warning CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1851 of 2438

INSTALLATION

(1) Before installing an injector, the rubber O-ring

must be lubricated with a drop of clean engine oil to aid

in installation. (2) Being careful not to damage the O-ring, install

injector top end into fuel rail receiver cup. (3) Install injector lock ring by sliding open end into

slot of the injector and onto the receiver cup ridge into

the side slots of ring (Fig. 11). (4) Repeat steps for remaining injectors.

(5) Install injector wiring harness to injectors. Place

harness into retaining clips.

FUEL PRESSURE REGULATOR

WARNING: THE 2.2L TURBO III FUEL SYSTEM IS

UNDER A CONSTANT PRESSURE OF APPROXI-

MATELY 380 KPA (55 PSI). PERFORM FUEL PRES-

SURE RELEASE PROCEDURE BEFORE SERVICING

THE FUEL PRESSURE REGULATOR.

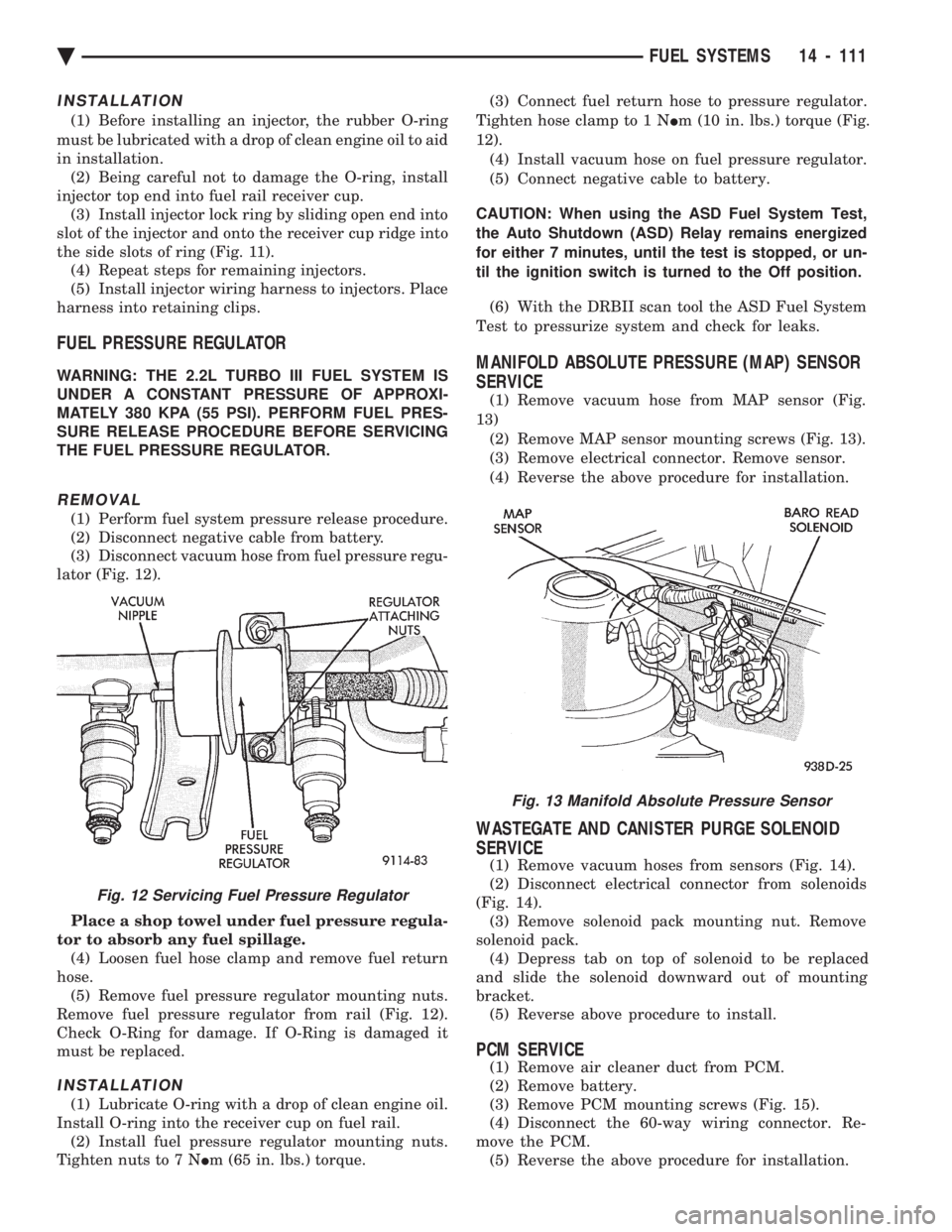

REMOVAL

(1) Perform fuel system pressure release procedure.

(2) Disconnect negative cable from battery.

(3) Disconnect vacuum hose from fuel pressure regu-

lator (Fig. 12).

Place a shop towel under fuel pressure regula-

tor to absorb any fuel spillage. (4) Loosen fuel hose clamp and remove fuel return

hose. (5) Remove fuel pressure regulator mounting nuts.

Remove fuel pressure regulator from rail (Fig. 12).

Check O-Ring for damage. If O-Ring is damaged it

must be replaced.

INSTALLATION

(1) Lubricate O-ring with a drop of clean engine oil.

Install O-ring into the receiver cup on fuel rail. (2) Install fuel pressure regulator mounting nuts.

Tighten nuts to 7 N Im (65 in. lbs.) torque. (3) Connect fuel return hose to pressure regulator.

Tighten hose clamp to 1 N Im (10 in. lbs.) torque (Fig.

12). (4) Install vacuum hose on fuel pressure regulator.

(5) Connect negative cable to battery.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or un-

til the ignition switch is turned to the Off position. (6) With the DRBII scan tool the ASD Fuel System

Test to pressurize system and check for leaks.

