seats CHEVROLET DYNASTY 1993 Owner's Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 722 of 2438

CONDITION: NO MOVEMENT OF BOTH MEMORY MIRRORS OR ONLY ONE MEMORY MIRROR DURING THE RECALL MODE,MEMORY MIRRORS WILL MOVE ONLY WHENTHE POWER MIRROR SWITCH IS ACTUATED.MEMORY SEAT AND RECLINER MOVE INRECALL.

PROCEDURE

(1) Determine the fault precisely. If all memory

mirror recall movements appear to be missing, first

set the mirrors to two different vertical and horizon-

tal positions for both mirrors. Refer to the General

Information paragraph at the beginning of this sec-

tion for position setting instructions. Try to recall

these set positions that were just placed in memory. (2) Observe for no movement in a specific direction

for a specific mirror. If there is still no movement of

either mirror in any direction, re place the control

module. Perform the memory seat diagnostic self

check so the control module will learn the new soft

limits of the assembly. If the non-movement is in a

specific direction or a specific mirror, continue with

the procedure. (3) Perform the diagnostic self tests, mirror check

mode, to determine if the fault is with a motor or

with a position sensing rheostat circuit. Refer to

Memory Seat and Mirror Diagnostic Self-Tests expla-

nation for further information and understanding of

the diagnostic process and identifying of the fault. If

the fault is with a motor, continue this procedure as

follows in step (4) below. If the fault is with a rheo-

stat, as indicated by the mirror nod in the vertical or

horizontal plane, continue the procedure with step (5)

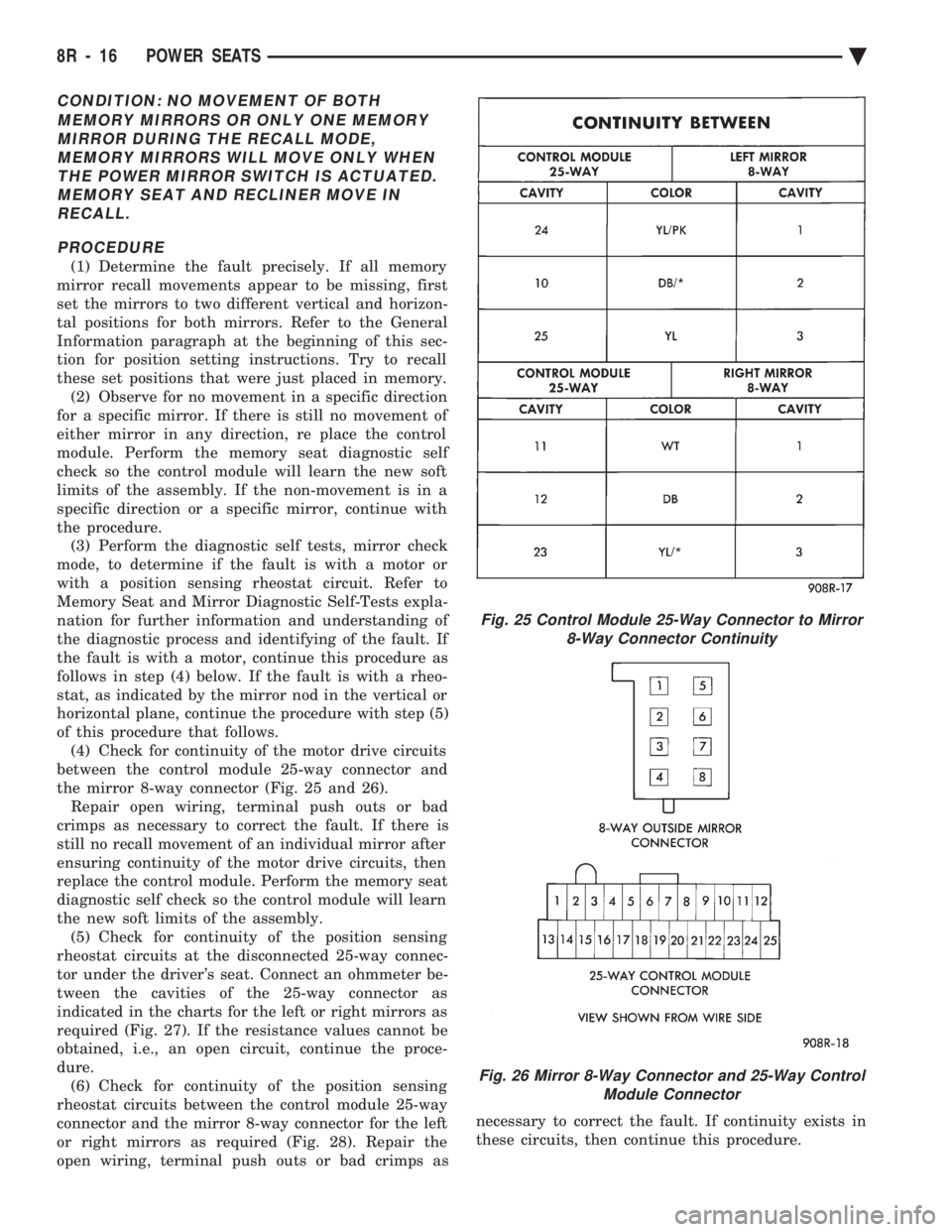

of this procedure that follows. (4) Check for continuity of the motor drive circuits

between the control module 25-way connector and

the mirror 8-way connector (Fig. 25 and 26). Repair open wiring, terminal push outs or bad

crimps as necessary to correct the fault. If there is

still no recall movement of an individual mirror after

ensuring continuity of the motor drive circuits, then

replace the control module. Perform the memory seat

diagnostic self check so the control module will learn

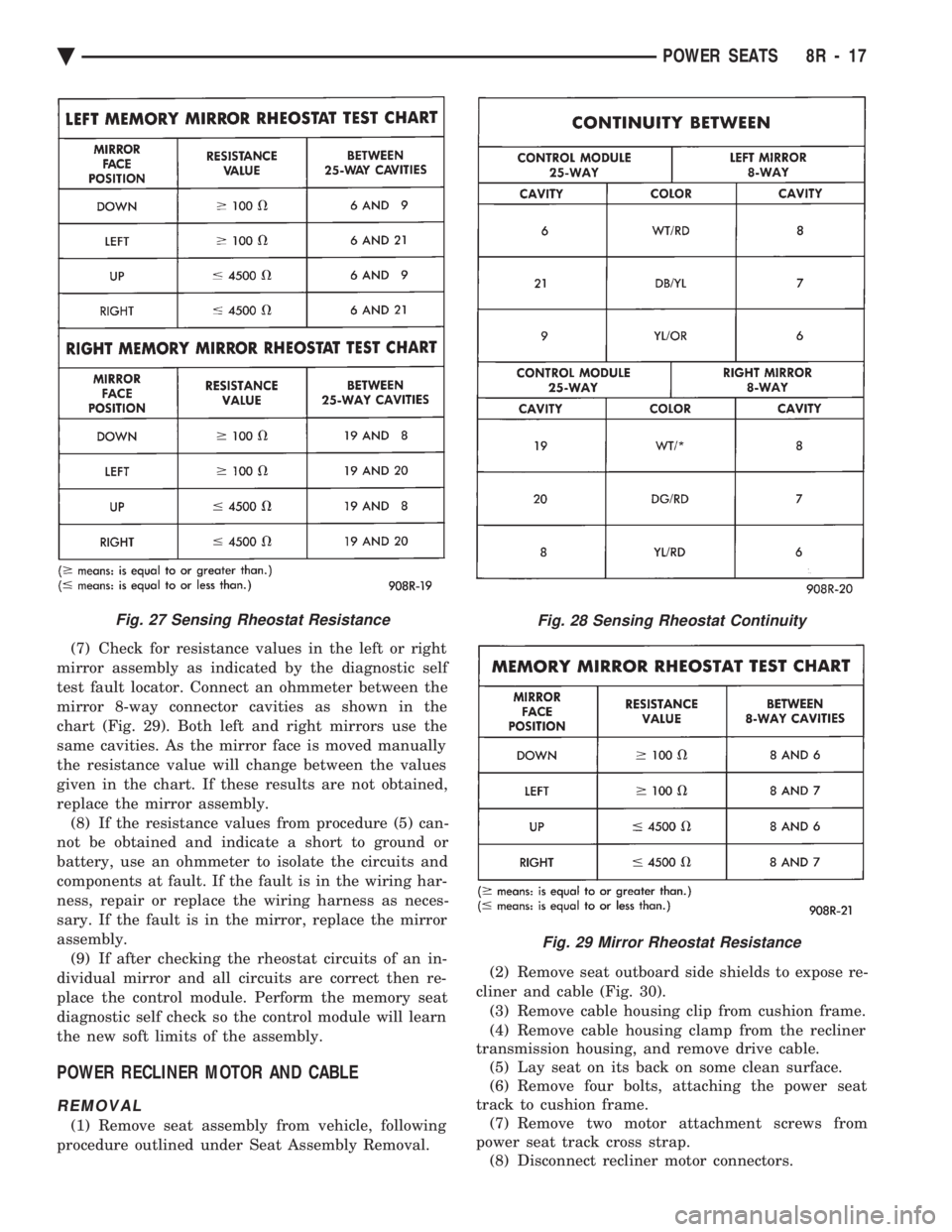

the new soft limits of the assembly. (5) Check for continuity of the position sensing

