parking brake CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 31 of 2438

COMPONENT AND SYSTEM INDEX

Name Group-page Name Group-page

BODY ................................... 23-1

AA-VEHICLE BODY COMPONENT SERVICE .......23-11

AC-VEHICLE BODY COMPONENT SERVICE .......23-37

AG-VEHICLE BODY COMPONENT SERVICE .......23-52

AJ/27-VEHICLE CONVERTIBLE BODY COMPONENT SERVICE ............................ 23-86

AJ-VEHICLE BODY COMPONENT SERVICE .......23-71

AP-VEHICLE BODY COMPONENT SERVICE .......23-97

AY-VEHICLE BODY COMPONENT SERVICE .......23-133

BODY DIAGNOSTIC PROCEDURES .............23-2

GENERAL SERVICE INFORMATION .............23-1

PAINT ................................. 23-4

POWER SUNROOF ........................ 23-6

WINDSHIELD ............................ 23-9

BRAKES ..................................5-1

ANTI-LOCK BRAKE SYSTEMÐBENDIX ANTI-LOCK 10 AC/Y BODY ......................... 5-72

ANTI-LOCK BRAKE SYSTEMÐBENDIX ANTI-LOCK 6 AA,AG,AJ,AP BODY .................... 5-113

BRAKE DISC (ROTOR) ...................... 5-53

BRAKE SUPPORT ASSEMBLY .................5-25

FRONT DISC BRAKES ...................... 5-31

GENERAL INFORMATION .....................5-1

HYDRAULIC SYSTEM CONTROL VALVES .........5-26

KELSEY HAYES DOUBLE PIN FAMILY CALIPER .....5-35

KELSEY HAYES DOUBLE PIN NON-FAMILY CALIPER ............................. 5-38

MASTER CYLINDER ....................... 5-66

PARKING BRAKES ........................ 5-57

POWER BRAKES ......................... 5-68

REAR DISC BRAKES ....................... 5-45

REAR WHEEL DRUM BRAKES ................5-18

SERVICE ADJUSTMENTS .....................5-4

WHEEL BEARINGS ........................ 5-70

WHEEL CYLINDERS ....................... 5-23

COOLING SYSTEM ...........................7-1

ACCESSORY DRIVE BELTS ................... 7-24

ENGINE BLOCK HEATER .................... 7-28

GENERAL INFORMATION .....................7-1

SERVICE PROCEDURES ..................... 7-10

SPECIFICATIONS ......................... 7-29

ENGINE ..................................9-1

2.2/2.5L ENGINES .........................9-8

3.0L ENGINE ............................ 9-66

3.3/3.8L ENGINE ......................... 9-98

STANDARD SERVICE PROCEDURES .............9-1

EXHAUST SYSTEM AND INTAKE MANIFOLD .........11-1

GENERAL INFORMATION .................... 11-1

SERVICE PROCEDURES ..................... 11-4

TORQUE SPECIFICATION ................... 11-25

FRAME AND BUMPERS ....................... 13-1

BUMPER AND FASCIA ...................... 13-1

FRAME ................................ 13-9

HEATING AND AIR CONDITIONING ...............24-1

AUTOMATIC TEMPERATURE CONTROL (ATC) .....24-66 COMPONENT SERVICE PROCEDURES

..........24-47

FIXED DISPLACEMENT COMPRESSORÐMODEL 10PA17............................. 24-24

FIXED DISPLACEMENT COMPRESSORÐMODEL SD709P ............................. 24-38

FIXED DISPLACEMENT COMPRESSORÐMODEL TR105 .............................. 24-32

GENERAL INFORMATION .................... 24-1

HEATER AND A/C PERFORMANCE TESTS .........24-6

REFRIGERANT SERVICE PROCEDURES ..........24-8

VACUUM CONTROL SYSTEM DIAGNOSIS .........24-4

VARIABLE DISPLACEMENT COMPRESSORÐMODEL 6C17 ............................... 24-13

INTRODUCTION .......................... Intro.-1

LUBRICATION AND MAINTENANCE ................0-1

CHASSIS AND BODY ....................... 0-19

DRIVETRAIN ............................ 0-16

ENGINE ................................0-8

GENERAL INFORMATION .....................0-1

MANUAL TRANSAXLE CLUTCH ...................6-1

STEERING ................................ 19-1

