ignition CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1790 of 2438

(5) Remove throttle cable. If equipped, remove the

speed control and transaxle kickdown cables. (6) Remove return spring.

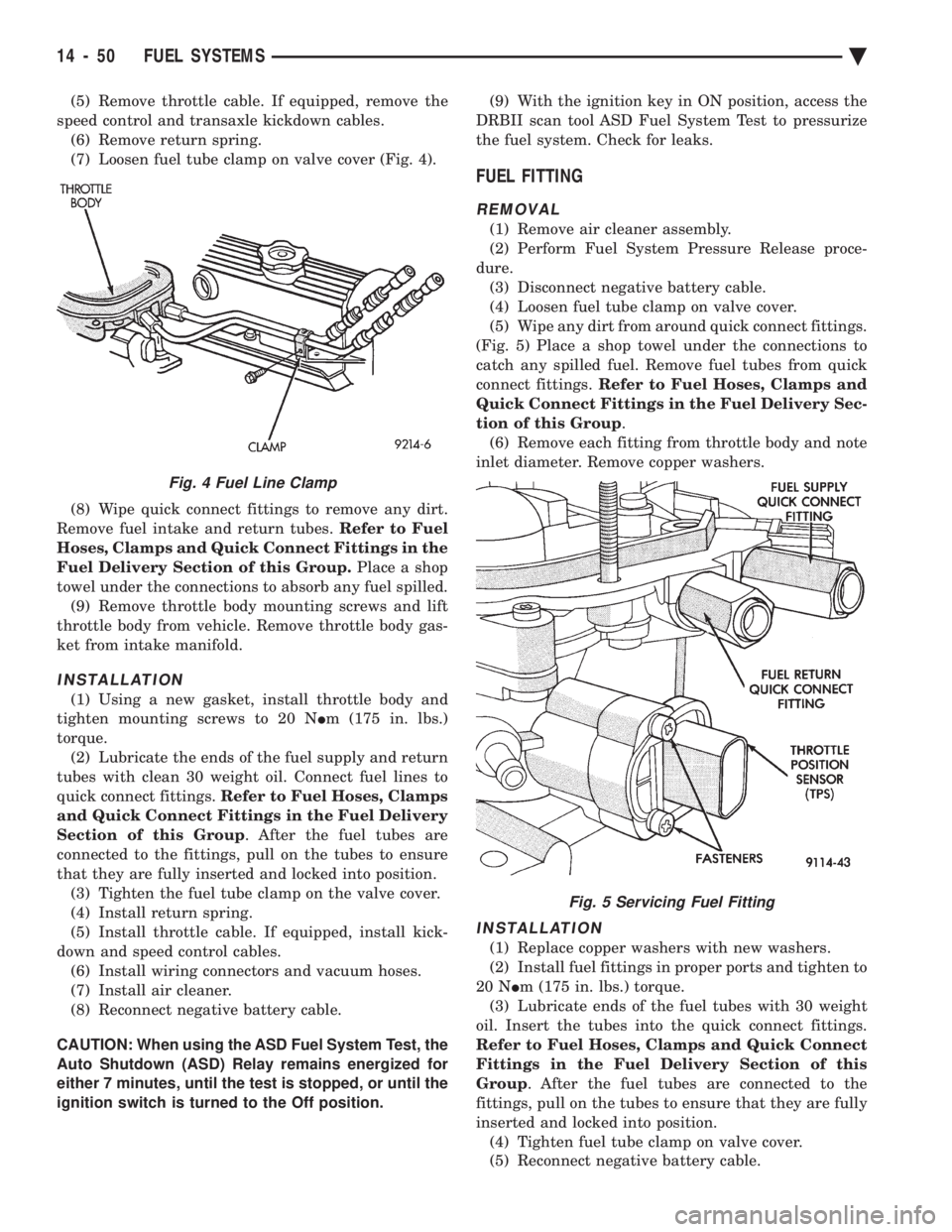

(7) Loosen fuel tube clamp on valve cover (Fig. 4).

(8) Wipe quick connect fittings to remove any dirt.

Remove fuel intake and return tubes. Refer to Fuel

Hoses, Clamps and Quick Connect Fittings in the

Fuel Delivery Section of this Group. Place a shop

towel under the connections to absorb any fuel spilled. (9) Remove throttle body mounting screws and lift

throttle body from vehicle. Remove throttle body gas-

ket from intake manifold.

INSTALLATION

(1) Using a new gasket, install throttle body and

tighten mounting screws to 20 N Im (175 in. lbs.)

torque. (2) Lubricate the ends of the fuel supply and return

tubes with clean 30 weight oil. Connect fuel lines to

quick connect fittings. Refer to Fuel Hoses, Clamps

and Quick Connect Fittings in the Fuel Delivery

Section of this Group . After the fuel tubes are

connected to the fittings, pull on the tubes to ensure

that they are fully inserted and locked into position. (3) Tighten the fuel tube clamp on the valve cover.

(4) Install return spring.

(5) Install throttle cable. If equipped, install kick-

down and speed control cables. (6) Install wiring connectors and vacuum hoses.

(7) Install air cleaner.

(8) Reconnect negative battery cable.

CAUTION: When using the ASD Fuel System Test, the

Auto Shutdown (ASD) Relay remains energized for

either 7 minutes, until the test is stopped, or until the

ignition switch is turned to the Off position. (9) With the ignition key in ON position, access the

DRBII scan tool ASD Fuel System Test to pressurize

the fuel system. Check for leaks.

FUEL FITTING

REMOVAL

(1) Remove air cleaner assembly.

(2) Perform Fuel System Pressure Release proce-

dure. (3) Disconnect negative battery cable.

(4) Loosen fuel tube clamp on valve cover.

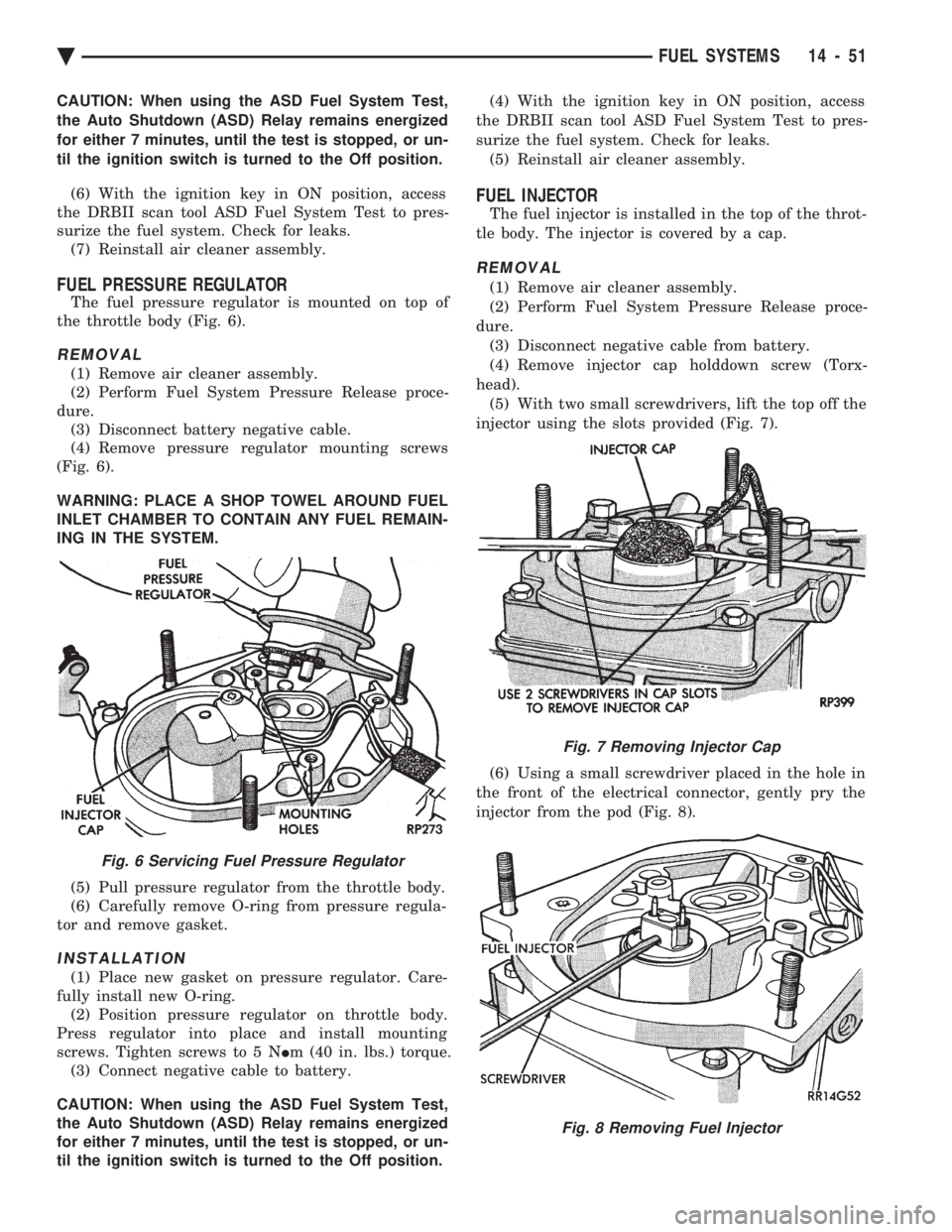

(5) Wipe any dirt from around quick connect fittings.

