lights CHEVROLET DYNASTY 1993 Owner's Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1065 of 2438

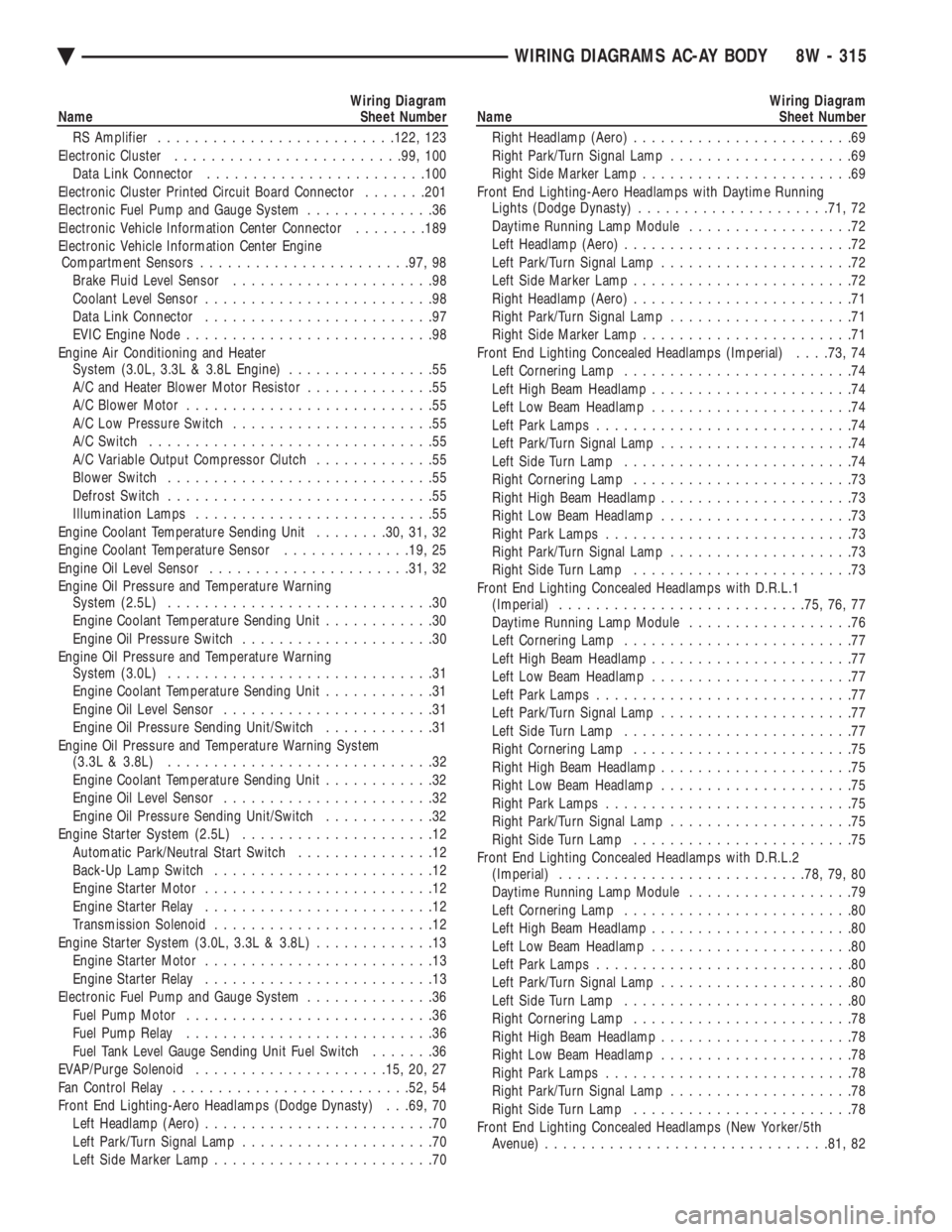

Wiring Diagram

Name Sheet Number

RS Amplifier ......................... .122, 123

Electronic Cluster ........................ .99, 100

Data Link Connector ....................... .100

Electronic Cluster Printed Circuit Board Connector .......201

Electronic Fuel Pump and Gauge System ..............36

Electronic Vehicle Information Center Connector ........189

Electronic Vehicle Information Center Engine Compartment Sensors ...................... .97, 98

Brake Fluid Level Sensor ......................98

Coolant Level Sensor .........................98

Data Link Connector .........................97

EVIC Engine Node ...........................98

Engine Air Conditioning and Heater System (3.0L, 3.3L & 3.8L Engine) ................55

A/C and Heater Blower Motor Resistor ..............55

A/C Blower Motor ...........................55

A/C Low Pressure Switch ......................55

A/C Switch ...............................55

A/C Variable Output Compressor Clutch .............55

Blower Switch .............................55

Defrost Switch .............................55

Illumination Lamps ..........................55

Engine Coolant Temperature Sending Unit ........30, 31, 32

Engine Coolant Temperature Sensor ..............19, 25

Engine Oil Level Sensor ..................... .31, 32

Engine Oil Pressure and Temperature Warning System (2.5L) .............................30

Engine Coolant Temperature Sending Unit ............30

Engine Oil Pressure Switch .....................30

Engine Oil Pressure and Temperature Warning System (3.0L) .............................31

Engine Coolant Temperature Sending Unit ............31

Engine Oil Level Sensor .......................31

Engine Oil Pressure Sending Unit/Switch ............31

Engine Oil Pressure and Temperature Warning System (3.3L & 3.8L) .............................32

Engine Coolant Temperature Sending Unit ............32

Engine Oil Level Sensor .......................32

Engine Oil Pressure Sending Unit/Switch ............32

Engine Starter System (2.5L) .....................12

Automatic Park/Neutral Start Switch ...............12

Back-Up Lamp Switch ........................12

Engine Starter Motor .........................12

Engine Starter Relay .........................12

Transmission Solenoid ........................12

Engine Starter System (3.0L, 3.3L & 3.8L) .............13

Engine Starter Motor .........................13

Engine Starter Relay .........................13

Electronic Fuel Pump and Gauge System ..............36

Fuel Pump Motor ...........................36

Fuel Pump Relay ...........................36

Fuel Tank Level Gauge Sending Unit Fuel Switch .......36

EVAP/Purge Solenoid .................... .15, 20, 27

Fan Control Relay ......................... .52, 54

Front End Lighting-Aero Headlamps (Dodge Dynasty) . . .69, 70 Left Headlamp (Aero) .........................70

