light CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1796 of 2438

² Methanol Concentration Sensor

² Pressure relief/Rollover valve

² PCV Valve

² All fuel system and emission system hoses and

tubes

SYSTEM OPERATION

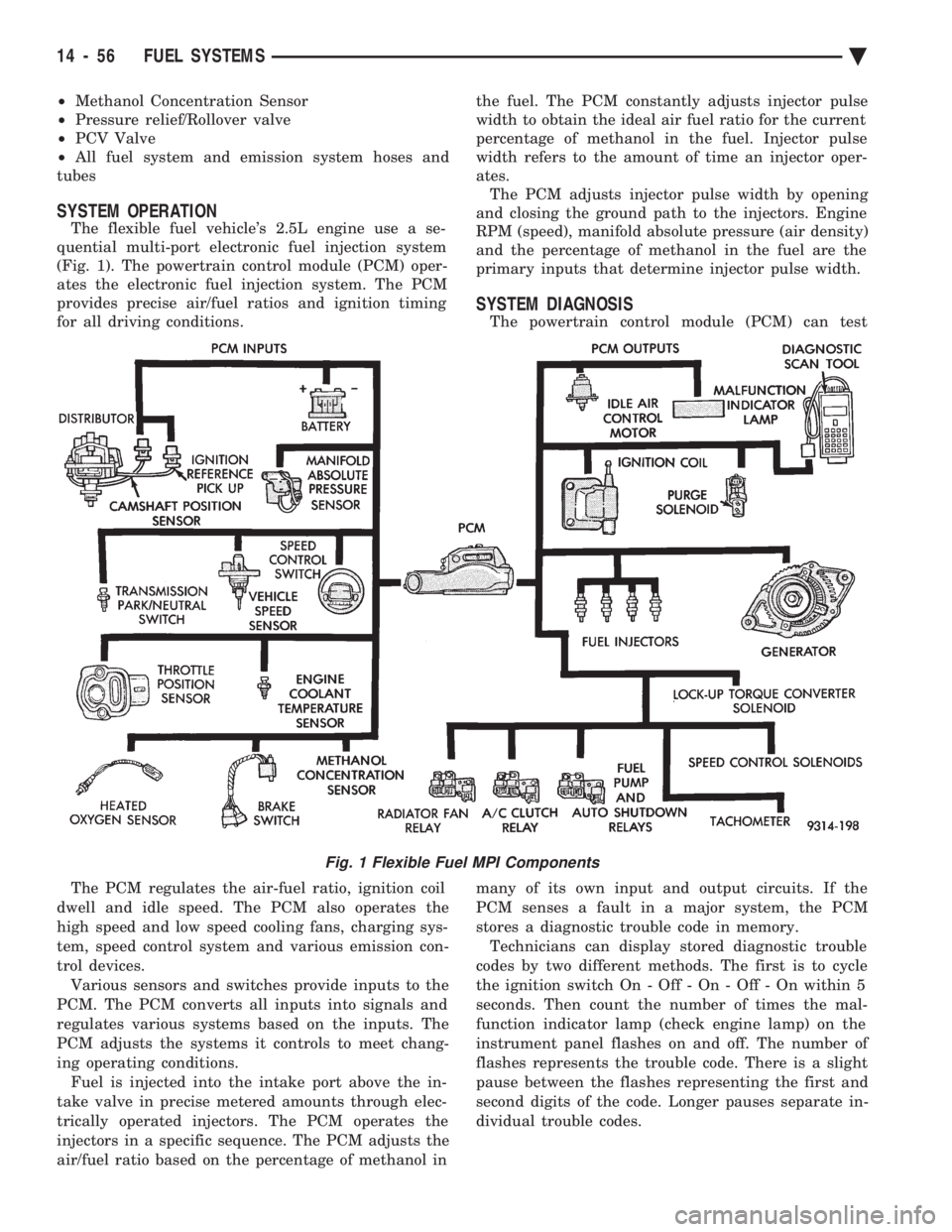

The flexible fuel vehicle's 2.5L engine use a se-

quential multi-port electronic fuel injection system

(Fig. 1). The powertrain control module (PCM) oper-

ates the electronic fuel injection system. The PCM

provides precise air/fuel ratios and ignition timing

for all driving conditions.

The PCM regulates the air-fuel ratio, ignition coil

dwell and idle speed. The PCM also operates the

high speed and low speed cooling fans, charging sys-

tem, speed control system and various emission con-

trol devices. Various sensors and switches provide inputs to the

PCM. The PCM converts all inputs into signals and

regulates various systems based on the inputs. The

PCM adjusts the systems it controls to meet chang-

ing operating conditions. Fuel is injected into the intake port above the in-

take valve in precise metered amounts through elec-

trically operated injectors. The PCM operates the

injectors in a specific sequence. The PCM adjusts the

air/fuel ratio based on the percentage of methanol in the fuel. The PCM constantly adjusts injector pulse

width to obtain the ideal air fuel ratio for the current

percentage of methanol in the fuel. Injector pulse

width refers to the amount of time an injector oper-

ates. The PCM adjusts injector pulse width by opening

and closing the ground path to the injectors. Engine

RPM (speed), manifold absolute pressure (air density)

and the percentage of methanol in the fuel are the

primary inputs that determine injector pulse width.

SYSTEM DIAGNOSIS

The powertrain control module (PCM) can test

many of its own input and output circuits. If the

PCM senses a fault in a major system, the PCM

stores a diagnostic trouble code in memory. Technicians can display stored diagnostic trouble

codes by two different methods. The first is to cycle

the ignition switch On - Off - On - Off - On within 5

seconds. Then count the number of times the mal-

function indicator lamp (check engine lamp) on the

instrument panel flashes on and off. The number of

flashes represents the trouble code. There is a slight

pause between the flashes representing the first and

second digits of the code. Longer pauses separate in-

dividual trouble codes.

Fig. 1 Flexible Fuel MPI Components

14 - 56 FUEL SYSTEMS Ä

Page 1798 of 2438

A/C clutch relay. To compensate for increased engine

load, the PCM also adjusts idle speed to a scheduled

RPM.

BATTERY VOLTAGEÐPCM INPUT

The powertrain control module (PCM) monitors the

battery voltage input to determine fuel injector pulse

width and generator field control. If battery voltage

is low, the PCM increases injector pulse width to

compensate.

BRAKE SWITCHÐPCM INPUT

When the brake switch activates, the powertrain

control module (PCM) receives an input indicating

that the brakes are being applied. After receiving the

input, the PCM vents the speed control servo. Vent-

ing the servo turns the speed control system off.