rheostat circuits at the disconnected 25-way connec-

tor under the driver's seat. Connect an ohmmeter be-

tween the cavities of the 25-way connector as

indicated in the charts for the left or right mirrors as

required (Fig. 27). If the resistance values cannot be

obtained, i.e., an open circuit, continue the proce-

dure. (6) Check for continuity of the position sensing

rheostat circuits between the control module 25-way

connector and the mirror 8-way connector for the left

or right mirrors as required (Fig. 28). Repair the

open wiring, terminal push outs or bad crimps as necessary to correct the fault. If continuity exists in

these circuits, then continue this procedure.

Fig. 25 Control Module 25-Way Connector to Mirror 8-Way Connector Continuity

Fig. 26 Mirror 8-Way Connector and 25-Way Control Module Connector

8R - 16 POWER SEATS Ä

Page 723 of 2438

(7) Check for resistance values in the left or right

mirror assembly as indicated by the diagnostic self

test fault locator. Connect an ohmmeter between the

mirror 8-way connector cavities as shown in the

chart (Fig. 29). Both left and right mirrors use the

same cavities. As the mirror face is moved manually

the resistance value will change between the values

given in the chart. If these results are not obtained,

replace the mirror assembly. (8) If the resistance values from procedure (5) can-

not be obtained and indicate a short to ground or

battery, use an ohmmeter to isolate the circuits and

components at fault. If the fault is in the wiring har-

ness, repair or replace the wiring harness as neces-

sary. If the fault is in the mirror, replace the mirror

assembly. (9) If after checking the rheostat circuits of an in-

dividual mirror and all circuits are correct then re-

place the control module. Perform the memory seat

diagnostic self check so the control module will learn

the new soft limits of the assembly.

POWER RECLINER MOTOR AND CABLE

REMOVAL

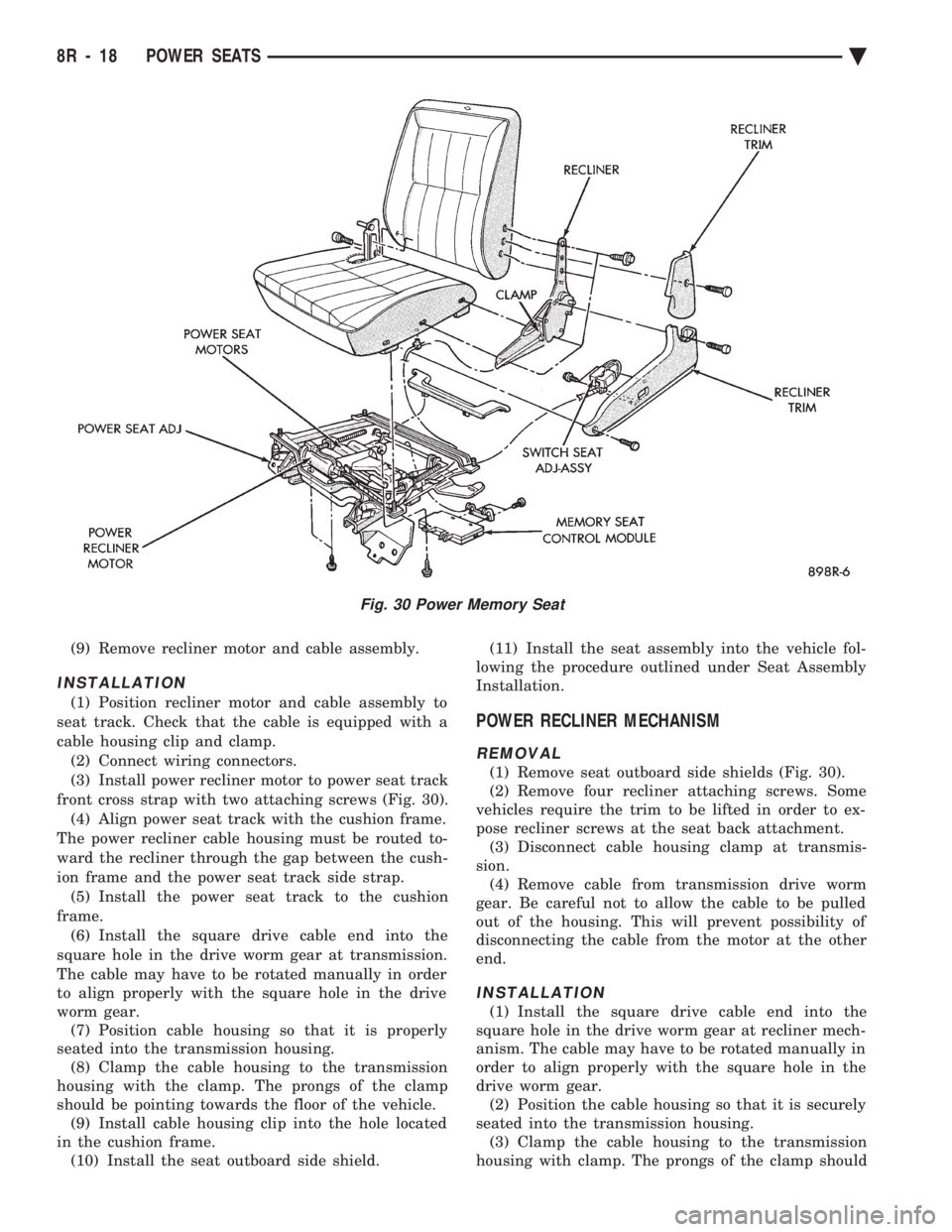

(1) Remove seat assembly from vehicle, following

procedure outlined under Seat Assembly Removal. (2) Remove seat outboard side shields to expose re-

cliner and cable (Fig. 30). (3) Remove cable housing clip from cushion frame.

(4) Remove cable housing clamp from the recliner

transmission housing, and remove drive cable. (5) Lay seat on its back on some clean surface.

(6) Remove four bolts, attaching the power seat

track to cushion frame. (7) Remove two motor attachment screws from

power seat track cross strap. (8) Disconnect recliner motor connectors.

Fig. 27 Sensing Rheostat ResistanceFig. 28 Sensing Rheostat Continuity

Fig. 29 Mirror Rheostat Resistance

Ä POWER SEATS 8R - 17

Page 724 of 2438

(9) Remove recliner motor and cable assembly.

INSTALLATION

(1) Position recliner motor and cable assembly to

seat track. Check that the cable is equipped with a

cable housing clip and clamp. (2) Connect wiring connectors.

(3) Install power recliner motor to power seat track

front cross strap with two attaching screws (Fig. 30). (4) Align power seat track with the cushion frame.

The power recliner cable housing must be routed to-

ward the recliner through the gap between the cush-

ion frame and the power seat track side strap. (5) Install the power seat track to the cushion

frame. (6) Install the square drive cable end into the

square hole in the drive worm gear at transmission.

The cable may have to be rotated manually in order

to align properly with the square hole in the drive

worm gear. (7) Position cable housing so that it is properly

seated into the transmission housing. (8) Clamp the cable housing to the transmission

housing with the clamp. The prongs of the clamp

should be pointing towards the floor of the vehicle. (9) Install cable housing clip into the hole located

in the cushion frame. (10) Install the seat outboard side shield. (11) Install the seat assembly into the vehicle fol-

lowing the procedure outlined under Seat Assembly

Installation.

POWER RECLINER MECHANISM

REMOVAL

(1) Remove seat outboard side shields (Fig. 30).

(2) Remove four recliner attaching screws. Some

vehicles require the trim to be lifted in order to ex-

pose recliner screws at the seat back attachment. (3) Disconnect cable housing clamp at transmis-

sion. (4) Remove cable from transmission drive worm

gear. Be careful not to allow the cable to be pulled

out of the housing. This will prevent possibility of

disconnecting the cable from the motor at the other

end.