Left Park/Turn Signal Lamp .....................70

Left Side Marker Lamp ........................70Wiring Diagram

Name Sheet Number

Right Headlamp (Aero) ........................69

Right Park/Turn Signal Lamp ....................69

Right Side Marker Lamp .......................69

Front End Lighting-Aero Headlamps with Daytime Running Lights (Dodge Dynasty) .................... .71, 72

Daytime Running Lamp Module ..................72

Left Headlamp (Aero) .........................72

Left Park/Turn Signal Lamp .....................72

Left Side Marker Lamp ........................72

Right Headlamp (Aero) ........................71

Right Park/Turn Signal Lamp ....................71

Right Side Marker Lamp .......................71

Front End Lighting Concealed Headlamps (Imperial) . . . .73, 74

Left Cornering Lamp .........................74

Left High Beam Headlamp ......................74

Left Low Beam Headlamp ......................74

Left Park Lamps ............................74

Left Park/Turn Signal Lamp .....................74

Left Side Turn Lamp .........................74

Right Cornering Lamp ........................73

Right High Beam Headlamp .....................73

Right Low Beam Headlamp .....................73

Right Park Lamps ...........................73

Right Park/Turn Signal Lamp ....................73

Right Side Turn Lamp ........................73

Front End Lighting Concealed Headlamps with D.R.L.1 (Imperial) .......................... .75, 76, 77

Daytime Running Lamp Module ..................76

Left Cornering Lamp .........................77

Left High Beam Headlamp ......................77

Left Low Beam Headlamp ......................77

Left Park Lamps ............................77

Left Park/Turn Signal Lamp .....................77

Left Side Turn Lamp .........................77

Right Cornering Lamp ........................75

Right High Beam Headlamp .....................75

Right Low Beam Headlamp .....................75

Right Park Lamps ...........................75

Right Park/Turn Signal Lamp ....................75

Right Side Turn Lamp ........................75

Front End Lighting Concealed Headlamps with D.R.L.2 (Imperial) .......................... .78, 79, 80

Daytime Running Lamp Module ..................79

Left Cornering Lamp .........................80

Left High Beam Headlamp ......................80

Left Low Beam Headlamp ......................80

Left Park Lamps ............................80

Left Park/Turn Signal Lamp .....................80

Left Side Turn Lamp .........................80

Right Cornering Lamp ........................78

Right High Beam Headlamp .....................78

Right Low Beam Headlamp .....................78

Right Park Lamps ...........................78

Right Park/Turn Signal Lamp ....................78

Right Side Turn Lamp ........................78

Front End Lighting Concealed Headlamps (New Yorker/5th Avenue) .............................. .81, 82

