fuel CHEVROLET DYNASTY 1993 Owner's Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 373 of 2438

BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS

CONTENTS

page page

BATTERY TEST PROCEDURES ON-VEHICLE . . 3

FAULT CODESÐON BOARD DIAGNOSTICS . . 23

GENERAL INFORMATION .................. 1

GENERATOR TEST PROCEDURES ON VEHICLE.19 IGNITION OFF DRAW (IOD)

............... 9

SPECIFICATIONS ....................... 28

STARTER TEST PROCEDURES ON VEHICLE . 11

GENERAL INFORMATION

² For Battery, Starter or Generator replacement re-

fer to Group 8B, Battery/Starter/Generator Service.

This Group 8A will cover diagnostics only. The Battery, Starting, and Charging Systems oper-

ate with one another, and must be thoroughly tested

as a complete system. To enable the vehicle to start

and charge properly, it must have a battery that will

perform to specifications. The starter motor, genera-

tor, wiring, and electronics also must perform within

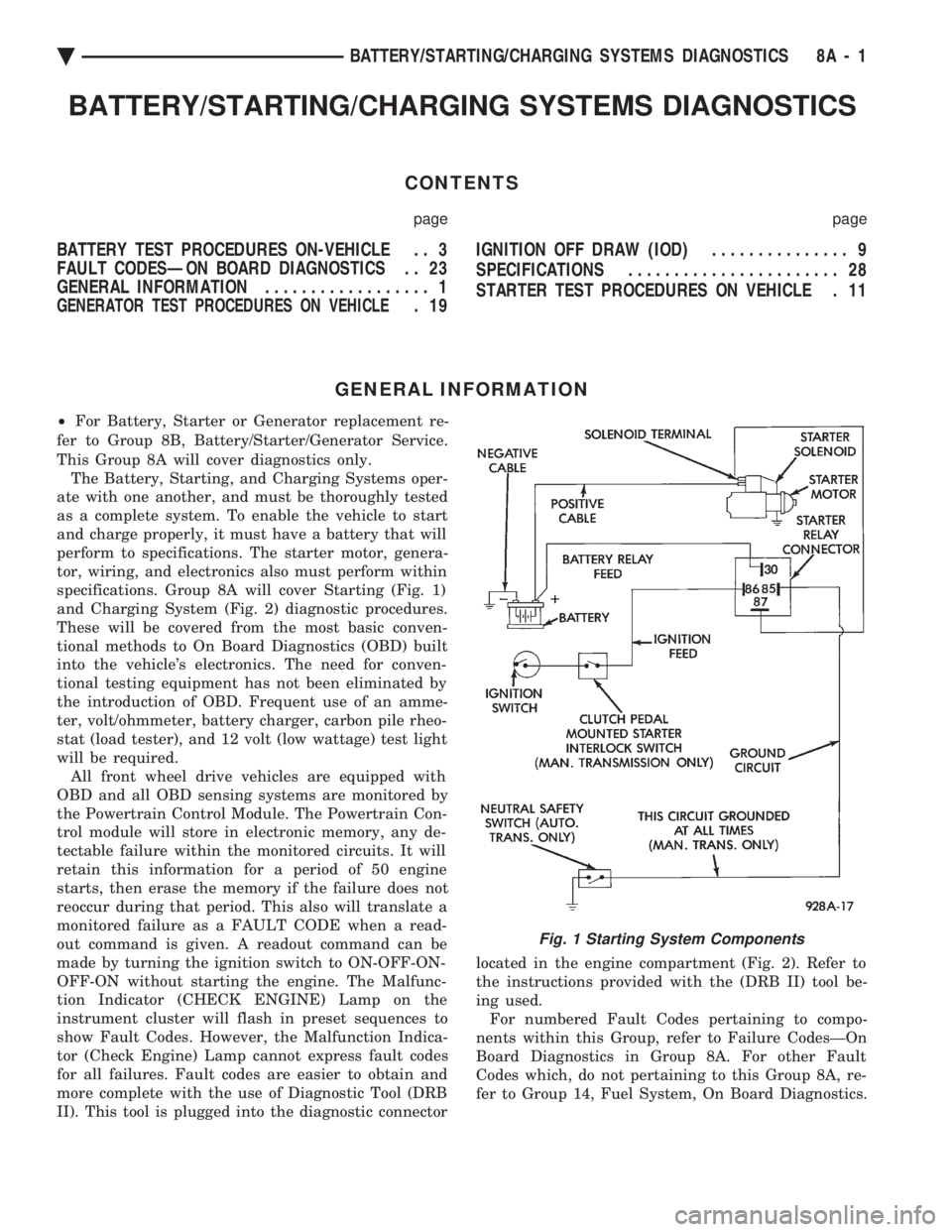

specifications. Group 8A will cover Starting (Fig. 1)

and Charging System (Fig. 2) diagnostic procedures.

These will be covered from the most basic conven-

tional methods to On Board Diagnostics (OBD) built

into the vehicle's electronics. The need for conven-

tional testing equipment has not been eliminated by

the introduction of OBD. Frequent use of an amme-

ter, volt/ohmmeter, battery charger, carbon pile rheo-

stat (load tester), and 12 volt (low wattage) test light

will be required. All front wheel drive vehicles are equipped with

OBD and all OBD sensing systems are monitored by

the Powertrain Control Module. The Powertrain Con-

trol module will store in electronic memory, any de-

tectable failure within the monitored circuits. It will

retain this information for a period of 50 engine

starts, then erase the memory if the failure does not

reoccur during that period. This also will translate a

monitored failure as a FAULT CODE when a read-

out command is given. A readout command can be

made by turning the ignition switch to ON-OFF-ON-

OFF-ON without starting the engine. The Malfunc-

tion Indicator (CHECK ENGINE) Lamp on the

instrument cluster will flash in preset sequences to

show Fault Codes. However, the Malfunction Indica-

tor (Check Engine) Lamp cannot express fault codes

for all failures. Fault codes are easier to obtain and

more complete with the use of Diagnostic Tool (DRB

II). This tool is plugged into the diagnostic connector located in the engine compartment (Fig. 2). Refer to

the instructions provided with the (DRB II) tool be-

ing used. For numbered Fault Codes pertaining to compo-

nents within this Group, refer to Failure CodesÐOn

Board Diagnostics in Group 8A. For other Fault

Codes which, do not pertaining to this Group 8A, re-

fer to Group 14, Fuel System, On Board Diagnostics.

