height CHEVROLET DYNASTY 1993 Owner's Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 149 of 2438

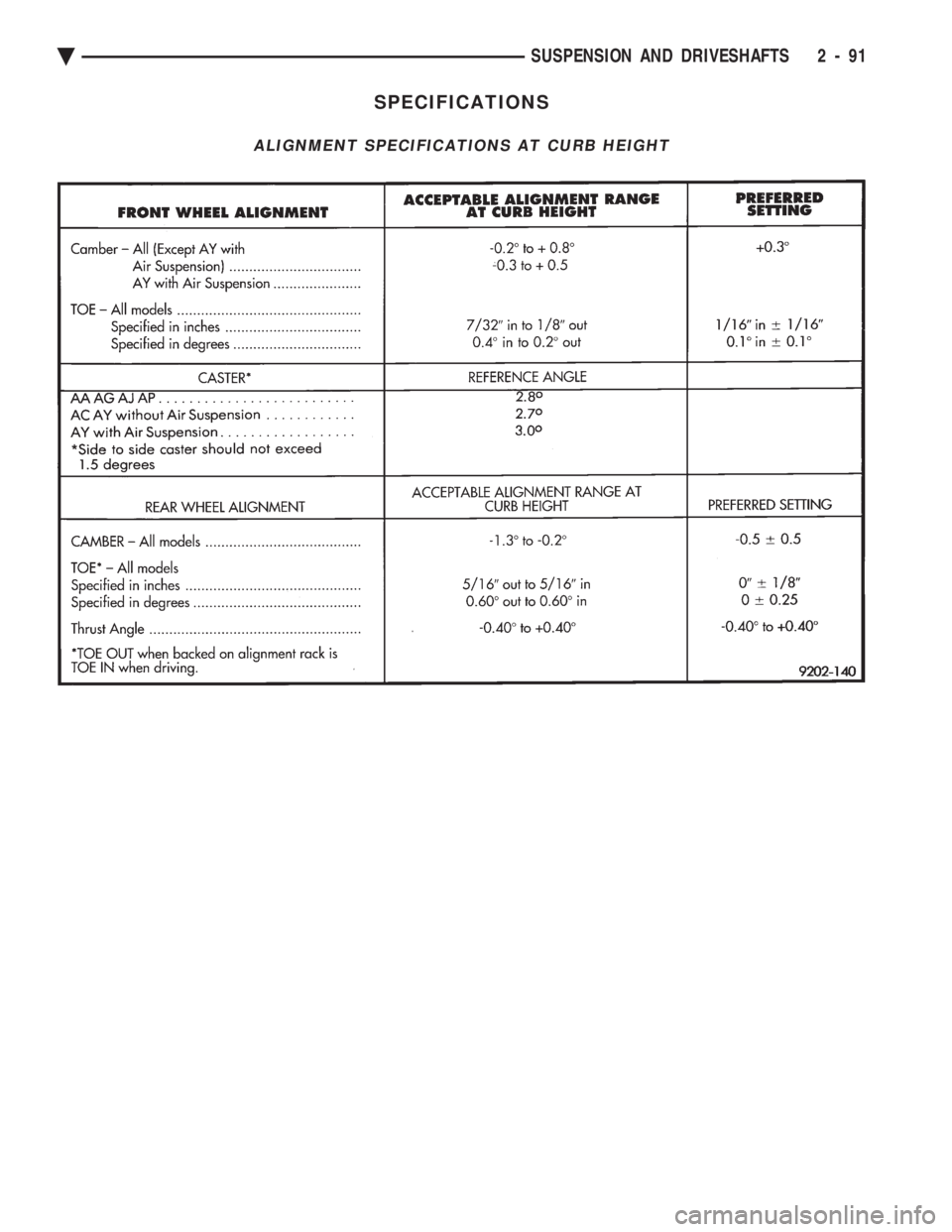

SPECIFICATIONS

ALIGNMENT SPECIFICATIONS AT CURB HEIGHT

Ä SUSPENSION AND DRIVESHAFTS 2 - 91

Page 228 of 2438

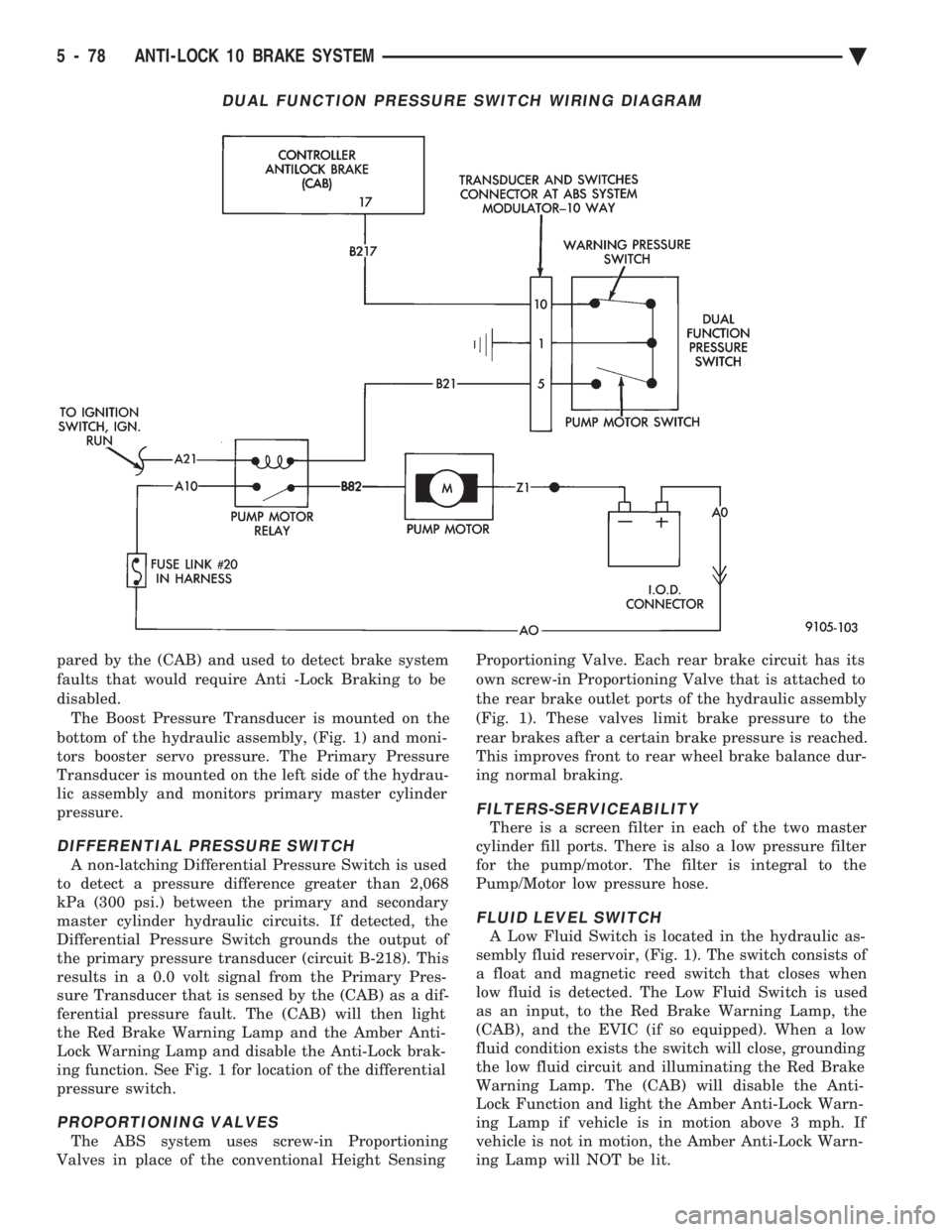

pared by the (CAB) and used to detect brake system

faults that would require Anti -Lock Braking to be

disabled.The Boost Pressure Transducer is mounted on the

bottom of the hydraulic assembly, (Fig. 1) and moni-

tors booster servo pressure. The Primary Pressure

Transducer is mounted on the left side of the hydrau-

lic assembly and monitors primary master cylinder

pressure.