INSTALLATION

(1) Install the square drive cable end into the

square hole in the drive worm gear at recliner mech-

anism. The cable may have to be rotated manually in

order to align properly with the square hole in the

drive worm gear. (2) Position the cable housing so that it is securely

seated into the transmission housing. (3) Clamp the cable housing to the transmission

housing with clamp. The prongs of the clamp should

Fig. 30 Power Memory Seat

8R - 18 POWER SEATS Ä

Page 725 of 2438

be pointing towards the floor of the vehicle. (4) Install the four recliner to seat frame fasteners

(Fig. 30). (5) Install seat outboard side shields and fix all

trim so that no foam is exposed. (6) Set system soft limits.

MEMORY CONTROL MODULE REPLACEMENT

(1) Remove seat assembly from vehicle and follow the

procedure outlined under Seat Assembly Removal.

(2) Lay seat on its back on a clean surface.

(3) Remove screws attaching control module to

seat track (Fig. 30). (4) Disconnect control module wiring.

(5) Remove control module.

(6) For installation reverse above procedures. Set

system soft limits by performing the memory seat di-

agnostic self check. So that the control module will

learn the soft limits of the assembly.

RECLINER SWITCH REPLACEMENT

(1) Remove seat side shields (Fig. 30).

(2) Disconnect wiring from switch.

(3) Remove attaching screws from side shields.

(4) Remove switch.

(5) For installation reverse above procedures.

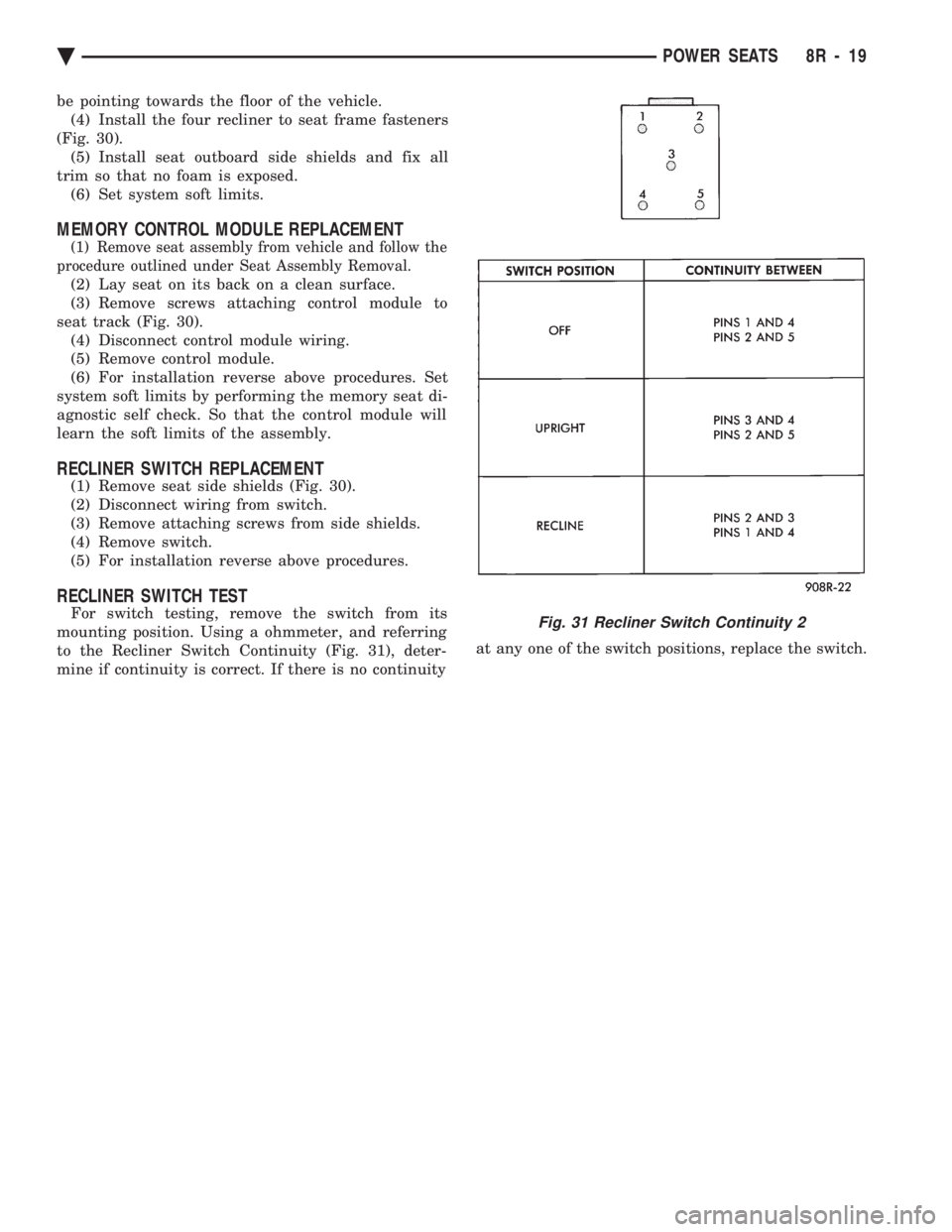

RECLINER SWITCH TEST

For switch testing, remove the switch from its

mounting position. Using a ohmmeter, and referring

to the Recliner Switch Continuity (Fig. 31), deter-

mine if continuity is correct. If there is no continuity at any one of the switch positions, replace the switch.Fig. 31 Recliner Switch Continuity 2

Ä

POWER SEATS 8R - 19

Page 1064 of 2438

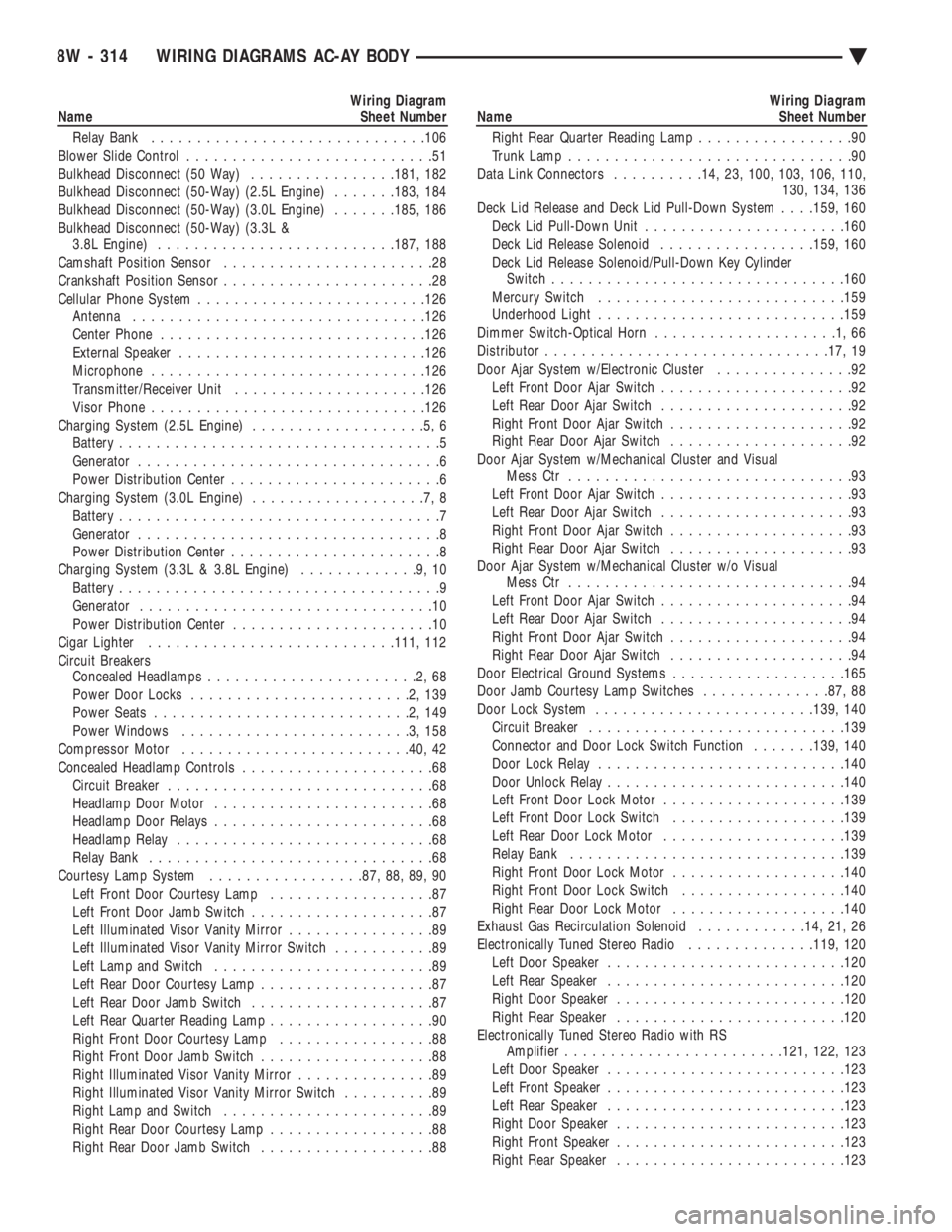

Wiring Diagram

Name Sheet Number

Relay Bank ............................. .106

Blower Slide Control ...........................51

Bulkhead Disconnect (50 Way) ................181, 182

Bulkhead Disconnect (50-Way) (2.5L Engine) .......183, 184

Bulkhead Disconnect (50-Way) (3.0L Engine) .......185, 186

Bulkhead Disconnect (50-Way) (3.3L & 3.8L Engine) ......................... .187, 188

