ignition CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1831 of 2438

diagnostic trouble codes stored in the PCM will be

displayed. Refer to the 2.2L Turbo III Multi-port Fuel

InjectionÐOn-Board Diagnostics section of this

Group for Diagnostic trouble code Descriptions.

DATA LINK CONNECTORÐPCM OUTPUT

The data link connector provides the technician

with the means to connect the DRBII scan tool to di-

agnosis the vehicle.

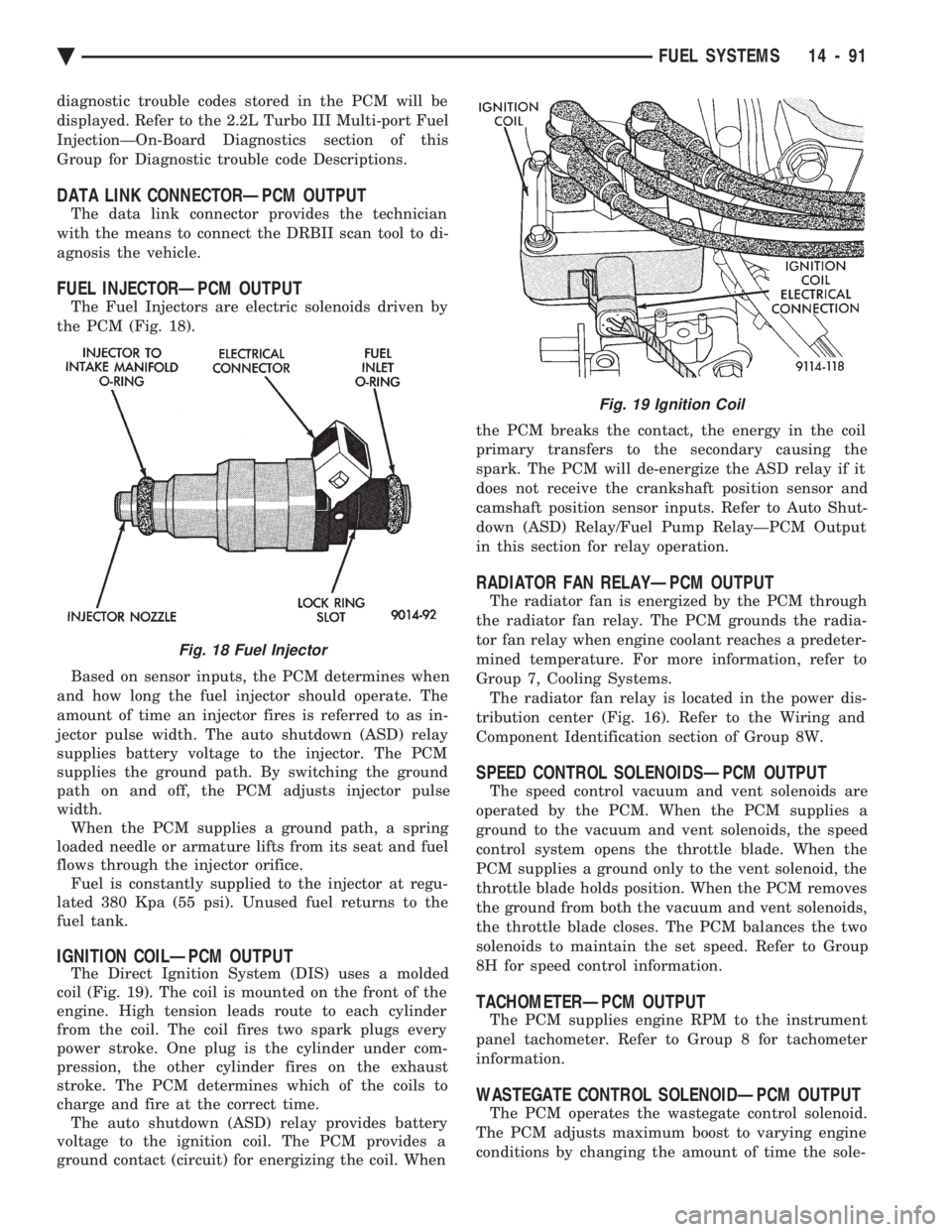

FUEL INJECTORÐPCM OUTPUT

The Fuel Injectors are electric solenoids driven by

the PCM (Fig. 18).

Based on sensor inputs, the PCM determines when

and how long the fuel injector should operate. The

amount of time an injector fires is referred to as in-

jector pulse width. The auto shutdown (ASD) relay

supplies battery voltage to the injector. The PCM

supplies the ground path. By switching the ground

path on and off, the PCM adjusts injector pulse

width. When the PCM supplies a ground path, a spring

loaded needle or armature lifts from its seat and fuel

flows through the injector orifice. Fuel is constantly supplied to the injector at regu-

lated 380 Kpa (55 psi). Unused fuel returns to the

fuel tank.

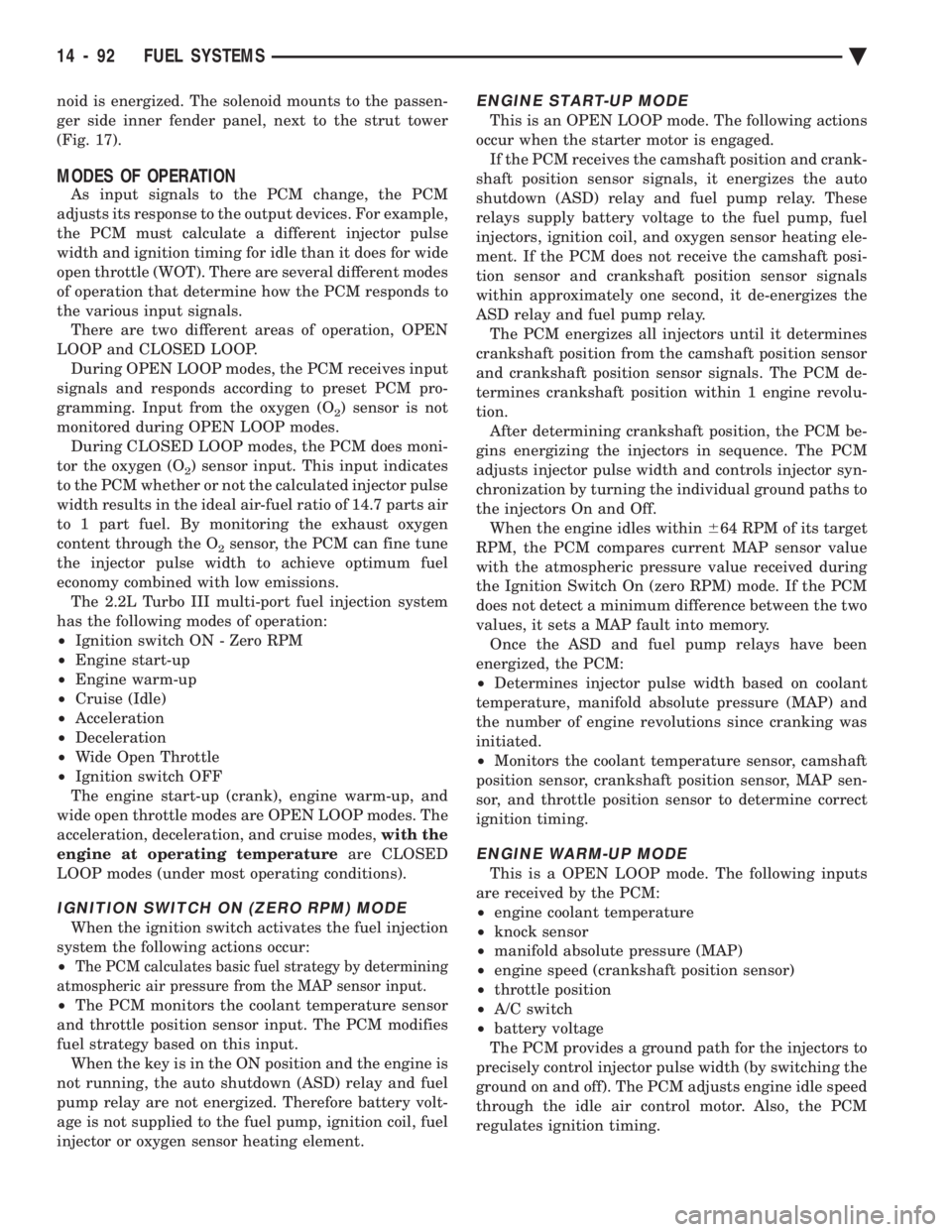

IGNITION COILÐPCM OUTPUT

The Direct Ignition System (DIS) uses a molded

coil (Fig. 19). The coil is mounted on the front of the

engine. High tension leads route to each cylinder

from the coil. The coil fires two spark plugs every

power stroke. One plug is the cylinder under com-

pression, the other cylinder fires on the exhaust

stroke. The PCM determines which of the coils to

charge and fire at the correct time. The auto shutdown (ASD) relay provides battery