Fig. 1 Starting System Components

Ä BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS 8A - 1

Page 396 of 2438

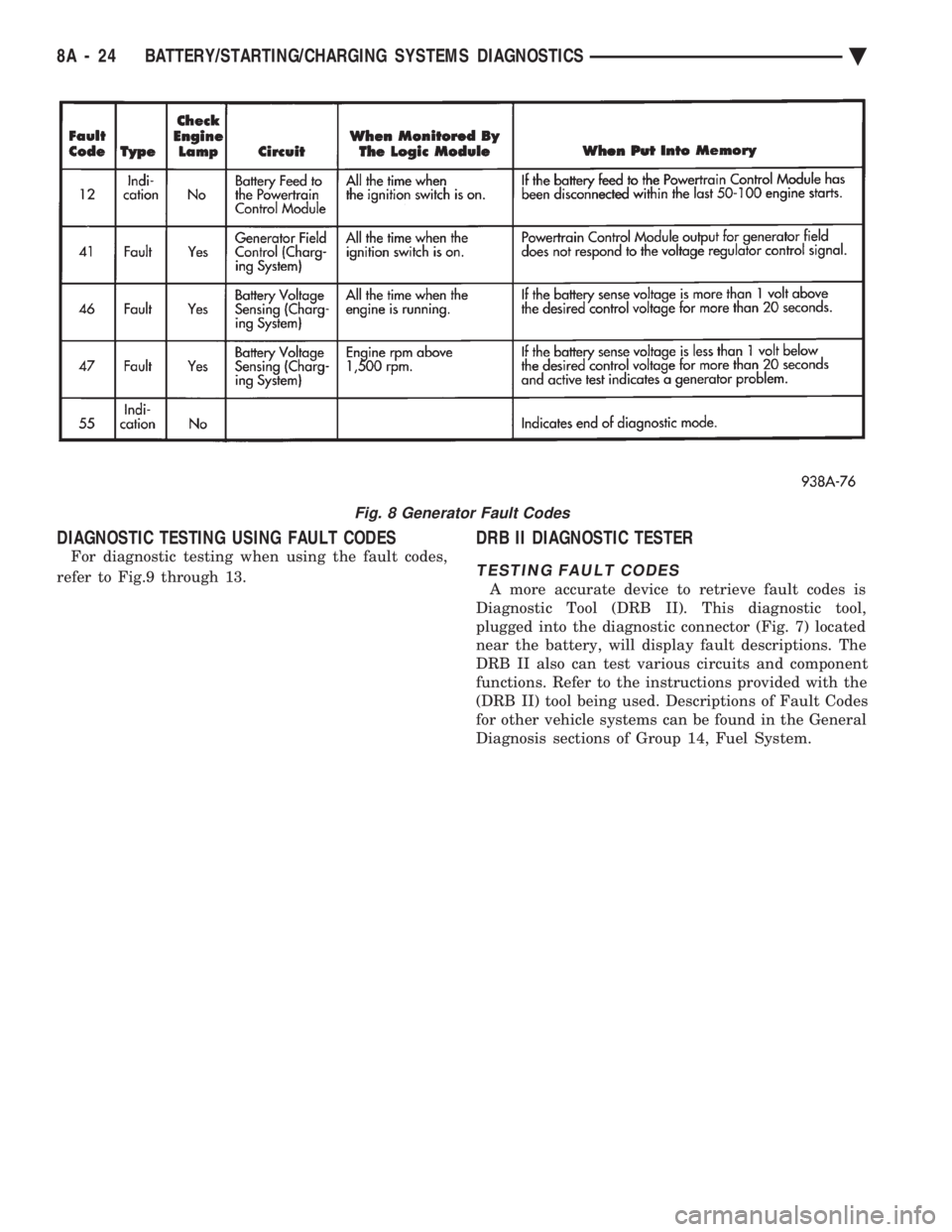

DIAGNOSTIC TESTING USING FAULT CODES

For diagnostic testing when using the fault codes,

refer to Fig.9 through 13.

DRB II DIAGNOSTIC TESTER

TESTING FAULT CODES

A more accurate device to retrieve fault codes is

Diagnostic Tool (DRB II). This diagnostic tool,

plugged into the diagnostic connector (Fig. 7) located

near the battery, will display fault descriptions. The

DRB II also can test various circuits and component

functions. Refer to the instructions provided with the

(DRB II) tool being used. Descriptions of Fault Codes

for other vehicle systems can be found in the General

Diagnosis sections of Group 14, Fuel System.

Fig. 8 Generator Fault Codes

8A - 24 BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS Ä

Page 423 of 2438

² To set DAY of WEEK, press TIME button. An ar-

row will appear on the display and point to the Day.

Press and hold the SET button to move the day for-

ward or INFO button to move it backward.

² To set DAY of MONTH, press TIME button. The

arrow will point to Date. Press and hold the SET

button to advance the date or INFO button to move

it backwards.

² To set MONTH of YEAR, press TIME button. The

arrow will point to the Month. Press and hold the

SET button to advance the Month forward or INFO

button to move backward. TEMP button, pressing the Temp button will dis-

play:

² The temperature outside the vehicle

² Vehicle direction define by an eight point compass

If Compass has lost calibration or not receiving

good information from the engine compartment node,

an asterisk (*) will flash on the display and the word

calibrate will appear. Refer to Compass Calibration. FUEL BUTTON, WILL DISPLAY:

² Pressing FUEL button the first time will show, the

estimated number of miles that can be driven with

the remaining fuel. The destination to empty indica-

tion will vary every few seconds as the amount of

fuel and fuel efficiency is calculated. This function

can not be reset.

² Pressing the FUEL button second time; will dis-

play the fuel consumed.

²

Pressing the FUEL button third time; will display

the average fuel economy in miles per gallon since last

reset. The display will be updated every 16 seconds.

² Pressing the FUEL button forth time, the current

fuel economy will be displayed. The current fuel

economy will be up updated every two seconds.

² To reset Fuel consumed, press SET button until

the fuel consumed message is displayed and then

within five seconds press SET button.

² To reset AVERAGE FUEL ECONOMY, press the

FUEL button until average fuel economy is displayed

and within five seconds press SET button. TRIP RESET, press FUEL button and wait four

seconds press the SET button twice. This clears all

trip information and the message Trip Reset will be

displayed. This will occur only if a reset function is

currently being displayed. The reset functions:

² Fuel consumed

² Average fuel economy message

INFO button, will active a MONITORED SYS-

TEMS OK message on display if all monitored sys-

tems are operating properly. If a problem is detected,

the appropriate message will be displayed. SET button, will clear the various functions after

they have been displayed. It is used to enter the

clock set or compass variance modes. This button is

also used to reset certain trip computer functions and

the maintenance reminder message.

The EVIC display may be turned off by pressing the

TIME and SET buttons at the same time. Pressing the

buttons a second time will restore the display.

