ignition CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1902 of 2438

3.3L AND 3.8L MULTI-PORT FUEL INJECTIONÐON-BOARD DIAGNOSTICS INDEX

page page

60-Way Pcm Wiring Connector ............. 167

Circuit Actuation Test Mode ................ 166

Diagnostic Trouble Code Description ......... 163

General Information ...................... 162

High and Low Limits ..................... 163

Monitored Circuits ....................... 162 Non-Monitored Circuits

................... 162

State Display Test Mode .................. 163

System Tests .......................... 163

Throttle Body Minimum Air Flow Check Procedure ............................ 166

GENERAL INFORMATION

The powertrain control module (PCM) has been

programmed to monitor many different circuits of the

fuel injection system. If a problem is sensed with a

monitored circuit often enough to indicate an actual

problem, the PCM stores a fault. If the problem is re-

paired or ceases to exist, the PCM cancels the Diag-

nostic trouble code after 51 vehicle key on/off cycles. Certain criteria must be met for a diagnostic trou-

ble code to be entered into the PCM memory. The

criteria may be a specific range of engine RPM, en-

gine temperature, and/or input voltage to the PCM. It is possible a diagnostic trouble code for a moni-

tored circuit may not be entered into memory even

though a malfunction has occurred. This may happen

because one of the diagnostic trouble code criteria for

the circuit has not been met. For example, assume

one of the diagnostic trouble code criteria for a sen-

sor circuit is the engine must be operating between

750 and 2000 RPM. If the sensor output circuit

shorts to ground when engine RPM is above 2400

RPM (resulting i n a 0 volt input to the PCM) a diag-

nostic trouble code will not be entered into memory.

This is because the condition does not occur within

the specified RPM range. There are several operating conditions that the

PCM does not monitor and set diagnostic trouble

codes for. Refer to Monitored Circuits and Non-Mon-

itored Circuits in this section. Stored diagnostic trouble codes can be displayed ei-

ther by cycling the ignition key On - Off - On - Off -

On, or through use of the DRBII scan tool. The

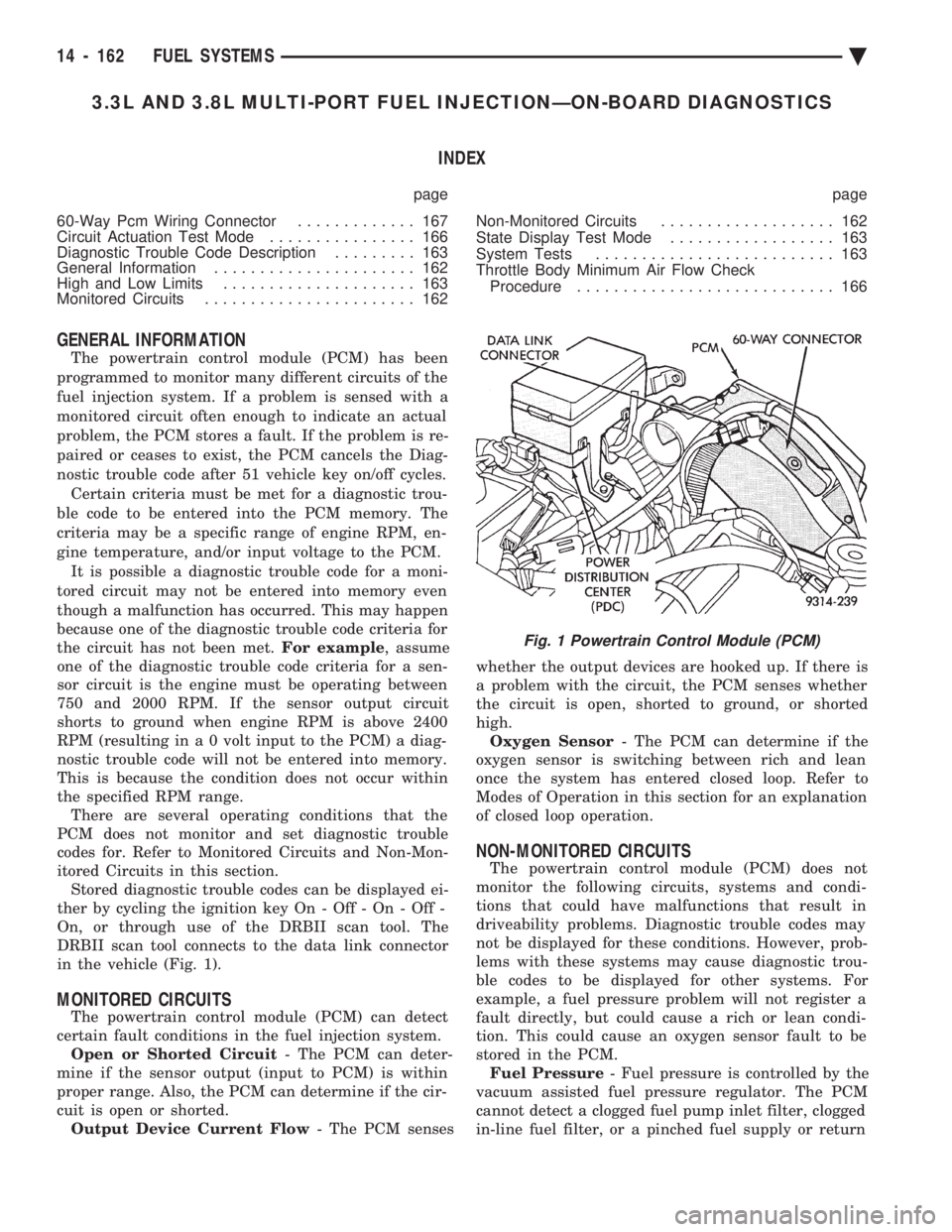

DRBII scan tool connects to the data link connector

in the vehicle (Fig. 1).

MONITORED CIRCUITS

The powertrain control module (PCM) can detect

certain fault conditions in the fuel injection system. Open or Shorted Circuit - The PCM can deter-

mine if the sensor output (input to PCM) is within

proper range. Also, the PCM can determine if the cir-

cuit is open or shorted. Output Device Current Flow - The PCM senses whether the output devices are hooked up. If there is

a problem with the circuit, the PCM senses whether

the circuit is open, shorted to ground, or shorted

high. Oxygen Sensor - The PCM can determine if the

oxygen sensor is switching between rich and lean

once the system has entered closed loop. Refer to

Modes of Operation in this section for an explanation

of closed loop operation.