ACUSTAR STANDARD AND TILT STEERING COLUMN ............................ 19-28

AUTOMATIC TRANSMISSION SHIFTER/IGNITION INTERLOCK .......................... 19-36

GENERAL INFORMATION .................... 19-1

POWER STEERING GEAR ................... 19-25

POWER STEERING PUMPS ..................19-1

SPECIFICATIONS AND TIGHTENING REFERENCE . . . 19-42

SUSPENSION AND DRIVESHAFTS .................2-1

AUTOMATIC AIR LOAD LEVELING SYSTEM ........2-59

AUTOMATIC AIR SUSPENSION ................2-73

DRIVESHAFTS ........................... 2-25

FRONT SUSPENSION .......................2-2

FRONT SUSPENSION SERVICE PROCEDURES .......2-5

GENERAL INFORMATION .....................2-1

REAR (STUB) AXLE ALIGNMENT ALL MODELS .....2-89

REAR SUSPENSION ....................... 2-50

SPECIFICATIONS ......................... 2-91

TRANSAXLE .............................. 21-85

41TE FOUR SPEED AUTOMATIC TRANSAXLE ......21-85

41TE FOUR SPEED TRANSAXLE HYDRAULIC SCHEMATICS ........................ 21-170

41TE ON-BOARD DIAGNOSTICS .............21-145

A-523, A-543, and A-568 MANUAL TRANSAXLE ....21-1

SPECIFICATIONS ........................ 21-183

THREE SPEED TORQUEFLITE AUTOMATIC TRANSAXLE .......................... 21-35

THREE SPEED TRANSAXLE HYDRAULIC SCHEMATICS ........................ 21-162

WHEELSÐTIRES ........................... 22-1

SPECIFICATIONS ......................... 22-8

TIRE SERVICE PROCEDURES .................22-1

WHEELS SERVICE PROCEDURES ..............22-6

Page 116 of 2438

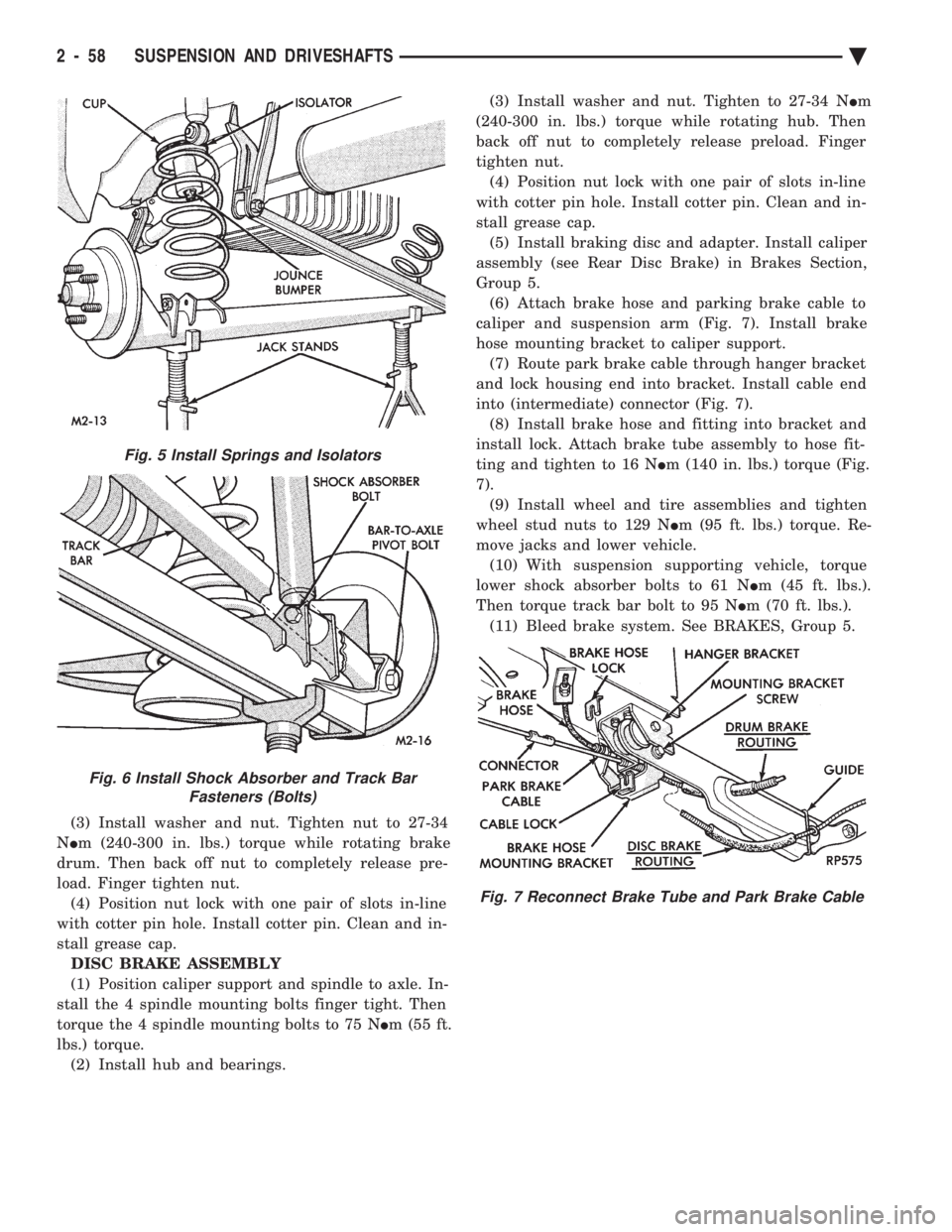

(3) Install washer and nut. Tighten nut to 27-34

N Im (240-300 in. lbs.) torque while rotating brake

drum. Then back off nut to completely release pre-

load. Finger tighten nut. (4) Position nut lock with one pair of slots in-line

with cotter pin hole. Install cotter pin. Clean and in-

stall grease cap. DISC BRAKE ASSEMBLY

(1) Position caliper support and spindle to axle. In-

stall the 4 spindle mounting bolts finger tight. Then

torque the 4 spindle mounting bolts to 75 N Im (55 ft.

lbs.) torque. (2) Install hub and bearings. (3) Install washer and nut. Tighten to 27-34 N

Im

(240-300 in. lbs.) torque while rotating hub. Then

back off nut to completely release preload. Finger

tighten nut. (4) Position nut lock with one pair of slots in-line

with cotter pin hole. Install cotter pin. Clean and in-

stall grease cap. (5) Install braking disc and adapter. Install caliper

assembly (see Rear Disc Brake) in Brakes Section,

Group 5. (6) Attach brake hose and parking brake cable to

caliper and suspension arm (Fig. 7). Install brake

hose mounting bracket to caliper support. (7) Route park brake cable through hanger bracket

and lock housing end into bracket. Install cable end

into (intermediate) connector (Fig. 7). (8) Install brake hose and fitting into bracket and

install lock. Attach brake tube assembly to hose fit-

ting and tighten to 16 N Im (140 in. lbs.) torque (Fig.

7). (9) Install wheel and tire assemblies and tighten

wheel stud nuts to 129 N Im (95 ft. lbs.) torque. Re-

move jacks and lower vehicle. (10) With suspension supporting vehicle, torque

lower shock absorber bolts to 61 N Im (45 ft. lbs.).

Then torque track bar bolt to 95 N Im (70 ft. lbs.).

(11) Bleed brake system. See BRAKES, Group 5.

Fig. 5 Install Springs and Isolators

Fig. 6 Install Shock Absorber and Track Bar Fasteners (Bolts)

Fig. 7 Reconnect Brake Tube and Park Brake Cable

2 - 58 SUSPENSION AND DRIVESHAFTS Ä

Page 147 of 2438

REAR (STUB) AXLE ALIGNMENT ALL MODELS INDEX

page page

General Information ....................... 89 Rear Wheel Alignment..................... 89