DIFFERENTIAL PRESSURE SWITCH

A non-latching Differential Pressure Switch is used

to detect a pressure difference greater than 2,068

kPa (300 psi.) between the primary and secondary

master cylinder hydraulic circuits. If detected, the

Differential Pressure Switch grounds the output of

the primary pressure transducer (circuit B-218). This

results in a 0.0 volt signal from the Primary Pres-

sure Transducer that is sensed by the (CAB) as a dif-

ferential pressure fault. The (CAB) will then light

the Red Brake Warning Lamp and the Amber Anti-

Lock Warning Lamp and disable the Anti-Lock brak-

ing function. See Fig. 1 for location of the differential

pressure switch.

PROPORTIONING VALVES

The ABS system uses screw-in Proportioning

Valves in place of the conventional Height Sensing Proportioning Valve. Each rear brake circuit has its

own screw-in Proportioning Valve that is attached to

the rear brake outlet ports of the hydraulic assembly

(Fig. 1). These valves limit brake pressure to the

rear brakes after a certain brake pressure is reached.

This improves front to rear wheel brake balance dur-

ing normal braking.

FILTERS-SERVICEABILITY

There is a screen filter in each of the two master

cylinder fill ports. There is also a low pressure filter

for the pump/motor. The filter is integral to the

Pump/Motor low pressure hose.

FLUID LEVEL SWITCH

A Low Fluid Switch is located in the hydraulic as-

sembly fluid reservoir, (Fig. 1). The switch consists of

a float and magnetic reed switch that closes when

low fluid is detected. The Low Fluid Switch is used

as an input, to the Red Brake Warning Lamp, the

(CAB), and the EVIC (if so equipped). When a low

fluid condition exists the switch will close, grounding

the low fluid circuit and illuminating the Red Brake

Warning Lamp. The (CAB) will disable the Anti-

Lock Function and light the Amber Anti-Lock Warn-

ing Lamp if vehicle is in motion above 3 mph. If

vehicle is not in motion, the Amber Anti-Lock Warn-

ing Lamp will NOT be lit.