Camshaft Position Sensor .......................28

Crankshaft Position Sensor .......................28

Cellular Phone System ........................ .126

Antenna ............................... .126

Center Phone ............................ .126

External Speaker .......................... .126

Microphone ............................. .126

Transmitter/Receiver Unit .................... .126

Visor Phone ............................. .126

Charging System (2.5L Engine) ...................5,6

Battery ...................................5

Generator .................................6

Power Distribution Center .......................6

Charging System (3.0L Engine) ...................7,8

Battery ...................................7

Generator .................................8

Power Distribution Center .......................8

Charging System (3.3L & 3.8L Engine) .............9,10

Battery ...................................9

Generator ................................10

Power Distribution Center ......................10

Cigar Lighter .......................... .111, 112

Circuit Breakers Concealed Headlamps .......................2,68

Power Door Locks ........................2,139

Power Seats ............................2,149

Power Windows .........................3,158

Compressor Motor ........................ .40, 42

Concealed Headlamp Controls .....................68

Circuit Breaker .............................68

Headlamp Door Motor ........................68

Headlamp Door Relays ........................68

Headlamp Relay ............................68

Relay Bank ...............................68

Courtesy Lamp System .................87, 88, 89, 90

Left Front Door Courtesy Lamp ..................87

Left Front Door Jamb Switch ....................87

Left Illuminated Visor Vanity Mirror ................89

Left Illuminated Visor Vanity Mirror Switch ...........89

Left Lamp and Switch ........................89

Left Rear Door Courtesy Lamp ...................87

Left Rear Door Jamb Switch ....................87

Left Rear Quarter Reading Lamp ..................90

Right Front Door Courtesy Lamp .................88

Right Front Door Jamb Switch ...................88

Right Illuminated Visor Vanity Mirror ...............89

Right Illuminated Visor Vanity Mirror Switch ..........89

Right Lamp and Switch .......................89

Right Rear Door Courtesy Lamp ..................88

Right Rear Door Jamb Switch ...................88Wiring Diagram

Name Sheet Number

Right Rear Quarter Reading Lamp .................90

Trunk Lamp ...............................90

Data Link Connectors ..........14, 23, 100, 103, 106, 110,

130, 134, 136

Deck Lid Release and Deck Lid Pull-Down System . . . .159, 160

Deck Lid Pull-Down Unit ..................... .160

Deck Lid Release Solenoid .................159, 160

Deck Lid Release Solenoid/Pull-Down Key Cylinder Switch ............................... .160

Mercury Switch .......................... .159

Underhood Light .......................... .159

Dimmer Switch-Optical Horn ....................1,66

Distributor .............................. .17, 19

Door Ajar System w/Electronic Cluster ...............92

Left Front Door Ajar Switch .....................92

Left Rear Door Ajar Switch .....................92

Right Front Door Ajar Switch ....................92

Right Rear Door Ajar Switch ....................92

Door Ajar System w/Mechanical Cluster and Visual Mess Ctr ...............................93

Left Front Door Ajar Switch .....................93

Left Rear Door Ajar Switch .....................93

Right Front Door Ajar Switch ....................93

Right Rear Door Ajar Switch ....................93

Door Ajar System w/Mechanical Cluster w/o Visual Mess Ctr ...............................94

Left Front Door Ajar Switch .....................94

Left Rear Door Ajar Switch .....................94

Right Front Door Ajar Switch ....................94

Right Rear Door Ajar Switch ....................94

Door Electrical Ground Systems ...................165

Door Jamb Courtesy Lamp Switches ..............87, 88

Door Lock System ....................... .139, 140

Circuit Breaker ........................... .139

Connector and Door Lock Switch Function .......139, 140

Door Lock Relay .......................... .140

Door Unlock Relay ......................... .140

Left Front Door Lock Motor ................... .139

Left Front Door Lock Switch ...................139

Left Rear Door Lock Motor ................... .139

Relay Bank ............................. .139

Right Front Door Lock Motor ...................140

Right Front Door Lock Switch ..................140

Right Rear Door Lock Motor ...................140

Exhaust Gas Recirculation Solenoid ............14, 21, 26

Electronically Tuned Stereo Radio ..............119, 120

Left Door Speaker ......................... .120

Left Rear Speaker ......................... .120

Right Door Speaker ........................ .120

Right Rear Speaker ........................ .120

Electronically Tuned Stereo Radio with RS Amplifier ....................... .121, 122, 123

