lights CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 496 of 2438

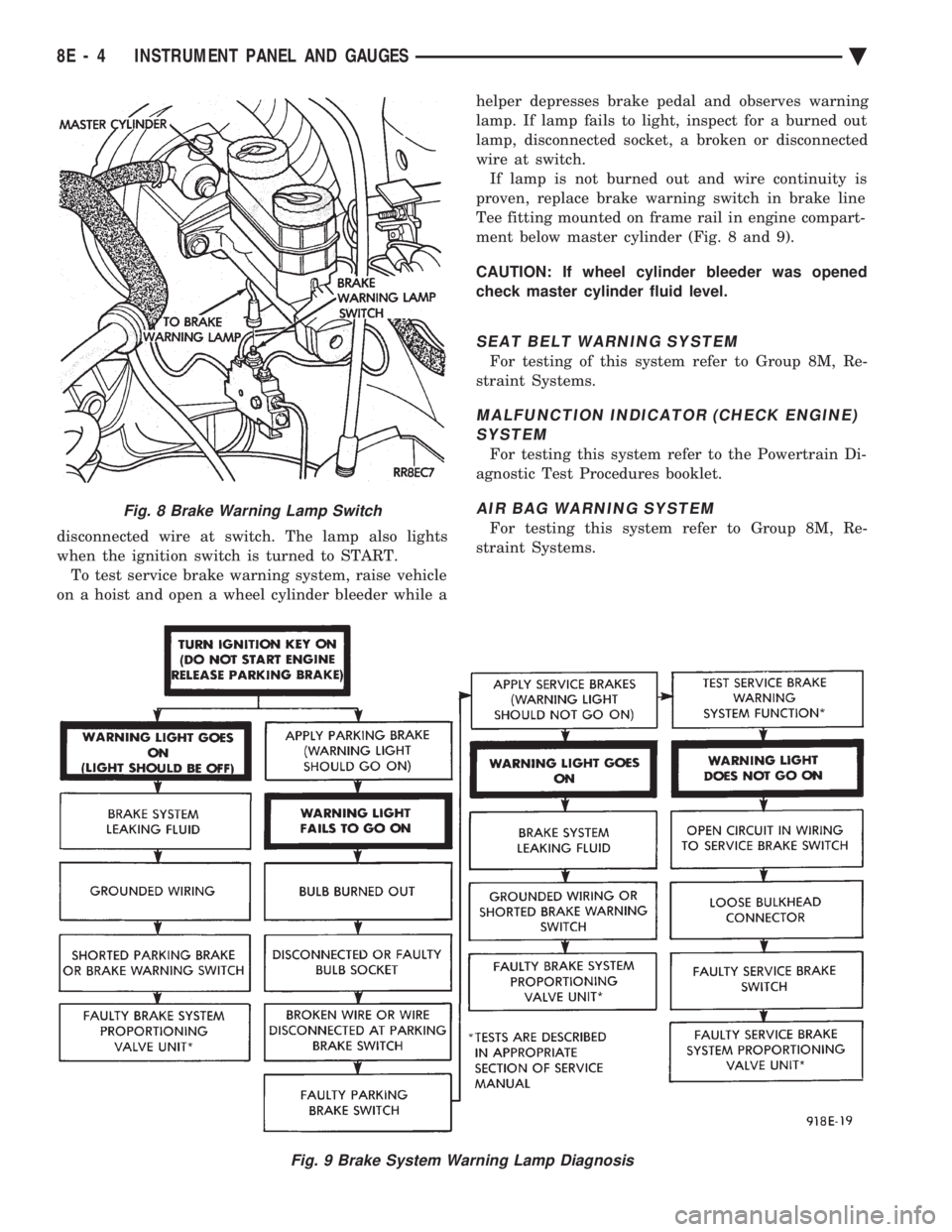

disconnected wire at switch. The lamp also lights

when the ignition switch is turned to START.To test service brake warning system, raise vehicle

on a hoist and open a wheel cylinder bleeder while a helper depresses brake pedal and observes warning

lamp. If lamp fails to light, inspect for a burned out

lamp, disconnected socket, a broken or disconnected

wire at switch. If lamp is not burned out and wire continuity is

proven, replace brake warning switch in brake line

Tee fitting mounted on frame rail in engine compart-

ment below master cylinder (Fig. 8 and 9).

CAUTION: If wheel cylinder bleeder was opened

check master cylinder fluid level.

SEAT BELT WARNING SYSTEM

For testing of this system refer to Group 8M, Re-

straint Systems.

MALFUNCTION INDICATOR (CHECK ENGINE) SYSTEM

For testing this system refer to the Powertrain Di-

agnostic Test Procedures booklet.

AIR BAG WARNING SYSTEM

For testing this system refer to Group 8M, Re-

straint Systems.