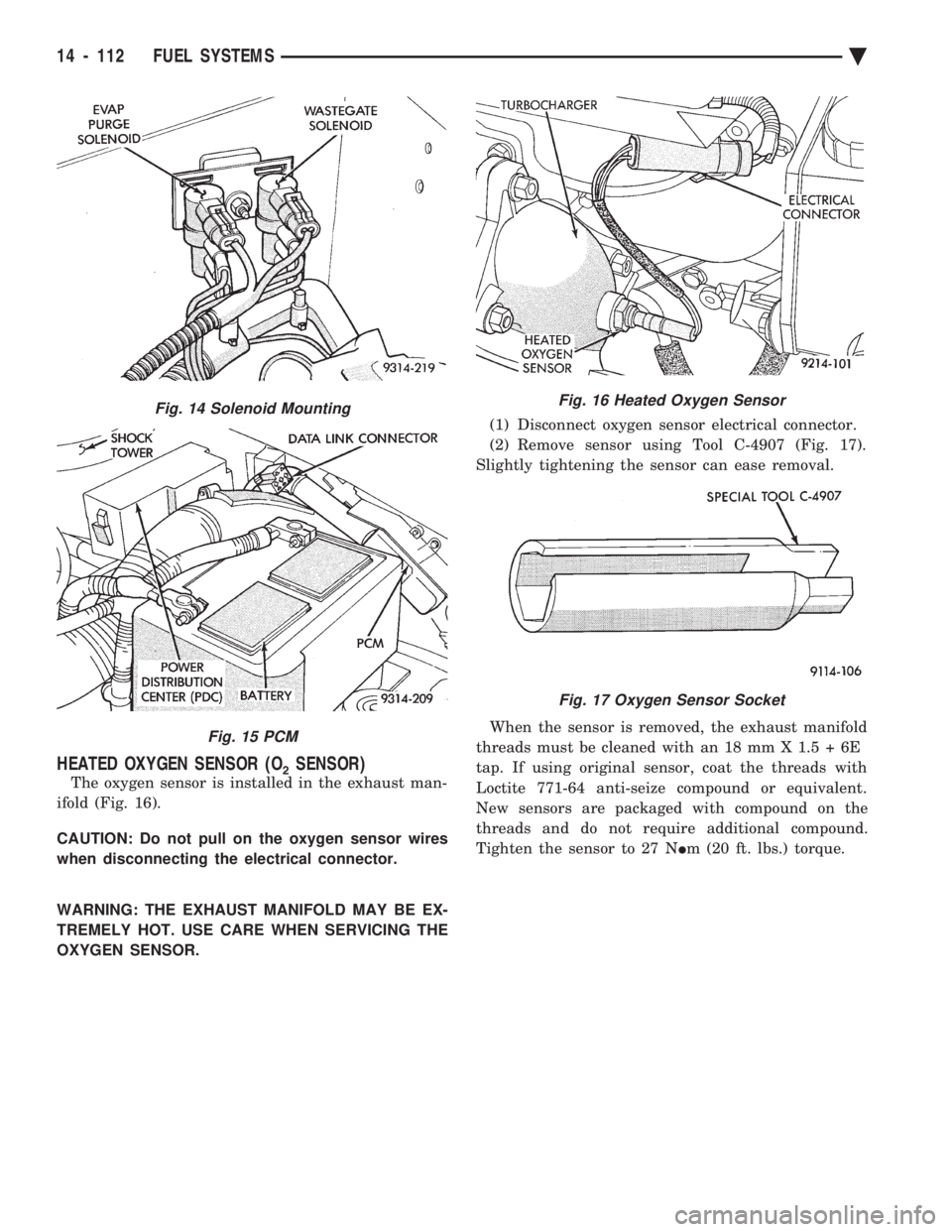

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

SERVICE

(1) Remove vacuum hose from MAP sensor (Fig.

13) (2) Remove MAP sensor mounting screws (Fig. 13).

(3) Remove electrical connector. Remove sensor.

(4) Reverse the above procedure for installation.

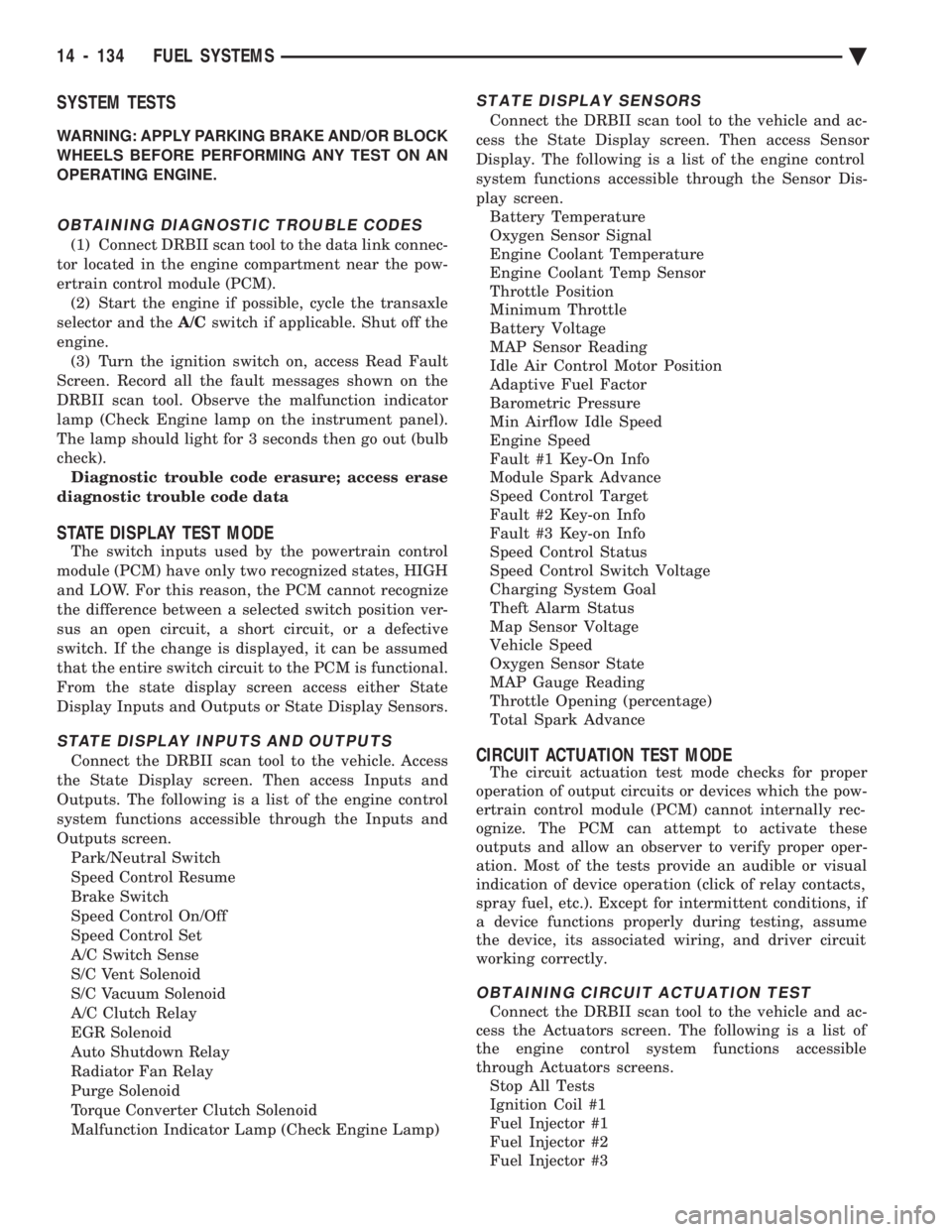

WASTEGATE AND CANISTER PURGE SOLENOID

SERVICE

(1) Remove vacuum hoses from sensors (Fig. 14).

(2) Disconnect electrical connector from solenoids

(Fig. 14). (3) Remove solenoid pack mounting nut. Remove

solenoid pack. (4) Depress tab on top of solenoid to be replaced

and slide the solenoid downward out of mounting

bracket. (5) Reverse above procedure to install.

PCM SERVICE

(1) Remove air cleaner duct from PCM.

(2) Remove battery.

(3) Remove PCM mounting screws (Fig. 15).

(4) Disconnect the 60-way wiring connector. Re-

move the PCM. (5) Reverse the above procedure for installation.