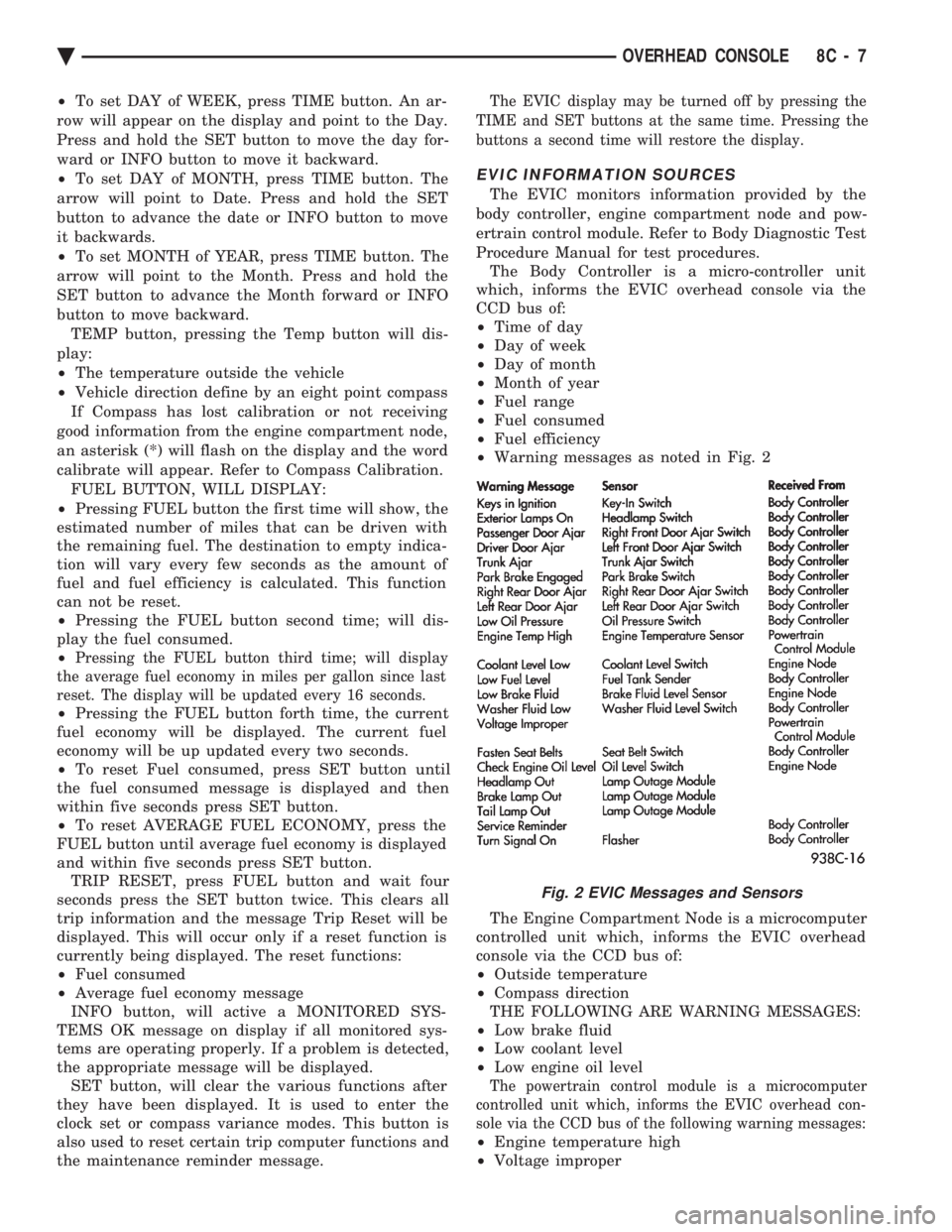

EVIC INFORMATION SOURCES

The EVIC monitors information provided by the

body controller, engine compartment node and pow-

ertrain control module. Refer to Body Diagnostic Test

Procedure Manual for test procedures. The Body Controller is a micro-controller unit

which, informs the EVIC overhead console via the

CCD bus of:

² Time of day

² Day of week

² Day of month

² Month of year

² Fuel range

² Fuel consumed

² Fuel efficiency

² Warning messages as noted in Fig. 2

The Engine Compartment Node is a microcomputer

controlled unit which, informs the EVIC overhead

console via the CCD bus of:

² Outside temperature

² Compass direction

THE FOLLOWING ARE WARNING MESSAGES:

² Low brake fluid

² Low coolant level

² Low engine oil level

The powertrain control module is a microcomputer

controlled unit which, informs the EVIC overhead con-

sole via the CCD bus of the following warning messages:

² Engine temperature high

² Voltage improper

Fig. 2 EVIC Messages and Sensors

Ä OVERHEAD CONSOLE 8C - 7

Page 424 of 2438

VISUAL MESSAGES

Following are the visual messages and the condi-

tions under which, the messages will be given:

² Keys in ignition

² Exterior lamps on

These messages will appear if the conditions are

present and the driver's door is open while the igni-

tion switch is in the OFF, LOCK, or ACC positions.

A tone will sound until the condition is corrected or

the door is closed.

² Passenger door ajar

² Driver door ajar

² Trunk ajar

² Park brake engaged

² Right rear door ajar

² Left rear door ajar

These messages will appear if a condition is de-

tected after the vehicle is in motion. When the con-

dition is corrected, a short tone will sound to

acknowledge the action. LOW OIL PRESSURE

If this message is displayed while the vehicle is at

cruising speeds, immediate attention is required. If

this message appears at idle speed, increase the idle

speed and the message should go off. If the message

remains on, immediate attention is required. ENGINE TEMP CRITICAL

This message appears when a sensor has determined

that the engine coolant is overheating. If this message

comes on and stays on, immediate action is required.

COOLANT LEVEL LOW

LOW FUEL LEVEL

LOW BRAKE FLUID

WASHER FLUID LOW

These messages will appear if a continuous warn-

ing condition is detected while the engine is running.

Inspection is required. To clear this message from

the display, after the condition is corrected, the igni-

tion switch must be turned OFF. CHECK TRANS

This message will appear if a continuous warning

condition is detected while the engine is running. Im-

mediate attention is recommended. To clear this mes-

sage from the display, after the condition has been

corrected, the ignition switch must be turned OFF. VOLTAGE IMPROPER

This message will appear if a continuous warning

condition is detected. Immediate attention is re-

quired. To clear this message from the display, after

the condition has been corrected, the ignition switch

must be turned OFF. TURN SIGNAL ON

This message will appear if the turn signal is left

on while vehicle speed is over 15 mph and the vehi-

cle has traveled over one-half mile. FASTEN SEAT BELTS An intermittent chime tone will sound for several

seconds if the seat belt is not fastened. CHK ENGINE OIL LEVEL

If this message is delivered, a check of the engine

oil dipstick is suggested. To clear this message, after

the condition is corrected, the ignition switch must

be turned OFF. HEADLAMP OUT

BRAKE LAMP OUT

TAIL LAMP OUT

These conditions are monitored only when the lamps

are on. The message will remain, even after the lamp is

replaced, until the lamp is turned on and operates.

SERVICE REMINDER

The maintenance reminder statement is programmed

to provide general information only. Refer to Group 0,

Lubrication & Maintenance for specific vehicle require-

ments.

The service reminder message is displayed at 7,500

miles or 12 months intervals, which ever comes first. MONITORED SYSTEMS OK

If there is no warning condition to report, the mes-

sage Monitored Systems OK is displayed (Fig. 2).

AUTOMATIC CALIBRATION SET PROCEDURE

The engine compartment node will continuously

and automatically recalibrate the compass under nor-

mal driving conditions. As long as the vehicle is

turning, the engine compartment node will record

new compass data. This new data will be used to

recalibrate the compass at a rate of at least once per

full (360 degree) turn of the vehicle. Automatic cali-

bration does not require operator interface.

MANUAL CALIBRATION SET PROCEDURE

Manual compass calibration has been replaced by

automatic calibration set procedure. The manual cal-

ibration set procedure is available, but no longer

serves any useful purpose.

EVIC SELF CHECK DIAGNOSTICS

Ignition switch ON, the EVIC not displaying any

message, may imply a system failure and not an

EVIC failure. Turn the ignition OFF, close all vehi-

cle doors and wait at least 60 seconds before begin-

ning test. Turn ignition switch to the ON position.

Pressing the TEMP, FUEL and INFO buttons at the

same time shall provide the visual message MOD-

ULE SELF CHECK for two seconds. Following at

two second interval there will be messages:

² E2-0 SELF CHECK

² E3-0 SELF CHECK

² END OF SELF CHECK

Showing the microcomputer is working properly.

When the self check mode and message shows:

² E2-1

² E3-2

This would show a fault exists in the EVIC's micro-

computer and the EVIC should be replaced (Fig. 3).

8C - 8 OVERHEAD CONSOLE Ä

Page 430 of 2438

dition exists. These messages are displayed on the

center of the instrument panel.For complete EVIC operating instructions, refer to

the Owners Manual provided with the vehicle.

EVIC BUTTON FUNCTIONS

TIME button will display:

² Time of day

² Day of week

² Day of month

² Month of year

² To set HOURS, press TIME button and within four

seconds press the SET button. An arrow will appear

on the display and point to the hours. Press and hold

the SET button to advance the hours or INFO button

to set back the hours.

² To set MINUTES, press TIME button. The arrow

will point to the minutes. Press and hold the SET

button to advance the minutes or INFO button to set

back the minutes.

² To set DAY of WEEK, press TIME button. An ar-

row will appear on the display and point to the Day.

Press and hold the SET button to move the day for-

ward or INFO button to move it backward.

² To set DAY of MONTH, press TIME button. The

arrow will point to Date. Press and hold the SET

button to advance the date or INFO button to move

it backwards.

² To set MONTH of YEAR, press TIME button. The

arrow will point to the Month. Press and hold the

SET button to advance the Month forward or INFO

button to move backward. TEMP button, pressing the Temp button will dis-

play:

² The temperature outside the vehicle

² Vehicle direction define by an eight point compass

If Compass has lost calibration or not receiving

good information from the engine compartment node,

an asterisk (*) will flash on the display and the word

calibrate will appear. Refer to Compass Calibration. FUEL BUTTON, WILL DISPLAY:

² Pressing FUEL button the first time will show, the

estimated number of miles that can be driven with

the remaining fuel. The destination to empty indica-

tion will vary every few seconds as the amount of

fuel and fuel efficiency is calculated. This function

can not be reset.

