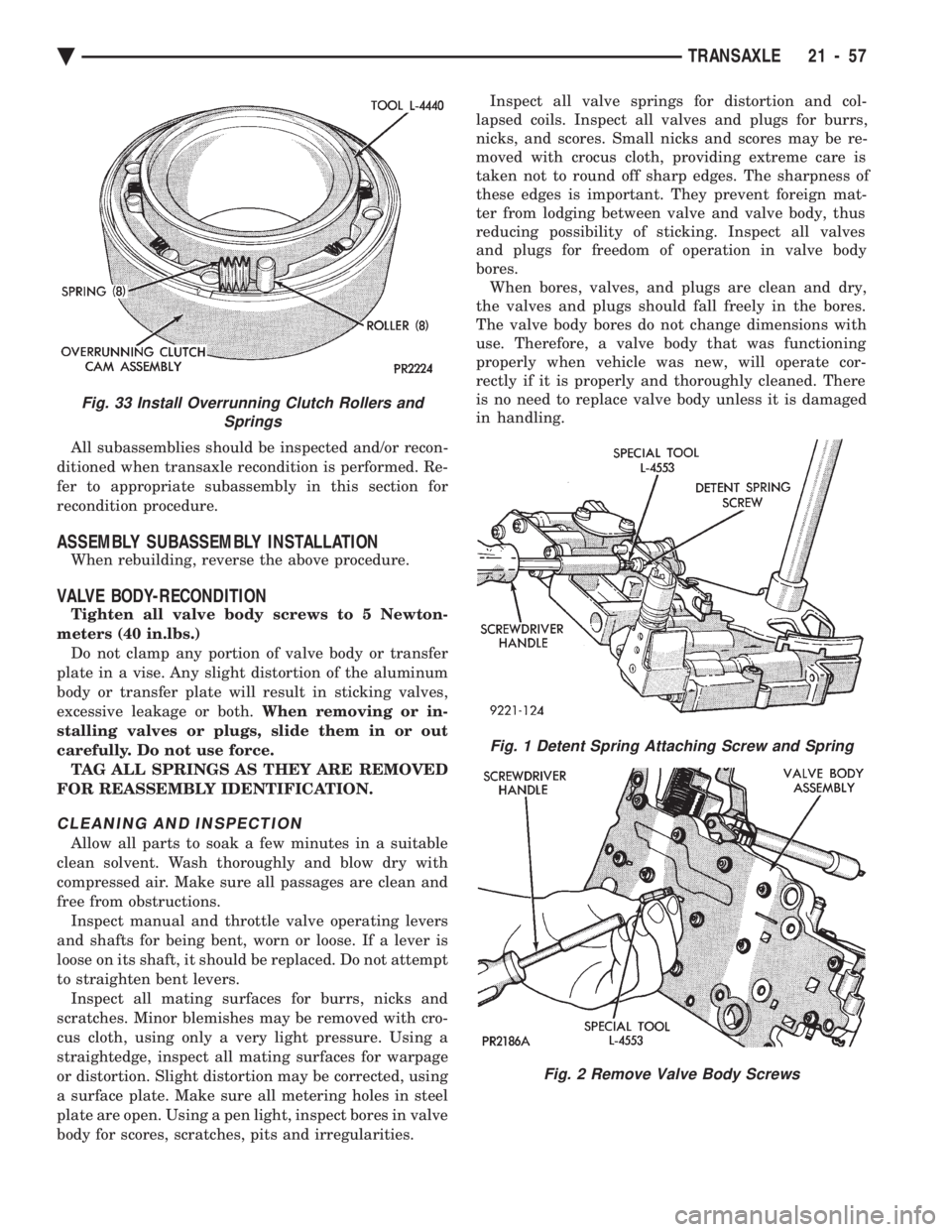

All subassemblies should be inspected and/or recon-

ditioned when transaxle recondition is performed. Re-

fer to appropriate subassembly in this section for

recondition procedure.

ASSEMBLY SUBASSEMBLY INSTALLATION

When rebuilding, reverse the above procedure.

VALVE BODY-RECONDITION

Tighten all valve body screws to 5 Newton-

meters (40 in.lbs.) Do not clamp any portion of valve body or transfer

plate in a vise. Any slight distortion of the aluminum

body or transfer plate will result in sticking valves,

excessive leakage or both. When removing or in-

stalling valves or plugs, slide them in or out

carefully. Do not use force. TAG ALL SPRINGS AS THEY ARE REMOVED

FOR REASSEMBLY IDENTIFICATION.

CLEANING AND INSPECTION

Allow all parts to soak a few minutes in a suitable

clean solvent. Wash thoroughly and blow dry with

compressed air. Make sure all passages are clean and

free from obstructions. Inspect manual and throttle valve operating levers

and shafts for being bent, worn or loose. If a lever is

loose on its shaft, it should be replaced. Do not attempt

to straighten bent levers. Inspect all mating surfaces for burrs, nicks and

scratches. Minor blemishes may be removed with cro-

cus cloth, using only a very light pressure. Using a

straightedge, inspect all mating surfaces for warpage

or distortion. Slight distortion may be corrected, using

a surface plate. Make sure all metering holes in steel

plate are open. Using a pen light, inspect bores in valve

body for scores, scratches, pits and irregularities. Inspect all valve springs for distortion and col-

lapsed coils. Inspect all valves and plugs for burrs,

nicks, and scores. Small nicks and scores may be re-

moved with crocus cloth, providing extreme care is

taken not to round off sharp edges. The sharpness of

these edges is important. They prevent foreign mat-

ter from lodging between valve and valve body, thus

reducing possibility of sticking. Inspect all valves

and plugs for freedom of operation in valve body

bores. When bores, valves, and plugs are clean and dry,

the valves and plugs should fall freely in the bores.

The valve body bores do not change dimensions with

use. Therefore, a valve body that was functioning

properly when vehicle was new, will operate cor-

rectly if it is properly and thoroughly cleaned. There

is no need to replace valve body unless it is damaged

in handling.