Fig. 13 Manifold Absolute Pressure Sensor

Fig. 12 Servicing Fuel Pressure Regulator

Ä FUEL SYSTEMS 14 - 111

Page 1852 of 2438

HEATED OXYGEN SENSOR (O2SENSOR)

The oxygen sensor is installed in the exhaust man-

ifold (Fig. 16).

CAUTION: Do not pull on the oxygen sensor wires

when disconnecting the electrical connector.

WARNING: THE EXHAUST MANIFOLD MAY BE EX-

TREMELY HOT. USE CARE WHEN SERVICING THE

OXYGEN SENSOR. (1) Disconnect oxygen sensor electrical connector.

(2) Remove sensor using Tool C-4907 (Fig. 17).

Slightly tightening the sensor can ease removal.

When the sensor is removed, the exhaust manifold

threads must be cleaned with an 18 mm X 1.5 + 6E

tap. If using original sensor, coat the threads with

Loctite 771-64 anti-seize compound or equivalent.

New sensors are packaged with compound on the

threads and do not require additional compound.

Tighten the sensor to 27 N Im (20 ft. lbs.) torque.

Fig. 14 Solenoid Mounting

Fig. 15 PCM

Fig. 16 Heated Oxygen Sensor

Fig. 17 Oxygen Sensor Socket

14 - 112 FUEL SYSTEMS Ä

Page 1874 of 2438

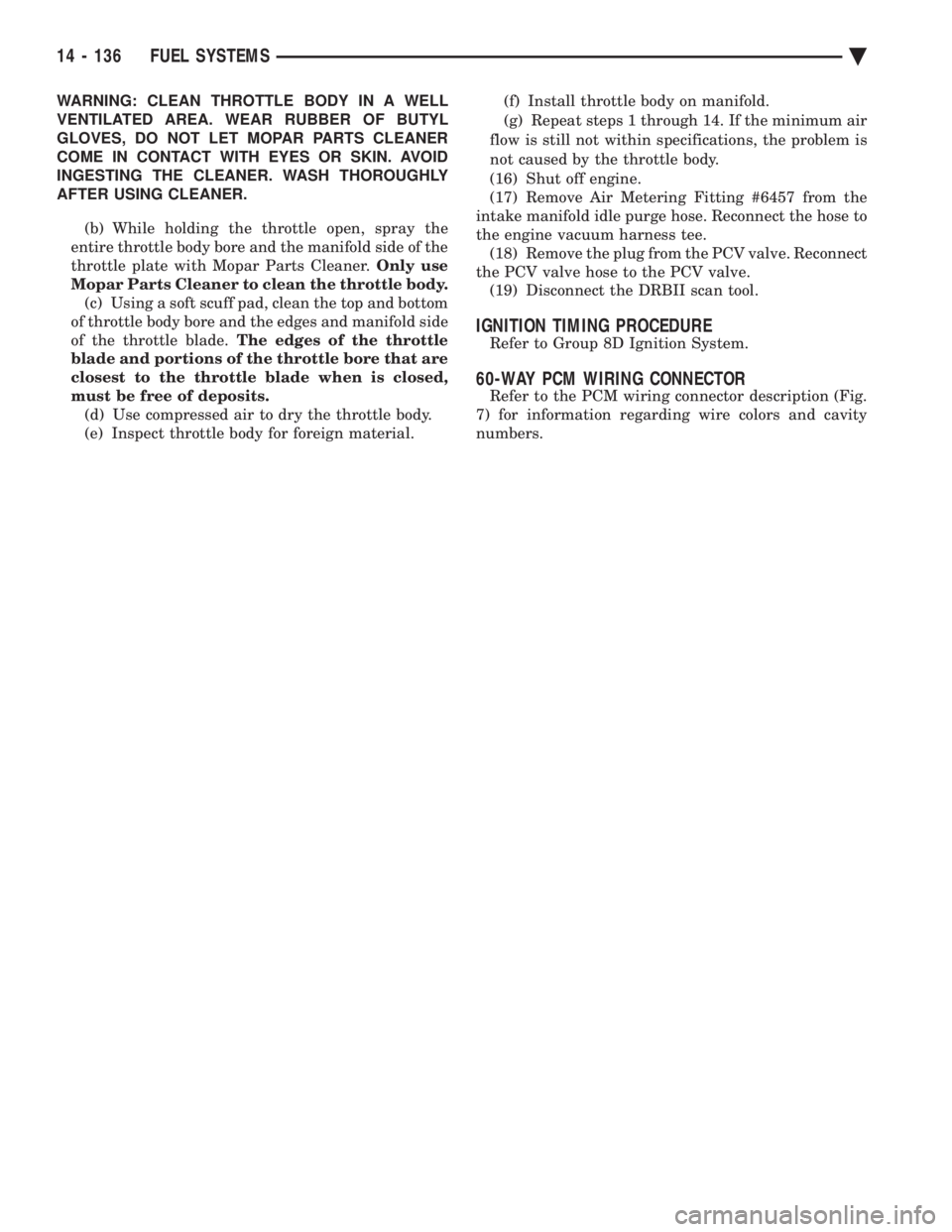

SYSTEM TESTS

WARNING: APPLY PARKING BRAKE AND/OR BLOCK

WHEELS BEFORE PERFORMING ANY TEST ON AN

OPERATING ENGINE.

OBTAINING DIAGNOSTIC TROUBLE CODES

(1) Connect DRBII scan tool to the data link connec-

tor located in the engine compartment near the pow-

ertrain control module (PCM). (2) Start the engine if possible, cycle the transaxle

selector and the A/Cswitch if applicable. Shut off the

engine. (3) Turn the ignition switch on, access Read Fault

Screen. Record all the fault messages shown on the

DRBII scan tool. Observe the malfunction indicator

lamp (Check Engine lamp on the instrument panel).

The lamp should light for 3 seconds then go out (bulb

check). Diagnostic trouble code erasure; access erase

diagnostic trouble code data

STATE DISPLAY TEST MODE

The switch inputs used by the powertrain control

module (PCM) have only two recognized states, HIGH

and LOW. For this reason, the PCM cannot recognize

the difference between a selected switch position ver-

sus an open circuit, a short circuit, or a defective

switch. If the change is displayed, it can be assumed

that the entire switch circuit to the PCM is functional.

From the state display screen access either State

Display Inputs and Outputs or State Display Sensors.