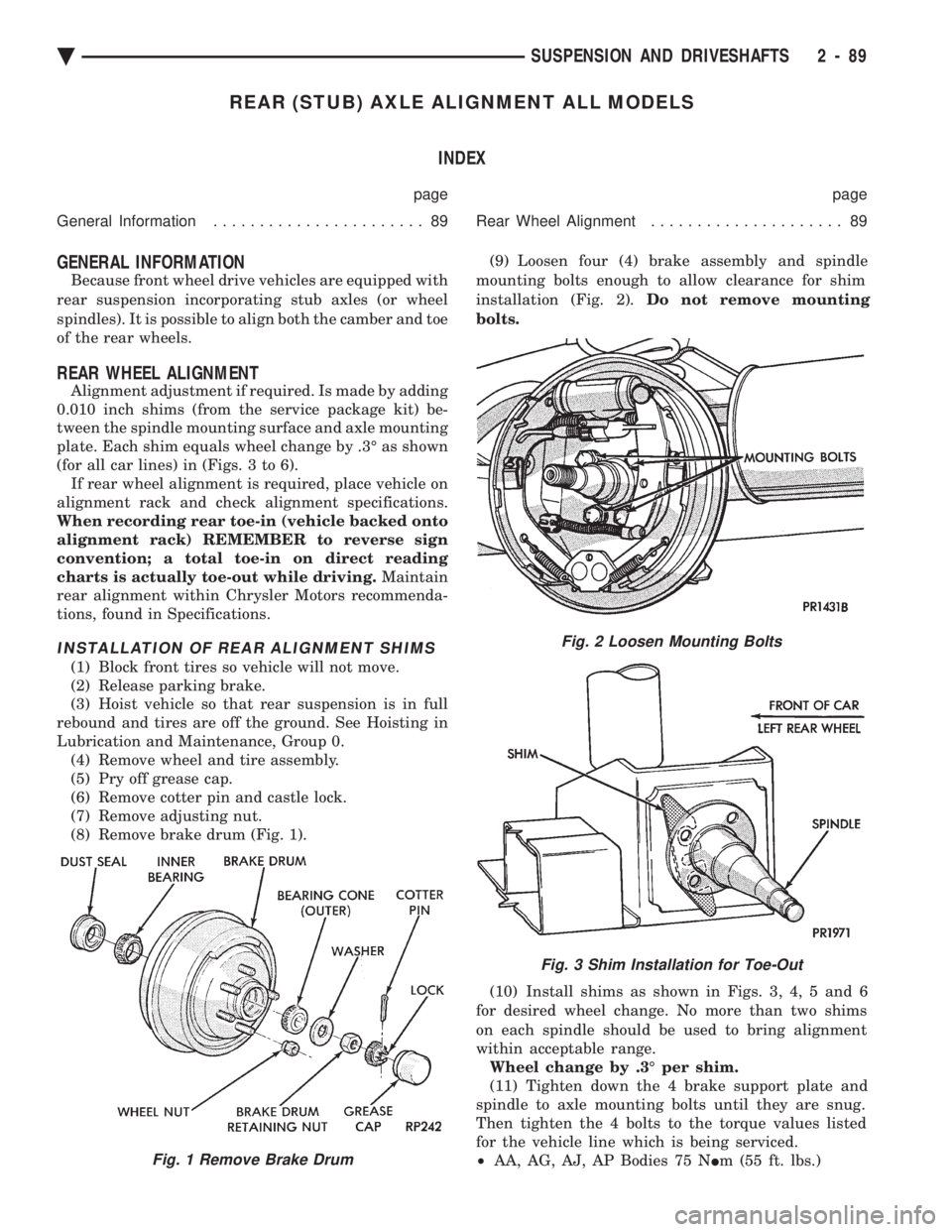

GENERAL INFORMATION

Because front wheel drive vehicles are equipped with

rear suspension incorporating stub axles (or wheel

spindles). It is possible to align both the camber and toe

of the rear wheels.

REAR WHEEL ALIGNMENT

Alignment adjustment if required. Is made by adding

0.010 inch shims (from the service package kit) be-

tween the spindle mounting surface and axle mounting

plate. Each shim equals wheel change by .3É as shown

(for all car lines) in (Figs. 3 to 6). If rear wheel alignment is required, place vehicle on

alignment rack and check alignment specifications.

When recording rear toe-in (vehicle backed onto

alignment rack) REMEMBER to reverse sign

convention; a total toe-in on direct reading

charts is actually toe-out while driving. Maintain

rear alignment within Chrysler Motors recommenda-

tions, found in Specifications.

INSTALLATION OF REAR ALIGNMENT SHIMS

(1) Block front tires so vehicle will not move.

(2) Release parking brake.

(3) Hoist vehicle so that rear suspension is in full

rebound and tires are off the ground. See Hoisting in

Lubrication and Maintenance, Group 0. (4) Remove wheel and tire assembly.

(5) Pry off grease cap.

(6) Remove cotter pin and castle lock.

(7) Remove adjusting nut.

(8) Remove brake drum (Fig. 1). (9) Loosen four (4) brake assembly and spindle

mounting bolts enough to allow clearance for shim

installation (Fig. 2). Do not remove mounting

bolts.

(10) Install shims as shown in Figs. 3, 4, 5 and 6

for desired wheel change. No more than two shims

on each spindle should be used to bring alignment

within acceptable range. Wheel change by .3É per shim.

(11) Tighten down the 4 brake support plate and

spindle to axle mounting bolts until they are snug.

Then tighten the 4 bolts to the torque values listed

for the vehicle line which is being serviced.

² AA, AG, AJ, AP Bodies 75 N Im (55 ft. lbs.)

Fig. 2 Loosen Mounting Bolts

Fig. 3 Shim Installation for Toe-Out

Fig. 1 Remove Brake Drum

Ä SUSPENSION AND DRIVESHAFTS 2 - 89

Page 151 of 2438

BRAKES

CONTENTS

page page

ANTI-LOCK BRAKE SYSTEMÐBENDIX ANTI-LOCK 10 AC/Y BODY ............. 72

ANTI-LOCK BRAKE SYSTEMÐBENDIX ANTI-LOCK 6 AA,AG,AJ,AP BODY ....... 113

BRAKE DISC (ROTOR) ................... 53

BRAKE SUPPORT ASSEMBLY ............. 25

FRONT DISC BRAKES ................... 31

GENERAL INFORMATION .................. 1

HYDRAULIC SYSTEM CONTROL VALVES . . . 26

KELSEY HAYES DOUBLE PIN FAMILY CALIPER ............................ 35 KELSEY HAYES DOUBLE PIN NON-FAMILY

CALIPER ............................ 38

MASTER CYLINDER ..................... 66

PARKING BRAKES ...................... 57

POWER BRAKES ....................... 68

REAR DISC BRAKES .................... 45

REAR WHEEL DRUM BRAKES ............ 18

SERVICE ADJUSTMENTS .................. 4

WHEEL BEARINGS ...................... 70

WHEEL CYLINDERS ..................... 23

GENERAL INFORMATION

Throughout this group, references may be made to

a particular vehicle by letter or number designation.

A chart showing the break down of these designa-

tions is included in the Introduction Section at the

front of this service manual. Standard brake equipment consists of:

² Double pin floating caliper disc front brakes.

² Rear automatic adjusting drum brakes.

² Differential valve with a brake warning switch.

² Master cylinder.

² Vacuum power booster.

² Double pin floating caliper rear disc brakes are

available on some models. The Bendix Anti-Lock 10 braking system, uses the

standard power brake system caliper assemblies,

braking discs, pedal assembly, brake lines and hoses.

The unique parts of the Bendix Anti-Lock 10 braking

system consists of the following components. Propor-

tioning valves, wheel speed sensors, tone wheels,

electronic control unit, modulator assembly and hy-

draulic assembly. These components replace the con-

ventional master cylinder and power booster. The

components will be described in detail in the Bendix

Anti-Lock 10 brake section in this group of the ser-

vice manual. The Bendix Anti-Lock 6 braking system, uses the

following standard brake system components. Master

cylinder, power booster, caliper assemblies, braking

discs, pedal assembly, brake lines and hoses. The

unique parts of the Bendix Anti-Lock 6 braking sys-

tem consists of the following components. Modulator

assembly, unique proportioning valves, wheel speed

sensors, tone wheels, and electronic control unit.

These components will be described in detail in the

Bendix Anti-Lock 6 brake section in this group of the

service manual. The front disc brake shoes have semi-metallic lin-

ings. The hydraulic brake system (Fig .123and4)is

diagonally split on both the Non-ABS and ABS brak-

ing system. With the left front and right rear brakes

on one hydraulic system and the right front and left

rear on the other. The Non-ABS and ABS brake system may use dif-

ferent types of brake line fittings and tubing flares.