(Fig. 5) Place a shop towel under the connections to

catch any spilled fuel. Remove fuel tubes from quick

connect fittings. Refer to Fuel Hoses, Clamps and

Quick Connect Fittings in the Fuel Delivery Sec-

tion of this Group .

(6) Remove each fitting from throttle body and note

inlet diameter. Remove copper washers.

INSTALLATION

(1) Replace copper washers with new washers.

(2) Install fuel fittings in proper ports and tighten to

20 N Im (175 in. lbs.) torque.

(3) Lubricate ends of the fuel tubes with 30 weight

oil. Insert the tubes into the quick connect fittings.

Refer to Fuel Hoses, Clamps and Quick Connect

Fittings in the Fuel Delivery Section of this

Group . After the fuel tubes are connected to the

fittings, pull on the tubes to ensure that they are fully

inserted and locked into position. (4) Tighten fuel tube clamp on valve cover.

(5) Reconnect negative battery cable.

Fig. 5 Servicing Fuel Fitting

Fig. 4 Fuel Line Clamp

14 - 50 FUEL SYSTEMS Ä

Page 1791 of 2438

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or un-

til the ignition switch is turned to the Off position. (6) With the ignition key in ON position, access

the DRBII scan tool ASD Fuel System Test to pres-

surize the fuel system. Check for leaks. (7) Reinstall air cleaner assembly.

FUEL PRESSURE REGULATOR

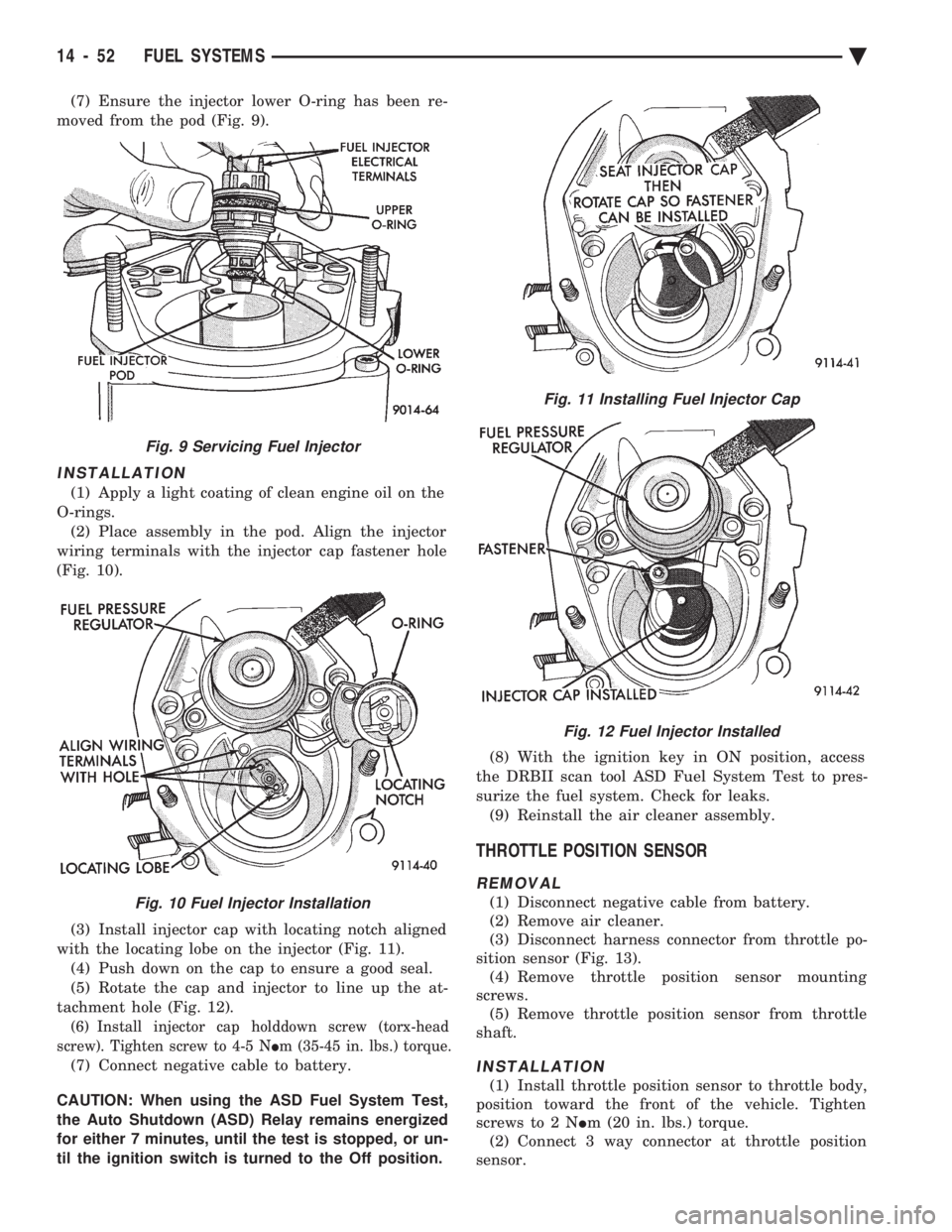

The fuel pressure regulator is mounted on top of

the throttle body (Fig. 6).

REMOVAL

(1) Remove air cleaner assembly.

(2) Perform Fuel System Pressure Release proce-

dure. (3) Disconnect battery negative cable.

(4) Remove pressure regulator mounting screws

(Fig. 6).

WARNING: PLACE A SHOP TOWEL AROUND FUEL

INLET CHAMBER TO CONTAIN ANY FUEL REMAIN-

ING IN THE SYSTEM.

(5) Pull pressure regulator from the throttle body.

(6) Carefully remove O-ring from pressure regula-

tor and remove gasket.

INSTALLATION

(1) Place new gasket on pressure regulator. Care-

fully install new O-ring. (2) Position pressure regulator on throttle body.

Press regulator into place and install mounting

screws. Tighten screws to 5 N Im (40 in. lbs.) torque.

(3) Connect negative cable to battery.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or un-

til the ignition switch is turned to the Off position. (4) With the ignition key in ON position, access

the DRBII scan tool ASD Fuel System Test to pres-

surize the fuel system. Check for leaks. (5) Reinstall air cleaner assembly.

FUEL INJECTOR

The fuel injector is installed in the top of the throt-

tle body. The injector is covered by a cap.

REMOVAL

(1) Remove air cleaner assembly.

(2) Perform Fuel System Pressure Release proce-

dure. (3) Disconnect negative cable from battery.

(4) Remove injector cap holddown screw (Torx-

head). (5) With two small screwdrivers, lift the top off the

injector using the slots provided (Fig. 7).

(6) Using a small screwdriver placed in the hole in

the front of the electrical connector, gently pry the

injector from the pod (Fig. 8).

Fig. 6 Servicing Fuel Pressure Regulator

Fig. 7 Removing Injector Cap

Fig. 8 Removing Fuel Injector

Ä FUEL SYSTEMS 14 - 51

Page 1792 of 2438

(7) Ensure the injector lower O-ring has been re-

moved from the pod (Fig. 9).