STATE DISPLAY INPUTS AND OUTPUTS

Connect the DRBII scan tool to the vehicle. Access

the State Display screen. Then access Inputs and

Outputs. The following is a list of the engine control

system functions accessible through the Inputs and

Outputs screen. Park/Neutral Switch

Speed Control Resume

Brake Switch

Speed Control On/Off

Speed Control Set

A/C Switch Sense

S/C Vent Solenoid

S/C Vacuum Solenoid

A/C Clutch Relay

EGR Solenoid

Auto Shutdown Relay

Radiator Fan Relay

Purge Solenoid

Torque Converter Clutch Solenoid

Malfunction Indicator Lamp (Check Engine Lamp)

STATE DISPLAY SENSORS

Connect the DRBII scan tool to the vehicle and ac-

cess the State Display screen. Then access Sensor

Display. The following is a list of the engine control

system functions accessible through the Sensor Dis-

play screen. Battery Temperature

Oxygen Sensor Signal

Engine Coolant Temperature

Engine Coolant Temp Sensor

Throttle Position

Minimum Throttle

Battery Voltage

MAP Sensor Reading

Idle Air Control Motor Position

Adaptive Fuel Factor

Barometric Pressure

Min Airflow Idle Speed

Engine Speed

Fault #1 Key-On Info

Module Spark Advance

Speed Control Target

Fault #2 Key-on Info

Fault #3 Key-on Info

Speed Control Status

Speed Control Switch Voltage

Charging System Goal

Theft Alarm Status

Map Sensor Voltage

Vehicle Speed

Oxygen Sensor State

MAP Gauge Reading

Throttle Opening (percentage)

Total Spark Advance

CIRCUIT ACTUATION TEST MODE

The circuit actuation test mode checks for proper

operation of output circuits or devices which the pow-

ertrain control module (PCM) cannot internally rec-

ognize. The PCM can attempt to activate these

outputs and allow an observer to verify proper oper-

ation. Most of the tests provide an audible or visual

indication of device operation (click of relay contacts,

spray fuel, etc.). Except for intermittent conditions, if

a device functions properly during testing, assume

the device, its associated wiring, and driver circuit

working correctly.

OBTAINING CIRCUIT ACTUATION TEST

Connect the DRBII scan tool to the vehicle and ac-

cess the Actuators screen. The following is a list of

the engine control system functions accessible

through Actuators screens. Stop All Tests

Ignition Coil #1

Fuel Injector #1

Fuel Injector #2

Fuel Injector #3

14 - 134 FUEL SYSTEMS Ä

Page 1876 of 2438

WARNING: CLEAN THROTTLE BODY IN A WELL

VENTILATED AREA. WEAR RUBBER OF BUTYL

GLOVES, DO NOT LET MOPAR PARTS CLEANER

COME IN CONTACT WITH EYES OR SKIN. AVOID

INGESTING THE CLEANER. WASH THOROUGHLY

AFTER USING CLEANER.

(b) While holding the throttle open, spray the

entire throttle body bore and the manifold side of the

throttle plate with Mopar Parts Cleaner. Only use

Mopar Parts Cleaner to clean the throttle body. (c) Using a soft scuff pad, clean the top and bottom

of throttle body bore and the edges and manifold side

of the throttle blade. The edges of the throttle

blade and portions of the throttle bore that are

closest to the throttle blade when is closed,

must be free of deposits. (d) Use compressed air to dry the throttle body.

(e) Inspect throttle body for foreign material. (f) Install throttle body on manifold.

(g) Repeat steps 1 through 14. If the minimum air

flow is still not within specifications, the problem is

not caused by the throttle body.

(16) Shut off engine.

(17) Remove Air Metering Fitting #6457 from the

intake manifold idle purge hose. Reconnect the hose to

the engine vacuum harness tee. (18) Remove the plug from the PCV valve. Reconnect

the PCV valve hose to the PCV valve. (19) Disconnect the DRBII scan tool.

IGNITION TIMING PROCEDURE

Refer to Group 8D Ignition System.

60-WAY PCM WIRING CONNECTOR

Refer to the PCM wiring connector description (Fig.

7) for information regarding wire colors and cavity

numbers.

14 - 136 FUEL SYSTEMS Ä

Page 1879 of 2438

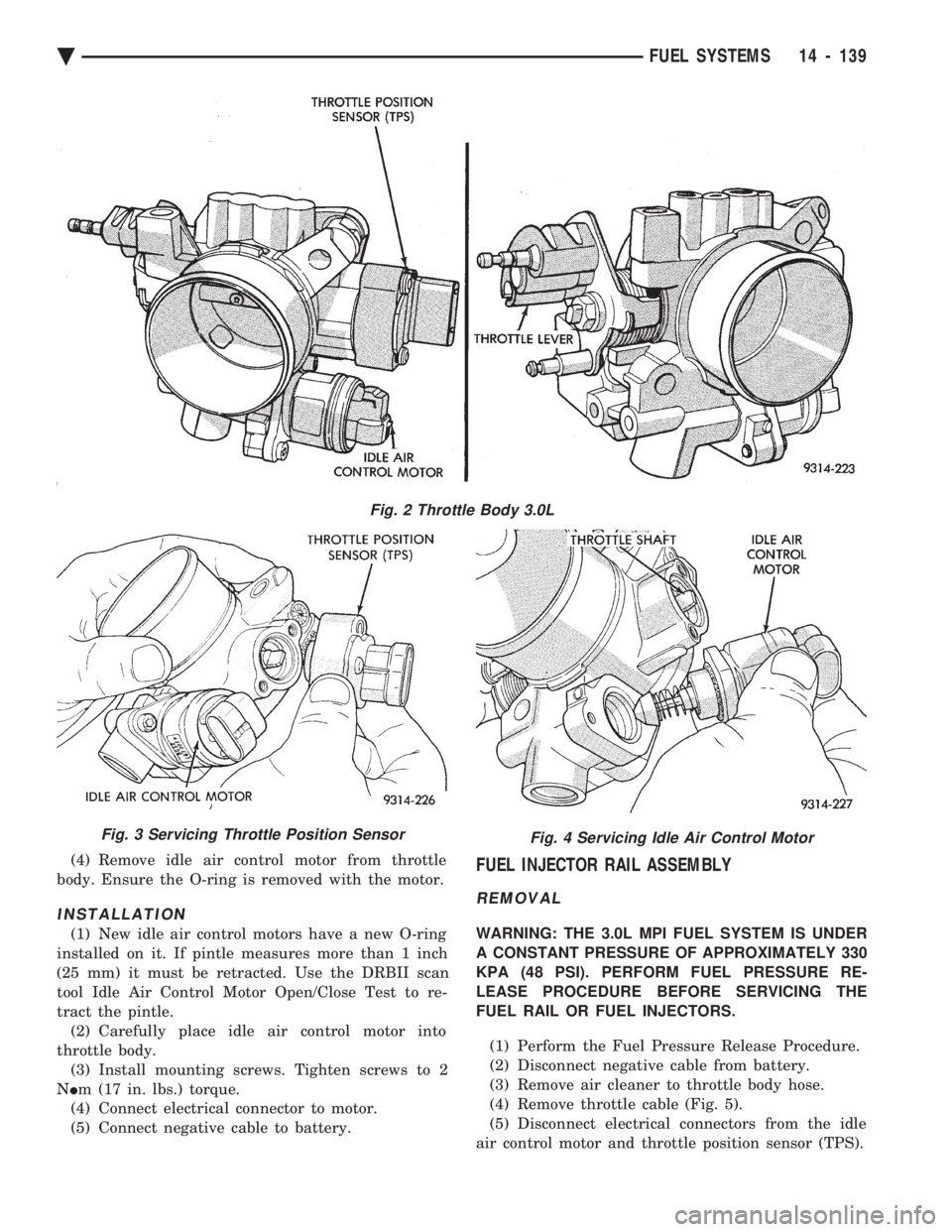

(4) Remove idle air control motor from throttle

body. Ensure the O-ring is removed with the motor.