Fig. 1 Detent Spring Attaching Screw and Spring

Fig. 2 Remove Valve Body Screws

Fig. 33 Install Overrunning Clutch Rollers and Springs

Ä TRANSAXLE 21 - 57

Page 2022 of 2438

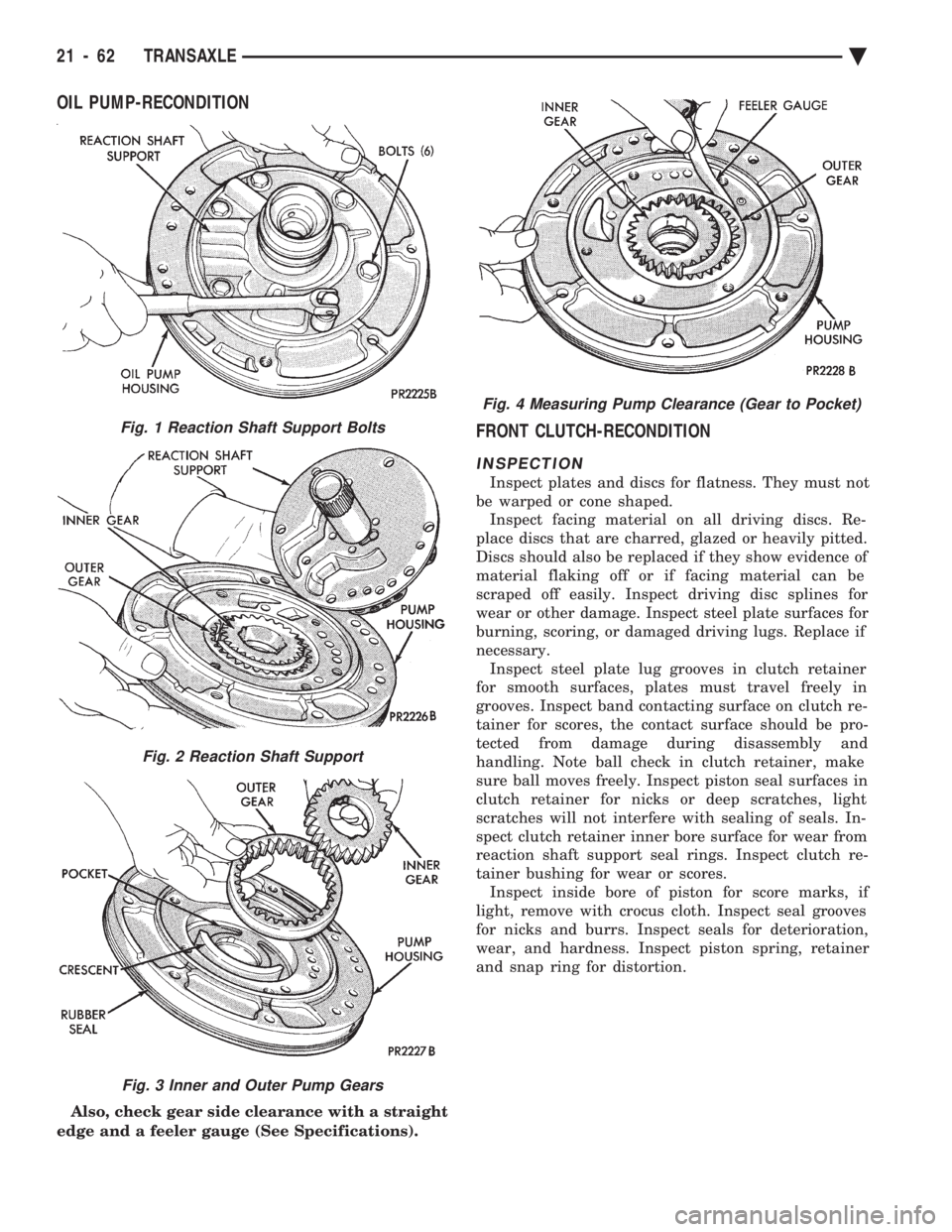

OIL PUMP-RECONDITION

Also, check gear side clearance with a straight

edge and a feeler gauge (See Specifications).

FRONT CLUTCH-RECONDITION

INSPECTION

Inspect plates and discs for flatness. They must not

be warped or cone shaped. Inspect facing material on all driving discs. Re-

place discs that are charred, glazed or heavily pitted.

Discs should also be replaced if they show evidence of

material flaking off or if facing material can be

scraped off easily. Inspect driving disc splines for

wear or other damage. Inspect steel plate surfaces for

burning, scoring, or damaged driving lugs. Replace if

necessary. Inspect steel plate lug grooves in clutch retainer

for smooth surfaces, plates must travel freely in

grooves. Inspect band contacting surface on clutch re-

tainer for scores, the contact surface should be pro-

tected from damage during disassembly and

handling. Note ball check in clutch retainer, make

sure ball moves freely. Inspect piston seal surfaces in

clutch retainer for nicks or deep scratches, light

scratches will not interfere with sealing of seals. In-

spect clutch retainer inner bore surface for wear from

reaction shaft support seal rings. Inspect clutch re-

tainer bushing for wear or scores. Inspect inside bore of piston for score marks, if

light, remove with crocus cloth. Inspect seal grooves

for nicks and burrs. Inspect seals for deterioration,

wear, and hardness. Inspect piston spring, retainer

and snap ring for distortion.

Fig. 4 Measuring Pump Clearance (Gear to Pocket)