DUAL FUNCTION PRESSURE SWITCH WIRING DIAGRAM

5 - 78 ANTI-LOCK 10 BRAKE SYSTEM Ä

Page 1063 of 2438

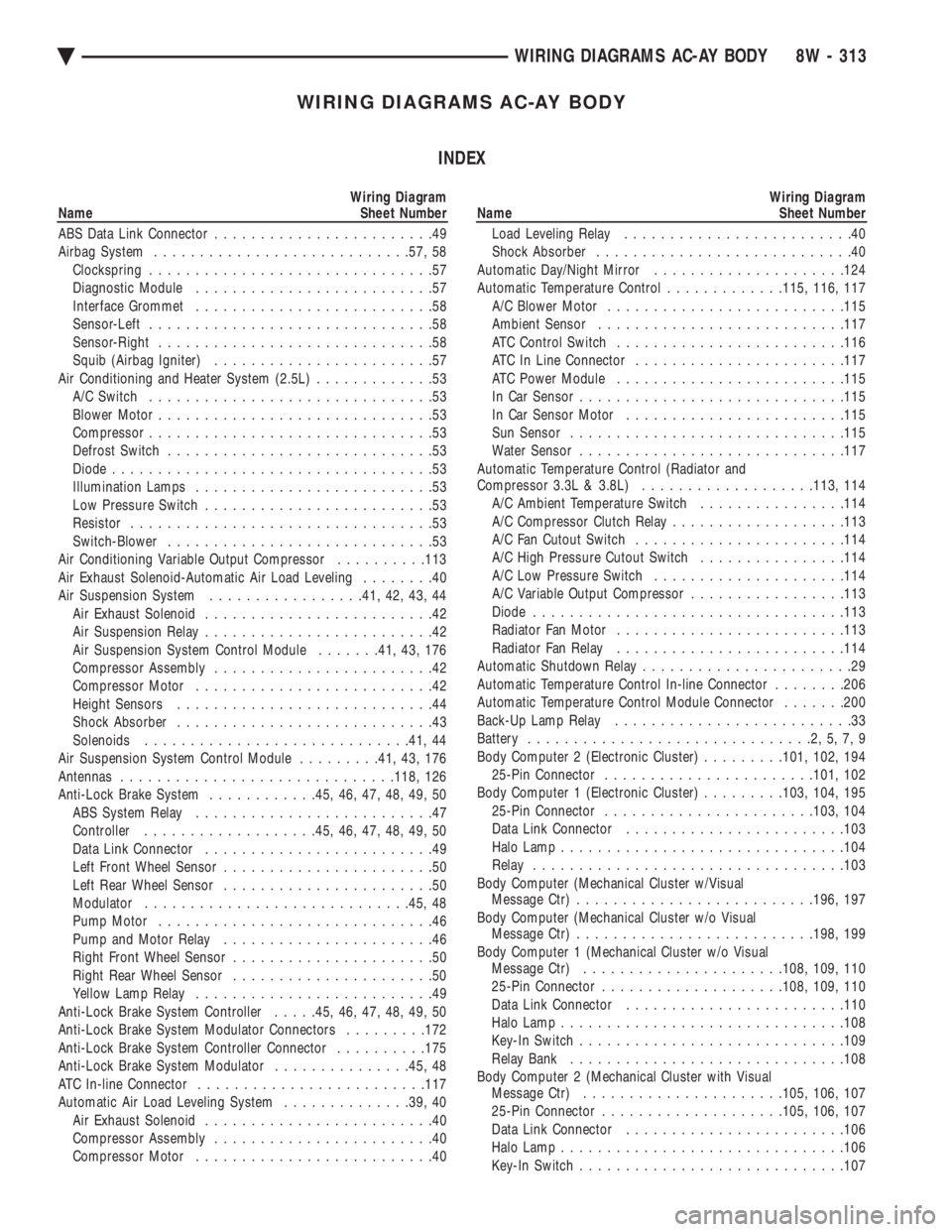

WIRING DIAGRAMS AC-AY BODY INDEX

Wiring Diagram

Name Sheet Number

ABS Data Link Connector ........................49

Airbag System ........................... .57, 58

Clockspring ...............................57

Diagnostic Module ..........................57

Interface Grommet ..........................58

Sensor-Left ...............................58

Sensor-Right ..............................58

Squib (Airbag Igniter) ........................57

Air Conditioning and Heater System (2.5L) .............53

A/C Switch ...............................53

Blower Motor ..............................53

Compressor ...............................53

Defrost Switch .............................53

Diode ...................................53

Illumination Lamps ..........................53

Low Pressure Switch .........................53

Resistor .................................53

Switch-Blower .............................53

Air Conditioning Variable Output Compressor ..........113

Air Exhaust Solenoid-Automatic Air Load Leveling ........40

Air Suspension System .................41, 42, 43, 44

Air Exhaust Solenoid .........................42

Air Suspension Relay .........................42

Air Suspension System Control Module .......41, 43, 176

Compressor Assembly ........................42

Compressor Motor ..........................42

Height Sensors ............................44

Shock Absorber ............................43

Solenoids ............................ .41, 44

Air Suspension System Control Module .........41, 43, 176

Antennas ............................. .118, 126

Anti-Lock Brake System ............45, 46, 47, 48, 49, 50

ABS System Relay ..........................47

Controller .................. .45, 46, 47, 48, 49, 50

Data Link Connector .........................49

Left Front Wheel Sensor .......................50

Left Rear Wheel Sensor .......................50

Modulator ............................ .45, 48

Pump Motor ..............................46

Pump and Motor Relay .......................46

Right Front Wheel Sensor ......................50

Right Rear Wheel Sensor ......................50

Yellow Lamp Relay ..........................49

Anti-Lock Brake System Controller .....45, 46, 47, 48, 49, 50

Anti-Lock Brake System Modulator Connectors .........172

Anti-Lock Brake System Controller Connector ..........175

Anti-Lock Brake System Modulator ...............45, 48

ATC In-line Connector ........................ .117

Automatic Air Load Leveling System ..............39, 40

Air Exhaust Solenoid .........................40

Compressor Assembly ........................40

Compressor Motor ..........................40Wiring Diagram

Name Sheet Number

Load Leveling Relay .........................40

Shock Absorber ............................40

Automatic Day/Night Mirror .................... .124

Automatic Temperature Control .............115, 116, 117

A/C Blower Motor ......................... .115

Ambient Sensor .......................... .117

ATC Control Switch ........................ .116

ATC In Line Connector ...................... .117

ATC Power Module ........................ .115

In Car Senso r............................ .115

In Car Sensor Motor ....................... .115

Sun Sensor ............................. .115

Water Sensor ............................ .117

Automatic Temperature Control (Radiator and

Compressor 3.3L & 3.8L) .................. .113, 114

A/C Ambient Temperature Switch ................114

A/C Compressor Clutch Relay ...................113

A/C Fan Cutout Switch ...................... .114

A/C High Pressure Cutout Switch ................114

A/C Low Pressure Switch .................... .114

A/C Variable Output Compressor .................113

Diode ................................. .113

Radiator Fan Motor ........................ .113

Radiator Fan Relay ........................ .114

Automatic Shutdown Relay .......................29

Automatic Temperature Control In-line Connector ........206

Automatic Temperature Control Module Connector .......200

Back-Up Lamp Relay ..........................33

Battery ...............................2,5,7,9

Body Computer 2 (Electronic Cluster) .........101, 102, 194

25-Pin Connector ...................... .101, 102

Body Computer 1 (Electronic Cluster) .........103, 104, 195

25-Pin Connector ...................... .103, 104

Data Link Connector ....................... .103

Halo Lamp .............................. .104

Relay ................................. .103

Body Computer (Mechanical Cluster w/Visual Message Ctr) ......................... .196, 197

Body Computer (Mechanical Cluster w/o Visual Message Ctr) ......................... .198, 199

Body Computer 1 (Mechanical Cluster w/o Visual Message Ctr) ..................... .108, 109, 110

25-Pin Connector ................... .108, 109, 110

Data Link Connector ....................... .110

Halo Lamp .............................. .108

Key-In Switch ............................ .109

Relay Bank ............................. .108

Body Computer 2 (Mechanical Cluster with Visual Message Ctr) ..................... .105, 106, 107