INSTALLATION

(1) New idle air control motors have a new O-ring

installed on it. If pintle measures more than 1 inch

(25 mm) it must be retracted. Use the DRBII scan

tool Idle Air Control Motor Open/Close Test to re-

tract the pintle. (2) Carefully place idle air control motor into

throttle body. (3) Install mounting screws. Tighten screws to 2

N Im (17 in. lbs.) torque.

(4) Connect electrical connector to motor.

(5) Connect negative cable to battery.

FUEL INJECTOR RAIL ASSEMBLY

REMOVAL

WARNING: THE 3.0L MPI FUEL SYSTEM IS UNDER

A CONSTANT PRESSURE OF APPROXIMATELY 330

KPA (48 PSI). PERFORM FUEL PRESSURE RE-

LEASE PROCEDURE BEFORE SERVICING THE

FUEL RAIL OR FUEL INJECTORS.

(1) Perform the Fuel Pressure Release Procedure.

(2) Disconnect negative cable from battery.

(3) Remove air cleaner to throttle body hose.

(4) Remove throttle cable (Fig. 5).

(5) Disconnect electrical connectors from the idle

air control motor and throttle position sensor (TPS).

Fig. 2 Throttle Body 3.0L

Fig. 3 Servicing Throttle Position SensorFig. 4 Servicing Idle Air Control Motor

Ä FUEL SYSTEMS 14 - 139

Page 1881 of 2438

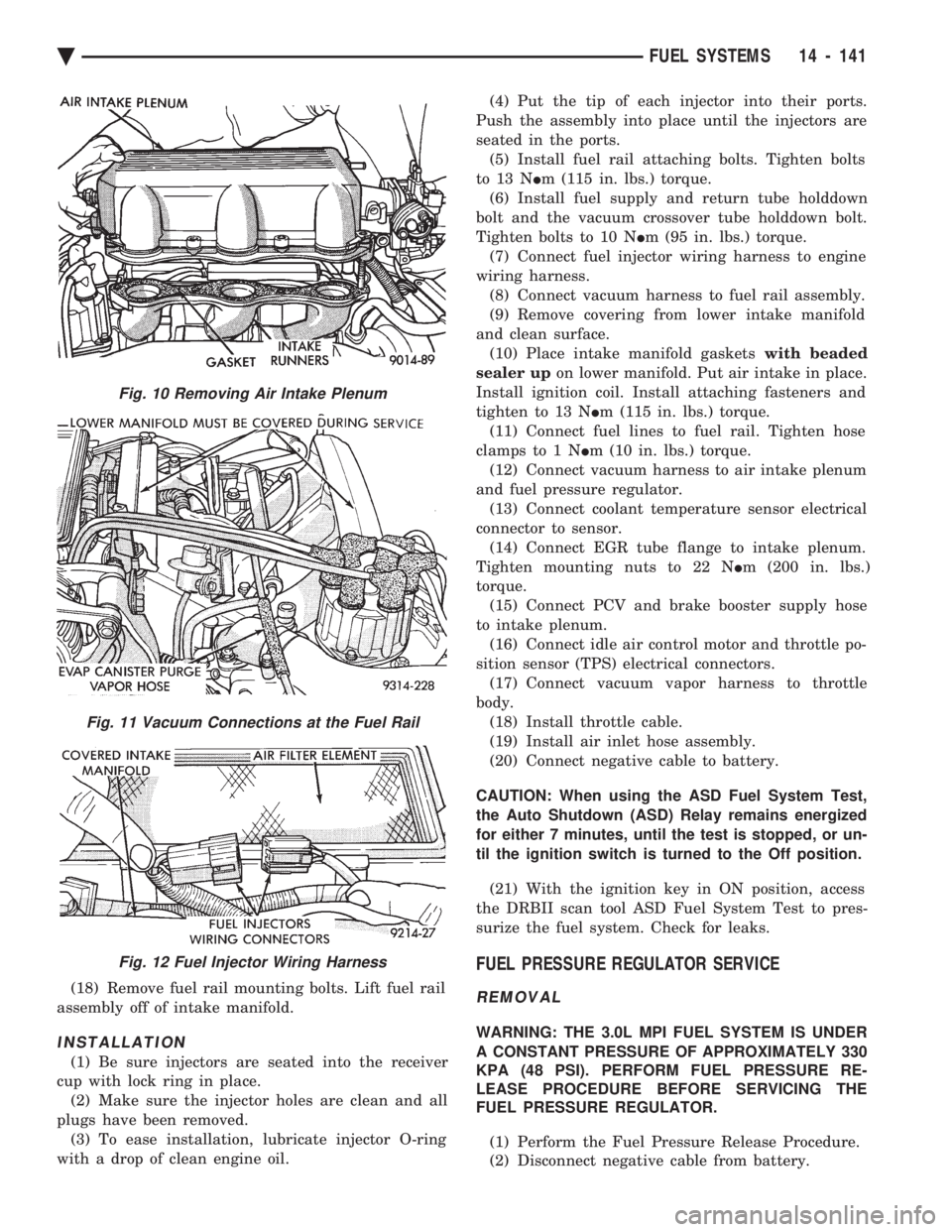

(18) Remove fuel rail mounting bolts. Lift fuel rail

assembly off of intake manifold.

INSTALLATION

(1) Be sure injectors are seated into the receiver

cup with lock ring in place. (2) Make sure the injector holes are clean and all

plugs have been removed. (3) To ease installation, lubricate injector O-ring

with a drop of clean engine oil. (4) Put the tip of each injector into their ports.

Push the assembly into place until the injectors are

seated in the ports. (5) Install fuel rail attaching bolts. Tighten bolts

to 13 N Im (115 in. lbs.) torque.

(6) Install fuel supply and return tube holddown

bolt and the vacuum crossover tube holddown bolt.

Tighten bolts to 10 N Im (95 in. lbs.) torque.

(7) Connect fuel injector wiring harness to engine

wiring harness. (8) Connect vacuum harness to fuel rail assembly.

(9) Remove covering from lower intake manifold

and clean surface. (10) Place intake manifold gaskets with beaded

sealer up on lower manifold. Put air intake in place.

Install ignition coil. Install attaching fasteners and

tighten to 13 N Im (115 in. lbs.) torque.

(11) Connect fuel lines to fuel rail. Tighten hose

clamps to 1 N Im (10 in. lbs.) torque.

(12) Connect vacuum harness to air intake plenum

and fuel pressure regulator. (13) Connect coolant temperature sensor electrical

connector to sensor. (14) Connect EGR tube flange to intake plenum.

Tighten mounting nuts to 22 N Im (200 in. lbs.)

torque. (15) Connect PCV and brake booster supply hose

to intake plenum. (16) Connect idle air control motor and throttle po-

sition sensor (TPS) electrical connectors. (17) Connect vacuum vapor harness to throttle

body. (18) Install throttle cable.

(19) Install air inlet hose assembly.

(20) Connect negative cable to battery.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or un-

til the ignition switch is turned to the Off position. (21) With the ignition key in ON position, access

the DRBII scan tool ASD Fuel System Test to pres-

surize the fuel system. Check for leaks.