Fig. 8 Brake Warning Lamp Switch

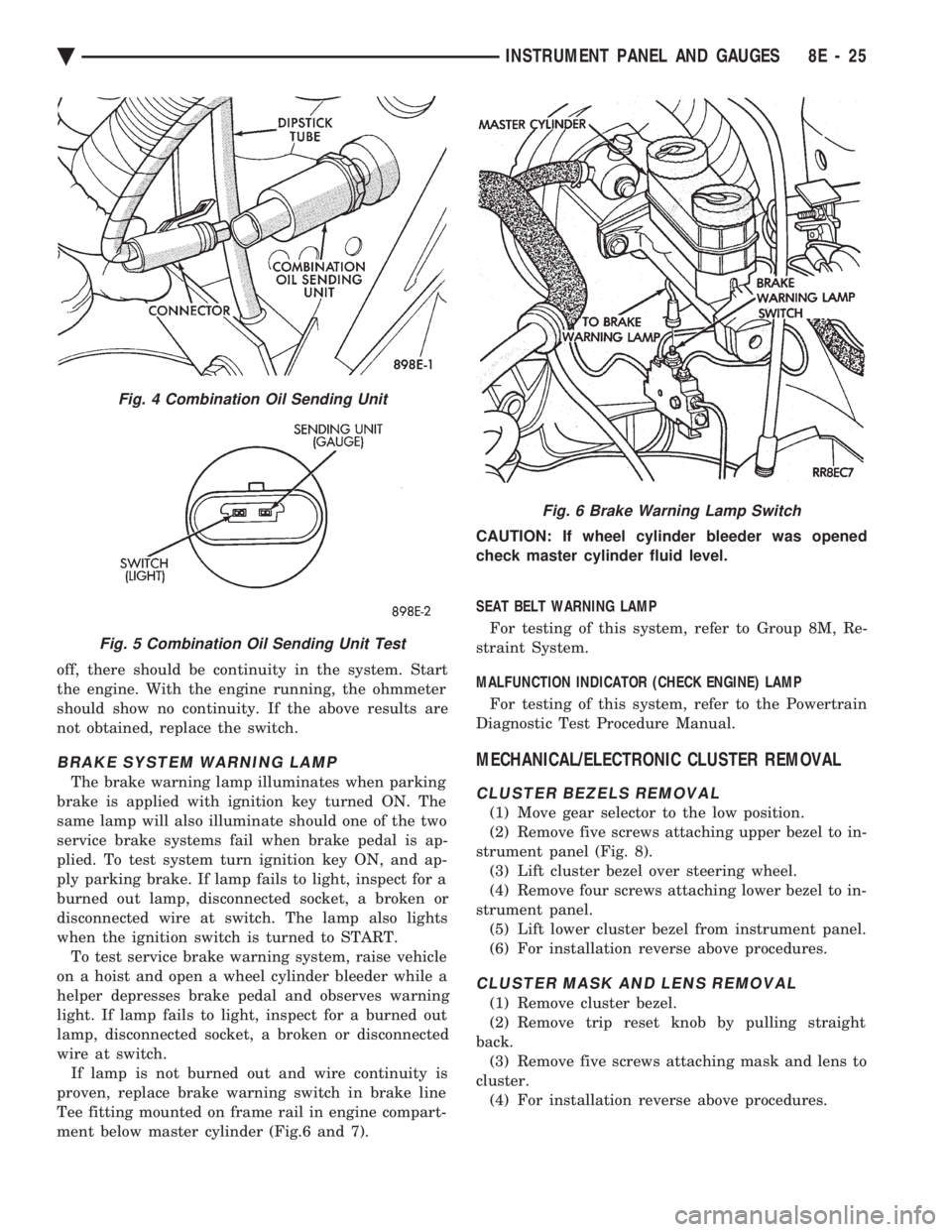

Fig. 9 Brake System Warning Lamp Diagnosis

8E - 4 INSTRUMENT PANEL AND GAUGES Ä

Page 517 of 2438

off, there should be continuity in the system. Start

the engine. With the engine running, the ohmmeter

should show no continuity. If the above results are

not obtained, replace the switch.

BRAKE SYSTEM WARNING LAMP

The brake warning lamp illuminates when parking

brake is applied with ignition key turned ON. The

same lamp will also illuminate should one of the two

service brake systems fail when brake pedal is ap-

plied. To test system turn ignition key ON, and ap-

ply parking brake. If lamp fails to light, inspect for a

burned out lamp, disconnected socket, a broken or

disconnected wire at switch. The lamp also lights

when the ignition switch is turned to START. To test service brake warning system, raise vehicle

on a hoist and open a wheel cylinder bleeder while a

helper depresses brake pedal and observes warning

light. If lamp fails to light, inspect for a burned out

lamp, disconnected socket, a broken or disconnected

wire at switch. If lamp is not burned out and wire continuity is

proven, replace brake warning switch in brake line

Tee fitting mounted on frame rail in engine compart-

ment below master cylinder (Fig.6 and 7). CAUTION: If wheel cylinder bleeder was opened

check master cylinder fluid level.

SEAT BELT WARNING LAMP

For testing of this system, refer to Group 8M, Re-

straint System.

MALFUNCTION INDICATOR (CHECK ENGINE) LAMP

For testing of this system, refer to the Powertrain

Diagnostic Test Procedure Manual.

MECHANICAL/ELECTRONIC CLUSTER REMOVAL

CLUSTER BEZELS REMOVAL

(1) Move gear selector to the low position.

(2) Remove five screws attaching upper bezel to in-

strument panel (Fig. 8). (3) Lift cluster bezel over steering wheel.

(4) Remove four screws attaching lower bezel to in-

strument panel. (5) Lift lower cluster bezel from instrument panel.

(6) For installation reverse above procedures.

CLUSTER MASK AND LENS REMOVAL

(1) Remove cluster bezel.

(2) Remove trip reset knob by pulling straight

back. (3) Remove five screws attaching mask and lens to

cluster. (4) For installation reverse above procedures.