25-Pin Connector ................... .105, 106, 107

Data Link Connector ....................... .106

Halo Lamp .............................. .106

Key-In Switch ............................ .107

Ä WIRING DIAGRAMS AC-AY BODY 8W - 313

Page 1069 of 2438

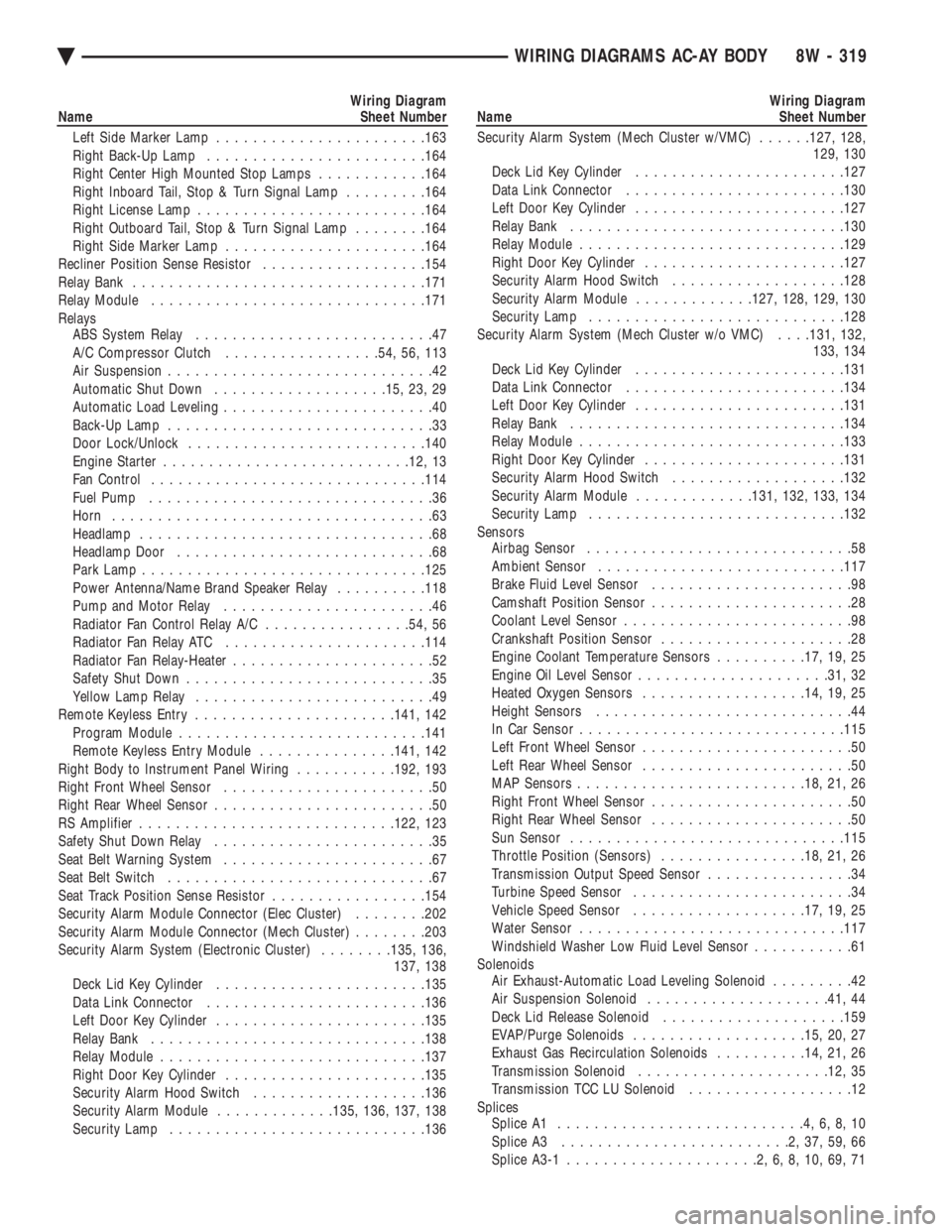

Wiring Diagram

Name Sheet Number

Left Side Marker Lamp ...................... .163

Right Back-Up Lamp ....................... .164

Right Center High Mounted Stop Lamps ............164

Right Inboard Tail, Stop & Turn Signal Lamp .........164

Right License Lamp ........................ .164

Right Outboard Tail, Stop & Turn Signal Lamp ........164

Right Side Marker Lamp ..................... .164

Recliner Position Sense Resistor ..................154

Relay Bank ............................... .171

Relay Module ............................. .171

Relays ABS System Relay ..........................47

A/C Compressor Clutch .................54, 56, 113

Air Suspension .............................42

Automatic Shut Down .................. .15, 23, 29

Automatic Load Leveling .......................40

Back-Up Lamp .............................33

Door Lock/Unlock ......................... .140

Engine Starter .......................... .12, 13

Fan Control ............................. .114

Fuel Pump ...............................36

Horn ...................................63

Headlamp ................................68

Headlamp Door ............................68

Park Lamp .............................. .125

Power Antenna/Name Brand Speaker Relay ..........118

Pump and Motor Relay .......................46

Radiator Fan Control Relay A/C ................54, 56

Radiator Fan Relay ATC ..................... .114

Radiator Fan Relay-Heater ......................52

Safety Shut Down ...........................35

Yellow Lamp Relay ..........................49

Remote Keyless Entry ..................... .141, 142

Program Module .......................... .141

Remote Keyless Entry Module ...............141, 142

Right Body to Instrument Panel Wiring ...........192, 193

Right Front Wheel Sensor .......................50

Right Rear Wheel Sensor ........................50

RS Amplifier ........................... .122, 123

Safety Shut Down Relay ........................35

Seat Belt Warning System .......................67

Seat Belt Switch .............................67

Seat Track Position Sense Resistor .................154

Security Alarm Module Connector (Elec Cluster) ........202

Security Alarm Module Connector (Mech Cluster) ........203

Security Alarm System (Electronic Cluster) ........135, 136,

137, 138

Deck Lid Key Cylinder ...................... .135

Data Link Connector ....................... .136

Left Door Key Cylinder ...................... .135

Relay Bank ............................. .138

Relay Module ............................ .137

Right Door Key Cylinder ..................... .135

Security Alarm Hood Switch ...................136

Security Alarm Module .............135, 136, 137, 138

Security Lamp ........................... .136Wiring Diagram

Name Sheet Number

Security Alarm System (Mech Cluster w/VMC) ......127, 128,

129, 130

Deck Lid Key Cylinder ...................... .127

Data Link Connector ....................... .130

Left Door Key Cylinder ...................... .127

Relay Bank ............................. .130

Relay Module ............................ .129

Right Door Key Cylinder ..................... .127

Security Alarm Hood Switch ...................128

Security Alarm Module .............127, 128, 129, 130

Security Lamp ........................... .128

Security Alarm System (Mech Cluster w/o VMC) . . . .131, 132,

133, 134

Deck Lid Key Cylinder ...................... .131

Data Link Connector ....................... .134

Left Door Key Cylinder ...................... .131

Relay Bank ............................. .134

Relay Module ............................ .133

Right Door Key Cylinder ..................... .131

Security Alarm Hood Switch ...................132

Security Alarm Module .............131, 132, 133, 134

Security Lamp ........................... .132

Sensors Airbag Sensor .............................58

Ambient Sensor .......................... .117

Brake Fluid Level Sensor ......................98

Camshaft Position Sensor ......................28

Coolant Level Sensor .........................98

Crankshaft Position Sensor .....................28

Engine Coolant Temperature Sensors ..........17, 19, 25

Engine Oil Level Sensor .................... .31, 32

Heated Oxygen Sensors ................. .14, 19, 25

Height Sensors ............................44

In Car Senso r............................ .115

Left Front Wheel Sensor .......................50

Left Rear Wheel Sensor .......................50

MAP Sensors ........................ .18, 21, 26

Right Front Wheel Sensor ......................50

Right Rear Wheel Sensor ......................50

Sun Sensor ............................. .115

Throttle Position (Sensors) ................18, 21, 26

Transmission Output Speed Sensor ................34

Turbine Speed Sensor ........................34

Vehicle Speed Sensor .................. .17, 19, 25

Water Sensor ............................ .117

Windshield Washer Low Fluid Level Sensor ...........61

Solenoids Air Exhaust-Automatic Load Leveling Solenoid .........42

Air Suspension Solenoid ................... .41, 44

Deck Lid Release Solenoid ................... .159

EVAP/Purge Solenoids .................. .15, 20, 27

Exhaust Gas Recirculation Solenoids ..........14, 21, 26

Transmission Solenoid .................... .12, 35

Transmission TCC LU Solenoid ..................12

Splices Splice A1 ...........................4,6,8,10

Splice A3 .........................2,37,59,66

Splice A3-1 .....................2,6,8,10,69,71

Ä WIRING DIAGRAMS AC-AY BODY 8W - 319

Page 1594 of 2438

springs using Tool C-3422-B. (2) Remove valve retaining locks, valve spring re-

tainers, valve stem seals and valve springs. (3) Before removing valves, remove any burrs

from valve stem lock grooves to prevent damage

to the valve guides. Identify valves to insure instal-

lation in original location.

VALVE INSPECTION (1) Clean valves thoroughly and discard burned,

warped and cracked valves. (2) Measure valve stems for wear.

(3) If valve stems are worn more than 0.05 mm (.002

inch.) replace valve.