Ä WIRING DIAGRAMS AC-AY BODY 8W - 315

Page 1283 of 2438

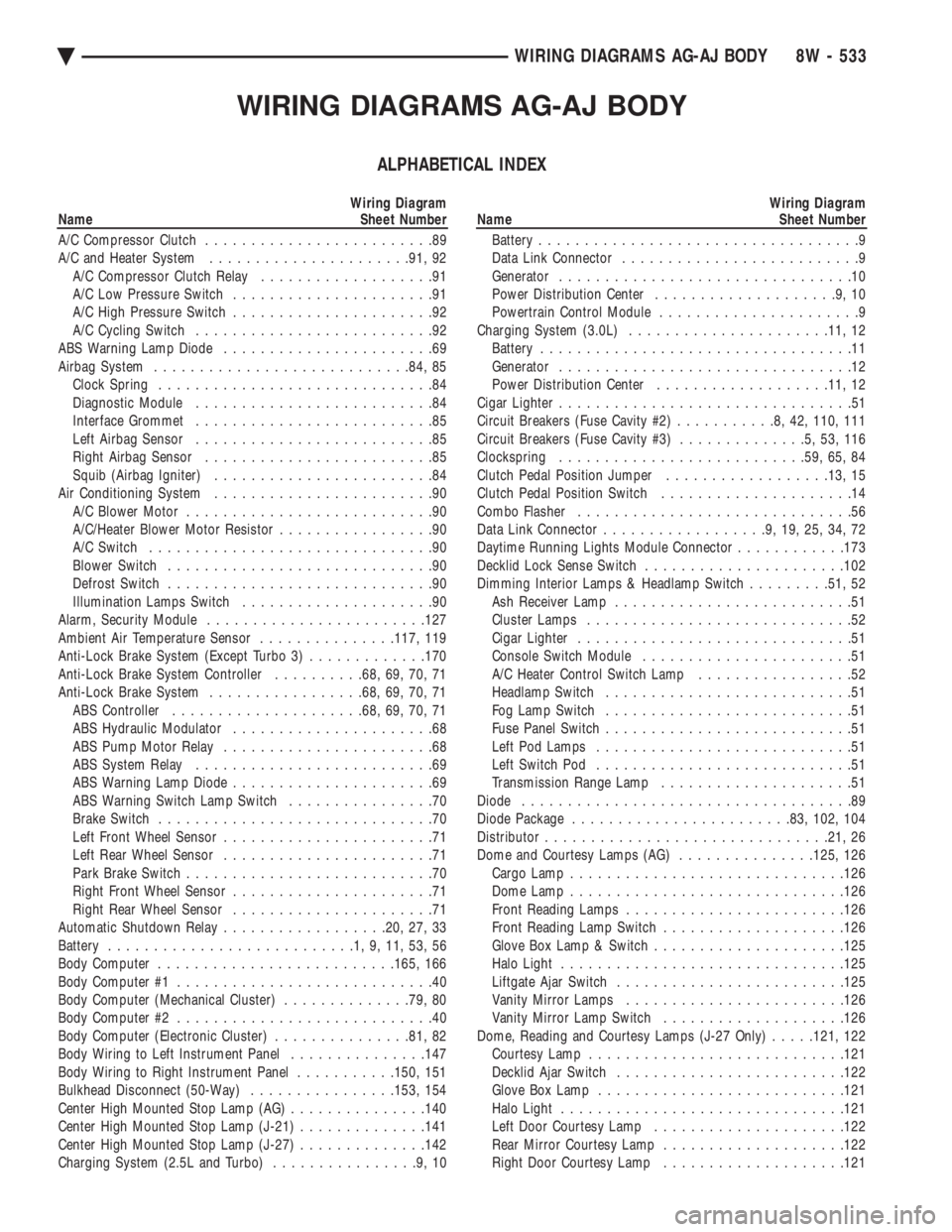

WIRING DIAGRAMS AG-AJ BODY

ALPHABETICAL INDEX

Wiring Diagram

Name Sheet Number

A/C Compressor Clutch .........................89

A/C and Heater System ..................... .91, 92

A/C Compressor Clutch Relay ...................91

A/C Low Pressure Switch ......................91

A/C High Pressure Switch ......................92

A/C Cycling Switch ..........................92

ABS Warning Lamp Diode .......................69

Airbag System ........................... .84, 85

Clock Spring ..............................84

Diagnostic Module ..........................84

Interface Grommet ..........................85

Left Airbag Sensor ..........................85

Right Airbag Sensor .........................85

Squib (Airbag Igniter) ........................84

Air Conditioning System ........................90

A/C Blower Motor ...........................90

A/C/Heater Blower Motor Resistor .................90

A/C Switch ...............................90

Blower Switch .............................90

Defrost Switch .............................90

Illumination Lamps Switch .....................90

Alarm, Security Module ....................... .127

Ambient Air Temperature Sensor ...............117, 119

Anti-Lock Brake System (Except Turbo 3) .............170

Anti-Lock Brake System Controller ..........68, 69, 70, 71

Anti-Lock Brake System .................68, 69, 70, 71

ABS Controller .................... .68, 69, 70, 71

ABS Hydraulic Modulator ......................68

ABS Pump Motor Relay .......................68

ABS System Relay ..........................69

ABS Warning Lamp Diode ......................69

ABS Warning Switch Lamp Switch ................70

Brake Switch ..............................70

Left Front Wheel Sensor .......................71

Left Rear Wheel Sensor .......................71

Park Brake Switch ...........................70

Right Front Wheel Sensor ......................71

Right Rear Wheel Sensor ......................71

Automatic Shutdown Relay ..................20, 27, 33

Battery ...........................1,9,11,53,56

Body Computer ......................... .165, 166

Body Computer #1 ............................40

Body Computer (Mechanical Cluster) ..............79, 80

Body Computer #2 ............................40

Body Computer (Electronic Cluster) ...............81, 82

Body Wiring to Left Instrument Panel ...............147

Body Wiring to Right Instrument Panel ...........150, 151

Bulkhead Disconnect (50-Way) ................153, 154

Center High Mounted Stop Lamp (AG) ...............140

Center High Mounted Stop Lamp (J-21) ..............141

Center High Mounted Stop Lamp (J-27) ..............142

Charging System (2.5L and Turbo) ................9,10Wiring Diagram

Name Sheet Number

Battery ...................................9

Data Link Connector ..........................9

Generator ................................10

Power Distribution Center ....................9,10

Powertrain Control Module ......................9

Charging System (3.0L) ..................... .11, 12

Battery ..................................11

Generator ................................12

Power Distribution Center .................. .11, 12

Cigar Lighter ................................51

Circuit Breakers (Fuse Cavity #2) ...........8,42,110, 111

Circuit Breakers (Fuse Cavity #3) ..............5,53,116

Clockspring .......................... .59, 65, 84

Clutch Pedal Position Jumper ..................13, 15

Clutch Pedal Position Switch .....................14

Combo Flasher ..............................56

Data Link Connector ..................9,19,25,34,72

Daytime Running Lights Module Connector ............173

Decklid Lock Sense Switch ..................... .102

Dimming Interior Lamps & Headlamp Switch .........51, 52

Ash Receiver Lamp ..........................51

Cluster Lamps .............................52

Cigar Lighter ..............................51

Console Switch Module .......................51

A/C Heater Control Switch Lamp .................52

Headlamp Switch ...........................51

Fog Lamp Switch ...........................51

Fuse Panel Switch ...........................51

Left Pod Lamps ............................51

Left Switch Pod ............................51

Transmission Range Lamp .....................51

Diode ....................................89

Diode Package ....................... .83, 102, 104

Distributor .............................. .21, 26

Dome and Courtesy Lamps (AG) ...............125, 126

Cargo Lamp ............................. .126

Dome Lamp ............................. .126

Front Reading Lamps ....................... .126

Front Reading Lamp Switch ................... .126

Glove Box Lamp & Switch .................... .125

Halo Light .............................. .125

Liftgate Ajar Switch ........................ .125

Vanity Mirror Lamps ....................... .126

Vanity Mirror Lamp Switch ................... .126

Dome, Reading and Courtesy Lamps (J-27 Only) .....121, 122

Courtesy Lamp ........................... .121

Decklid Ajar Switch ........................ .122

Glove Box Lamp .......................... .121

Halo Light .............................. .121

Left Door Courtesy Lamp .................... .122

Rear Mirror Courtesy Lamp ................... .122

Right Door Courtesy Lamp ................... .121

Ä WIRING DIAGRAMS AG-AJ BODY 8W - 533