voltage to the ignition coil. The PCM provides a

ground contact (circuit) for energizing the coil. When the PCM breaks the contact, the energy in the coil

primary transfers to the secondary causing the

spark. The PCM will de-energize the ASD relay if it

does not receive the crankshaft position sensor and

camshaft position sensor inputs. Refer to Auto Shut-

down (ASD) Relay/Fuel Pump RelayÐPCM Output

in this section for relay operation.

RADIATOR FAN RELAYÐPCM OUTPUT

The radiator fan is energized by the PCM through

the radiator fan relay. The PCM grounds the radia-

tor fan relay when engine coolant reaches a predeter-

mined temperature. For more information, refer to

Group 7, Cooling Systems. The radiator fan relay is located in the power dis-

tribution center (Fig. 16). Refer to the Wiring and

Component Identification section of Group 8W.

SPEED CONTROL SOLENOIDSÐPCM OUTPUT

The speed control vacuum and vent solenoids are

operated by the PCM. When the PCM supplies a

ground to the vacuum and vent solenoids, the speed

control system opens the throttle blade. When the

PCM supplies a ground only to the vent solenoid, the

throttle blade holds position. When the PCM removes

the ground from both the vacuum and vent solenoids,

the throttle blade closes. The PCM balances the two

solenoids to maintain the set speed. Refer to Group

8H for speed control information.

TACHOMETERÐPCM OUTPUT

The PCM supplies engine RPM to the instrument

panel tachometer. Refer to Group 8 for tachometer

information.

WASTEGATE CONTROL SOLENOIDÐPCM OUTPUT

The PCM operates the wastegate control solenoid.

The PCM adjusts maximum boost to varying engine

conditions by changing the amount of time the sole-

Fig. 18 Fuel Injector

Fig. 19 Ignition Coil

Ä FUEL SYSTEMS 14 - 91

Page 1832 of 2438

noid is energized. The solenoid mounts to the passen-

ger side inner fender panel, next to the strut tower

(Fig. 17).

MODES OF OPERATION

As input signals to the PCM change, the PCM

adjusts its response to the output devices. For example,

the PCM must calculate a different injector pulse

width and ignition timing for idle than it does for wide

open throttle (WOT). There are several different modes

of operation that determine how the PCM responds to

the various input signals. There are two different areas of operation, OPEN

LOOP and CLOSED LOOP. During OPEN LOOP modes, the PCM receives input

signals and responds according to preset PCM pro-

gramming. Input from the oxygen (O

2) sensor is not

monitored during OPEN LOOP modes. During CLOSED LOOP modes, the PCM does moni-

tor the oxygen (O

2) sensor input. This input indicates

to the PCM whether or not the calculated injector pulse

width results in the ideal air-fuel ratio of 14.7 parts air

to 1 part fuel. By monitoring the exhaust oxygen

content through the O

2sensor, the PCM can fine tune

the injector pulse width to achieve optimum fuel

economy combined with low emissions. The 2.2L Turbo III multi-port fuel injection system

has the following modes of operation:

² Ignition switch ON - Zero RPM

² Engine start-up

² Engine warm-up

² Cruise (Idle)

² Acceleration

² Deceleration

² Wide Open Throttle

² Ignition switch OFF

The engine start-up (crank), engine warm-up, and

wide open throttle modes are OPEN LOOP modes. The

acceleration, deceleration, and cruise modes, with the

engine at operating temperature are CLOSED

LOOP modes (under most operating conditions).

IGNITION SWITCH ON (ZERO RPM) MODE

When the ignition switch activates the fuel injection

system the following actions occur:

²

The PCM calculates basic fuel strategy by determining

atmospheric air pressure from the MAP sensor input.

² The PCM monitors the coolant temperature sensor

and throttle position sensor input. The PCM modifies

fuel strategy based on this input. When the key is in the ON position and the engine is

not running, the auto shutdown (ASD) relay and fuel

pump relay are not energized. Therefore battery volt-

age is not supplied to the fuel pump, ignition coil, fuel

injector or oxygen sensor heating element.

ENGINE START-UP MODE

This is an OPEN LOOP mode. The following actions

occur when the starter motor is engaged. If the PCM receives the camshaft position and crank-

shaft position sensor signals, it energizes the auto

shutdown (ASD) relay and fuel pump relay. These

relays supply battery voltage to the fuel pump, fuel

injectors, ignition coil, and oxygen sensor heating ele-

ment. If the PCM does not receive the camshaft posi-

tion sensor and crankshaft position sensor signals

within approximately one second, it de-energizes the

ASD relay and fuel pump relay. The PCM energizes all injectors until it determines

crankshaft position from the camshaft position sensor

and crankshaft position sensor signals. The PCM de-

termines crankshaft position within 1 engine revolu-

tion. After determining crankshaft position, the PCM be-

gins energizing the injectors in sequence. The PCM

adjusts injector pulse width and controls injector syn-

chronization by turning the individual ground paths to

the injectors On and Off. When the engine idles within 664 RPM of its target

RPM, the PCM compares current MAP sensor value

with the atmospheric pressure value received during

the Ignition Switch On (zero RPM) mode. If the PCM

does not detect a minimum difference between the two

values, it sets a MAP fault into memory. Once the ASD and fuel pump relays have been

energized, the PCM:

² Determines injector pulse width based on coolant

temperature, manifold absolute pressure (MAP) and

the number of engine revolutions since cranking was

initiated.

² Monitors the coolant temperature sensor, camshaft

position sensor, crankshaft position sensor, MAP sen-

sor, and throttle position sensor to determine correct

ignition timing.

ENGINE WARM-UP MODE

This is a OPEN LOOP mode. The following inputs

are received by the PCM:

² engine coolant temperature

² knock sensor

² manifold absolute pressure (MAP)

² engine speed (crankshaft position sensor)

² throttle position

² A/C switch

² battery voltage

The PCM provides a ground path for the injectors to

precisely control injector pulse width (by switching the

ground on and off). The PCM adjusts engine idle speed

through the idle air control motor. Also, the PCM

regulates ignition timing.