The Non-ABS brake system uses double wall tubing

flares and fittings at all tubing joint locations. Some

ABS brake systems use both ISO style tubing flares

and double wall tubing flares and corresponding fit-

tings at different joint locations. See (Figs . 2 3 and 4)

for specific joint locations and type of tubing flare. The front disc brakes consist of two different types

of caliper assemblies. A double pin Kelsey-Hayes cal-

iper (family caliper) with a bolt-on adapter attached

to the steering knuckle. Or a double pin Kelsey-

Hayes caliper (non-family caliper) which mounts di-

rectly to rails on the steering knuckle. The non-

family caliper is only used on the AY Body

(Imperials).

CAUTION: Caliper pistons, boots and seals for the

different caliper assemblies used on the front and

rear disc brake assemblies are not interchangeable.

Misusage could result in a complete brake system

failure. Be sure that the parts are replaced with the

correct replacement parts, refer to the parts book

for the type and model year of the vehicle being

worked on.

The master cylinder is anodized, lightweight alu-

minum, with a bore size of 24.0mm, 21.0mm or 7/8

inch.

Ä BRAKES 5 - 1

Page 154 of 2438

SERVICE ADJUSTMENTS INDEX

page page

Adjusting Rear Service Brakes ............... 4

Bleeding Brake System ..................... 6

Brake Hose and Tubing ................... 11

Master Cylinder Fluid Level .................. 4 Stop Lamp Switch Adjustment (All Vehicles)

.... 13

Test for Fluid Contamination ................. 7

Testing Application Adjuster Operation ......... 6

Wheel Stud Nut Tightening .................. 7

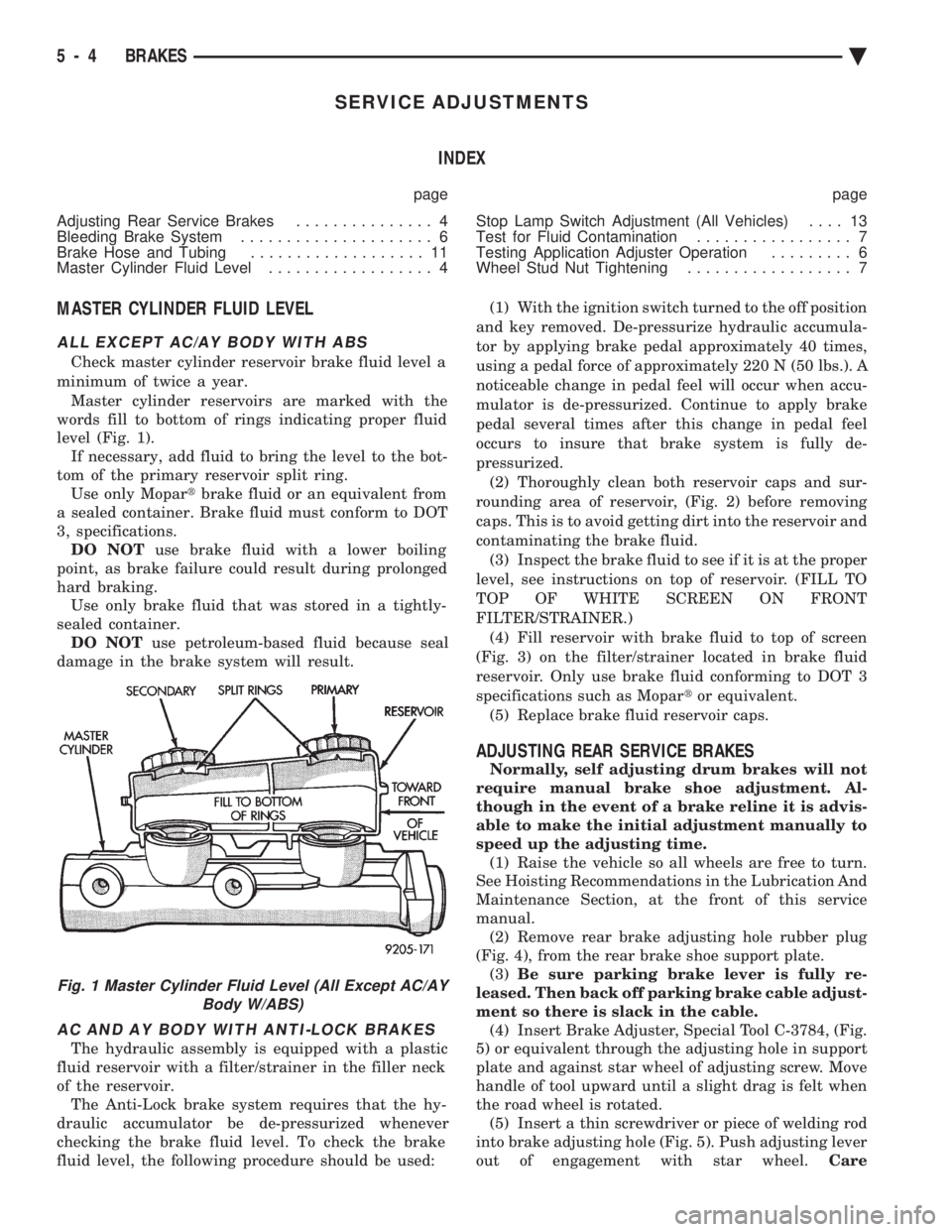

MASTER CYLINDER FLUID LEVEL

ALL EXCEPT AC/AY BODY WITH ABS

Check master cylinder reservoir brake fluid level a

minimum of twice a year. Master cylinder reservoirs are marked with the

words fill to bottom of rings indicating proper fluid

level (Fig. 1). If necessary, add fluid to bring the level to the bot-

tom of the primary reservoir split ring. Use only Mopar tbrake fluid or an equivalent from

a sealed container. Brake fluid must conform to DOT

3, specifications. DO NOT use brake fluid with a lower boiling

point, as brake failure could result during prolonged

hard braking. Use only brake fluid that was stored in a tightly-

sealed container. DO NOT use petroleum-based fluid because seal

damage in the brake system will result.