NON-MONITORED CIRCUITS

The powertrain control module (PCM) does not

monitor the following circuits, systems and condi-

tions that could have malfunctions that result in

driveability problems. Diagnostic trouble codes may

not be displayed for these conditions. However, prob-

lems with these systems may cause diagnostic trou-

ble codes to be displayed for other systems. For

example, a fuel pressure problem will not register a

fault directly, but could cause a rich or lean condi-

tion. This could cause an oxygen sensor fault to be

stored in the PCM. Fuel Pressure - Fuel pressure is controlled by the

vacuum assisted fuel pressure regulator. The PCM

cannot detect a clogged fuel pump inlet filter, clogged

in-line fuel filter, or a pinched fuel supply or return

Fig. 1 Powertrain Control Module (PCM)

14 - 162 FUEL SYSTEMS Ä

Page 1903 of 2438

line. However, these could result in a rich or lean

condition causing an oxygen sensor fault to be stored in

the PCM. Secondary Ignition Circuit - The PCM cannot

detect an inoperative ignition coil, fouled or worn spark

plugs, ignition cross firing, or open spark plug cables. Engine Timing - The PCM cannot detect an incor-

rectly indexed timing chain, camshaft sprocket and

crankshaft sprocket. However, these could result in a

rich or lean condition causing an oxygen sensor fault to

be stored in the PCM. Cylinder Compression - The PCM cannot detect

uneven, low, or high engine cylinder compression. Exhaust System - The PCM cannot detect a

plugged, restricted or leaking exhaust system. Fuel Injector Malfunctions - The PCM cannot

determine if a fuel injector is clogged, the needle is

sticking or the wrong injector is installed. However,

these could result in a rich or lean condition causing an

oxygen sensor fault to be stored in the PCM. Excessive Oil Consumption - Although the PCM

monitors exhaust stream oxygen content when the

system is in closed loop, it cannot determine excessive

oil consumption. Throttle Body Air Flow - The PCM cannot detect a

clogged or restricted air cleaner inlet or filter element. Evaporative System - The PCM will not detect a

restricted, plugged or loaded evaporative purge canis-

ter. Vacuum Assist - Leaks or restrictions in the

vacuum circuits of vacuum assisted engine control

system devices are not monitored by the PCM. How-

ever, these could result in a MAP sensor fault being

stored in the PCM. PCM System Ground - The PCM cannot determine

a poor system ground. However, a diagnostic trouble

code may be generated as a result of this condition. PCM Connector Engagement - The PCM cannot

determine spread or damaged connector pins. How-

ever, a diagnostic trouble code may be generated as a

result of this condition.

HIGH AND LOW LIMITS

The powertrain control module (PCM) compares in-

put signal voltages from each input device with estab-

lished high and low limits for the device. If the input

voltage is not within limits and other diagnostic

trouble code criteria are met, a diagnostic trouble code

will be stored in memory. Other diagnostic trouble code

criteria might include engine RPM limits or input

voltages from other sensors or switches that must be

present before a fault condition can be verified.

DIAGNOSTIC TROUBLE CODE DESCRIPTION

A diagnostic trouble code indicates that the power-

train control module (PCM) has recognized an abnor- mal condition in the system. Diagnostic trouble codes

can be obtained from the malfunction indicator lamp

(Check Engine lamp on the instrument panel) or from

the DRBII scan tool. Diagnostic trouble codes indicate

the results of a failure but do not identify the failed

component directly.

SYSTEM TESTS

WARNING: APPLY PARKING BRAKE AND/OR BLOCK

WHEELS BEFORE PERFORMING ANY TEST ON AN

OPERATING ENGINE.

OBTAINING DIAGNOSTIC TROUBLE CODES

(1) Connect the DRBII scan tool to the data link

connector located in the engine compartment near the

driver side strut tower (Fig. 1). (2) Start the engine if possible, cycle the transaxle

selector and the A/Cswitch if applicable. Shut off the

engine. (3) Turn the ignition switch on, access Read Fault

Screen. Record all the fault messages shown on the

DRBII scan tool. Observe the malfunction indicator

lamp (check engine lamp on the instrument panel). The

lamp should light for 2 seconds then go out (bulb

check). Diagnostic trouble code erasure; access erase

diagnostic trouble code data

STATE DISPLAY TEST MODE

The switch inputs used by the powertrain control

module (PCM) have only two recognized states, HIGH

and LOW. For this reason, the PCM cannot recognize

the difference between a selected switch position ver-

sus an open circuit, a short circuit, or a defective

switch. If the change is displayed, it can be assumed

that the entire switch circuit to the PCM is functional.

From the state display screen access either State

Display Inputs and Outputs or State Display Sensors.

STATE DISPLAY INPUTS AND OUTPUTS

Connect the DRBII scan tool to the vehicle and access

the State Display screen. Then access Inputs and

Outputs. The following is a list of the engine control

system functions accessible through the Inputs and

Outputs screen. Park/Neutral Switch

Speed Control Resume

Brake Switch

Speed Control On/Off

Speed Control Set

A/C Switch Sense

S/C Vent Solenoid

Ä FUEL SYSTEMS 14 - 163

Page 1906 of 2438

S/C Vacuum Solenoid

A/C Clutch Relay

EGR Solenoid

Auto Shutdown Relay

Radiator Fan Relay

Purge Solenoid

Malfunction Indicator Lamp (Check Engine Lamp)

STATE DISPLAY SENSORS

Connect the DRBII scan tool to the vehicle and ac-

cess the State Display screen. Then access Sensor

Display. The following is a list of the engine control

system functions accessible through the Sensor Dis-

play screen. Oxygen Sensor Signal

Engine Coolant Temperature

Engine Coolant Temp Sensor

Throttle Position

Minimum Throttle

Battery Voltage

MAP Sensor Reading

Idle Air Control Motor Position

Adaptive Fuel Factor

Barometric Pressure

Min Airflow Idle Spd (speed)

Engine Speed

DIS Sensor Status

Fault #1 Key-On Info

Module Spark Advance

Speed Control Target

Fault #2 Key-on Info

Fault #3 Key-on Info

Speed Control Status

Speed Control Switch Voltage

Charging System Goal

Theft Alarm Status

Map Sensor Voltage

Vehicle Speed

Oxygen Sensor State

MAP Gauge Reading

Throttle Opening (percentage)

Total Spark Advance

CIRCUIT ACTUATION TEST MODE

The circuit actuation test mode checks for proper

operation of output circuits or devices which the pow-

ertrain control module (PCM) cannot internally rec-

ognize. The PCM can attempt to activate these

outputs and allow an observer to verify proper oper-

ation. Most of the tests provide an audible or visual

indication of device operation (click of relay contacts,

spray fuel, etc.). Except for intermittent conditions, if

a device functions properly during testing, assume

the device, its associated wiring, and driver circuit

working correctly.

