ECU CHEVROLET DYNASTY 1993 Owner's Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 404 of 2438

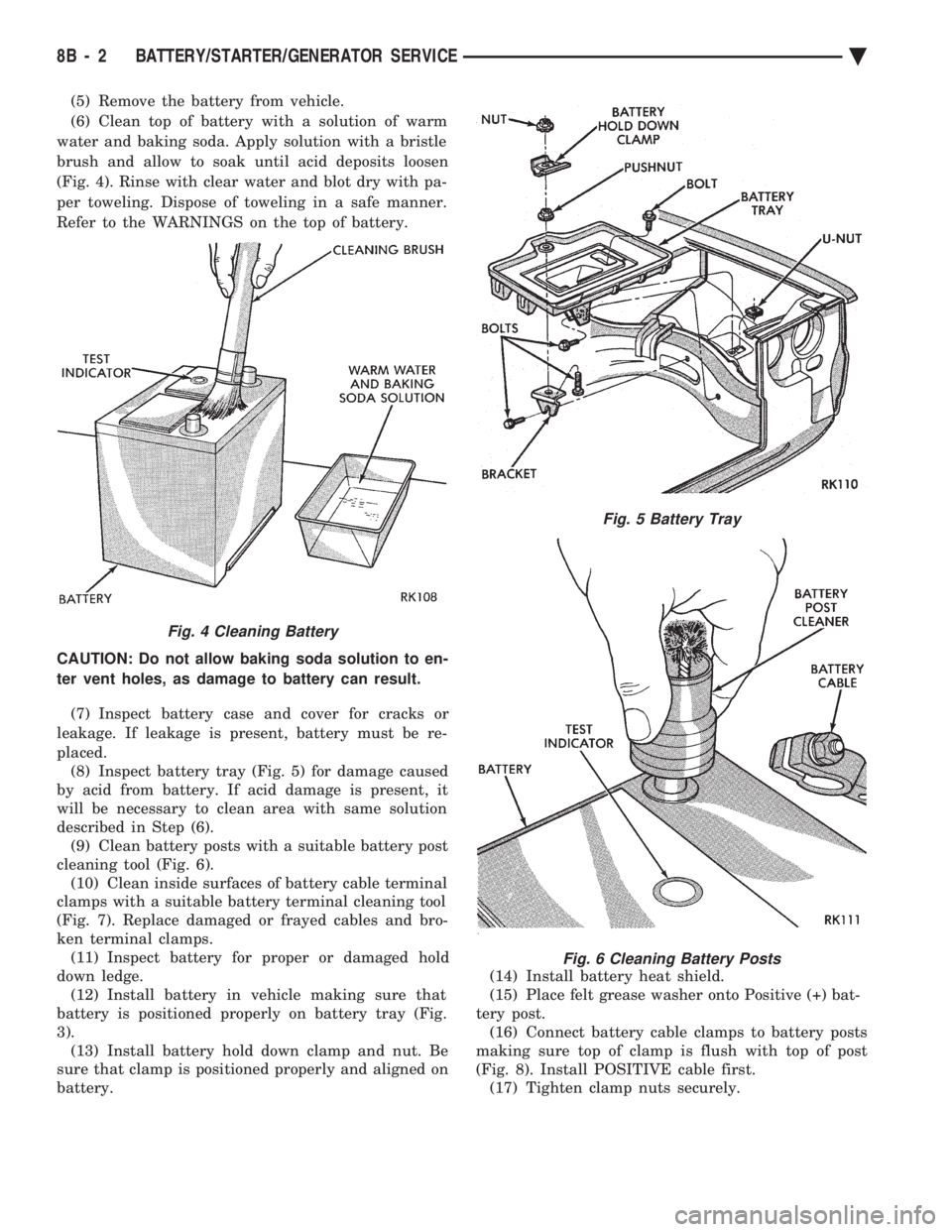

(5) Remove the battery from vehicle.

(6) Clean top of battery with a solution of warm

water and baking soda. Apply solution with a bristle

brush and allow to soak until acid deposits loosen

(Fig. 4). Rinse with clear water and blot dry with pa-

per toweling. Dispose of toweling in a safe manner.

Refer to the WARNINGS on the top of battery.

CAUTION: Do not allow baking soda solution to en-

ter vent holes, as damage to battery can result.

(7) Inspect battery case and cover for cracks or

leakage. If leakage is present, battery must be re-

placed. (8) Inspect battery tray (Fig. 5) for damage caused

by acid from battery. If acid damage is present, it

will be necessary to clean area with same solution

described in Step (6). (9) Clean battery posts with a suitable battery post

cleaning tool (Fig. 6). (10) Clean inside surfaces of battery cable terminal

clamps with a suitable battery terminal cleaning tool

(Fig. 7). Replace damaged or frayed cables and bro-

ken terminal clamps. (11) Inspect battery for proper or damaged hold

down ledge. (12) Install battery in vehicle making sure that

battery is positioned properly on battery tray (Fig.

3). (13) Install battery hold down clamp and nut. Be

sure that clamp is positioned properly and aligned on

battery. (14) Install battery heat shield.

(15) Place felt grease washer onto Positive (+) bat-

tery post. (16) Connect battery cable clamps to battery posts

making sure top of clamp is flush with top of post

(Fig. 8). Install POSITIVE cable first. (17) Tighten clamp nuts securely.