² Pressing the FUEL button second time; will dis-

play the fuel consumed.

² Pressing the FUEL button third time; will display

the average fuel economy in miles per gallon since

last reset. The display will be updated every 16 sec-

onds.

² Pressing the FUEL button forth time, the current

fuel economy will be displayed. The current fuel

economy will be up updated every two seconds. ²

To reset Fuel consumed, press SET button until

the fuel consumed message is displayed and then

within five seconds press SET button.

² To reset AVERAGE FUEL ECONOMY, press the

FUEL button until average fuel economy is displayed

and within five seconds press SET button. TRIP RESET, press FUEL button and wait four

seconds press the SET button twice. This clears all

trip information and the message Trip Reset will be

displayed. This will occur only if a reset function is

currently being displayed. The reset functions:

² Fuel consumed

² Average fuel economy message

INFO button, will active a MONITORED SYS-

TEMS OK message on display if all monitored sys-

tems are operating properly. If a problem is detected,

the appropriate message will be displayed. SET button, will clear the various functions after

they have been displayed. It is used to enter the

clock set or compass variance modes. This button is

also used to reset certain trip computer functions and

the maintenance reminder message. The EVIC display may be turned off by pressing

the TIME and SET buttons at the same time. Press-

ing the buttons a second time will restore the dis-

play.