OBTAINING CIRCUIT ACTUATION TEST

Connect the DRBII scan tool to the vehicle and ac-

cess the Actuators screen. The following is a list of

the engine control system functions accessible

through Actuators screens. Stop All Tests

Ignition Coil #1

Ignition Coil #2

Ignition Coil #3

Fuel Injector #1

Fuel Injector #2

Fuel Injector #3

Fuel Injector #4

Fuel Injector #5

Fuel Injector #6

Idle Air Control Motor Open/Close

Radiator Fan Relay

A/C Clutch Relay

Auto Shutdown Relay

EVAP Purge Solenoid

S/C Servo Solenoids

Generator Field

EGR Solenoid

All Solenoids/Relays

ASD Fuel System Test

Speed Control Vacuum Solenoid

Speed Control Vent Solenoid

THROTTLE BODY MINIMUM AIR FLOW CHECK

PROCEDURE

(1) Warm engine in Park or Neutral until the cool-

ing fan has cycled on and off at least once. (2) Ensure that all accessories are off.

(3) Shut off engine.

(4) Disconnect the PCV valve hose from the intake

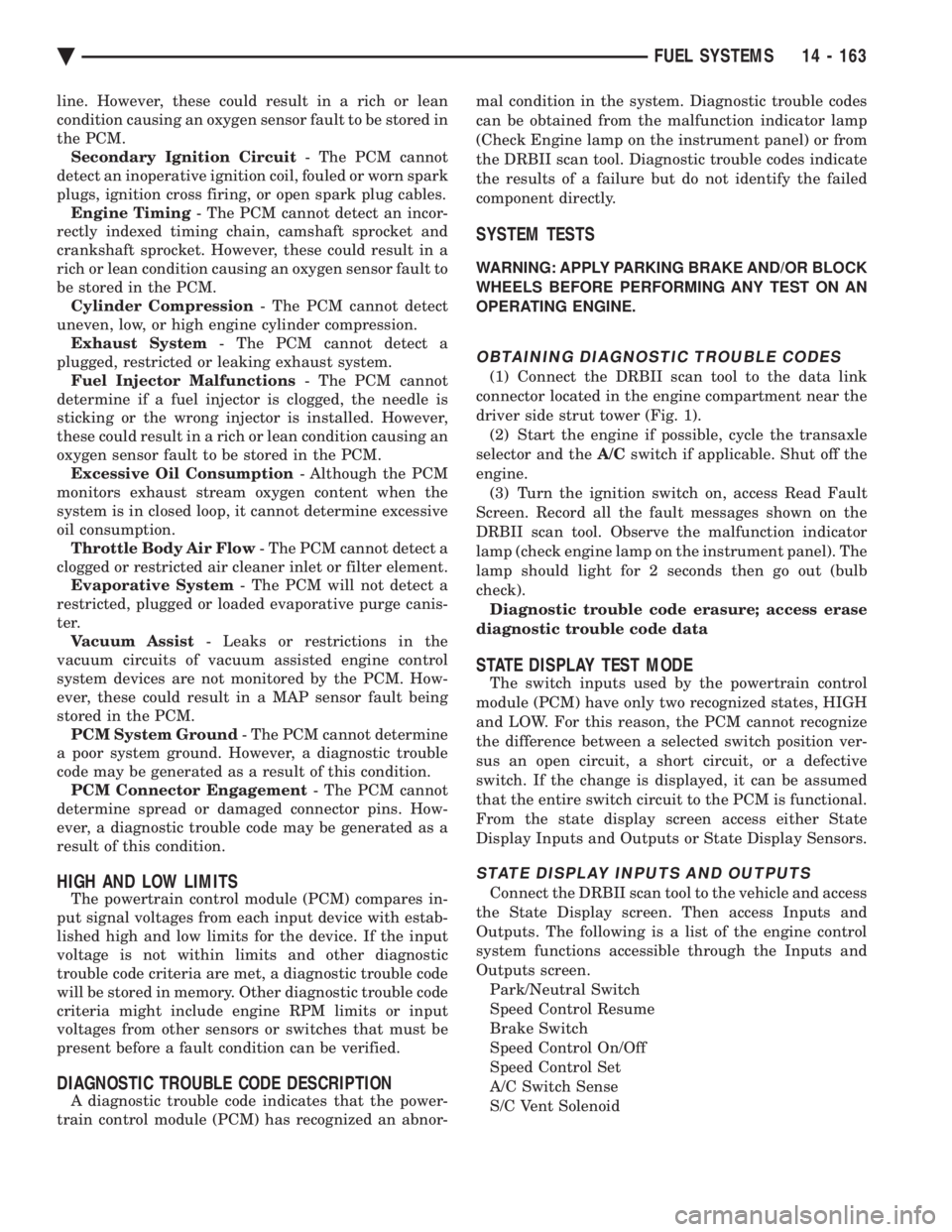

manifold nipple. (5) Attach Air Metering Fitting #6457 (0.125 in.

orifice) to the intake manifold PCV nipple (Fig. 2).

(6) Disconnect the 3/16 inch idle purge line from

the throttle body nipple. Cap the 3/16 inch nipple. (7) Connect DRBII scan tool to vehicle.

(8) Restart the engine. Allow engine to idle for at

least one minute. (9) Using the DRBII scan tool, access Min. Airflow

Idle Spd.