Fig. 4 Cleaning Battery

Fig. 5 Battery Tray

Fig. 6 Cleaning Battery Posts

8B - 2 BATTERY/STARTER/GENERATOR SERVICE Ä

Page 409 of 2438

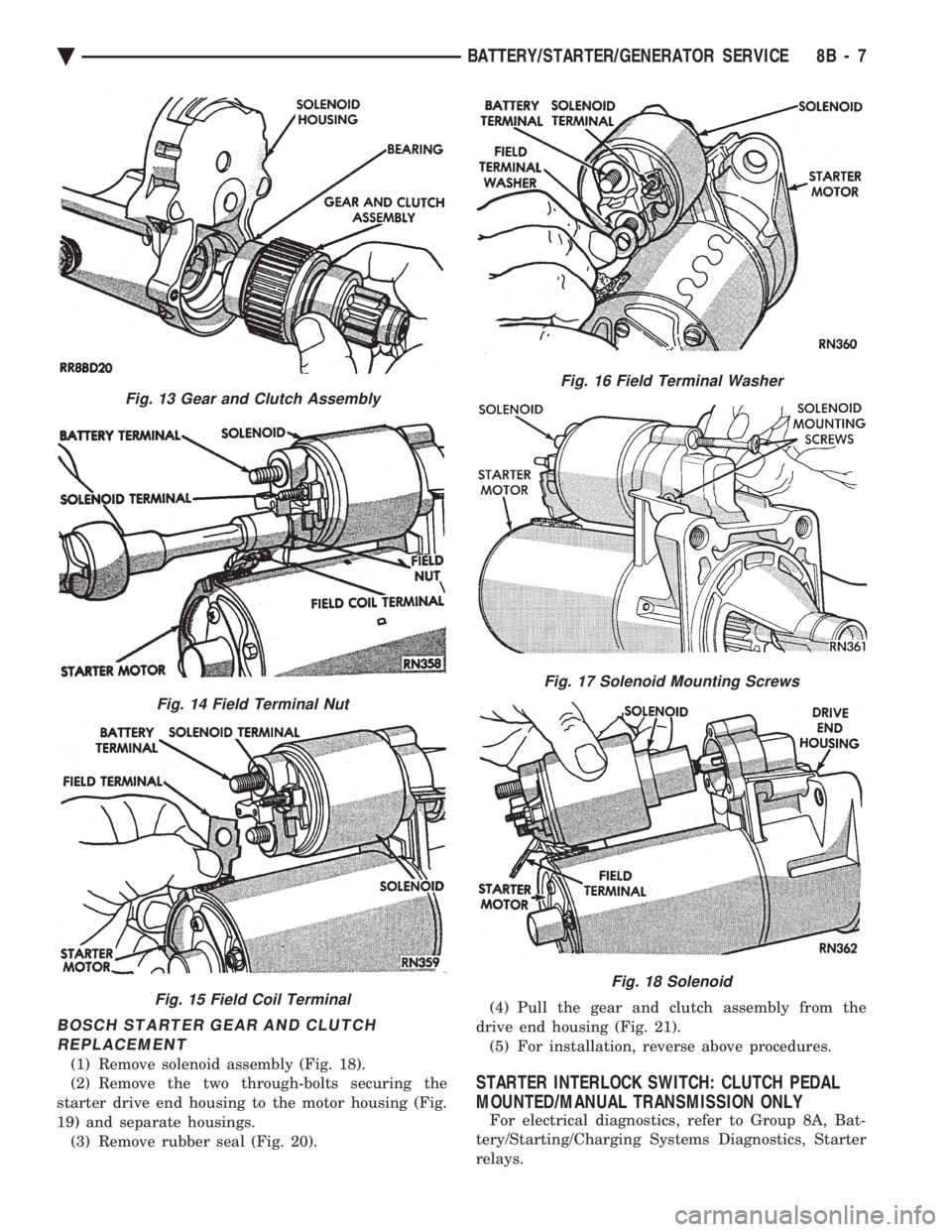

BOSCH STARTER GEAR AND CLUTCH REPLACEMENT

(1) Remove solenoid assembly (Fig. 18).

(2) Remove the two through-bolts securing the

starter drive end housing to the motor housing (Fig.

19) and separate housings. (3) Remove rubber seal (Fig. 20). (4) Pull the gear and clutch assembly from the

drive end housing (Fig. 21). (5) For installation, reverse above procedures.

STARTER INTERLOCK SWITCH: CLUTCH PEDAL

MOUNTED/MANUAL TRANSMISSION ONLY

For electrical diagnostics, refer to Group 8A, Bat-

tery/Starting/Charging Systems Diagnostics, Starter

relays.

Fig. 13 Gear and Clutch Assembly

Fig. 14 Field Terminal Nut

Fig. 15 Field Coil Terminal

Fig. 16 Field Terminal Washer

Fig. 17 Solenoid Mounting Screws

Fig. 18 Solenoid

Ä BATTERY/STARTER/GENERATOR SERVICE 8B - 7

Page 426 of 2438

BUS ACCESSED DIAGNOSTICS

The following diagnostic test may be used to check

the integrity of the EVIC's internal connections and

operations. Refer to the Body Chassis Diagnostic Test

Procedure Manual for test procedures. MODULE RESET TEST, when the EVIC receives

this request from the DRB II, the EVIC will immedi-

ately enter into reset. DISPLAY TEST: The EVIC receives a request from

the DBR II, the EVIC will enter into a visual display

mode. Also checks the integrity of the display driver

to anode connections. The test shall consist of walk-

ing through the vertical and horizontal rows of an-

odes in the dot matrix display. SWITCH STATUS TEST, when the EVIC receives

this request from the DRB II, the EVIC will report

the open/closed status of each individual switch. FAULT BYTE TEST, when the EVIC receives this

request from the DRB II, the EVIC will report fault

status. Messages reported are:

² NO FAULT

² DISPLAY DRIVER FAULT

² EVIC MISSING MESSAGES

² POWER SUPPLY FAILURE

² FAULT IN RAM

² FAULT IN ROM

EVIC missing message implies that there may be a

system failure and/or the body controller is not pro-

viding EVIC with sufficient information. DISPLAY DRIVER FAULT, power supply failure

and fault in RAM/ROM implies that the EVIC is de-

fective.

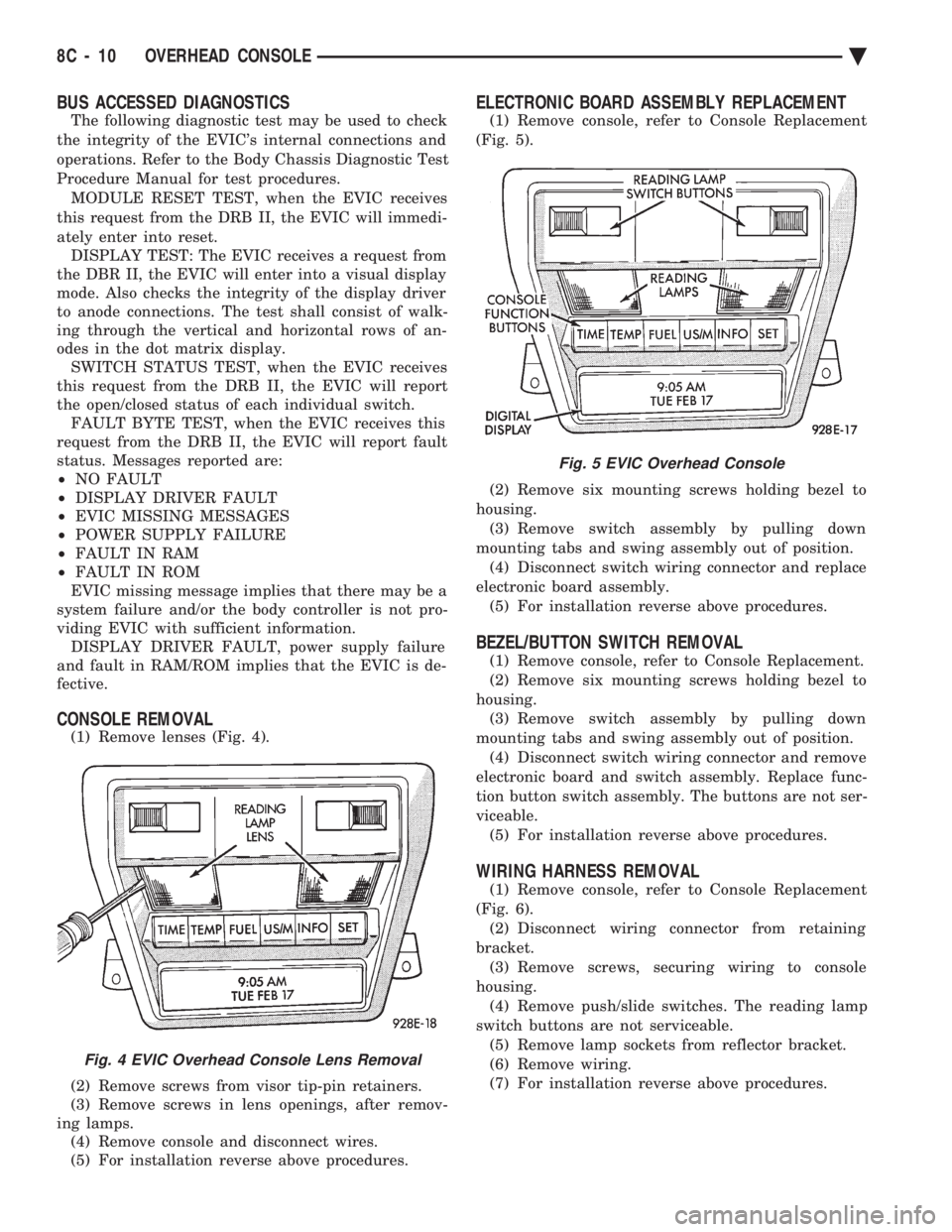

CONSOLE REMOVAL

(1) Remove lenses (Fig. 4).