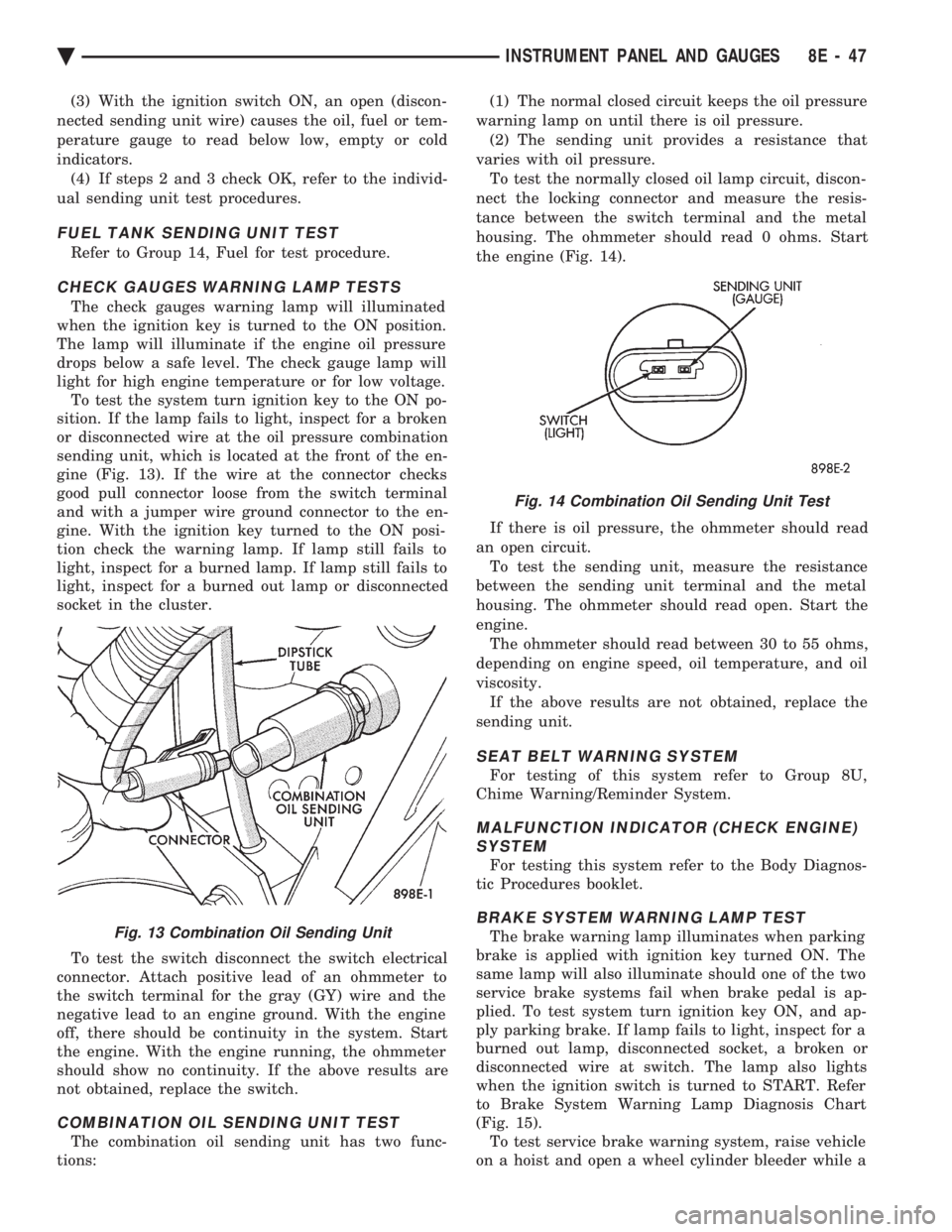

Fig. 4 Combination Oil Sending Unit

Fig. 5 Combination Oil Sending Unit Test

Fig. 6 Brake Warning Lamp Switch

Ä INSTRUMENT PANEL AND GAUGES 8E - 25

Page 539 of 2438

(3) With the ignition switch ON, an open (discon-

nected sending unit wire) causes the oil, fuel or tem-

perature gauge to read below low, empty or cold

indicators. (4) If steps 2 and 3 check OK, refer to the individ-

ual sending unit test procedures.

FUEL TANK SENDING UNIT TEST

Refer to Group 14, Fuel for test procedure.

CHECK GAUGES WARNING LAMP TESTS

The check gauges warning lamp will illuminated

when the ignition key is turned to the ON position.

The lamp will illuminate if the engine oil pressure

drops below a safe level. The check gauge lamp will

light for high engine temperature or for low voltage. To test the system turn ignition key to the ON po-

sition. If the lamp fails to light, inspect for a broken

or disconnected wire at the oil pressure combination

sending unit, which is located at the front of the en-

gine (Fig. 13). If the wire at the connector checks

good pull connector loose from the switch terminal

and with a jumper wire ground connector to the en-

gine. With the ignition key turned to the ON posi-

tion check the warning lamp. If lamp still fails to

light, inspect for a burned lamp. If lamp still fails to

light, inspect for a burned out lamp or disconnected

socket in the cluster.

To test the switch disconnect the switch electrical

connector. Attach positive lead of an ohmmeter to

the switch terminal for the gray (GY) wire and the

negative lead to an engine ground. With the engine

off, there should be continuity in the system. Start

the engine. With the engine running, the ohmmeter

should show no continuity. If the above results are

not obtained, replace the switch.

COMBINATION OIL SENDING UNIT TEST

The combination oil sending unit has two func-

tions: (1) The normal closed circuit keeps the oil pressure

warning lamp on until there is oil pressure. (2) The sending unit provides a resistance that

varies with oil pressure. To test the normally closed oil lamp circuit, discon-

nect the locking connector and measure the resis-

tance between the switch terminal and the metal

housing. The ohmmeter should read 0 ohms. Start

the engine (Fig. 14).

If there is oil pressure, the ohmmeter should read

an open circuit. To test the sending unit, measure the resistance

between the sending unit terminal and the metal

housing. The ohmmeter should read open. Start the

engine. The ohmmeter should read between 30 to 55 ohms,

depending on engine speed, oil temperature, and oil

viscosity. If the above results are not obtained, replace the

sending unit.

SEAT BELT WARNING SYSTEM

For testing of this system refer to Group 8U,

Chime Warning/Reminder System.

MALFUNCTION INDICATOR (CHECK ENGINE) SYSTEM

For testing this system refer to the Body Diagnos-

tic Procedures booklet.

BRAKE SYSTEM WARNING LAMP TEST

The brake warning lamp illuminates when parking

brake is applied with ignition key turned ON. The

same lamp will also illuminate should one of the two

service brake systems fail when brake pedal is ap-

plied. To test system turn ignition key ON, and ap-

ply parking brake. If lamp fails to light, inspect for a

burned out lamp, disconnected socket, a broken or

disconnected wire at switch. The lamp also lights

when the ignition switch is turned to START. Refer

to Brake System Warning Lamp Diagnosis Chart

(Fig. 15). To test service brake warning system, raise vehicle

on a hoist and open a wheel cylinder bleeder while aFig. 13 Combination Oil Sending Unit

Fig. 14 Combination Oil Sending Unit Test

Ä INSTRUMENT PANEL AND GAUGES 8E - 47

Page 550 of 2438

AP BODY INDEX

page page

Cluster and Gauge Service and Testing ....... 58

Gauges ................................ 61

General Information ....................... 58 Instrument Panel Replacement

.............. 72

Interior Lamp Replacement ................. 73

Switch and Panel Component Service ......... 67

GENERAL INFORMATION

INSTRUMENT CLUSTER

There are two conventional instrument cluster as-

semblies available. The clusters incorporates mag-

netic type gauges and an electronically driven

speedometer and odometer assembly (Fig. 1 and 2).

MAGNETIC GAUGES

All gauges on the AP Body clusters are the mag-

netic type gauges. When the ignition switch is in the

OFF position each gauge, except for the voltmeter

and tachometer will show a reading. However, the

readings are only accurate when the ignition switch

is in the ON position.

TACHOMETER DRIVE MODULE

The tachometer drive module is an electronic mod-

ule used to drive the magnetic tachometer in the

high line cluster. This module is located on top of the instrument

cluster.

ELECTRONIC DIGITAL CLOCK

The electronic digital clock is in the radio. The

clock and radio each use the display panel built into

the radio. A digital readout indicates the time in

hours and minutes whenever the ignition switch is in

the ON or ACC position. When the ignition switch is in the OFF position, or

when the radio frequency is being displayed, time

keeping is accurately maintained. The procedure for setting the clock varies slightly

with each radio. The correct procedure is described

under the individual radio operating instructions re-

fer to the Sound Systems Manual supplied with the

vehicle.

WARNING LAMPS AND INDICATOR LIGHTS

The instrument cluster has warning and indicators

lamps for eight different systems:

² Low oil pressure

² Brake warning

² Seat belt warning

² Malfunction indicator (check engine) lamp

² Air Bag

² High beam indicator

² Right and left turn signals.