Page 1467 of 2438

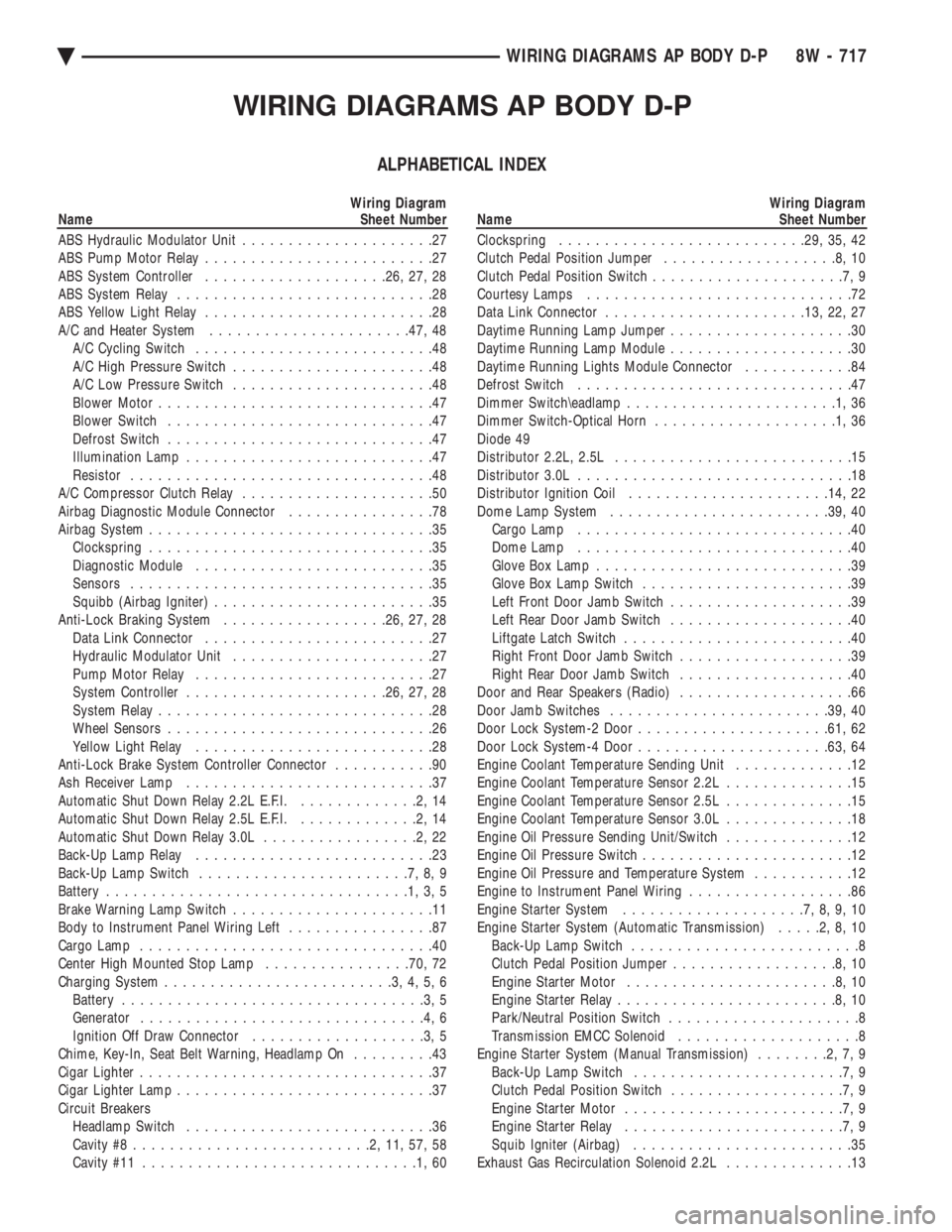

WIRING DIAGRAMS AP BODY D-P

ALPHABETICAL INDEX

Wiring Diagram

Name Sheet Number

ABS Hydraulic Modulator Unit .....................27

ABS Pump Motor Relay .........................27

ABS System Controller ................... .26, 27, 28

ABS System Relay ............................28

ABS Yellow Light Relay .........................28

A/C and Heater System ..................... .47, 48

A/C Cycling Switch ..........................48

A/C High Pressure Switch ......................48

A/C Low Pressure Switch ......................48

Blower Motor ..............................47

Blower Switch .............................47

Defrost Switch .............................47

Illumination Lamp ...........................47

Resistor .................................48

A/C Compressor Clutch Relay .....................50

Airbag Diagnostic Module Connector ................78

Airbag System ...............................35

Clockspring ...............................35

Diagnostic Module ..........................35

Sensors .................................35

Squibb (Airbag Igniter) ........................35

Anti-Lock Braking System ..................26, 27, 28

Data Link Connector .........................27

Hydraulic Modulator Unit ......................27

Pump Motor Relay ..........................27

System Controller ..................... .26, 27, 28

System Relay ..............................28

Wheel Sensors .............................26

Yellow Light Relay ..........................28

Anti-Lock Brake System Controller Connector ...........90

Ash Receiver Lamp ...........................37

Automatic Shut Down Relay 2.2L E.F.I. .............2,14

Automatic Shut Down Relay 2.5L E.F.I. .............2,14

Automatic Shut Down Relay 3.0L .................2,22

Back-Up Lamp Relay ..........................23

Back-Up Lamp Switch .......................7,8,9

Battery .................................1,3,5

Brake Warning Lamp Switch ......................11

Body to Instrument Panel Wiring Left ................87

Cargo Lamp ................................40

Center High Mounted Stop Lamp ................70, 72

Charging System .........................3,4,5,6

Battery .................................3,5

Generator ...............................4,6

Ignition Off Draw Connector ...................3,5

Chime, Key-In, Seat Belt Warning, Headlamp On .........43

Cigar Lighter ................................37

Cigar Lighter Lamp ............................37

Circuit Breakers Headlamp Switch ...........................36

Cavity #8 ..........................2,11,57,58

Cavity #11 ..............................1,60Wiring Diagram

Name Sheet Number

Clockspring .......................... .29, 35, 42

Clutch Pedal Position Jumper ...................8,10

Clutch Pedal Position Switch .....................7,9

Courtesy Lamps .............................72

Data Link Connector ..................... .13, 22, 27

Daytime Running Lamp Jumper ....................30

Daytime Running Lamp Module ....................30

Daytime Running Lights Module Connector ............84

Defrost Switch ..............................47

Dimmer Switch\eadlamp .......................1,36

Dimmer Switch-Optical Horn ....................1,36

Diode 49

Distributor 2.2L, 2.5L ..........................15

Distributor 3.0L ..............................18

Distributor Ignition Coil ..................... .14, 22

Dome Lamp System ....................... .39, 40

Cargo Lamp ..............................40

Dome Lamp ..............................40

Glove Box Lamp ............................39

Glove Box Lamp Switch .......................39

Left Front Door Jamb Switch ....................39

Left Rear Door Jamb Switch ....................40

Liftgate Latch Switch .........................40

Right Front Door Jamb Switch ...................39

Right Rear Door Jamb Switch ...................40

Door and Rear Speakers (Radio) ...................66

Door Jamb Switches ....................... .39, 40

Door Lock System-2 Door .................... .61, 62

Door Lock System-4 Door .................... .63, 64

Engine Coolant Temperature Sending Unit .............12

Engine Coolant Temperature Sensor 2.2L ..............15

Engine Coolant Temperature Sensor 2.5L ..............15

Engine Coolant Temperature Sensor 3.0L ..............18

Engine Oil Pressure Sending Unit/Switch ..............12

Engine Oil Pressure Switch .......................12

Engine Oil Pressure and Temperature System ...........12

Engine to Instrument Panel Wiring ..................86

Engine Starter System ....................7,8,9,10

Engine Starter System (Automatic Transmission) .....2,8,10

Back-Up Lamp Switch .........................8

Clutch Pedal Position Jumper ..................8,10

Engine Starter Motor .......................8,10

Engine Starter Relay ........................8,10

Park/Neutral Position Switch .....................8

Transmission EMCC Solenoid ....................8

Engine Starter System (Manual Transmission) ........2,7,9

Back-Up Lamp Switch .......................7,9

Clutch Pedal Position Switch ...................7,9

Engine Starter Motor ........................7,9

Engine Starter Relay ........................7,9

Squib Igniter (Airbag) ........................35

Exhaust Gas Recirculation Solenoid 2.2L ..............13

Ä WIRING DIAGRAMS AP BODY D-P 8W - 717

Page 1952 of 2438

(16) Connect the battery ground (negative) cable.