(2) Remove screws from visor tip-pin retainers.

(3) Remove screws in lens openings, after remov-

ing lamps. (4) Remove console and disconnect wires.

(5) For installation reverse above procedures.

ELECTRONIC BOARD ASSEMBLY REPLACEMENT

(1) Remove console, refer to Console Replacement

(Fig. 5).

(2) Remove six mounting screws holding bezel to

housing. (3) Remove switch assembly by pulling down

mounting tabs and swing assembly out of position. (4) Disconnect switch wiring connector and replace

electronic board assembly. (5) For installation reverse above procedures.

BEZEL/BUTTON SWITCH REMOVAL

(1) Remove console, refer to Console Replacement.

(2) Remove six mounting screws holding bezel to

housing. (3) Remove switch assembly by pulling down

mounting tabs and swing assembly out of position. (4) Disconnect switch wiring connector and remove

electronic board and switch assembly. Replace func-

tion button switch assembly. The buttons are not ser-

viceable. (5) For installation reverse above procedures.

WIRING HARNESS REMOVAL

(1) Remove console, refer to Console Replacement

(Fig. 6). (2) Disconnect wiring connector from retaining

bracket. (3) Remove screws, securing wiring to console

housing. (4) Remove push/slide switches. The reading lamp

switch buttons are not serviceable. (5) Remove lamp sockets from reflector bracket.

(6) Remove wiring.

(7) For installation reverse above procedures.

Fig. 4 EVIC Overhead Console Lens Removal

Fig. 5 EVIC Overhead Console

8C - 10 OVERHEAD CONSOLE Ä

Page 448 of 2438

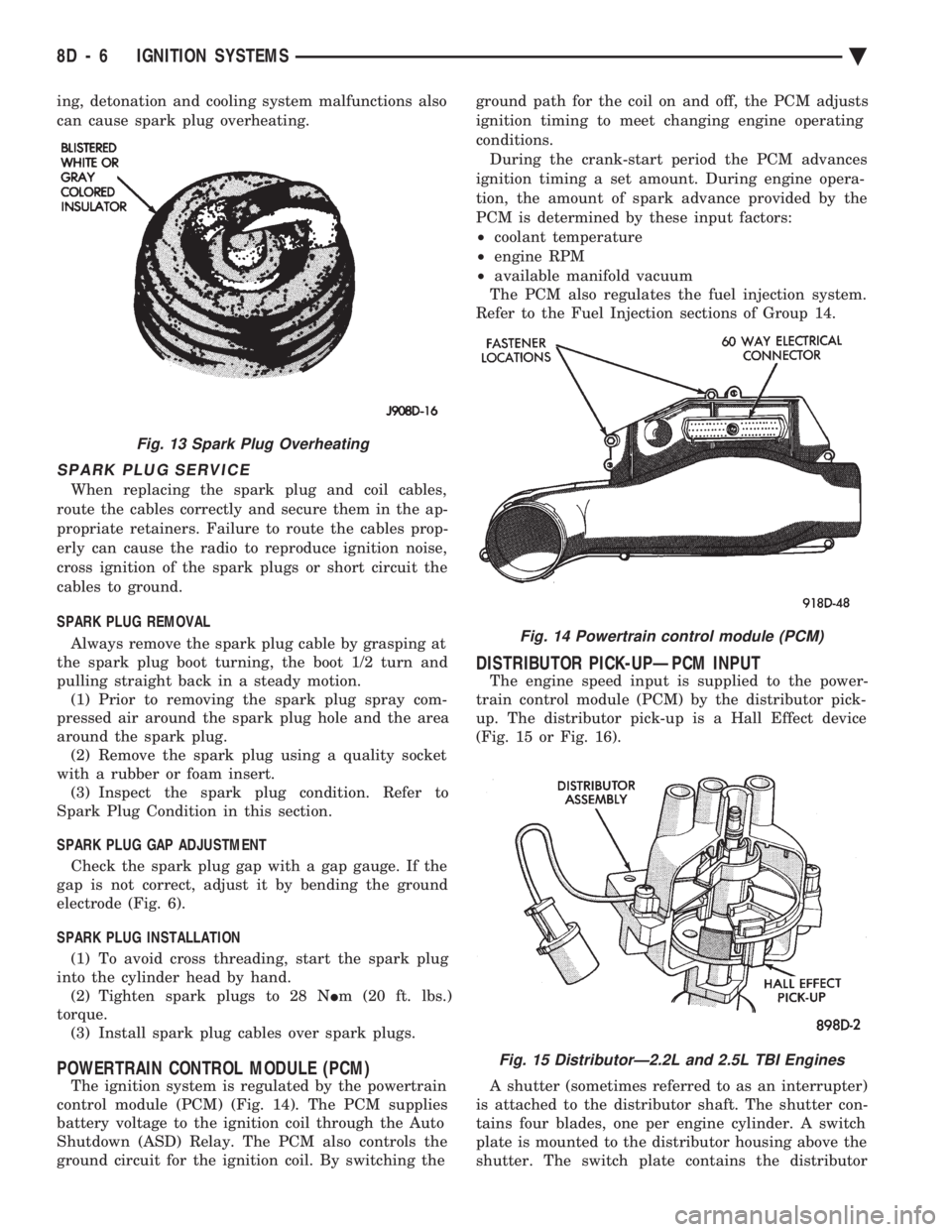

ing, detonation and cooling system malfunctions also

can cause spark plug overheating.

SPARK PLUG SERVICE

When replacing the spark plug and coil cables,

route the cables correctly and secure them in the ap-

propriate retainers. Failure to route the cables prop-

erly can cause the radio to reproduce ignition noise,

cross ignition of the spark plugs or short circuit the

cables to ground.

SPARK PLUG REMOVAL

Always remove the spark plug cable by grasping at

the spark plug boot turning, the boot 1/2 turn and

pulling straight back in a steady motion. (1) Prior to removing the spark plug spray com-

pressed air around the spark plug hole and the area

around the spark plug. (2) Remove the spark plug using a quality socket

with a rubber or foam insert. (3) Inspect the spark plug condition. Refer to

Spark Plug Condition in this section.

SPARK PLUG GAP ADJUSTMENT Check the spark plug gap with a gap gauge. If the

gap is not correct, adjust it by bending the ground

electrode (Fig. 6).

SPARK PLUG INSTALLATION (1) To avoid cross threading, start the spark plug

into the cylinder head by hand. (2) Tighten spark plugs to 28 N Im (20 ft. lbs.)

torque. (3) Install spark plug cables over spark plugs.

POWERTRAIN CONTROL MODULE (PCM)

The ignition system is regulated by the powertrain

control module (PCM) (Fig. 14). The PCM supplies

battery voltage to the ignition coil through the Auto

Shutdown (ASD) Relay. The PCM also controls the

ground circuit for the ignition coil. By switching the ground path for the coil on and off, the PCM adjusts

ignition timing to meet changing engine operating

conditions.

During the crank-start period the PCM advances

ignition timing a set amount. During engine opera-

tion, the amount of spark advance provided by the

PCM is determined by these input factors:

² coolant temperature

² engine RPM

² available manifold vacuum

The PCM also regulates the fuel injection system.