INSTALLATION

(1) Apply a light coating of clean engine oil on the

O-rings. (2) Place assembly in the pod. Align the injector

wiring terminals with the injector cap fastener hole

(Fig. 10).

(3) Install injector cap with locating notch aligned

with the locating lobe on the injector (Fig. 11). (4) Push down on the cap to ensure a good seal.

(5) Rotate the cap and injector to line up the at-

tachment hole (Fig. 12).

(6) Install injector cap holddown screw (torx-head

screw). Tighten screw to 4-5 N Im (35-45 in. lbs.) torque.

(7) Connect negative cable to battery.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or un-

til the ignition switch is turned to the Off position. (8) With the ignition key in ON position, access

the DRBII scan tool ASD Fuel System Test to pres-

surize the fuel system. Check for leaks. (9) Reinstall the air cleaner assembly.

THROTTLE POSITION SENSOR

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove air cleaner.

(3) Disconnect harness connector from throttle po-

sition sensor (Fig. 13). (4) Remove throttle position sensor mounting

screws. (5) Remove throttle position sensor from throttle

shaft.

INSTALLATION

(1) Install throttle position sensor to throttle body,

position toward the front of the vehicle. Tighten

screws to 2 N Im (20 in. lbs.) torque.

(2) Connect 3 way connector at throttle position

sensor.

Fig. 9 Servicing Fuel Injector

Fig. 10 Fuel Injector Installation

Fig. 11 Installing Fuel Injector Cap

Fig. 12 Fuel Injector Installed

14 - 52 FUEL SYSTEMS Ä

Page 1795 of 2438

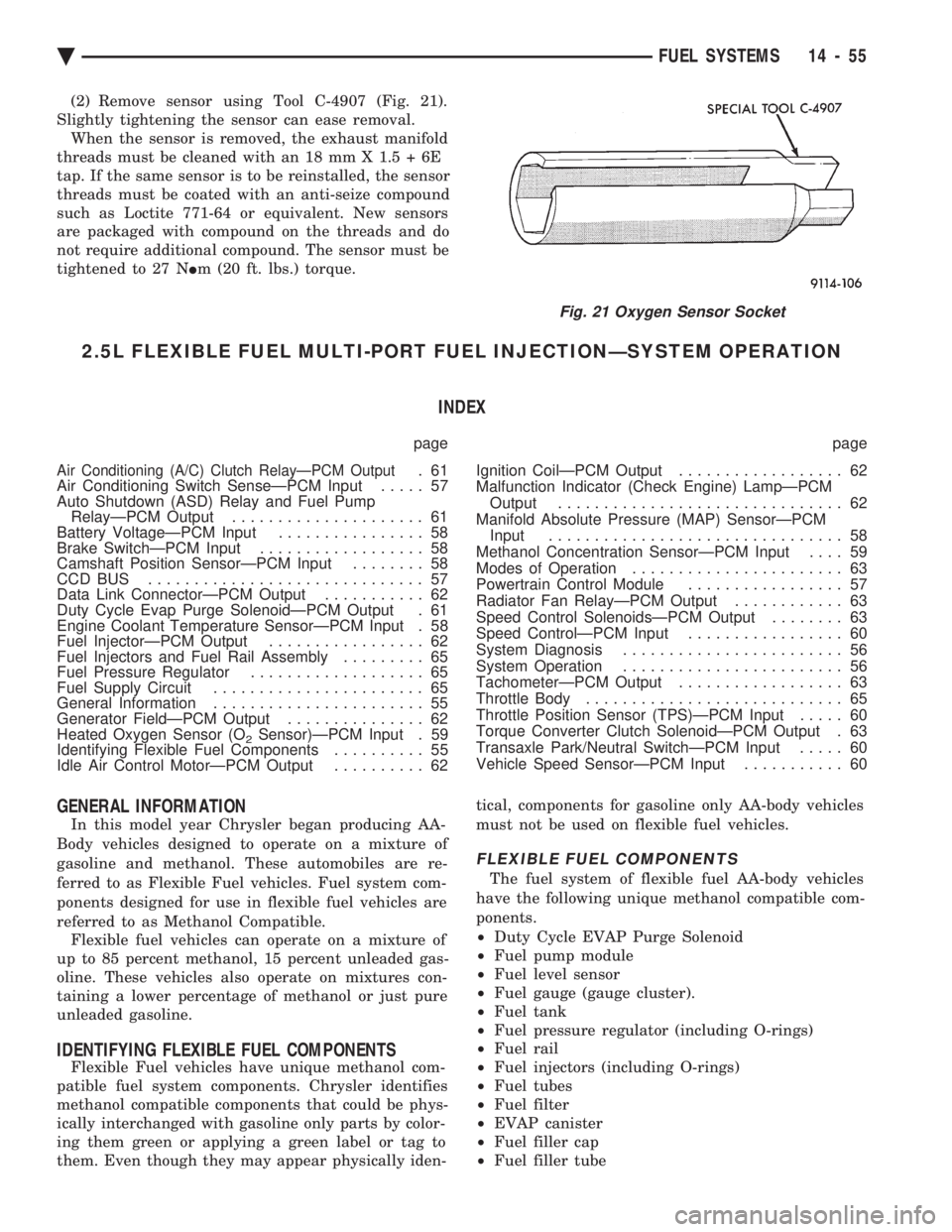

(2) Remove sensor using Tool C-4907 (Fig. 21).

Slightly tightening the sensor can ease removal. When the sensor is removed, the exhaust manifold

threads must be cleaned with an 18 mm X 1.5 + 6E

tap. If the same sensor is to be reinstalled, the sensor

threads must be coated with an anti-seize compound

such as Loctite 771-64 or equivalent. New sensors

are packaged with compound on the threads and do

not require additional compound. The sensor must be

tightened to 27 N Im (20 ft. lbs.) torque.

2.5L FLEXIBLE FUEL MULTI-PORT FUEL INJECTIONÐSYSTEM OPERATION

INDEX

page page

Air Conditioning (A/C) Clutch RelayÐPCM Output.61

Air Conditioning Switch SenseÐPCM Input ..... 57

Auto Shutdown (ASD) Relay and Fuel Pump RelayÐPCM Output ..................... 61

Battery VoltageÐPCM Input ................ 58

Brake SwitchÐPCM Input .................. 58

Camshaft Position SensorÐPCM Input ........ 58

CCD BUS .............................. 57

Data Link ConnectorÐPCM Output ........... 62

Duty Cycle Evap Purge SolenoidÐPCM Output . 61

Engine Coolant Temperature SensorÐPCM Input . 58

Fuel InjectorÐPCM Output ................. 62

Fuel Injectors and Fuel Rail Assembly ......... 65

Fuel Pressure Regulator ................... 65

Fuel Supply Circuit ....................... 65

General Information ....................... 55

Generator FieldÐPCM Output ............... 62

Heated Oxygen Sensor (O

2Sensor)ÐPCM Input . 59

Identifying Flexible Fuel Components .......... 55

Idle Air Control MotorÐPCM Output .......... 62 Ignition CoilÐPCM Output

.................. 62

Malfunction Indicator (Check Engine) LampÐPCM Output ............................... 62

Manifold Absolute Pressure (MAP) SensorÐPCM Input ................................ 58

Methanol Concentration SensorÐPCM Input .... 59

Modes of Operation ....................... 63

Powertrain Control Module ................. 57

Radiator Fan RelayÐPCM Output ............ 63

Speed Control SolenoidsÐPCM Output ........ 63

Speed ControlÐPCM Input ................. 60

System Diagnosis ........................ 56

System Operation ........................ 56

TachometerÐPCM Output .................. 63

Throttle Body ............................ 65

Throttle Position Sensor (TPS)ÐPCM Input ..... 60

Torque Converter Clutch SolenoidÐPCM Output . 63

Transaxle Park/Neutral SwitchÐPCM Input ..... 60

Vehicle Speed SensorÐPCM Input ........... 60

GENERAL INFORMATION

In this model year Chrysler began producing AA-

Body vehicles designed to operate on a mixture of

gasoline and methanol. These automobiles are re-

ferred to as Flexible Fuel vehicles. Fuel system com-

ponents designed for use in flexible fuel vehicles are

referred to as Methanol Compatible. Flexible fuel vehicles can operate on a mixture of

up to 85 percent methanol, 15 percent unleaded gas-

oline. These vehicles also operate on mixtures con-

taining a lower percentage of methanol or just pure

unleaded gasoline.