14 - 92 FUEL SYSTEMS Ä

Page 1833 of 2438

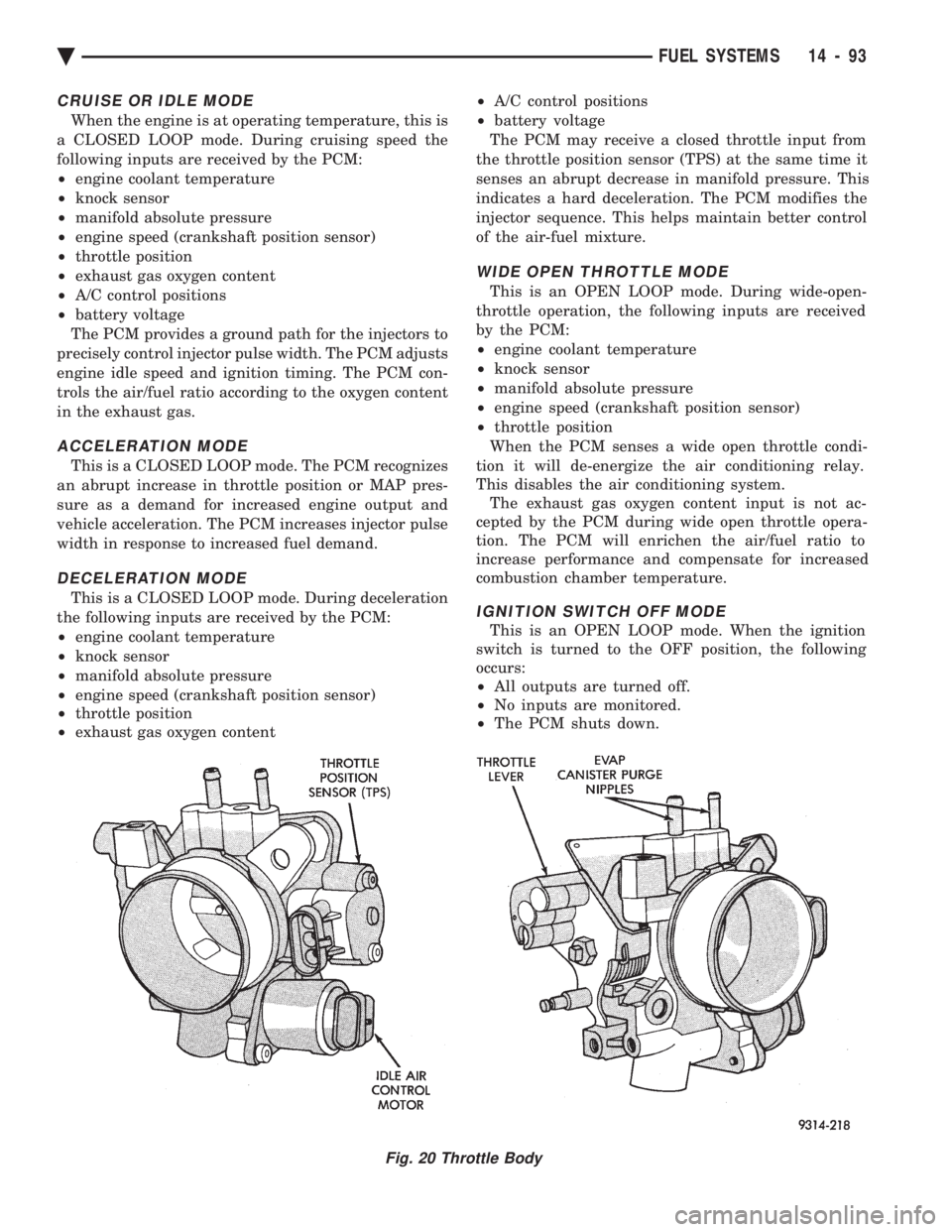

CRUISE OR IDLE MODE

When the engine is at operating temperature, this is

a CLOSED LOOP mode. During cruising speed the

following inputs are received by the PCM:

² engine coolant temperature

² knock sensor

² manifold absolute pressure

² engine speed (crankshaft position sensor)

² throttle position

² exhaust gas oxygen content

² A/C control positions

² battery voltage

The PCM provides a ground path for the injectors to

precisely control injector pulse width. The PCM adjusts

engine idle speed and ignition timing. The PCM con-

trols the air/fuel ratio according to the oxygen content

in the exhaust gas.

ACCELERATION MODE

This is a CLOSED LOOP mode. The PCM recognizes

an abrupt increase in throttle position or MAP pres-

sure as a demand for increased engine output and

vehicle acceleration. The PCM increases injector pulse

width in response to increased fuel demand.

DECELERATION MODE

This is a CLOSED LOOP mode. During deceleration

the following inputs are received by the PCM:

² engine coolant temperature

² knock sensor

² manifold absolute pressure

² engine speed (crankshaft position sensor)

² throttle position

² exhaust gas oxygen content ²

A/C control positions

² battery voltage

The PCM may receive a closed throttle input from

the throttle position sensor (TPS) at the same time it

senses an abrupt decrease in manifold pressure. This

indicates a hard deceleration. The PCM modifies the

injector sequence. This helps maintain better control

of the air-fuel mixture.

WIDE OPEN THROTTLE MODE

This is an OPEN LOOP mode. During wide-open-

throttle operation, the following inputs are received

by the PCM:

² engine coolant temperature

² knock sensor

² manifold absolute pressure

² engine speed (crankshaft position sensor)

² throttle position

When the PCM senses a wide open throttle condi-

tion it will de-energize the air conditioning relay.

This disables the air conditioning system. The exhaust gas oxygen content input is not ac-

cepted by the PCM during wide open throttle opera-

tion. The PCM will enrichen the air/fuel ratio to

increase performance and compensate for increased

combustion chamber temperature.

IGNITION SWITCH OFF MODE

This is an OPEN LOOP mode. When the ignition

switch is turned to the OFF position, the following

occurs:

² All outputs are turned off.

² No inputs are monitored.

² The PCM shuts down.

Fig. 20 Throttle Body

Ä FUEL SYSTEMS 14 - 93

Page 1835 of 2438

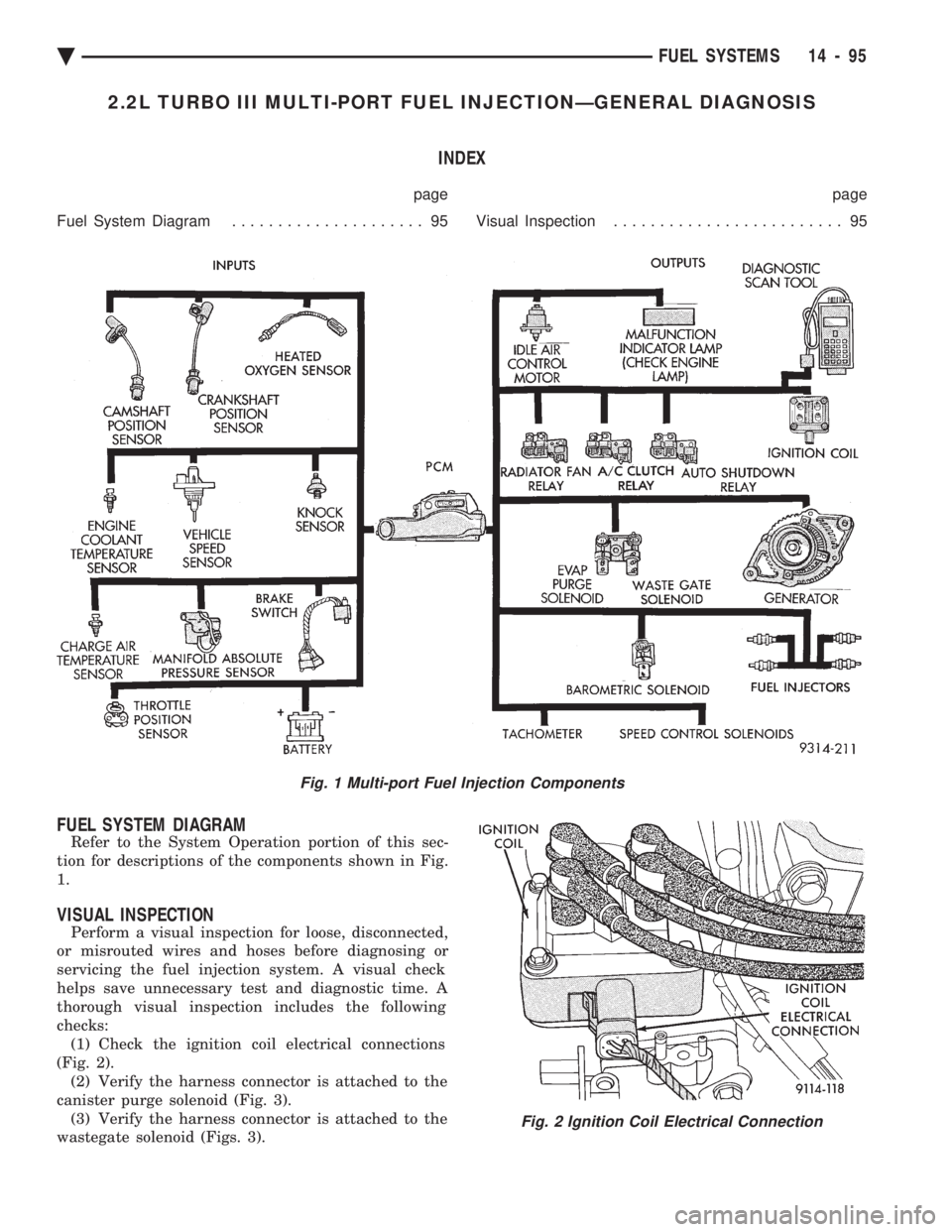

2.2L TURBO III MULTI-PORT FUEL INJECTIONÐGENERAL DIAGNOSIS INDEX

page page

Fuel System Diagram ..................... 95 Visual Inspection......................... 95

FUEL SYSTEM DIAGRAM

Refer to the System Operation portion of this sec-

tion for descriptions of the components shown in Fig.