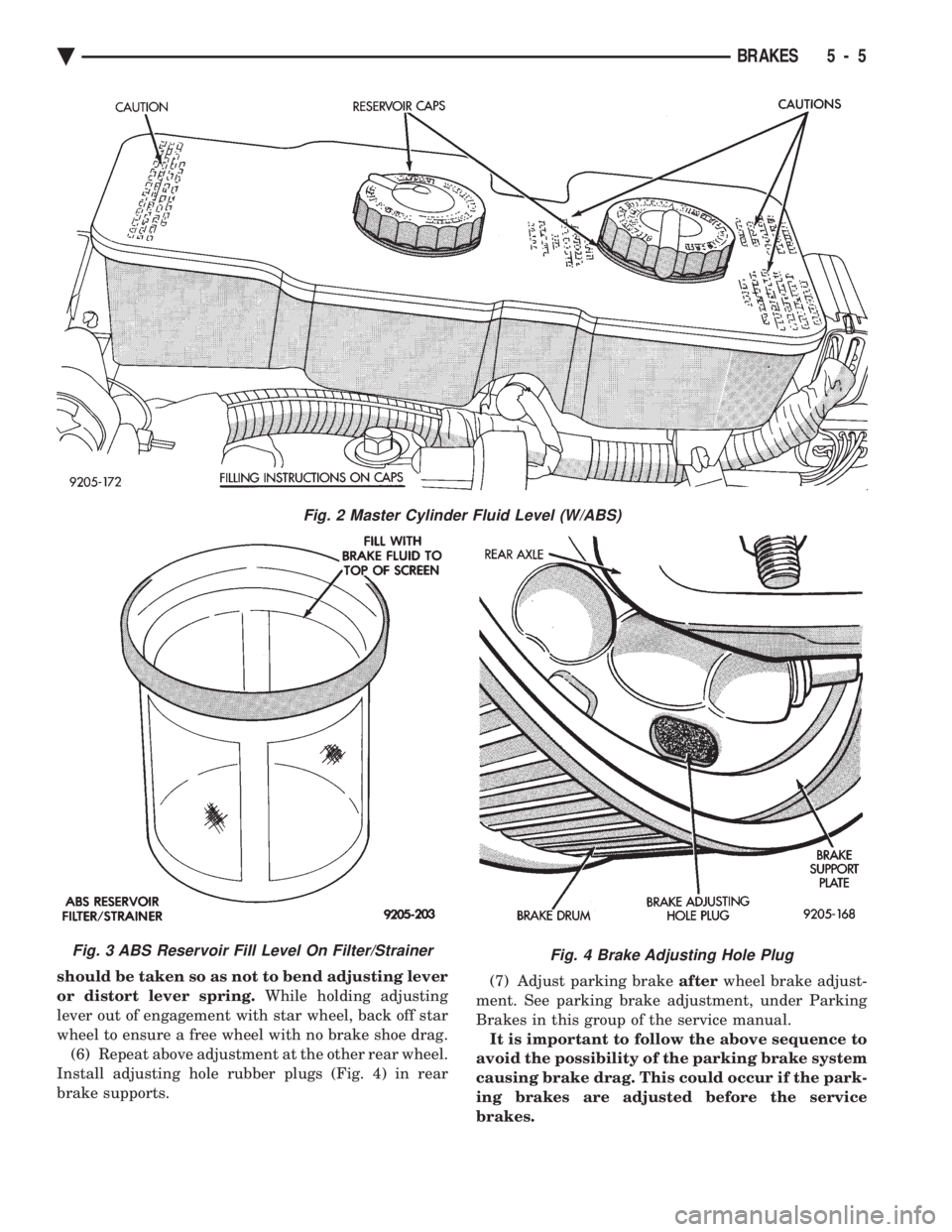

AC AND AY BODY WITH ANTI-LOCK BRAKES

The hydraulic assembly is equipped with a plastic

fluid reservoir with a filter/strainer in the filler neck

of the reservoir. The Anti-Lock brake system requires that the hy-

draulic accumulator be de-pressurized whenever

checking the brake fluid level. To check the brake

fluid level, the following procedure should be used: (1) With the ignition switch turned to the off position

and key removed. De-pressurize hydraulic accumula-

tor by applying brake pedal approximately 40 times,

using a pedal force of approximately 220 N (50 lbs.). A

noticeable change in pedal feel will occur when accu-

mulator is de-pressurized. Continue to apply brake

pedal several times after this change in pedal feel

occurs to insure that brake system is fully de-

pressurized. (2) Thoroughly clean both reservoir caps and sur-

rounding area of reservoir, (Fig. 2) before removing

caps. This is to avoid getting dirt into the reservoir and

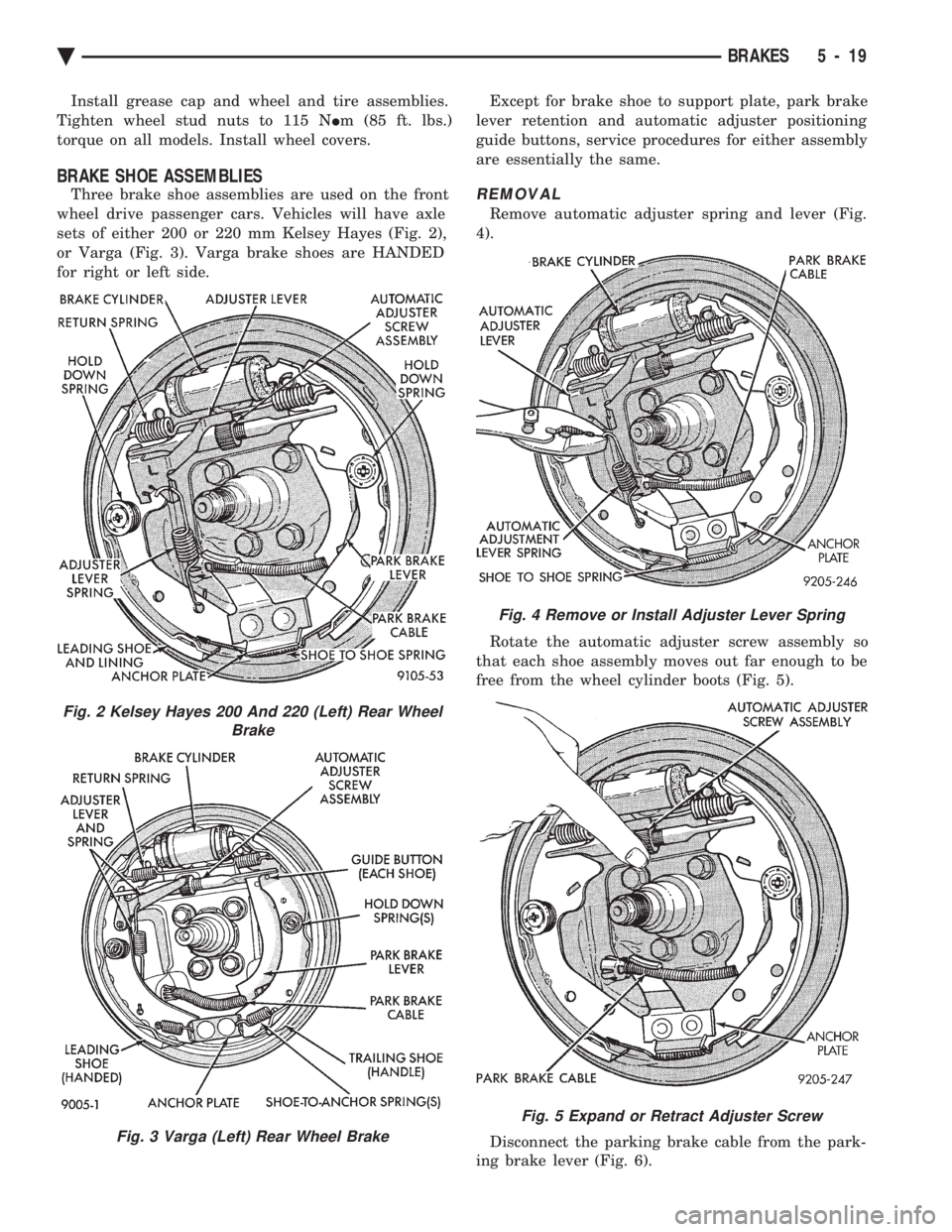

contaminating the brake fluid. (3) Inspect the brake fluid to see if it is at the proper

level, see instructions on top of reservoir. (FILL TO

TOP OF WHITE SCREEN ON FRONT

FILTER/STRAINER.) (4) Fill reservoir with brake fluid to top of screen

(Fig. 3) on the filter/strainer located in brake fluid

reservoir. Only use brake fluid conforming to DOT 3

specifications such as Mopar tor equivalent.