ENGINE COOLANT TEMPERATURE SENSORÐPCM

INPUT

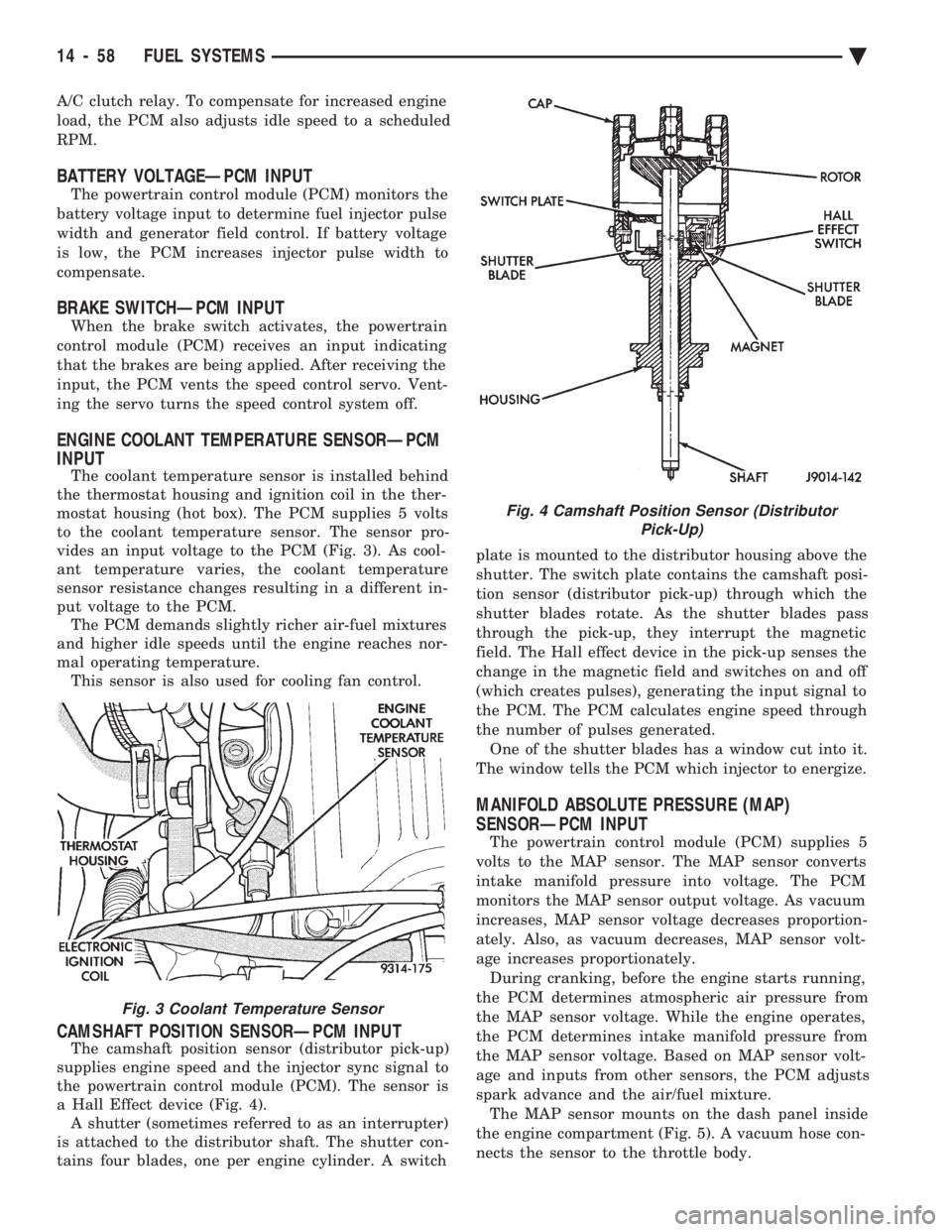

The coolant temperature sensor is installed behind

the thermostat housing and ignition coil in the ther-

mostat housing (hot box). The PCM supplies 5 volts

to the coolant temperature sensor. The sensor pro-

vides an input voltage to the PCM (Fig. 3). As cool-

ant temperature varies, the coolant temperature

sensor resistance changes resulting in a different in-

put voltage to the PCM. The PCM demands slightly richer air-fuel mixtures

and higher idle speeds until the engine reaches nor-

mal operating temperature. This sensor is also used for cooling fan control.

CAMSHAFT POSITION SENSORÐPCM INPUT

The camshaft position sensor (distributor pick-up)

supplies engine speed and the injector sync signal to

the powertrain control module (PCM). The sensor is

a Hall Effect device (Fig. 4). A shutter (sometimes referred to as an interrupter)

is attached to the distributor shaft. The shutter con-

tains four blades, one per engine cylinder. A switch plate is mounted to the distributor housing above the

shutter. The switch plate contains the camshaft posi-

tion sensor (distributor pick-up) through which the

shutter blades rotate. As the shutter blades pass

through the pick-up, they interrupt the magnetic

field. The Hall effect device in the pick-up senses the

change in the magnetic field and switches on and off

(which creates pulses), generating the input signal to

the PCM. The PCM calculates engine speed through

the number of pulses generated. One of the shutter blades has a window cut into it.

The window tells the PCM which injector to energize.

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSORÐPCM INPUT

The powertrain control module (PCM) supplies 5

volts to the MAP sensor. The MAP sensor converts

intake manifold pressure into voltage. The PCM

monitors the MAP sensor output voltage. As vacuum

increases, MAP sensor voltage decreases proportion-

ately. Also, as vacuum decreases, MAP sensor volt-

age increases proportionately. During cranking, before the engine starts running,

the PCM determines atmospheric air pressure from

the MAP sensor voltage. While the engine operates,

the PCM determines intake manifold pressure from

the MAP sensor voltage. Based on MAP sensor volt-

age and inputs from other sensors, the PCM adjusts

spark advance and the air/fuel mixture. The MAP sensor mounts on the dash panel inside

the engine compartment (Fig. 5). A vacuum hose con-

nects the sensor to the throttle body.

Fig. 3 Coolant Temperature Sensor

Fig. 4 Camshaft Position Sensor (Distributor Pick-Up)