Fig. 2 Air Metering Fitting #6457

14 - 166 FUEL SYSTEMS Ä

Page 1912 of 2438

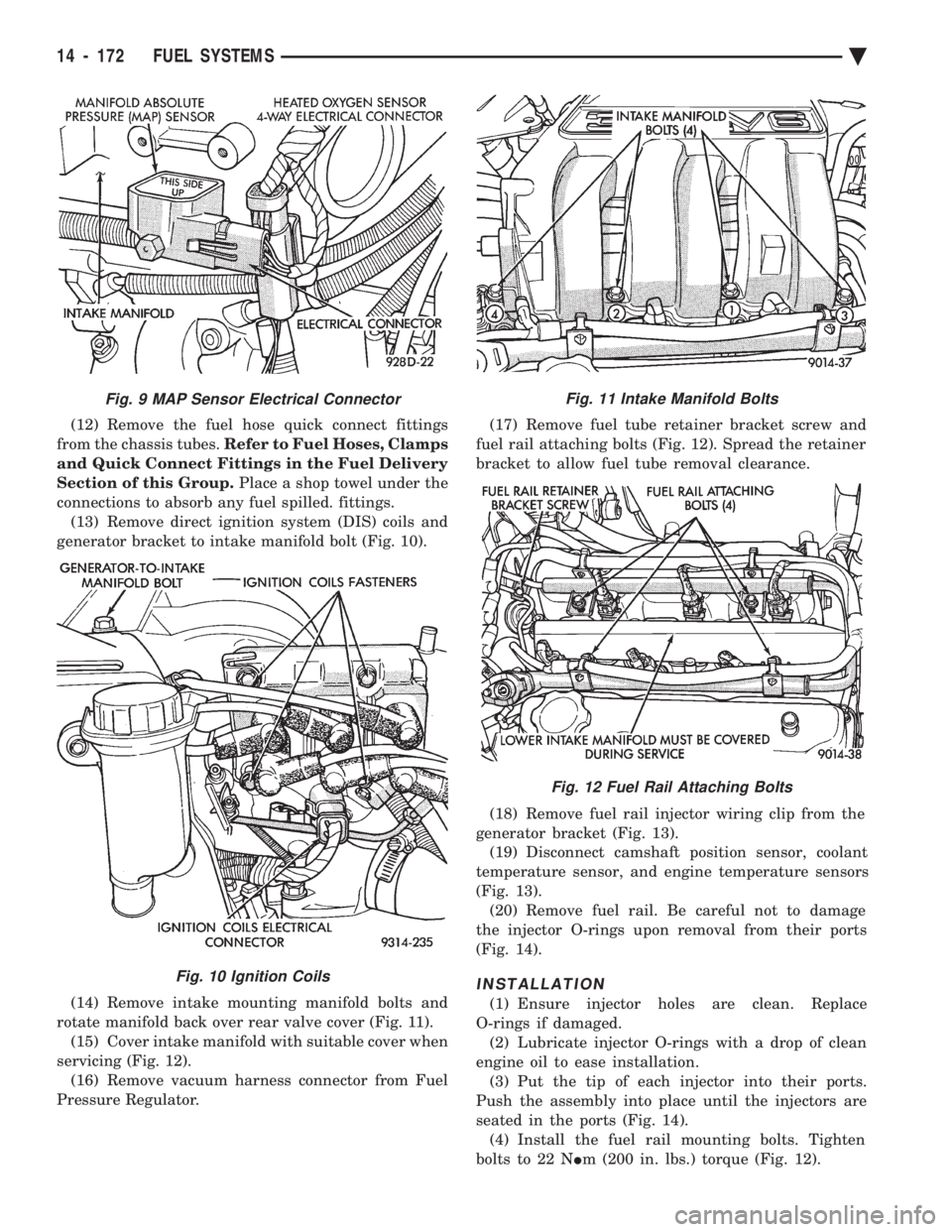

(12) Remove the fuel hose quick connect fittings

from the chassis tubes. Refer to Fuel Hoses, Clamps

and Quick Connect Fittings in the Fuel Delivery

Section of this Group. Place a shop towel under the

connections to absorb any fuel spilled. fittings. (13) Remove direct ignition system (DIS) coils and

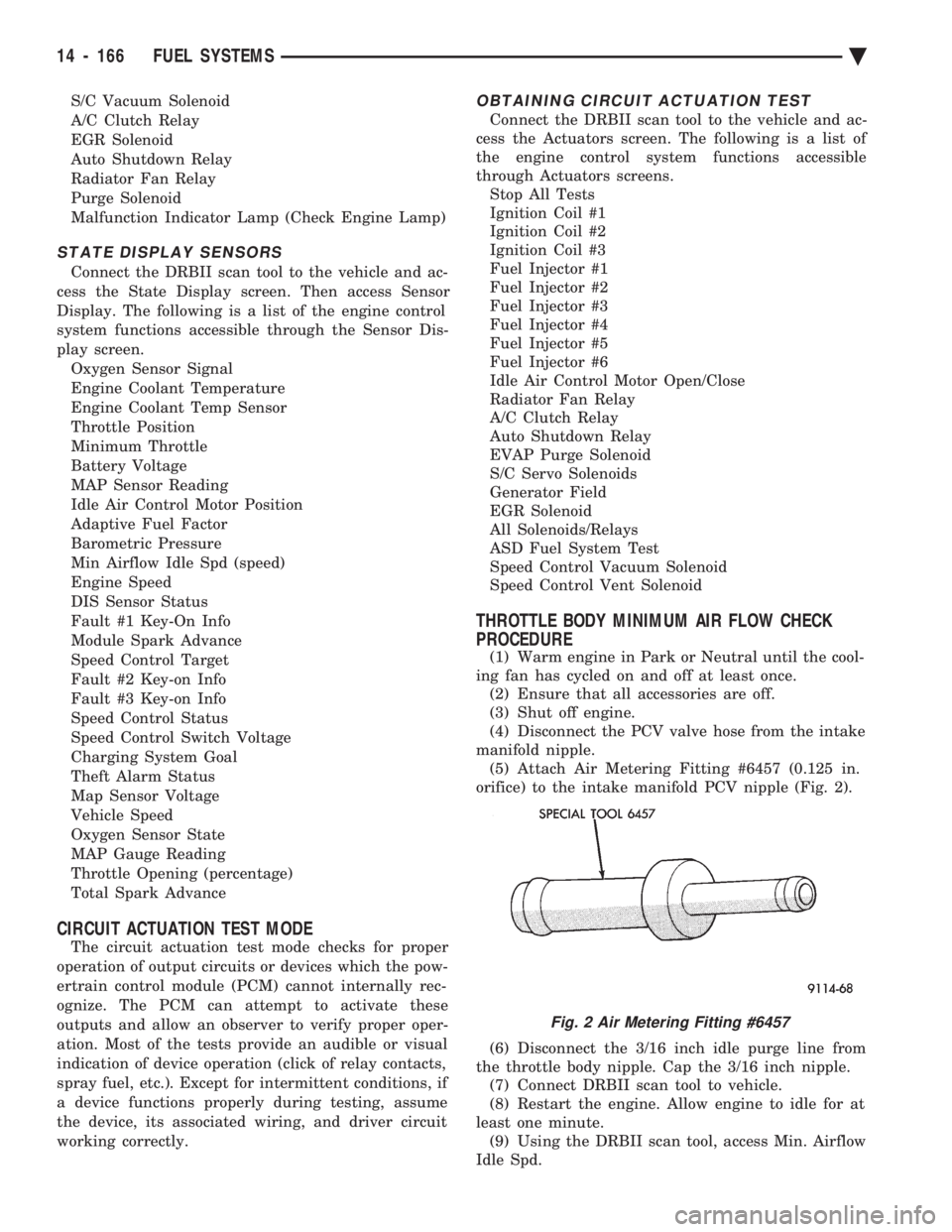

generator bracket to intake manifold bolt (Fig. 10).

(14) Remove intake mounting manifold bolts and

rotate manifold back over rear valve cover (Fig. 11). (15) Cover intake manifold with suitable cover when

servicing (Fig. 12). (16) Remove vacuum harness connector from Fuel

Pressure Regulator. (17) Remove fuel tube retainer bracket screw and

fuel rail attaching bolts (Fig. 12). Spread the retainer

bracket to allow fuel tube removal clearance.

