warning CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1909 of 2438

3.3L AND 3.8L MULTI-PORT FUEL INJECTIONÐSERVICE PROCEDURES INDEX

page page

Camshaft Position Sensor Service ........... 176

Crankshaft Position Sensor ................ 176

EVAP Canister Purge Solenoid Service ....... 175

Fuel Injector ........................... 174

Fuel Injector Rail Assembly ................ 170

Fuel Pressure Regulator .................. 173

Fuel System Pressure Release Procedure ..... 169 Heated Oxygen Sensor (O

2Sensor) Service . . . 177

Idle Air Control Motor .................... 170

Manifold Absolute Pressure (MAP) Sensor ..... 175

PCM Service ........................... 175

Throttle Body ........................... 169

Throttle Body Removal ................... 169

Throttle Position Sensor .................. 169

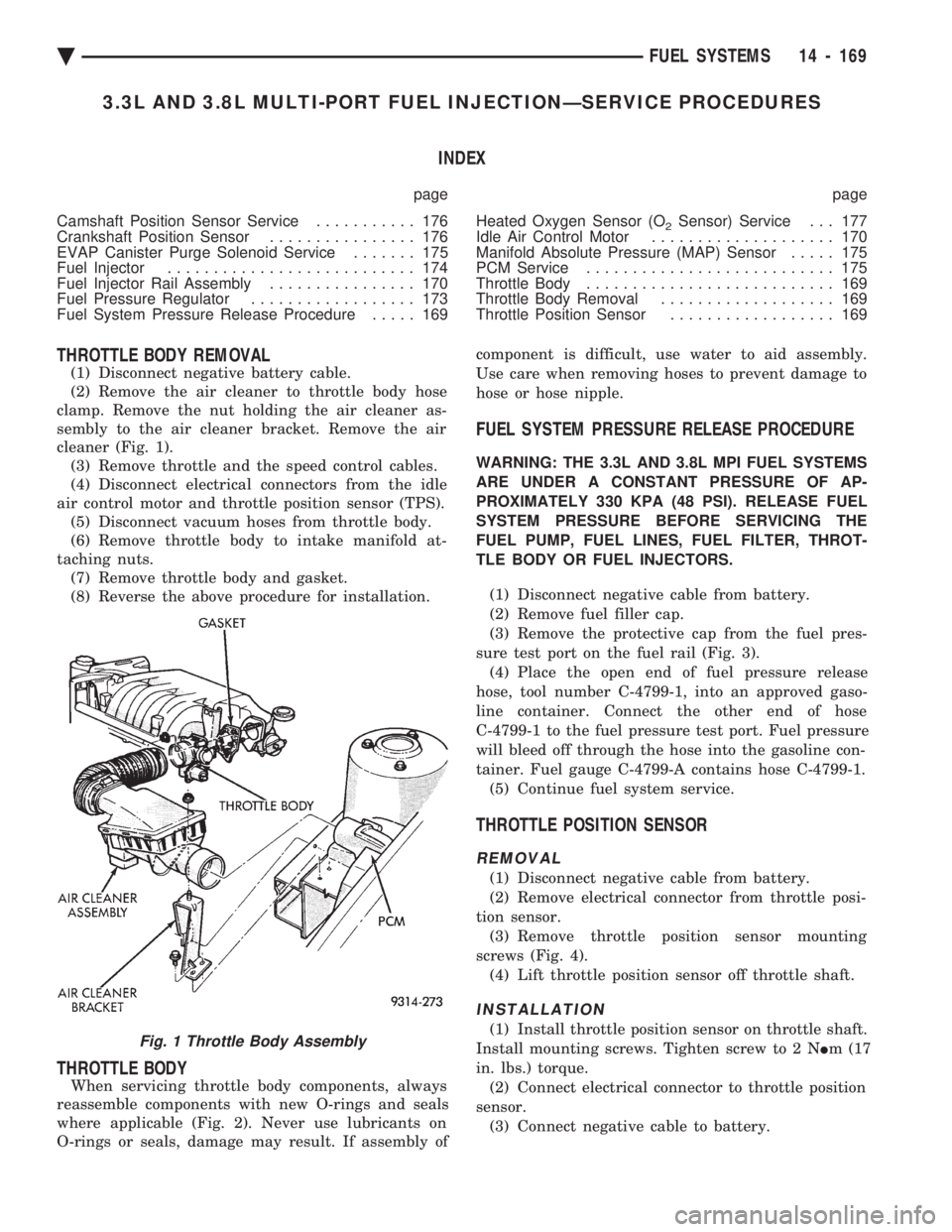

THROTTLE BODY REMOVAL

(1) Disconnect negative battery cable.

(2) Remove the air cleaner to throttle body hose

clamp. Remove the nut holding the air cleaner as-

sembly to the air cleaner bracket. Remove the air

cleaner (Fig. 1). (3) Remove throttle and the speed control cables.

(4) Disconnect electrical connectors from the idle

air control motor and throttle position sensor (TPS). (5) Disconnect vacuum hoses from throttle body.

(6) Remove throttle body to intake manifold at-

taching nuts. (7) Remove throttle body and gasket.

(8) Reverse the above procedure for installation.

THROTTLE BODY

When servicing throttle body components, always

reassemble components with new O-rings and seals

where applicable (Fig. 2). Never use lubricants on

O-rings or seals, damage may result. If assembly of component is difficult, use water to aid assembly.

Use care when removing hoses to prevent damage to

hose or hose nipple.

FUEL SYSTEM PRESSURE RELEASE PROCEDURE

WARNING: THE 3.3L AND 3.8L MPI FUEL SYSTEMS

ARE UNDER A CONSTANT PRESSURE OF AP-

PROXIMATELY 330 KPA (48 PSI). RELEASE FUEL

SYSTEM PRESSURE BEFORE SERVICING THE

FUEL PUMP, FUEL LINES, FUEL FILTER, THROT-

TLE BODY OR FUEL INJECTORS.

(1) Disconnect negative cable from battery.

(2) Remove fuel filler cap.

(3) Remove the protective cap from the fuel pres-

sure test port on the fuel rail (Fig. 3). (4) Place the open end of fuel pressure release

hose, tool number C-4799-1, into an approved gaso-

line container. Connect the other end of hose

C-4799-1 to the fuel pressure test port. Fuel pressure

will bleed off through the hose into the gasoline con-

tainer. Fuel gauge C-4799-A contains hose C-4799-1. (5) Continue fuel system service.

THROTTLE POSITION SENSOR

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove electrical connector from throttle posi-

tion sensor. (3) Remove throttle position sensor mounting

screws (Fig. 4). (4) Lift throttle position sensor off throttle shaft.

INSTALLATION

(1) Install throttle position sensor on throttle shaft.