Test the operation of the lights and horns. If applica-

ble, reset the clock and radio.

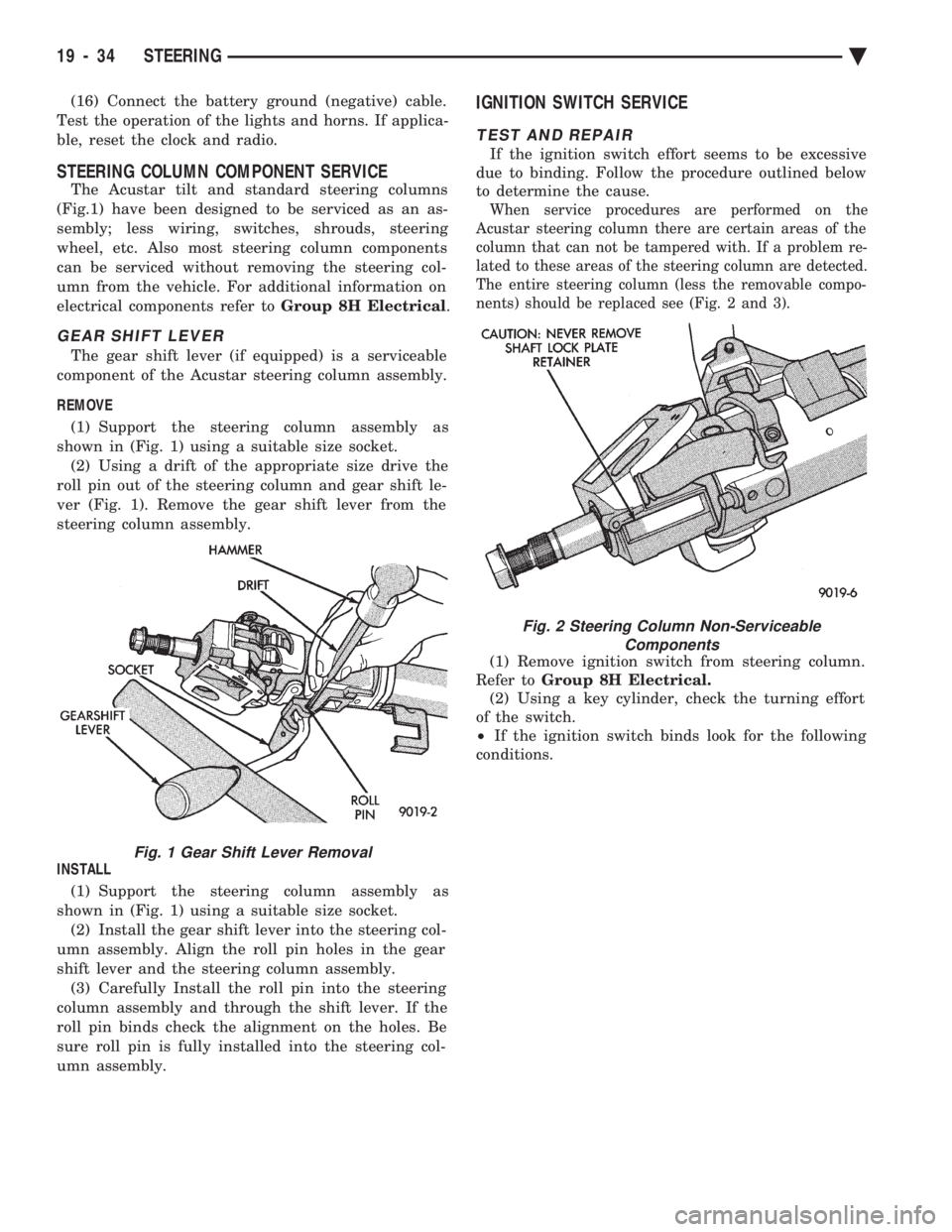

STEERING COLUMN COMPONENT SERVICE

The Acustar tilt and standard steering columns

(Fig.1) have been designed to be serviced as an as-

sembly; less wiring, switches, shrouds, steering

wheel, etc. Also most steering column components

can be serviced without removing the steering col-

umn from the vehicle. For additional information on

electrical components refer to Group 8H Electrical.

GEAR SHIFT LEVER

The gear shift lever (if equipped) is a serviceable

component of the Acustar steering column assembly.

REMOVE (1) Support the steering column assembly as

shown in (Fig. 1) using a suitable size socket. (2) Using a drift of the appropriate size drive the

roll pin out of the steering column and gear shift le-

ver (Fig. 1). Remove the gear shift lever from the

steering column assembly.

INSTALL (1) Support the steering column assembly as

shown in (Fig. 1) using a suitable size socket. (2) Install the gear shift lever into the steering col-

umn assembly. Align the roll pin holes in the gear

shift lever and the steering column assembly. (3) Carefully Install the roll pin into the steering

column assembly and through the shift lever. If the

roll pin binds check the alignment on the holes. Be

sure roll pin is fully installed into the steering col-

umn assembly.

IGNITION SWITCH SERVICE

TEST AND REPAIR

If the ignition switch effort seems to be excessive

due to binding. Follow the procedure outlined below

to determine the cause.

When service procedures are performed on the

Acustar steering column there are certain areas of the

column that can not be tampered with. If a problem re-

lated to these areas of the steering column are detected.

The entire steering column (less the removable compo-

nents) should be replaced see (Fig. 2 and 3).