FUEL PRESSURE REGULATOR SERVICE

REMOVAL

WARNING: THE 3.0L MPI FUEL SYSTEM IS UNDER

A CONSTANT PRESSURE OF APPROXIMATELY 330

KPA (48 PSI). PERFORM FUEL PRESSURE RE-

LEASE PROCEDURE BEFORE SERVICING THE

FUEL PRESSURE REGULATOR.

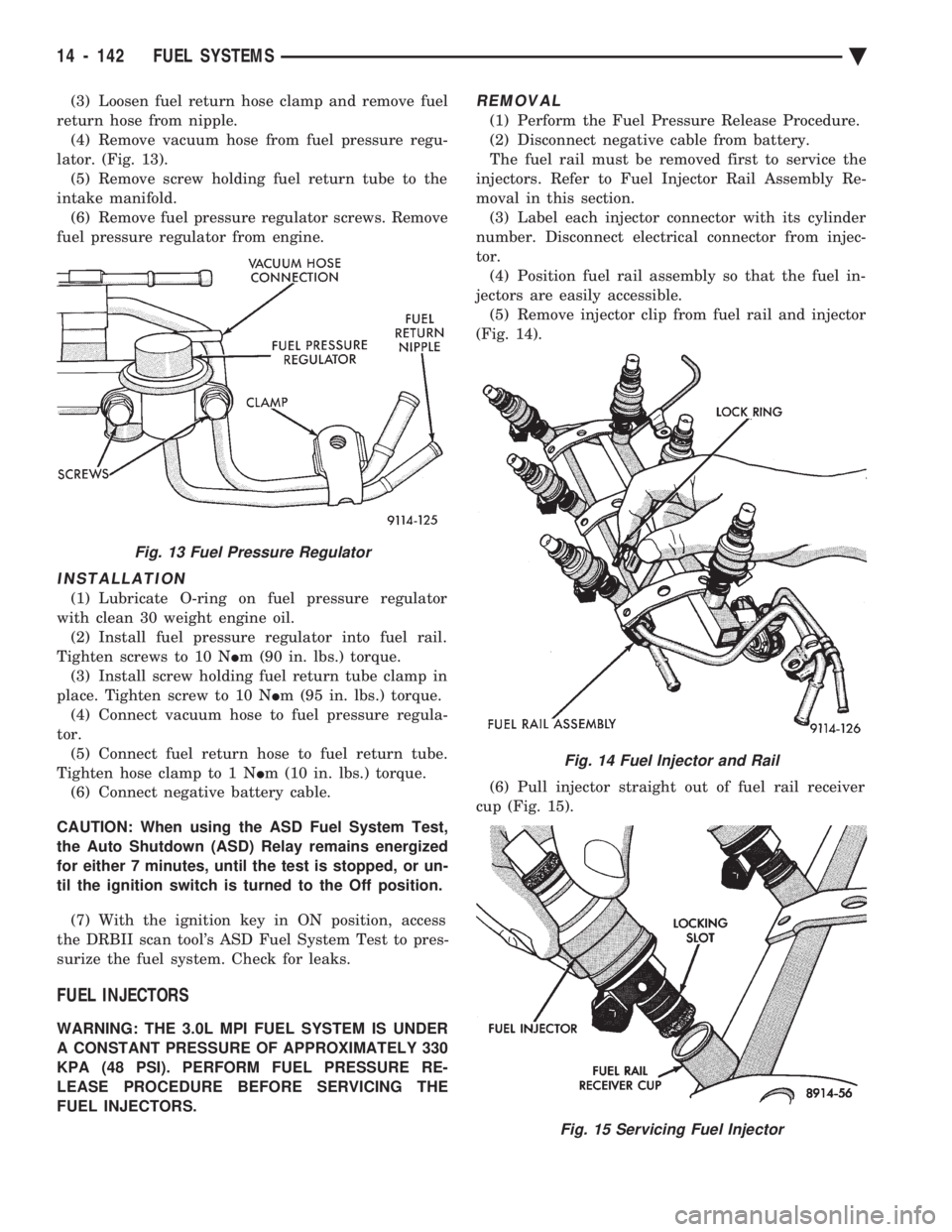

(1) Perform the Fuel Pressure Release Procedure.

(2) Disconnect negative cable from battery.

Fig. 10 Removing Air Intake Plenum

Fig. 11 Vacuum Connections at the Fuel Rail

Fig. 12 Fuel Injector Wiring Harness

Ä FUEL SYSTEMS 14 - 141

Page 1882 of 2438

(3) Loosen fuel return hose clamp and remove fuel

return hose from nipple. (4) Remove vacuum hose from fuel pressure regu-

lator. (Fig. 13). (5) Remove screw holding fuel return tube to the

intake manifold. (6) Remove fuel pressure regulator screws. Remove

fuel pressure regulator from engine.

INSTALLATION

(1) Lubricate O-ring on fuel pressure regulator

with clean 30 weight engine oil. (2) Install fuel pressure regulator into fuel rail.

Tighten screws to 10 N Im (90 in. lbs.) torque.

(3) Install screw holding fuel return tube clamp in

place. Tighten screw to 10 N Im (95 in. lbs.) torque.

(4) Connect vacuum hose to fuel pressure regula-

tor. (5) Connect fuel return hose to fuel return tube.

Tighten hose clamp to 1 N Im (10 in. lbs.) torque.

(6) Connect negative battery cable.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or un-

til the ignition switch is turned to the Off position.

(7) With the ignition key in ON position, access

the DRBII scan tool's ASD Fuel System Test to pres-

surize the fuel system. Check for leaks.

FUEL INJECTORS

WARNING: THE 3.0L MPI FUEL SYSTEM IS UNDER

A CONSTANT PRESSURE OF APPROXIMATELY 330

KPA (48 PSI). PERFORM FUEL PRESSURE RE-

LEASE PROCEDURE BEFORE SERVICING THE

FUEL INJECTORS.

REMOVAL

(1) Perform the Fuel Pressure Release Procedure.

(2) Disconnect negative cable from battery.

The fuel rail must be removed first to service the

injectors. Refer to Fuel Injector Rail Assembly Re-

moval in this section. (3) Label each injector connector with its cylinder

number. Disconnect electrical connector from injec-

tor. (4) Position fuel rail assembly so that the fuel in-

jectors are easily accessible. (5) Remove injector clip from fuel rail and injector

(Fig. 14).

(6) Pull injector straight out of fuel rail receiver

cup (Fig. 15).