Install mounting screws. Tighten screw to 2 N Im (17

in. lbs.) torque. (2) Connect electrical connector to throttle position

sensor. (3) Connect negative cable to battery.Fig. 1 Throttle Body Assembly

Ä FUEL SYSTEMS 14 - 169

Page 1911 of 2438

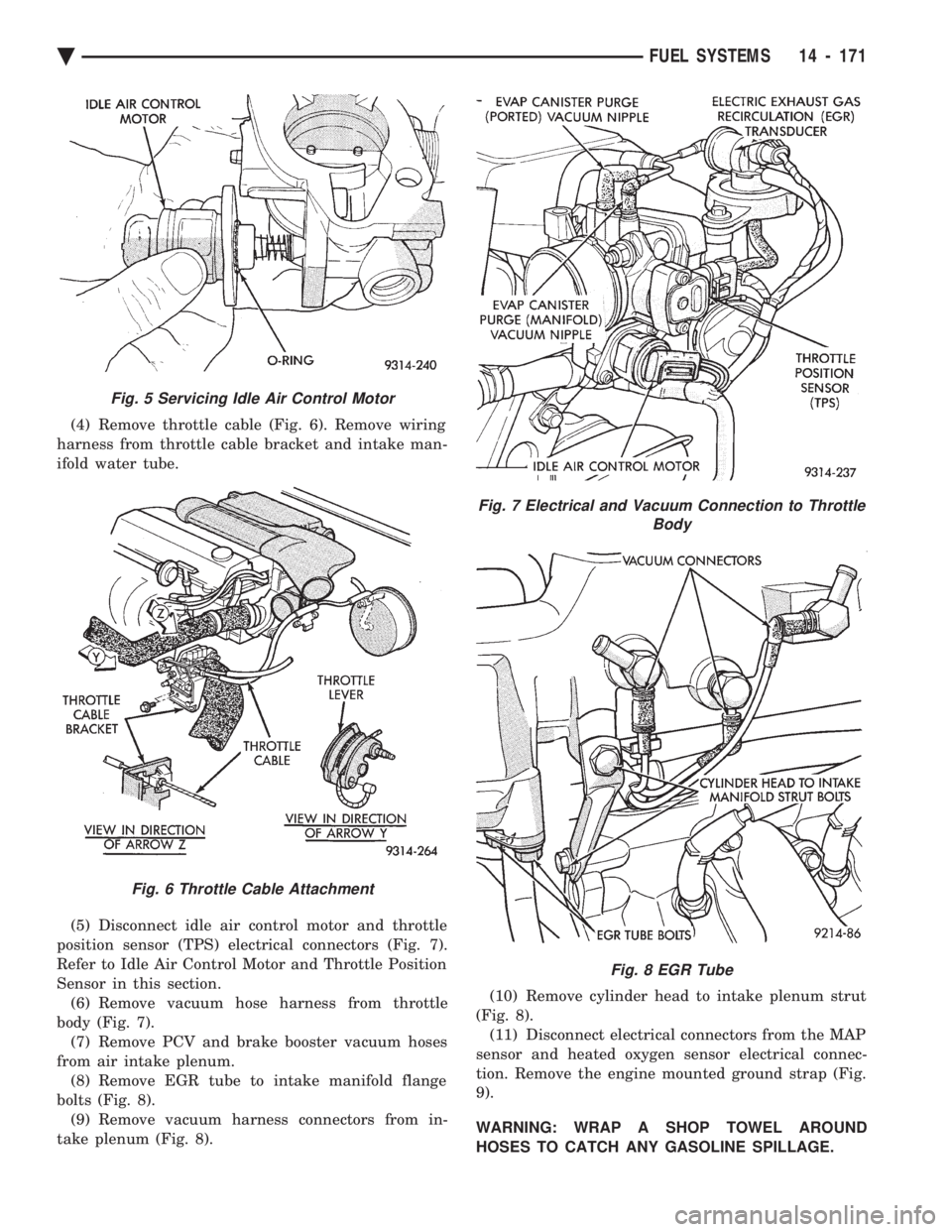

(4) Remove throttle cable (Fig. 6). Remove wiring

harness from throttle cable bracket and intake man-

ifold water tube.

(5) Disconnect idle air control motor and throttle

position sensor (TPS) electrical connectors (Fig. 7).

Refer to Idle Air Control Motor and Throttle Position

Sensor in this section. (6) Remove vacuum hose harness from throttle

body (Fig. 7). (7) Remove PCV and brake booster vacuum hoses

from air intake plenum. (8) Remove EGR tube to intake manifold flange

bolts (Fig. 8). (9) Remove vacuum harness connectors from in-

take plenum (Fig. 8). (10) Remove cylinder head to intake plenum strut

(Fig. 8). (11) Disconnect electrical connectors from the MAP

sensor and heated oxygen sensor electrical connec-

tion. Remove the engine mounted ground strap (Fig.

9).

WARNING: WRAP A SHOP TOWEL AROUND

HOSES TO CATCH ANY GASOLINE SPILLAGE.