(1) Remove ignition switch from steering column.

Refer to Group 8H Electrical.

(2) Using a key cylinder, check the turning effort

of the switch.

² If the ignition switch binds look for the following

conditions.

Fig. 1 Gear Shift Lever Removal

Fig. 2 Steering Column Non-Serviceable Components

19 - 34 STEERING Ä

Page 2063 of 2438

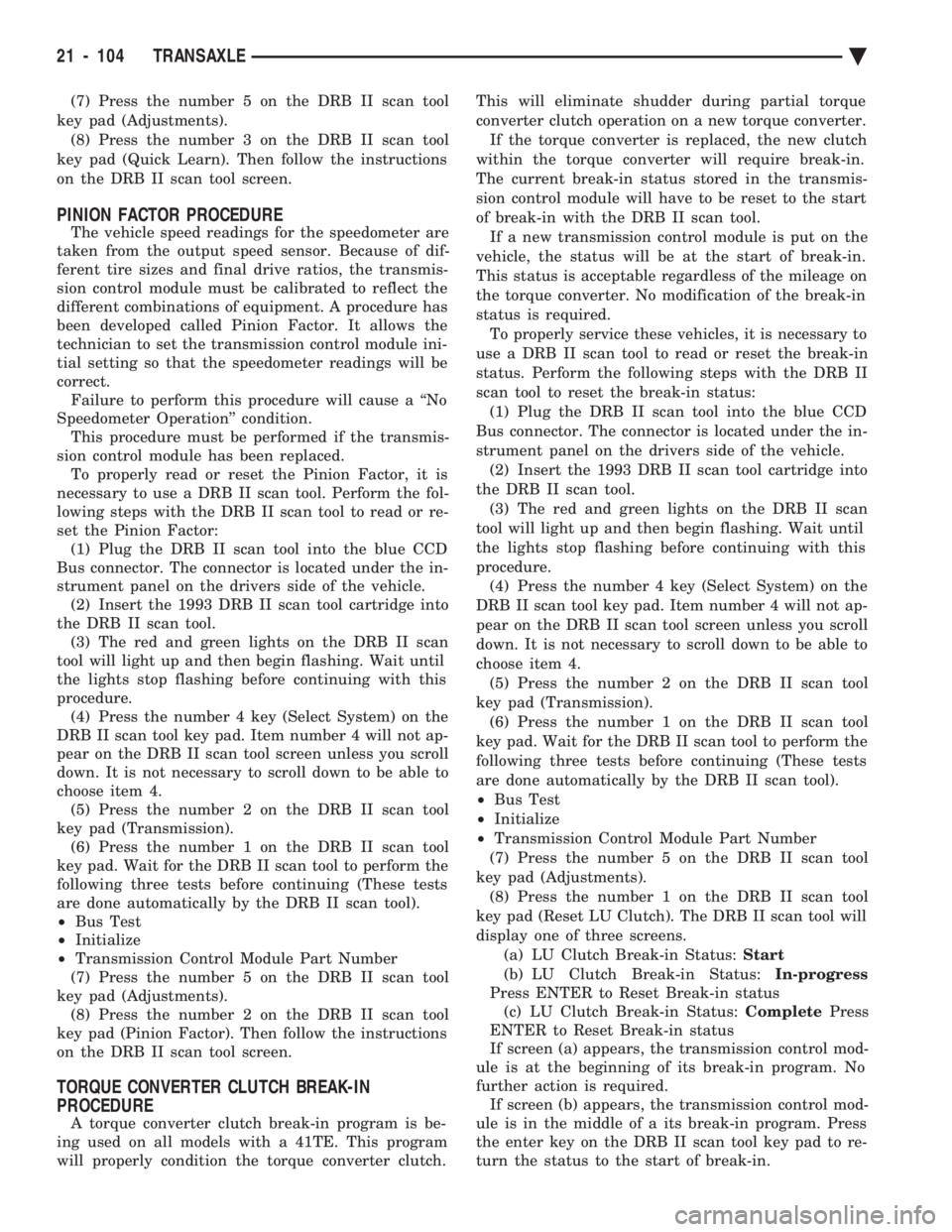

SPEED SENSOR-OUTPUT

CAUTION: When disconnecting speed sensor con-

nector, be sure that the weather seal does not fall

off or remain in old sensor. The output speed sensor is located to the left of the

manual shift lever (Fig. 8).

TRANSMISSION CONTROL MODULE

When replacing a transmission control module, do

not interchange transmission control modules with

previous year transmission control modules. If a

same year transmission control module is being used

from a different vehicle, the following procedures

must be performed before operating the transaxle:

² Quick Learn Procedure

² Torque Converter Clutch Break-in Procedure

² Electronic Pinion Procedure

The transmission control module is located on the

passenger side of the engine compartment. It is held

in place by four mounting screws. If the transmission control module has been

replaced, the following procedures must be per-

formed:

² ``Quick Learn Procedure''. This procedure will al-

low the transmission control module to learn the

characteristics of the vehicle.

² ``Electronic Pinion Procedure''. This procedure will

reprogram settings within the transmission control

module to compensate for different tire sizes and fi-

nal drive ratios.

² ``Converter Clutch Break-In Procedure'' This proce-

dure will reset the torque converter clutch status.

REMOVAL AND INSTALLATION

(1) Loosen 60 way retaining screw, located in the

center of the 60 way connector. Then disconnect the

60 way connector on transmission control module. (2) Remove transmission control module mounting

screws and lift module from vehicle. To install, reverse removal procedure.

TRANSAXLE QUICK LEARN PROCEDURE

The quick learn procedure requires the use of the

DRB II scan tool and the 1993 DRB II scan tool car-

tridge. This program allows the electronic transaxle sys-

tem to recelebrate itself to provide the best possible

transaxle operation. The quick learn procedure

should be performed if any of the following proce-

dures are performed:

² Transaxle Assembly Replacement

² Transmission Control Module Replacement

² Solenoid Pack Replacement

² Clutch Plate and/or Seal Replacement

² Valve Body Replacement or Recondition

(1) Plug the DRB II scan tool into the blue CCD

Buss connector. The connector is located under the

instrument panel on the drivers side of the vehicle. (2) Insert the 1993 DRB II scan tool cartridge into

the DRB II scan tool. (3) The red and green lights on the DRB II scan

tool will light up and then begin flashing. Wait until

the lights stop flashing before continuing with this

procedure. (4) Press the number 4 key on the DRB II scan

tool key pad. Item number 4 will not appear on the

DRB II scan tool screen unless you scroll down. It is

not necessary to scroll down to be able to choose item

4. (5) Press the number 2 on the DRB II scan tool

key pad (Transmission). (6) Press the number 1 on the DRB II scan tool

key pad. Wait for the DRB II scan tool to perform the

following three tests before continuing (These tests

are done automatically by the DRB II scan tool).