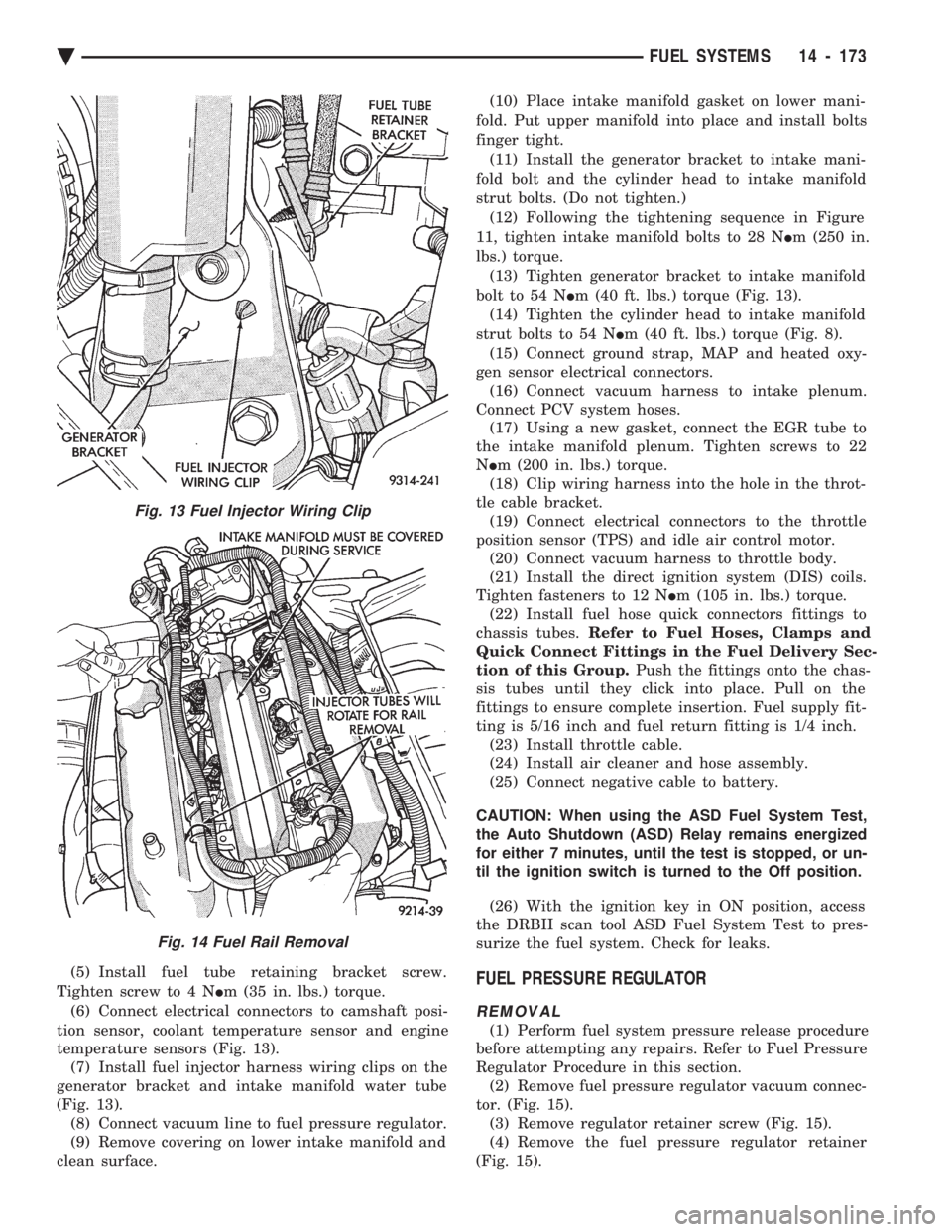

(18) Remove fuel rail injector wiring clip from the

generator bracket (Fig. 13). (19) Disconnect camshaft position sensor, coolant

temperature sensor, and engine temperature sensors

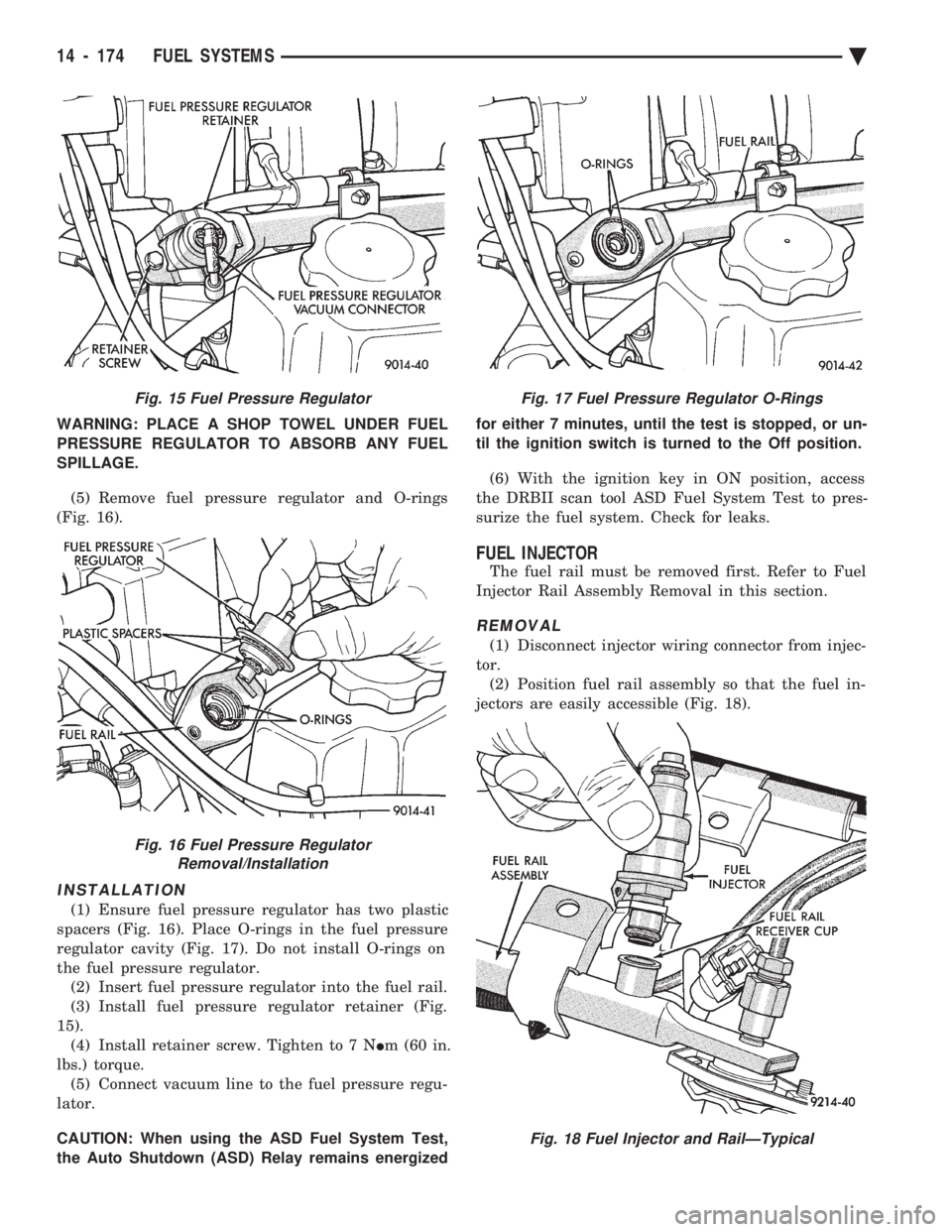

(Fig. 13). (20) Remove fuel rail. Be careful not to damage

the injector O-rings upon removal from their ports

(Fig. 14).