Fig. 1 Reaction Shaft Support Bolts

Fig. 2 Reaction Shaft Support

Fig. 3 Inner and Outer Pump Gears

21 - 62 TRANSAXLE Ä

Page 2024 of 2438

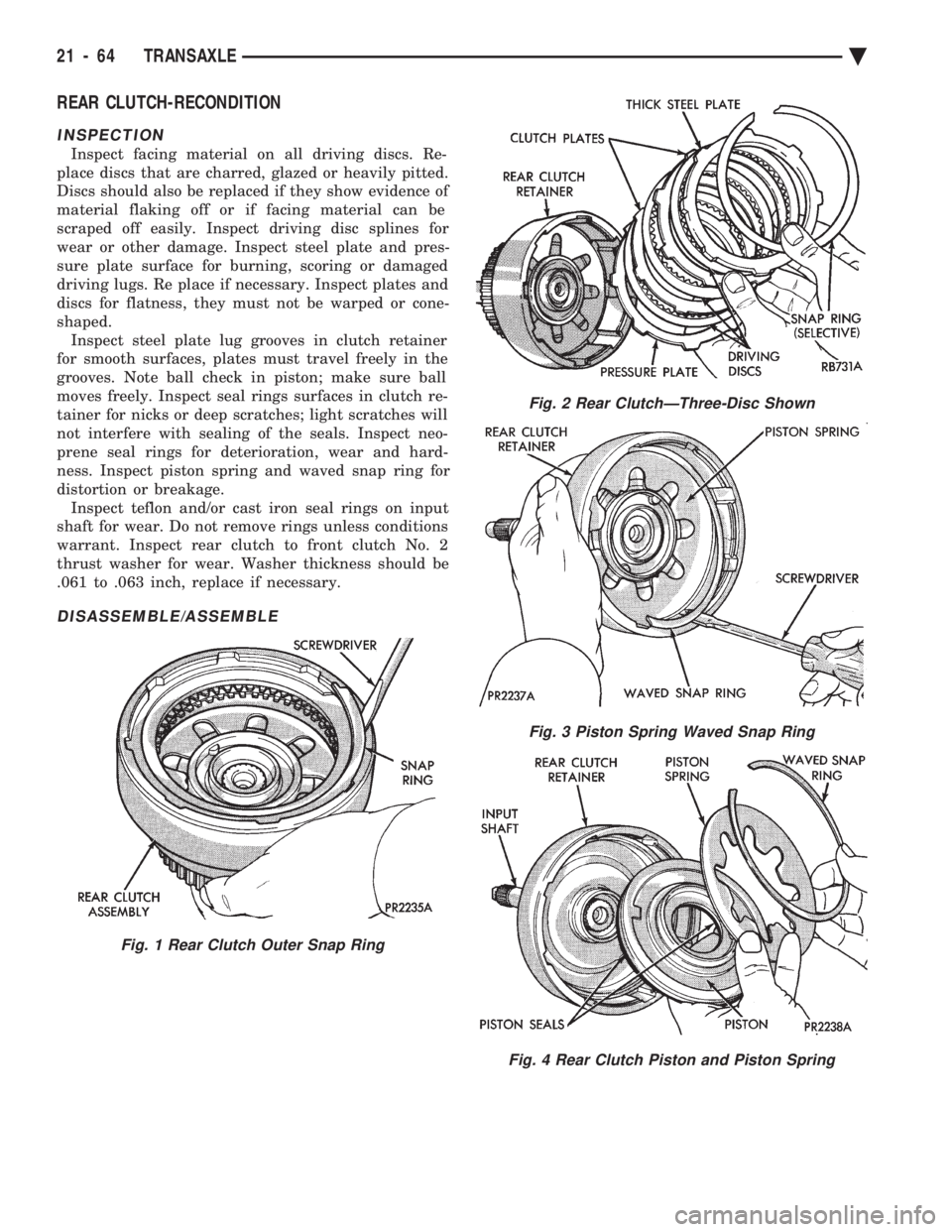

REAR CLUTCH-RECONDITION

INSPECTION

Inspect facing material on all driving discs. Re-

place discs that are charred, glazed or heavily pitted.

Discs should also be replaced if they show evidence of

material flaking off or if facing material can be

scraped off easily. Inspect driving disc splines for

wear or other damage. Inspect steel plate and pres-

sure plate surface for burning, scoring or damaged

driving lugs. Re place if necessary. Inspect plates and

discs for flatness, they must not be warped or cone-

shaped. Inspect steel plate lug grooves in clutch retainer

for smooth surfaces, plates must travel freely in the

grooves. Note ball check in piston; make sure ball

moves freely. Inspect seal rings surfaces in clutch re-

tainer for nicks or deep scratches; light scratches will

not interfere with sealing of the seals. Inspect neo-

prene seal rings for deterioration, wear and hard-

ness. Inspect piston spring and waved snap ring for

distortion or breakage. Inspect teflon and/or cast iron seal rings on input

shaft for wear. Do not remove rings unless conditions

warrant. Inspect rear clutch to front clutch No. 2

thrust washer for wear. Washer thickness should be

.061 to .063 inch, replace if necessary.