IDENTIFYING FLEXIBLE FUEL COMPONENTS

Flexible Fuel vehicles have unique methanol com-

patible fuel system components. Chrysler identifies

methanol compatible components that could be phys-

ically interchanged with gasoline only parts by color-

ing them green or applying a green label or tag to

them. Even though they may appear physically iden- tical, components for gasoline only AA-body vehicles

must not be used on flexible fuel vehicles.

FLEXIBLE FUEL COMPONENTS

The fuel system of flexible fuel AA-body vehicles

have the following unique methanol compatible com-

ponents.

² Duty Cycle EVAP Purge Solenoid

² Fuel pump module

² Fuel level sensor

² Fuel gauge (gauge cluster).

² Fuel tank

² Fuel pressure regulator (including O-rings)

² Fuel rail

² Fuel injectors (including O-rings)

² Fuel tubes

² Fuel filter

² EVAP canister

² Fuel filler cap

² Fuel filler tube

Fig. 21 Oxygen Sensor Socket

Ä FUEL SYSTEMS 14 - 55

Page 1796 of 2438

² Methanol Concentration Sensor

² Pressure relief/Rollover valve

² PCV Valve

² All fuel system and emission system hoses and

tubes

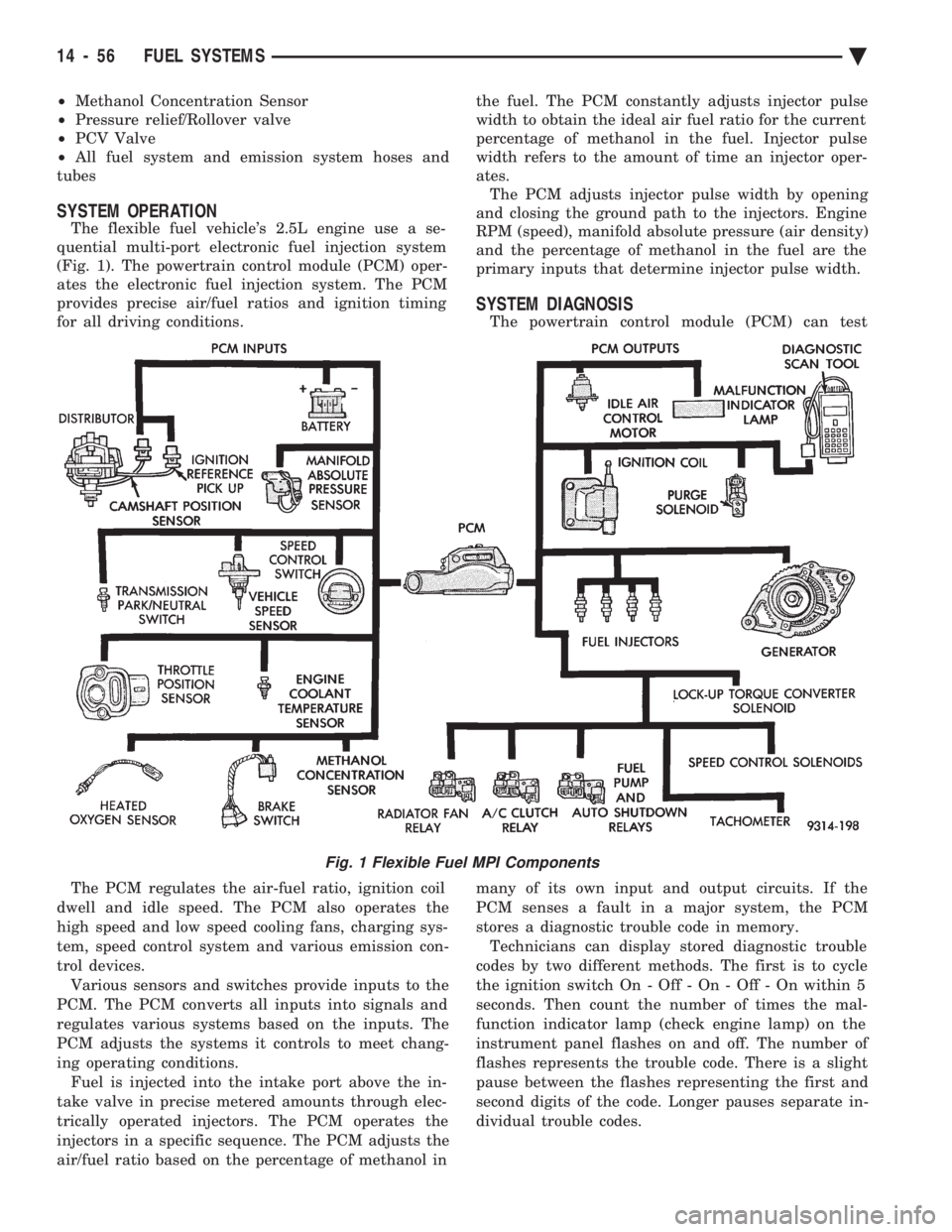

SYSTEM OPERATION

The flexible fuel vehicle's 2.5L engine use a se-

quential multi-port electronic fuel injection system

(Fig. 1). The powertrain control module (PCM) oper-

ates the electronic fuel injection system. The PCM

provides precise air/fuel ratios and ignition timing

for all driving conditions.

The PCM regulates the air-fuel ratio, ignition coil

dwell and idle speed. The PCM also operates the

high speed and low speed cooling fans, charging sys-

tem, speed control system and various emission con-

trol devices. Various sensors and switches provide inputs to the

PCM. The PCM converts all inputs into signals and

regulates various systems based on the inputs. The

PCM adjusts the systems it controls to meet chang-

ing operating conditions. Fuel is injected into the intake port above the in-

take valve in precise metered amounts through elec-

trically operated injectors. The PCM operates the

injectors in a specific sequence. The PCM adjusts the

air/fuel ratio based on the percentage of methanol in the fuel. The PCM constantly adjusts injector pulse

width to obtain the ideal air fuel ratio for the current

percentage of methanol in the fuel. Injector pulse

width refers to the amount of time an injector oper-

ates. The PCM adjusts injector pulse width by opening

and closing the ground path to the injectors. Engine

RPM (speed), manifold absolute pressure (air density)

and the percentage of methanol in the fuel are the

primary inputs that determine injector pulse width.

SYSTEM DIAGNOSIS

The powertrain control module (PCM) can test

many of its own input and output circuits. If the

PCM senses a fault in a major system, the PCM

stores a diagnostic trouble code in memory. Technicians can display stored diagnostic trouble

codes by two different methods. The first is to cycle

the ignition switch On - Off - On - Off - On within 5

seconds. Then count the number of times the mal-

function indicator lamp (check engine lamp) on the

instrument panel flashes on and off. The number of

flashes represents the trouble code. There is a slight

pause between the flashes representing the first and

second digits of the code. Longer pauses separate in-

dividual trouble codes.

Fig. 1 Flexible Fuel MPI Components

14 - 56 FUEL SYSTEMS Ä

Page 1797 of 2438

The second method of reading diagnostic trouble

codes uses the DRBII scan tool. For diagnostic trou-

ble code information, refer to the On-Board Diagnos-

tics section in this group.

CCD BUS

Various modules exchange information through a

communications port called the CCD Bus. The pow-

ertrain control module transmits vehicle load data on

the CCD Bus.