Left Door Speaker ......................... .123

Left Front Speaker ......................... .123

Left Rear Speaker ......................... .123

Right Door Speaker ........................ .123

Right Front Speaker ........................ .123

Right Rear Speaker ........................ .123

8W - 314 WIRING DIAGRAMS AC-AY BODY Ä

Page 1068 of 2438

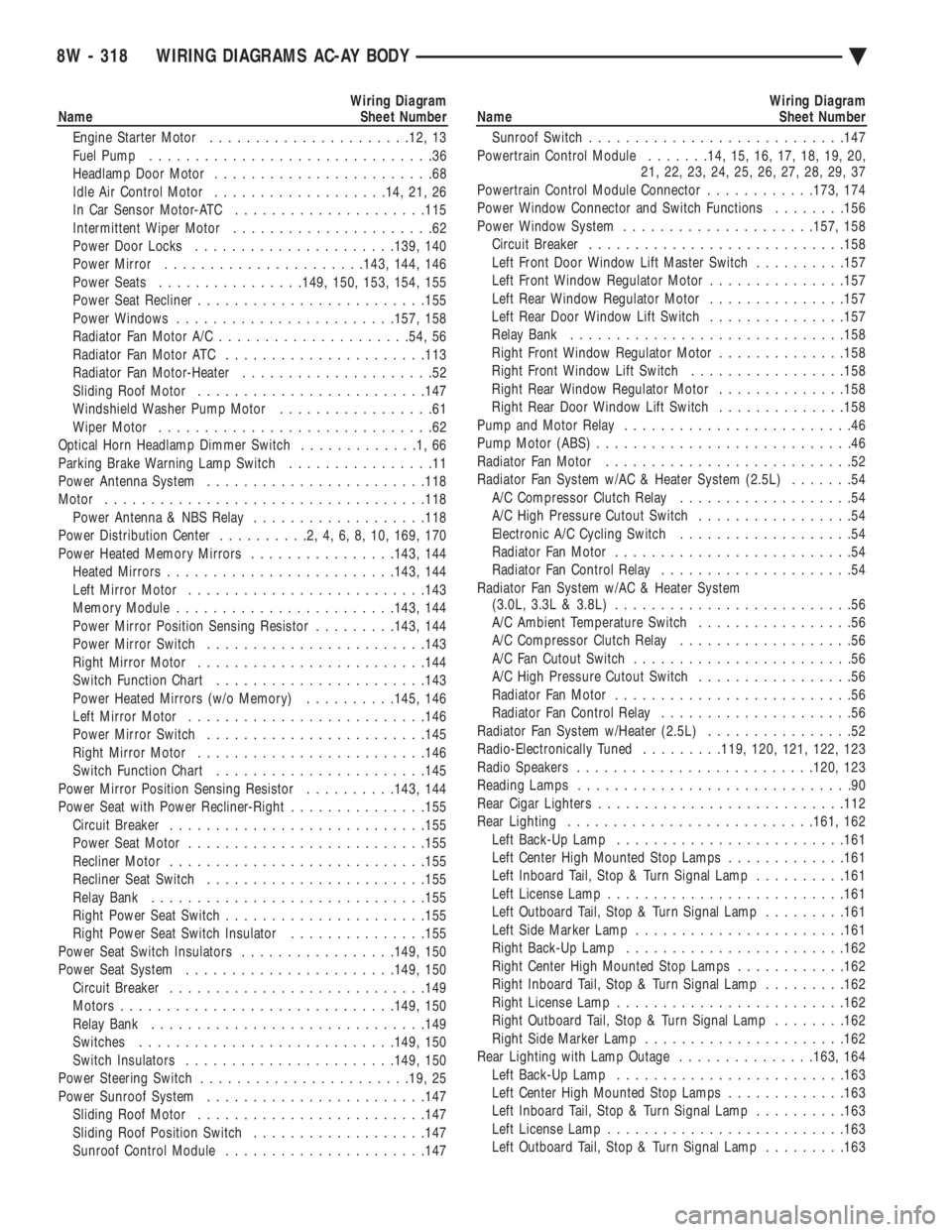

Wiring Diagram

Name Sheet Number

Engine Starter Motor ..................... .12, 13

Fuel Pump ...............................36

Headlamp Door Motor ........................68

Idle Air Control Motor .................. .14, 21, 26

In Car Sensor Motor-ATC .................... .115

Intermittent Wiper Motor ......................62

Power Door Locks ..................... .139, 140

Power Mirror ..................... .143, 144, 146

Power Seats ............... .149, 150, 153, 154, 155

Power Seat Recliner ........................ .155

Power Windows ....................... .157, 158

Radiator Fan Motor A/C .................... .54, 56

Radiator Fan Motor ATC ..................... .113

Radiator Fan Motor-Heater .....................52

Sliding Roof Motor ........................ .147

Windshield Washer Pump Motor .................61

Wiper Motor ..............................62

Optical Horn Headlamp Dimmer Switch .............1,66

Parking Brake Warning Lamp Switch ................11

Power Antenna System ....................... .118

Motor .................................. .118

Power Antenna & NBS Relay ...................118

Power Distribution Center ..........2,4,6,8,10, 169, 170

Power Heated Memory Mirrors ................143, 144

Heated Mirror s........................ .143, 144

Left Mirror Motor ......................... .143

Memory Module ....................... .143, 144

Power Mirror Position Sensing Resistor .........143, 144

Power Mirror Switch ....................... .143

Right Mirror Motor ........................ .144

Switch Function Chart ...................... .143

Power Heated Mirrors (w/o Memory) ..........145, 146

Left Mirror Motor ......................... .146

Power Mirror Switch ....................... .145

Right Mirror Motor ........................ .146

Switch Function Chart ...................... .145

Power Mirror Position Sensing Resistor ..........143, 144

Power Seat with Power Recliner-Right ...............155

Circuit Breaker ........................... .155

Power Seat Motor ......................... .155

Recliner Motor ........................... .155

Recliner Seat Switch ....................... .155

Relay Bank ............................. .155

Right Power Seat Switch ..................... .155

Right Power Seat Switch Insulator ...............155

Power Seat Switch Insulators .................149, 150

Power Seat System ...................... .149, 150

Circuit Breaker ........................... .149

Motors ............................. .149, 150

Relay Bank ............................. .149

Switches ........................... .149, 150

Switch Insulators ...................... .149, 150

Power Steering Switch ...................... .19, 25

Power Sunroof System ....................... .147

Sliding Roof Motor ........................ .147

Sliding Roof Position Switch ...................147

Sunroof Control Module ..................... .147Wiring Diagram

Name Sheet Number

Sunroof Switch ........................... .147

Powertrain Control Module .......14, 15, 16, 17, 18, 19, 20,

21, 22, 23, 24, 25, 26, 27, 28, 29, 37

Powertrain Control Module Connector ............173, 174

Power Window Connector and Switch Functions ........156

Power Window System .................... .157, 158

Circuit Breaker ........................... .158

Left Front Door Window Lift Master Switch ..........157

Left Front Window Regulator Motor ...............157

Left Rear Window Regulator Motor ...............157

Left Rear Door Window Lift Switch ...............157

Relay Bank ............................. .158

Right Front Window Regulator Motor ..............158

Right Front Window Lift Switch .................158

Right Rear Window Regulator Motor ..............158

Right Rear Door Window Lift Switch ..............158

Pump and Motor Relay .........................46

Pump Motor (ABS) ............................46

Radiator Fan Motor ...........................52

Radiator Fan System w/AC & Heater System (2.5L) .......54

A/C Compressor Clutch Relay ...................54

A/C High Pressure Cutout Switch .................54

Electronic A/C Cycling Switch ...................54

Radiator Fan Motor ..........................54

Radiator Fan Control Relay .....................54

Radiator Fan System w/AC & Heater System (3.0L, 3.3L & 3.8L) ..........................56