DISASSEMBLE/ASSEMBLE

Fig. 1 Rear Clutch Outer Snap Ring

Fig. 2 Rear ClutchÐThree-Disc Shown

Fig. 3 Piston Spring Waved Snap Ring

Fig. 4 Rear Clutch Piston and Piston Spring

21 - 64 TRANSAXLE Ä

Page 2048 of 2438

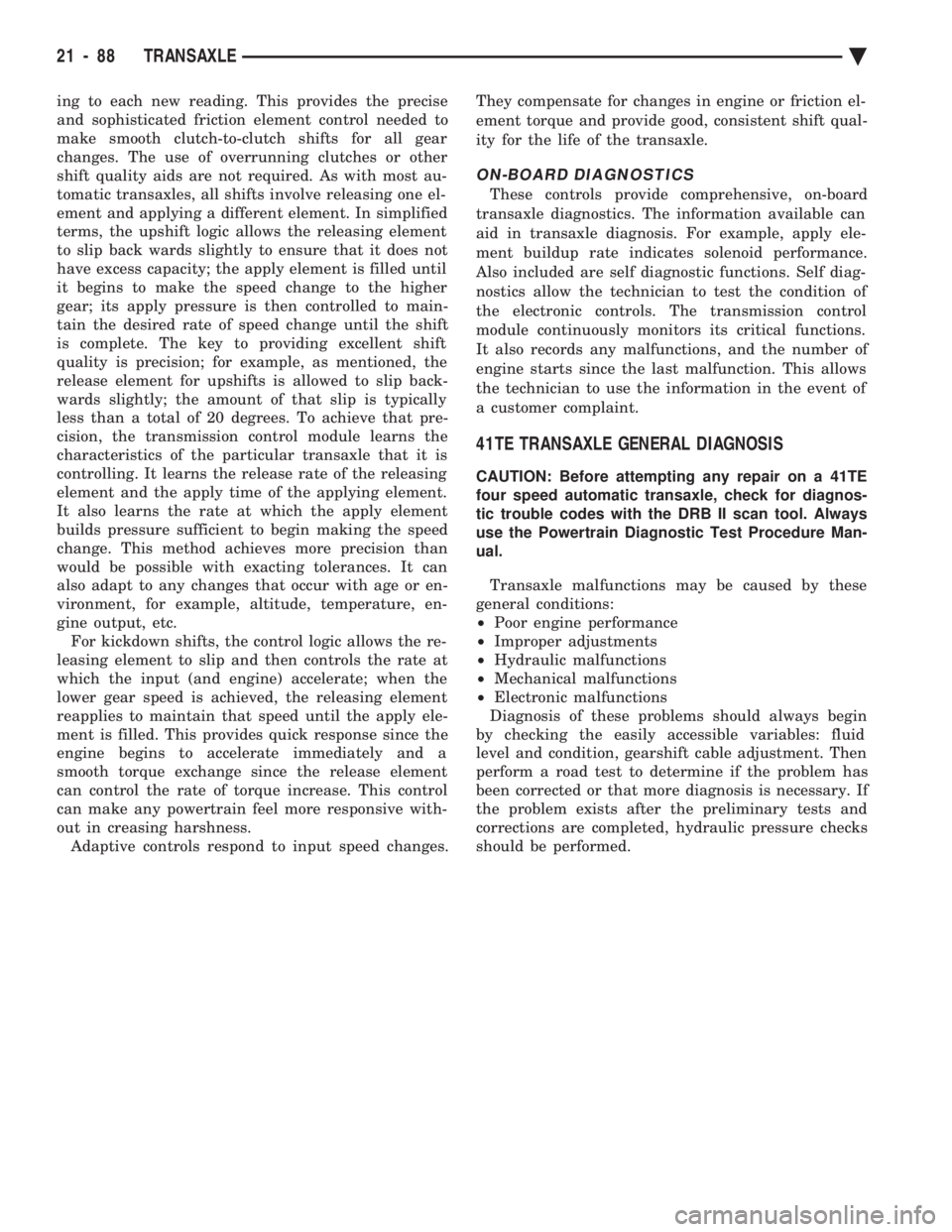

ing to each new reading. This provides the precise

and sophisticated friction element control needed to

make smooth clutch-to-clutch shifts for all gear

changes. The use of overrunning clutches or other

shift quality aids are not required. As with most au-

tomatic transaxles, all shifts involve releasing one el-

ement and applying a different element. In simplified

terms, the upshift logic allows the releasing element

to slip back wards slightly to ensure that it does not

have excess capacity; the apply element is filled until

it begins to make the speed change to the higher

gear; its apply pressure is then controlled to main-

tain the desired rate of speed change until the shift

is complete. The key to providing excellent shift

quality is precision; for example, as mentioned, the

release element for upshifts is allowed to slip back-

wards slightly; the amount of that slip is typically

less than a total of 20 degrees. To achieve that pre-

cision, the transmission control module learns the

characteristics of the particular transaxle that it is

controlling. It learns the release rate of the releasing

element and the apply time of the applying element.

It also learns the rate at which the apply element

builds pressure sufficient to begin making the speed

change. This method achieves more precision than

would be possible with exacting tolerances. It can

also adapt to any changes that occur with age or en-

vironment, for example, altitude, temperature, en-

gine output, etc. For kickdown shifts, the control logic allows the re-

leasing element to slip and then controls the rate at

which the input (and engine) accelerate; when the

lower gear speed is achieved, the releasing element

reapplies to maintain that speed until the apply ele-

ment is filled. This provides quick response since the

engine begins to accelerate immediately and a

smooth torque exchange since the release element

can control the rate of torque increase. This control

can make any powertrain feel more responsive with-

out in creasing harshness. Adaptive controls respond to input speed changes. They compensate for changes in engine or friction el-

ement torque and provide good, consistent shift qual-

ity for the life of the transaxle.

ON-BOARD DIAGNOSTICS

These controls provide comprehensive, on-board

transaxle diagnostics. The information available can

aid in transaxle diagnosis. For example, apply ele-

ment buildup rate indicates solenoid performance.

Also included are self diagnostic functions. Self diag-

nostics allow the technician to test the condition of

the electronic controls. The transmission control

module continuously monitors its critical functions.

It also records any malfunctions, and the number of

engine starts since the last malfunction. This allows

the technician to use the information in the event of

a customer complaint.

41TE TRANSAXLE GENERAL DIAGNOSIS

CAUTION: Before attempting any repair on a 41TE

four speed automatic transaxle, check for diagnos-

tic trouble codes with the DRB II scan tool. Always

use the Powertrain Diagnostic Test Procedure Man-

ual.

Transaxle malfunctions may be caused by these

general conditions:

² Poor engine performance

² Improper adjustments

² Hydraulic malfunctions

² Mechanical malfunctions

² Electronic malfunctions

Diagnosis of these problems should always begin

by checking the easily accessible variables: fluid

level and condition, gearshift cable adjustment. Then

perform a road test to determine if the problem has

been corrected or that more diagnosis is necessary. If

the problem exists after the preliminary tests and

corrections are completed, hydraulic pressure checks

should be performed.