INSTALLATION

(1) Ensure injector holes are clean. Replace

O-rings if damaged. (2) Lubricate injector O-rings with a drop of clean

engine oil to ease installation. (3) Put the tip of each injector into their ports.

Push the assembly into place until the injectors are

seated in the ports (Fig. 14). (4) Install the fuel rail mounting bolts. Tighten

bolts to 22 N Im (200 in. lbs.) torque (Fig. 12).

Fig. 11 Intake Manifold Bolts

Fig. 12 Fuel Rail Attaching Bolts

Fig. 9 MAP Sensor Electrical Connector

Fig. 10 Ignition Coils

14 - 172 FUEL SYSTEMS Ä

Page 1913 of 2438

(5) Install fuel tube retaining bracket screw.

Tighten screw to 4 N Im (35 in. lbs.) torque.

(6) Connect electrical connectors to camshaft posi-

tion sensor, coolant temperature sensor and engine

temperature sensors (Fig. 13). (7) Install fuel injector harness wiring clips on the

generator bracket and intake manifold water tube

(Fig. 13). (8) Connect vacuum line to fuel pressure regulator.

(9) Remove covering on lower intake manifold and

clean surface. (10) Place intake manifold gasket on lower mani-

fold. Put upper manifold into place and install bolts

finger tight. (11) Install the generator bracket to intake mani-

fold bolt and the cylinder head to intake manifold

strut bolts. (Do not tighten.) (12) Following the tightening sequence in Figure

11, tighten intake manifold bolts to 28 N Im (250 in.

lbs.) torque. (13) Tighten generator bracket to intake manifold

bolt to 54 N Im (40 ft. lbs.) torque (Fig. 13).

(14) Tighten the cylinder head to intake manifold

strut bolts to 54 N Im (40 ft. lbs.) torque (Fig. 8).

(15) Connect ground strap, MAP and heated oxy-

gen sensor electrical connectors. (16) Connect vacuum harness to intake plenum.

Connect PCV system hoses. (17) Using a new gasket, connect the EGR tube to

the intake manifold plenum. Tighten screws to 22

N Im (200 in. lbs.) torque.

(18) Clip wiring harness into the hole in the throt-

tle cable bracket. (19) Connect electrical connectors to the throttle

position sensor (TPS) and idle air control motor. (20) Connect vacuum harness to throttle body.

(21) Install the direct ignition system (DIS) coils.

Tighten fasteners to 12 N Im (105 in. lbs.) torque.

(22) Install fuel hose quick connectors fittings to

chassis tubes. Refer to Fuel Hoses, Clamps and

Quick Connect Fittings in the Fuel Delivery Sec-

tion of this Group. Push the fittings onto the chas-

sis tubes until they click into place. Pull on the

fittings to ensure complete insertion. Fuel supply fit-

ting is 5/16 inch and fuel return fitting is 1/4 inch. (23) Install throttle cable.

(24) Install air cleaner and hose assembly.

(25) Connect negative cable to battery.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or un-

til the ignition switch is turned to the Off position.

(26) With the ignition key in ON position, access

the DRBII scan tool ASD Fuel System Test to pres-

surize the fuel system. Check for leaks.FUEL PRESSURE REGULATOR

REMOVAL

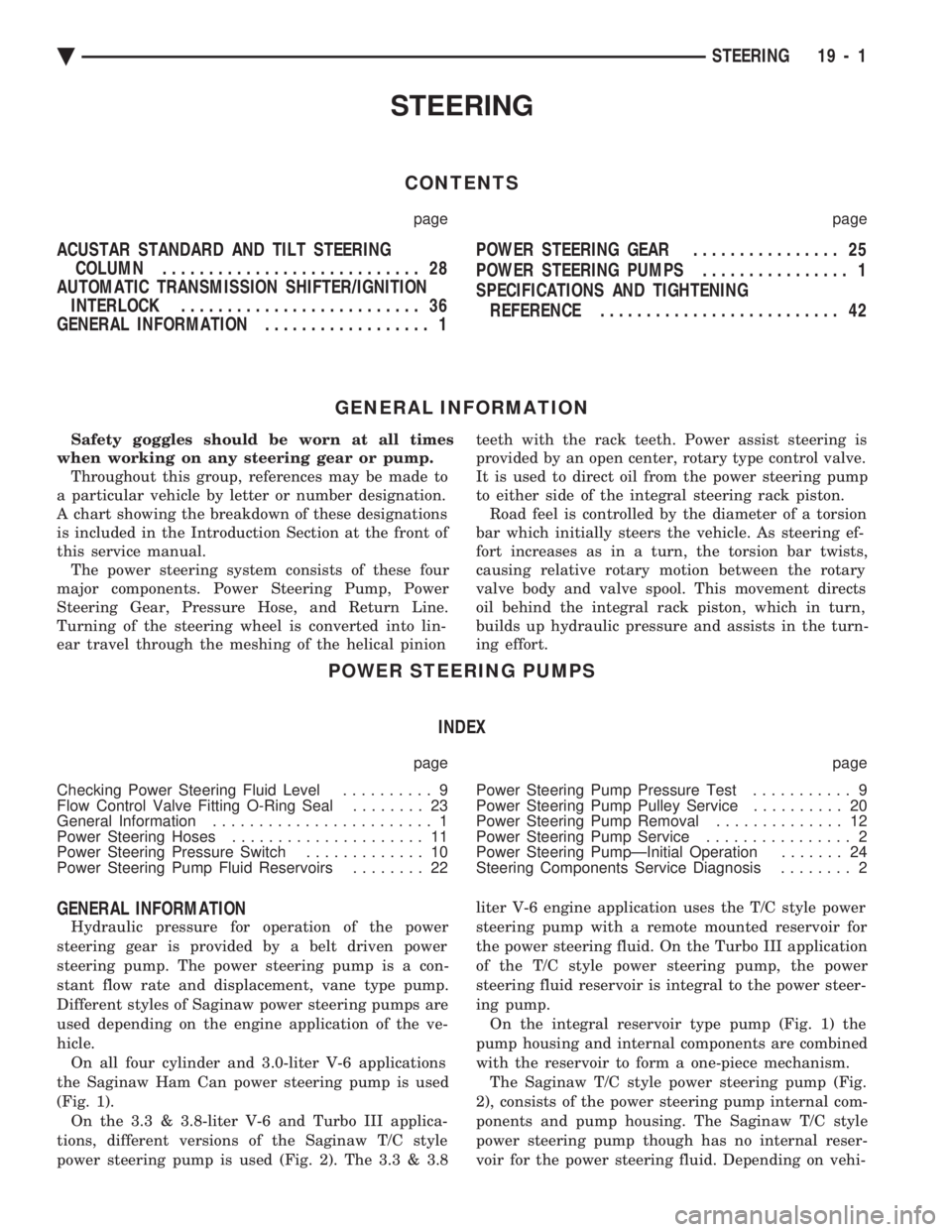

(1) Perform fuel system pressure release procedure

before attempting any repairs. Refer to Fuel Pressure

Regulator Procedure in this section. (2) Remove fuel pressure regulator vacuum connec-

tor. (Fig. 15). (3) Remove regulator retainer screw (Fig. 15).