² Anti-lock (ABS)

CLUSTER AND GAUGE SERVICE AND TESTING

CAUTION: Disconnect the negative battery cable

before servicing the instrument panel. When power

is required for test purposes, reconnect battery ca-

ble for test only. Disconnect the negative battery

cable after test and before continuing service pro-

cedures.

SENDING UNIT TEST

Check for a defective sending unit or wiring, when

a problem occurs with a cluster gauge. Do this before

disassembling the cluster. (1) Sending units and wiring can be checked by

grounding the connector leads, at the sending unit,

in the vehicle. (2) With the ignition in the ON position, a

grounded input will cause the fuel or temperature

gauge to read at or above maximum.

Fig. 1 Instrument Cluster With Tachometer

Fig. 2 Instrument Cluster Without Tachometer

8E - 58 INSTRUMENT PANEL AND GAUGES Ä

Page 551 of 2438

FUEL TANK SENDING UNIT TEST

Refer to Group 14, Fuel for test procedures.

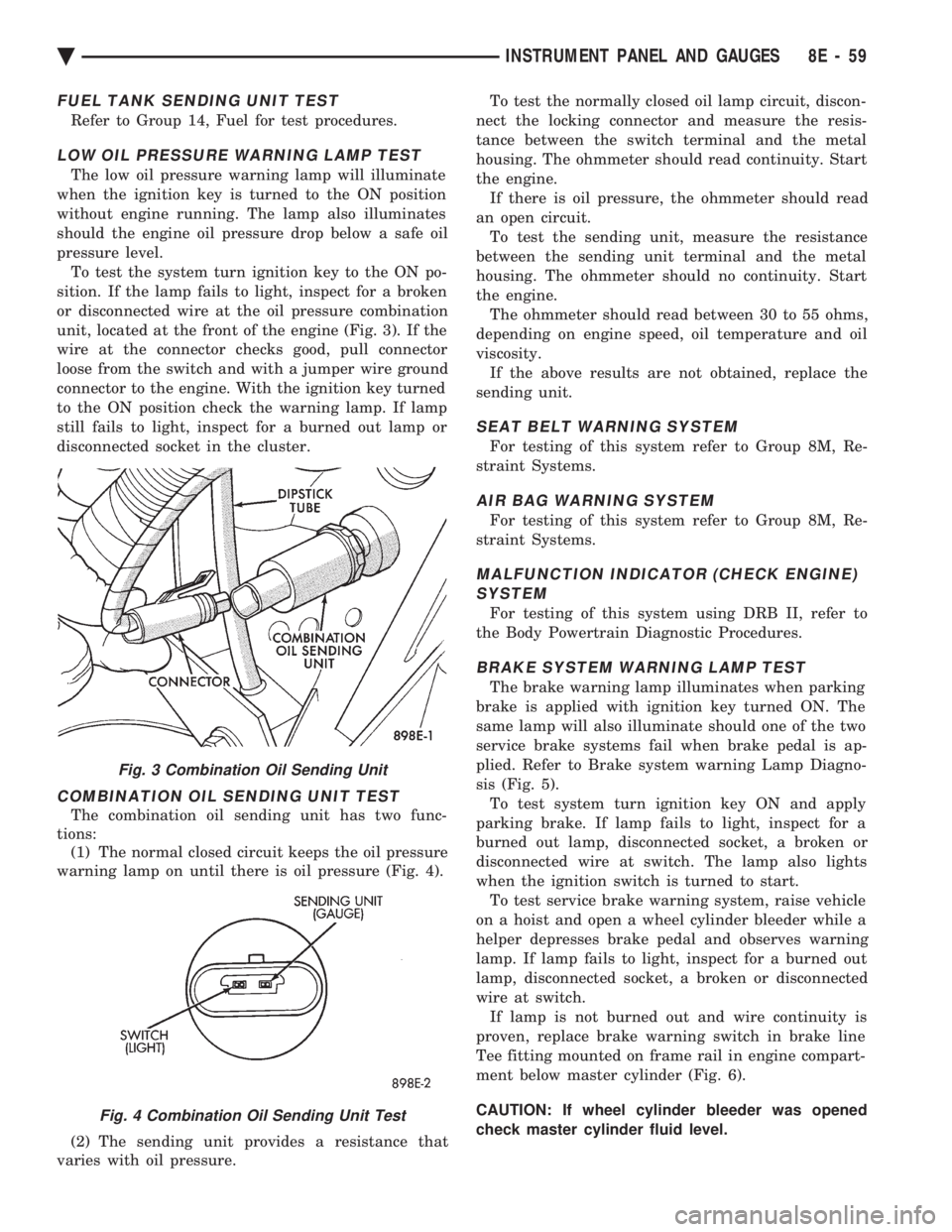

LOW OIL PRESSURE WARNING LAMP TEST

The low oil pressure warning lamp will illuminate

when the ignition key is turned to the ON position

without engine running. The lamp also illuminates

should the engine oil pressure drop below a safe oil

pressure level. To test the system turn ignition key to the ON po-

sition. If the lamp fails to light, inspect for a broken

or disconnected wire at the oil pressure combination

unit, located at the front of the engine (Fig. 3). If the

wire at the connector checks good, pull connector

loose from the switch and with a jumper wire ground

connector to the engine. With the ignition key turned

to the ON position check the warning lamp. If lamp

still fails to light, inspect for a burned out lamp or

disconnected socket in the cluster.

COMBINATION OIL SENDING UNIT TEST

The combination oil sending unit has two func-

tions: (1) The normal closed circuit keeps the oil pressure

warning lamp on until there is oil pressure (Fig. 4).

(2) The sending unit provides a resistance that

varies with oil pressure. To test the normally closed oil lamp circuit, discon-

nect the locking connector and measure the resis-

tance between the switch terminal and the metal

housing. The ohmmeter should read continuity. Start

the engine. If there is oil pressure, the ohmmeter should read

an open circuit. To test the sending unit, measure the resistance

between the sending unit terminal and the metal

housing. The ohmmeter should no continuity. Start

the engine. The ohmmeter should read between 30 to 55 ohms,

depending on engine speed, oil temperature and oil

viscosity. If the above results are not obtained, replace the

sending unit.

SEAT BELT WARNING SYSTEM

For testing of this system refer to Group 8M, Re-

straint Systems.

AIR BAG WARNING SYSTEM

For testing of this system refer to Group 8M, Re-

straint Systems.

MALFUNCTION INDICATOR (CHECK ENGINE) SYSTEM

For testing of this system using DRB II, refer to

the Body Powertrain Diagnostic Procedures.