² Buss Test

² Initialize

² Controller Part Number

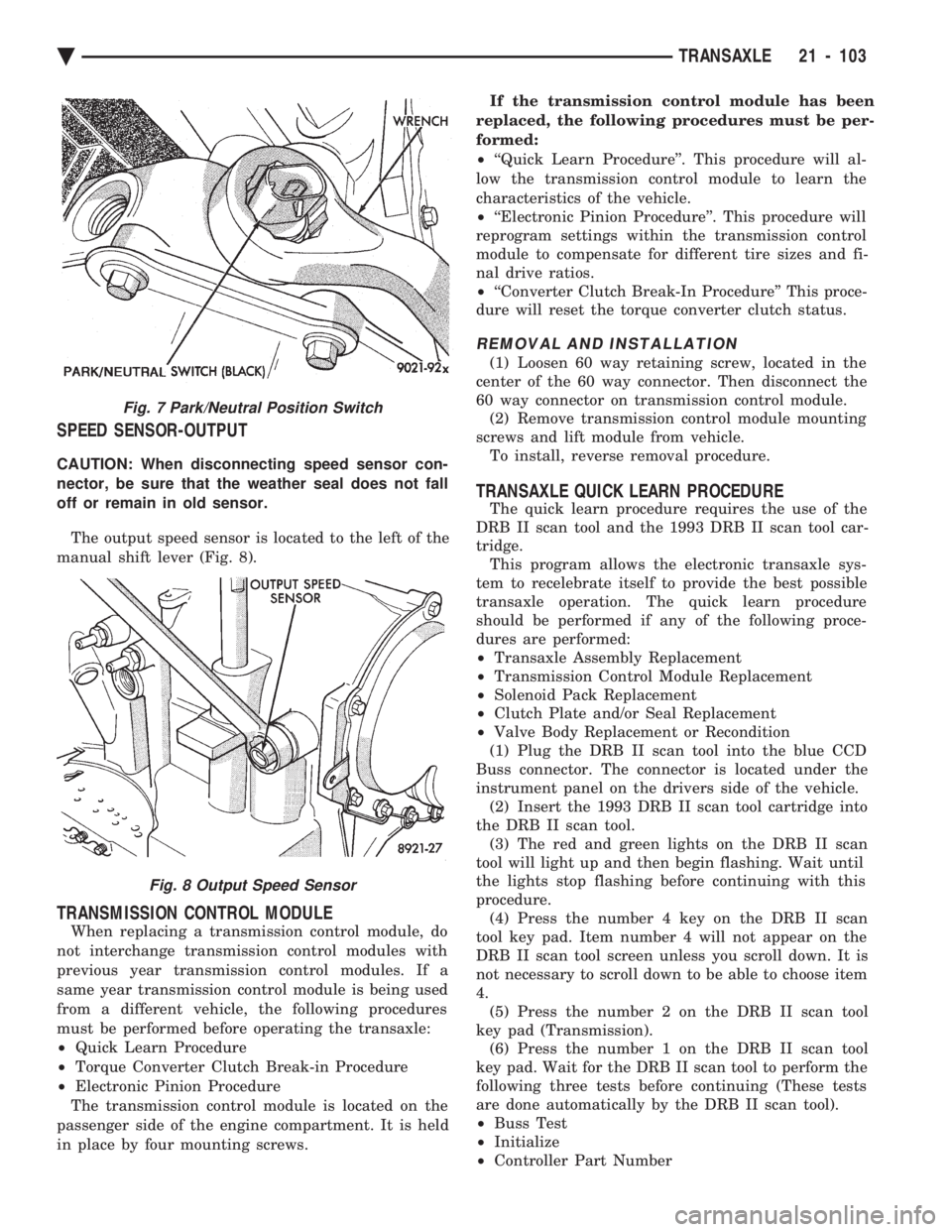

Fig. 7 Park/Neutral Position Switch

Fig. 8 Output Speed Sensor

Ä TRANSAXLE 21 - 103

Page 2064 of 2438

(7) Press the number 5 on the DRB II scan tool

key pad (Adjustments). (8) Press the number 3 on the DRB II scan tool

key pad (Quick Learn). Then follow the instructions

on the DRB II scan tool screen.

PINION FACTOR PROCEDURE

The vehicle speed readings for the speedometer are

taken from the output speed sensor. Because of dif-

ferent tire sizes and final drive ratios, the transmis-

sion control module must be calibrated to reflect the

different combinations of equipment. A procedure has

been developed called Pinion Factor. It allows the

technician to set the transmission control module ini-

tial setting so that the speedometer readings will be

correct. Failure to perform this procedure will cause a ``No

Speedometer Operation'' condition. This procedure must be performed if the transmis-

sion control module has been replaced. To properly read or reset the Pinion Factor, it is

necessary to use a DRB II scan tool. Perform the fol-

lowing steps with the DRB II scan tool to read or re-

set the Pinion Factor: (1) Plug the DRB II scan tool into the blue CCD

Bus connector. The connector is located under the in-

strument panel on the drivers side of the vehicle. (2) Insert the 1993 DRB II scan tool cartridge into

the DRB II scan tool. (3) The red and green lights on the DRB II scan

tool will light up and then begin flashing. Wait until

the lights stop flashing before continuing with this

procedure. (4) Press the number 4 key (Select System) on the

DRB II scan tool key pad. Item number 4 will not ap-

pear on the DRB II scan tool screen unless you scroll

down. It is not necessary to scroll down to be able to

choose item 4. (5) Press the number 2 on the DRB II scan tool

key pad (Transmission). (6) Press the number 1 on the DRB II scan tool

key pad. Wait for the DRB II scan tool to perform the

following three tests before continuing (These tests

are done automatically by the DRB II scan tool).

² Bus Test

² Initialize

² Transmission Control Module Part Number

(7) Press the number 5 on the DRB II scan tool

key pad (Adjustments). (8) Press the number 2 on the DRB II scan tool

key pad (Pinion Factor). Then follow the instructions

on the DRB II scan tool screen.