Fig. 5 Servicing Idle Air Control Motor

Fig. 6 Throttle Cable Attachment

Fig. 7 Electrical and Vacuum Connection to Throttle Body

Fig. 8 EGR Tube

Ä FUEL SYSTEMS 14 - 171

Page 1914 of 2438

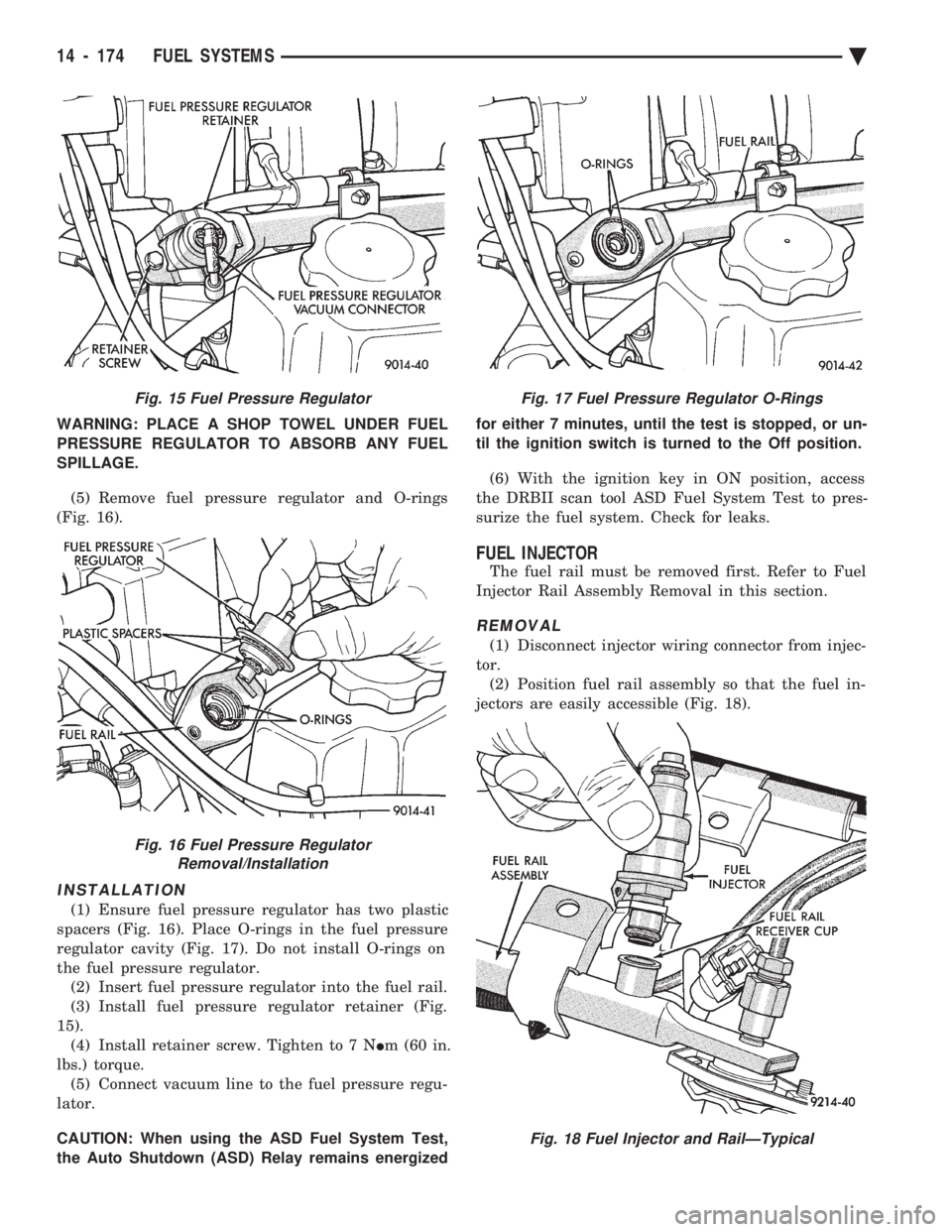

WARNING: PLACE A SHOP TOWEL UNDER FUEL

PRESSURE REGULATOR TO ABSORB ANY FUEL

SPILLAGE.

(5) Remove fuel pressure regulator and O-rings

(Fig. 16).

INSTALLATION

(1) Ensure fuel pressure regulator has two plastic

spacers (Fig. 16). Place O-rings in the fuel pressure

regulator cavity (Fig. 17). Do not install O-rings on

the fuel pressure regulator. (2) Insert fuel pressure regulator into the fuel rail.

(3) Install fuel pressure regulator retainer (Fig.

15). (4) Install retainer screw. Tighten to 7 N Im (60 in.

lbs.) torque. (5) Connect vacuum line to the fuel pressure regu-

lator.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized for either 7 minutes, until the test is stopped, or un-

til the ignition switch is turned to the Off position.

(6) With the ignition key in ON position, access

the DRBII scan tool ASD Fuel System Test to pres-

surize the fuel system. Check for leaks.

FUEL INJECTOR

The fuel rail must be removed first. Refer to Fuel

Injector Rail Assembly Removal in this section.

REMOVAL

(1) Disconnect injector wiring connector from injec-

tor. (2) Position fuel rail assembly so that the fuel in-

jectors are easily accessible (Fig. 18).

Fig. 15 Fuel Pressure Regulator

Fig. 16 Fuel Pressure Regulator Removal/Installation

Fig. 17 Fuel Pressure Regulator O-Rings

Fig. 18 Fuel Injector and RailÐTypical

14 - 174 FUEL SYSTEMS Ä

Page 1917 of 2438

is made with the camshaft gear. While holding the

sensor in this position, install and tighten the retain-

ing bolt 12 N Im (105 in. lbs.) torque.

(2) Connect camshaft position sensor electrical con-

nector to harness connector. Position connector away

from the accessory belt.