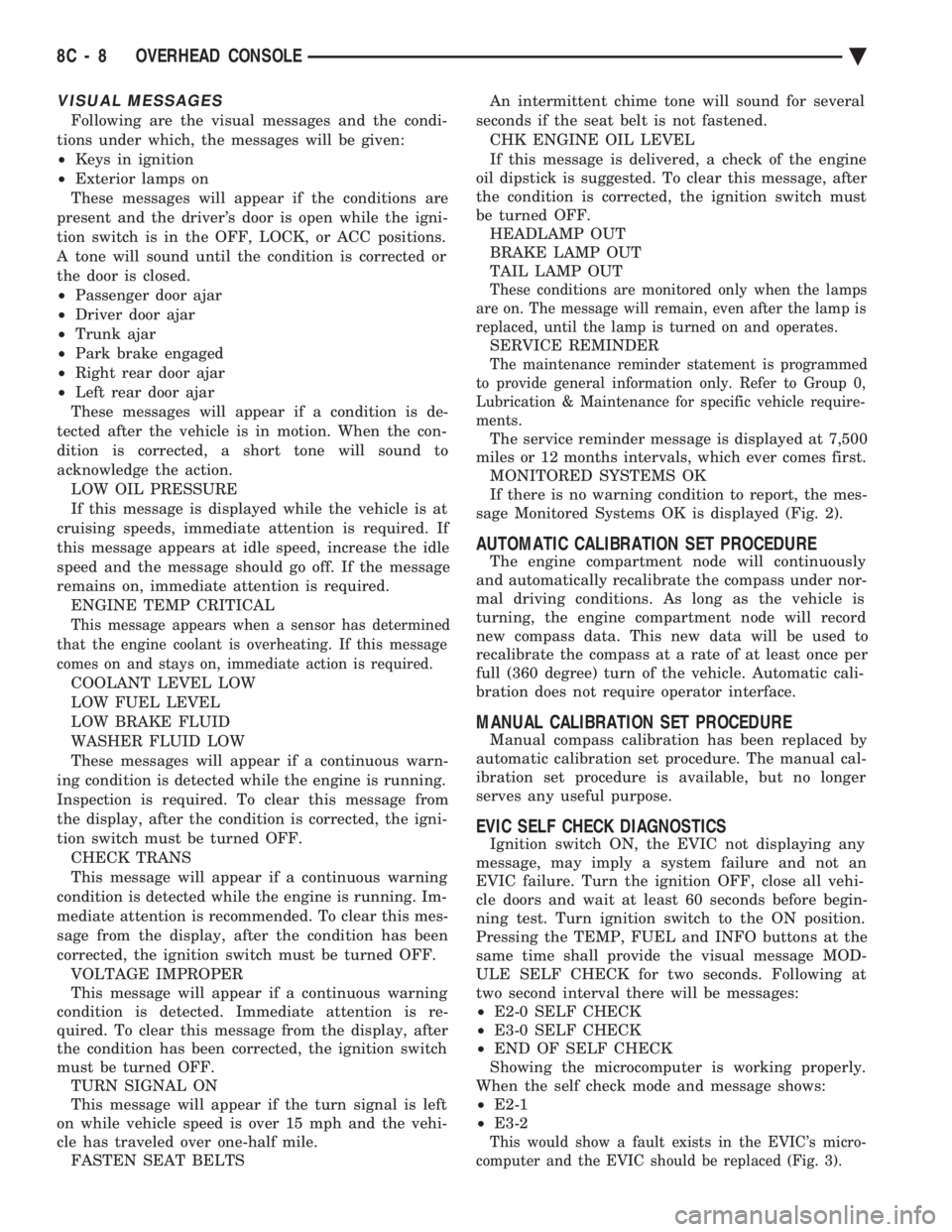

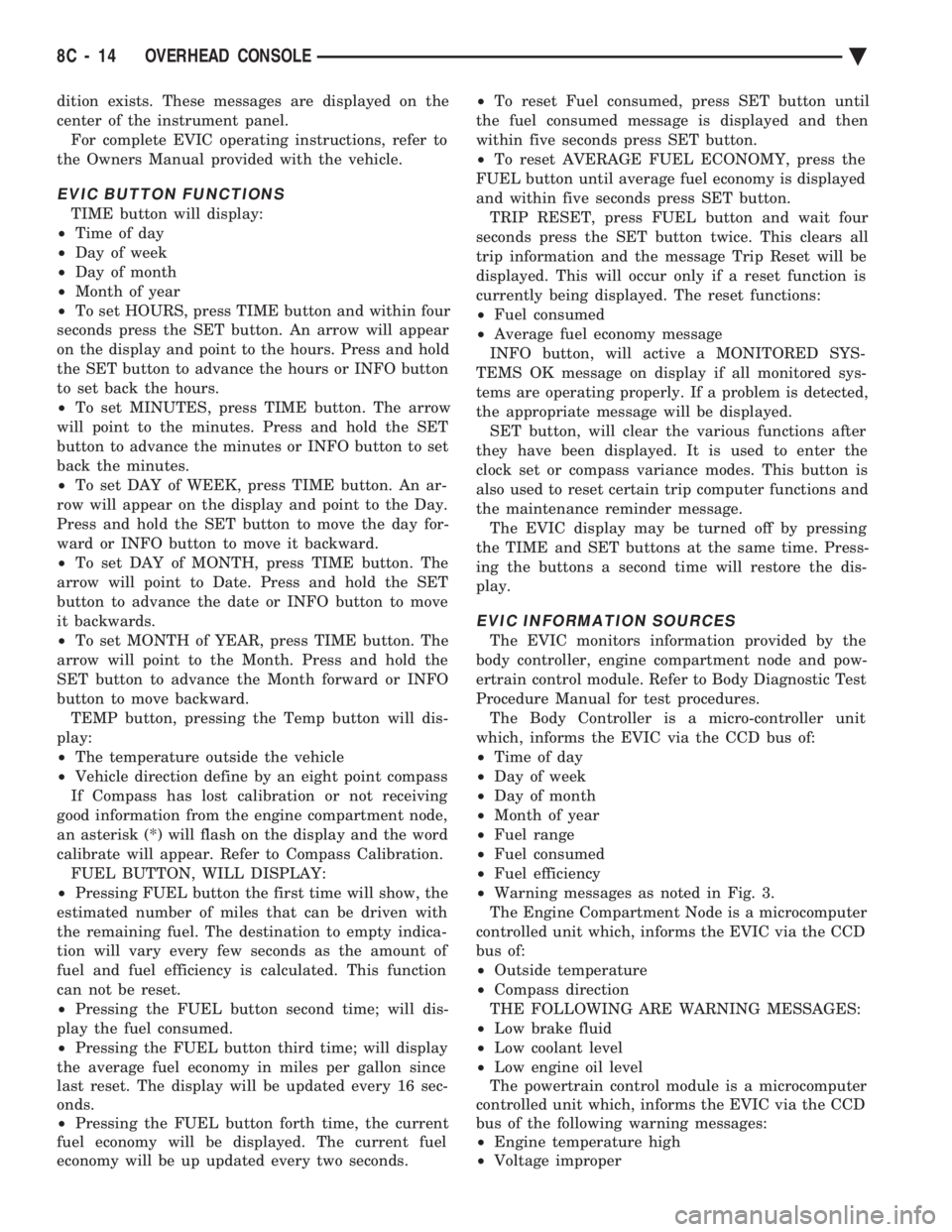

EVIC INFORMATION SOURCES

The EVIC monitors information provided by the

body controller, engine compartment node and pow-

ertrain control module. Refer to Body Diagnostic Test

Procedure Manual for test procedures. The Body Controller is a micro-controller unit

which, informs the EVIC via the CCD bus of:

² Time of day

² Day of week

² Day of month

² Month of year

² Fuel range

² Fuel consumed

² Fuel efficiency

² Warning messages as noted in Fig. 3.

The Engine Compartment Node is a microcomputer

controlled unit which, informs the EVIC via the CCD

bus of:

² Outside temperature

² Compass direction

THE FOLLOWING ARE WARNING MESSAGES:

² Low brake fluid

² Low coolant level

² Low engine oil level

The powertrain control module is a microcomputer

controlled unit which, informs the EVIC via the CCD

bus of the following warning messages:

² Engine temperature high

² Voltage improper

8C - 14 OVERHEAD CONSOLE Ä

Page 431 of 2438

VISUAL MESSAGES

Following are the visual messages and the condi-

tions under which, the messages will be given:

² Keys in ignition

² Exterior lamps on

These messages will appear if the conditions are

present and the driver's door is open while the igni-

tion switch is in the OFF, LOCK, or ACC positions.

A tone will sound until the condition is corrected or

the door is closed.

² Passenger door ajar

² Driver door ajar

² Trunk ajar

² Park brake engaged

² Right rear door ajar

² Left rear door ajar

These messages will appear if a condition is de-

tected after the vehicle is in motion. When the con-

dition is corrected, a short tone will sound to

acknowledge the action. LOW OIL PRESSURE

If this message is displayed while the vehicle is at

cruising speeds, immediate attention is required. If

this message appears at idle speed, increase the idle

speed and the message should go off. If the message

remains on, immediate attention is required. ENGINE TEMP CRITICAL

This message appears when a sensor has deter-

mined that the engine coolant is overheating. If this

message comes on and stays on, immediate action is

required. COOLANT LEVEL LOW

LOW FUEL LEVEL

LOW BRAKE FLUID WASHER FLUID LOW

These messages will appear if a continuous warn-

ing condition is detected while the engine is running.

Inspection is required. To clear this message from

the display, after the condition is corrected, the igni-

tion switch must be turned OFF. CHECK TRANS

This message will appear if a continuous warning

condition is detected while the engine is running. Im-

mediate attention is recommended. To clear this mes-

sage from the display, after the condition has been

corrected, the ignition switch must be turned OFF. VOLTAGE IMPROPER

This message will appear if a continuous warning

condition is detected. Immediate attention is re-

quired. To clear this message from the display, after

the condition has been corrected, the ignition switch

must be turned OFF. TURN SIGNAL ON

This message will appear if the turn signal is left

on while vehicle speed is over 15 mph and the vehi-

cle has traveled over one-half mile. FASTEN SEAT BELTS

An intermittent chime tone will sound for several

seconds if the seat belt is not fastened. CHK ENGINE OIL LEVEL

If this message is delivered, a check of the engine

oil dipstick is suggested. To clear this message, after

the condition is corrected, the ignition switch must

be turned OFF. HEADLAMP OUT

BRAKE LAMP OUT

TAIL LAMP OUT

These conditions are monitored only when the

lamps are on. The message will remain, even after

the lamp is replaced, until the lamp is turned on and

operates. SERVICE REMINDER

The maintenance reminder statement is pro-

grammed to provide general information only. Refer

to Group 0, Lubrication & Maintenance for specific

vehicle requirements. The service reminder message is displayed at 7,500

miles or 12 months intervals, which ever comes first. MONITORED SYSTEMS OK

If there is no warning condition to report, the mes-

sage Monitored Systems OK is displayed (Fig. 3).

ENGINE COMPARTMENT NODE (ECN)

The Engine Compartment Node is a microcomputer

controlled unit which, informs the Electronic Vehicle

Information Center (EVIC) via the CCD bus of:

² Outside temperature

² Compass direction

and the following warning messages:

² Low Brake Fluid

² Low Coolant Level

² Low Engine Oil Level

Fig. 3 EVIC Messages and Sensors

Ä OVERHEAD CONSOLE 8C - 15

Page 443 of 2438

IGNITION SYSTEMS

CONTENTS

page page

2.2L TBI, 2.5L TBI, 2.5L MPI AND 3.0L IGNITION SYSTEMSÐDIAGNOSTIC PROCEDURES

..... 11

2.2L TBI, 2.5L TBI, 2.5L MPI AND 3.0L IGNI- TION SYSTEMSÐSERVICE PROCEDURES . 14

2.2L TBI, 2.5L TBI, 2.5L MPI AND 3.0L IGNI- TION SYSTEMSÐSYSTEM OPERATION .... 1

2.2L TURBO III, 3.3L AND 3.8L IGNITION SYSTEMÐDIAGNOSTIC PROCEDURES

.... 35

2.2L TURBO III, 3.3L AND 3.8L IGNITION SYSTEMÐSYSTEM OPERATION ......... 24

2.2L TURBO III, 3.3L AND 3.8L IGNITION SYSTEMSÐSERVICE PROCEDURES ...... 39

IGNITION SWITCH ...................... 45

SPECIFICATIONS ....................... 47

GENERAL INFORMATION

Throughout this group, references are made to par-

ticular vehicles by letter designation. A chart ex-

plaining the designations appears in the Introduction

Section of this manual.

2.2L TBI, 2.5L TBI, 2.5L MPI AND 3.0L IGNITION SYSTEMSÐSYSTEM OPERATION

INDEX

page page

Auto Shutdown (ASD) Relay and Fuel Pump Relay . 8

Coolant Temperature Sensor ................. 7

Distributor Cap ........................... 1

Distributor Pick-UpÐ3.0L Engine .............. 7

Distributor Pick-UpÐPCM Input ............... 6

General Information ........................ 1 Ignition Coil

.............................. 9

Manifold Absolute Pressure (MAP) Sensor ...... 8

Powertrain Control Module (PCM) ............. 6

Rotor .................................. 2

Spark Plug Cables ........................ 2

Spark Plugs ............................. 3

GENERAL INFORMATION

This section describes the ignition systems of the

2.2L TBI, 2.5L TBI, 2.5L MPI (flexible fuel AA-body)

and 3.0L engines. The Fuel Injection sections of Group 14 explain On

Board Diagnostics. Group 0, Lubrication and Maintenance, contains

general maintenance information for ignition related

items. The Owner's Manual also contains mainte-

nance information.