Refer to the Fuel Injection sections of Group 14.

DISTRIBUTOR PICK-UPÐPCM INPUT

The engine speed input is supplied to the power-

train control module (PCM) by the distributor pick-

up. The distributor pick-up is a Hall Effect device

(Fig. 15 or Fig. 16).

A shutter (sometimes referred to as an interrupter)

is attached to the distributor shaft. The shutter con-

tains four blades, one per engine cylinder. A switch

plate is mounted to the distributor housing above the

shutter. The switch plate contains the distributor

Fig. 14 Powertrain control module (PCM)

Fig. 15 DistributorÐ2.2L and 2.5L TBI Engines

Fig. 13 Spark Plug Overheating

8D - 6 IGNITION SYSTEMS Ä

Page 457 of 2438

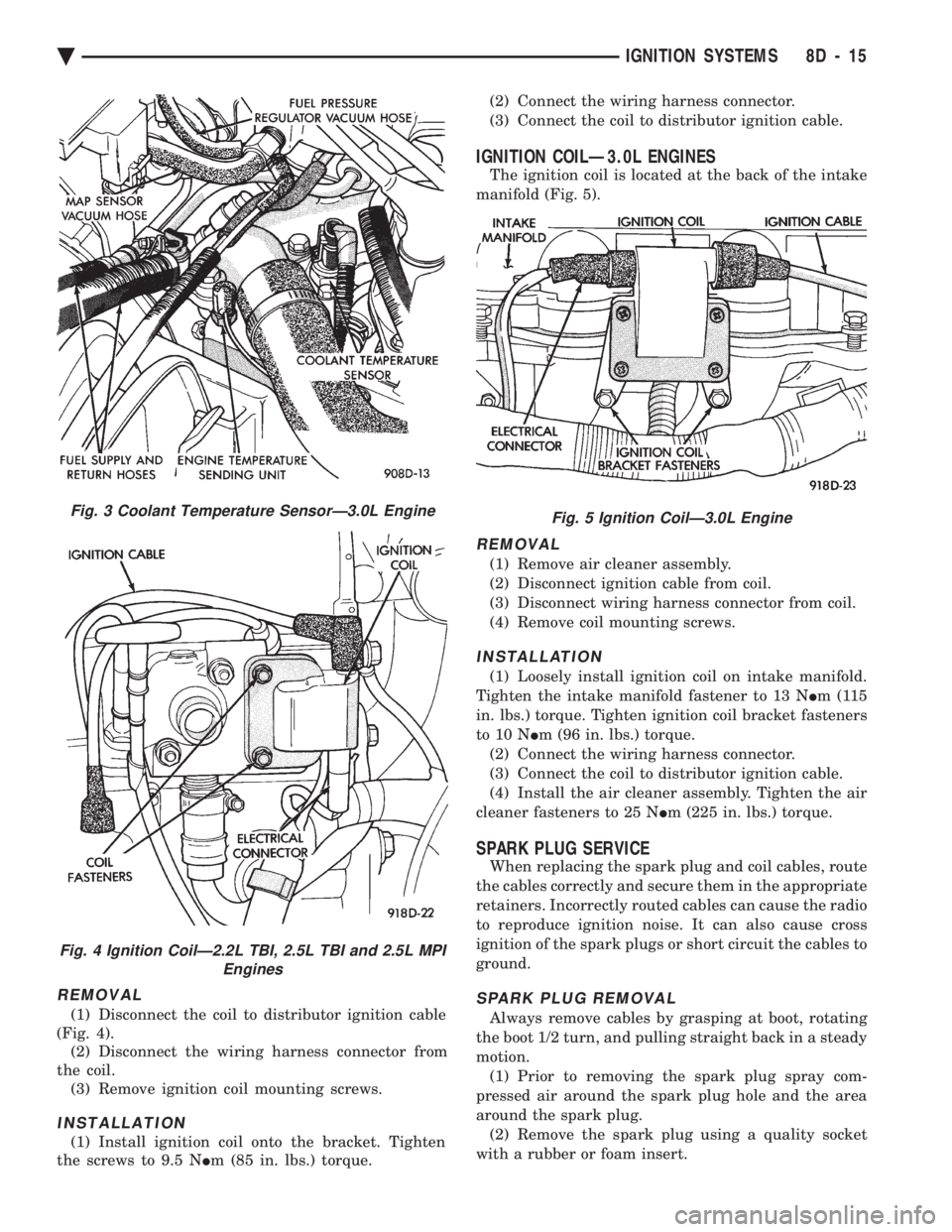

REMOVAL

(1) Disconnect the coil to distributor ignition cable

(Fig. 4). (2) Disconnect the wiring harness connector from

the coil. (3) Remove ignition coil mounting screws.

INSTALLATION

(1) Install ignition coil onto the bracket. Tighten

the screws to 9.5 N Im (85 in. lbs.) torque. (2) Connect the wiring harness connector.

(3) Connect the coil to distributor ignition cable.

IGNITION COILÐ3.0L ENGINES

The ignition coil is located at the back of the intake

manifold (Fig. 5).

REMOVAL

(1) Remove air cleaner assembly.

(2) Disconnect ignition cable from coil.

(3) Disconnect wiring harness connector from coil.

(4) Remove coil mounting screws.

INSTALLATION

(1) Loosely install ignition coil on intake manifold.

Tighten the intake manifold fastener to 13 N Im(115

in. lbs.) torque. Tighten ignition coil bracket fasteners

to 10 N Im (96 in. lbs.) torque.

(2) Connect the wiring harness connector.

(3) Connect the coil to distributor ignition cable.

(4) Install the air cleaner assembly. Tighten the air

cleaner fasteners to 25 N Im (225 in. lbs.) torque.

SPARK PLUG SERVICE

When replacing the spark plug and coil cables, route

the cables correctly and secure them in the appropriate

retainers. Incorrectly routed cables can cause the radio

to reproduce ignition noise. It can also cause cross

ignition of the spark plugs or short circuit the cables to

ground.

SPARK PLUG REMOVAL

Always remove cables by grasping at boot, rotating

the boot 1/2 turn, and pulling straight back in a steady

motion. (1) Prior to removing the spark plug spray com-

pressed air around the spark plug hole and the area

around the spark plug. (2) Remove the spark plug using a quality socket

with a rubber or foam insert.

Fig. 3 Coolant Temperature SensorÐ3.0L Engine

Fig. 4 Ignition CoilÐ2.2L TBI, 2.5L TBI and 2.5L MPI Engines

Fig. 5 Ignition CoilÐ3.0L Engine

Ä IGNITION SYSTEMS 8D - 15

Page 483 of 2438

(2) With engine running, move test probe along

entire length of all cables (approximately 0 to 1/8

inch gap). If punctures or cracks are present there

will be a noticeable spark jump from the faulty area

to the probe. Cracked, leaking or faulty cables should

be replaced. Use the following procedure when removing the

high tension cable from the spark plug. First, remove

the cable from the retaining bracket. Then grasp the

terminal as close as possible to the spark plug. Ro-

tate the cover (boot) slightly and pull straight back.

Do not use pliers and do not pull the cable at an

angle. Doing so will damage the insulation, cable

terminal or the spark plug insulator. Wipe spark

plug insulator clean before reinstalling cable

and cover. Resistance cables are identified by the words Elec-

tronic Suppression .

Use an ohmmeter to check cables for opens, loose

terminals or high resistance. (a) Remove cable from spark plug.