Fig. 13 Fuel Pressure Regulator

Fig. 14 Fuel Injector and Rail

Fig. 15 Servicing Fuel Injector

14 - 142 FUEL SYSTEMS Ä

Page 1884 of 2438

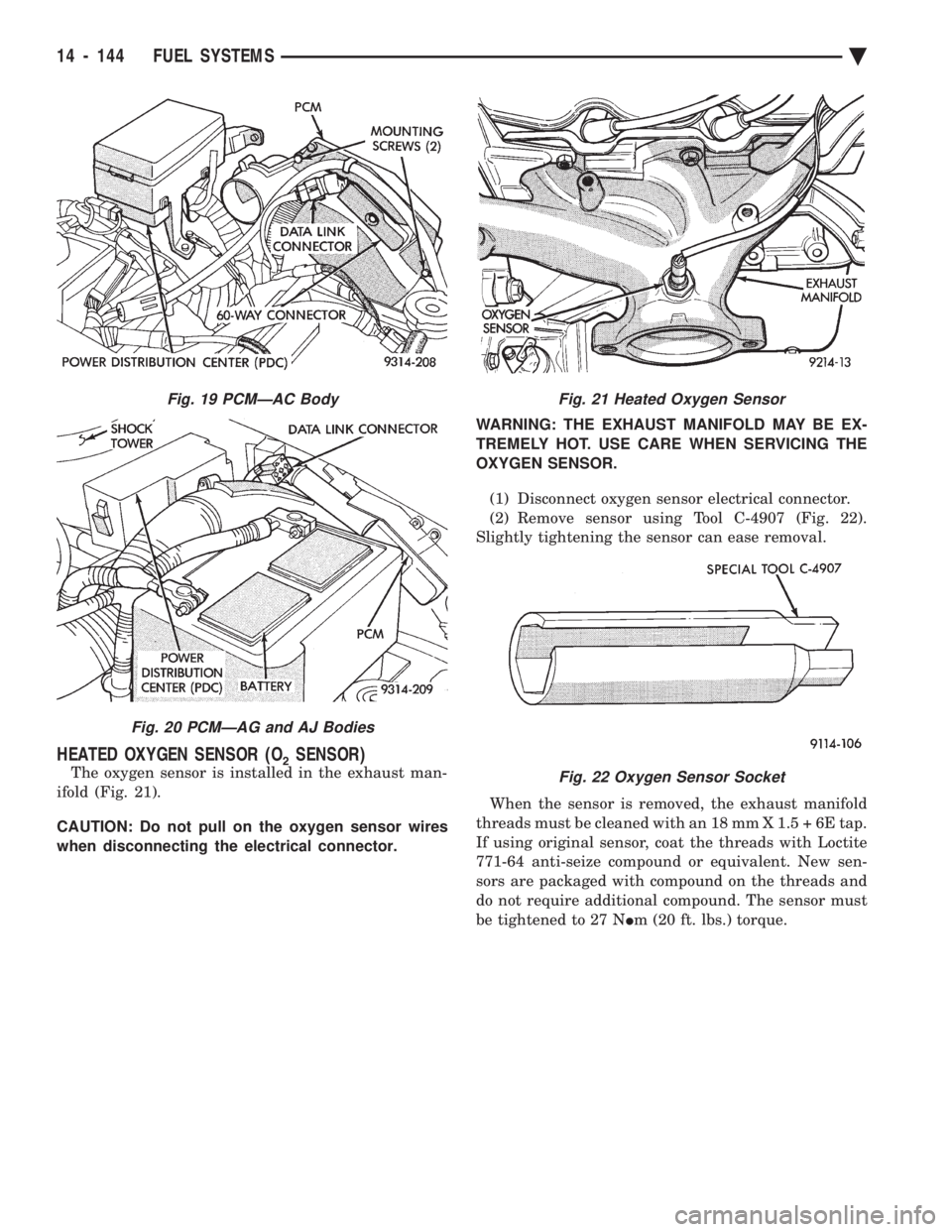

HEATED OXYGEN SENSOR (O2SENSOR)

The oxygen sensor is installed in the exhaust man-

ifold (Fig. 21).

CAUTION: Do not pull on the oxygen sensor wires

when disconnecting the electrical connector. WARNING: THE EXHAUST MANIFOLD MAY BE EX-

TREMELY HOT. USE CARE WHEN SERVICING THE

OXYGEN SENSOR.

(1) Disconnect oxygen sensor electrical connector.

(2) Remove sensor using Tool C-4907 (Fig. 22).

Slightly tightening the sensor can ease removal.

When the sensor is removed, the exhaust manifold

threads must be cleaned with an 18 mm X 1.5 + 6E tap.

If using original sensor, coat the threads with Loctite

771-64 anti-seize compound or equivalent. New sen-

sors are packaged with compound on the threads and

do not require additional compound. The sensor must

be tightened to 27 N Im (20 ft. lbs.) torque.

Fig. 19 PCMÐAC Body

Fig. 20 PCMÐAG and AJ Bodies

Fig. 21 Heated Oxygen Sensor

Fig. 22 Oxygen Sensor Socket

14 - 144 FUEL SYSTEMS Ä

Page 1903 of 2438

line. However, these could result in a rich or lean

condition causing an oxygen sensor fault to be stored in

the PCM. Secondary Ignition Circuit - The PCM cannot

detect an inoperative ignition coil, fouled or worn spark

plugs, ignition cross firing, or open spark plug cables. Engine Timing - The PCM cannot detect an incor-

rectly indexed timing chain, camshaft sprocket and

crankshaft sprocket. However, these could result in a

rich or lean condition causing an oxygen sensor fault to

be stored in the PCM. Cylinder Compression - The PCM cannot detect

uneven, low, or high engine cylinder compression. Exhaust System - The PCM cannot detect a

plugged, restricted or leaking exhaust system. Fuel Injector Malfunctions - The PCM cannot

determine if a fuel injector is clogged, the needle is

sticking or the wrong injector is installed. However,

these could result in a rich or lean condition causing an

oxygen sensor fault to be stored in the PCM. Excessive Oil Consumption - Although the PCM

monitors exhaust stream oxygen content when the

system is in closed loop, it cannot determine excessive

oil consumption. Throttle Body Air Flow - The PCM cannot detect a

clogged or restricted air cleaner inlet or filter element. Evaporative System - The PCM will not detect a

restricted, plugged or loaded evaporative purge canis-

ter. Vacuum Assist - Leaks or restrictions in the

vacuum circuits of vacuum assisted engine control

system devices are not monitored by the PCM. How-

ever, these could result in a MAP sensor fault being

stored in the PCM. PCM System Ground - The PCM cannot determine

a poor system ground. However, a diagnostic trouble

code may be generated as a result of this condition. PCM Connector Engagement - The PCM cannot

determine spread or damaged connector pins. How-

ever, a diagnostic trouble code may be generated as a

result of this condition.

HIGH AND LOW LIMITS

The powertrain control module (PCM) compares in-

put signal voltages from each input device with estab-

lished high and low limits for the device. If the input

voltage is not within limits and other diagnostic

trouble code criteria are met, a diagnostic trouble code

will be stored in memory. Other diagnostic trouble code

criteria might include engine RPM limits or input

voltages from other sensors or switches that must be

present before a fault condition can be verified.

DIAGNOSTIC TROUBLE CODE DESCRIPTION

A diagnostic trouble code indicates that the power-

train control module (PCM) has recognized an abnor- mal condition in the system. Diagnostic trouble codes

can be obtained from the malfunction indicator lamp

(Check Engine lamp on the instrument panel) or from

the DRBII scan tool. Diagnostic trouble codes indicate

the results of a failure but do not identify the failed

component directly.

SYSTEM TESTS

WARNING: APPLY PARKING BRAKE AND/OR BLOCK

WHEELS BEFORE PERFORMING ANY TEST ON AN

OPERATING ENGINE.