1.

VISUAL INSPECTION

Perform a visual inspection for loose, disconnected,

or misrouted wires and hoses before diagnosing or

servicing the fuel injection system. A visual check

helps save unnecessary test and diagnostic time. A

thorough visual inspection includes the following

checks: (1) Check the ignition coil electrical connections

(Fig. 2). (2) Verify the harness connector is attached to the

canister purge solenoid (Fig. 3). (3) Verify the harness connector is attached to the

wastegate solenoid (Figs. 3).

Fig. 1 Multi-port Fuel Injection Components

Fig. 2 Ignition Coil Electrical Connection

Ä FUEL SYSTEMS 14 - 95

Page 1836 of 2438

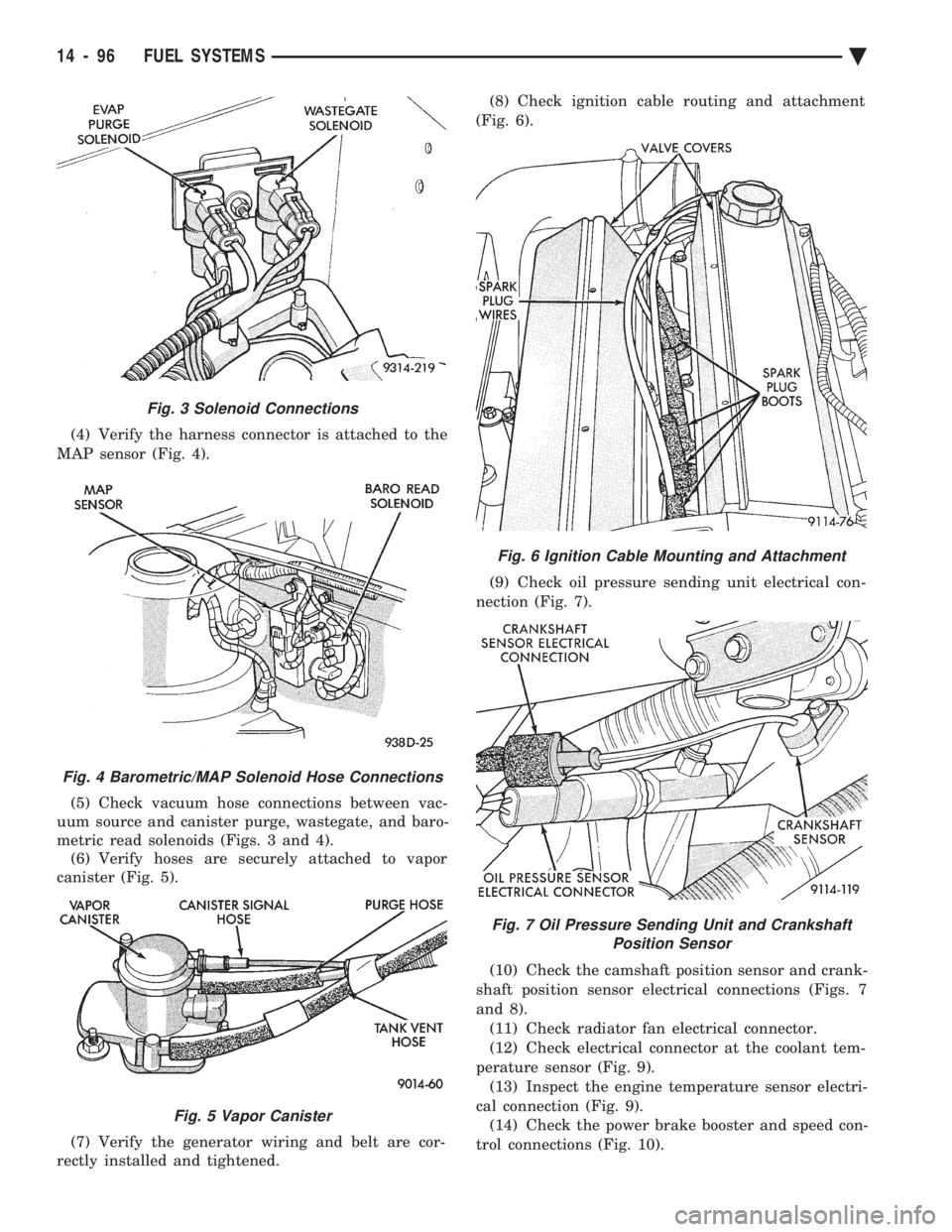

(4) Verify the harness connector is attached to the

MAP sensor (Fig. 4).

(5) Check vacuum hose connections between vac-

uum source and canister purge, wastegate, and baro-

metric read solenoids (Figs. 3 and 4). (6) Verify hoses are securely attached to vapor

canister (Fig. 5).