BRAKE SYSTEM WARNING LAMP TEST

The brake warning lamp illuminates when parking

brake is applied with ignition key turned ON. The

same lamp will also illuminate should one of the two

service brake systems fail when brake pedal is ap-

plied. Refer to Brake system warning Lamp Diagno-

sis (Fig. 5). To test system turn ignition key ON and apply

parking brake. If lamp fails to light, inspect for a

burned out lamp, disconnected socket, a broken or

disconnected wire at switch. The lamp also lights

when the ignition switch is turned to start. To test service brake warning system, raise vehicle

on a hoist and open a wheel cylinder bleeder while a

helper depresses brake pedal and observes warning

lamp. If lamp fails to light, inspect for a burned out

lamp, disconnected socket, a broken or disconnected

wire at switch. If lamp is not burned out and wire continuity is

proven, replace brake warning switch in brake line

Tee fitting mounted on frame rail in engine compart-

ment below master cylinder (Fig. 6).

CAUTION: If wheel cylinder bleeder was opened

check master cylinder fluid level.

Fig. 3 Combination Oil Sending Unit

Fig. 4 Combination Oil Sending Unit Test

Ä INSTRUMENT PANEL AND GAUGES 8E - 59

Page 595 of 2438

² If no short to ground at connector, check speaker

resistance at amplifier connector for an reading of

three to five ohms.

² If resistance is OK, refer to Radio Diagnosis. If ra-

dio checks OK, replace amplifier.

² If resistance is less than three ohms check

speaker. Check across the speaker connector if less

than three ohms replace speaker. If resistance is OK

repair wires

CONDITION: MECHANICAL NOISE DISTORTION

² Check trim for loose parts and speaker attach-

ments for buzzes

² Remove speaker still connected and listen for dis-

tortion. Distortion replace speaker.

CONDITION: ONE SPEAKER NON-OPERATIVE

² Remove output signal connector from amplifier

and check for three to five ohms resistance to the

non-operative speaker. Refer to Fig. 34 for the appro-

priate pin numbers.

² If resistance is less than three ohms, test speaker

for resistance.

² If OK repair wire. If not replace speaker.

CONDITION: ALL SPEAKERS NON-OPERATIVE

²Check radio for being ON, are the display lights

on

² Radio not ON, refer to Radio Diagnosis

² Check Amplifier Connectors and wires for proper

connection

² Check pin 9 and pin 27 for battery voltage

² If voltage OK replace amplifier ²

If pin 27 has battery voltage and pin 9 has 0 volt-

age. Refer to Power Antenna Diagnosis and test volt-

age at antenna relay.

² If pin 9 has battery voltage and pin 27 has 0 volt-

age. Check pin 27 for short to ground.

² If shorted to ground repair wire

² If no short to ground check fuse cavity number 16

for blown fuse.

² If fuse blows again replace amplifier

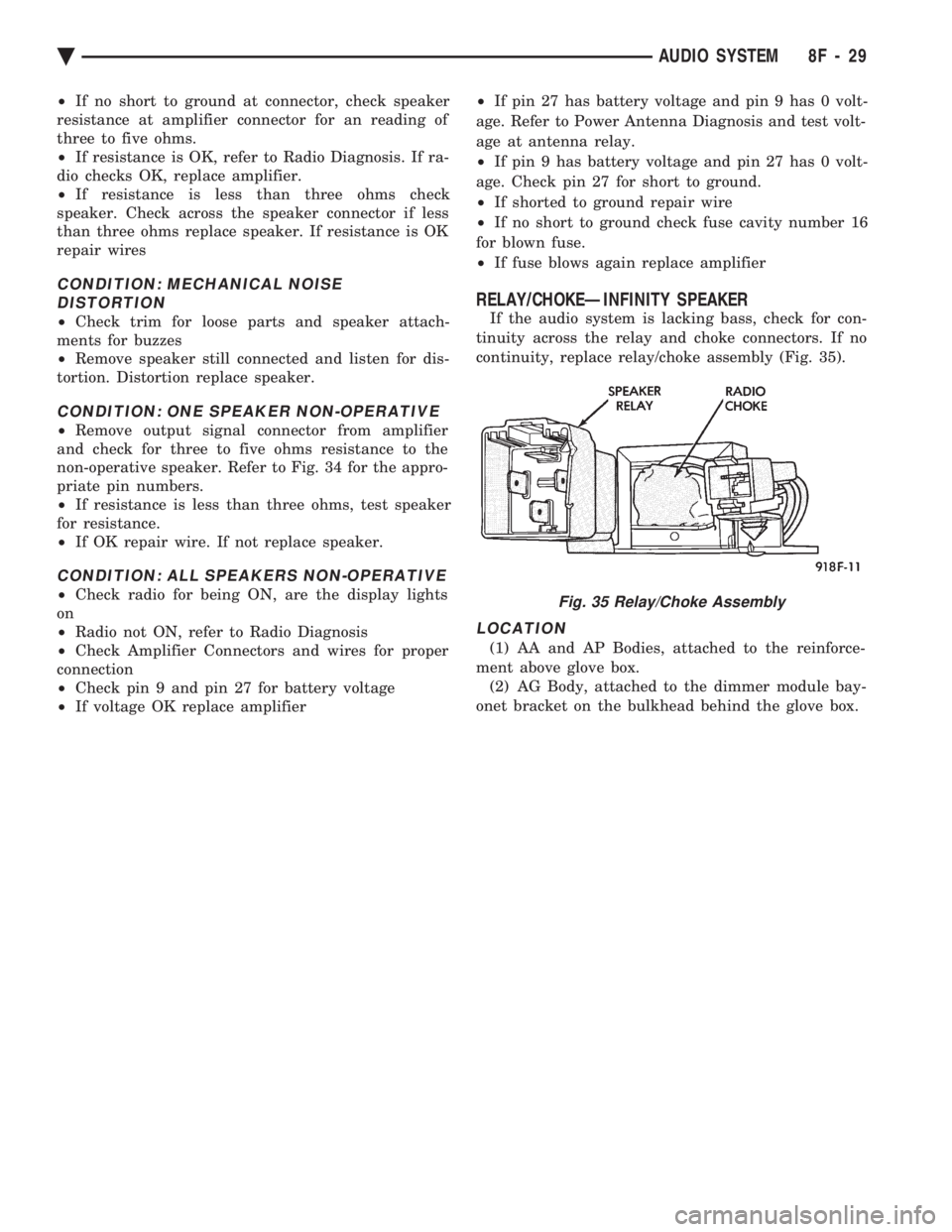

RELAY/CHOKEÐINFINITY SPEAKER

If the audio system is lacking bass, check for con-

tinuity across the relay and choke connectors. If no

continuity, replace relay/choke assembly (Fig. 35).