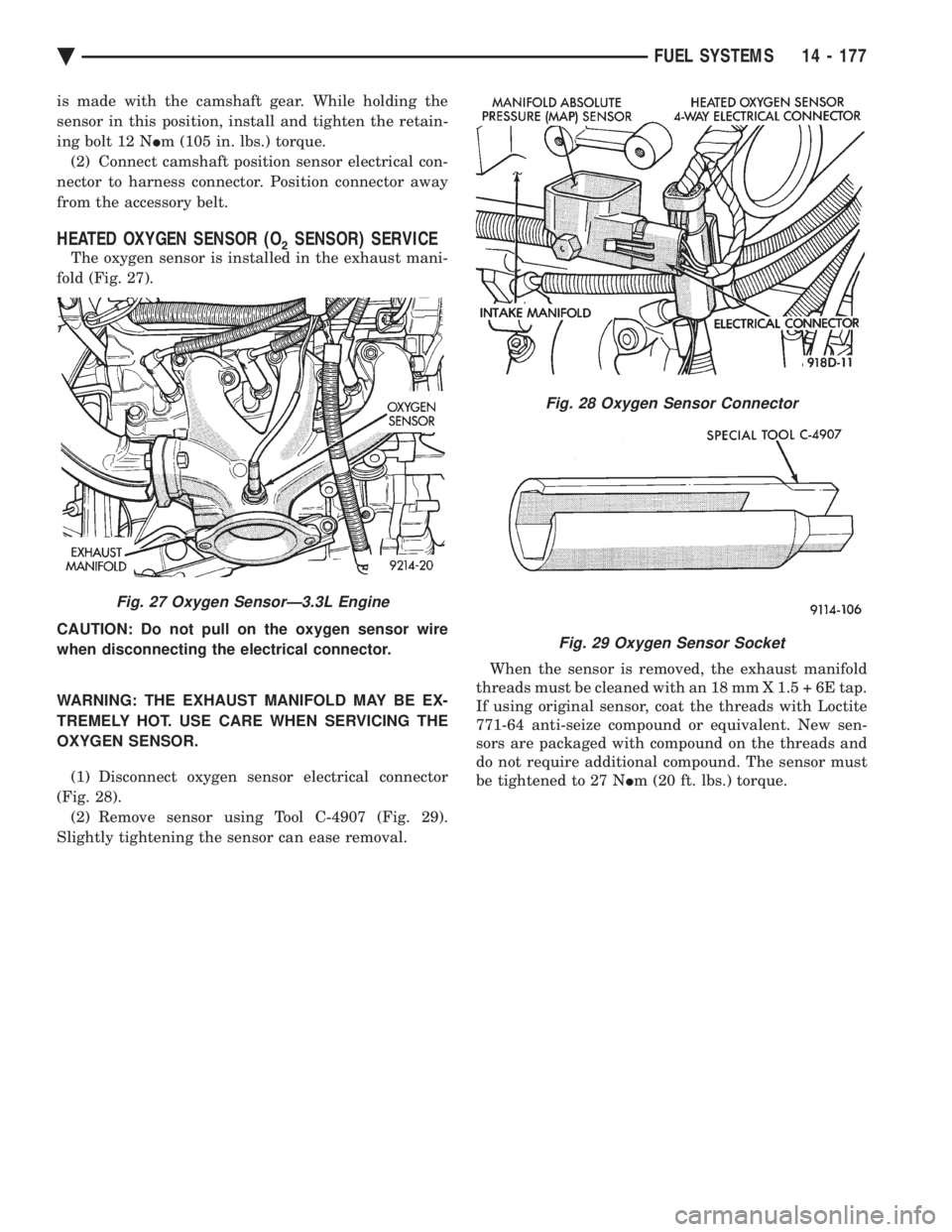

HEATED OXYGEN SENSOR (O2SENSOR) SERVICE

The oxygen sensor is installed in the exhaust mani-

fold (Fig. 27).

CAUTION: Do not pull on the oxygen sensor wire

when disconnecting the electrical connector.

WARNING: THE EXHAUST MANIFOLD MAY BE EX-

TREMELY HOT. USE CARE WHEN SERVICING THE

OXYGEN SENSOR.

(1) Disconnect oxygen sensor electrical connector

(Fig. 28). (2) Remove sensor using Tool C-4907 (Fig. 29).

Slightly tightening the sensor can ease removal. When the sensor is removed, the exhaust manifold

threads must be cleaned with an 18 mm X 1.5 + 6E tap.

If using original sensor, coat the threads with Loctite

771-64 anti-seize compound or equivalent. New sen-

sors are packaged with compound on the threads and

do not require additional compound. The sensor must

be tightened to 27 N Im (20 ft. lbs.) torque.

Fig. 27 Oxygen SensorÐ3.3L Engine

Fig. 28 Oxygen Sensor Connector

Fig. 29 Oxygen Sensor Socket

Ä FUEL SYSTEMS 14 - 177

Page 1927 of 2438

When steering conditions exceed maximum pres-

sure requirements, such as when the wheels are

turned against the stops. The pressure built up in

the steering gear exerts pressure on the spring end of

the flow control valve. The high pressure lifts the re-

lief valve ball from its seat and allows oil to flow

through a trigger orifice located in the outlet fitting.

This reduces pressure on the spring end of the flow

control valve which then opens and allows the oil to

return to the intake side of the pump. This action

limits maximum pressure output of the pump to a

safe level. Under normal power steering pump operating con-

ditions, pressure requirements of the pump are below

maximum, causing the pressure relief valve to re-

main closed.

CHECKING POWER STEERING FLUID LEVEL

WARNING: FLUID LEVEL SHOULD BE CHECKED

WITH ENGINE OFF TO PREVENT INJURY FROM

MOVING PARTS. DO NOT USE AUTOMATIC TRANS-

MISSION FLUID IN THE POWER STEERING SYS-

TEM. DO NOT OVERFILL THE POWER STEERING

SYSTEM.

Wipe reservoir filler cap free of dirt, before check-

ing power steering fluid level. The dipstick should in- dicate FULL COLD when fluid is at normal ambient

temperature, approximately 21ÉC to 27ÉC (70ÉF to

80ÉF). In all pumps add fluid as necessary to obtain

proper level, using only MopartPower Steering

Fluid, or equivalent. DO NOT USE ANY TYPE

OF AUTOMATIC TRANSMISSION FLUID.

POWER STEERING PUMP PRESSURE TEST

The following procedure can be used to test the op-

eration of the power steering system on the vehicle. (1) Check power steering pump drive belt tension

and adjust as necessary. (2) Disconnect power steering fluid pressure hose,

at steering gear or power steering pump. Use a con-

tainer for dripping fluid. (3) Connect Pressure Gauge, Special Tool C-3309-E

(Fig. 1) to both hoses using adapter fittings. Connect

spare pressure hose to gear or pump. (4) Completely open valve on Special Tool

C-3309-E (Fig. 1). (5) Start engine and let idle.

(6) Check power steering fluid level, and add fluid

as necessary. (7) Gauge should read below 862 kPa (125 psi), if

above, inspect the hoses for restrictions and repair as

necessary. The initial pressure should be in the

range of 345-552 kPa (50-80 psi).

PUMP LEAKAGE DIAGNOSIS

Ä STEERING 19 - 9

Page 1929 of 2438

INSTALL

(1) Install power steering pressure switch into fit-

ting on power steering pressure hose by hand until

fully seated. Then torque power steering pressure

switch to 12 N Im (106 in. lbs.).

(2) Install vehicle wiring harness connector onto

power steering pressure switch. Be sure latch on wir-

ing harness connector is fully engaged with locking

tab on power steering pressure switch.

CAUTION: Do not use automatic transmission fluid

in power steering system. Only use Mopar T, Power

Steering Fluid, or equivalent.

(3) Fill power steering pump reservoir to correct

fluid level. (4) Connect negative cable back on negative post of

battery. (5) Start engine and turn steering wheel several

times from stop to stop to bleed air from fluid in sys-

tem. Stop engine, check fluid level, and inspect sys-

tem for leaks. See Checking Fluid Level.

POWER STEERING HOSES

Service all power steering hoses with the vehicle

raised on a hoist. Cap all open ends of hoses, power

steering pump fittings and steering gear ports to pre-

vent entry of foreign material into the components.

WARNING: POWER STEERING OIL, ENGINE PARTS

AND EXHAUST SYSTEM MAY BE EXTREMELY HOT

IF ENGINE HAS BEEN RUNNING. DO NOT START

ENGINE WITH ANY LOOSE OR DISCONNECTED

HOSES. DO NOT ALLOW HOSES TO TOUCH HOT

EXHAUST MANIFOLD OR CATALYST.