A/C Ambient Temperature Switch .................56

A/C Compressor Clutch Relay ...................56

A/C Fan Cutout Switch ........................56

A/C High Pressure Cutout Switch .................56

Radiator Fan Motor ..........................56

Radiator Fan Control Relay .....................56

Radiator Fan System w/Heater (2.5L) ................52

Radio-Electronically Tuned .........119, 120, 121, 122, 123

Radio Speakers ......................... .120, 123

Reading Lamps ..............................90

Rear Cigar Lighters .......................... .112

Rear Lighting .......................... .161, 162

Left Back-Up Lamp ........................ .161

Left Center High Mounted Stop Lamps .............161

Left Inboard Tail, Stop & Turn Signal Lamp ..........161

Left License Lamp ......................... .161

Left Outboard Tail, Stop & Turn Signal Lamp .........161

Left Side Marker Lamp ...................... .161

Right Back-Up Lamp ....................... .162

Right Center High Mounted Stop Lamps ............162

Right Inboard Tail, Stop & Turn Signal Lamp .........162

Right License Lamp ........................ .162

Right Outboard Tail, Stop & Turn Signal Lamp ........162

Right Side Marker Lamp ..................... .162

Rear Lighting with Lamp Outage ...............163, 164

Left Back-Up Lamp ........................ .163

Left Center High Mounted Stop Lamps .............163

Left Inboard Tail, Stop & Turn Signal Lamp ..........163

Left License Lamp ......................... .163

Left Outboard Tail, Stop & Turn Signal Lamp .........163

8W - 318 WIRING DIAGRAMS AC-AY BODY Ä

Page 1287 of 2438

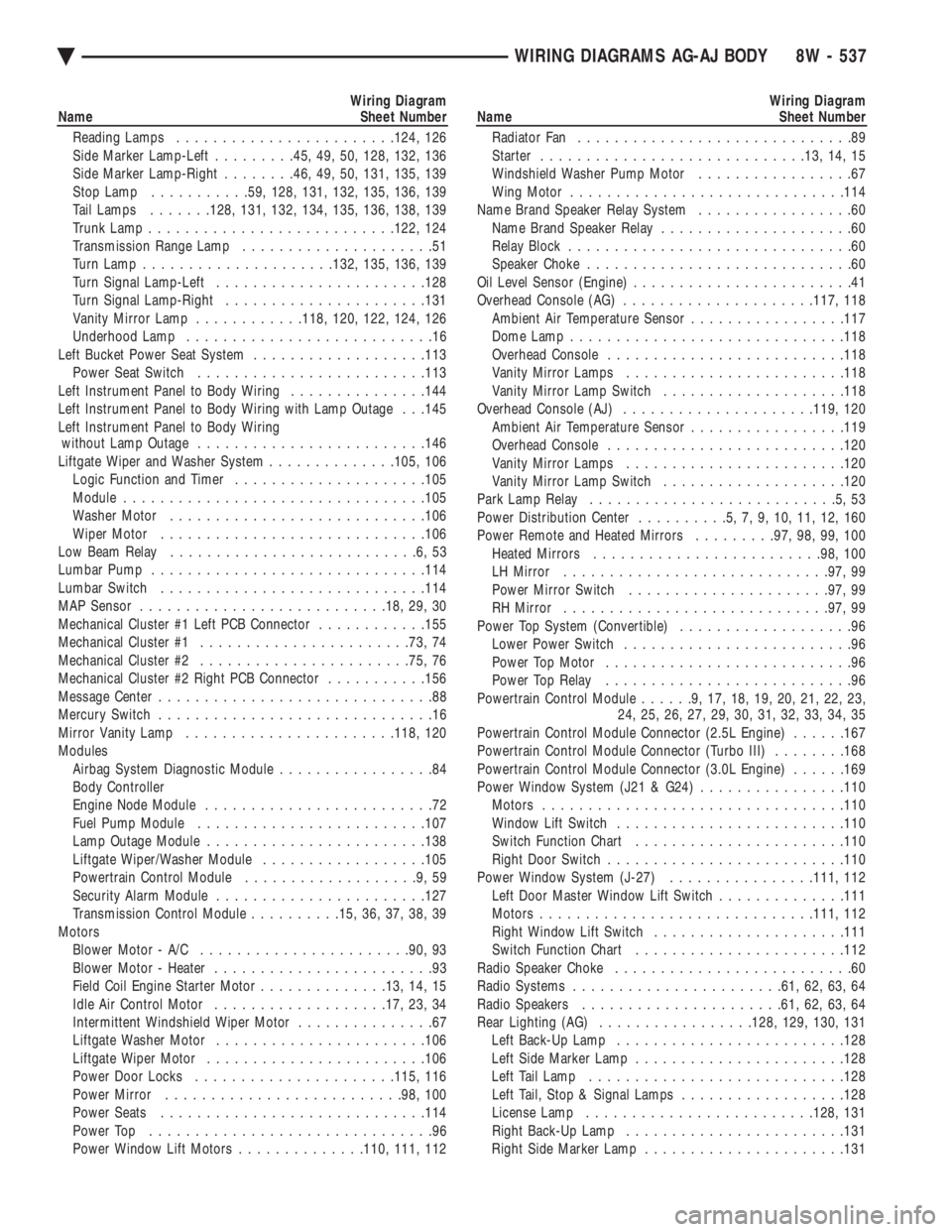

Wiring Diagram

Name Sheet Number

Reading Lamps ....................... .124, 126

Side Marker Lamp-Left .........45, 49, 50, 128, 132, 136

Side Marker Lamp-Right ........46, 49, 50, 131, 135, 139

Stop Lamp .......... .59, 128, 131, 132, 135, 136, 139

Tail Lamps .......128, 131, 132, 134, 135, 136, 138, 139

Trunk Lamp .......................... .122, 124

Transmission Range Lamp .....................51

Turn Lamp .................... .132, 135, 136, 139

Turn Signal Lamp-Left ...................... .128

Turn Signal Lamp-Right ..................... .131

Vanity Mirror Lamp ............118, 120, 122, 124, 126

Underhood Lamp ...........................16

Left Bucket Power Seat System ...................113

Power Seat Switch ........................ .113

Left Instrument Panel to Body Wiring ...............144

Left Instrument Panel to Body Wiring with Lamp Outage . . .145

Left Instrument Panel to Body Wiring without Lamp Outage ........................ .146

Liftgate Wiper and Washer System ..............105, 106

Logic Function and Timer .................... .105

Module ................................ .105

Washer Motor ........................... .106

Wiper Motor ............................ .106

Low Beam Relay ...........................6,53

Lumbar Pump ............................. .114

Lumbar Switch ............................ .114

MAP Sensor .......................... .18, 29, 30

Mechanical Cluster #1 Left PCB Connector ............155

Mechanical Cluster #1 ...................... .73, 74

Mechanical Cluster #2 ...................... .75, 76

Mechanical Cluster #2 Right PCB Connector ...........156

Message Center ..............................88

Mercury Switch ..............................16

Mirror Vanity Lamp ...................... .118, 120

Modules Airbag System Diagnostic Module .................84

Body Controller

Engine Node Module .........................72

Fuel Pump Module ........................ .107

Lamp Outage Module ....................... .138

Liftgate Wiper/Washer Module ..................105

Powertrain Control Module ...................9,59

Security Alarm Module ...................... .127

Transmission Control Module ..........15, 36, 37, 38, 39

Motors Blower Motor - A/C ...................... .90, 93

Blower Motor - Heater ........................93

Field Coil Engine Starter Motor ..............13, 14, 15

Idle Air Control Motor .................. .17, 23, 34

Intermittent Windshield Wiper Motor ...............67

Liftgate Washer Motor ...................... .106

Liftgate Wiper Motor ....................... .106

Power Door Locks ..................... .115, 116

Power Mirror ......................... .98, 100

Power Seats ............................ .114

Power Top ...............................96

Power Window Lift Motors ..............110, 111, 112Wiring Diagram

Name Sheet Number

Radiator Fan ..............................89

Starter ............................ .13, 14, 15

Windshield Washer Pump Motor .................67

Wing Motor ............................. .114

Name Brand Speaker Relay System .................60

Name Brand Speaker Relay .....................60

Relay Block ...............................60

Speaker Choke .............................60

Oil Level Sensor (Engine) ........................41

Overhead Console (AG) .................... .117, 118

Ambient Air Temperature Sensor .................117

Dome Lamp ............................. .118

Overhead Console ......................... .118

Vanity Mirror Lamps ....................... .118

Vanity Mirror Lamp Switch ................... .118

Overhead Console (AJ) .................... .119, 120

Ambient Air Temperature Sensor .................119

Overhead Console ......................... .120

Vanity Mirror Lamps ....................... .120

Vanity Mirror Lamp Switch ................... .120

Park Lamp Relay ...........................5,53

Power Distribution Center ..........5,7,9,10,11,12,160

Power Remote and Heated Mirrors .........97, 98, 99, 100

Heated Mirrors ........................ .98, 100

LH Mirror ............................ .97, 99

Power Mirror Switch ..................... .97, 99

RH Mirror ............................ .97, 99

Power Top System (Convertible) ...................96

Lower Power Switch .........................96

Power Top Motor ...........................96

Power Top Relay ...........................96

Powertrain Control Module ......9,17,18,19,20,21,22,23,

24, 25, 26, 27, 29, 30, 31, 32, 33, 34, 35

Powertrain Control Module Connector (2.5L Engine) ......167

Powertrain Control Module Connector (Turbo III) ........168

Powertrain Control Module Connector (3.0L Engine) ......169

Power Window System (J21 & G24) ................110

Motors ................................ .110

Window Lift Switch ........................ .110

Switch Function Chart ...................... .110

Right Door Switch ......................... .110

Power Window System (J-27) ................111, 112

Left Door Master Window Lift Switch ..............111

Motors ............................. .111, 112

Right Window Lift Switch .................... .111

Switch Function Chart ...................... .112

Radio Speaker Choke ..........................60

Radio Systems ...................... .61, 62, 63, 64

Radio Speakers ..................... .61, 62, 63, 64

Rear Lighting (AG) ................ .128, 129, 130, 131

Left Back-Up Lamp ........................ .128

Left Side Marker Lamp ...................... .128

Left Tail Lamp ........................... .128

Left Tail, Stop & Signal Lamps ..................128

License Lamp ........................ .128, 131

Right Back-Up Lamp ....................... .131

Right Side Marker Lamp ..................... .131

Ä WIRING DIAGRAMS AG-AJ BODY 8W - 537

Page 1594 of 2438

springs using Tool C-3422-B. (2) Remove valve retaining locks, valve spring re-

tainers, valve stem seals and valve springs. (3) Before removing valves, remove any burrs

from valve stem lock grooves to prevent damage

to the valve guides. Identify valves to insure instal-

lation in original location.

VALVE INSPECTION (1) Clean valves thoroughly and discard burned,

warped and cracked valves. (2) Measure valve stems for wear.

(3) If valve stems are worn more than 0.05 mm (.002

inch.) replace valve.