LOCATION

(1) AA and AP Bodies, attached to the reinforce-

ment above glove box. (2) AG Body, attached to the dimmer module bay-

onet bracket on the bulkhead behind the glove box.

Fig. 35 Relay/Choke Assembly

Ä AUDIO SYSTEM 8F - 29

Page 597 of 2438

HORNS

CONTENTS

page page

GENERAL INFORMATION .................. 1

HORN SWITCH REPLACEMENT ............ 3 TESTING HORN SYSTEM

................. 1

GENERAL INFORMATION

WARNING: ON VEHICLES EQUIPPED WITH AIR

BAG, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

STEERING WHEEL OR COLUMN REMOVAL PROCE-

DURES.

The horn circuit consists of a horn switch, horn re-

lay, and horns. The horn circuit feed is from the fuse

box to the number 1 terminal on the horn relay.

When the horn switch is depressed, this completes

the circuit to ground. This activates the horn relay

and an set of contacts in the relay to close, which al-

lows current to flow to the horn(s). The horn ground

wire is attached to the headlamp ground screw (Fig.

1).

TESTING HORN SYSTEM

HORNS WILL NOT SOUND

If the horns do not sound, check for a blown horn

fuse in the fuse block. If the fuse is blown, replace it

with the same fuse type. If the horns fail to sound

and the new fuse blows when depressing the horn

switch, a short circuit in the horn or the horn wiring

between the fuse terminal and the horn is responsi-

ble. If the fuse is good, disconnect wire connector at

horn. Using an test lamp, connect one lead to the

negative terminal and the other to the positive ter-

minal (Fig. 2). Depress the horn switch, the test

lamp should illuminate. If not connect the test lamp wire to a good ground and depress the horn switch. If

test lamp lights inspect ground wire circuit and re-

pair as needed.

If the test lamp fails to illuminate, check for a de-

fective horn relay. Substituting a known good horn

relay in the circuit. If the test lamp illuminates

when depressing the horn switch, the original relay

is defective. If the test lamp fails to illuminate with

a known good relay, unplug that relay. Connect a

jumper wire from the battery terminal to the horn

terminal on the relay terminal board (Fig. 3, 4, or 5).

If the test lamp connected in place of the horns, fails

to illuminate an open circuit in the wiring between

the relay terminal and the horn switch is at fault re-

pair as necessary.

HORNS SOUND CONTINUOUSLY

CAUTION: Continuous sounding of horns may

cause relay to fail.

Should the horns sound continuously, unplug the

horn relay from the terminal board inside the pas-

senger compartment. Plug in a known good relay. If

the horns stop blowing, relay is defective and must

be replaced. Should the horns still sound, proceed as

follows: Connect one voltmeter lead to battery termi-

nal on relay board and the other lead to switch ter-

minal. Refer to Figs. 6, 7, or 8. Voltmeter will

Fig. 1 Conventional Horn System

Fig. 2 Horn and Connector

Ä HORNS 8G - 1

Page 625 of 2438

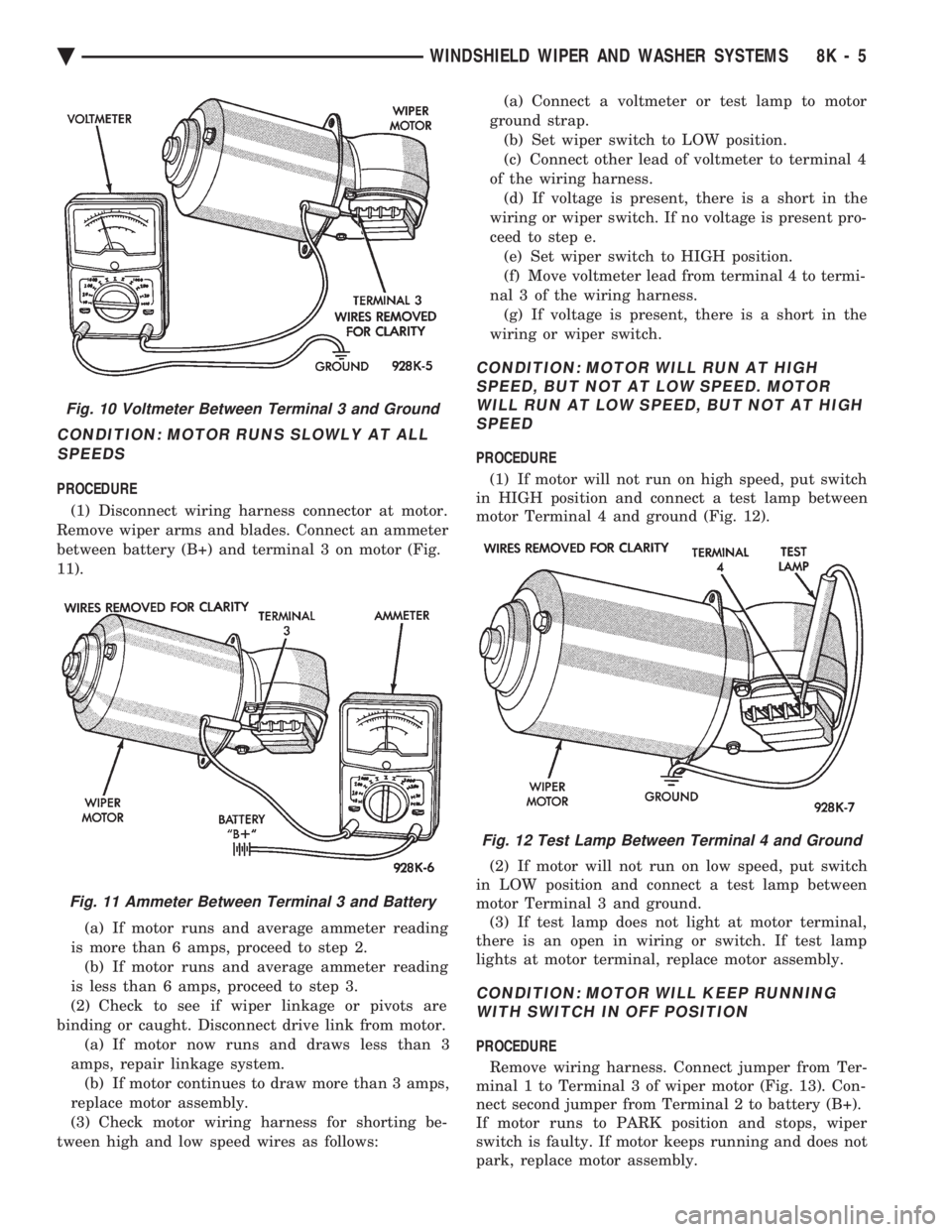

CONDITION: MOTOR RUNS SLOWLY AT ALL SPEEDS

PROCEDURE

(1) Disconnect wiring harness connector at motor.