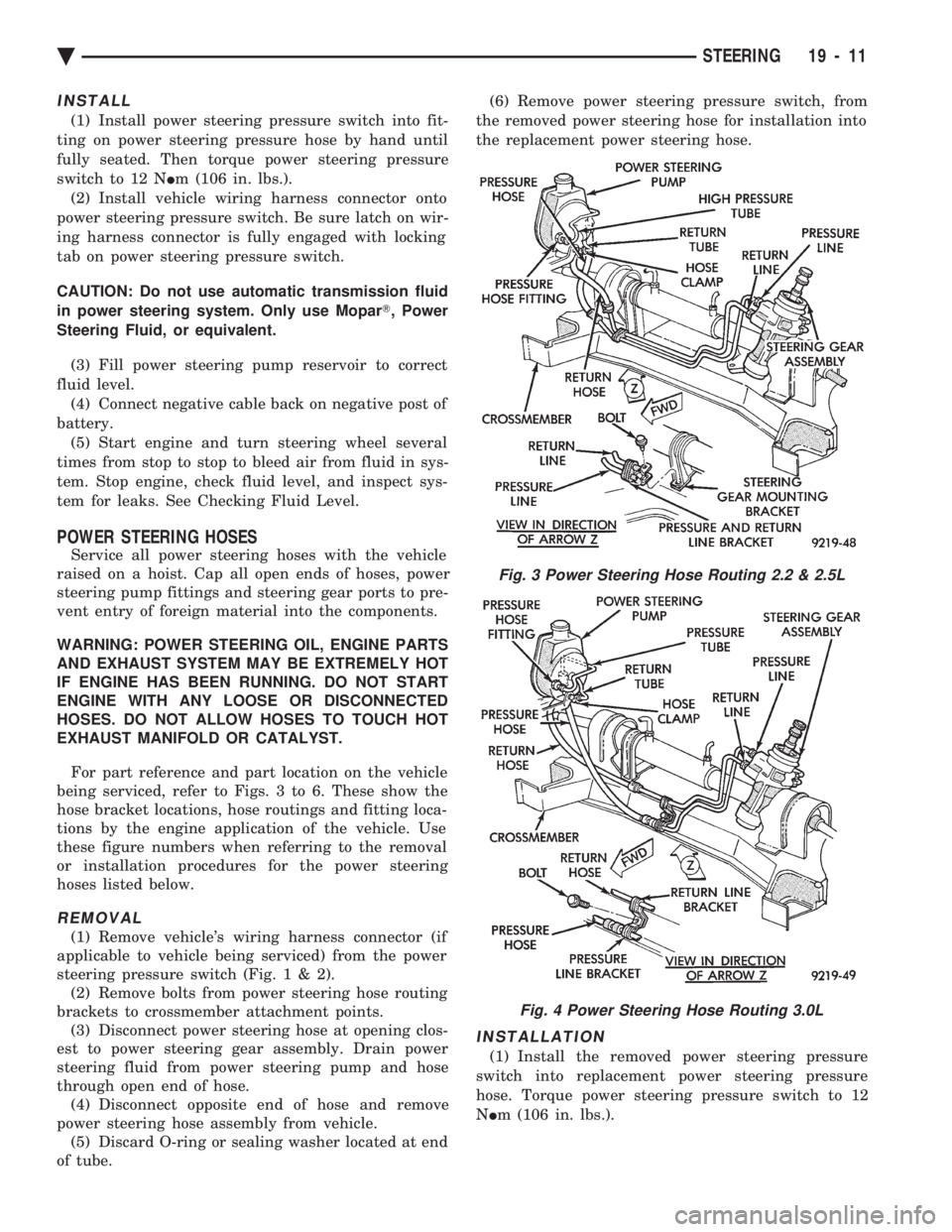

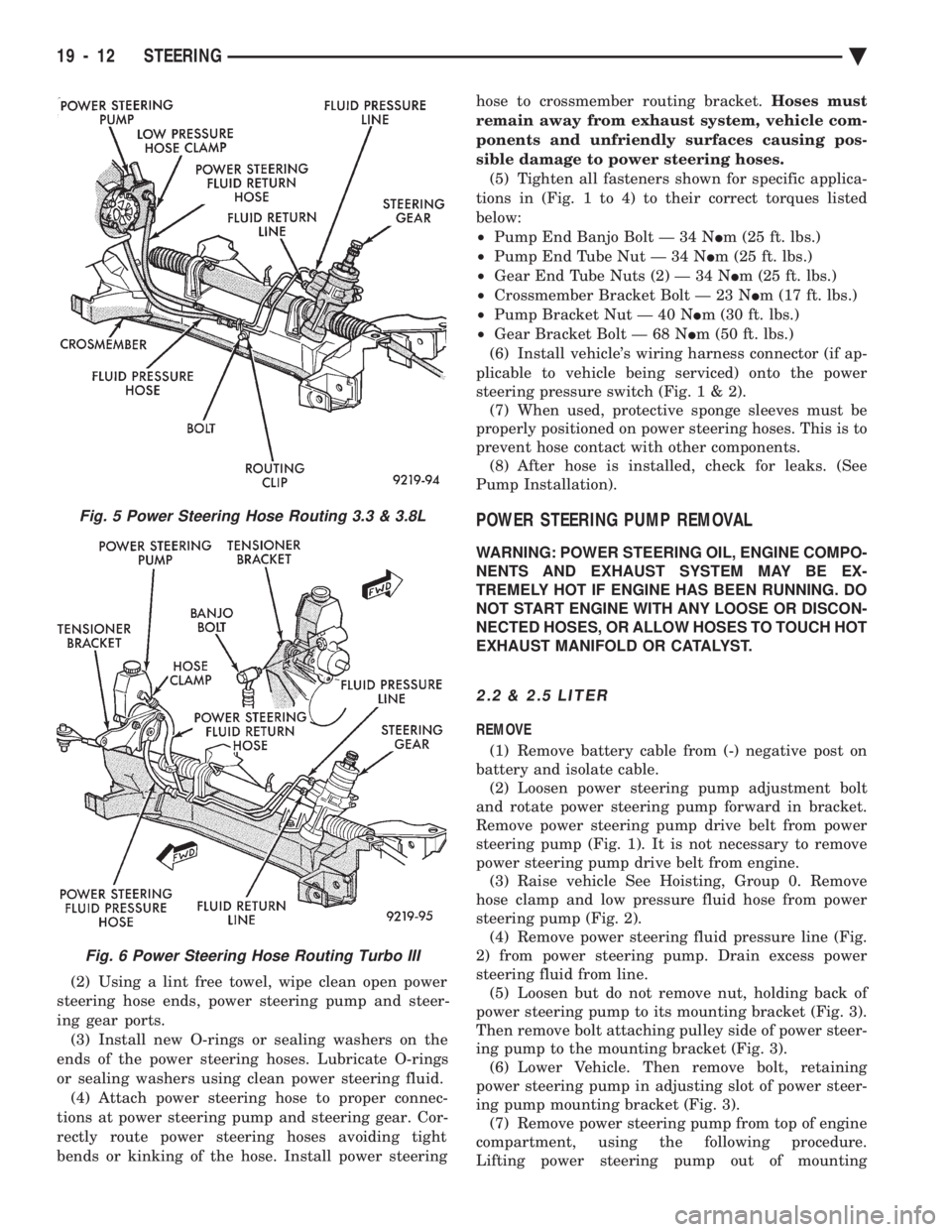

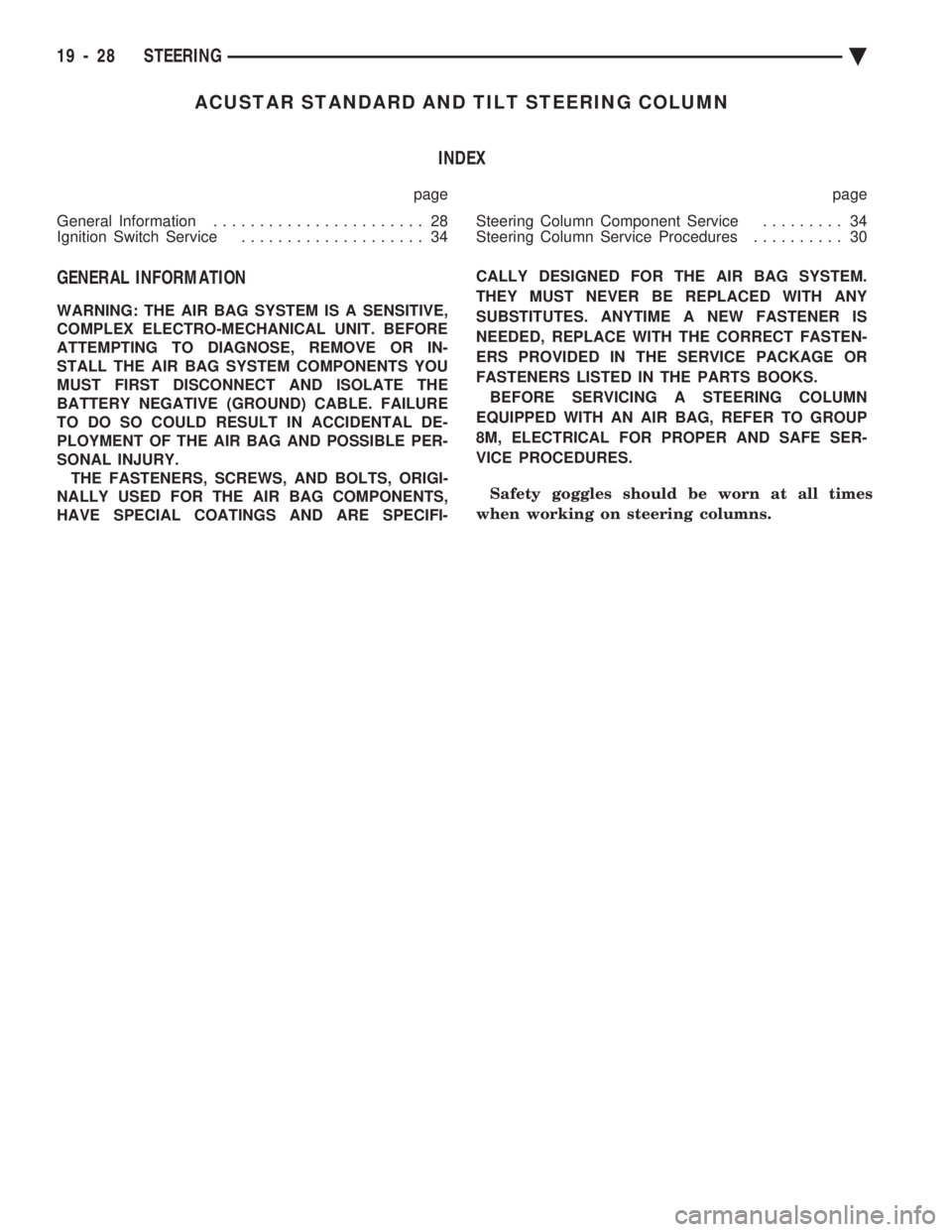

For part reference and part location on the vehicle

being serviced, refer to Figs. 3 to 6. These show the

hose bracket locations, hose routings and fitting loca-

tions by the engine application of the vehicle. Use

these figure numbers when referring to the removal

or installation procedures for the power steering

hoses listed below.

REMOVAL

(1) Remove vehicle's wiring harness connector (if

applicable to vehicle being serviced) from the power

steering pressure switch (Fig .1&2).

(2) Remove bolts from power steering hose routing

brackets to crossmember attachment points. (3) Disconnect power steering hose at opening clos-

est to power steering gear assembly. Drain power

steering fluid from power steering pump and hose

through open end of hose. (4) Disconnect opposite end of hose and remove

power steering hose assembly from vehicle. (5) Discard O-ring or sealing washer located at end

of tube. (6) Remove power steering pressure switch, from

the removed power steering hose for installation into

the replacement power steering hose.

INSTALLATION

(1) Install the removed power steering pressure

switch into replacement power steering pressure

hose. Torque power steering pressure switch to 12

N Im (106 in. lbs.).

Fig. 3 Power Steering Hose Routing 2.2 & 2.5L

Fig. 4 Power Steering Hose Routing 3.0L

Ä STEERING 19 - 11

Page 1930 of 2438

(2) Using a lint free towel, wipe clean open power

steering hose ends, power steering pump and steer-