(7) Verify the generator wiring and belt are cor-

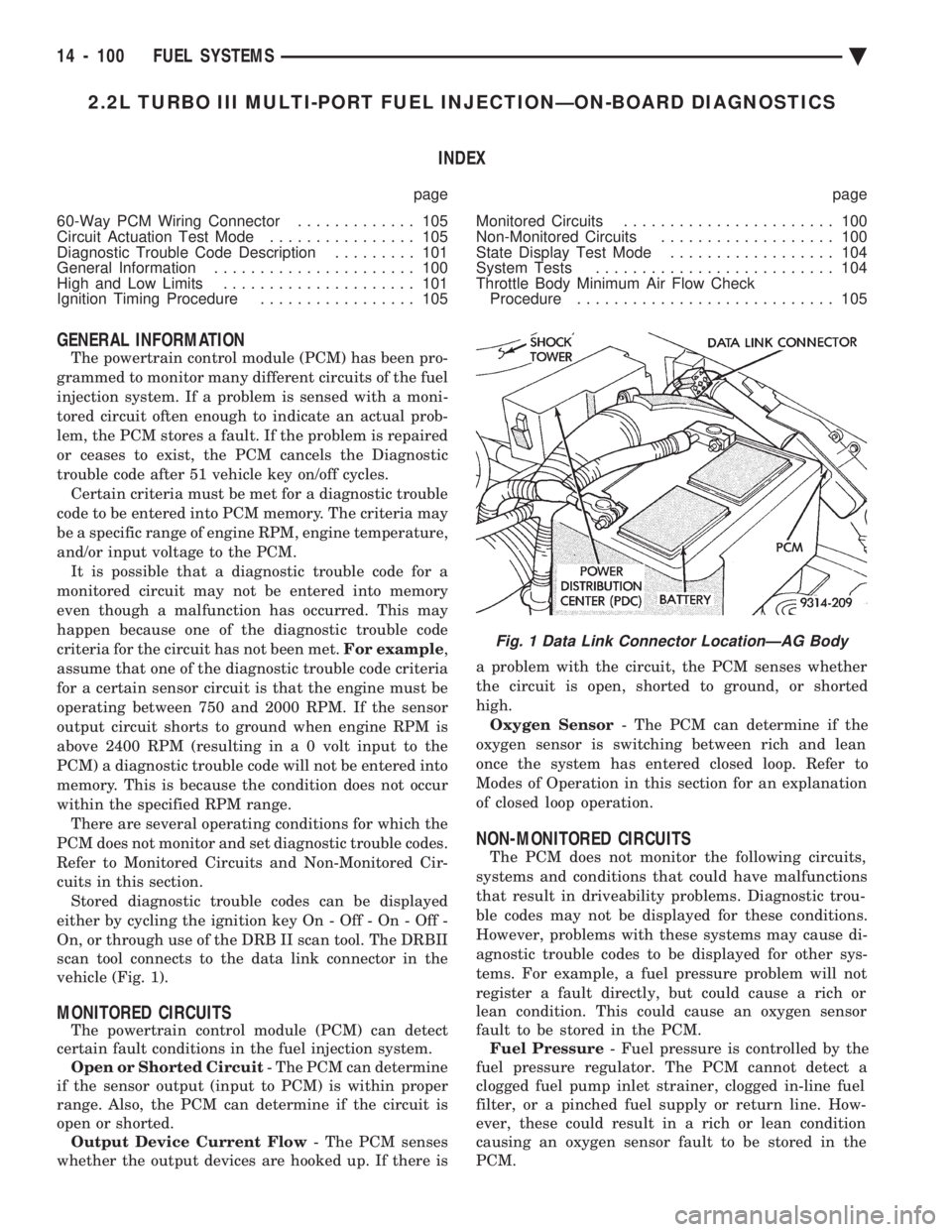

rectly installed and tightened. (8) Check ignition cable routing and attachment

(Fig. 6).

(9) Check oil pressure sending unit electrical con-

nection (Fig. 7).

(10) Check the camshaft position sensor and crank-

shaft position sensor electrical connections (Figs. 7

and 8). (11) Check radiator fan electrical connector.

(12) Check electrical connector at the coolant tem-

perature sensor (Fig. 9). (13) Inspect the engine temperature sensor electri-

cal connection (Fig. 9). (14) Check the power brake booster and speed con-

trol connections (Fig. 10).

Fig. 6 Ignition Cable Mounting and Attachment

Fig. 7 Oil Pressure Sending Unit and Crankshaft Position Sensor

Fig. 3 Solenoid Connections

Fig. 4 Barometric/MAP Solenoid Hose Connections

Fig. 5 Vapor Canister

14 - 96 FUEL SYSTEMS Ä

Page 1840 of 2438

2.2L TURBO III MULTI-PORT FUEL INJECTIONÐON-BOARD DIAGNOSTICS INDEX

page page

60-Way PCM Wiring Connector ............. 105

Circuit Actuation Test Mode ................ 105

Diagnostic Trouble Code Description ......... 101

General Information ...................... 100

High and Low Limits ..................... 101

Ignition Timing Procedure ................. 105 Monitored Circuits

....................... 100

Non-Monitored Circuits ................... 100

State Display Test Mode .................. 104

System Tests .......................... 104

Throttle Body Minimum Air Flow Check Procedure ............................ 105

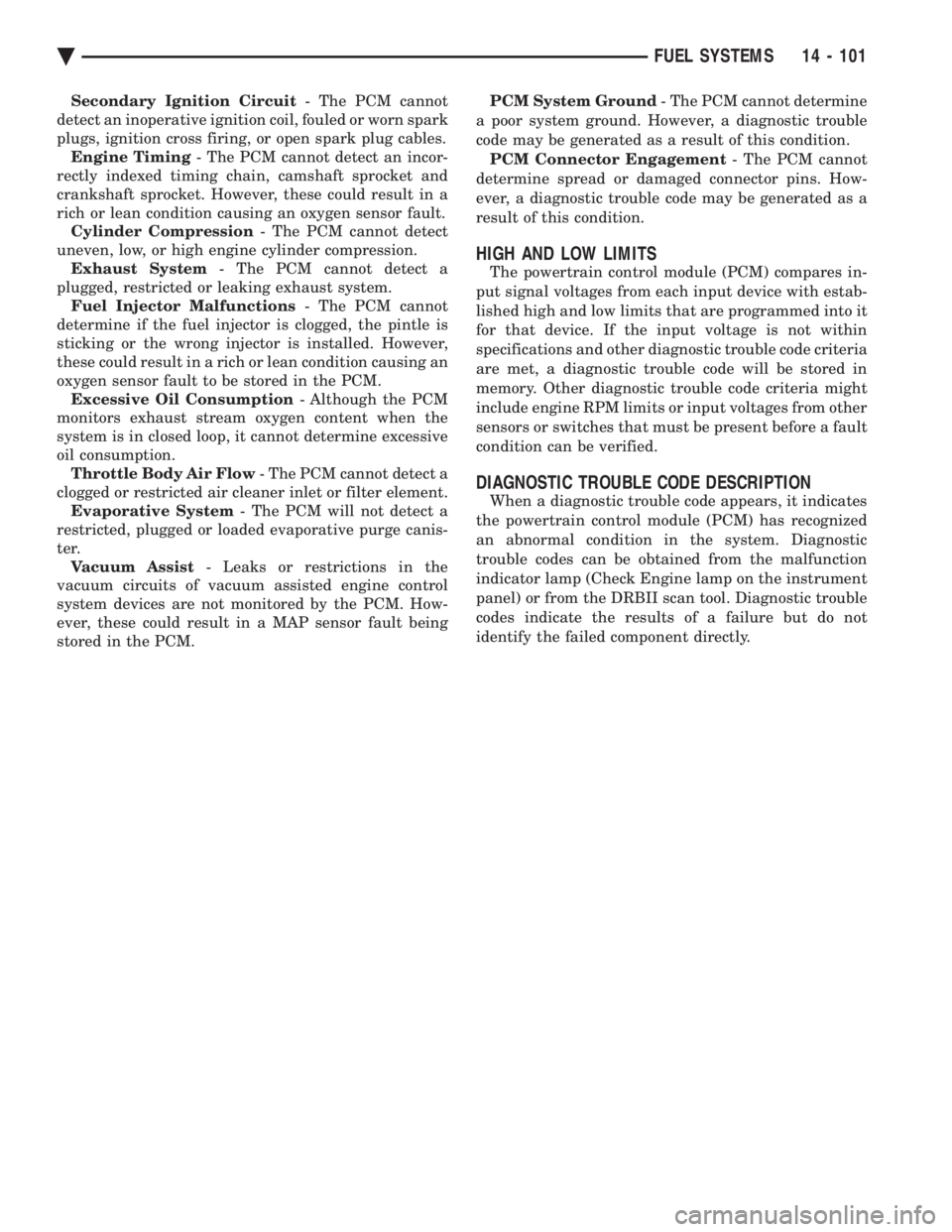

GENERAL INFORMATION

The powertrain control module (PCM) has been pro-

grammed to monitor many different circuits of the fuel

injection system. If a problem is sensed with a moni-

tored circuit often enough to indicate an actual prob-

lem, the PCM stores a fault. If the problem is repaired

or ceases to exist, the PCM cancels the Diagnostic

trouble code after 51 vehicle key on/off cycles. Certain criteria must be met for a diagnostic trouble

code to be entered into PCM memory. The criteria may

be a specific range of engine RPM, engine temperature,

and/or input voltage to the PCM. It is possible that a diagnostic trouble code for a

monitored circuit may not be entered into memory

even though a malfunction has occurred. This may

happen because one of the diagnostic trouble code

criteria for the circuit has not been met. For example,

assume that one of the diagnostic trouble code criteria

for a certain sensor circuit is that the engine must be

operating between 750 and 2000 RPM. If the sensor

output circuit shorts to ground when engine RPM is

above 2400 RPM (resulting i n a 0 volt input to the

PCM) a diagnostic trouble code will not be entered into

memory. This is because the condition does not occur

within the specified RPM range. There are several operating conditions for which the

PCM does not monitor and set diagnostic trouble codes.