(5) Replace brake fluid reservoir caps.

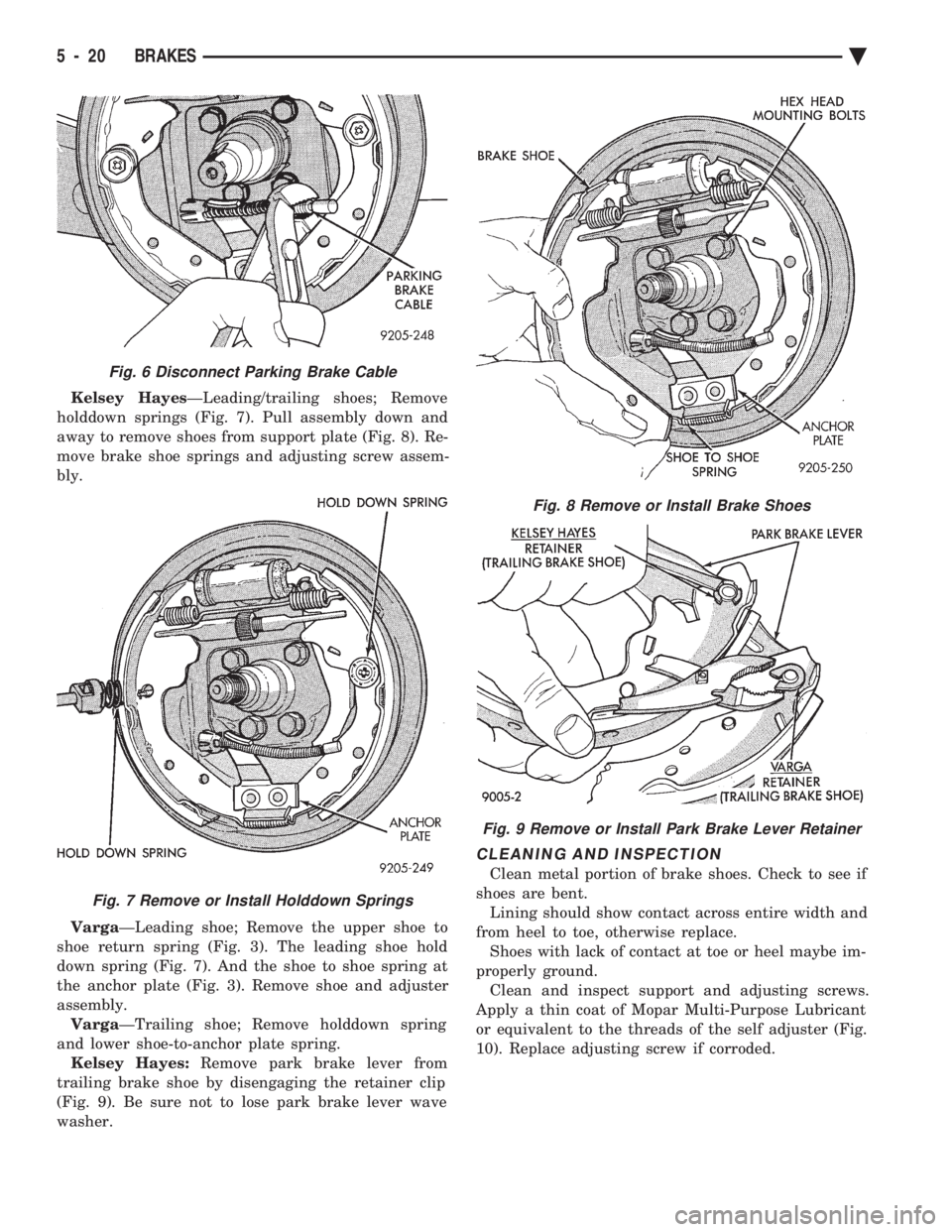

ADJUSTING REAR SERVICE BRAKES

Normally, self adjusting drum brakes will not

require manual brake shoe adjustment. Al-

though in the event of a brake reline it is advis-

able to make the initial adjustment manually to

speed up the adjusting time. (1) Raise the vehicle so all wheels are free to turn.

See Hoisting Recommendations in the Lubrication And

Maintenance Section, at the front of this service

manual. (2) Remove rear brake adjusting hole rubber plug

(Fig. 4), from the rear brake shoe support plate. (3) Be sure parking brake lever is fully re-

leased. Then back off parking brake cable adjust-

ment so there is slack in the cable. (4) Insert Brake Adjuster, Special Tool C-3784, (Fig.

5) or equivalent through the adjusting hole in support

plate and against star wheel of adjusting screw. Move

handle of tool upward until a slight drag is felt when

the road wheel is rotated. (5) Insert a thin screwdriver or piece of welding rod

into brake adjusting hole (Fig. 5). Push adjusting lever

out of engagement with star wheel. Care

Fig. 1 Master Cylinder Fluid Level (All Except AC/AY

Body W/ABS)

5 - 4 BRAKES Ä

Page 155 of 2438

should be taken so as not to bend adjusting lever

or distort lever spring. While holding adjusting

lever out of engagement with star wheel, back off star

wheel to ensure a free wheel with no brake shoe drag. (6) Repeat above adjustment at the other rear wheel.

Install adjusting hole rubber plugs (Fig. 4) in rear

brake supports. (7) Adjust parking brake

afterwheel brake adjust-

ment. See parking brake adjustment, under Parking

Brakes in this group of the service manual. It is important to follow the above sequence to

avoid the possibility of the parking brake system

causing brake drag. This could occur if the park-

ing brakes are adjusted before the service

brakes.

Fig. 4 Brake Adjusting Hole Plug

Fig. 2 Master Cylinder Fluid Level (W/ABS)

Fig. 3 ABS Reservoir Fill Level On Filter/Strainer

Ä BRAKES 5 - 5

Page 169 of 2438

Install grease cap and wheel and tire assemblies.

Tighten wheel stud nuts to 115 N Im (85 ft. lbs.)

torque on all models. Install wheel covers.