ing gear ports. (3) Install new O-rings or sealing washers on the

ends of the power steering hoses. Lubricate O-rings

or sealing washers using clean power steering fluid. (4) Attach power steering hose to proper connec-

tions at power steering pump and steering gear. Cor-

rectly route power steering hoses avoiding tight

bends or kinking of the hose. Install power steering hose to crossmember routing bracket.

Hoses must

remain away from exhaust system, vehicle com-

ponents and unfriendly surfaces causing pos-

sible damage to power steering hoses. (5) Tighten all fasteners shown for specific applica-

tions in (Fig. 1 to 4) to their correct torques listed

below:

² Pump End Banjo Bolt Ð 34 N Im (25 ft. lbs.)

² Pump End Tube Nut Ð 34 N Im (25 ft. lbs.)

² Gear End Tube Nuts (2) Ð 34 N Im (25 ft. lbs.)

² Crossmember Bracket Bolt Ð 23 N Im (17 ft. lbs.)

² Pump Bracket Nut Ð 40 N Im (30 ft. lbs.)

² Gear Bracket Bolt Ð 68 N Im (50 ft. lbs.)

(6) Install vehicle's wiring harness connector (if ap-

plicable to vehicle being serviced) onto the power

steering pressure switch (Fig .1&2).

(7) When used, protective sponge sleeves must be

properly positioned on power steering hoses. This is to

prevent hose contact with other components. (8) After hose is installed, check for leaks. (See

Pump Installation).

POWER STEERING PUMP REMOVAL

WARNING: POWER STEERING OIL, ENGINE COMPO-

NENTS AND EXHAUST SYSTEM MAY BE EX-

TREMELY HOT IF ENGINE HAS BEEN RUNNING. DO

NOT START ENGINE WITH ANY LOOSE OR DISCON-

NECTED HOSES, OR ALLOW HOSES TO TOUCH HOT

EXHAUST MANIFOLD OR CATALYST.