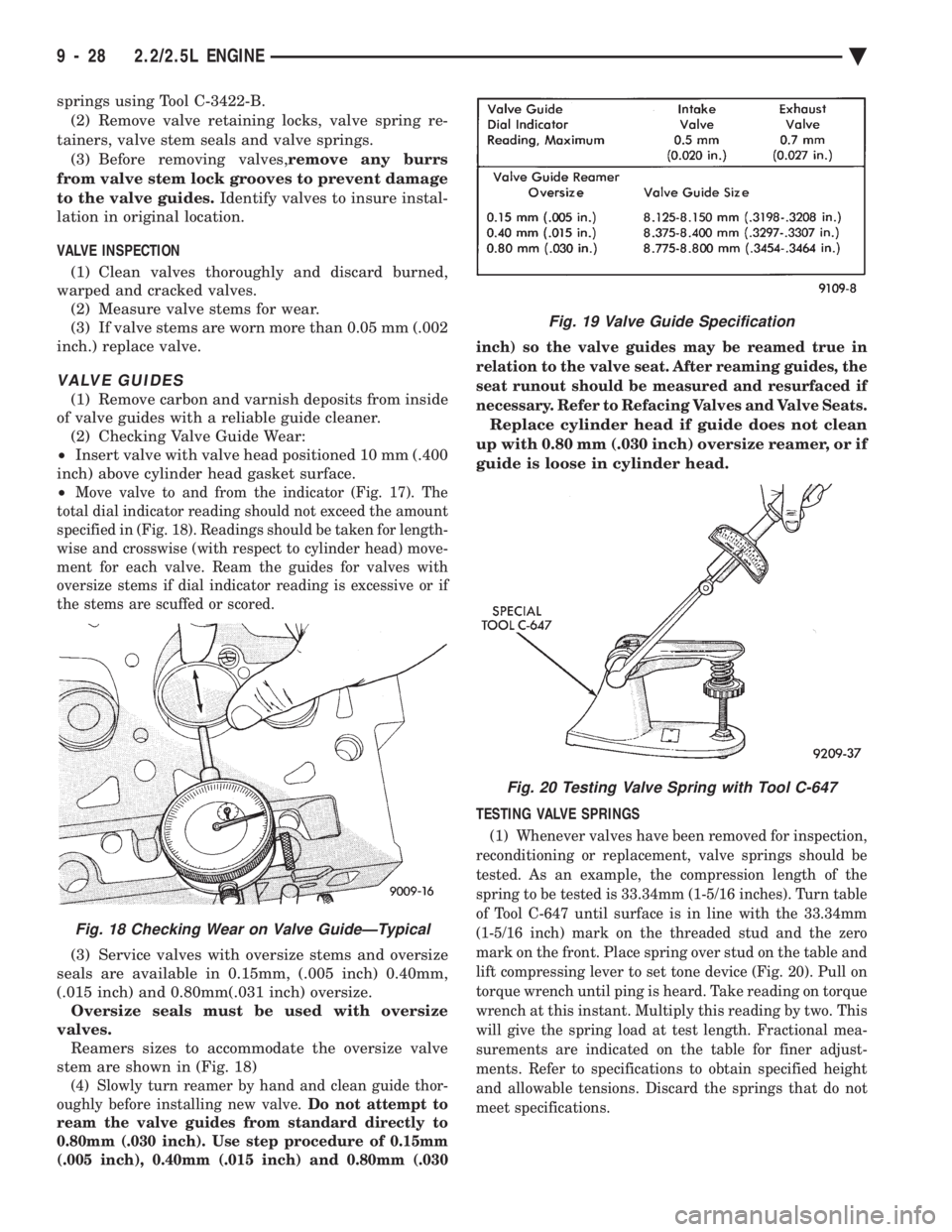

VALVE GUIDES

(1) Remove carbon and varnish deposits from inside

of valve guides with a reliable guide cleaner. (2) Checking Valve Guide Wear:

² Insert valve with valve head positioned 10 mm (.400

inch) above cylinder head gasket surface.

²

Move valve to and from the indicator (Fig. 17). The

total dial indicator reading should not exceed the amount

specified in (Fig. 18). Readings should be taken for length-

wise and crosswise (with respect to cylinder head) move-

ment for each valve. Ream the guides for valves with

oversize stems if dial indicator reading is excessive or if

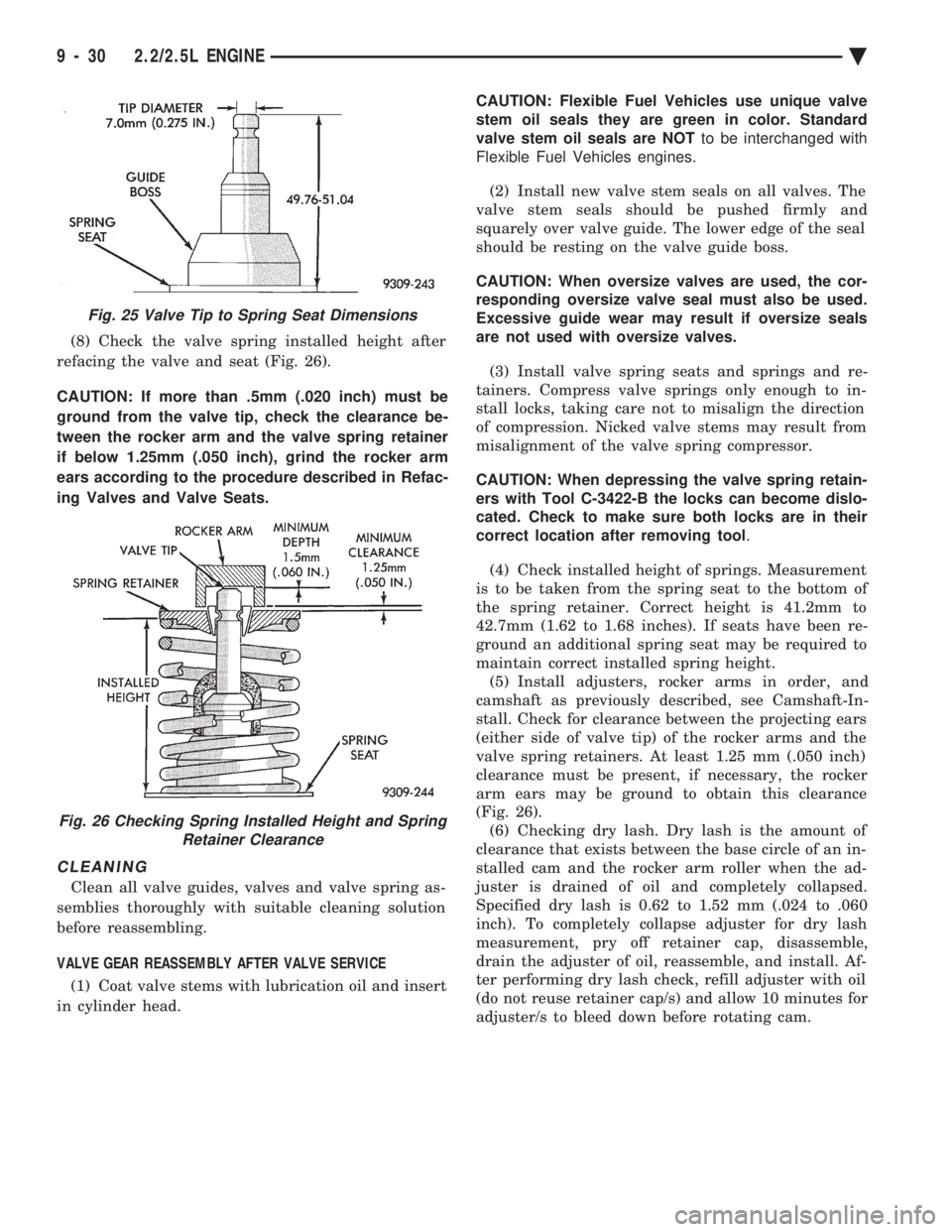

the stems are scuffed or scored.

(3) Service valves with oversize stems and oversize

seals are available in 0.15mm, (.005 inch) 0.40mm,

(.015 inch) and 0.80mm(.031 inch) oversize. Oversize seals must be used with oversize

valves. Reamers sizes to accommodate the oversize valve

stem are shown in (Fig. 18)

(4) Slowly turn reamer by hand and clean guide thor-

oughly before installing new valve. Do not attempt to

ream the valve guides from standard directly to

0.80mm (.030 inch). Use step procedure of 0.15mm

(.005 inch), 0.40mm (.015 inch) and 0.80mm (.030 inch) so the valve guides may be reamed true in

relation to the valve seat. After reaming guides, the

seat runout should be measured and resurfaced if

necessary. Refer to Refacing Valves and Valve Seats.

Replace cylinder head if guide does not clean

up with 0.80 mm (.030 inch) oversize reamer, or if

guide is loose in cylinder head.