21 - 88 TRANSAXLE Ä

Page 2063 of 2438

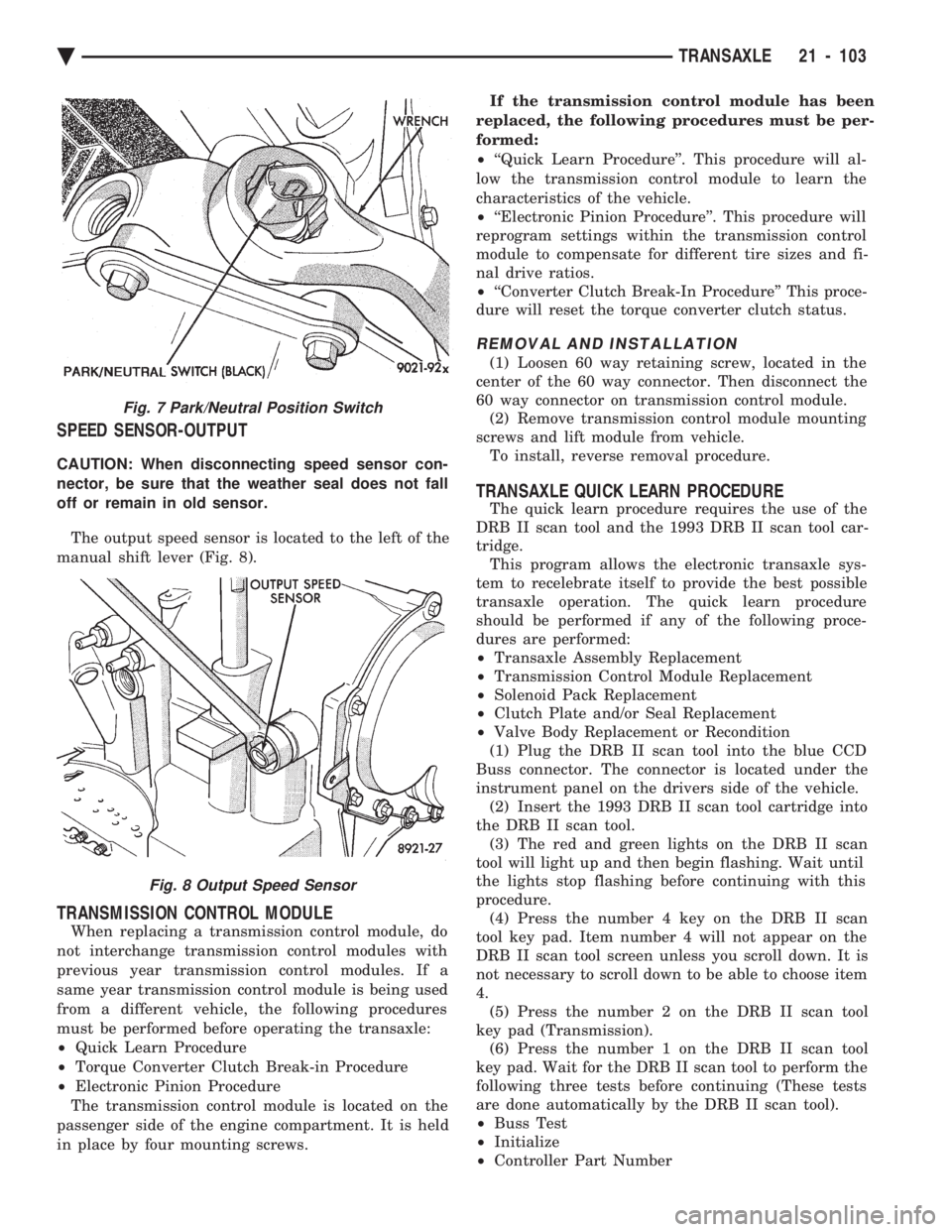

SPEED SENSOR-OUTPUT

CAUTION: When disconnecting speed sensor con-

nector, be sure that the weather seal does not fall

off or remain in old sensor. The output speed sensor is located to the left of the

manual shift lever (Fig. 8).

TRANSMISSION CONTROL MODULE

When replacing a transmission control module, do

not interchange transmission control modules with

previous year transmission control modules. If a

same year transmission control module is being used

from a different vehicle, the following procedures

must be performed before operating the transaxle:

² Quick Learn Procedure

² Torque Converter Clutch Break-in Procedure

² Electronic Pinion Procedure

The transmission control module is located on the

passenger side of the engine compartment. It is held

in place by four mounting screws. If the transmission control module has been

replaced, the following procedures must be per-

formed:

² ``Quick Learn Procedure''. This procedure will al-

low the transmission control module to learn the

characteristics of the vehicle.

² ``Electronic Pinion Procedure''. This procedure will

reprogram settings within the transmission control

module to compensate for different tire sizes and fi-

nal drive ratios.

² ``Converter Clutch Break-In Procedure'' This proce-

dure will reset the torque converter clutch status.

REMOVAL AND INSTALLATION

(1) Loosen 60 way retaining screw, located in the

center of the 60 way connector. Then disconnect the

60 way connector on transmission control module. (2) Remove transmission control module mounting

screws and lift module from vehicle. To install, reverse removal procedure.

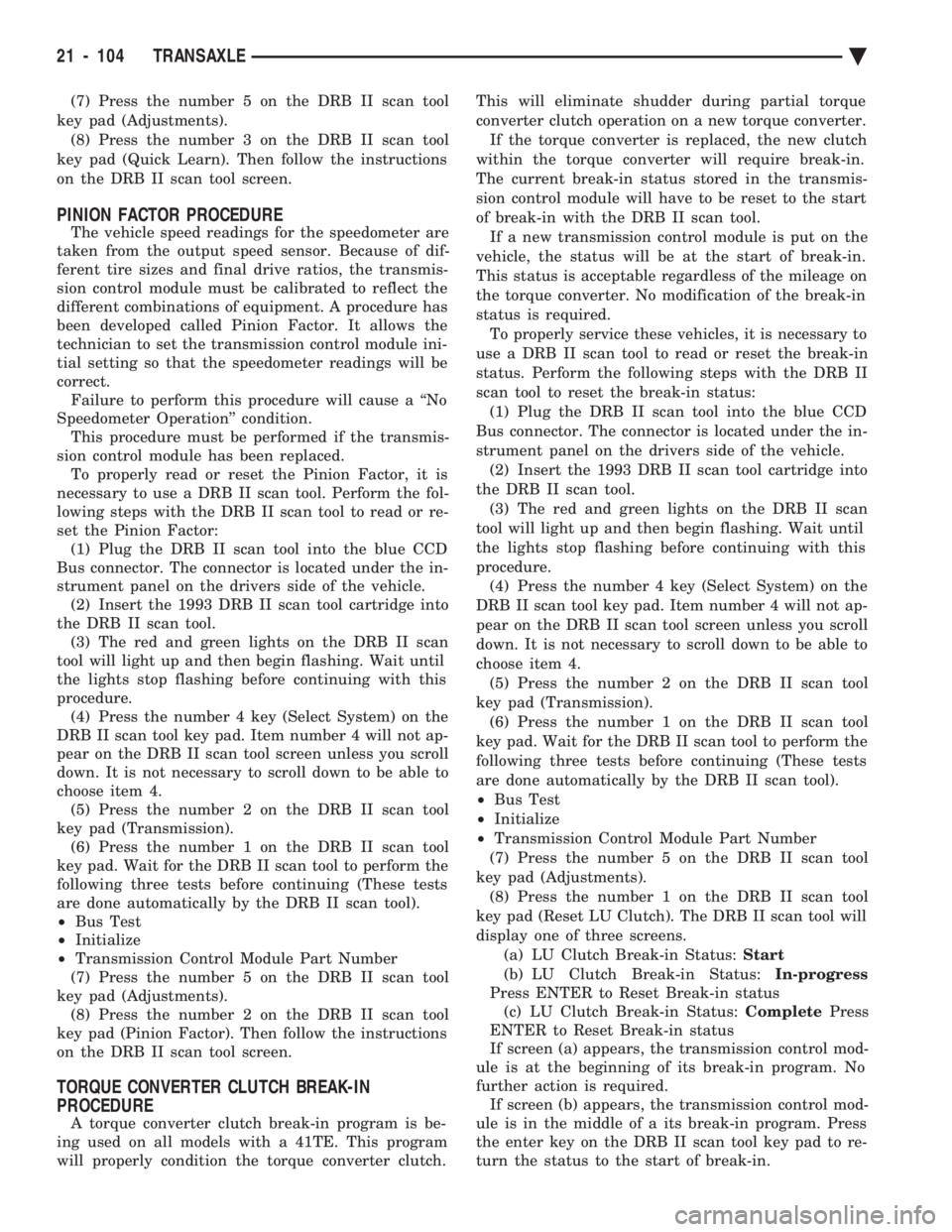

TRANSAXLE QUICK LEARN PROCEDURE

The quick learn procedure requires the use of the

DRB II scan tool and the 1993 DRB II scan tool car-

tridge. This program allows the electronic transaxle sys-

tem to recelebrate itself to provide the best possible

transaxle operation. The quick learn procedure

should be performed if any of the following proce-

dures are performed:

² Transaxle Assembly Replacement

² Transmission Control Module Replacement

² Solenoid Pack Replacement

² Clutch Plate and/or Seal Replacement

² Valve Body Replacement or Recondition

(1) Plug the DRB II scan tool into the blue CCD

Buss connector. The connector is located under the

instrument panel on the drivers side of the vehicle. (2) Insert the 1993 DRB II scan tool cartridge into

the DRB II scan tool. (3) The red and green lights on the DRB II scan

tool will light up and then begin flashing. Wait until

the lights stop flashing before continuing with this

procedure. (4) Press the number 4 key on the DRB II scan

tool key pad. Item number 4 will not appear on the

DRB II scan tool screen unless you scroll down. It is

not necessary to scroll down to be able to choose item

4. (5) Press the number 2 on the DRB II scan tool

key pad (Transmission). (6) Press the number 1 on the DRB II scan tool

key pad. Wait for the DRB II scan tool to perform the

following three tests before continuing (These tests

are done automatically by the DRB II scan tool).

² Buss Test

² Initialize

² Controller Part Number

Fig. 7 Park/Neutral Position Switch

Fig. 8 Output Speed Sensor

Ä TRANSAXLE 21 - 103

Page 2064 of 2438

(7) Press the number 5 on the DRB II scan tool

key pad (Adjustments). (8) Press the number 3 on the DRB II scan tool

key pad (Quick Learn). Then follow the instructions

on the DRB II scan tool screen.

PINION FACTOR PROCEDURE

The vehicle speed readings for the speedometer are

taken from the output speed sensor. Because of dif-

ferent tire sizes and final drive ratios, the transmis-

sion control module must be calibrated to reflect the

different combinations of equipment. A procedure has

been developed called Pinion Factor. It allows the

technician to set the transmission control module ini-

tial setting so that the speedometer readings will be

correct. Failure to perform this procedure will cause a ``No

Speedometer Operation'' condition. This procedure must be performed if the transmis-

sion control module has been replaced. To properly read or reset the Pinion Factor, it is

necessary to use a DRB II scan tool. Perform the fol-

lowing steps with the DRB II scan tool to read or re-

set the Pinion Factor: (1) Plug the DRB II scan tool into the blue CCD

Bus connector. The connector is located under the in-

strument panel on the drivers side of the vehicle. (2) Insert the 1993 DRB II scan tool cartridge into

the DRB II scan tool. (3) The red and green lights on the DRB II scan

tool will light up and then begin flashing. Wait until

the lights stop flashing before continuing with this

procedure. (4) Press the number 4 key (Select System) on the

DRB II scan tool key pad. Item number 4 will not ap-

pear on the DRB II scan tool screen unless you scroll

down. It is not necessary to scroll down to be able to

choose item 4. (5) Press the number 2 on the DRB II scan tool

key pad (Transmission). (6) Press the number 1 on the DRB II scan tool

key pad. Wait for the DRB II scan tool to perform the

following three tests before continuing (These tests

are done automatically by the DRB II scan tool).

² Bus Test

² Initialize

² Transmission Control Module Part Number

(7) Press the number 5 on the DRB II scan tool

key pad (Adjustments). (8) Press the number 2 on the DRB II scan tool

key pad (Pinion Factor). Then follow the instructions

on the DRB II scan tool screen.

TORQUE CONVERTER CLUTCH BREAK-IN

PROCEDURE

A torque converter clutch break-in program is be-

ing used on all models with a 41TE. This program

will properly condition the torque converter clutch. This will eliminate shudder during partial torque

converter clutch operation on a new torque converter.

If the torque converter is replaced, the new clutch

within the torque converter will require break-in.

The current break-in status stored in the transmis-

sion control module will have to be reset to the start

of break-in with the DRB II scan tool. If a new transmission control module is put on the

vehicle, the status will be at the start of break-in.

This status is acceptable regardless of the mileage on

the torque converter. No modification of the break-in

status is required. To properly service these vehicles, it is necessary to

use a DRB II scan tool to read or reset the break-in

status. Perform the following steps with the DRB II

scan tool to reset the break-in status: (1) Plug the DRB II scan tool into the blue CCD

Bus connector. The connector is located under the in-

strument panel on the drivers side of the vehicle. (2) Insert the 1993 DRB II scan tool cartridge into

the DRB II scan tool. (3) The red and green lights on the DRB II scan

tool will light up and then begin flashing. Wait until

the lights stop flashing before continuing with this

procedure. (4) Press the number 4 key (Select System) on the

DRB II scan tool key pad. Item number 4 will not ap-

pear on the DRB II scan tool screen unless you scroll

down. It is not necessary to scroll down to be able to

choose item 4. (5) Press the number 2 on the DRB II scan tool

key pad (Transmission). (6) Press the number 1 on the DRB II scan tool

key pad. Wait for the DRB II scan tool to perform the

following three tests before continuing (These tests

are done automatically by the DRB II scan tool).

² Bus Test

² Initialize

² Transmission Control Module Part Number

(7) Press the number 5 on the DRB II scan tool

key pad (Adjustments). (8) Press the number 1 on the DRB II scan tool

key pad (Reset LU Clutch). The DRB II scan tool will

display one of three screens. (a) LU Clutch Break-in Status: Start

(b) LU Clutch Break-in Status: In-progress

Press ENTER to Reset Break-in status (c) LU Clutch Break-in Status: CompletePress

ENTER to Reset Break-in status

If screen (a) appears, the transmission control mod-

ule is at the beginning of its break-in program. No

further action is required. If screen (b) appears, the transmission control mod-

ule is in the middle of a its break-in program. Press

the enter key on the DRB II scan tool key pad to re-

turn the status to the start of break-in.