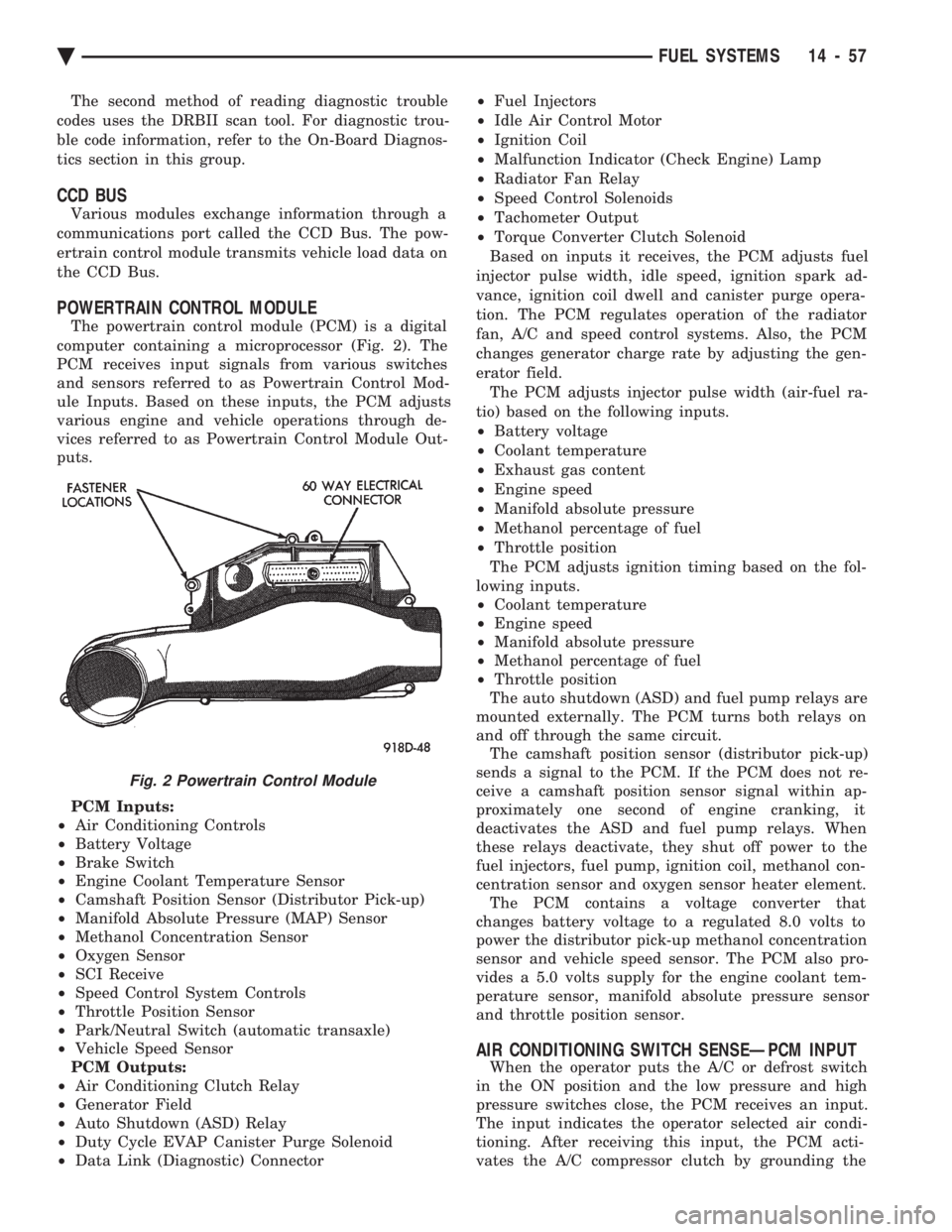

POWERTRAIN CONTROL MODULE

The powertrain control module (PCM) is a digital

computer containing a microprocessor (Fig. 2). The

PCM receives input signals from various switches

and sensors referred to as Powertrain Control Mod-

ule Inputs. Based on these inputs, the PCM adjusts

various engine and vehicle operations through de-

vices referred to as Powertrain Control Module Out-

puts.

PCM Inputs:

² Air Conditioning Controls

² Battery Voltage

² Brake Switch

² Engine Coolant Temperature Sensor

² Camshaft Position Sensor (Distributor Pick-up)

² Manifold Absolute Pressure (MAP) Sensor

² Methanol Concentration Sensor

² Oxygen Sensor

² SCI Receive

² Speed Control System Controls

² Throttle Position Sensor

² Park/Neutral Switch (automatic transaxle)

² Vehicle Speed Sensor

PCM Outputs:

² Air Conditioning Clutch Relay

² Generator Field

² Auto Shutdown (ASD) Relay

² Duty Cycle EVAP Canister Purge Solenoid

² Data Link (Diagnostic) Connector ²

Fuel Injectors

² Idle Air Control Motor

² Ignition Coil

² Malfunction Indicator (Check Engine) Lamp

² Radiator Fan Relay

² Speed Control Solenoids

² Tachometer Output

² Torque Converter Clutch Solenoid

Based on inputs it receives, the PCM adjusts fuel

injector pulse width, idle speed, ignition spark ad-

vance, ignition coil dwell and canister purge opera-

tion. The PCM regulates operation of the radiator

fan, A/C and speed control systems. Also, the PCM

changes generator charge rate by adjusting the gen-

erator field. The PCM adjusts injector pulse width (air-fuel ra-

tio) based on the following inputs.

² Battery voltage

² Coolant temperature

² Exhaust gas content

² Engine speed

² Manifold absolute pressure

² Methanol percentage of fuel

² Throttle position

The PCM adjusts ignition timing based on the fol-

lowing inputs.

² Coolant temperature

² Engine speed

² Manifold absolute pressure

² Methanol percentage of fuel

² Throttle position

The auto shutdown (ASD) and fuel pump relays are

mounted externally. The PCM turns both relays on

and off through the same circuit. The camshaft position sensor (distributor pick-up)

sends a signal to the PCM. If the PCM does not re-

ceive a camshaft position sensor signal within ap-

proximately one second of engine cranking, it

deactivates the ASD and fuel pump relays. When

these relays deactivate, they shut off power to the

fuel injectors, fuel pump, ignition coil, methanol con-

centration sensor and oxygen sensor heater element. The PCM contains a voltage converter that

changes battery voltage to a regulated 8.0 volts to

power the distributor pick-up methanol concentration

sensor and vehicle speed sensor. The PCM also pro-

vides a 5.0 volts supply for the engine coolant tem-

perature sensor, manifold absolute pressure sensor

and throttle position sensor.

AIR CONDITIONING SWITCH SENSEÐPCM INPUT

When the operator puts the A/C or defrost switch

in the ON position and the low pressure and high

pressure switches close, the PCM receives an input.

The input indicates the operator selected air condi-

tioning. After receiving this input, the PCM acti-

vates the A/C compressor clutch by grounding the

Fig. 2 Powertrain Control Module

Ä FUEL SYSTEMS 14 - 57

Page 1798 of 2438

A/C clutch relay. To compensate for increased engine

load, the PCM also adjusts idle speed to a scheduled

RPM.

BATTERY VOLTAGEÐPCM INPUT

The powertrain control module (PCM) monitors the

battery voltage input to determine fuel injector pulse

width and generator field control. If battery voltage

is low, the PCM increases injector pulse width to

compensate.

BRAKE SWITCHÐPCM INPUT

When the brake switch activates, the powertrain

control module (PCM) receives an input indicating

that the brakes are being applied. After receiving the

input, the PCM vents the speed control servo. Vent-

ing the servo turns the speed control system off.