TESTING VALVE SPRINGS

(1) Whenever valves have been removed for inspection,

reconditioning or replacement, valve springs should be

tested. As an example, the compression length of the

spring to be tested is 33.34mm (1-5/16 inches). Turn table

of Tool C-647 until surface is in line with the 33.34mm

(1-5/16 inch) mark on the threaded stud and the zero

mark on the front. Place spring over stud on the table and

lift compressing lever to set tone device (Fig. 20). Pull on

torque wrench until ping is heard. Take reading on torque

wrench at this instant. Multiply this reading by two. This

will give the spring load at test length. Fractional mea-

surements are indicated on the table for finer adjust-

ments. Refer to specifications to obtain specified height

and allowable tensions. Discard the springs that do not

meet specifications.

Fig. 18 Checking Wear on Valve GuideÐTypical

Fig. 19 Valve Guide Specification

Fig. 20 Testing Valve Spring with Tool C-647

9 - 28 2.2/2.5L ENGINE Ä

Page 1596 of 2438

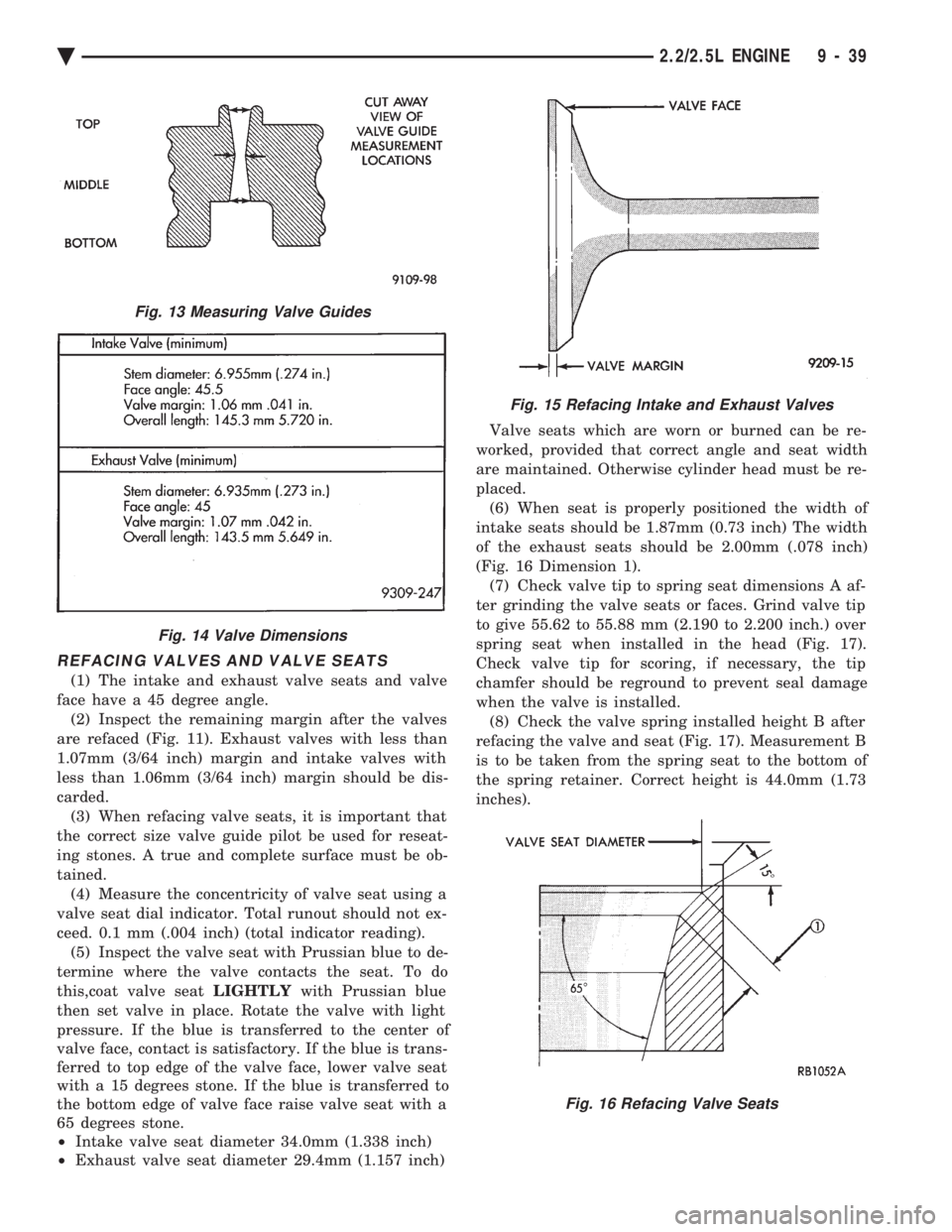

(8) Check the valve spring installed height after

refacing the valve and seat (Fig. 26).

CAUTION: If more than .5mm (.020 inch) must be

ground from the valve tip, check the clearance be-

tween the rocker arm and the valve spring retainer

if below 1.25mm (.050 inch), grind the rocker arm

ears according to the procedure described in Refac-

ing Valves and Valve Seats.

CLEANING

Clean all valve guides, valves and valve spring as-

semblies thoroughly with suitable cleaning solution

before reassembling.

VALVE GEAR REASSEMBLY AFTER VALVE SERVICE (1) Coat valve stems with lubrication oil and insert

in cylinder head. CAUTION: Flexible Fuel Vehicles use unique valve

stem oil seals they are green in color. Standard

valve stem oil seals are NOT to be interchanged with

Flexible Fuel Vehicles engines.

(2) Install new valve stem seals on all valves. The

valve stem seals should be pushed firmly and

squarely over valve guide. The lower edge of the seal

should be resting on the valve guide boss.

CAUTION: When oversize valves are used, the cor-

responding oversize valve seal must also be used.

Excessive guide wear may result if oversize seals

are not used with oversize valves.

(3) Install valve spring seats and springs and re-

tainers. Compress valve springs only enough to in-

stall locks, taking care not to misalign the direction

of compression. Nicked valve stems may result from

misalignment of the valve spring compressor.

CAUTION: When depressing the valve spring retain-

ers with Tool C-3422-B the locks can become dislo-

cated. Check to make sure both locks are in their

correct location after removing tool .

(4) Check installed height of springs. Measurement

is to be taken from the spring seat to the bottom of

the spring retainer. Correct height is 41.2mm to

42.7mm (1.62 to 1.68 inches). If seats have been re-

ground an additional spring seat may be required to

maintain correct installed spring height. (5) Install adjusters, rocker arms in order, and

camshaft as previously described, see Camshaft-In-

stall. Check for clearance between the projecting ears

(either side of valve tip) of the rocker arms and the

valve spring retainers. At least 1.25 mm (.050 inch)

clearance must be present, if necessary, the rocker

arm ears may be ground to obtain this clearance

(Fig. 26). (6) Checking dry lash. Dry lash is the amount of

clearance that exists between the base circle of an in-

stalled cam and the rocker arm roller when the ad-

juster is drained of oil and completely collapsed.

Specified dry lash is 0.62 to 1.52 mm (.024 to .060

inch). To completely collapse adjuster for dry lash

measurement, pry off retainer cap, disassemble,

drain the adjuster of oil, reassemble, and install. Af-

ter performing dry lash check, refill adjuster with oil

(do not reuse retainer cap/s) and allow 10 minutes for

adjuster/s to bleed down before rotating cam.