Refer to Monitored Circuits and Non-Monitored Cir-

cuits in this section. Stored diagnostic trouble codes can be displayed

either by cycling the ignition key On - Off - On - Off -

On, or through use of the DRB II scan tool. The DRBII

scan tool connects to the data link connector in the

vehicle (Fig. 1).

MONITORED CIRCUITS

The powertrain control module (PCM) can detect

certain fault conditions in the fuel injection system. Open or Shorted Circuit - The PCM can determine

if the sensor output (input to PCM) is within proper

range. Also, the PCM can determine if the circuit is

open or shorted. Output Device Current Flow - The PCM senses

whether the output devices are hooked up. If there is a problem with the circuit, the PCM senses whether

the circuit is open, shorted to ground, or shorted

high. Oxygen Sensor - The PCM can determine if the

oxygen sensor is switching between rich and lean

once the system has entered closed loop. Refer to

Modes of Operation in this section for an explanation

of closed loop operation.

NON-MONITORED CIRCUITS

The PCM does not monitor the following circuits,

systems and conditions that could have malfunctions

that result in driveability problems. Diagnostic trou-

ble codes may not be displayed for these conditions.

However, problems with these systems may cause di-

agnostic trouble codes to be displayed for other sys-

tems. For example, a fuel pressure problem will not

register a fault directly, but could cause a rich or

lean condition. This could cause an oxygen sensor

fault to be stored in the PCM. Fuel Pressure - Fuel pressure is controlled by the

fuel pressure regulator. The PCM cannot detect a

clogged fuel pump inlet strainer, clogged in-line fuel

filter, or a pinched fuel supply or return line. How-

ever, these could result in a rich or lean condition

causing an oxygen sensor fault to be stored in the

PCM.

Fig. 1 Data Link Connector LocationÐAG Body

14 - 100 FUEL SYSTEMS Ä

Page 1841 of 2438

Secondary Ignition Circuit - The PCM cannot

detect an inoperative ignition coil, fouled or worn spark

plugs, ignition cross firing, or open spark plug cables. Engine Timing - The PCM cannot detect an incor-

rectly indexed timing chain, camshaft sprocket and

crankshaft sprocket. However, these could result in a

rich or lean condition causing an oxygen sensor fault. Cylinder Compression - The PCM cannot detect

uneven, low, or high engine cylinder compression. Exhaust System - The PCM cannot detect a

plugged, restricted or leaking exhaust system. Fuel Injector Malfunctions - The PCM cannot

determine if the fuel injector is clogged, the pintle is

sticking or the wrong injector is installed. However,

these could result in a rich or lean condition causing an

oxygen sensor fault to be stored in the PCM. Excessive Oil Consumption - Although the PCM

monitors exhaust stream oxygen content when the

system is in closed loop, it cannot determine excessive

oil consumption. Throttle Body Air Flow - The PCM cannot detect a

clogged or restricted air cleaner inlet or filter element. Evaporative System - The PCM will not detect a

restricted, plugged or loaded evaporative purge canis-

ter. Vacuum Assist - Leaks or restrictions in the

vacuum circuits of vacuum assisted engine control

system devices are not monitored by the PCM. How-

ever, these could result in a MAP sensor fault being

stored in the PCM. PCM System Ground

- The PCM cannot determine

a poor system ground. However, a diagnostic trouble

code may be generated as a result of this condition. PCM Connector Engagement - The PCM cannot

determine spread or damaged connector pins. How-

ever, a diagnostic trouble code may be generated as a

result of this condition.

HIGH AND LOW LIMITS

The powertrain control module (PCM) compares in-

put signal voltages from each input device with estab-

lished high and low limits that are programmed into it

for that device. If the input voltage is not within

specifications and other diagnostic trouble code criteria

are met, a diagnostic trouble code will be stored in

memory. Other diagnostic trouble code criteria might

include engine RPM limits or input voltages from other

sensors or switches that must be present before a fault

condition can be verified.

DIAGNOSTIC TROUBLE CODE DESCRIPTION

When a diagnostic trouble code appears, it indicates

the powertrain control module (PCM) has recognized

an abnormal condition in the system. Diagnostic

trouble codes can be obtained from the malfunction

indicator lamp (Check Engine lamp on the instrument

panel) or from the DRBII scan tool. Diagnostic trouble

codes indicate the results of a failure but do not

identify the failed component directly.

Ä FUEL SYSTEMS 14 - 101

Page 1844 of 2438

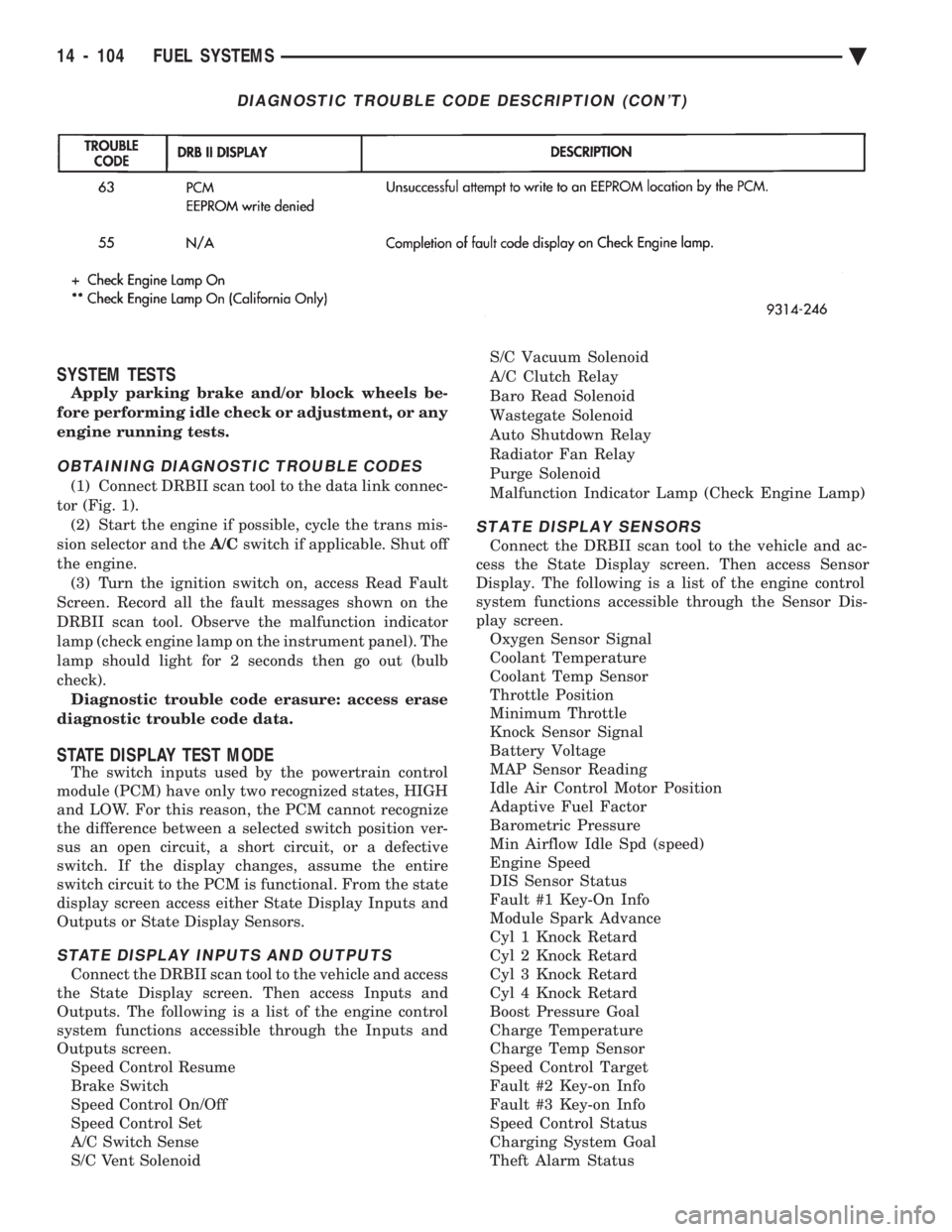

SYSTEM TESTS

Apply parking brake and/or block wheels be-

fore performing idle check or adjustment, or any

engine running tests.