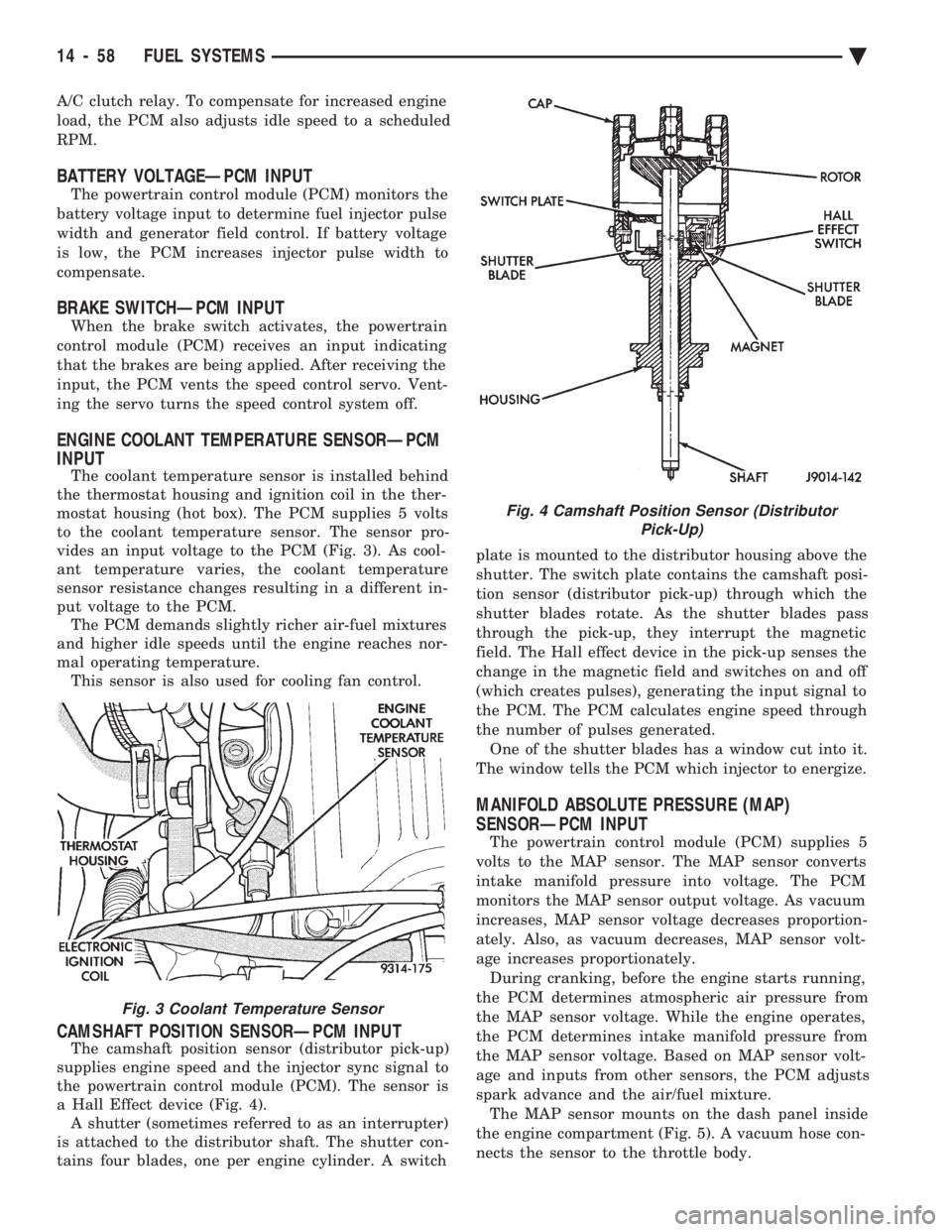

ENGINE COOLANT TEMPERATURE SENSORÐPCM

INPUT

The coolant temperature sensor is installed behind

the thermostat housing and ignition coil in the ther-

mostat housing (hot box). The PCM supplies 5 volts

to the coolant temperature sensor. The sensor pro-

vides an input voltage to the PCM (Fig. 3). As cool-

ant temperature varies, the coolant temperature

sensor resistance changes resulting in a different in-

put voltage to the PCM. The PCM demands slightly richer air-fuel mixtures

and higher idle speeds until the engine reaches nor-

mal operating temperature. This sensor is also used for cooling fan control.

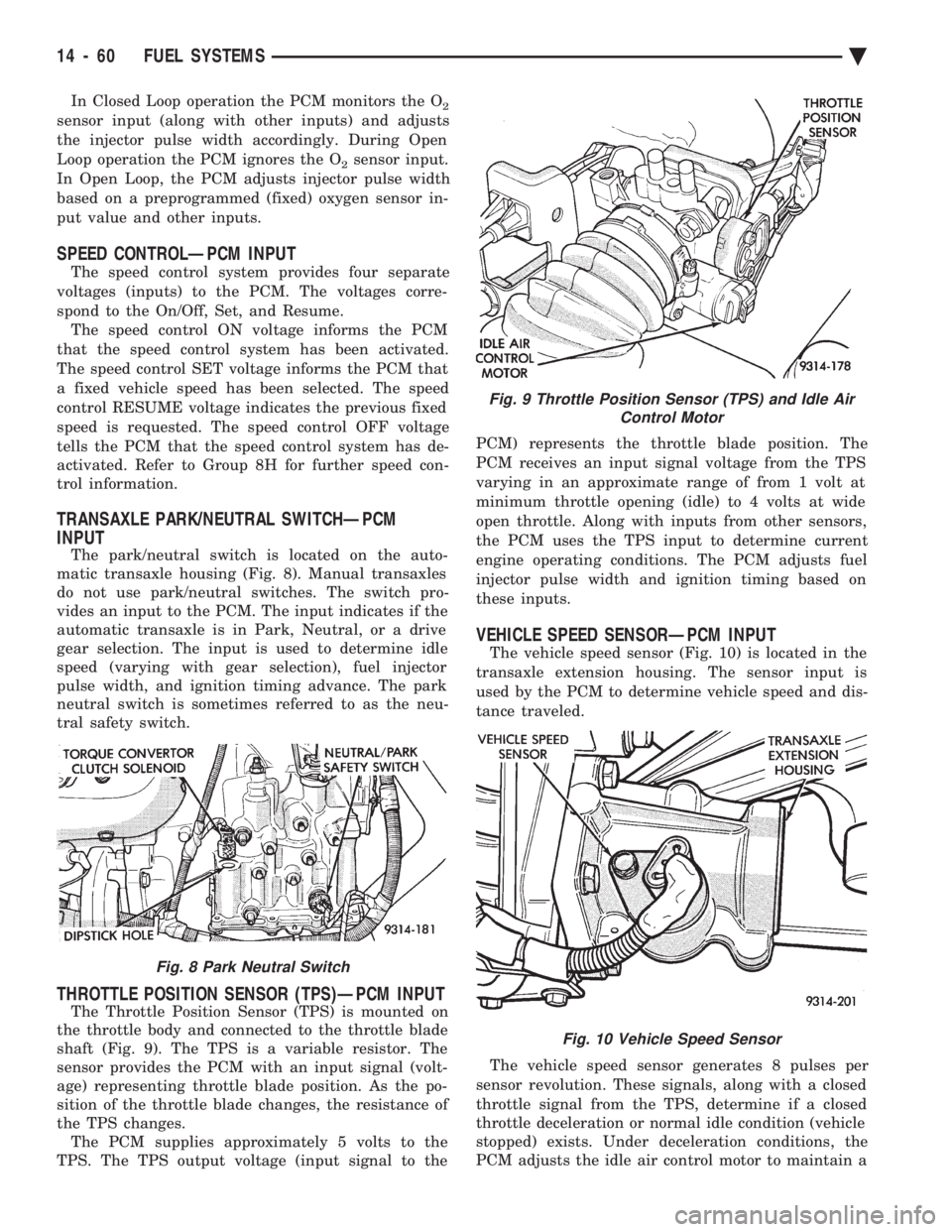

CAMSHAFT POSITION SENSORÐPCM INPUT

The camshaft position sensor (distributor pick-up)

supplies engine speed and the injector sync signal to

the powertrain control module (PCM). The sensor is

a Hall Effect device (Fig. 4). A shutter (sometimes referred to as an interrupter)

is attached to the distributor shaft. The shutter con-

tains four blades, one per engine cylinder. A switch plate is mounted to the distributor housing above the

shutter. The switch plate contains the camshaft posi-

tion sensor (distributor pick-up) through which the

shutter blades rotate. As the shutter blades pass

through the pick-up, they interrupt the magnetic

field. The Hall effect device in the pick-up senses the

change in the magnetic field and switches on and off

(which creates pulses), generating the input signal to

the PCM. The PCM calculates engine speed through

the number of pulses generated. One of the shutter blades has a window cut into it.

The window tells the PCM which injector to energize.

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSORÐPCM INPUT

The powertrain control module (PCM) supplies 5

volts to the MAP sensor. The MAP sensor converts

intake manifold pressure into voltage. The PCM

monitors the MAP sensor output voltage. As vacuum

increases, MAP sensor voltage decreases proportion-

ately. Also, as vacuum decreases, MAP sensor volt-

age increases proportionately. During cranking, before the engine starts running,

the PCM determines atmospheric air pressure from

the MAP sensor voltage. While the engine operates,

the PCM determines intake manifold pressure from

the MAP sensor voltage. Based on MAP sensor volt-

age and inputs from other sensors, the PCM adjusts

spark advance and the air/fuel mixture. The MAP sensor mounts on the dash panel inside

the engine compartment (Fig. 5). A vacuum hose con-

nects the sensor to the throttle body.

Fig. 3 Coolant Temperature Sensor

Fig. 4 Camshaft Position Sensor (Distributor Pick-Up)

14 - 58 FUEL SYSTEMS Ä

Page 1800 of 2438

In Closed Loop operation the PCM monitors the O2

sensor input (along with other inputs) and adjusts

the injector pulse width accordingly. During Open

Loop operation the PCM ignores the O

2sensor input.