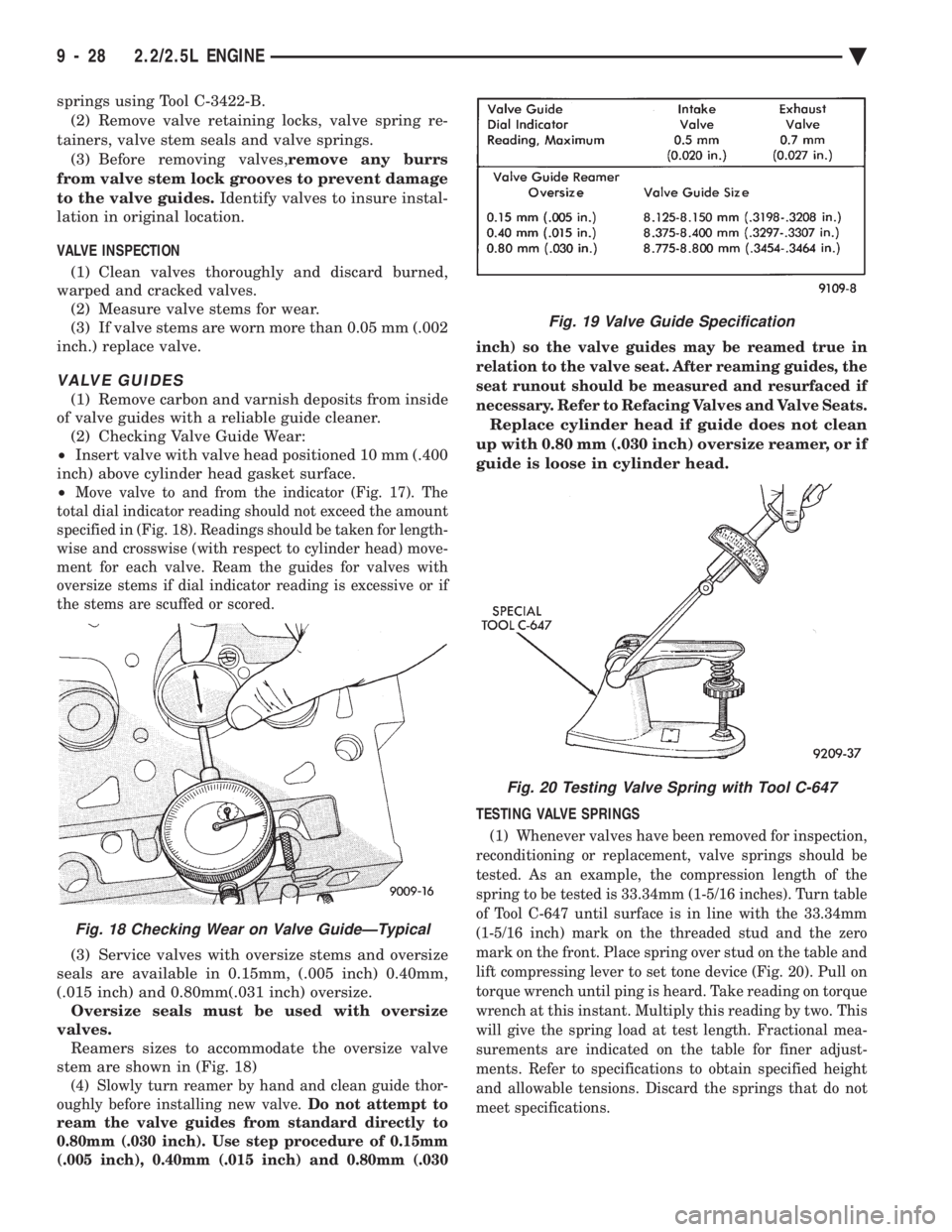

VALVE GUIDES

(1) Remove carbon and varnish deposits from inside

of valve guides with a reliable guide cleaner. (2) Checking Valve Guide Wear:

² Insert valve with valve head positioned 10 mm (.400

inch) above cylinder head gasket surface.

²

Move valve to and from the indicator (Fig. 17). The

total dial indicator reading should not exceed the amount

specified in (Fig. 18). Readings should be taken for length-

wise and crosswise (with respect to cylinder head) move-

ment for each valve. Ream the guides for valves with

oversize stems if dial indicator reading is excessive or if

the stems are scuffed or scored.

(3) Service valves with oversize stems and oversize

seals are available in 0.15mm, (.005 inch) 0.40mm,

(.015 inch) and 0.80mm(.031 inch) oversize. Oversize seals must be used with oversize

valves. Reamers sizes to accommodate the oversize valve

stem are shown in (Fig. 18)

(4) Slowly turn reamer by hand and clean guide thor-

oughly before installing new valve. Do not attempt to

ream the valve guides from standard directly to

0.80mm (.030 inch). Use step procedure of 0.15mm

(.005 inch), 0.40mm (.015 inch) and 0.80mm (.030 inch) so the valve guides may be reamed true in

relation to the valve seat. After reaming guides, the

seat runout should be measured and resurfaced if

necessary. Refer to Refacing Valves and Valve Seats.

Replace cylinder head if guide does not clean

up with 0.80 mm (.030 inch) oversize reamer, or if

guide is loose in cylinder head.

TESTING VALVE SPRINGS

(1) Whenever valves have been removed for inspection,

reconditioning or replacement, valve springs should be

tested. As an example, the compression length of the

spring to be tested is 33.34mm (1-5/16 inches). Turn table

of Tool C-647 until surface is in line with the 33.34mm

(1-5/16 inch) mark on the threaded stud and the zero

mark on the front. Place spring over stud on the table and

lift compressing lever to set tone device (Fig. 20). Pull on

torque wrench until ping is heard. Take reading on torque

wrench at this instant. Multiply this reading by two. This

will give the spring load at test length. Fractional mea-

surements are indicated on the table for finer adjust-

ments. Refer to specifications to obtain specified height

and allowable tensions. Discard the springs that do not

meet specifications.

Fig. 18 Checking Wear on Valve GuideÐTypical

Fig. 19 Valve Guide Specification

Fig. 20 Testing Valve Spring with Tool C-647

9 - 28 2.2/2.5L ENGINE Ä

Page 1595 of 2438

(2) Inspect each valve spring for squareness with a

steel square and surface plate, test springs from both

ends. If the spring is more than 1.5mm (1/16 inch)

out of square, install a new spring.

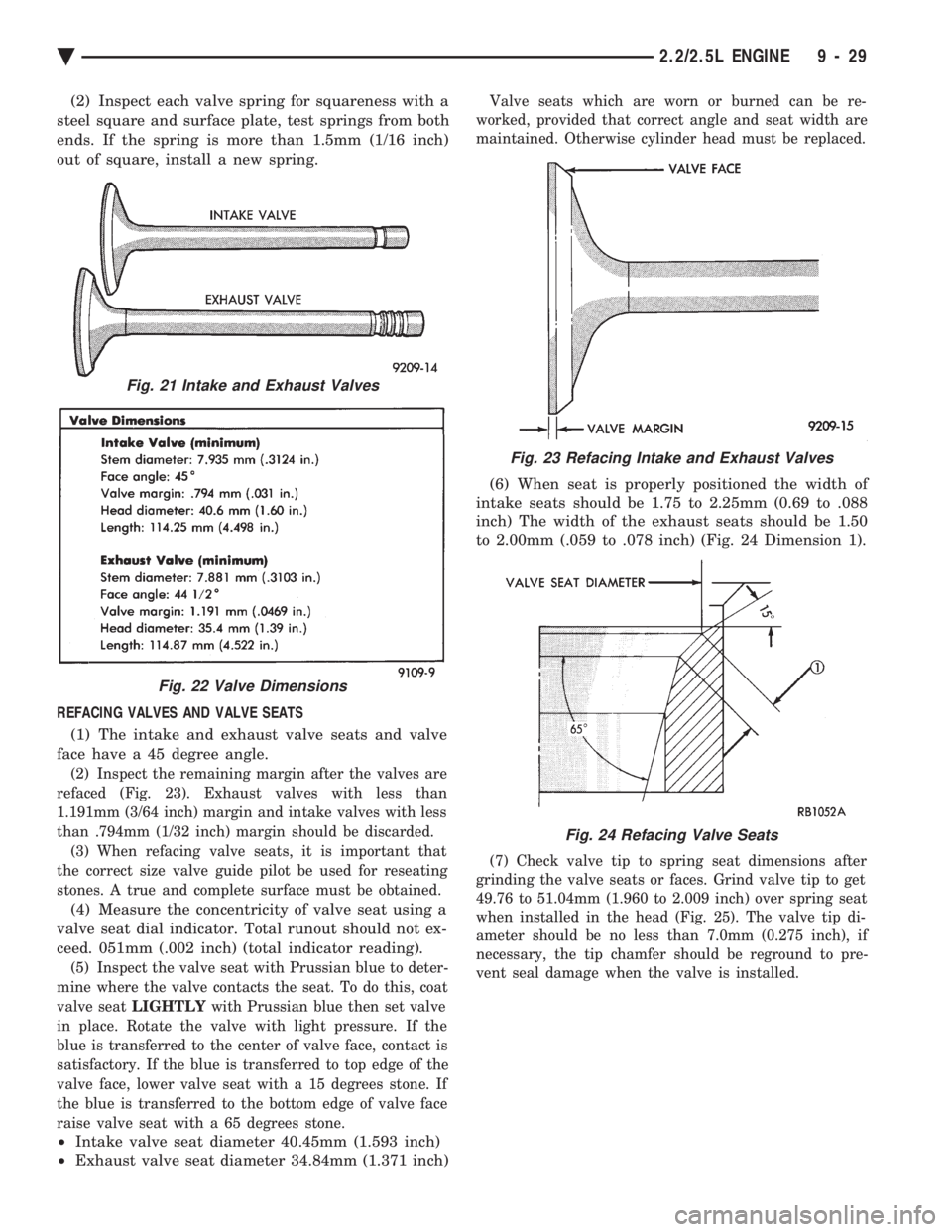

REFACING VALVES AND VALVE SEATS (1) The intake and exhaust valve seats and valve

face have a 45 degree angle.