2.2 & 2.5 LITER

REMOVE

(1) Remove battery cable from (-) negative post on

battery and isolate cable. (2) Loosen power steering pump adjustment bolt

and rotate power steering pump forward in bracket.

Remove power steering pump drive belt from power

steering pump (Fig. 1). It is not necessary to remove

power steering pump drive belt from engine. (3) Raise vehicle See Hoisting, Group 0. Remove

hose clamp and low pressure fluid hose from power

steering pump (Fig. 2). (4) Remove power steering fluid pressure line (Fig.

2) from power steering pump. Drain excess power

steering fluid from line. (5) Loosen but do not remove nut, holding back of

power steering pump to its mounting bracket (Fig. 3).

Then remove bolt attaching pulley side of power steer-

ing pump to the mounting bracket (Fig. 3). (6) Lower Vehicle. Then remove bolt, retaining

power steering pump in adjusting slot of power steer-

ing pump mounting bracket (Fig. 3). (7) Remove power steering pump from top of engine

compartment, using the following procedure.

Lifting power steering pump out of mounting

Fig. 5 Power Steering Hose Routing 3.3 & 3.8L

Fig. 6 Power Steering Hose Routing Turbo III

19 - 12 STEERING Ä

Page 1946 of 2438

ACUSTAR STANDARD AND TILT STEERING COLUMN INDEX

page page

General Information ....................... 28

Ignition Switch Service .................... 34 Steering Column Component Service

......... 34

Steering Column Service Procedures .......... 30

GENERAL INFORMATION

WARNING: THE AIR BAG SYSTEM IS A SENSITIVE,

COMPLEX ELECTRO-MECHANICAL UNIT. BEFORE

ATTEMPTING TO DIAGNOSE, REMOVE OR IN-

STALL THE AIR BAG SYSTEM COMPONENTS YOU

MUST FIRST DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE. FAILURE

TO DO SO COULD RESULT IN ACCIDENTAL DE-

PLOYMENT OF THE AIR BAG AND POSSIBLE PER-

SONAL INJURY. THE FASTENERS, SCREWS, AND BOLTS, ORIGI-

NALLY USED FOR THE AIR BAG COMPONENTS,

HAVE SPECIAL COATINGS AND ARE SPECIFI- CALLY DESIGNED FOR THE AIR BAG SYSTEM.

THEY MUST NEVER BE REPLACED WITH ANY

SUBSTITUTES. ANYTIME A NEW FASTENER IS

NEEDED, REPLACE WITH THE CORRECT FASTEN-

ERS PROVIDED IN THE SERVICE PACKAGE OR

FASTENERS LISTED IN THE PARTS BOOKS. BEFORE SERVICING A STEERING COLUMN

EQUIPPED WITH AN AIR BAG, REFER TO GROUP

8M, ELECTRICAL FOR PROPER AND SAFE SER-

VICE PROCEDURES.

Safety goggles should be worn at all times

when working on steering columns.

19 - 28 STEERING Ä

Page 1948 of 2438

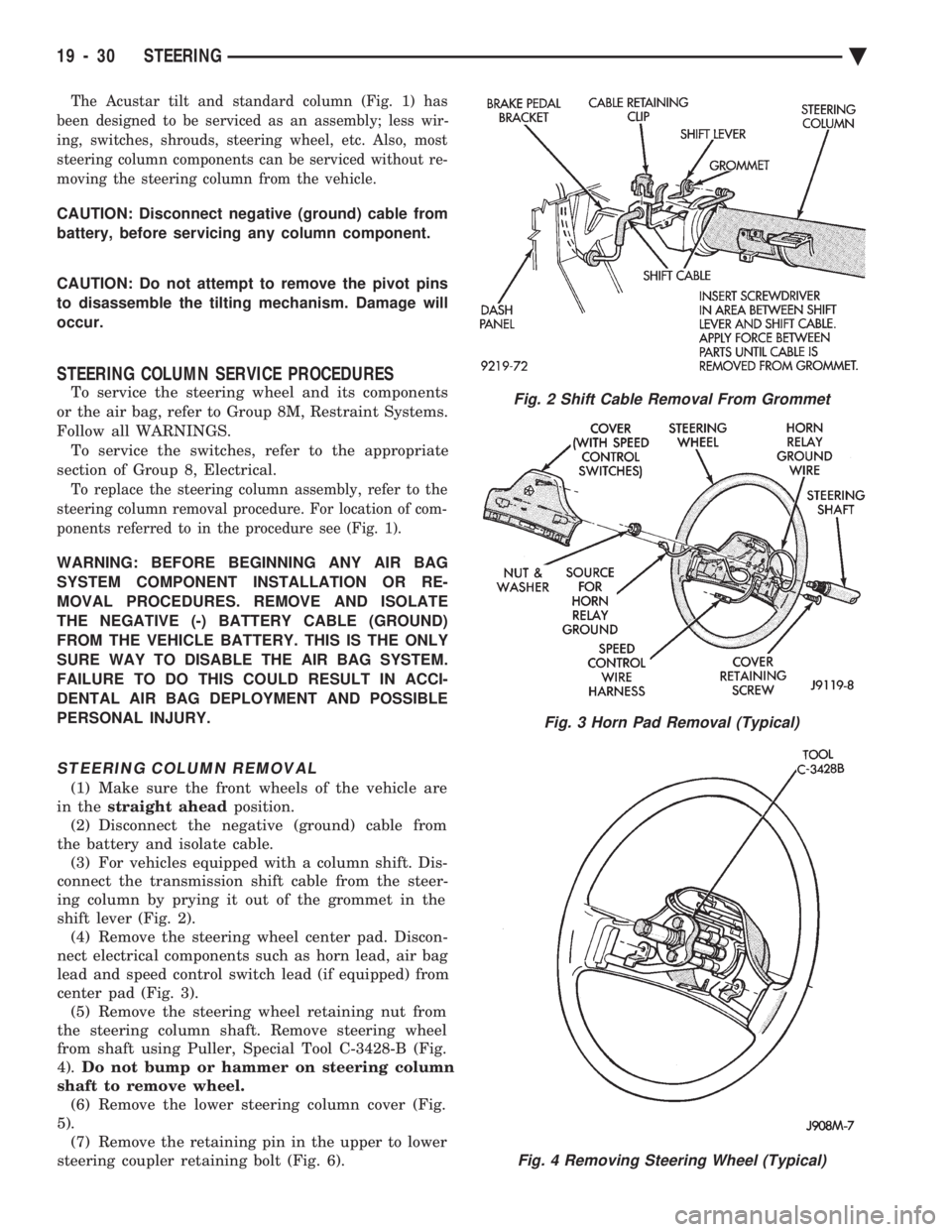

The Acustar tilt and standard column (Fig. 1) has

been designed to be serviced as an assembly; less wir-

ing, switches, shrouds, steering wheel, etc. Also, most

steering column components can be serviced without re-

moving the steering column from the vehicle.