OBTAINING DIAGNOSTIC TROUBLE CODES

(1) Connect DRBII scan tool to the data link connec-

tor (Fig. 1). (2) Start the engine if possible, cycle the trans mis-

sion selector and the A/Cswitch if applicable. Shut off

the engine. (3) Turn the ignition switch on, access Read Fault

Screen. Record all the fault messages shown on the

DRBII scan tool. Observe the malfunction indicator

lamp (check engine lamp on the instrument panel). The

lamp should light for 2 seconds then go out (bulb

check). Diagnostic trouble code erasure: access erase

diagnostic trouble code data.

STATE DISPLAY TEST MODE

The switch inputs used by the powertrain control

module (PCM) have only two recognized states, HIGH

and LOW. For this reason, the PCM cannot recognize

the difference between a selected switch position ver-

sus an open circuit, a short circuit, or a defective

switch. If the display changes, assume the entire

switch circuit to the PCM is functional. From the state

display screen access either State Display Inputs and

Outputs or State Display Sensors.

STATE DISPLAY INPUTS AND OUTPUTS

Connect the DRBII scan tool to the vehicle and access

the State Display screen. Then access Inputs and

Outputs. The following is a list of the engine control

system functions accessible through the Inputs and

Outputs screen. Speed Control Resume

Brake Switch

Speed Control On/Off

Speed Control Set

A/C Switch Sense

S/C Vent Solenoid S/C Vacuum Solenoid

A/C Clutch Relay

Baro Read Solenoid

Wastegate Solenoid

Auto Shutdown Relay

Radiator Fan Relay

Purge Solenoid

Malfunction Indicator Lamp (Check Engine Lamp)

STATE DISPLAY SENSORS

Connect the DRBII scan tool to the vehicle and ac-

cess the State Display screen. Then access Sensor

Display. The following is a list of the engine control

system functions accessible through the Sensor Dis-

play screen. Oxygen Sensor Signal

Coolant Temperature

Coolant Temp Sensor

Throttle Position

Minimum Throttle

Knock Sensor Signal

Battery Voltage

MAP Sensor Reading

Idle Air Control Motor Position

Adaptive Fuel Factor

Barometric Pressure

Min Airflow Idle Spd (speed)

Engine Speed

DIS Sensor Status

Fault #1 Key-On Info

Module Spark Advance

Cyl 1 Knock Retard

Cyl 2 Knock Retard

Cyl 3 Knock Retard

Cyl 4 Knock Retard

Boost Pressure Goal

Charge Temperature

Charge Temp Sensor

Speed Control Target

Fault #2 Key-on Info

Fault #3 Key-on Info

Speed Control Status

Charging System Goal

Theft Alarm Status

DIAGNOSTIC TROUBLE CODE DESCRIPTION (CON'T)

14 - 104 FUEL SYSTEMS Ä

Page 1845 of 2438

Wastegate Duty Cycle

Battery Temperature

Map Sensor Voltage

Vehicle Speed

Oxygen Sensor State

Baro Read Update

MAP Gauge Reading

Throttle Opening (percentage)

Total Spark Advance

CIRCUIT ACTUATION TEST MODE

The purpose of the circuit actuation test mode is to

check for the proper operation of output circuits or

devices which the powertrain control module (PCM)

cannot internally recognize. The PCM can attempt to

activate these outputs and allow an observer to ver-

ify proper operation. Most of the tests available in

this mode provide an audible or visual indication of

device operation (click of relay contacts, spray fuel,

etc.). With the exception of an intermittent condition,

if a device functions properly during its test, assume

the device, its associated wiring, and its driver cir-

cuit are in working order.

OBTAINING CIRCUIT ACTUATION TEST

Connect the DRBII scan tool to the vehicle and ac-

cess the Actuators screen. The following is a list of

the engine control system functions accessible

through Actuators screens. Stop All Tests

Ignition Coil #1

Ignition Coil #2

Fuel Injector #1

Fuel Injector #2

Fuel Injector #3

Idle Air Control Motor Open/Close

Radiator Fan Relay

A/C Clutch Relay

Auto Shutdown Relay

Purge Solenoid

S/C Serv Solenoids

Generator Field

Tachometer Output

Wastegate Solenoid

Baro Read Solenoid

All Solenoids/Relays

Speed Control Vent Solenoid

Speed Control Vacuum Solenoid

ASD Fuel System Test

Fuel Injector #4

THROTTLE BODY MINIMUM AIR FLOW CHECK

PROCEDURE

(1) Warm the engine in neutral until the cooling

fan has cycled on and off at least once. (2) Shut off engine.

(3) Hook-up Tachometer.

(4) Disconnect the PCV valve hose from the nipple

on the intake manifold. (5) Attach air metering fitting, special tool 6457

(0.125 inch orifice), to the intake manifold PCV nip-

ple. (6) Disconnect 3/16 inch manifold vacuum purge

line from the top of the throttle body. Cap the 3/16

inch throttle body nipple. (7) Connect DRBII scan tool.

(8) Restart engine. Allow engine to idle for at least

one minute. (9) Using the DRBII scan tool, access Min. Airflow

Idle Spd. The following will then occur:

² Idle air control motor will fully close.

² Idle spark advance will become fixed.

² Engine RPM will be displayed on the DRBII scan

tool. (10) Check idle RPM with tachometer, if idle RPM

is within the below specification then the throttle

body minimum airflow is set correctly.

If the idle RPM is not within specification, replace

the throttle body. (11) Shut off engine.

(12) Remove air metering fitting 6457 from the in-

take manifold PCV nipple. Connect the PCV hose to

the nipple. (13) Remove DRBII scan tool.

(14) Disconnect tachometer.

(15) Reconnect purge line to throttle body.

IGNITION TIMING PROCEDURE

Ignition timing cannot be changed or set on the

Turbo III engine. Refer to Group 8D for a description

of the Direct Ignition System (DIS).

60-WAY PCM WIRING CONNECTOR

Refer to the PCM wiring connector diagram (Fig.

2) for information regarding wire colors and cavity

numbers.