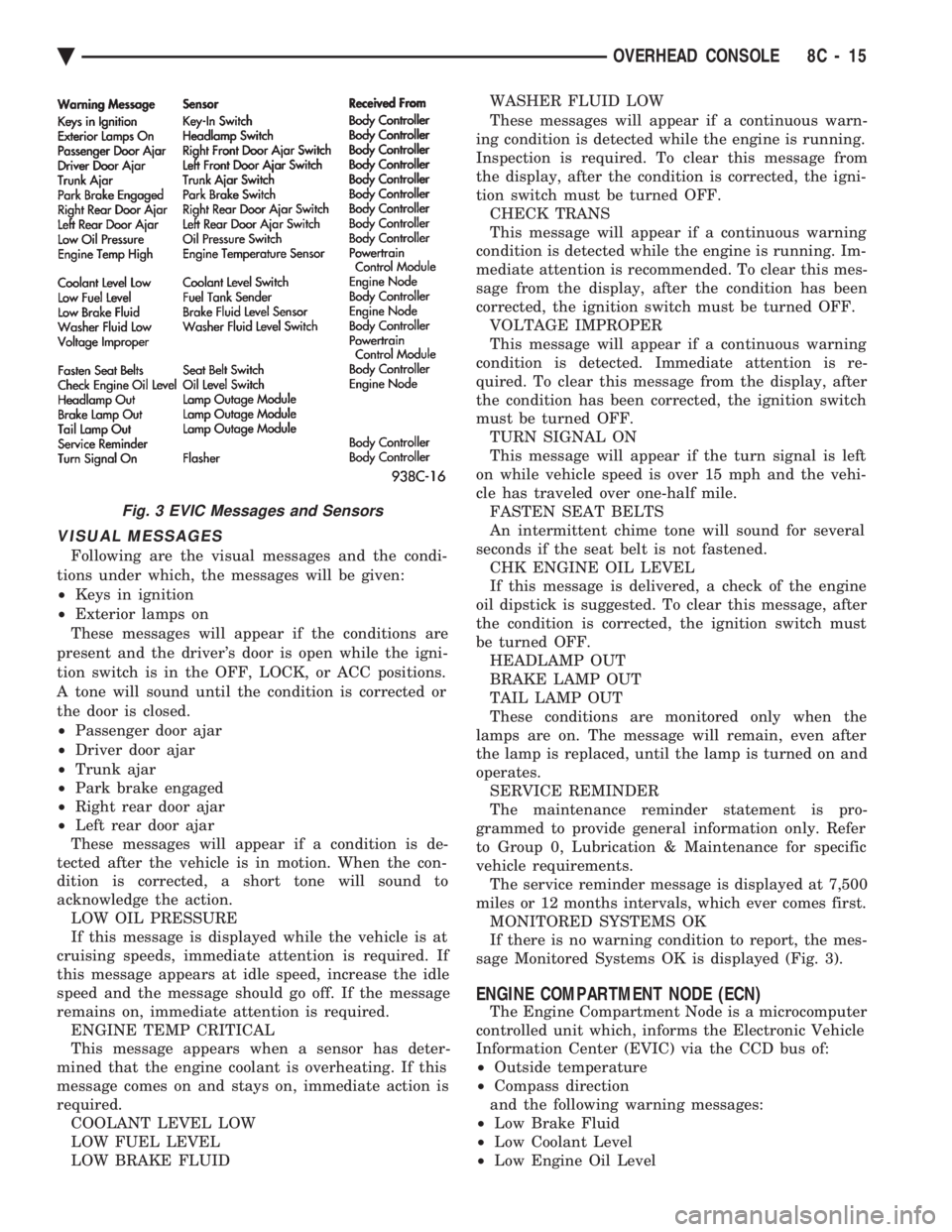

DISTRIBUTOR CAP

Remove the distributor cap and inspect the inside

for flash over, cracking of carbon button, lack of

spring tension on carbon button, cracking of cap, and

burned, worn terminals (Fig. 1). Also check for bro-

ken distributor cap towers. If any of these conditions

are present the distributor cap and/or cables should

be replaced. When replacing the distributor cap, transfer cables

from the original cap to the new cap one at a time.

Ensure each cable is installed into the corresponding tower of the new cap. Fully seat the wires into the

towers. If necessary, refer to the appropriate engine

firing order diagram (Fig. 2 or Fig. 3).

Fig. 1 Distributor Cap Inspection

Ä

IGNITION SYSTEMS 8D - 1

Page 445 of 2438

When testing secondary cables for punctures and

cracks with an oscilloscope follow the equipment

manufacturers instructions. If an oscilloscope is not available, secondary cables

can be tested as follows:

CAUTION: Do not leave any one spark plug cable

disconnected any longer than necessary during test-

ing. Excessive heat could damage the catalytic con-

verter. Total test time must not exceed ten minutes.

(a) With the engine not running, connect one end

of a test probe to a good ground. Use a probe made of

insulated wire with insulated alligator clips on each

end. (b) With engine running, move test probe along

entire length of all cables (approximately 0 to 1/8

inch gap). If punctures or cracks are present there

will be a noticeable spark jump from the faulty area

to the probe. Check the coil cable the same way.

Replace cracked, leaking or faulty cables.

When replacing cables, install the new high

tension cable and nipple assembly over cap or

coil tower. When entering the terminal into the

tower, push lightly, then pinch the large diam-

eter of nipple to release air trapped between the

nipple and tower. Continue pushing on the cable

and nipple until cables are properly seated in the

cap towers. A snap should be heard as terminal

goes into place. Use the same procedure to install cable in coil tower.

Wipe the spark plug insulator clean before reinstalling

cable and cover. Use the following procedure when removing the high

tension cable from the spark plug. First, remove the

cable from the retaining bracket. Then grasp the ter-

minal as close as possible to the spark plug. Rotate the

cover and pull the cable straight back. Pulling on the

cable itself will damage the conductor and termi-

nal connection. Do not use pliers and do not pull

the cable at an angle. Doing so will damage the

insulation, cable terminal or the spark plug in-

sulator. Wipe spark plug insulator clean before

reinstalling cable and cover. Resistance type cable is identified by the words

Electronic Suppression printed on the cable jacket.