In Open Loop, the PCM adjusts injector pulse width

based on a preprogrammed (fixed) oxygen sensor in-

put value and other inputs.

SPEED CONTROLÐPCM INPUT

The speed control system provides four separate

voltages (inputs) to the PCM. The voltages corre-

spond to the On/Off, Set, and Resume. The speed control ON voltage informs the PCM

that the speed control system has been activated.

The speed control SET voltage informs the PCM that

a fixed vehicle speed has been selected. The speed

control RESUME voltage indicates the previous fixed

speed is requested. The speed control OFF voltage

tells the PCM that the speed control system has de-

activated. Refer to Group 8H for further speed con-

trol information.

TRANSAXLE PARK/NEUTRAL SWITCHÐPCM

INPUT

The park/neutral switch is located on the auto-

matic transaxle housing (Fig. 8). Manual transaxles

do not use park/neutral switches. The switch pro-

vides an input to the PCM. The input indicates if the

automatic transaxle is in Park, Neutral, or a drive

gear selection. The input is used to determine idle

speed (varying with gear selection), fuel injector

pulse width, and ignition timing advance. The park

neutral switch is sometimes referred to as the neu-

tral safety switch.

THROTTLE POSITION SENSOR (TPS)ÐPCM INPUT

The Throttle Position Sensor (TPS) is mounted on

the throttle body and connected to the throttle blade

shaft (Fig. 9). The TPS is a variable resistor. The

sensor provides the PCM with an input signal (volt-

age) representing throttle blade position. As the po-

sition of the throttle blade changes, the resistance of

the TPS changes. The PCM supplies approximately 5 volts to the

TPS. The TPS output voltage (input signal to the PCM) represents the throttle blade position. The

PCM receives an input signal voltage from the TPS

varying in an approximate range of from 1 volt at

minimum throttle opening (idle) to 4 volts at wide

open throttle. Along with inputs from other sensors,

the PCM uses the TPS input to determine current

engine operating conditions. The PCM adjusts fuel

injector pulse width and ignition timing based on

these inputs.

VEHICLE SPEED SENSORÐPCM INPUT

The vehicle speed sensor (Fig. 10) is located in the

transaxle extension housing. The sensor input is

used by the PCM to determine vehicle speed and dis-

tance traveled.

The vehicle speed sensor generates 8 pulses per

sensor revolution. These signals, along with a closed

throttle signal from the TPS, determine if a closed

throttle deceleration or normal idle condition (vehicle

stopped) exists. Under deceleration conditions, the

PCM adjusts the idle air control motor to maintain a

Fig. 8 Park Neutral Switch

Fig. 9 Throttle Position Sensor (TPS) and Idle Air Control Motor

Fig. 10 Vehicle Speed Sensor

14 - 60 FUEL SYSTEMS Ä

Page 1801 of 2438

desired MAP value. Under idle conditions, the PCM

adjusts the idle air control motor to maintain a de-

sired engine speed.

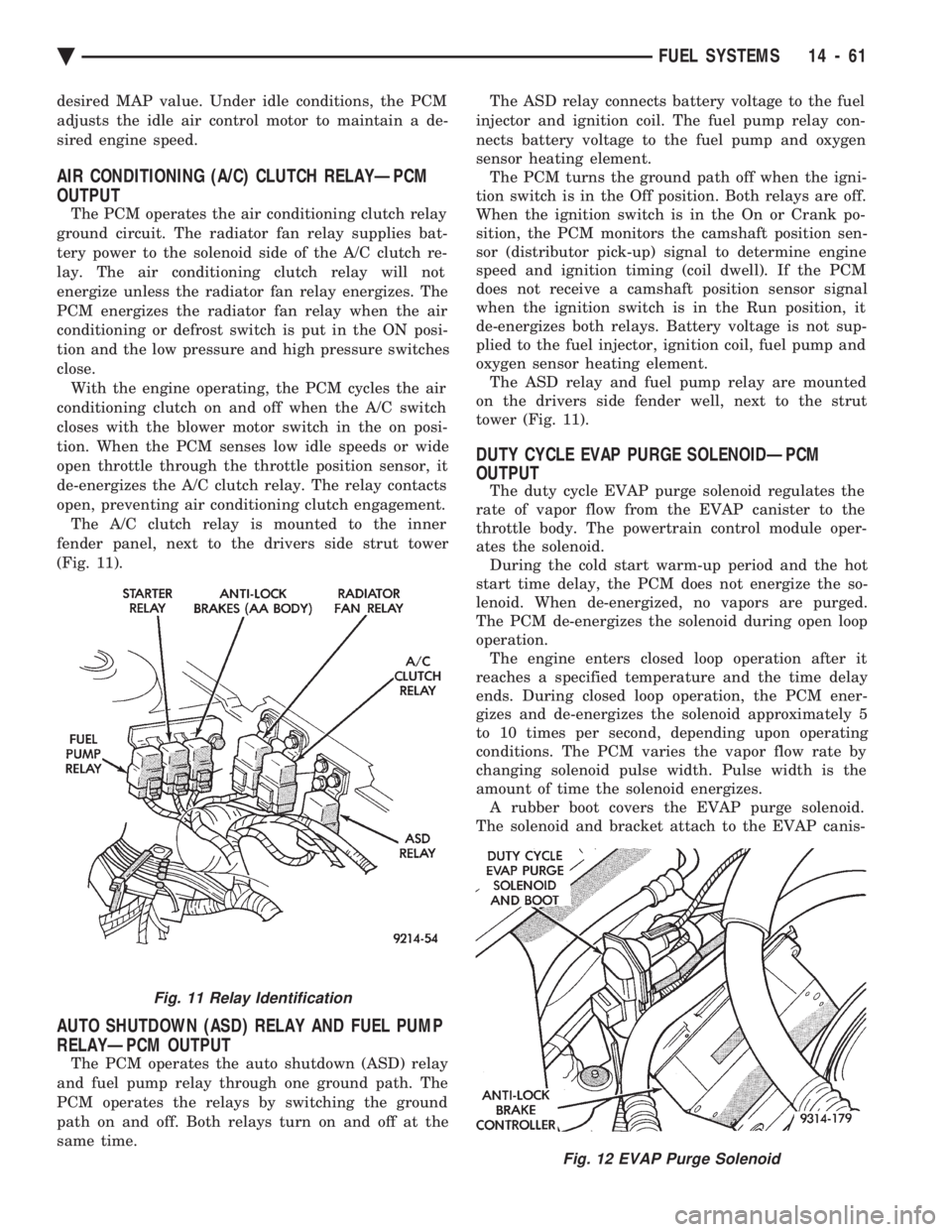

AIR CONDITIONING (A/C) CLUTCH RELAYÐPCM

OUTPUT

The PCM operates the air conditioning clutch relay

ground circuit. The radiator fan relay supplies bat-

tery power to the solenoid side of the A/C clutch re-

lay. The air conditioning clutch relay will not

energize unless the radiator fan relay energizes. The

PCM energizes the radiator fan relay when the air

conditioning or defrost switch is put in the ON posi-

tion and the low pressure and high pressure switches

close. With the engine operating, the PCM cycles the air

conditioning clutch on and off when the A/C switch

closes with the blower motor switch in the on posi-

tion. When the PCM senses low idle speeds or wide

open throttle through the throttle position sensor, it

de-energizes the A/C clutch relay. The relay contacts

open, preventing air conditioning clutch engagement. The A/C clutch relay is mounted to the inner

fender panel, next to the drivers side strut tower

(Fig. 11).

AUTO SHUTDOWN (ASD) RELAY AND FUEL PUMP

RELAYÐPCM OUTPUT

The PCM operates the auto shutdown (ASD) relay

and fuel pump relay through one ground path. The

PCM operates the relays by switching the ground

path on and off. Both relays turn on and off at the

same time. The ASD relay connects battery voltage to the fuel

injector and ignition coil. The fuel pump relay con-

nects battery voltage to the fuel pump and oxygen

sensor heating element. The PCM turns the ground path off when the igni-

tion switch is in the Off position. Both relays are off.