(b) Remove cable from the coil tower.

(c) Connect the ohmmeter between spark plug

end terminal and the coil end terminal. Resistance

should be within tolerance shown in the cable re-

sistance chart. If resistance is not within tolerance,

replace cable assembly. Test all spark plug cables

in same manner.

SPARK PLUG SERVICE

When replacing the spark plug cables, route the ca-

bles correctly and secure them in the appropriate re-

tainers. Incorrectly routed cables can cause the radio

to reproduce ignition noise. It can also cause cross ig-

nition of the spark plugs or short circuit the cables to

ground.

SPARK PLUG REMOVAL

Always remove cables by grasping at boot, rotating

the boot 1/2 turn, and pulling straight back in a

steady motion. (1) Prior to removing the spark plug spray com-

pressed air around the spark plug hole and the area

around the spark plug. (2) Remove the spark plug using a quality socket

with a rubber or foam insert. (3) Inspect the spark plug condition. Refer to

Spark Plug Condition in this section.

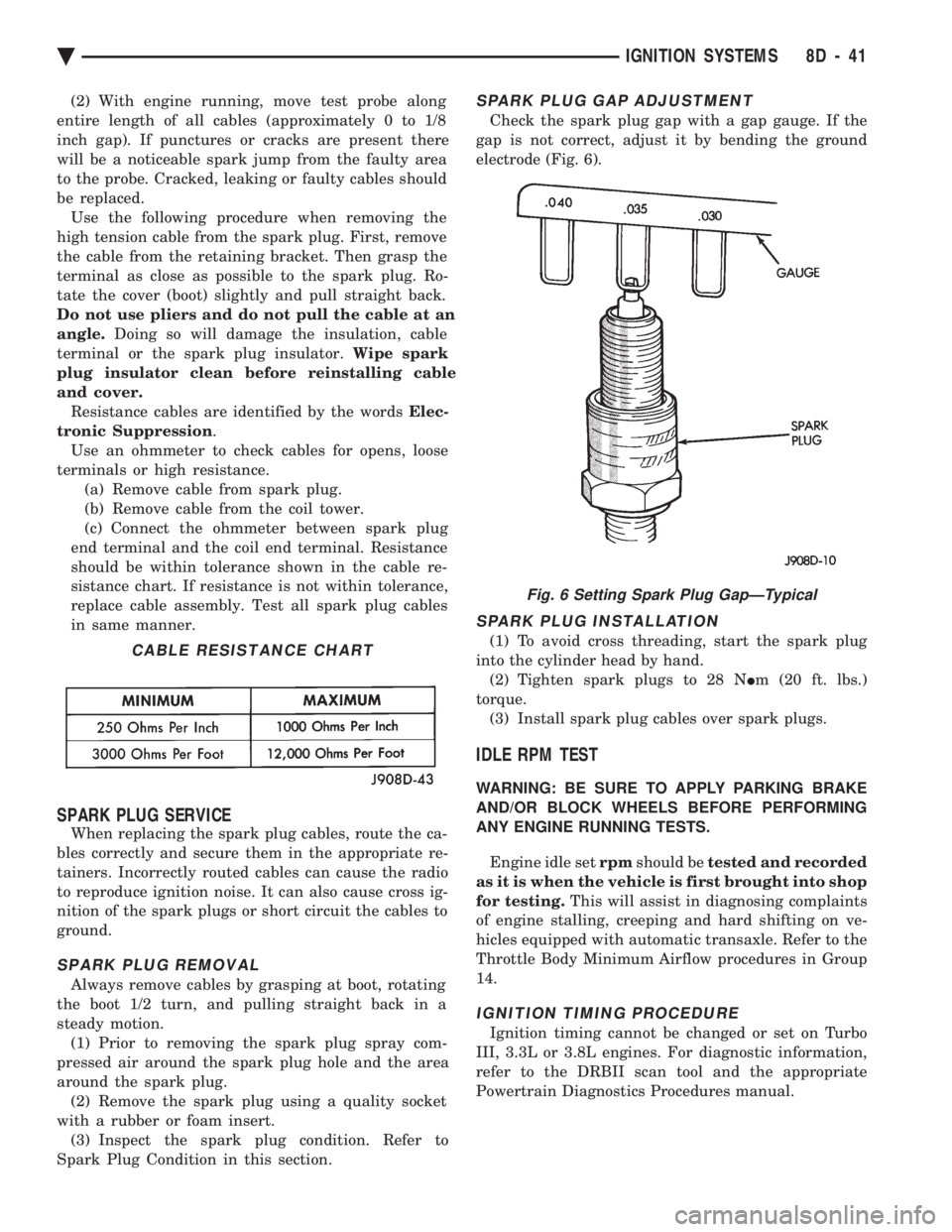

SPARK PLUG GAP ADJUSTMENT

Check the spark plug gap with a gap gauge. If the

gap is not correct, adjust it by bending the ground

electrode (Fig. 6).

SPARK PLUG INSTALLATION

(1) To avoid cross threading, start the spark plug

into the cylinder head by hand. (2) Tighten spark plugs to 28 N Im (20 ft. lbs.)

torque. (3) Install spark plug cables over spark plugs.

IDLE RPM TEST

WARNING: BE SURE TO APPLY PARKING BRAKE

AND/OR BLOCK WHEELS BEFORE PERFORMING

ANY ENGINE RUNNING TESTS.

Engine idle set rpmshould be tested and recorded

as it is when the vehicle is first brought into shop

for testing. This will assist in diagnosing complaints

of engine stalling, creeping and hard shifting on ve-

hicles equipped with automatic transaxle. Refer to the

Throttle Body Minimum Airflow procedures in Group

14.

IGNITION TIMING PROCEDURE

Ignition timing cannot be changed or set on Turbo

III, 3.3L or 3.8L engines. For diagnostic information,

refer to the DRBII scan tool and the appropriate

Powertrain Diagnostics Procedures manual.