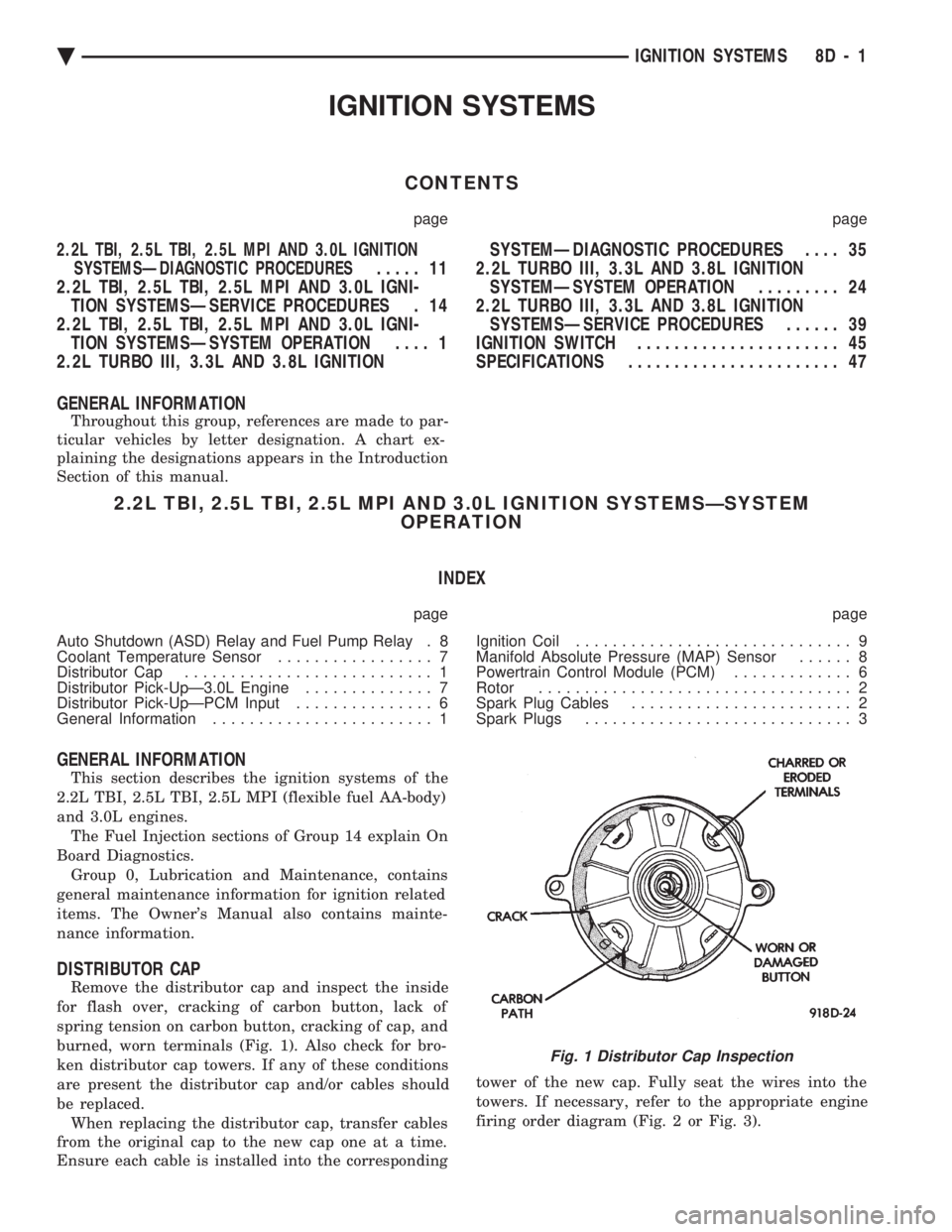

Use an ohmmeter to check resistance type cable for

open circuits, loose terminals or high resistance as

follows: (a) Remove cable from spark plug.

(b) Lift distributor cap from distributor with

cables intact. Do not remove cables from cap. The

cables must be removed from the spark plugs. (c) Connect the ohmmeter between spark plug end

terminal and the corresponding electrode inside the

cap, make sure ohmmeter probes are in good contact.

Resistance should be within tolerance shown in the cable resistance chart. If resistance is

not within tolerance, remove cable at cap tower

and check the cable. If resistance is still not within

tolerance, replace cable assembly. Test all spark

plug cables in same manner.

To test coil to distributor cap high tension cable,

remove distributor cap with the cable intact. Do not

remove cable from the cap. Connect the ohmmeter

between center contact in the cap and remove the ca-

ble at coil tower and check cable resistance. If resis-

tance is not within tolerance, replace the cable.

SPARK PLUGS

Resistor spark plugs are used in all engines and

have resistance values of 6,000 to 20,000 ohms when

checked with at least a 1000 volt tester. Remove the spark plugs and examine them for

burned electrodes and fouled, cracked or broken por-

celain insulators. Keep plugs arranged in the order

in which they were removed from the engine. An iso-

lated plug displaying an abnormal condition indi-

cates that a problem exists in the corresponding

cylinder. Replace spark plugs at the intervals recom-

mended in Group O. Undamaged low milage spark plugs can be cleaned

and reused. Refer to the Spark Plug Condition sec-

tion of this group. After cleaning, file the center elec-

trode flat with a small point file or jewelers file.

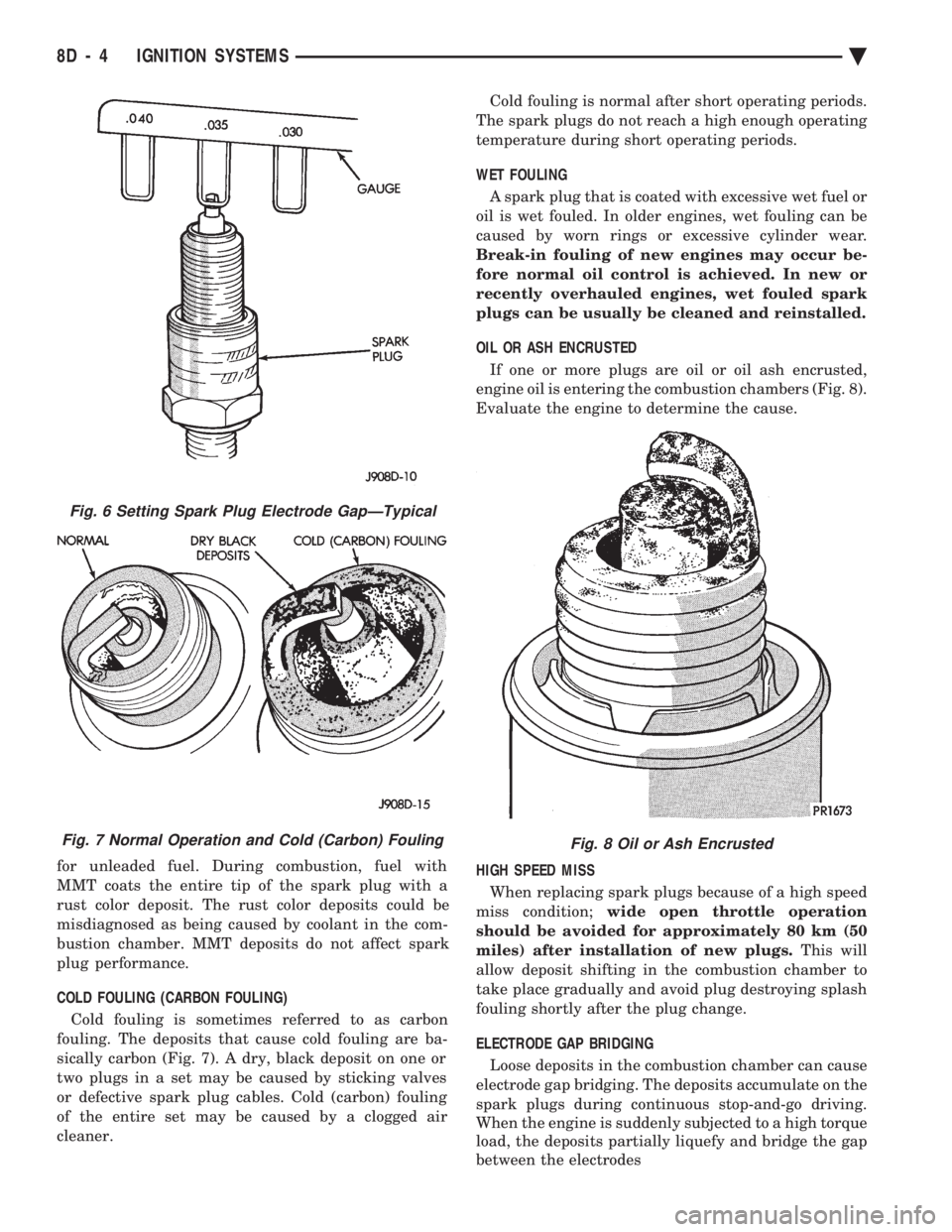

Adjust the gap between the electrodes (Fig. 6) to the

dimensions specified in the chart at the end of this

section. Always tighten spark plugs to the specified torque.

Over tightening can cause distortion and change

spark plug gap. Tighten spark plugs to 28 N Im (20 ft.

lbs.) torque.

SPARK PLUG CONDITION

NORMAL OPERATING CONDITIONS

The few deposits present will be probably light tan

or slightly gray in color with most grades of commer-

cial gasoline (Fig. 7). There will not be evidence of

electrode burning. Gap growth will not average more

than approximately 0.025 mm (.001 in) per 1600 km

(1000 miles) of operation. Spark plugs that have nor-

mal wear can usually be cleaned, have the electrodes

filed and regapped, and then reinstalled. Some fuel refiners in several areas of the United

States have introduced a manganese additive (MMT)

CABLE RESISTANCE CHART

Ä IGNITION SYSTEMS 8D - 3

Page 446 of 2438

for unleaded fuel. During combustion, fuel with

MMT coats the entire tip of the spark plug with a

rust color deposit. The rust color deposits could be

misdiagnosed as being caused by coolant in the com-

bustion chamber. MMT deposits do not affect spark

plug performance.