When the ignition switch is in the On or Crank po-

sition, the PCM monitors the camshaft position sen-

sor (distributor pick-up) signal to determine engine

speed and ignition timing (coil dwell). If the PCM

does not receive a camshaft position sensor signal

when the ignition switch is in the Run position, it

de-energizes both relays. Battery voltage is not sup-

plied to the fuel injector, ignition coil, fuel pump and

oxygen sensor heating element. The ASD relay and fuel pump relay are mounted

on the drivers side fender well, next to the strut

tower (Fig. 11).

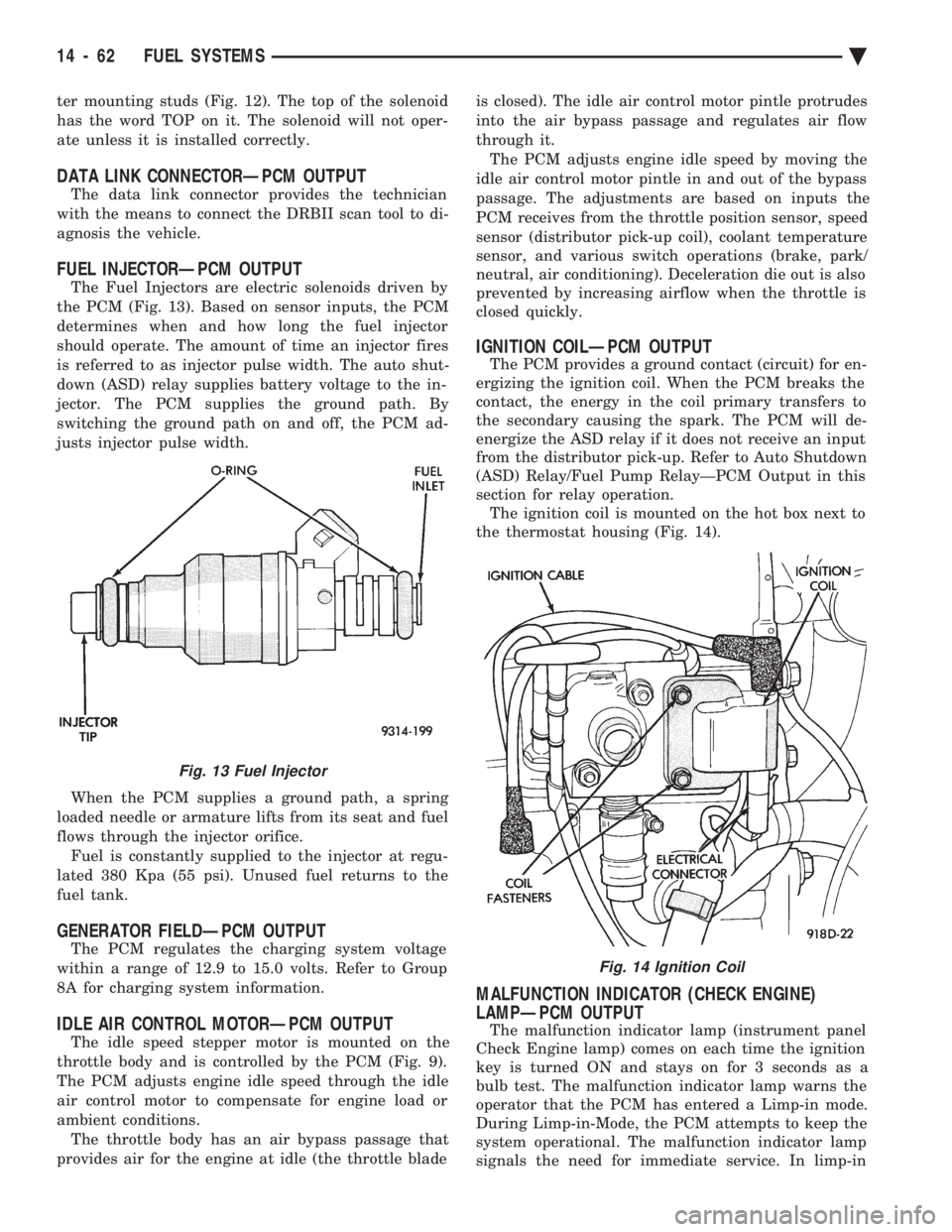

DUTY CYCLE EVAP PURGE SOLENOIDÐPCM

OUTPUT

The duty cycle EVAP purge solenoid regulates the

rate of vapor flow from the EVAP canister to the

throttle body. The powertrain control module oper-

ates the solenoid. During the cold start warm-up period and the hot

start time delay, the PCM does not energize the so-

lenoid. When de-energized, no vapors are purged.

The PCM de-energizes the solenoid during open loop

operation. The engine enters closed loop operation after it

reaches a specified temperature and the time delay

ends. During closed loop operation, the PCM ener-

gizes and de-energizes the solenoid approximately 5

to 10 times per second, depending upon operating

conditions. The PCM varies the vapor flow rate by

changing solenoid pulse width. Pulse width is the

amount of time the solenoid energizes. A rubber boot covers the EVAP purge solenoid.

The solenoid and bracket attach to the EVAP canis-

Fig. 12 EVAP Purge Solenoid

Fig. 11 Relay Identification

Ä FUEL SYSTEMS 14 - 61

Page 1802 of 2438

ter mounting studs (Fig. 12). The top of the solenoid

has the word TOP on it. The solenoid will not oper-

ate unless it is installed correctly.

DATA LINK CONNECTORÐPCM OUTPUT

The data link connector provides the technician

with the means to connect the DRBII scan tool to di-

agnosis the vehicle.

FUEL INJECTORÐPCM OUTPUT

The Fuel Injectors are electric solenoids driven by

the PCM (Fig. 13). Based on sensor inputs, the PCM

determines when and how long the fuel injector

should operate. The amount of time an injector fires

is referred to as injector pulse width. The auto shut-

down (ASD) relay supplies battery voltage to the in-

jector. The PCM supplies the ground path. By

switching the ground path on and off, the PCM ad-

justs injector pulse width.

When the PCM supplies a ground path, a spring

loaded needle or armature lifts from its seat and fuel

flows through the injector orifice. Fuel is constantly supplied to the injector at regu-

lated 380 Kpa (55 psi). Unused fuel returns to the

fuel tank.

GENERATOR FIELDÐPCM OUTPUT

The PCM regulates the charging system voltage

within a range of 12.9 to 15.0 volts. Refer to Group

8A for charging system information.

IDLE AIR CONTROL MOTORÐPCM OUTPUT

The idle speed stepper motor is mounted on the

throttle body and is controlled by the PCM (Fig. 9).

The PCM adjusts engine idle speed through the idle

air control motor to compensate for engine load or

ambient conditions. The throttle body has an air bypass passage that

provides air for the engine at idle (the throttle blade is closed). The idle air control motor pintle protrudes

into the air bypass passage and regulates air flow

through it. The PCM adjusts engine idle speed by moving the

idle air control motor pintle in and out of the bypass

passage. The adjustments are based on inputs the

PCM receives from the throttle position sensor, speed

sensor (distributor pick-up coil), coolant temperature

sensor, and various switch operations (brake, park/

neutral, air conditioning). Deceleration die out is also

prevented by increasing airflow when the throttle is

closed quickly.

IGNITION COILÐPCM OUTPUT

The PCM provides a ground contact (circuit) for en-

ergizing the ignition coil. When the PCM breaks the

contact, the energy in the coil primary transfers to

the secondary causing the spark. The PCM will de-

energize the ASD relay if it does not receive an input

from the distributor pick-up. Refer to Auto Shutdown

(ASD) Relay/Fuel Pump RelayÐPCM Output in this

section for relay operation. The ignition coil is mounted on the hot box next to

the thermostat housing (Fig. 14).

MALFUNCTION INDICATOR (CHECK ENGINE)

LAMPÐPCM OUTPUT

The malfunction indicator lamp (instrument panel

Check Engine lamp) comes on each time the ignition

key is turned ON and stays on for 3 seconds as a

bulb test. The malfunction indicator lamp warns the

operator that the PCM has entered a Limp-in mode.

During Limp-in-Mode, the PCM attempts to keep the

system operational. The malfunction indicator lamp

signals the need for immediate service. In limp-in

Fig. 13 Fuel Injector

Fig. 14 Ignition Coil

14 - 62 FUEL SYSTEMS Ä