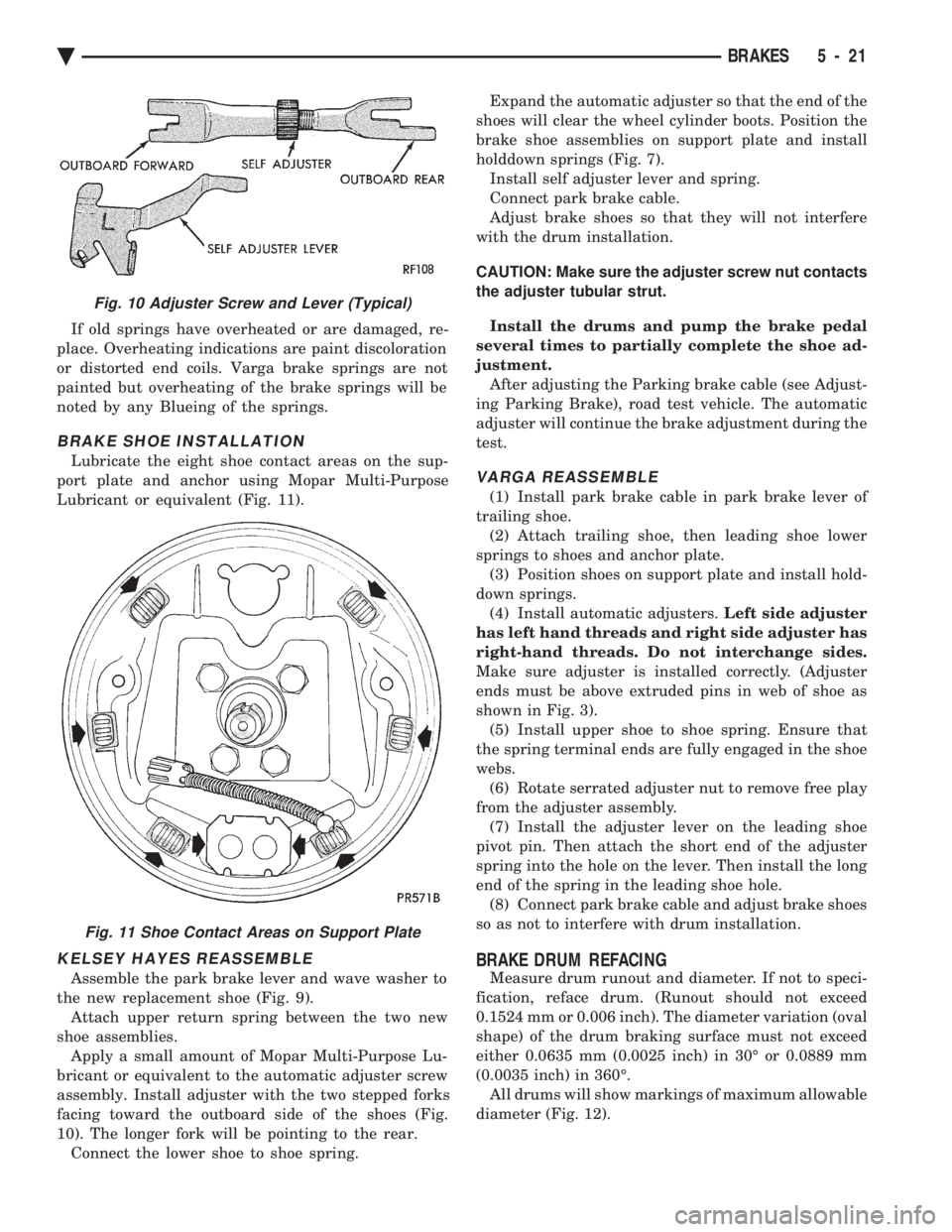

BRAKE SHOE ASSEMBLIES

Three brake shoe assemblies are used on the front

wheel drive passenger cars. Vehicles will have axle

sets of either 200 or 220 mm Kelsey Hayes (Fig. 2),

or Varga (Fig. 3). Varga brake shoes are HANDED

for right or left side. Except for brake shoe to support plate, park brake

lever retention and automatic adjuster positioning

guide buttons, service procedures for either assembly

are essentially the same.REMOVAL

Remove automatic adjuster spring and lever (Fig.

4).

Rotate the automatic adjuster screw assembly so

that each shoe assembly moves out far enough to be

free from the wheel cylinder boots (Fig. 5).

Disconnect the parking brake cable from the park-

ing brake lever (Fig. 6).

Fig. 2 Kelsey Hayes 200 And 220 (Left) Rear Wheel Brake

Fig. 3 Varga (Left) Rear Wheel Brake

Fig. 4 Remove or Install Adjuster Lever Spring

Fig. 5 Expand or Retract Adjuster Screw

Ä BRAKES 5 - 19

Page 170 of 2438

Kelsey Hayes ÐLeading/trailing shoes; Remove

holddown springs (Fig. 7). Pull assembly down and

away to remove shoes from support plate (Fig. 8). Re-

move brake shoe springs and adjusting screw assem-

bly.

Varga ÐLeading shoe; Remove the upper shoe to

shoe return spring (Fig. 3). The leading shoe hold

down spring (Fig. 7). And the shoe to shoe spring at

the anchor plate (Fig. 3). Remove shoe and adjuster

assembly. Varga ÐTrailing shoe; Remove holddown spring

and lower shoe-to-anchor plate spring. Kelsey Hayes: Remove park brake lever from

trailing brake shoe by disengaging the retainer clip

(Fig. 9). Be sure not to lose park brake lever wave

washer.

CLEANING AND INSPECTION

Clean metal portion of brake shoes. Check to see if

shoes are bent. Lining should show contact across entire width and

from heel to toe, otherwise replace. Shoes with lack of contact at toe or heel maybe im-

properly ground. Clean and inspect support and adjusting screws.

Apply a thin coat of Mopar Multi-Purpose Lubricant

or equivalent to the threads of the self adjuster (Fig.

10). Replace adjusting screw if corroded.

Fig. 6 Disconnect Parking Brake Cable

Fig. 7 Remove or Install Holddown Springs

Fig. 8 Remove or Install Brake Shoes

Fig. 9 Remove or Install Park Brake Lever Retainer

5 - 20 BRAKES Ä

Page 171 of 2438

If old springs have overheated or are damaged, re-

place. Overheating indications are paint discoloration

or distorted end coils. Varga brake springs are not

painted but overheating of the brake springs will be

noted by any Blueing of the springs.

BRAKE SHOE INSTALLATION

Lubricate the eight shoe contact areas on the sup-

port plate and anchor using Mopar Multi-Purpose

Lubricant or equivalent (Fig. 11).

KELSEY HAYES REASSEMBLE

Assemble the park brake lever and wave washer to

the new replacement shoe (Fig. 9). Attach upper return spring between the two new

shoe assemblies. Apply a small amount of Mopar Multi-Purpose Lu-

bricant or equivalent to the automatic adjuster screw

assembly. Install adjuster with the two stepped forks

facing toward the outboard side of the shoes (Fig.

10). The longer fork will be pointing to the rear. Connect the lower shoe to shoe spring. Expand the automatic adjuster so that the end of the

shoes will clear the wheel cylinder boots. Position the

brake shoe assemblies on support plate and install

holddown springs (Fig. 7). Install self adjuster lever and spring.

Connect park brake cable.

Adjust brake shoes so that they will not interfere

with the drum installation.