14 - 58 FUEL SYSTEMS Ä

Page 1810 of 2438

2.5L FLEXIBLE FUEL MULTI-PORT FUEL INJECTIONÐON-BOARD DIAGNOSTICS INDEX

page page

Circuit Actuation Test Mode ................. 72

Diagnostic Trouble Codes ................... 71

General Information ....................... 70

High and Low Limits ....................... 71

Ignition Timing Procedure ................... 73 Monitored Circuits

........................ 70

Non-Monitored Circuits ..................... 70

Powertrain Control Module 60-Way Connector . . . 73

State Display Test Mode .................... 72

Throttle Body Minimum Air Flow Check Procedure.. 73

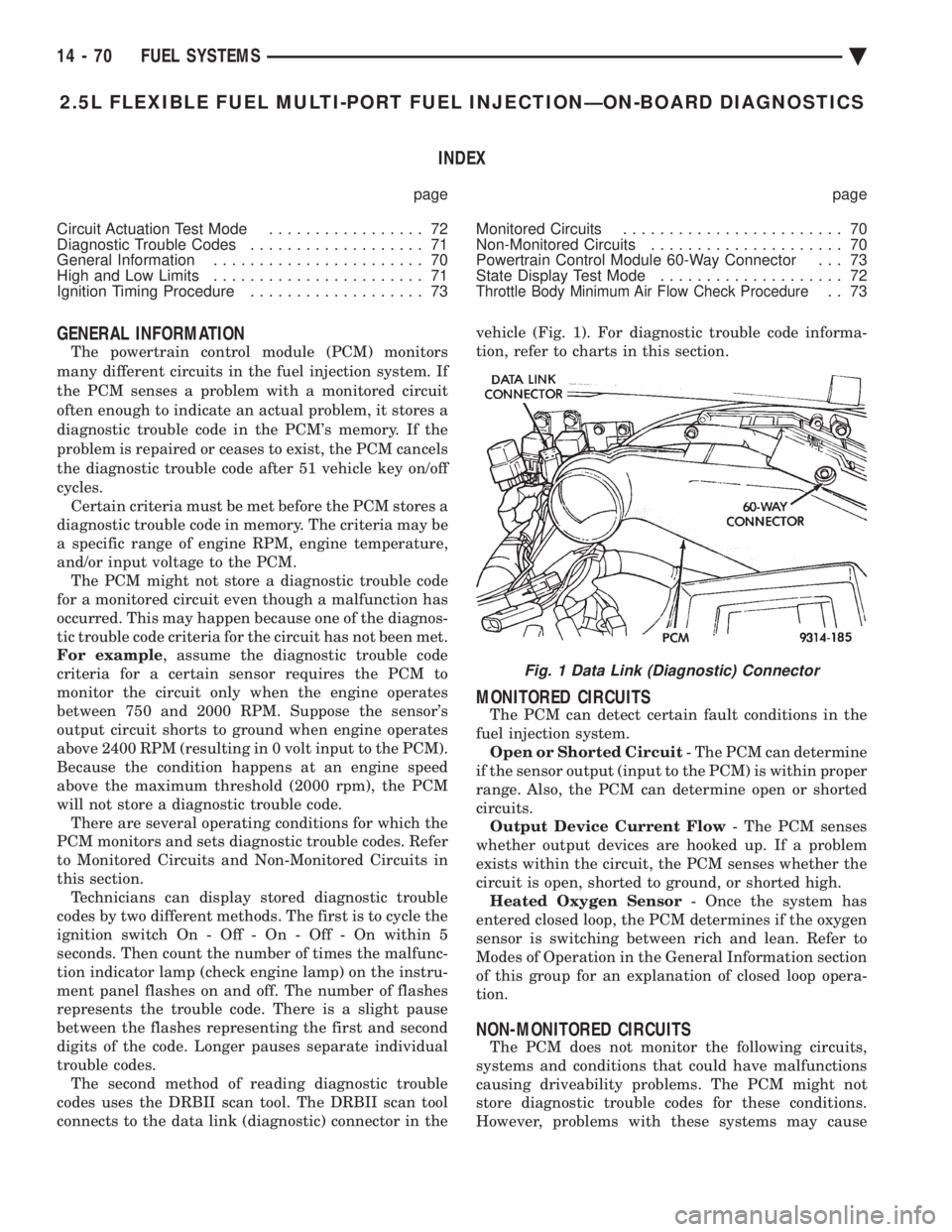

GENERAL INFORMATION

The powertrain control module (PCM) monitors

many different circuits in the fuel injection system. If

the PCM senses a problem with a monitored circuit

often enough to indicate an actual problem, it stores a

diagnostic trouble code in the PCM's memory. If the

problem is repaired or ceases to exist, the PCM cancels

the diagnostic trouble code after 51 vehicle key on/off

cycles. Certain criteria must be met before the PCM stores a

diagnostic trouble code in memory. The criteria may be

a specific range of engine RPM, engine temperature,

and/or input voltage to the PCM. The PCM might not store a diagnostic trouble code

for a monitored circuit even though a malfunction has

occurred. This may happen because one of the diagnos-

tic trouble code criteria for the circuit has not been met.

For example , assume the diagnostic trouble code

criteria for a certain sensor requires the PCM to

monitor the circuit only when the engine operates

between 750 and 2000 RPM. Suppose the sensor's

output circuit shorts to ground when engine operates

above 2400 RPM (resulting in 0 volt input to the PCM).

Because the condition happens at an engine speed

above the maximum threshold (2000 rpm), the PCM

will not store a diagnostic trouble code. There are several operating conditions for which the

PCM monitors and sets diagnostic trouble codes. Refer

to Monitored Circuits and Non-Monitored Circuits in

this section. Technicians can display stored diagnostic trouble

codes by two different methods. The first is to cycle the

ignition switch On - Off - On - Off - On within 5

seconds. Then count the number of times the malfunc-

tion indicator lamp (check engine lamp) on the instru-

ment panel flashes on and off. The number of flashes

represents the trouble code. There is a slight pause

between the flashes representing the first and second

digits of the code. Longer pauses separate individual

trouble codes. The second method of reading diagnostic trouble

codes uses the DRBII scan tool. The DRBII scan tool

connects to the data link (diagnostic) connector in the vehicle (Fig. 1). For diagnostic trouble code informa-

tion, refer to charts in this section.

MONITORED CIRCUITS

The PCM can detect certain fault conditions in the

fuel injection system. Open or Shorted Circuit - The PCM can determine

if the sensor output (input to the PCM) is within proper

range. Also, the PCM can determine open or shorted

circuits. Output Device Current Flow - The PCM senses

whether output devices are hooked up. If a problem

exists within the circuit, the PCM senses whether the

circuit is open, shorted to ground, or shorted high. Heated Oxygen Sensor - Once the system has

entered closed loop, the PCM determines if the oxygen

sensor is switching between rich and lean. Refer to

Modes of Operation in the General Information section

of this group for an explanation of closed loop opera-

tion.

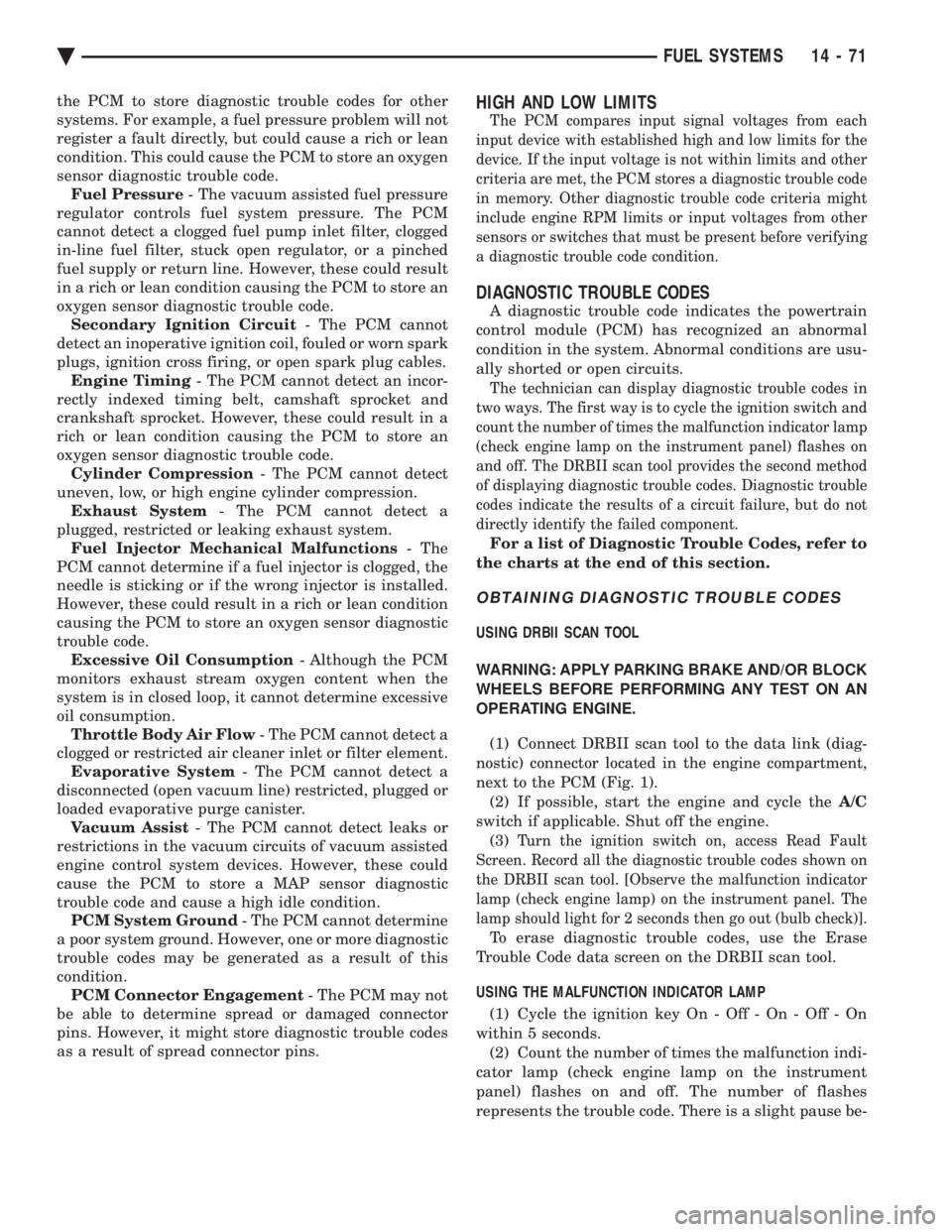

NON-MONITORED CIRCUITS

The PCM does not monitor the following circuits,

systems and conditions that could have malfunctions

causing driveability problems. The PCM might not

store diagnostic trouble codes for these conditions.