OBTAINING DIAGNOSTIC TROUBLE CODES

(1) Connect the DRBII scan tool to the data link

connector located in the engine compartment near the

driver side strut tower (Fig. 1). (2) Start the engine if possible, cycle the transaxle

selector and the A/Cswitch if applicable. Shut off the

engine. (3) Turn the ignition switch on, access Read Fault

Screen. Record all the fault messages shown on the

DRBII scan tool. Observe the malfunction indicator

lamp (check engine lamp on the instrument panel). The

lamp should light for 2 seconds then go out (bulb

check). Diagnostic trouble code erasure; access erase

diagnostic trouble code data

STATE DISPLAY TEST MODE

The switch inputs used by the powertrain control

module (PCM) have only two recognized states, HIGH

and LOW. For this reason, the PCM cannot recognize

the difference between a selected switch position ver-

sus an open circuit, a short circuit, or a defective

switch. If the change is displayed, it can be assumed

that the entire switch circuit to the PCM is functional.

From the state display screen access either State

Display Inputs and Outputs or State Display Sensors.

STATE DISPLAY INPUTS AND OUTPUTS

Connect the DRBII scan tool to the vehicle and access

the State Display screen. Then access Inputs and

Outputs. The following is a list of the engine control

system functions accessible through the Inputs and

Outputs screen. Park/Neutral Switch

Speed Control Resume

Brake Switch

Speed Control On/Off

Speed Control Set

A/C Switch Sense

S/C Vent Solenoid

Ä FUEL SYSTEMS 14 - 163

Page 1907 of 2438

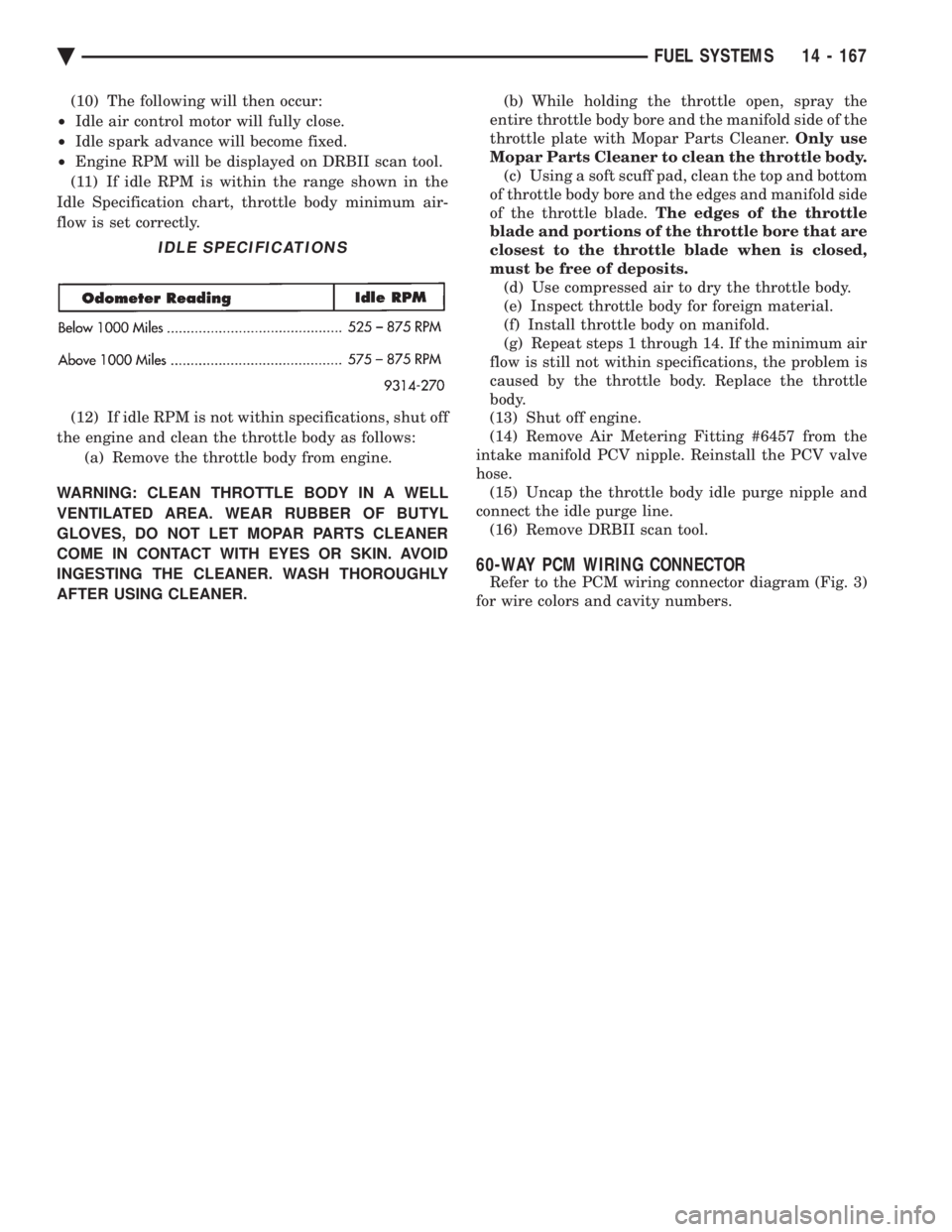

(10) The following will then occur:

² Idle air control motor will fully close.

² Idle spark advance will become fixed.

² Engine RPM will be displayed on DRBII scan tool.

(11) If idle RPM is within the range shown in the

Idle Specification chart, throttle body minimum air-

flow is set correctly.

(12) If idle RPM is not within specifications, shut off

the engine and clean the throttle body as follows: (a) Remove the throttle body from engine.

WARNING: CLEAN THROTTLE BODY IN A WELL

VENTILATED AREA. WEAR RUBBER OF BUTYL

GLOVES, DO NOT LET MOPAR PARTS CLEANER

COME IN CONTACT WITH EYES OR SKIN. AVOID

INGESTING THE CLEANER. WASH THOROUGHLY

AFTER USING CLEANER. (b) While holding the throttle open, spray the

entire throttle body bore and the manifold side of the

throttle plate with Mopar Parts Cleaner. Only use

Mopar Parts Cleaner to clean the throttle body. (c) Using a soft scuff pad, clean the top and bottom

of throttle body bore and the edges and manifold side

of the throttle blade. The edges of the throttle

blade and portions of the throttle bore that are

closest to the throttle blade when is closed,

must be free of deposits. (d) Use compressed air to dry the throttle body.

(e) Inspect throttle body for foreign material.

(f) Install throttle body on manifold.

(g) Repeat steps 1 through 14. If the minimum air

flow is still not within specifications, the problem is

caused by the throttle body. Replace the throttle

body.

(13) Shut off engine.

(14) Remove Air Metering Fitting #6457 from the

intake manifold PCV nipple. Reinstall the PCV valve

hose. (15) Uncap the throttle body idle purge nipple and

connect the idle purge line. (16) Remove DRBII scan tool.

60-WAY PCM WIRING CONNECTOR

Refer to the PCM wiring connector diagram (Fig. 3)

for wire colors and cavity numbers.

IDLE SPECIFICATIONS

Ä FUEL SYSTEMS 14 - 167