(4) Remove the fuel pressure regulator retainer

(Fig. 15).

Fig. 13 Fuel Injector Wiring Clip

Fig. 14 Fuel Rail Removal

Ä FUEL SYSTEMS 14 - 173

Page 1914 of 2438

WARNING: PLACE A SHOP TOWEL UNDER FUEL

PRESSURE REGULATOR TO ABSORB ANY FUEL

SPILLAGE.

(5) Remove fuel pressure regulator and O-rings

(Fig. 16).

INSTALLATION

(1) Ensure fuel pressure regulator has two plastic

spacers (Fig. 16). Place O-rings in the fuel pressure

regulator cavity (Fig. 17). Do not install O-rings on

the fuel pressure regulator. (2) Insert fuel pressure regulator into the fuel rail.

(3) Install fuel pressure regulator retainer (Fig.

15). (4) Install retainer screw. Tighten to 7 N Im (60 in.

lbs.) torque. (5) Connect vacuum line to the fuel pressure regu-

lator.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized for either 7 minutes, until the test is stopped, or un-

til the ignition switch is turned to the Off position.

(6) With the ignition key in ON position, access

the DRBII scan tool ASD Fuel System Test to pres-

surize the fuel system. Check for leaks.

FUEL INJECTOR

The fuel rail must be removed first. Refer to Fuel

Injector Rail Assembly Removal in this section.

REMOVAL

(1) Disconnect injector wiring connector from injec-

tor. (2) Position fuel rail assembly so that the fuel in-

jectors are easily accessible (Fig. 18).

Fig. 15 Fuel Pressure Regulator

Fig. 16 Fuel Pressure Regulator Removal/Installation

Fig. 17 Fuel Pressure Regulator O-Rings

Fig. 18 Fuel Injector and RailÐTypical

14 - 174 FUEL SYSTEMS Ä

Page 1919 of 2438

STEERING

CONTENTS

page page

ACUSTAR STANDARD AND TILT STEERING COLUMN ............................ 28

AUTOMATIC TRANSMISSION SHIFTER/IGNITION INTERLOCK .......................... 36

GENERAL INFORMATION .................. 1 POWER STEERING GEAR

................ 25

POWER STEERING PUMPS ................ 1

SPECIFICATIONS AND TIGHTENING REFERENCE .......................... 42

GENERAL INFORMATION

Safety goggles should be worn at all times

when working on any steering gear or pump. Throughout this group, references may be made to

a particular vehicle by letter or number designation.

A chart showing the breakdown of these designations

is included in the Introduction Section at the front of

this service manual. The power steering system consists of these four

major components. Power Steering Pump, Power

Steering Gear, Pressure Hose, and Return Line.

Turning of the steering wheel is converted into lin-

ear travel through the meshing of the helical pinion teeth with the rack teeth. Power assist steering is

provided by an open center, rotary type control valve.

It is used to direct oil from the power steering pump

to either side of the integral steering rack piston. Road feel is controlled by the diameter of a torsion

bar which initially steers the vehicle. As steering ef-

fort increases as in a turn, the torsion bar twists,

causing relative rotary motion between the rotary

valve body and valve spool. This movement directs

oil behind the integral rack piston, which in turn,

builds up hydraulic pressure and assists in the turn-

ing effort.

POWER STEERING PUMPS

INDEX

page page

Checking Power Steering Fluid Level .......... 9

Flow Control Valve Fitting O-Ring Seal ........ 23

General Information ........................ 1

Power Steering Hoses ..................... 11

Power Steering Pressure Switch ............. 10

Power Steering Pump Fluid Reservoirs ........ 22 Power Steering Pump Pressure Test

........... 9

Power Steering Pump Pulley Service .......... 20

Power Steering Pump Removal .............. 12

Power Steering Pump Service ................ 2

Power Steering PumpÐInitial Operation ....... 24

Steering Components Service Diagnosis ........ 2

GENERAL INFORMATION

Hydraulic pressure for operation of the power

steering gear is provided by a belt driven power

steering pump. The power steering pump is a con-

stant flow rate and displacement, vane type pump.

Different styles of Saginaw power steering pumps are

used depending on the engine application of the ve-

hicle. On all four cylinder and 3.0-liter V-6 applications

the Saginaw Ham Can power steering pump is used

(Fig. 1). On the 3.3 & 3.8-liter V-6 and Turbo III applica-

tions, different versions of the Saginaw T/C style

power steering pump is used (Fig. 2). The 3.3 & 3.8 liter V-6 engine application uses the T/C style power

steering pump with a remote mounted reservoir for

the power steering fluid. On the Turbo III application

of the T/C style power steering pump, the power

steering fluid reservoir is integral to the power steer-

ing pump. On the integral reservoir type pump (Fig. 1) the

pump housing and internal components are combined

with the reservoir to form a one-piece mechanism. The Saginaw T/C style power steering pump (Fig.

2), consists of the power steering pump internal com-

ponents and pump housing. The Saginaw T/C style

power steering pump though has no internal reser-

voir for the power steering fluid. Depending on vehi-

Ä STEERING 19 - 1

Page 1946 of 2438

ACUSTAR STANDARD AND TILT STEERING COLUMN INDEX

page page

General Information ....................... 28

Ignition Switch Service .................... 34 Steering Column Component Service

......... 34

Steering Column Service Procedures .......... 30

GENERAL INFORMATION

WARNING: THE AIR BAG SYSTEM IS A SENSITIVE,

COMPLEX ELECTRO-MECHANICAL UNIT. BEFORE

ATTEMPTING TO DIAGNOSE, REMOVE OR IN-

STALL THE AIR BAG SYSTEM COMPONENTS YOU

MUST FIRST DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE. FAILURE

TO DO SO COULD RESULT IN ACCIDENTAL DE-

PLOYMENT OF THE AIR BAG AND POSSIBLE PER-

SONAL INJURY. THE FASTENERS, SCREWS, AND BOLTS, ORIGI-

NALLY USED FOR THE AIR BAG COMPONENTS,

HAVE SPECIAL COATINGS AND ARE SPECIFI- CALLY DESIGNED FOR THE AIR BAG SYSTEM.