However, problems with these systems may cause

Fig. 1 Data Link (Diagnostic) Connector

14 - 70 FUEL SYSTEMS Ä

Page 1811 of 2438

the PCM to store diagnostic trouble codes for other

systems. For example, a fuel pressure problem will not

register a fault directly, but could cause a rich or lean

condition. This could cause the PCM to store an oxygen

sensor diagnostic trouble code. Fuel Pressure - The vacuum assisted fuel pressure

regulator controls fuel system pressure. The PCM

cannot detect a clogged fuel pump inlet filter, clogged

in-line fuel filter, stuck open regulator, or a pinched

fuel supply or return line. However, these could result

in a rich or lean condition causing the PCM to store an

oxygen sensor diagnostic trouble code. Secondary Ignition Circuit - The PCM cannot

detect an inoperative ignition coil, fouled or worn spark

plugs, ignition cross firing, or open spark plug cables. Engine Timing - The PCM cannot detect an incor-

rectly indexed timing belt, camshaft sprocket and

crankshaft sprocket. However, these could result in a

rich or lean condition causing the PCM to store an

oxygen sensor diagnostic trouble code. Cylinder Compression - The PCM cannot detect

uneven, low, or high engine cylinder compression. Exhaust System - The PCM cannot detect a

plugged, restricted or leaking exhaust system. Fuel Injector Mechanical Malfunctions - The

PCM cannot determine if a fuel injector is clogged, the

needle is sticking or if the wrong injector is installed.

However, these could result in a rich or lean condition

causing the PCM to store an oxygen sensor diagnostic

trouble code. Excessive Oil Consumption - Although the PCM

monitors exhaust stream oxygen content when the

system is in closed loop, it cannot determine excessive

oil consumption. Throttle Body Air Flow - The PCM cannot detect a

clogged or restricted air cleaner inlet or filter element. Evaporative System - The PCM cannot detect a

disconnected (open vacuum line) restricted, plugged or

loaded evaporative purge canister. Vacuum Assist - The PCM cannot detect leaks or

restrictions in the vacuum circuits of vacuum assisted

engine control system devices. However, these could

cause the PCM to store a MAP sensor diagnostic

trouble code and cause a high idle condition. PCM System Ground - The PCM cannot determine

a poor system ground. However, one or more diagnostic

trouble codes may be generated as a result of this

condition. PCM Connector Engagement - The PCM may not

be able to determine spread or damaged connector

pins. However, it might store diagnostic trouble codes

as a result of spread connector pins.HIGH AND LOW LIMITS

The PCM compares input signal voltages from each

input device with established high and low limits for the

device. If the input voltage is not within limits and other

criteria are met, the PCM stores a diagnostic trouble code

in memory. Other diagnostic trouble code criteria might

include engine RPM limits or input voltages from other

sensors or switches that must be present before verifying

a diagnostic trouble code condition.

DIAGNOSTIC TROUBLE CODES

A diagnostic trouble code indicates the powertrain

control module (PCM) has recognized an abnormal

condition in the system. Abnormal conditions are usu-

ally shorted or open circuits.

The technician can display diagnostic trouble codes in

two ways. The first way is to cycle the ignition switch and

count the number of times the malfunction indicator lamp

(check engine lamp on the instrument panel) flashes on

and off. The DRBII scan tool provides the second method

of displaying diagnostic trouble codes. Diagnostic trouble

codes indicate the results of a circuit failure, but do not

directly identify the failed component.

For a list of Diagnostic Trouble Codes, refer to

the charts at the end of this section.

OBTAINING DIAGNOSTIC TROUBLE CODES

USING DRBII SCAN TOOL

WARNING: APPLY PARKING BRAKE AND/OR BLOCK

WHEELS BEFORE PERFORMING ANY TEST ON AN

OPERATING ENGINE. (1) Connect DRBII scan tool to the data link (diag-

nostic) connector located in the engine compartment,

next to the PCM (Fig. 1). (2) If possible, start the engine and cycle the A/C

switch if applicable. Shut off the engine. (3)

Turn the ignition switch on, access Read Fault

Screen. Record all the diagnostic trouble codes shown on

the DRBII scan tool. [Observe the malfunction indicator

lamp (check engine lamp) on the instrument panel. The

lamp should light for 2 seconds then go out (bulb check)].

To erase diagnostic trouble codes, use the Erase

Trouble Code data screen on the DRBII scan tool.

USING THE MALFUNCTION INDICATOR LAMP (1) Cycle the ignition key On - Off - On - Off - On

within 5 seconds. (2) Count the number of times the malfunction indi-

cator lamp (check engine lamp on the instrument

panel) flashes on and off. The number of flashes

represents the trouble code. There is a slight pause be-

Ä FUEL SYSTEMS 14 - 71

Page 1813 of 2438

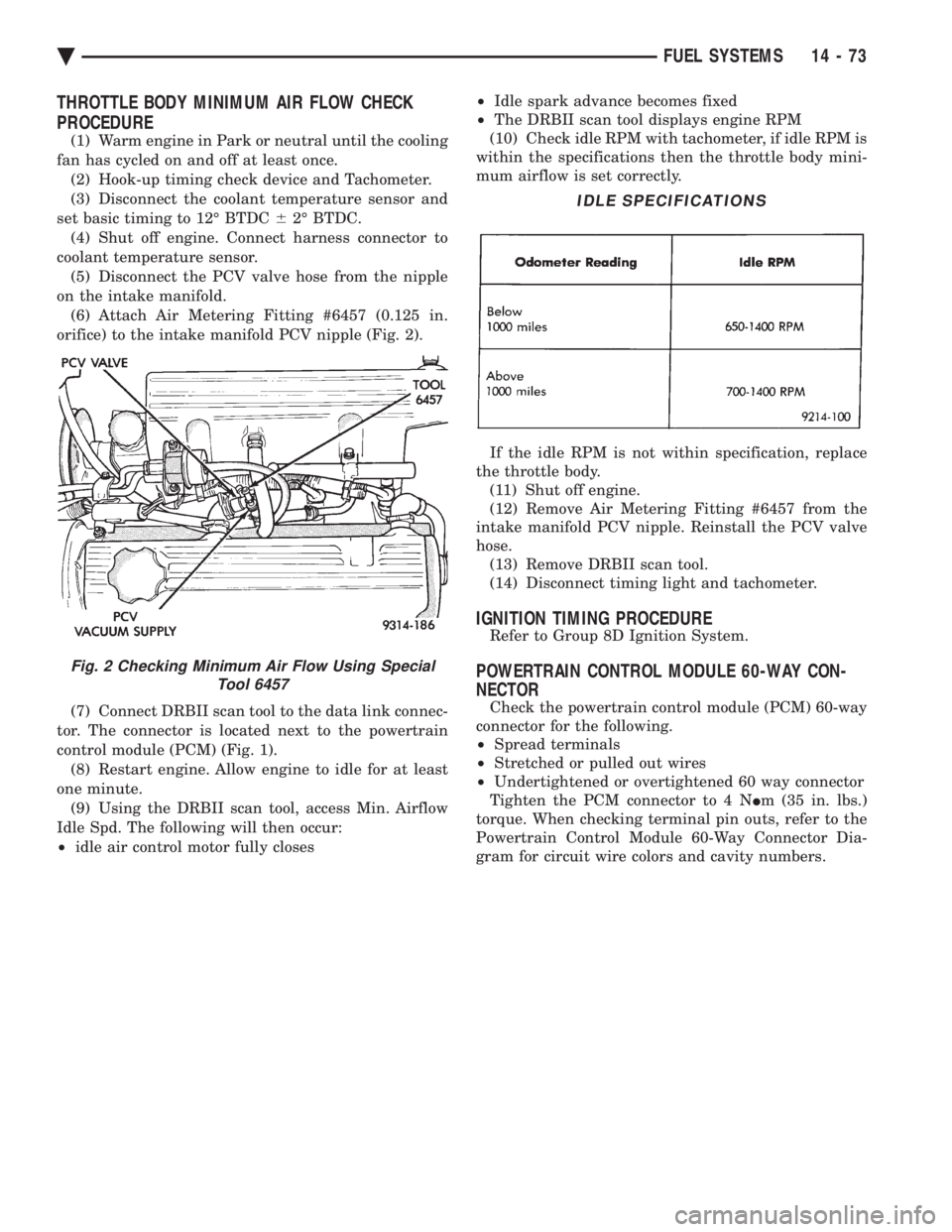

THROTTLE BODY MINIMUM AIR FLOW CHECK

PROCEDURE

(1) Warm engine in Park or neutral until the cooling

fan has cycled on and off at least once. (2) Hook-up timing check device and Tachometer.