21 - 104 TRANSAXLE Ä

Page 2154 of 2438

WHEELS SERVICE PROCEDURES INDEX

page page

General Information ........................ 6

Tire and Wheel Balance .................... 6

Tire and Wheel Run Out .................... 7 Wheel Installation

......................... 6

Wheel Replacement ....................... 6

GENERAL INFORMATION

Original equipment wheels are designed for proper

operation at all loads up to the maximum vehicle ca-

pacity. All models use steel or cast aluminum drop center

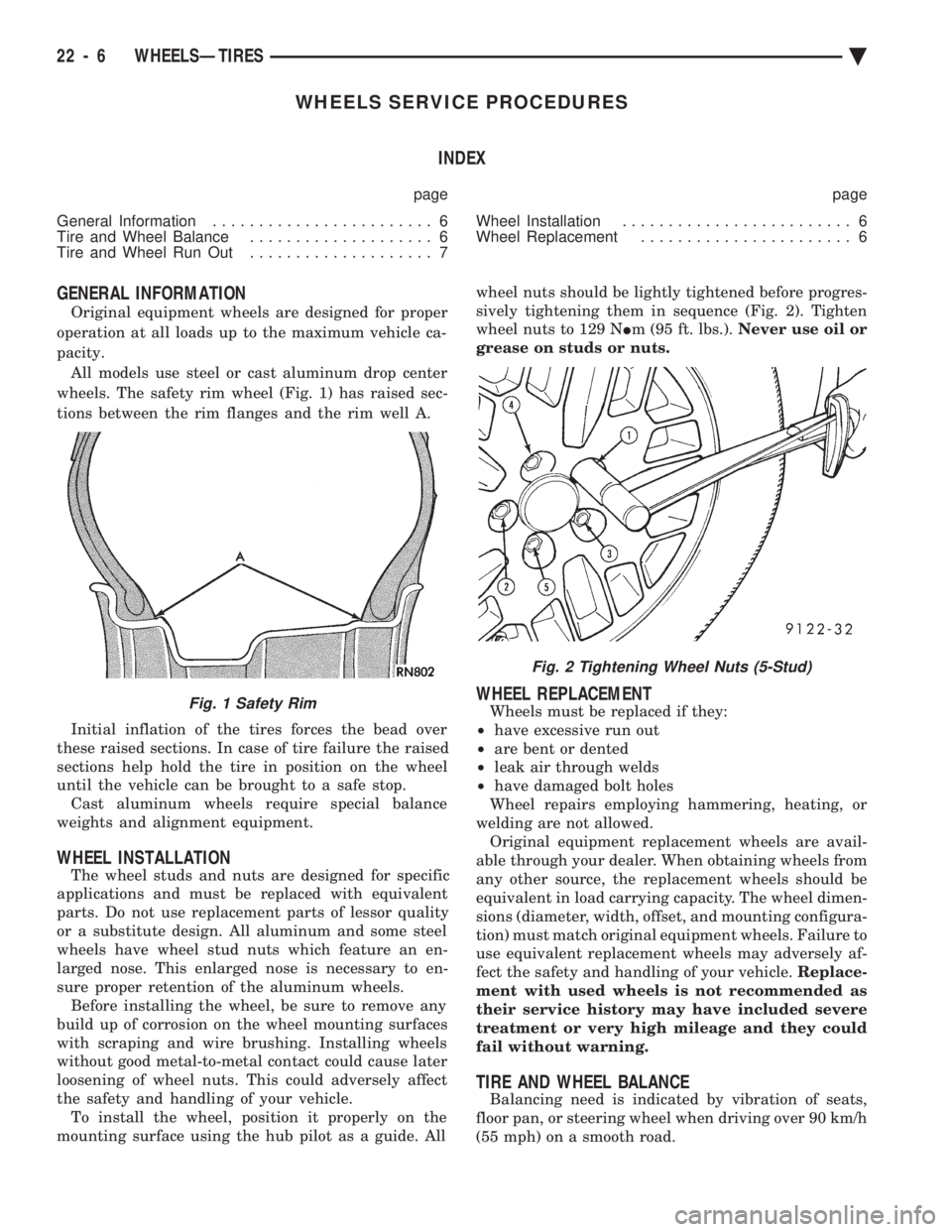

wheels. The safety rim wheel (Fig. 1) has raised sec-

tions between the rim flanges and the rim well A.

Initial inflation of the tires forces the bead over

these raised sections. In case of tire failure the raised

sections help hold the tire in position on the wheel

until the vehicle can be brought to a safe stop. Cast aluminum wheels require special balance

weights and alignment equipment.

WHEEL INSTALLATION

The wheel studs and nuts are designed for specific

applications and must be replaced with equivalent

parts. Do not use replacement parts of lessor quality

or a substitute design. All aluminum and some steel

wheels have wheel stud nuts which feature an en-

larged nose. This enlarged nose is necessary to en-

sure proper retention of the aluminum wheels. Before installing the wheel, be sure to remove any