Fig. 25 Valve Tip to Spring Seat Dimensions

Fig. 26 Checking Spring Installed Height and Spring Retainer Clearance

9 - 30 2.2/2.5L ENGINE Ä

Page 1605 of 2438

REFACING VALVES AND VALVE SEATS

(1) The intake and exhaust valve seats and valve

face have a 45 degree angle. (2) Inspect the remaining margin after the valves

are refaced (Fig. 11). Exhaust valves with less than

1.07mm (3/64 inch) margin and intake valves with

less than 1.06mm (3/64 inch) margin should be dis-

carded. (3) When refacing valve seats, it is important that

the correct size valve guide pilot be used for reseat-

ing stones. A true and complete surface must be ob-

tained. (4) Measure the concentricity of valve seat using a

valve seat dial indicator. Total runout should not ex-

ceed. 0.1 mm (.004 inch) (total indicator reading). (5) Inspect the valve seat with Prussian blue to de-

termine where the valve contacts the seat. To do

this,coat valve seat LIGHTLYwith Prussian blue

then set valve in place. Rotate the valve with light

pressure. If the blue is transferred to the center of

valve face, contact is satisfactory. If the blue is trans-

ferred to top edge of the valve face, lower valve seat

with a 15 degrees stone. If the blue is transferred to

the bottom edge of valve face raise valve seat with a

65 degrees stone.

² Intake valve seat diameter 34.0mm (1.338 inch)

² Exhaust valve seat diameter 29.4mm (1.157 inch) Valve seats which are worn or burned can be re-

worked, provided that correct angle and seat width

are maintained. Otherwise cylinder head must be re-

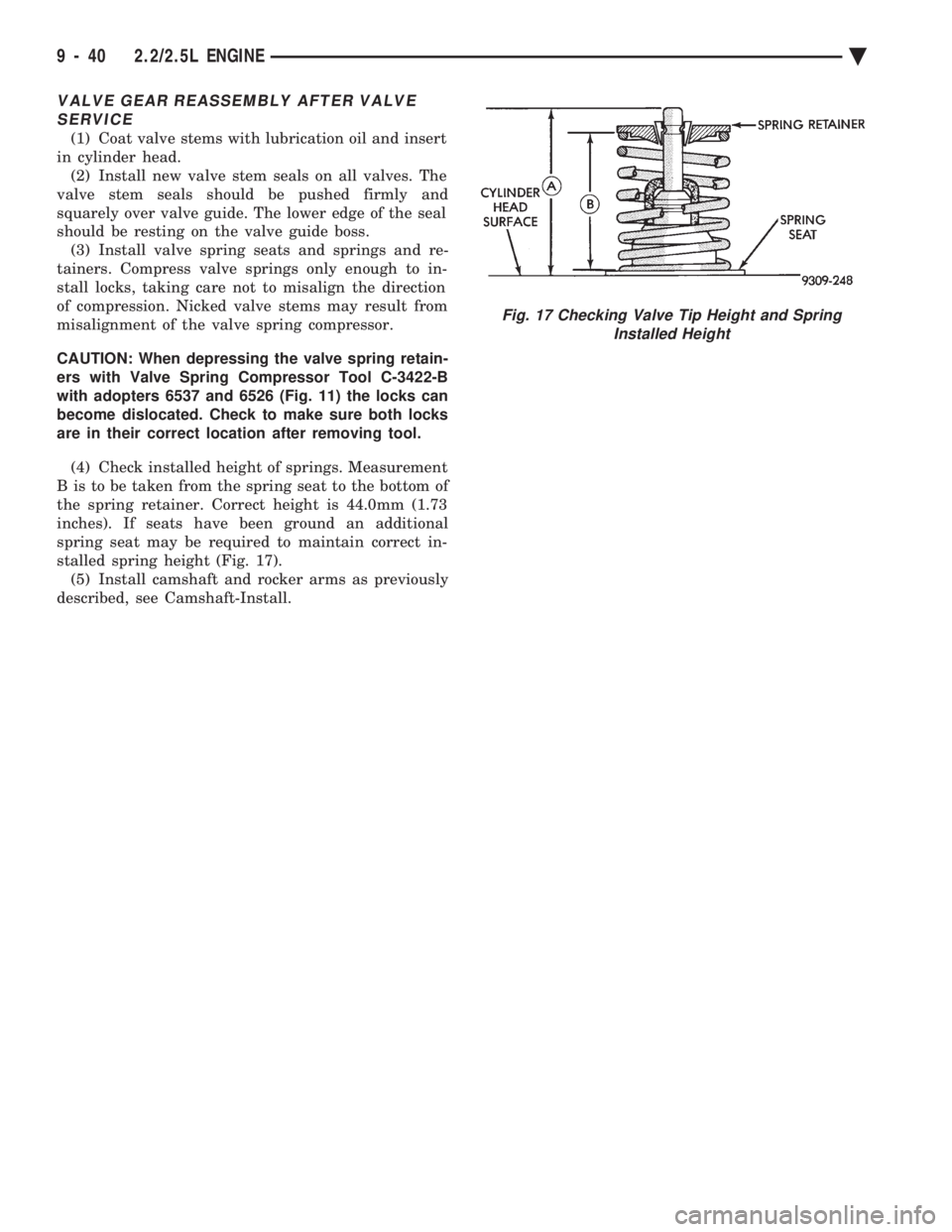

placed. (6) When seat is properly positioned the width of

intake seats should be 1.87mm (0.73 inch) The width

of the exhaust seats should be 2.00mm (.078 inch)

(Fig. 16 Dimension 1). (7) Check valve tip to spring seat dimensions A af-

ter grinding the valve seats or faces. Grind valve tip

to give 55.62 to 55.88 mm (2.190 to 2.200 inch.) over

spring seat when installed in the head (Fig. 17).

Check valve tip for scoring, if necessary, the tip

chamfer should be reground to prevent seal damage

when the valve is installed. (8) Check the valve spring installed height B after

refacing the valve and seat (Fig. 17). Measurement B

is to be taken from the spring seat to the bottom of

the spring retainer. Correct height is 44.0mm (1.73

inches).

Fig. 13 Measuring Valve Guides

Fig. 14 Valve Dimensions

Fig. 15 Refacing Intake and Exhaust Valves

Fig. 16 Refacing Valve Seats

Ä 2.2/2.5L ENGINE 9 - 39

Page 1606 of 2438

VALVE GEAR REASSEMBLY AFTER VALVE SERVICE

(1) Coat valve stems with lubrication oil and insert

in cylinder head. (2) Install new valve stem seals on all valves. The

valve stem seals should be pushed firmly and

squarely over valve guide. The lower edge of the seal

should be resting on the valve guide boss. (3) Install valve spring seats and springs and re-

tainers. Compress valve springs only enough to in-

stall locks, taking care not to misalign the direction

of compression. Nicked valve stems may result from

misalignment of the valve spring compressor.

CAUTION: When depressing the valve spring retain-

ers with Valve Spring Compressor Tool C-3422-B

with adopters 6537 and 6526 (Fig. 11) the locks can

become dislocated. Check to make sure both locks

are in their correct location after removing tool.

(4) Check installed height of springs. Measurement

B is to be taken from the spring seat to the bottom of

the spring retainer. Correct height is 44.0mm (1.73

inches). If seats have been ground an additional

spring seat may be required to maintain correct in-

stalled spring height (Fig. 17). (5) Install camshaft and rocker arms as previously

described, see Camshaft-Install.