IDLE SPECIFICATIONS

Ä FUEL SYSTEMS 14 - 105

Page 1850 of 2438

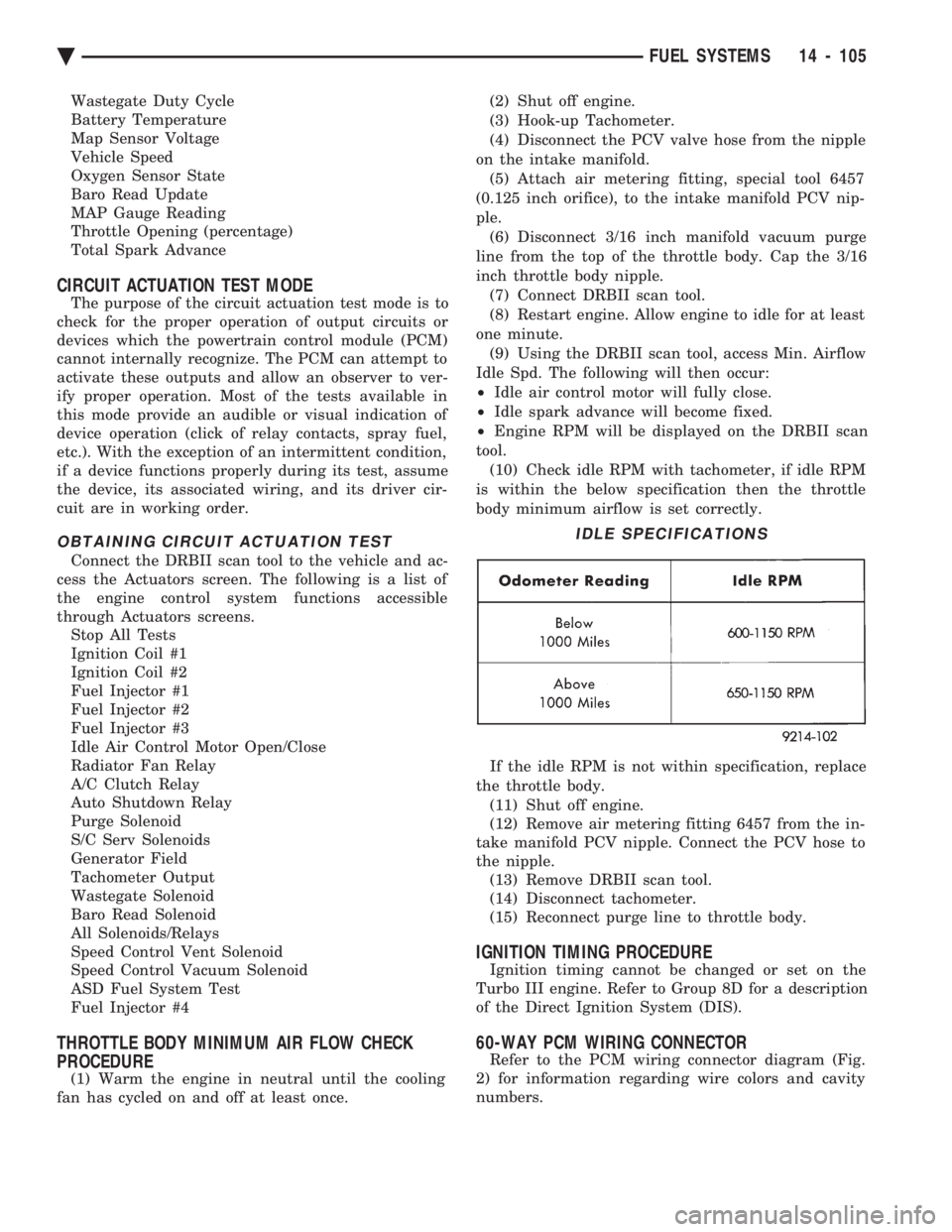

(8) Cover or plug the injector ports with while ser-

vicing the injectors (Fig. 9).

INSTALLATION

(1) Ensure the injectors are seated into the re-

ceiver cup, with the lock ring in place. (2) Ensure the injector wiring connectors are fully

inserted into the fuel injectors. (3) Make sure the injector holes are clean and all

plugs have been removed (Fig. 9). (4) Lubricate the injector O-rings with a drop of

clean engine oil. (5) Install the injector assemblies into their holes

and install the attaching bolts. Draw the fuel rail as-

sembly evenly into the intake manifold, making sure

each injector enters its own hole. The oil separator

bracket must be on top of the fuel rail bracket (Fig.

8). (6) Once all injectors are evenly seated, tighten the

fuel rail attaching bolts to 23 N Im (200 in. lbs.)

torque. (7) Connect the fuel injector wiring harness to the

main harness. (8) Lubricate the ends of the chassis tubes with

clean 30 weight engine oil. (9) Connect fuel hose quick connect fittings to the

chassis fuel tubes. Pull on the fittings to ensure com-

plete connection. Refer to Quick Connect Fittings in the Fuel Deliv-

ery Section of this group. (10) Connect the vacuum hose to the fuel pressure

regulator. (11) Connect negative cable to battery.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or un-

til the ignition switch is turned to the Off position. (12) With the DRBII scan tool the ASD Fuel Sys-

tem Test to pressurize the fuel system to check for

leaks.

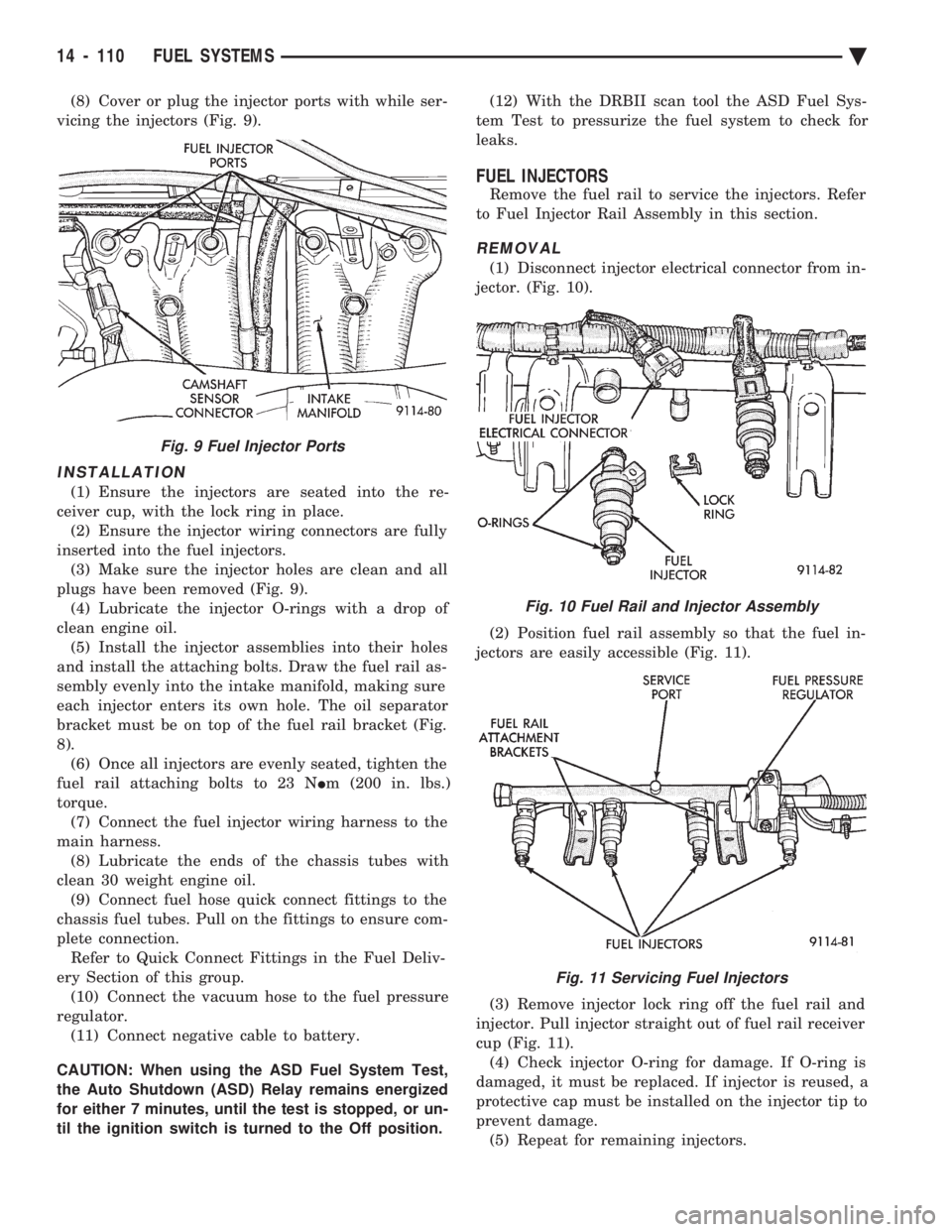

FUEL INJECTORS

Remove the fuel rail to service the injectors. Refer

to Fuel Injector Rail Assembly in this section.

REMOVAL

(1) Disconnect injector electrical connector from in-

jector. (Fig. 10).

(2) Position fuel rail assembly so that the fuel in-

jectors are easily accessible (Fig. 11).

(3) Remove injector lock ring off the fuel rail and

injector. Pull injector straight out of fuel rail receiver

cup (Fig. 11). (4) Check injector O-ring for damage. If O-ring is

damaged, it must be replaced. If injector is reused, a

protective cap must be installed on the injector tip to

prevent damage. (5) Repeat for remaining injectors.

Fig. 9 Fuel Injector Ports

Fig. 10 Fuel Rail and Injector Assembly

Fig. 11 Servicing Fuel Injectors

14 - 110 FUEL SYSTEMS Ä