Remove wiper arms and blades. Connect an ammeter

between battery (B+) and terminal 3 on motor (Fig.

11).

(a) If motor runs and average ammeter reading

is more than 6 amps, proceed to step 2. (b) If motor runs and average ammeter reading

is less than 6 amps, proceed to step 3.

(2) Check to see if wiper linkage or pivots are

binding or caught. Disconnect drive link from motor. (a) If motor now runs and draws less than 3

amps, repair linkage system. (b) If motor continues to draw more than 3 amps,

replace motor assembly.

(3) Check motor wiring harness for shorting be-

tween high and low speed wires as follows: (a) Connect a voltmeter or test lamp to motor

ground strap. (b) Set wiper switch to LOW position.

(c) Connect other lead of voltmeter to terminal 4

of the wiring harness. (d) If voltage is present, there is a short in the

wiring or wiper switch. If no voltage is present pro-

ceed to step e. (e) Set wiper switch to HIGH position.

(f) Move voltmeter lead from terminal 4 to termi-

nal 3 of the wiring harness. (g) If voltage is present, there is a short in the

wiring or wiper switch.

CONDITION: MOTOR WILL RUN AT HIGH SPEED, BUT NOT AT LOW SPEED. MOTORWILL RUN AT LOW SPEED, BUT NOT AT HIGHSPEED

PROCEDURE

(1) If motor will not run on high speed, put switch

in HIGH position and connect a test lamp between

motor Terminal 4 and ground (Fig. 12).

(2) If motor will not run on low speed, put switch

in LOW position and connect a test lamp between

motor Terminal 3 and ground. (3) If test lamp does not light at motor terminal,

there is an open in wiring or switch. If test lamp

lights at motor terminal, replace motor assembly.

CONDITION: MOTOR WILL KEEP RUNNING WITH SWITCH IN OFF POSITION

PROCEDURE

Remove wiring harness. Connect jumper from Ter-

minal 1 to Terminal 3 of wiper motor (Fig. 13). Con-

nect second jumper from Terminal 2 to battery (B+).

If motor runs to PARK position and stops, wiper

switch is faulty. If motor keeps running and does not

park, replace motor assembly.

Fig. 10 Voltmeter Between Terminal 3 and Ground

Fig. 11 Ammeter Between Terminal 3 and Battery

Fig. 12 Test Lamp Between Terminal 4 and Ground

Ä WINDSHIELD WIPER AND WASHER SYSTEMS 8K - 5

Page 669 of 2438

CONCEALED HEADLAMPS INDEX

page page

Concealed Headlamp MotorÐAC-Body ........ 29

Diagnostic Procedures ..................... 27

General Information ....................... 27 Headlamp DoorÐAC-Body

................. 29

Headlamp DoorÐAY Body ................. 29

Headlamp Drive MotorÐAY Body ............ 30

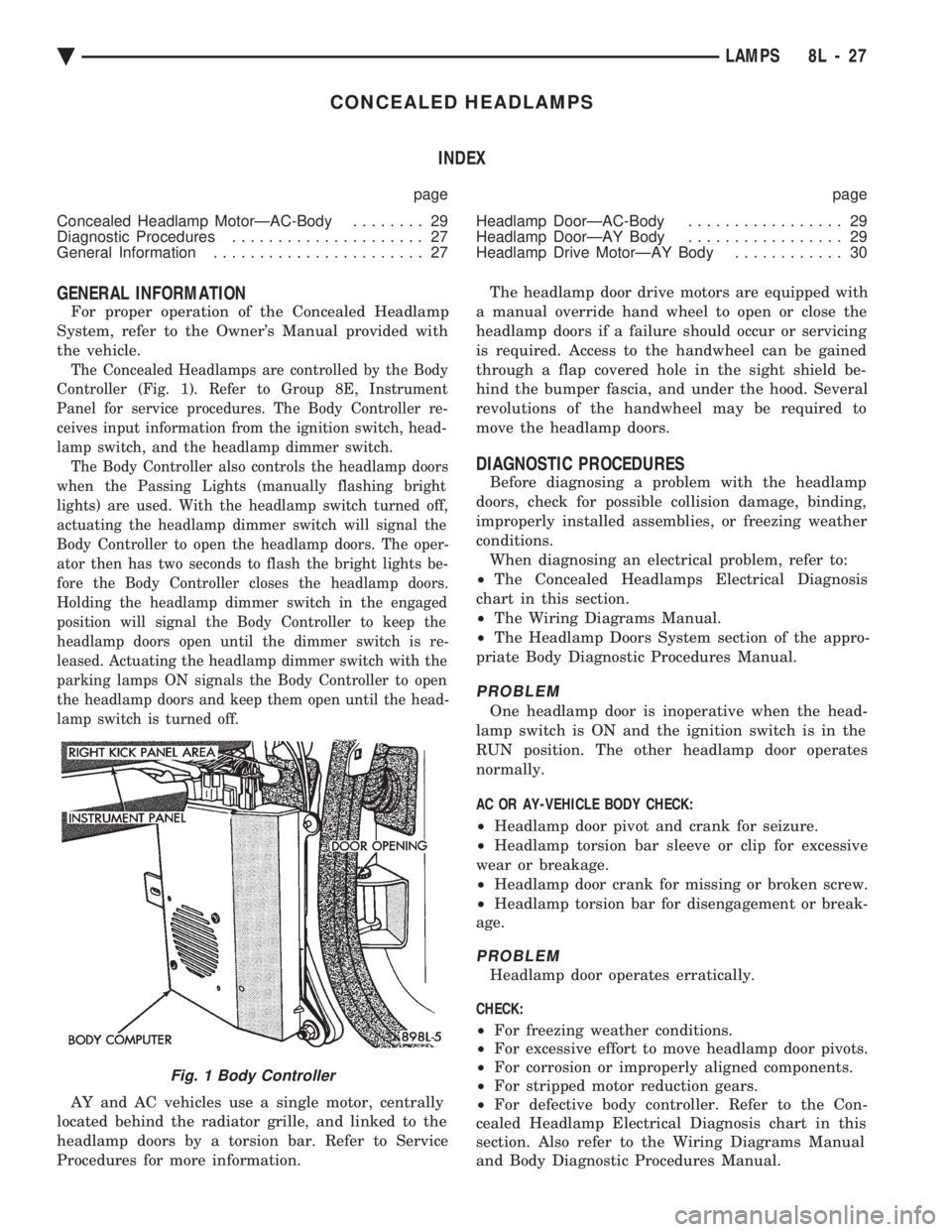

GENERAL INFORMATION

For proper operation of the Concealed Headlamp

System, refer to the Owner's Manual provided with

the vehicle.