build up of corrosion on the wheel mounting surfaces

with scraping and wire brushing. Installing wheels

without good metal-to-metal contact could cause later

loosening of wheel nuts. This could adversely affect

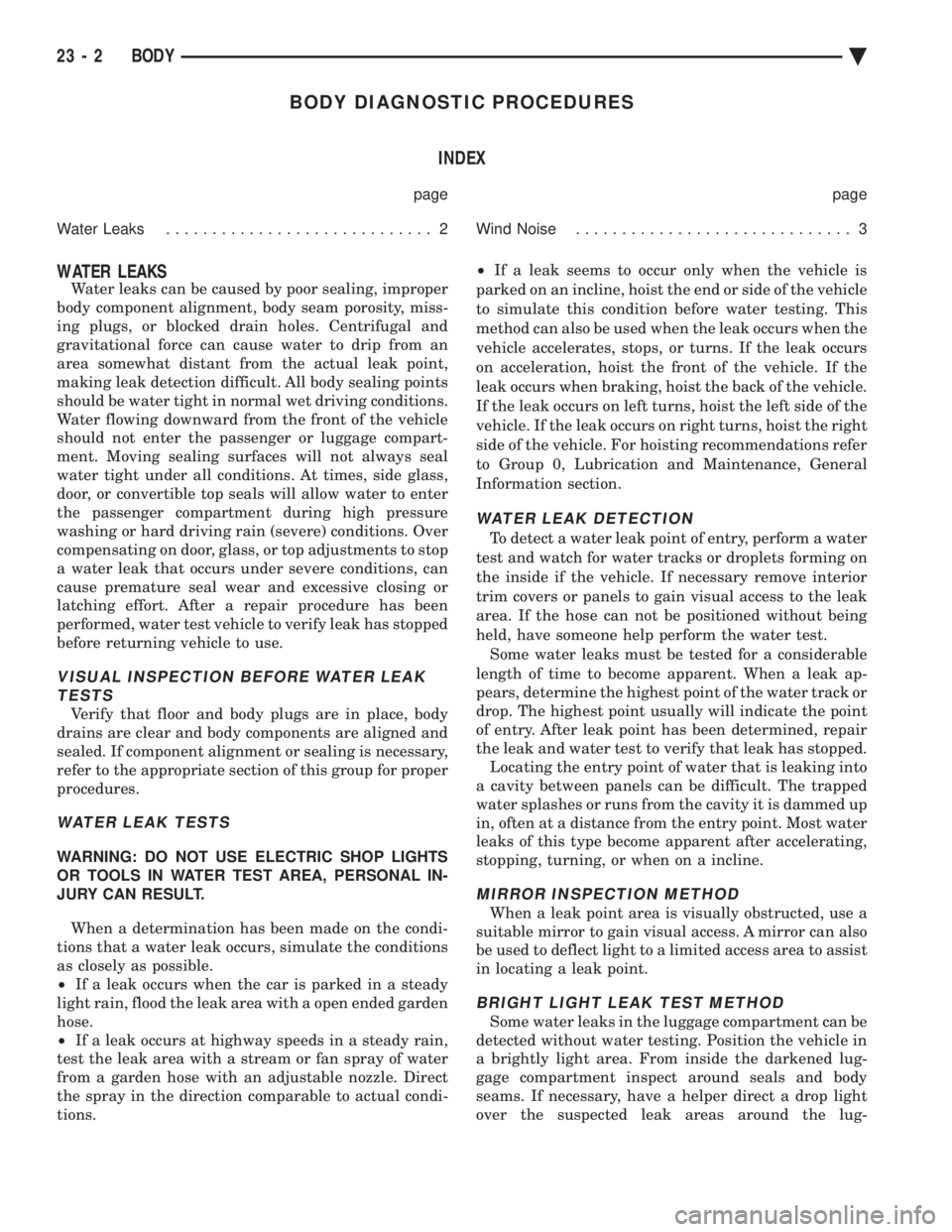

the safety and handling of your vehicle. To install the wheel, position it properly on the

mounting surface using the hub pilot as a guide. All wheel nuts should be lightly tightened before progres-

sively tightening them in sequence (Fig. 2). Tighten

wheel nuts to 129 N Im (95 ft. lbs.). Never use oil or

grease on studs or nuts.

WHEEL REPLACEMENT

Wheels must be replaced if they:

² have excessive run out

² are bent or dented

² leak air through welds

² have damaged bolt holes

Wheel repairs employing hammering, heating, or

welding are not allowed. Original equipment replacement wheels are avail-

able through your dealer. When obtaining wheels from

any other source, the replacement wheels should be

equivalent in load carrying capacity. The wheel dimen-

sions (diameter, width, offset, and mounting configura-

tion) must match original equipment wheels. Failure to

use equivalent replacement wheels may adversely af-

fect the safety and handling of your vehicle. Replace-

ment with used wheels is not recommended as

their service history may have included severe

treatment or very high mileage and they could

fail without warning.

TIRE AND WHEEL BALANCE

Balancing need is indicated by vibration of seats,

floor pan, or steering wheel when driving over 90 km/h

(55 mph) on a smooth road.

Fig. 1 Safety Rim

Fig. 2 Tightening Wheel Nuts (5-Stud)

22 - 6 WHEELSÐTIRES Ä

Page 2158 of 2438

BODY DIAGNOSTIC PROCEDURES INDEX

page page

Water Leaks ............................. 2 Wind Noise.............................. 3

WATER LEAKS

Water leaks can be caused by poor sealing, improper

body component alignment, body seam porosity, miss-

ing plugs, or blocked drain holes. Centrifugal and

gravitational force can cause water to drip from an

area somewhat distant from the actual leak point,

making leak detection difficult. All body sealing points

should be water tight in normal wet driving conditions.

Water flowing downward from the front of the vehicle

should not enter the passenger or luggage compart-

ment. Moving sealing surfaces will not always seal

water tight under all conditions. At times, side glass,

door, or convertible top seals will allow water to enter

the passenger compartment during high pressure

washing or hard driving rain (severe) conditions. Over

compensating on door, glass, or top adjustments to stop

a water leak that occurs under severe conditions, can

cause premature seal wear and excessive closing or

latching effort. After a repair procedure has been

performed, water test vehicle to verify leak has stopped

before returning vehicle to use.

VISUAL INSPECTION BEFORE WATER LEAK TESTS

Verify that floor and body plugs are in place, body

drains are clear and body components are aligned and

sealed. If component alignment or sealing is necessary,

refer to the appropriate section of this group for proper

procedures.

WATER LEAK TESTS

WARNING: DO NOT USE ELECTRIC SHOP LIGHTS

OR TOOLS IN WATER TEST AREA, PERSONAL IN-

JURY CAN RESULT.

When a determination has been made on the condi-

tions that a water leak occurs, simulate the conditions

as closely as possible.

² If a leak occurs when the car is parked in a steady

light rain, flood the leak area with a open ended garden

hose.

² If a leak occurs at highway speeds in a steady rain,

test the leak area with a stream or fan spray of water

from a garden hose with an adjustable nozzle. Direct

the spray in the direction comparable to actual condi-

tions. ²

If a leak seems to occur only when the vehicle is

parked on an incline, hoist the end or side of the vehicle

to simulate this condition before water testing. This

method can also be used when the leak occurs when the

vehicle accelerates, stops, or turns. If the leak occurs

on acceleration, hoist the front of the vehicle. If the

leak occurs when braking, hoist the back of the vehicle.

If the leak occurs on left turns, hoist the left side of the

vehicle. If the leak occurs on right turns, hoist the right

side of the vehicle. For hoisting recommendations refer

to Group 0, Lubrication and Maintenance, General

Information section.

WATER LEAK DETECTION

To detect a water leak point of entry, perform a water

test and watch for water tracks or droplets forming on

the inside if the vehicle. If necessary remove interior

trim covers or panels to gain visual access to the leak

area. If the hose can not be positioned without being

held, have someone help perform the water test. Some water leaks must be tested for a considerable

length of time to become apparent. When a leak ap-

pears, determine the highest point of the water track or

drop. The highest point usually will indicate the point

of entry. After leak point has been determined, repair

the leak and water test to verify that leak has stopped. Locating the entry point of water that is leaking into

a cavity between panels can be difficult. The trapped

water splashes or runs from the cavity it is dammed up

in, often at a distance from the entry point. Most water

leaks of this type become apparent after accelerating,

stopping, turning, or when on a incline.

MIRROR INSPECTION METHOD

When a leak point area is visually obstructed, use a

suitable mirror to gain visual access. A mirror can also

be used to deflect light to a limited access area to assist

in locating a leak point.

BRIGHT LIGHT LEAK TEST METHOD

Some water leaks in the luggage compartment can be

detected without water testing. Position the vehicle in

a brightly light area. From inside the darkened lug-

gage compartment inspect around seals and body

seams. If necessary, have a helper direct a drop light

over the suspected leak areas around the lug-

23 - 2 BODY Ä