Fig. 17 Checking Valve Tip Height and Spring Installed Height

9 - 40 2.2/2.5L ENGINE Ä

Page 1633 of 2438

PISTONS: Are aluminum alloy with a steel strut,

short height, and thin wall so as to be autothermic

and light weight. The piston head with valve re-

cesses, in combination with the cylinder head, forms

a compact spherical head with clearance for total

valve lift with pistons at top dead center. The piston

skirt, top and second ring lands are finished to a ta-

pered roughness for oil retention and high resistance

to scuffing. Piston pins, press-fitted into place, join

the pistons to the connecting rods. CYLINDER HEAD: The alloy cylinder heads fea- ture cross-flow type intake and exhaust ports. Valve

guides and inserts are hardened cast iron. Valves of

heat resistance steel are arranged i

n a V with each

camshaft on center. To improve combustion speed the

chambers are a compact spherical design with a

squish area of approximately 30 percent of the piston

top area. The cylinder heads are common to either

cylinder bank by reversing the direction of installa-

tion. CAMSHAFTS: Two overhead camshafts provide

valve actuation, one front (radiator side of cylinder

bank) and one rear. The front camshaft is provided

with a distributor drive and is longer. Both cam-

shafts are supported by four bearing journals, thrust

for the front camshaft is taken at journal two and

the rear at journal three. Front and rear camshaft

driving sprockets are interchangeable. The sprockets

and the engine water pump are driven by a single

notched timing belt. ROCKER ARM SHAFTS: The shafts are retained

by the camshaft bearing journal caps. Four shafts are

used, one for each intake and exhaust rocker arm as-

sembly on each cylinder head. The hollow shafts pro-

vide a duct for lubricating oil flow from the cylinder

head to the valve mechanisms. ROCKER ARMS: Are of light weight die-cast

with roller type follower operating against the cam

shaft. The valve actuating end of the rocker arms are

machined to retain hydraulic lash adjusters, elimi-

nating valve lash adjustment. VALVES: Are made of heat resistant steel and are

further treated to resist heat. VALVE SPRINGS: Are especially designed to be

short. The valve spring wire cross-section is oval

SPECIFICATIONS

Fig. 1 Engine Identification

Ä 3.0L ENGINE 9 - 67

Page 1642 of 2438

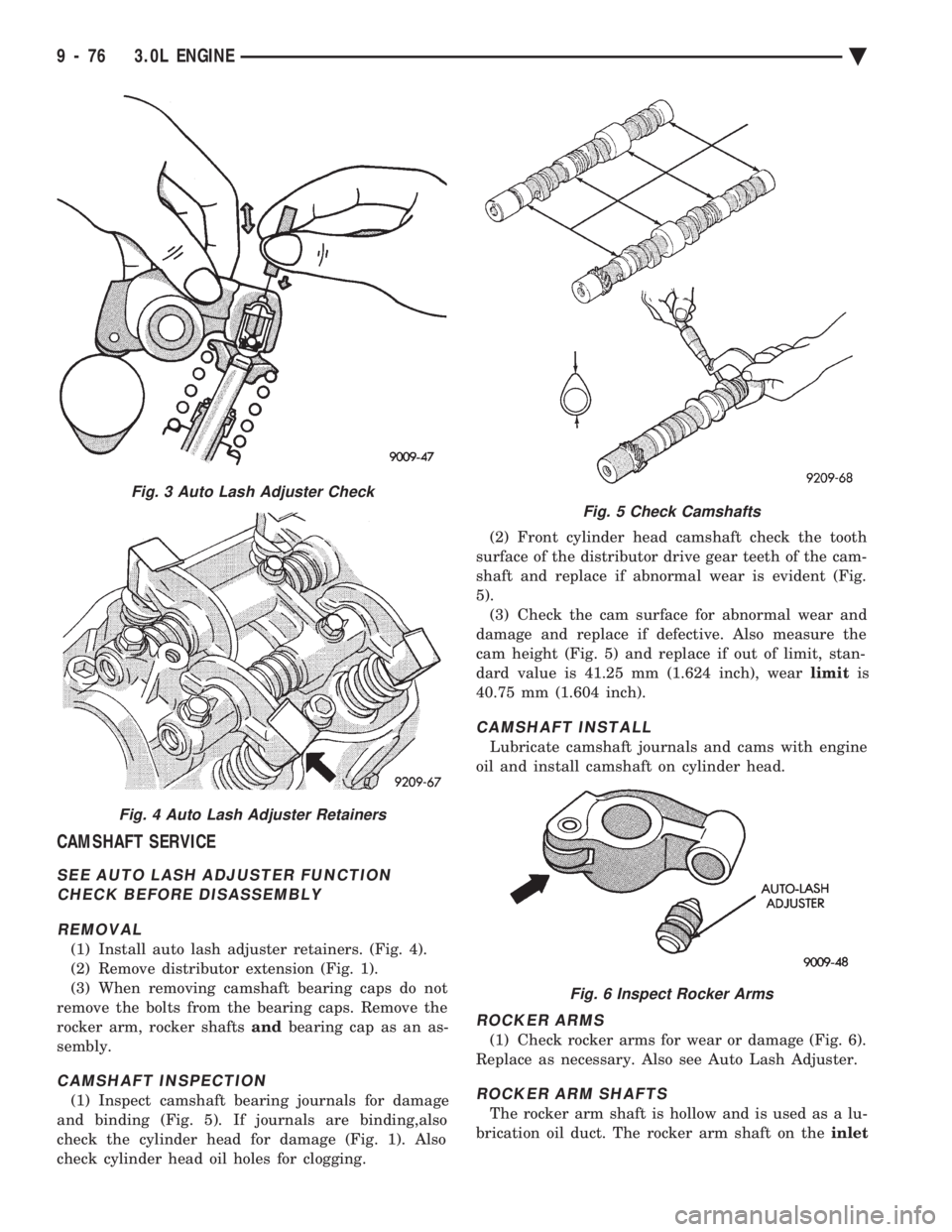

CAMSHAFT SERVICE

SEE AUTO LASH ADJUSTER FUNCTION CHECK BEFORE DISASSEMBLY

REMOVAL

(1) Install auto lash adjuster retainers. (Fig. 4).

(2) Remove distributor extension (Fig. 1).

(3) When removing camshaft bearing caps do not

remove the bolts from the bearing caps. Remove the

rocker arm, rocker shafts andbearing cap as an as-

sembly.

CAMSHAFT INSPECTION

(1) Inspect camshaft bearing journals for damage

and binding (Fig. 5). If journals are binding,also

check the cylinder head for damage (Fig. 1). Also

check cylinder head oil holes for clogging. (2) Front cylinder head camshaft check the tooth

surface of the distributor drive gear teeth of the cam-

shaft and replace if abnormal wear is evident (Fig.

5). (3) Check the cam surface for abnormal wear and

damage and replace if defective. Also measure the

cam height (Fig. 5) and replace if out of limit, stan-

dard value is 41.25 mm (1.624 inch), wear limitis

40.75 mm (1.604 inch).

CAMSHAFT INSTALL

Lubricate camshaft journals and cams with engine

oil and install camshaft on cylinder head.

ROCKER ARMS

(1) Check rocker arms for wear or damage (Fig. 6).

Replace as necessary. Also see Auto Lash Adjuster.

ROCKER ARM SHAFTS

The rocker arm shaft is hollow and is used as a lu-

brication oil duct. The rocker arm shaft on the inlet

Fig. 3 Auto Lash Adjuster Check

Fig. 4 Auto Lash Adjuster Retainers

Fig. 5 Check Camshafts

Fig. 6 Inspect Rocker Arms

9 - 76 3.0L ENGINE Ä