The Concealed Headlamps are controlled by the Body

Controller (Fig. 1). Refer to Group 8E, Instrument

Panel for service procedures. The Body Controller re-

ceives input information from the ignition switch, head-

lamp switch, and the headlamp dimmer switch. The Body Controller also controls the headlamp doors

when the Passing Lights (manually flashing bright

lights) are used. With the headlamp switch turned off,

actuating the headlamp dimmer switch will signal the

Body Controller to open the headlamp doors. The oper-

ator then has two seconds to flash the bright lights be-

fore the Body Controller closes the headlamp doors.

Holding the headlamp dimmer switch in the engaged

position will signal the Body Controller to keep the

headlamp doors open until the dimmer switch is re-

leased. Actuating the headlamp dimmer switch with the

parking lamps ON signals the Body Controller to open

the headlamp doors and keep them open until the head-

lamp switch is turned off.

AY and AC vehicles use a single motor, centrally

located behind the radiator grille, and linked to the

headlamp doors by a torsion bar. Refer to Service

Procedures for more information. The headlamp door drive motors are equipped with

a manual override hand wheel to open or close the

headlamp doors if a failure should occur or servicing

is required. Access to the handwheel can be gained

through a flap covered hole in the sight shield be-

hind the bumper fascia, and under the hood. Several

revolutions of the handwheel may be required to

move the headlamp doors.

DIAGNOSTIC PROCEDURES

Before diagnosing a problem with the headlamp

doors, check for possible collision damage, binding,

improperly installed assemblies, or freezing weather

conditions. When diagnosing an electrical problem, refer to:

² The Concealed Headlamps Electrical Diagnosis

chart in this section.

² The Wiring Diagrams Manual.

² The Headlamp Doors System section of the appro-

priate Body Diagnostic Procedures Manual.

PROBLEM

One headlamp door is inoperative when the head-

lamp switch is ON and the ignition switch is in the

RUN position. The other headlamp door operates

normally.

AC OR AY-VEHICLE BODY CHECK:

² Headlamp door pivot and crank for seizure.

² Headlamp torsion bar sleeve or clip for excessive

wear or breakage.

² Headlamp door crank for missing or broken screw.

² Headlamp torsion bar for disengagement or break-

age.

PROBLEM

Headlamp door operates erratically.

CHECK:

² For freezing weather conditions.

² For excessive effort to move headlamp door pivots.

² For corrosion or improperly aligned components.

² For stripped motor reduction gears.

² For defective body controller. Refer to the Con-

cealed Headlamp Electrical Diagnosis chart in this

section. Also refer to the Wiring Diagrams Manual

and Body Diagnostic Procedures Manual.

Fig. 1 Body Controller

Ä LAMPS 8L - 27

Page 685 of 2438

SERVICE OF DEPLOYED AIR BAG MODULE

After an air bag has been deployed, the air bag

module and clockspring must be replaced because

they cannot be reused. Other air bag system compo-

nents are replaced if damaged.

SCHEDULED MAINTENANCE INSPECTION

Vehicles equipped with a Air Bag System must be

inspected every three years or 30,000 miles / 48,000

Km. The following items should be inspected. (1) Inspect components for damage or deteriora-

tion. (a) If the air bag module housing shows signs of

physical damage or abuse, replace the module. (b) Check that both front impact sensors are

properly installed to the upper crossmember of the

radiator closure panel. Repair as required.

(2) Check the air bag warning lamp for proper op-

eration as follows: (a) Turn ignition switch to the ON position, the

air bag warning lamp should light. If not, test the system using the DRB II and Passive Restraint

System Diagnostic Procedures Manual. Repair as

required.

(b) The air bag warning lamp lights, but fails to go

out after ten seconds. Test the system using the DRB

II and Passive Restraint System Diagnostic Proce-

dures Manual. Repair as required. (c) Erasing of fault codes is not required.

AIR BAG SYSTEM CHECK

WARNING: BEFORE BEGINNING ANY AIR BAG SYS-

TEM CHECK PROCEDURES, REMOVE AND ISOLATE

THE BATTERY NEGATIVE (-) CABLE (GROUND)

FROM THE VEHICLE BATTERY. THIS IS THE ONLY

SURE WAY TO DISABLE THE AIR BAG SYSTEM.

FAILURE TO DO THIS COULD RESULT IN ACCIDEN-

TAL AIR BAG DEPLOYMENT AND POSSIBLE PER-

SONAL INJURY.

WHEN AN UNDEPLOYED AIR BAG ASSEMBLY IS

TO BE REMOVED FROM THE STEERING WHEEL,

DISCONNECT BATTERY GROUND CABLE AND

ISOLATE. ALLOW SYSTEM CAPACITOR TO DIS-

CHARGE FOR TWO MINUTES, THEN BEGIN AIR

BAG REMOVAL. (1) Disconnect the battery negative cable and iso-

late. (2) Remove forward console or cover as necessary.

(3) Connect DRB II to ASDM diagnostic 6-way con-

nector, located at right side of module. (4) Turn the ignition key to ON position. Exit vehicle

with DRB II. Use the latest version of the proper

cartridge. (5) After checking that no one is inside the vehicle,

connect the negative battery cable. (6) Using the DRB II, read and record active fault

data. (7) Read and record any stored faults.

(8) Refer to the Passive Restraint Diagnostic Test

Manual if any faults are found in steps 6 and 7. (9) Erase stored faults if there are no active fault

codes. If problems remain, fault codes will not erase. (10) With the ignition key in the ON position, make

sure no one is in the vehicle. (11) From the passenger side of vehicle, turn the

ignition key to OFF then ON and observe the instru-

ment cluster air bag lamp. It should go on for 6 to 8

seconds, then go out; indicating system is functioning

normally. If air bag warning lamp either fails to light,

blinks on and off or goes on and stays on, there is

a system malfunction. Refer to the Passive Re-

straint Diagnostic Test Manual to diagnose the

problem.

Fig. 3 Seal the Air Bag Exhaust Vents

Fig. 4 Vacuum Heater and A/C Outlets

Ä RESTRAINT SYSTEMS 8M - 3