(3) Disconnect the coolant temperature sensor and

set basic timing to 12É BTDC 62É BTDC.

(4) Shut off engine. Connect harness connector to

coolant temperature sensor. (5) Disconnect the PCV valve hose from the nipple

on the intake manifold. (6) Attach Air Metering Fitting #6457 (0.125 in.

orifice) to the intake manifold PCV nipple (Fig. 2).

(7) Connect DRBII scan tool to the data link connec-

tor. The connector is located next to the powertrain

control module (PCM) (Fig. 1). (8) Restart engine. Allow engine to idle for at least

one minute. (9) Using the DRBII scan tool, access Min. Airflow

Idle Spd. The following will then occur:

² idle air control motor fully closes ²

Idle spark advance becomes fixed

² The DRBII scan tool displays engine RPM

(10) Check idle RPM with tachometer, if idle RPM is

within the specifications then the throttle body mini-

mum airflow is set correctly.

If the idle RPM is not within specification, replace

the throttle body. (11) Shut off engine.

(12) Remove Air Metering Fitting #6457 from the

intake manifold PCV nipple. Reinstall the PCV valve

hose. (13) Remove DRBII scan tool.

(14) Disconnect timing light and tachometer.

IGNITION TIMING PROCEDURE

Refer to Group 8D Ignition System.

POWERTRAIN CONTROL MODULE 60-WAY CON-

NECTOR

Check the powertrain control module (PCM) 60-way

connector for the following.

² Spread terminals

² Stretched or pulled out wires

² Undertightened or overtightened 60 way connector

Tighten the PCM connector to 4 N Im (35 in. lbs.)

torque. When checking terminal pin outs, refer to the

Powertrain Control Module 60-Way Connector Dia-

gram for circuit wire colors and cavity numbers.

Fig. 2 Checking Minimum Air Flow Using Special Tool 6457

IDLE SPECIFICATIONS

Ä FUEL SYSTEMS 14 - 73

Page 1820 of 2438

(3) Ensure the injector holes are clean and all plugs

have been removed. (4) Lubricate the injector O-rings with a drop of

clean engine oil to ease installation. (5) Install the injector assembly into their holes.

Install mounting screws. Fuel rail assembly must be

drawn into the intake manifold evenly making sure

each injector enters its own hole. Once all injectors are

seated, tighten bolts to 23 N Im (200 in. lbs) torque.

(6) Connect vacuum hose to fuel pressure regulator.

(7) Close fuel tube clip around fuel tubes and install

fastener. (8) Lubricate the ends of the chassis fuel tubes with

a light coating of clean 30 weight engine oil. Connect

fuel supply and return hoses to chassis fuel tube

assembly. Pull back on the quick connect fittings to

ensure complete insertion. Refer to Quick Connect

Fittings in the Fuel Delivery section of this group. (9) Connect vacuum hose intake manifold nipple.

(10) Connect negative cable to battery.

CAUTION: When using the ASD Fuel System Test, the

Auto Shutdown (ASD) Relay remains energized for

either 7 minutes, until the test is stopped, or until the

ignition switch is turned to the Off position.

(11) With the DRBII scan tool, use the ASD Fuel

System Test to pressurize system and check for leaks.

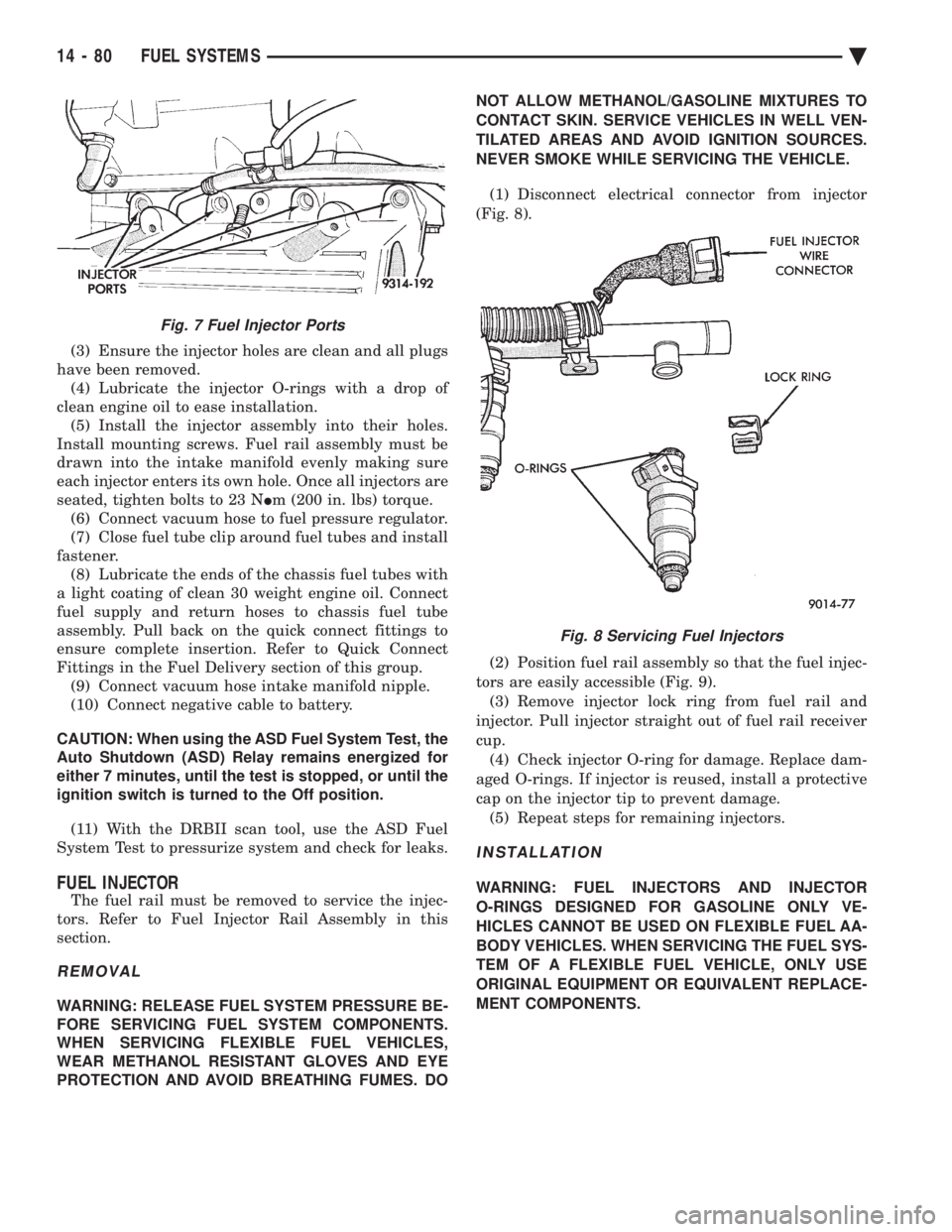

FUEL INJECTOR

The fuel rail must be removed to service the injec-

tors. Refer to Fuel Injector Rail Assembly in this

section.