CAUTION: Disconnect negative (ground) cable from

battery, before servicing any column component.

CAUTION: Do not attempt to remove the pivot pins

to disassemble the tilting mechanism. Damage will

occur.

STEERING COLUMN SERVICE PROCEDURES

To service the steering wheel and its components

or the air bag, refer to Group 8M, Restraint Systems.

Follow all WARNINGS. To service the switches, refer to the appropriate

section of Group 8, Electrical.

To replace the steering column assembly, refer to the

steering column removal procedure. For location of com-

ponents referred to in the procedure see (Fig. 1).

WARNING: BEFORE BEGINNING ANY AIR BAG

SYSTEM COMPONENT INSTALLATION OR RE-

MOVAL PROCEDURES. REMOVE AND ISOLATE

THE NEGATIVE (-) BATTERY CABLE (GROUND)

FROM THE VEHICLE BATTERY. THIS IS THE ONLY

SURE WAY TO DISABLE THE AIR BAG SYSTEM.

FAILURE TO DO THIS COULD RESULT IN ACCI-

DENTAL AIR BAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

STEERING COLUMN REMOVAL

(1) Make sure the front wheels of the vehicle are

in the straight ahead position.

(2) Disconnect the negative (ground) cable from

the battery and isolate cable. (3) For vehicles equipped with a column shift. Dis-

connect the transmission shift cable from the steer-

ing column by prying it out of the grommet in the

shift lever (Fig. 2). (4) Remove the steering wheel center pad. Discon-

nect electrical components such as horn lead, air bag

lead and speed control switch lead (if equipped) from

center pad (Fig. 3). (5) Remove the steering wheel retaining nut from

the steering column shaft. Remove steering wheel

from shaft using Puller, Special Tool C-3428-B (Fig.

4). Do not bump or hammer on steering column

shaft to remove wheel. (6) Remove the lower steering column cover (Fig.

5). (7) Remove the retaining pin in the upper to lower

steering coupler retaining bolt (Fig. 6).

Fig. 2 Shift Cable Removal From Grommet

Fig. 3 Horn Pad Removal (Typical)

Fig. 4 Removing Steering Wheel (Typical)

19 - 30 STEERING Ä

Page 2038 of 2438

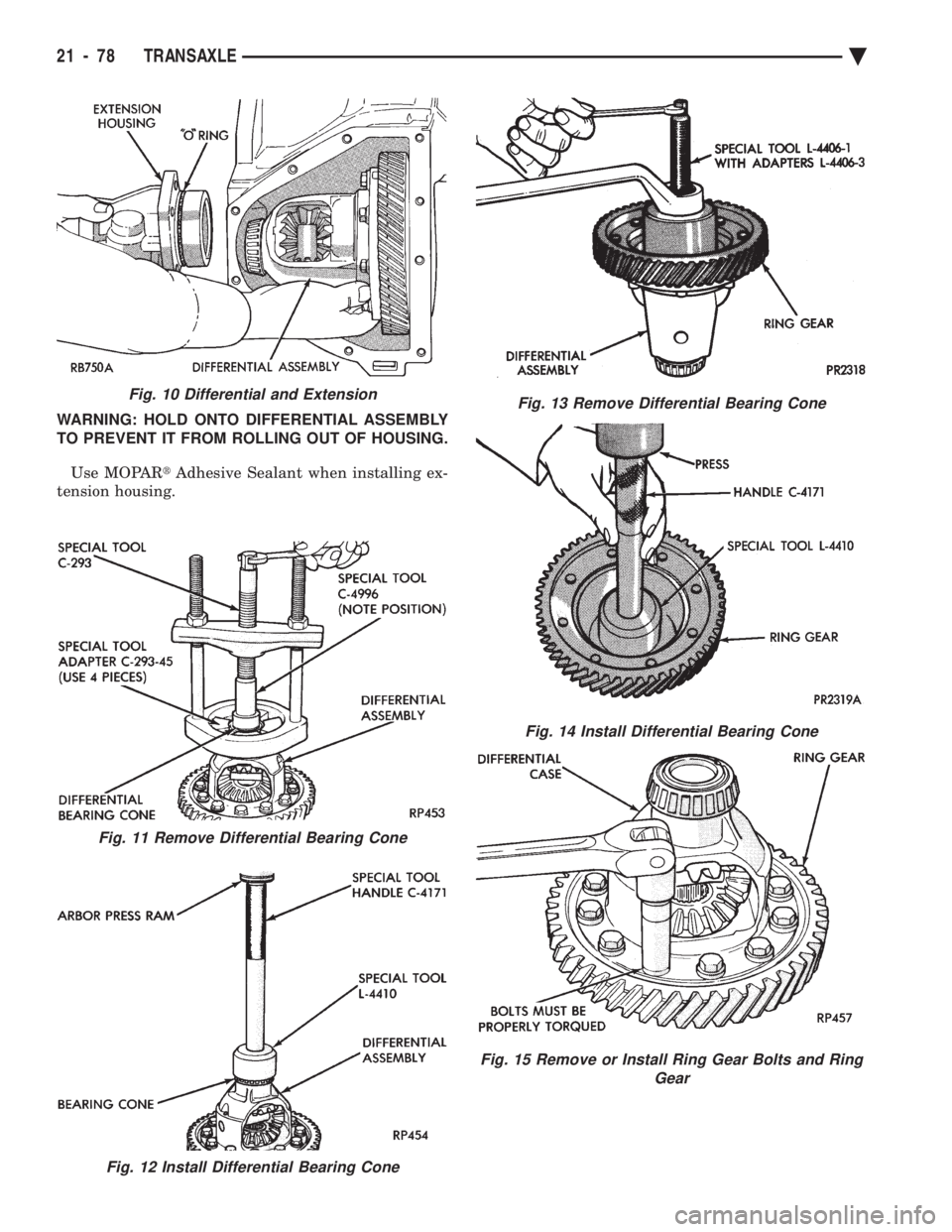

WARNING: HOLD ONTO DIFFERENTIAL ASSEMBLY

TO PREVENT IT FROM ROLLING OUT OF HOUSING.

Use MOPAR tAdhesive Sealant when installing ex-

tension housing.

Fig. 10 Differential and Extension

Fig. 11 Remove Differential Bearing Cone

Fig. 12 Install Differential Bearing Cone

Fig. 13 Remove Differential Bearing Cone

Fig. 14 Install Differential Bearing Cone

Fig. 15 Remove or Install Ring Gear Bolts and Ring Gear

21 - 78 TRANSAXLE Ä