TORQUE CONVERTER CLUTCH BREAK-IN

PROCEDURE

A torque converter clutch break-in program is be-

ing used on all models with a 41TE. This program

will properly condition the torque converter clutch. This will eliminate shudder during partial torque

converter clutch operation on a new torque converter.

If the torque converter is replaced, the new clutch

within the torque converter will require break-in.

The current break-in status stored in the transmis-

sion control module will have to be reset to the start

of break-in with the DRB II scan tool. If a new transmission control module is put on the

vehicle, the status will be at the start of break-in.

This status is acceptable regardless of the mileage on

the torque converter. No modification of the break-in

status is required. To properly service these vehicles, it is necessary to

use a DRB II scan tool to read or reset the break-in

status. Perform the following steps with the DRB II

scan tool to reset the break-in status: (1) Plug the DRB II scan tool into the blue CCD

Bus connector. The connector is located under the in-

strument panel on the drivers side of the vehicle. (2) Insert the 1993 DRB II scan tool cartridge into

the DRB II scan tool. (3) The red and green lights on the DRB II scan

tool will light up and then begin flashing. Wait until

the lights stop flashing before continuing with this

procedure. (4) Press the number 4 key (Select System) on the

DRB II scan tool key pad. Item number 4 will not ap-

pear on the DRB II scan tool screen unless you scroll

down. It is not necessary to scroll down to be able to

choose item 4. (5) Press the number 2 on the DRB II scan tool

key pad (Transmission). (6) Press the number 1 on the DRB II scan tool

key pad. Wait for the DRB II scan tool to perform the

following three tests before continuing (These tests

are done automatically by the DRB II scan tool).

² Bus Test

² Initialize

² Transmission Control Module Part Number

(7) Press the number 5 on the DRB II scan tool

key pad (Adjustments). (8) Press the number 1 on the DRB II scan tool

key pad (Reset LU Clutch). The DRB II scan tool will

display one of three screens. (a) LU Clutch Break-in Status: Start

(b) LU Clutch Break-in Status: In-progress

Press ENTER to Reset Break-in status (c) LU Clutch Break-in Status: CompletePress

ENTER to Reset Break-in status

If screen (a) appears, the transmission control mod-

ule is at the beginning of its break-in program. No

further action is required. If screen (b) appears, the transmission control mod-

ule is in the middle of a its break-in program. Press

the enter key on the DRB II scan tool key pad to re-

turn the status to the start of break-in.

21 - 104 TRANSAXLE Ä

Page 2158 of 2438

BODY DIAGNOSTIC PROCEDURES INDEX

page page

Water Leaks ............................. 2 Wind Noise.............................. 3

WATER LEAKS

Water leaks can be caused by poor sealing, improper

body component alignment, body seam porosity, miss-

ing plugs, or blocked drain holes. Centrifugal and

gravitational force can cause water to drip from an

area somewhat distant from the actual leak point,

making leak detection difficult. All body sealing points

should be water tight in normal wet driving conditions.

Water flowing downward from the front of the vehicle

should not enter the passenger or luggage compart-

ment. Moving sealing surfaces will not always seal

water tight under all conditions. At times, side glass,

door, or convertible top seals will allow water to enter

the passenger compartment during high pressure

washing or hard driving rain (severe) conditions. Over

compensating on door, glass, or top adjustments to stop

a water leak that occurs under severe conditions, can

cause premature seal wear and excessive closing or

latching effort. After a repair procedure has been

performed, water test vehicle to verify leak has stopped

before returning vehicle to use.

VISUAL INSPECTION BEFORE WATER LEAK TESTS

Verify that floor and body plugs are in place, body

drains are clear and body components are aligned and

sealed. If component alignment or sealing is necessary,

refer to the appropriate section of this group for proper

procedures.

WATER LEAK TESTS

WARNING: DO NOT USE ELECTRIC SHOP LIGHTS

OR TOOLS IN WATER TEST AREA, PERSONAL IN-

JURY CAN RESULT.

When a determination has been made on the condi-

tions that a water leak occurs, simulate the conditions

as closely as possible.

² If a leak occurs when the car is parked in a steady

light rain, flood the leak area with a open ended garden

hose.

² If a leak occurs at highway speeds in a steady rain,

test the leak area with a stream or fan spray of water

from a garden hose with an adjustable nozzle. Direct

the spray in the direction comparable to actual condi-

tions. ²

If a leak seems to occur only when the vehicle is

parked on an incline, hoist the end or side of the vehicle

to simulate this condition before water testing. This

method can also be used when the leak occurs when the

vehicle accelerates, stops, or turns. If the leak occurs

on acceleration, hoist the front of the vehicle. If the

leak occurs when braking, hoist the back of the vehicle.

If the leak occurs on left turns, hoist the left side of the

vehicle. If the leak occurs on right turns, hoist the right

side of the vehicle. For hoisting recommendations refer

to Group 0, Lubrication and Maintenance, General

Information section.

WATER LEAK DETECTION

To detect a water leak point of entry, perform a water

test and watch for water tracks or droplets forming on

the inside if the vehicle. If necessary remove interior

trim covers or panels to gain visual access to the leak

area. If the hose can not be positioned without being

held, have someone help perform the water test. Some water leaks must be tested for a considerable

length of time to become apparent. When a leak ap-

pears, determine the highest point of the water track or

drop. The highest point usually will indicate the point

of entry. After leak point has been determined, repair

the leak and water test to verify that leak has stopped. Locating the entry point of water that is leaking into

a cavity between panels can be difficult. The trapped

water splashes or runs from the cavity it is dammed up

in, often at a distance from the entry point. Most water

leaks of this type become apparent after accelerating,

stopping, turning, or when on a incline.

MIRROR INSPECTION METHOD

When a leak point area is visually obstructed, use a

suitable mirror to gain visual access. A mirror can also

be used to deflect light to a limited access area to assist

in locating a leak point.

BRIGHT LIGHT LEAK TEST METHOD

Some water leaks in the luggage compartment can be

detected without water testing. Position the vehicle in

a brightly light area. From inside the darkened lug-

gage compartment inspect around seals and body

seams. If necessary, have a helper direct a drop light

over the suspected leak areas around the lug-

23 - 2 BODY Ä