REMOVAL

WARNING: RELEASE FUEL SYSTEM PRESSURE BE-

FORE SERVICING FUEL SYSTEM COMPONENTS.

WHEN SERVICING FLEXIBLE FUEL VEHICLES,

WEAR METHANOL RESISTANT GLOVES AND EYE

PROTECTION AND AVOID BREATHING FUMES. DO NOT ALLOW METHANOL/GASOLINE MIXTURES TO

CONTACT SKIN. SERVICE VEHICLES IN WELL VEN-

TILATED AREAS AND AVOID IGNITION SOURCES.

NEVER SMOKE WHILE SERVICING THE VEHICLE.

(1) Disconnect electrical connector from injector

(Fig. 8).

(2) Position fuel rail assembly so that the fuel injec-

tors are easily accessible (Fig. 9). (3) Remove injector lock ring from fuel rail and

injector. Pull injector straight out of fuel rail receiver

cup. (4) Check injector O-ring for damage. Replace dam-

aged O-rings. If injector is reused, install a protective

cap on the injector tip to prevent damage. (5) Repeat steps for remaining injectors.

INSTALLATION

WARNING: FUEL INJECTORS AND INJECTOR

O-RINGS DESIGNED FOR GASOLINE ONLY VE-

HICLES CANNOT BE USED ON FLEXIBLE FUEL AA-

BODY VEHICLES. WHEN SERVICING THE FUEL SYS-

TEM OF A FLEXIBLE FUEL VEHICLE, ONLY USE

ORIGINAL EQUIPMENT OR EQUIVALENT REPLACE-

MENT COMPONENTS.

Fig. 7 Fuel Injector Ports

Fig. 8 Servicing Fuel Injectors

14 - 80 FUEL SYSTEMS Ä

Page 1823 of 2438

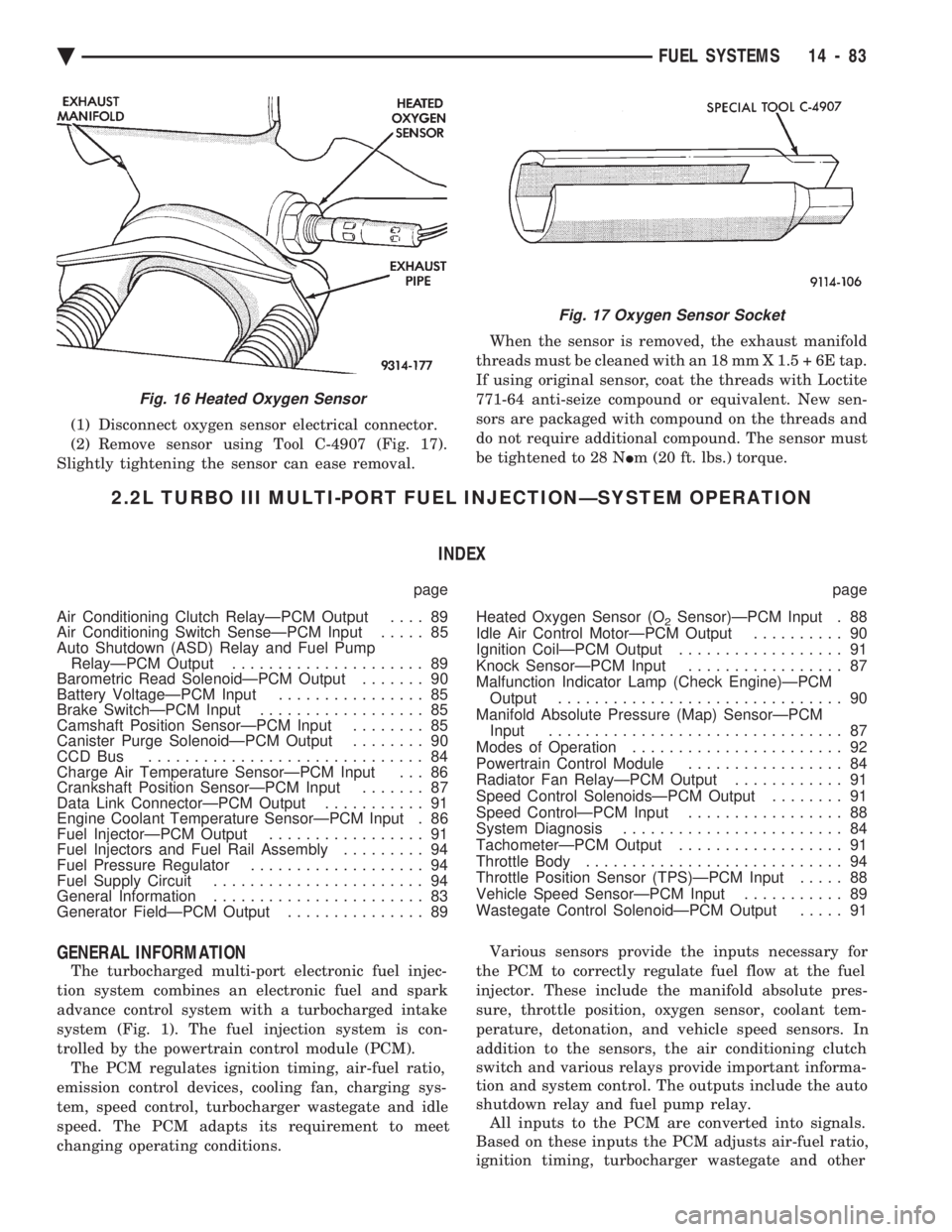

(1) Disconnect oxygen sensor electrical connector.

(2) Remove sensor using Tool C-4907 (Fig. 17).

Slightly tightening the sensor can ease removal. When the sensor is removed, the exhaust manifold

threads must be cleaned with an 18 mm X 1.5 + 6E tap.

If using original sensor, coat the threads with Loctite

771-64 anti-seize compound or equivalent. New sen-

sors are packaged with compound on the threads and

do not require additional compound. The sensor must

be tightened to 28 N Im (20 ft. lbs.) torque.

2.2L TURBO III MULTI-PORT FUEL INJECTIONÐSYSTEM OPERATION

INDEX

page page

Air Conditioning Clutch RelayÐPCM Output .... 89

Air Conditioning Switch SenseÐPCM Input ..... 85

Auto Shutdown (ASD) Relay and Fuel Pump RelayÐPCM Output ..................... 89

Barometric Read SolenoidÐPCM Output ....... 90

Battery VoltageÐPCM Input ................ 85

Brake SwitchÐPCM Input .................. 85

Camshaft Position SensorÐPCM Input ........ 85

Canister Purge SolenoidÐPCM Output ........ 90

CCD Bus .............................. 84

Charge Air Temperature SensorÐPCM Input . . . 86

Crankshaft Position SensorÐPCM Input ....... 87

Data Link ConnectorÐPCM Output ........... 91

Engine Coolant Temperature SensorÐPCM Input . 86

Fuel InjectorÐPCM Output ................. 91

Fuel Injectors and Fuel Rail Assembly ......... 94

Fuel Pressure Regulator ................... 94

Fuel Supply Circuit ....................... 94

General Information ....................... 83

Generator FieldÐPCM Output ............... 89 Heated Oxygen Sensor (O

2Sensor)ÐPCM Input . 88

Idle Air Control MotorÐPCM Output .......... 90

Ignition CoilÐPCM Output .................. 91

Knock SensorÐPCM Input ................. 87

Malfunction Indicator Lamp (Check Engine)ÐPCM Output ............................... 90

Manifold Absolute Pressure (Map) SensorÐPCM Input ................................ 87