CABLE RESISTANCE CHART

Fig. 6 Setting Spark Plug GapÐTypical

Ä IGNITION SYSTEMS 8D - 41

Page 498 of 2438

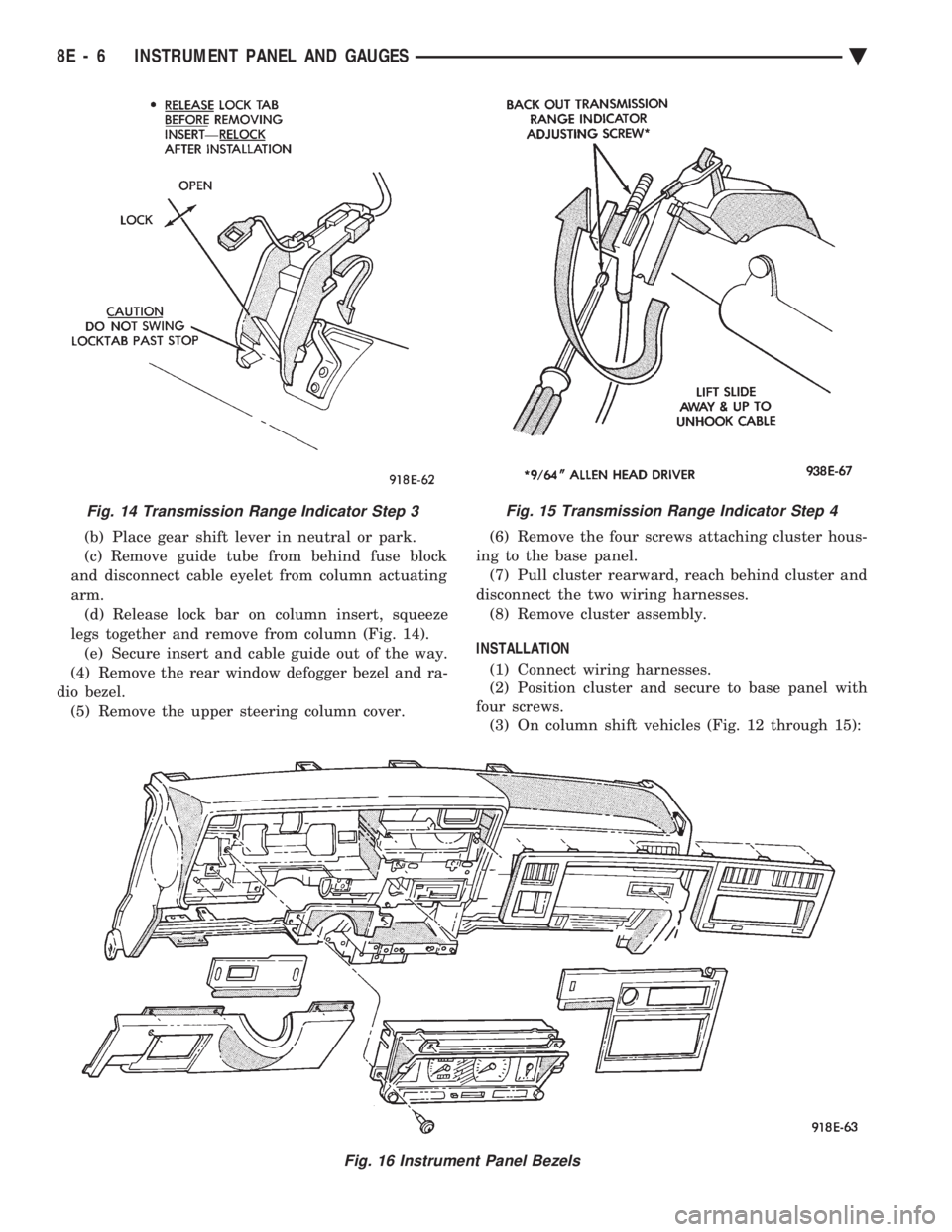

(b) Place gear shift lever in neutral or park.

(c) Remove guide tube from behind fuse block

and disconnect cable eyelet from column actuating

arm. (d) Release lock bar on column insert, squeeze

legs together and remove from column (Fig. 14). (e) Secure insert and cable guide out of the way.

(4) Remove the rear window defogger bezel and ra-

dio bezel. (5) Remove the upper steering column cover. (6) Remove the four screws attaching cluster hous-

ing to the base panel. (7) Pull cluster rearward, reach behind cluster and

disconnect the two wiring harnesses. (8) Remove cluster assembly.

INSTALLATION (1) Connect wiring harnesses.

(2) Position cluster and secure to base panel with

four screws. (3) On column shift vehicles (Fig. 12 through 15):

Fig. 15 Transmission Range Indicator Step 4

Fig. 16 Instrument Panel Bezels

Fig. 14 Transmission Range Indicator Step 3

8E - 6 INSTRUMENT PANEL AND GAUGES Ä

Page 499 of 2438

(a) Route transmission range indicator guide as-

sembly under left steering column wing and down

left side of column (Fig. 12). (b) Insert flange of column insert into column,

squeeze legs together with tabs under column

jacket and engage lock bar to secure insert (Fig.

14). (c) Hook cable eyelet to steering column actuator

check pointer, should indicate neutral. Do not kink

or bind transmission range indicator guide tube

and position guide tube in original location. (d) Adjust with tool if necessary to center pointer

on N (Neutral) and check in other gears (Fig. 15).

(4) Install upper and lower steering column cover.

(5) Install the rear window defogger bezel and ra-

dio bezel. (6) Install cluster bezel.

(7) Reconnect battery.

REMOVALÐCLUSTER WITHOUT TRANSMISSION RANGE

INDICATOR FROM STEERING COLUMN (1) Remove cluster bezel (Fig. 10).

(2) Remove four screws attaching cluster to base

panel. (3) Pull cluster rearward carefully, reach behind

and disconnect the two harness connectors. (4) Carefully rotate cluster and remove the two

transmission range indicator screws. (5) Remove cluster assembly.

(6) For installation reverse above procedures. (a) Do not kink guide tube when installing clus-

ter. (b) Replace guide tube behind fuse block.

GAUGES

It is not necessary to remove instrument clus-

ter assembly from vehicle for gauge replace-

ment. When removing gauge assemblies from cluster,

gauge must be pulled straight out, not twisted, or

damage to gauge pin may result.

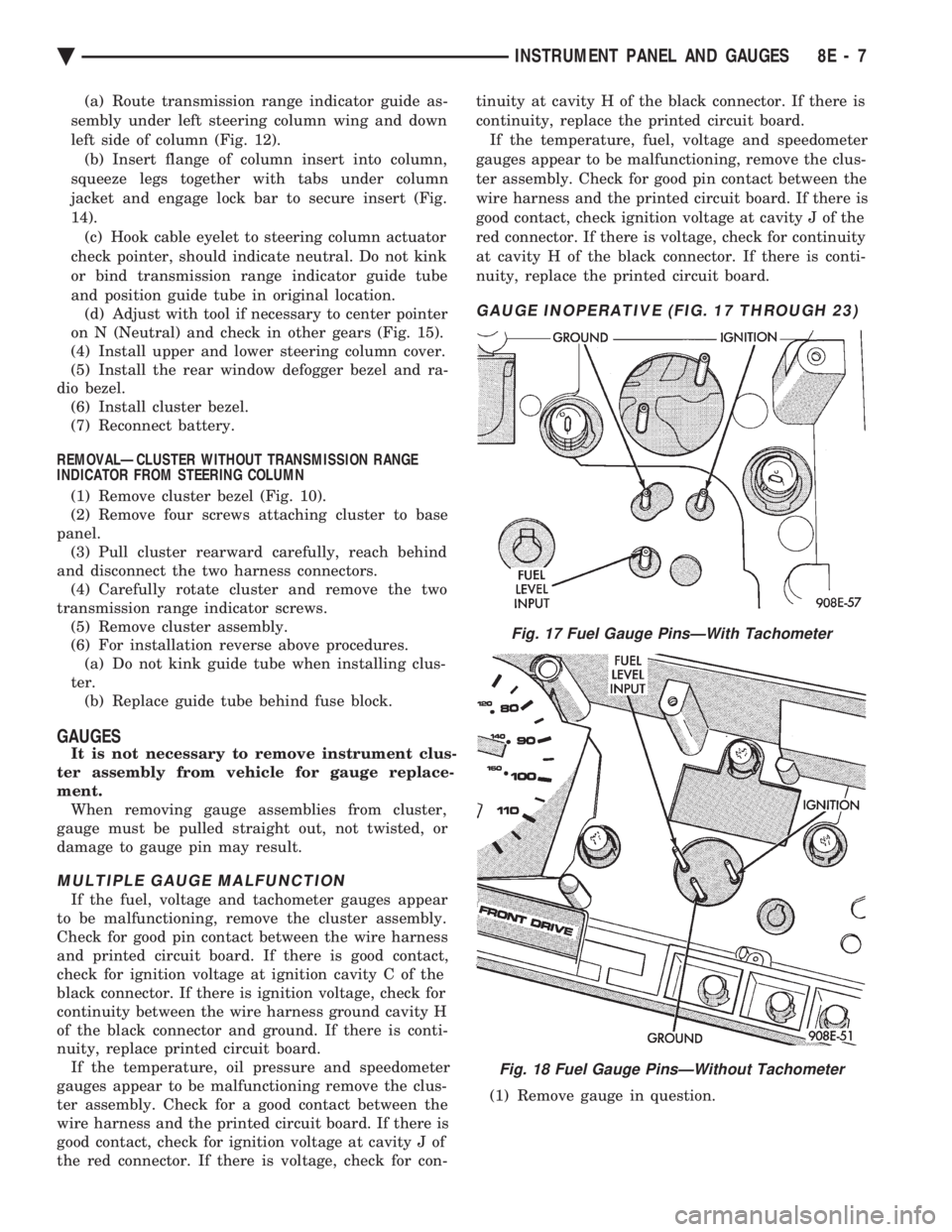

MULTIPLE GAUGE MALFUNCTION

If the fuel, voltage and tachometer gauges appear

to be malfunctioning, remove the cluster assembly.