COLD FOULING (CARBON FOULING)

Cold fouling is sometimes referred to as carbon

fouling. The deposits that cause cold fouling are ba-

sically carbon (Fig. 7). A dry, black deposit on one or

two plugs in a set may be caused by sticking valves

or defective spark plug cables. Cold (carbon) fouling

of the entire set may be caused by a clogged air

cleaner. Cold fouling is normal after short operating periods.

The spark plugs do not reach a high enough operating

temperature during short operating periods.

WET FOULING

A spark plug that is coated with excessive wet fuel or

oil is wet fouled. In older engines, wet fouling can be

caused by worn rings or excessive cylinder wear.

Break-in fouling of new engines may occur be-

fore normal oil control is achieved. In new or

recently overhauled engines, wet fouled spark

plugs can be usually be cleaned and reinstalled.

OIL OR ASH ENCRUSTED

If one or more plugs are oil or oil ash encrusted,

engine oil is entering the combustion chambers (Fig. 8).

Evaluate the engine to determine the cause.

HIGH SPEED MISS When replacing spark plugs because of a high speed

miss condition; wide open throttle operation

should be avoided for approximately 80 km (50

miles) after installation of new plugs. This will

allow deposit shifting in the combustion chamber to

take place gradually and avoid plug destroying splash

fouling shortly after the plug change.

ELECTRODE GAP BRIDGING

Loose deposits in the combustion chamber can cause

electrode gap bridging. The deposits accumulate on the

spark plugs during continuous stop-and-go driving.

When the engine is suddenly subjected to a high torque

load, the deposits partially liquefy and bridge the gap

between the electrodes

Fig. 6 Setting Spark Plug Electrode GapÐTypical

Fig. 7 Normal Operation and Cold (Carbon) FoulingFig. 8 Oil or Ash Encrusted

8D - 4 IGNITION SYSTEMS Ä

Page 447 of 2438

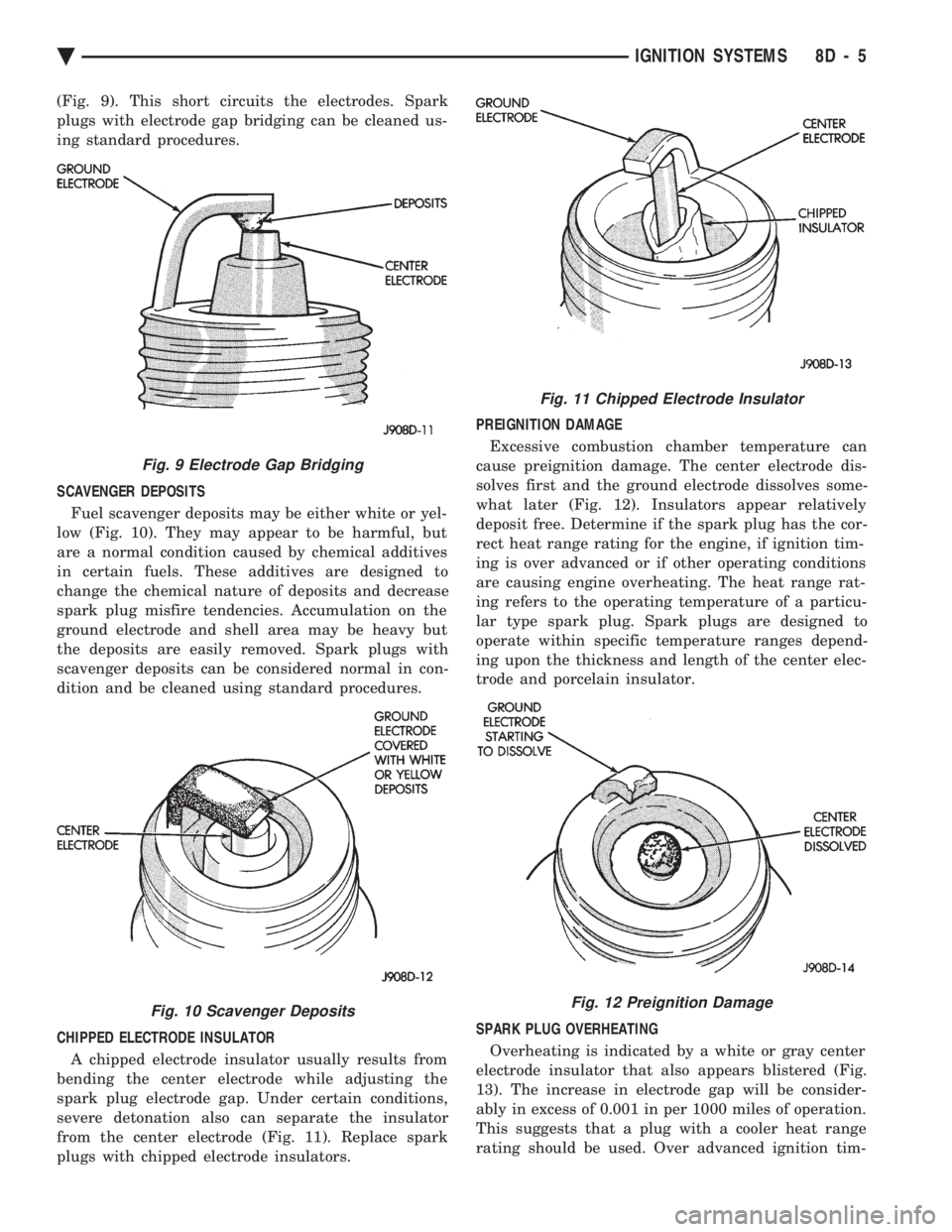

(Fig. 9). This short circuits the electrodes. Spark

plugs with electrode gap bridging can be cleaned us-

ing standard procedures.

SCAVENGER DEPOSITS Fuel scavenger deposits may be either white or yel-

low (Fig. 10). They may appear to be harmful, but

are a normal condition caused by chemical additives

in certain fuels. These additives are designed to

change the chemical nature of deposits and decrease

spark plug misfire tendencies. Accumulation on the

ground electrode and shell area may be heavy but

the deposits are easily removed. Spark plugs with

scavenger deposits can be considered normal in con-

dition and be cleaned using standard procedures.

CHIPPED ELECTRODE INSULATOR A chipped electrode insulator usually results from

bending the center electrode while adjusting the

spark plug electrode gap. Under certain conditions,

severe detonation also can separate the insulator

from the center electrode (Fig. 11). Replace spark

plugs with chipped electrode insulators. PREIGNITION DAMAGE

Excessive combustion chamber temperature can

cause preignition damage. The center electrode dis-

solves first and the ground electrode dissolves some-

what later (Fig. 12). Insulators appear relatively

deposit free. Determine if the spark plug has the cor-

rect heat range rating for the engine, if ignition tim-

ing is over advanced or if other operating conditions

are causing engine overheating. The heat range rat-

ing refers to the operating temperature of a particu-

lar type spark plug. Spark plugs are designed to

operate within specific temperature ranges depend-

ing upon the thickness and length of the center elec-

trode and porcelain insulator.

SPARK PLUG OVERHEATING Overheating is indicated by a white or gray center

electrode insulator that also appears blistered (Fig.

13). The increase in electrode gap will be consider-

ably in excess of 0.001 in per 1000 miles of operation.

This suggests that a plug with a cooler heat range

rating should be used. Over advanced ignition tim-

Fig. 9 Electrode Gap Bridging

Fig. 10 Scavenger Deposits

Fig. 11 Chipped Electrode Insulator

Fig. 12 Preignition Damage

Ä IGNITION SYSTEMS 8D - 5