CAUTION: Make sure the adjuster screw nut contacts

the adjuster tubular strut.

Install the drums and pump the brake pedal

several times to partially complete the shoe ad-

justment. After adjusting the Parking brake cable (see Adjust-

ing Parking Brake), road test vehicle. The automatic

adjuster will continue the brake adjustment during the

test.

VARGA REASSEMBLE

(1) Install park brake cable in park brake lever of

trailing shoe. (2) Attach trailing shoe, then leading shoe lower

springs to shoes and anchor plate. (3) Position shoes on support plate and install hold-

down springs. (4) Install automatic adjusters. Left side adjuster

has left hand threads and right side adjuster has

right-hand threads. Do not interchange sides.

Make sure adjuster is installed correctly. (Adjuster

ends must be above extruded pins in web of shoe as

shown in Fig. 3). (5) Install upper shoe to shoe spring. Ensure that

the spring terminal ends are fully engaged in the shoe

webs. (6) Rotate serrated adjuster nut to remove free play

from the adjuster assembly. (7) Install the adjuster lever on the leading shoe

pivot pin. Then attach the short end of the adjuster

spring into the hole on the lever. Then install the long

end of the spring in the leading shoe hole. (8) Connect park brake cable and adjust brake shoes

so as not to interfere with drum installation.

BRAKE DRUM REFACING

Measure drum runout and diameter. If not to speci-

fication, reface drum. (Runout should not exceed

0.1524 mm or 0.006 inch). The diameter variation (oval

shape) of the drum braking surface must not exceed

either 0.0635 mm (0.0025 inch) in 30É or 0.0889 mm

(0.0035 inch) in 360É. All drums will show markings of maximum allowable

diameter (Fig. 12).

Fig. 10 Adjuster Screw and Lever (Typical)

Fig. 11 Shoe Contact Areas on Support Plate

Ä BRAKES 5 - 21

Page 175 of 2438

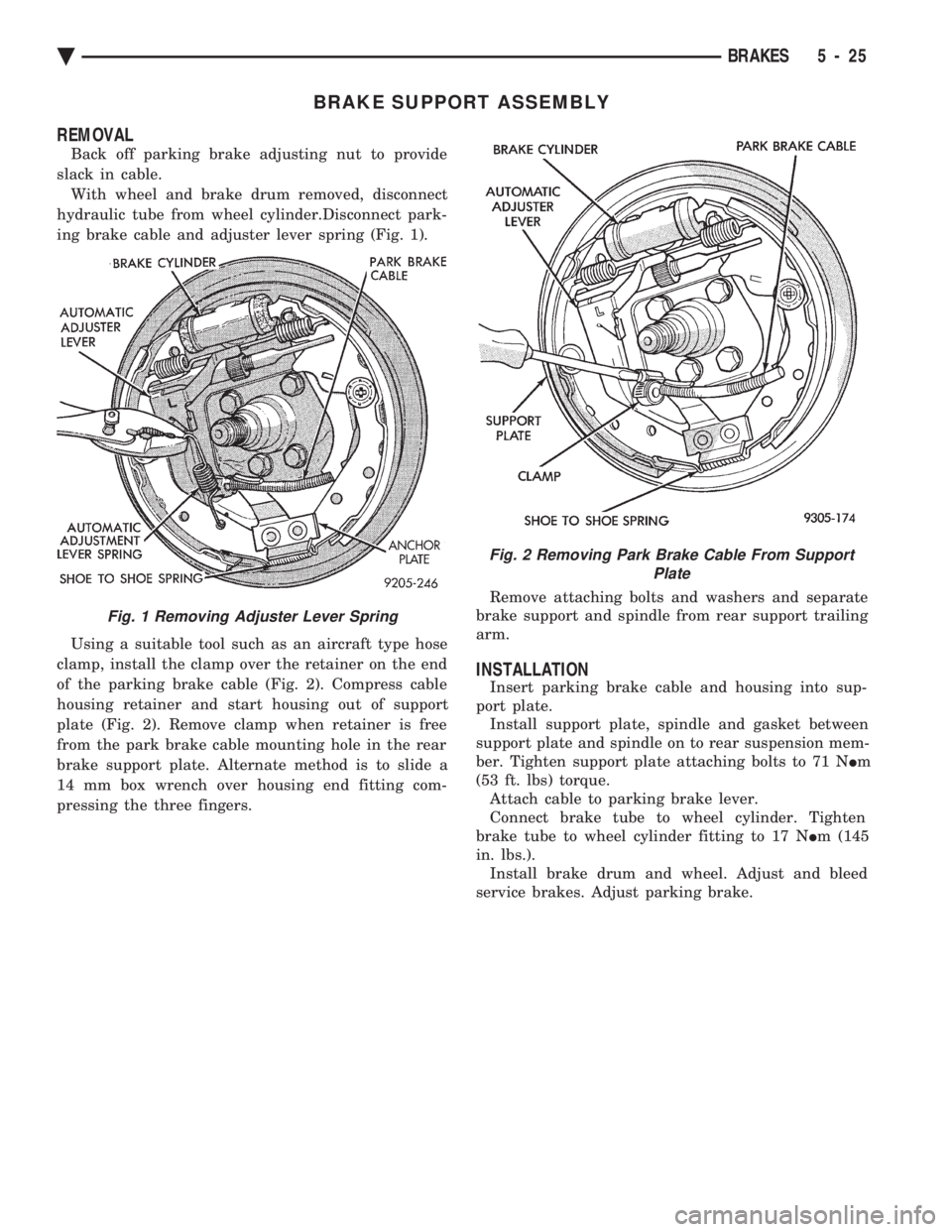

BRAKE SUPPORT ASSEMBLY

REMOVAL

Back off parking brake adjusting nut to provide

slack in cable. With wheel and brake drum removed, disconnect

hydraulic tube from wheel cylinder.Disconnect park-

ing brake cable and adjuster lever spring (Fig. 1).

Using a suitable tool such as an aircraft type hose

clamp, install the clamp over the retainer on the end

of the parking brake cable (Fig. 2). Compress cable

housing retainer and start housing out of support

plate (Fig. 2). Remove clamp when retainer is free

from the park brake cable mounting hole in the rear

brake support plate. Alternate method is to slide a

14 mm box wrench over housing end fitting com-

pressing the three fingers. Remove attaching bolts and washers and separate

brake support and spindle from rear support trailing

arm.

INSTALLATION

Insert parking brake cable and housing into sup-

port plate. Install support plate, spindle and gasket between

support plate and spindle on to rear suspension mem-

ber. Tighten support plate attaching bolts to 71 N Im

(53 ft. lbs) torque. Attach cable to parking brake lever.

Connect brake tube to wheel cylinder. Tighten

brake tube to wheel cylinder fitting to 17 N Im (145

in. lbs.). Install brake drum and wheel. Adjust and bleed

service brakes. Adjust parking brake.

Fig. 1 Removing Adjuster Lever Spring

Fig. 2 Removing Park Brake Cable From Support Plate

Ä BRAKES 5 - 25