Check for good pin contact between the wire harness

and printed circuit board. If there is good contact,

check for ignition voltage at ignition cavity C of the

black connector. If there is ignition voltage, check for

continuity between the wire harness ground cavity H

of the black connector and ground. If there is conti-

nuity, replace printed circuit board. If the temperature, oil pressure and speedometer

gauges appear to be malfunctioning remove the clus-

ter assembly. Check for a good contact between the

wire harness and the printed circuit board. If there is

good contact, check for ignition voltage at cavity J of

the red connector. If there is voltage, check for con- tinuity at cavity H of the black connector. If there is

continuity, replace the printed circuit board.

If the temperature, fuel, voltage and speedometer

gauges appear to be malfunctioning, remove the clus-

ter assembly. Check for good pin contact between the

wire harness and the printed circuit board. If there is

good contact, check ignition voltage at cavity J of the

red connector. If there is voltage, check for continuity

at cavity H of the black connector. If there is conti-

nuity, replace the printed circuit board.

GAUGE INOPERATIVE (FIG. 17 THROUGH 23)

(1) Remove gauge in question.

Fig. 17 Fuel Gauge PinsÐWith Tachometer

Fig. 18 Fuel Gauge PinsÐWithout Tachometer

Ä INSTRUMENT PANEL AND GAUGES 8E - 7

Page 505 of 2438

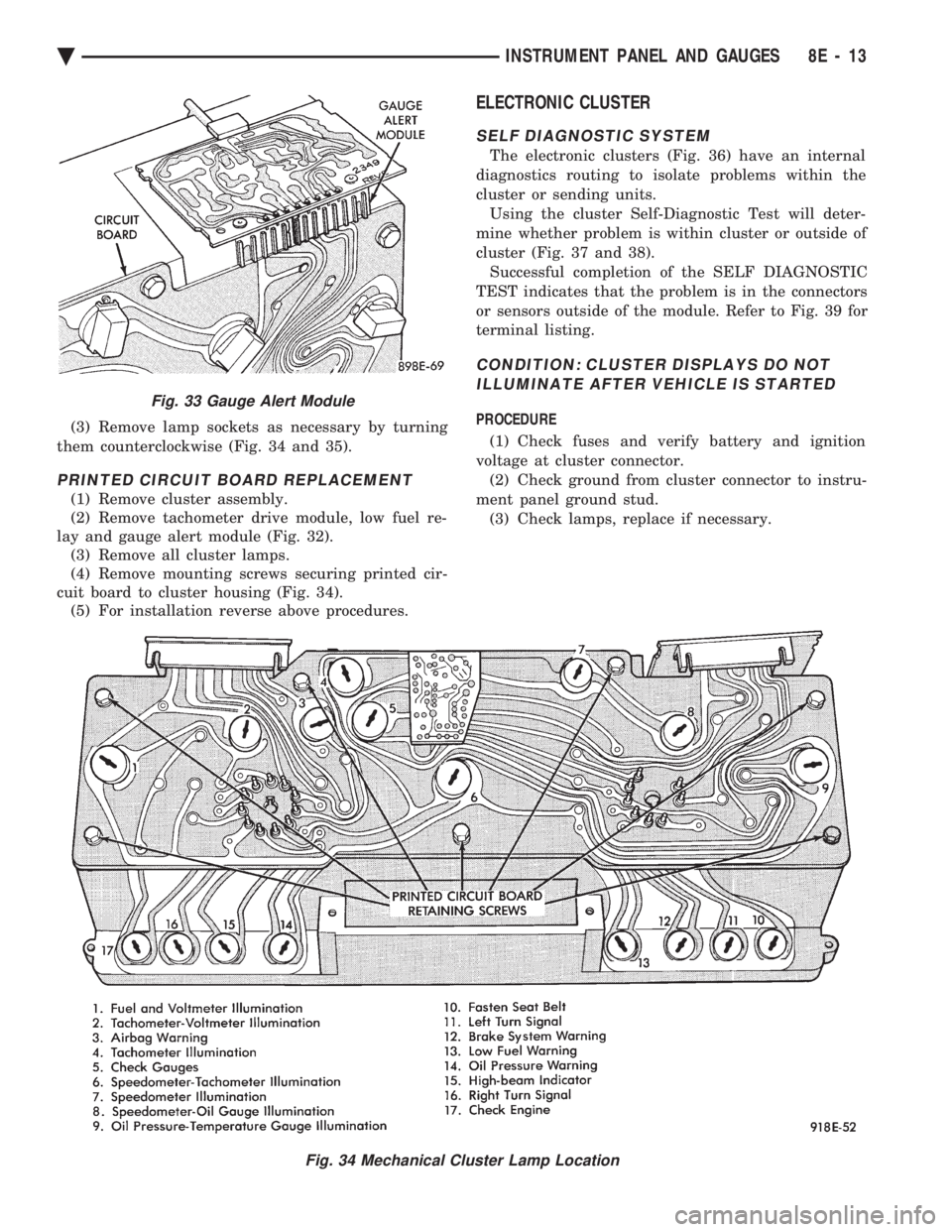

(3) Remove lamp sockets as necessary by turning

them counterclockwise (Fig. 34 and 35).

PRINTED CIRCUIT BOARD REPLACEMENT

(1) Remove cluster assembly.

(2) Remove tachometer drive module, low fuel re-

lay and gauge alert module (Fig. 32). (3) Remove all cluster lamps.

(4) Remove mounting screws securing printed cir-

cuit board to cluster housing (Fig. 34). (5) For installation reverse above procedures.