(2) Inspect the remaining margin after the valves are

refaced (Fig. 23). Exhaust valves with less than

1.191mm (3/64 inch) margin and intake valves with less

than .794mm (1/32 inch) margin should be discarded. (3) When refacing valve seats, it is important that

the correct size valve guide pilot be used for reseating

stones. A true and complete surface must be obtained.

(4) Measure the concentricity of valve seat using a

valve seat dial indicator. Total runout should not ex-

ceed. 051mm (.002 inch) (total indicator reading).

(5) Inspect the valve seat with Prussian blue to deter-

mine where the valve contacts the seat. To do this, coat

valve seat LIGHTLY with Prussian blue then set valve

in place. Rotate the valve with light pressure. If the

blue is transferred to the center of valve face, contact is

satisfactory. If the blue is transferred to top edge of the

valve face, lower valve seat with a 15 degrees stone. If

the blue is transferred to the bottom edge of valve face

raise valve seat with a 65 degrees stone.

² Intake valve seat diameter 40.45mm (1.593 inch)

² Exhaust valve seat diameter 34.84mm (1.371 inch)

Valve seats which are worn or burned can be re-

worked, provided that correct angle and seat width are

maintained. Otherwise cylinder head must be replaced.

(6) When seat is properly positioned the width of

intake seats should be 1.75 to 2.25mm (0.69 to .088

inch) The width of the exhaust seats should be 1.50

to 2.00mm (.059 to .078 inch) (Fig. 24 Dimension 1).

(7) Check valve tip to spring seat dimensions after

grinding the valve seats or faces. Grind valve tip to get

49.76 to 51.04mm (1.960 to 2.009 inch) over spring seat

when installed in the head (Fig. 25). The valve tip di-

ameter should be no less than 7.0mm (0.275 inch), if

necessary, the tip chamfer should be reground to pre-

vent seal damage when the valve is installed.

Fig. 21 Intake and Exhaust Valves

Fig. 22 Valve Dimensions

Fig. 23 Refacing Intake and Exhaust Valves

Fig. 24 Refacing Valve Seats

Ä 2.2/2.5L ENGINE 9 - 29

Page 1596 of 2438

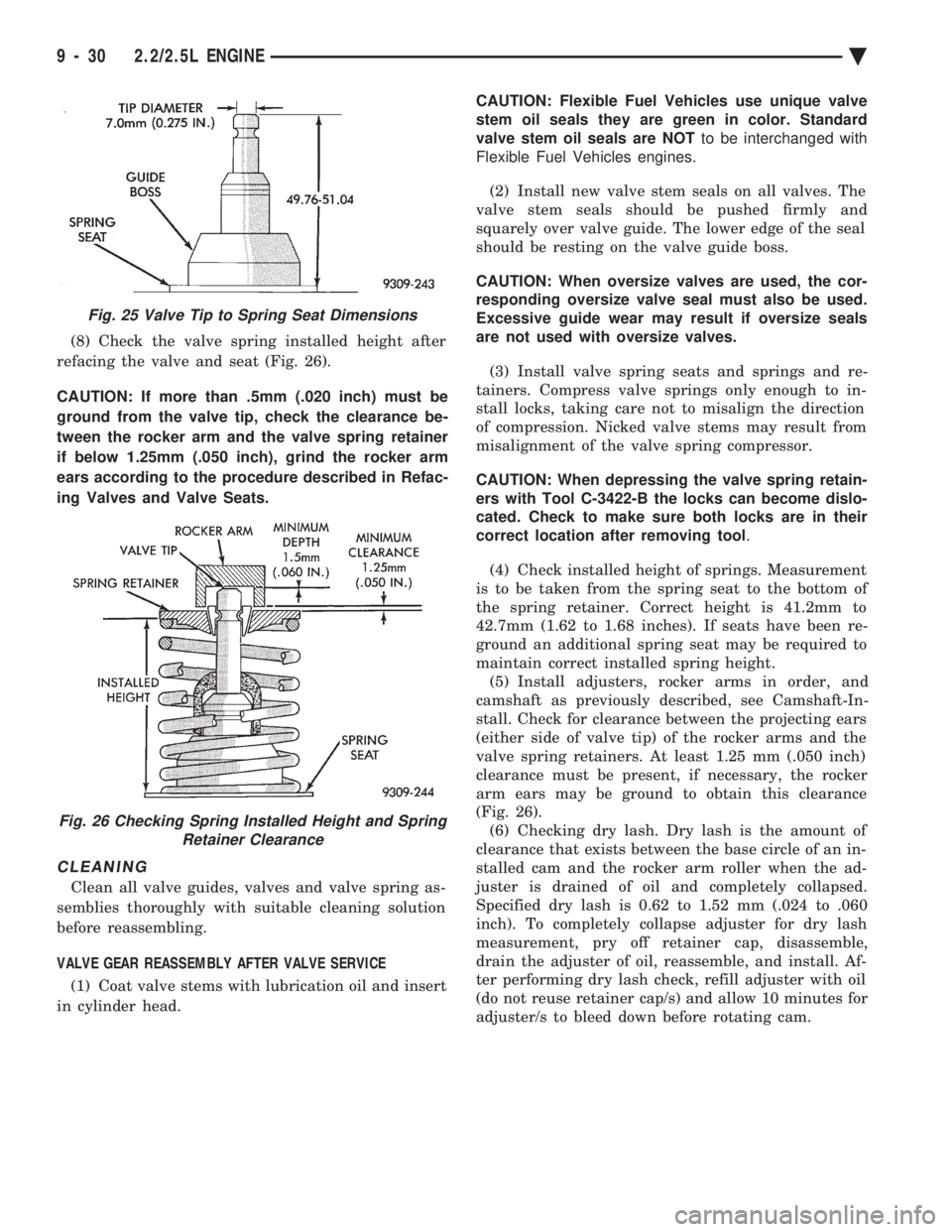

(8) Check the valve spring installed height after

refacing the valve and seat (Fig. 26).

CAUTION: If more than .5mm (.020 inch) must be

ground from the valve tip, check the clearance be-

tween the rocker arm and the valve spring retainer

if below 1.25mm (.050 inch), grind the rocker arm

ears according to the procedure described in Refac-

ing Valves and Valve Seats.

CLEANING

Clean all valve guides, valves and valve spring as-

semblies thoroughly with suitable cleaning solution

before reassembling.

VALVE GEAR REASSEMBLY AFTER VALVE SERVICE (1) Coat valve stems with lubrication oil and insert

in cylinder head. CAUTION: Flexible Fuel Vehicles use unique valve

stem oil seals they are green in color. Standard

valve stem oil seals are NOT to be interchanged with

Flexible Fuel Vehicles engines.

(2) Install new valve stem seals on all valves. The

valve stem seals should be pushed firmly and

squarely over valve guide. The lower edge of the seal

should be resting on the valve guide boss.

CAUTION: When oversize valves are used, the cor-

responding oversize valve seal must also be used.

Excessive guide wear may result if oversize seals

are not used with oversize valves.

(3) Install valve spring seats and springs and re-

tainers. Compress valve springs only enough to in-

stall locks, taking care not to misalign the direction

of compression. Nicked valve stems may result from

misalignment of the valve spring compressor.

CAUTION: When depressing the valve spring retain-

ers with Tool C-3422-B the locks can become dislo-

cated. Check to make sure both locks are in their

correct location after removing tool .

(4) Check installed height of springs. Measurement

is to be taken from the spring seat to the bottom of

the spring retainer. Correct height is 41.2mm to

42.7mm (1.62 to 1.68 inches). If seats have been re-

ground an additional spring seat may be required to

maintain correct installed spring height. (5) Install adjusters, rocker arms in order, and

camshaft as previously described, see Camshaft-In-

stall. Check for clearance between the projecting ears

(either side of valve tip) of the rocker arms and the

valve spring retainers. At least 1.25 mm (.050 inch)

clearance must be present, if necessary, the rocker

arm ears may be ground to obtain this clearance

(Fig. 26). (6) Checking dry lash. Dry lash is the amount of

clearance that exists between the base circle of an in-

stalled cam and the rocker arm roller when the ad-

juster is drained of oil and completely collapsed.

Specified dry lash is 0.62 to 1.52 mm (.024 to .060

inch). To completely collapse adjuster for dry lash

measurement, pry off retainer cap, disassemble,

drain the adjuster of oil, reassemble, and install. Af-

ter performing dry lash check, refill adjuster with oil

(do not reuse retainer cap/s) and allow 10 minutes for

adjuster/s to bleed down before rotating cam.

Fig. 25 Valve Tip to Spring Seat Dimensions

Fig. 26 Checking Spring Installed Height and Spring Retainer Clearance

9 - 30 2.2/2.5L ENGINE Ä