Modes of Operation ....................... 92

Powertrain Control Module ................. 84

Radiator Fan RelayÐPCM Output ............ 91

Speed Control SolenoidsÐPCM Output ........ 91

Speed ControlÐPCM Input ................. 88

System Diagnosis ........................ 84

TachometerÐPCM Output .................. 91

Throttle Body ............................ 94

Throttle Position Sensor (TPS)ÐPCM Input ..... 88

Vehicle Speed SensorÐPCM Input ........... 89

Wastegate Control SolenoidÐPCM Output ..... 91

GENERAL INFORMATION

The turbocharged multi-port electronic fuel injec-

tion system combines an electronic fuel and spark

advance control system with a turbocharged intake

system (Fig. 1). The fuel injection system is con-

trolled by the powertrain control module (PCM). The PCM regulates ignition timing, air-fuel ratio,

emission control devices, cooling fan, charging sys-

tem, speed control, turbocharger wastegate and idle

speed. The PCM adapts its requirement to meet

changing operating conditions. Various sensors provide the inputs necessary for

the PCM to correctly regulate fuel flow at the fuel

injector. These include the manifold absolute pres-

sure, throttle position, oxygen sensor, coolant tem-

perature, detonation, and vehicle speed sensors. In

addition to the sensors, the air conditioning clutch

switch and various relays provide important informa-

tion and system control. The outputs include the auto

shutdown relay and fuel pump relay. All inputs to the PCM are converted into signals.

Based on these inputs the PCM adjusts air-fuel ratio,

ignition timing, turbocharger wastegate and other

Fig. 16 Heated Oxygen Sensor

Fig. 17 Oxygen Sensor Socket

Ä FUEL SYSTEMS 14 - 83

Page 1826 of 2438

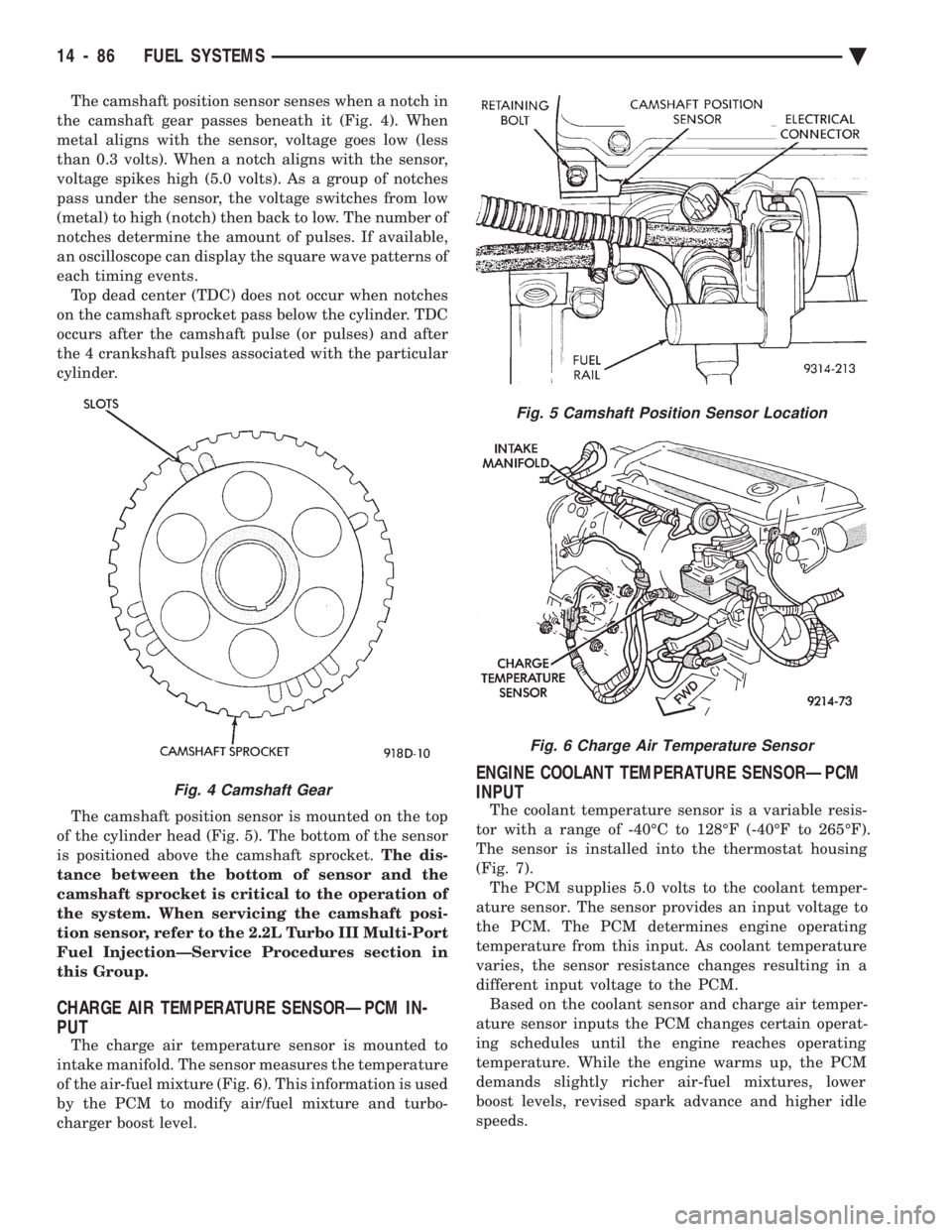

The camshaft position sensor senses when a notch in

the camshaft gear passes beneath it (Fig. 4). When

metal aligns with the sensor, voltage goes low (less

than 0.3 volts). When a notch aligns with the sensor,

voltage spikes high (5.0 volts). As a group of notches

pass under the sensor, the voltage switches from low

(metal) to high (notch) then back to low. The number of

notches determine the amount of pulses. If available,

an oscilloscope can display the square wave patterns of

each timing events. Top dead center (TDC) does not occur when notches

on the camshaft sprocket pass below the cylinder. TDC

occurs after the camshaft pulse (or pulses) and after

the 4 crankshaft pulses associated with the particular

cylinder.

The camshaft position sensor is mounted on the top

of the cylinder head (Fig. 5). The bottom of the sensor

is positioned above the camshaft sprocket. The dis-

tance between the bottom of sensor and the

camshaft sprocket is critical to the operation of

the system. When servicing the camshaft posi-

tion sensor, refer to the 2.2L Turbo III Multi-Port

Fuel InjectionÐService Procedures section in

this Group.

CHARGE AIR TEMPERATURE SENSORÐPCM IN-

PUT

The charge air temperature sensor is mounted to

intake manifold. The sensor measures the temperature

of the air-fuel mixture (Fig. 6). This information is used

by the PCM to modify air/fuel mixture and turbo-

charger boost level.

ENGINE COOLANT TEMPERATURE SENSORÐPCM

INPUT

The coolant temperature sensor is a variable resis-

tor with a range of -40ÉC to 128ÉF (-40ÉF to 265ÉF).

The sensor is installed into the thermostat housing

(Fig. 7). The PCM supplies 5.0 volts to the coolant temper-

ature sensor. The sensor provides an input voltage to

the PCM. The PCM determines engine operating

temperature from this input. As coolant temperature

varies, the sensor resistance changes resulting in a

different input voltage to the PCM. Based on the coolant sensor and charge air temper-

ature sensor inputs the PCM changes certain operat-

ing schedules until the engine reaches operating

temperature. While the engine warms up, the PCM

demands slightly richer air-fuel mixtures, lower

boost levels, revised spark advance and higher idle

speeds.

Fig. 5 Camshaft Position Sensor Location

Fig. 6 Charge Air Temperature Sensor

Fig. 4 Camshaft Gear

14 - 86 FUEL SYSTEMS Ä

Page 1844 of 2438

SYSTEM TESTS

Apply parking brake and/or block wheels be-

fore performing idle check or adjustment, or any

engine running tests.