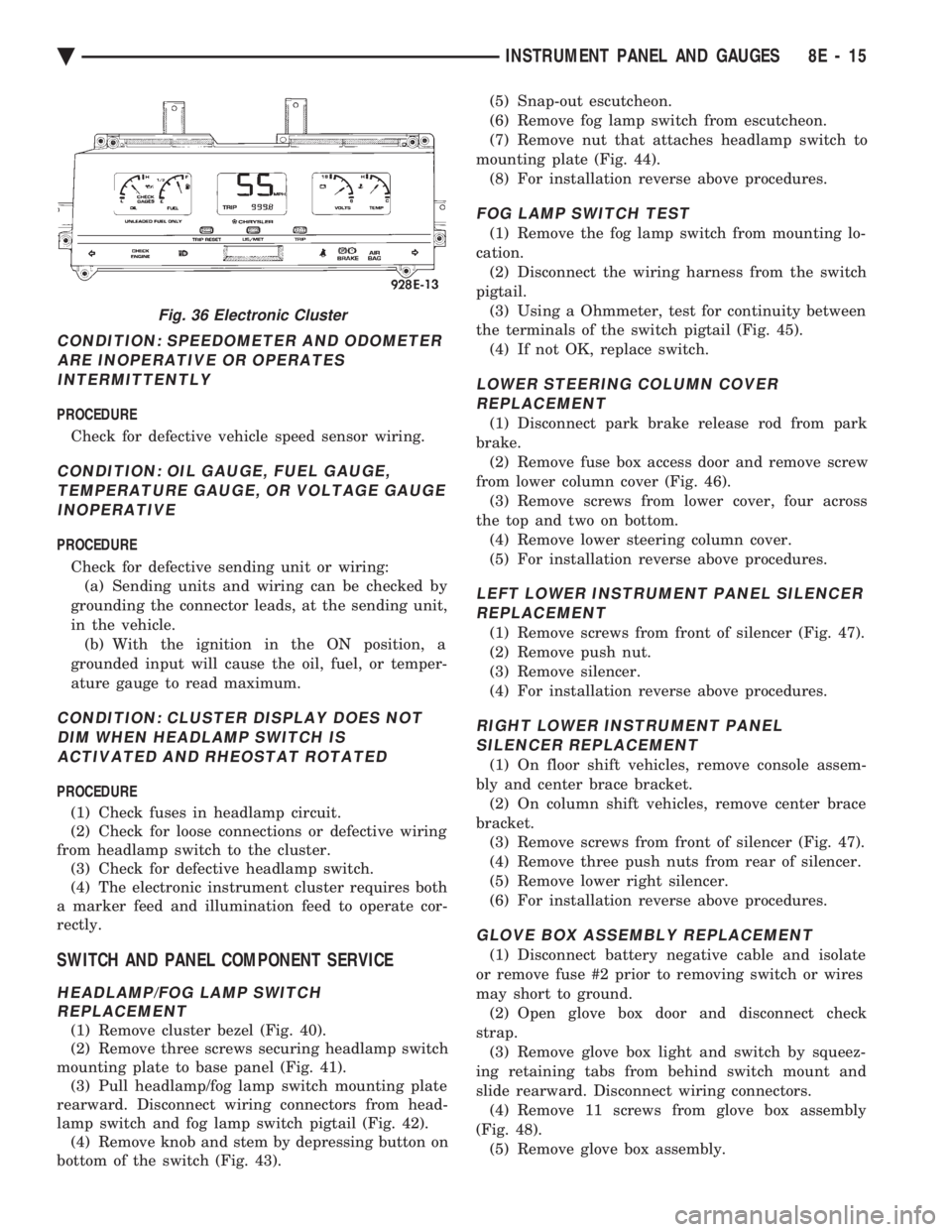

ELECTRONIC CLUSTER

SELF DIAGNOSTIC SYSTEM

The electronic clusters (Fig. 36) have an internal

diagnostics routing to isolate problems within the

cluster or sending units. Using the cluster Self-Diagnostic Test will deter-

mine whether problem is within cluster or outside of

cluster (Fig. 37 and 38). Successful completion of the SELF DIAGNOSTIC

TEST indicates that the problem is in the connectors

or sensors outside of the module. Refer to Fig. 39 for

terminal listing.

CONDITION: CLUSTER DISPLAYS DO NOT ILLUMINATE AFTER VEHICLE IS STARTED

PROCEDURE

(1) Check fuses and verify battery and ignition

voltage at cluster connector. (2) Check ground from cluster connector to instru-

ment panel ground stud. (3) Check lamps, replace if necessary.

Fig. 34 Mechanical Cluster Lamp Location

Fig. 33 Gauge Alert Module

Ä INSTRUMENT PANEL AND GAUGES 8E - 13

Page 507 of 2438

CONDITION: SPEEDOMETER AND ODOMETER ARE INOPERATIVE OR OPERATESINTERMITTENTLY

PROCEDURE

Check for defective vehicle speed sensor wiring.

CONDITION: OIL GAUGE, FUEL GAUGE, TEMPERATURE GAUGE, OR VOLTAGE GAUGEINOPERATIVE

PROCEDURE

Check for defective sending unit or wiring: (a) Sending units and wiring can be checked by

grounding the connector leads, at the sending unit,

in the vehicle. (b) With the ignition in the ON position, a

grounded input will cause the oil, fuel, or temper-

ature gauge to read maximum.

CONDITION: CLUSTER DISPLAY DOES NOT DIM WHEN HEADLAMP SWITCH ISACTIVATED AND RHEOSTAT ROTATED

PROCEDURE

(1) Check fuses in headlamp circuit.

(2) Check for loose connections or defective wiring

from headlamp switch to the cluster. (3) Check for defective headlamp switch.

(4) The electronic instrument cluster requires both

a marker feed and illumination feed to operate cor-

rectly.

SWITCH AND PANEL COMPONENT SERVICE

HEADLAMP/FOG LAMP SWITCH REPLACEMENT

(1) Remove cluster bezel (Fig. 40).

(2) Remove three screws securing headlamp switch

mounting plate to base panel (Fig. 41). (3) Pull headlamp/fog lamp switch mounting plate

rearward. Disconnect wiring connectors from head-

lamp switch and fog lamp switch pigtail (Fig. 42). (4) Remove knob and stem by depressing button on

bottom of the switch (Fig. 43). (5) Snap-out escutcheon.

(6) Remove fog lamp switch from escutcheon.

(7) Remove nut that attaches headlamp switch to

mounting plate (Fig. 44). (8) For installation reverse above procedures.

FOG LAMP SWITCH TEST

(1) Remove the fog lamp switch from mounting lo-

cation. (2) Disconnect the wiring harness from the switch

pigtail. (3) Using a Ohmmeter, test for continuity between

the terminals of the switch pigtail (Fig. 45). (4) If not OK, replace switch.

LOWER STEERING COLUMN COVERREPLACEMENT

(1) Disconnect park brake release rod from park

brake. (2) Remove fuse box access door and remove screw

from lower column cover (Fig. 46). (3) Remove screws from lower cover, four across

the top and two on bottom. (4) Remove lower steering column cover.

(5) For installation reverse above procedures.

LEFT LOWER INSTRUMENT PANEL SILENCER REPLACEMENT

(1) Remove screws from front of silencer (Fig. 47).

(2) Remove push nut.

(3) Remove silencer.

(4) For installation reverse above procedures.

RIGHT LOWER INSTRUMENT PANEL SILENCER REPLACEMENT

(1) On floor shift vehicles, remove console assem-

bly and center brace bracket. (2) On column shift vehicles, remove center brace

bracket. (3) Remove screws from front of silencer (Fig. 47).

(4) Remove three push nuts from rear of silencer.

(5) Remove lower right silencer.

(6) For installation reverse above procedures.

GLOVE BOX ASSEMBLY REPLACEMENT

(1) Disconnect battery negative cable and isolate

or remove fuse #2 prior to removing switch or wires

may short to ground. (2) Open glove box door and disconnect check

strap. (3) Remove glove box light and switch by squeez-

ing retaining tabs from behind switch mount and

slide rearward. Disconnect wiring connectors. (4) Remove 11 screws from glove box assembly

(Fig. 48). (5) Remove glove box assembly.

Fig. 36 Electronic Cluster

Ä INSTRUMENT PANEL AND GAUGES 8E - 15