OBTAINING DIAGNOSTIC TROUBLE CODES

(1) Connect DRBII scan tool to the data link connec-

tor (Fig. 1). (2) Start the engine if possible, cycle the trans mis-

sion selector and the A/Cswitch if applicable. Shut off

the engine. (3) Turn the ignition switch on, access Read Fault

Screen. Record all the fault messages shown on the

DRBII scan tool. Observe the malfunction indicator

lamp (check engine lamp on the instrument panel). The

lamp should light for 2 seconds then go out (bulb

check). Diagnostic trouble code erasure: access erase

diagnostic trouble code data.

STATE DISPLAY TEST MODE

The switch inputs used by the powertrain control

module (PCM) have only two recognized states, HIGH

and LOW. For this reason, the PCM cannot recognize

the difference between a selected switch position ver-

sus an open circuit, a short circuit, or a defective

switch. If the display changes, assume the entire

switch circuit to the PCM is functional. From the state

display screen access either State Display Inputs and

Outputs or State Display Sensors.

STATE DISPLAY INPUTS AND OUTPUTS

Connect the DRBII scan tool to the vehicle and access

the State Display screen. Then access Inputs and

Outputs. The following is a list of the engine control

system functions accessible through the Inputs and

Outputs screen. Speed Control Resume

Brake Switch

Speed Control On/Off

Speed Control Set

A/C Switch Sense

S/C Vent Solenoid S/C Vacuum Solenoid

A/C Clutch Relay

Baro Read Solenoid

Wastegate Solenoid

Auto Shutdown Relay

Radiator Fan Relay

Purge Solenoid

Malfunction Indicator Lamp (Check Engine Lamp)

STATE DISPLAY SENSORS

Connect the DRBII scan tool to the vehicle and ac-

cess the State Display screen. Then access Sensor

Display. The following is a list of the engine control

system functions accessible through the Sensor Dis-

play screen. Oxygen Sensor Signal

Coolant Temperature

Coolant Temp Sensor

Throttle Position

Minimum Throttle

Knock Sensor Signal

Battery Voltage

MAP Sensor Reading

Idle Air Control Motor Position

Adaptive Fuel Factor

Barometric Pressure

Min Airflow Idle Spd (speed)

Engine Speed

DIS Sensor Status

Fault #1 Key-On Info

Module Spark Advance

Cyl 1 Knock Retard

Cyl 2 Knock Retard

Cyl 3 Knock Retard

Cyl 4 Knock Retard

Boost Pressure Goal

Charge Temperature

Charge Temp Sensor

Speed Control Target

Fault #2 Key-on Info

Fault #3 Key-on Info

Speed Control Status

Charging System Goal

Theft Alarm Status

DIAGNOSTIC TROUBLE CODE DESCRIPTION (CON'T)

14 - 104 FUEL SYSTEMS Ä

Page 1852 of 2438

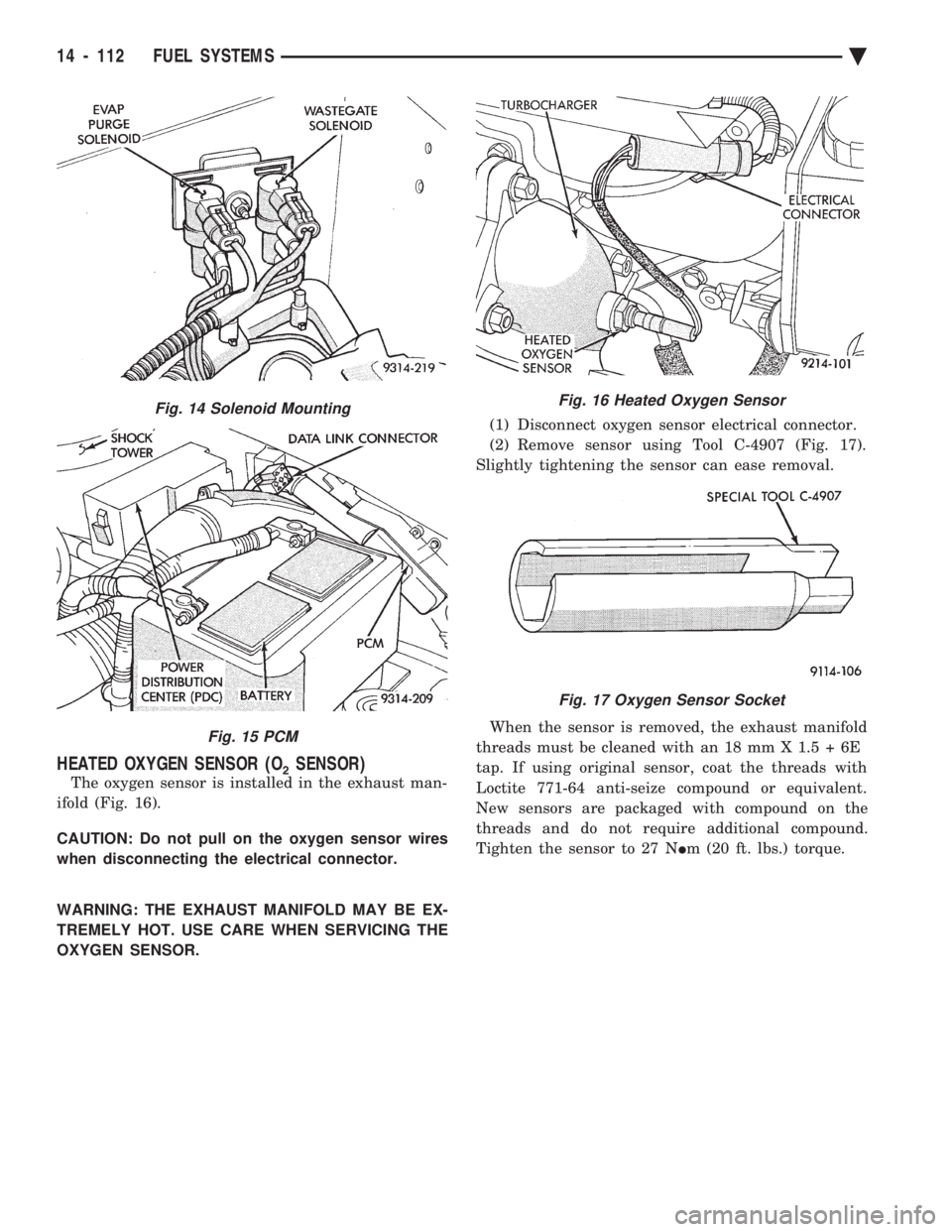

HEATED OXYGEN SENSOR (O2SENSOR)

The oxygen sensor is installed in the exhaust man-

ifold (Fig. 16).

CAUTION: Do not pull on the oxygen sensor wires

when disconnecting the electrical connector.

WARNING: THE EXHAUST MANIFOLD MAY BE EX-

TREMELY HOT. USE CARE WHEN SERVICING THE

OXYGEN SENSOR. (1) Disconnect oxygen sensor electrical connector.

(2) Remove sensor using Tool C-4907 (Fig. 17).

Slightly tightening the sensor can ease removal.

When the sensor is removed, the exhaust manifold

threads must be cleaned with an 18 mm X 1.5 + 6E

tap. If using original sensor, coat the threads with

Loctite 771-64 anti-seize compound or equivalent.

New sensors are packaged with compound on the

threads and do not require additional compound.

Tighten the sensor to 27 N Im (20 ft. lbs.) torque.

Fig. 14 Solenoid Mounting

Fig. 15 PCM

Fig. 16 Heated Oxygen Sensor

Fig. 17 Oxygen Sensor Socket

14 - 112 FUEL SYSTEMS Ä