THEY MUST NEVER BE REPLACED WITH ANY

SUBSTITUTES. ANYTIME A NEW FASTENER IS

NEEDED, REPLACE WITH THE CORRECT FASTEN-

ERS PROVIDED IN THE SERVICE PACKAGE OR

FASTENERS LISTED IN THE PARTS BOOKS. BEFORE SERVICING A STEERING COLUMN

EQUIPPED WITH AN AIR BAG, REFER TO GROUP

8M, ELECTRICAL FOR PROPER AND SAFE SER-

VICE PROCEDURES.

Safety goggles should be worn at all times

when working on steering columns.

19 - 28 STEERING Ä

Page 1949 of 2438

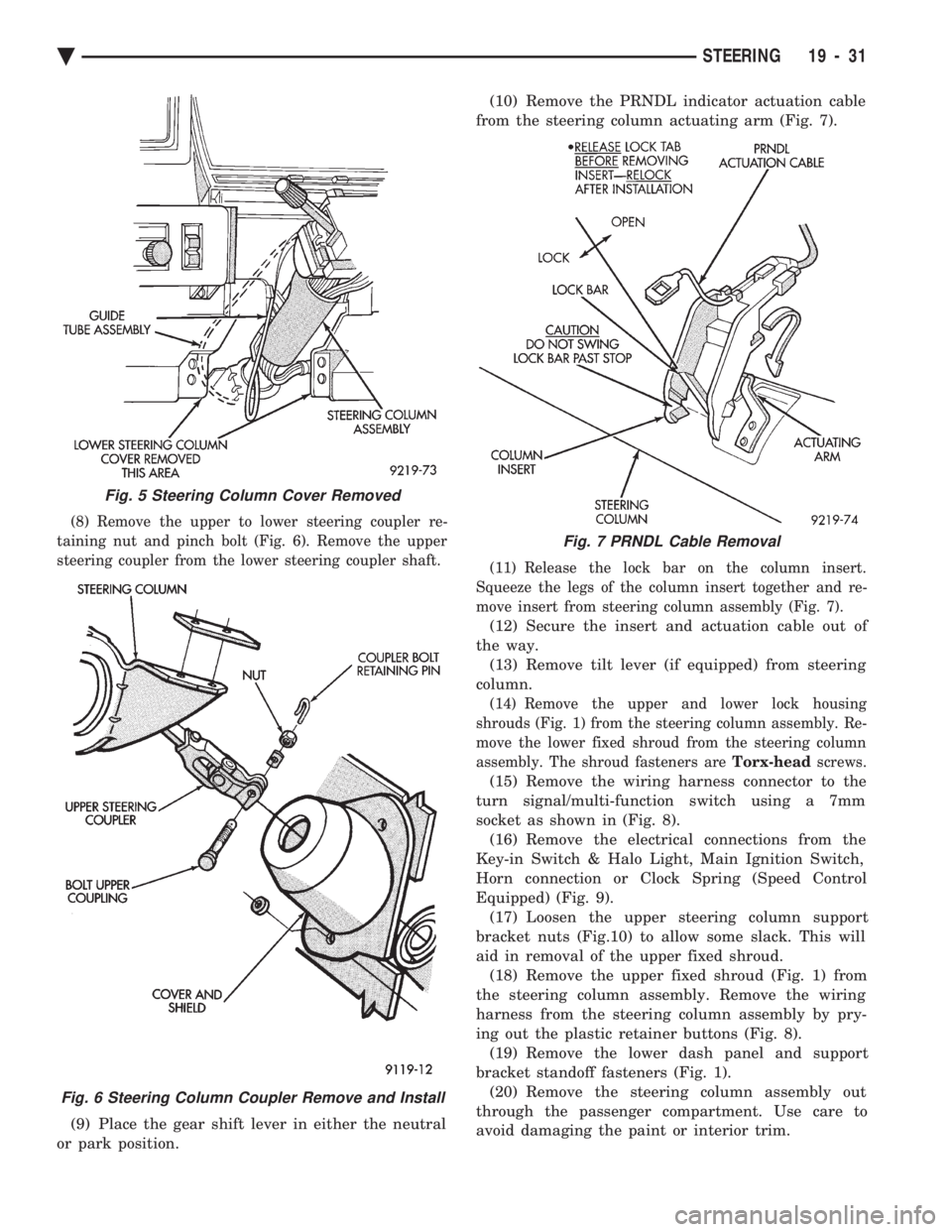

(8) Remove the upper to lower steering coupler re-

taining nut and pinch bolt (Fig. 6). Remove the upper

steering coupler from the lower steering coupler shaft.

(9) Place the gear shift lever in either the neutral

or park position. (10) Remove the PRNDL indicator actuation cable

from the steering column actuating arm (Fig. 7).

(11) Release the lock bar on the column insert.

Squeeze the legs of the column insert together and re-

move insert from steering column assembly (Fig. 7).

(12) Secure the insert and actuation cable out of

the way. (13) Remove tilt lever (if equipped) from steering

column.

(14) Remove the upper and lower lock housing

shrouds (Fig. 1) from the steering column assembly. Re-

move the lower fixed shroud from the steering column

assembly. The shroud fasteners are Torx-headscrews.

(15) Remove the wiring harness connector to the

turn signal/multi-function switch using a 7mm

socket as shown in (Fig. 8). (16) Remove the electrical connections from the

Key-in Switch & Halo Light, Main Ignition Switch,

Horn connection or Clock Spring (Speed Control

Equipped) (Fig. 9). (17) Loosen the upper steering column support

bracket nuts (Fig.10) to allow some slack. This will

aid in removal of the upper fixed shroud. (18) Remove the upper fixed shroud (Fig. 1) from

the steering column assembly. Remove the wiring

harness from the steering column assembly by pry-

ing out the plastic retainer buttons (Fig. 8). (19) Remove the lower dash panel and support

bracket standoff fasteners (Fig. 1). (20) Remove the steering column assembly out

through the passenger compartment. Use care to

avoid damaging the paint or interior trim.

Fig. 5 Steering Column Cover Removed

Fig. 6 Steering Column Coupler Remove and Install

Fig. 7 PRNDL Cable Removal

Ä STEERING 19 - 31

Page 1952 of 2438

(16) Connect the battery ground (negative) cable.

Test the operation of the lights and horns. If applica-

ble, reset the clock and radio.

STEERING COLUMN COMPONENT SERVICE

The Acustar tilt and standard steering columns

(Fig.1) have been designed to be serviced as an as-

sembly; less wiring, switches, shrouds, steering

wheel, etc. Also most steering column components

can be serviced without removing the steering col-

umn from the vehicle. For additional information on

electrical components refer to Group 8H Electrical.

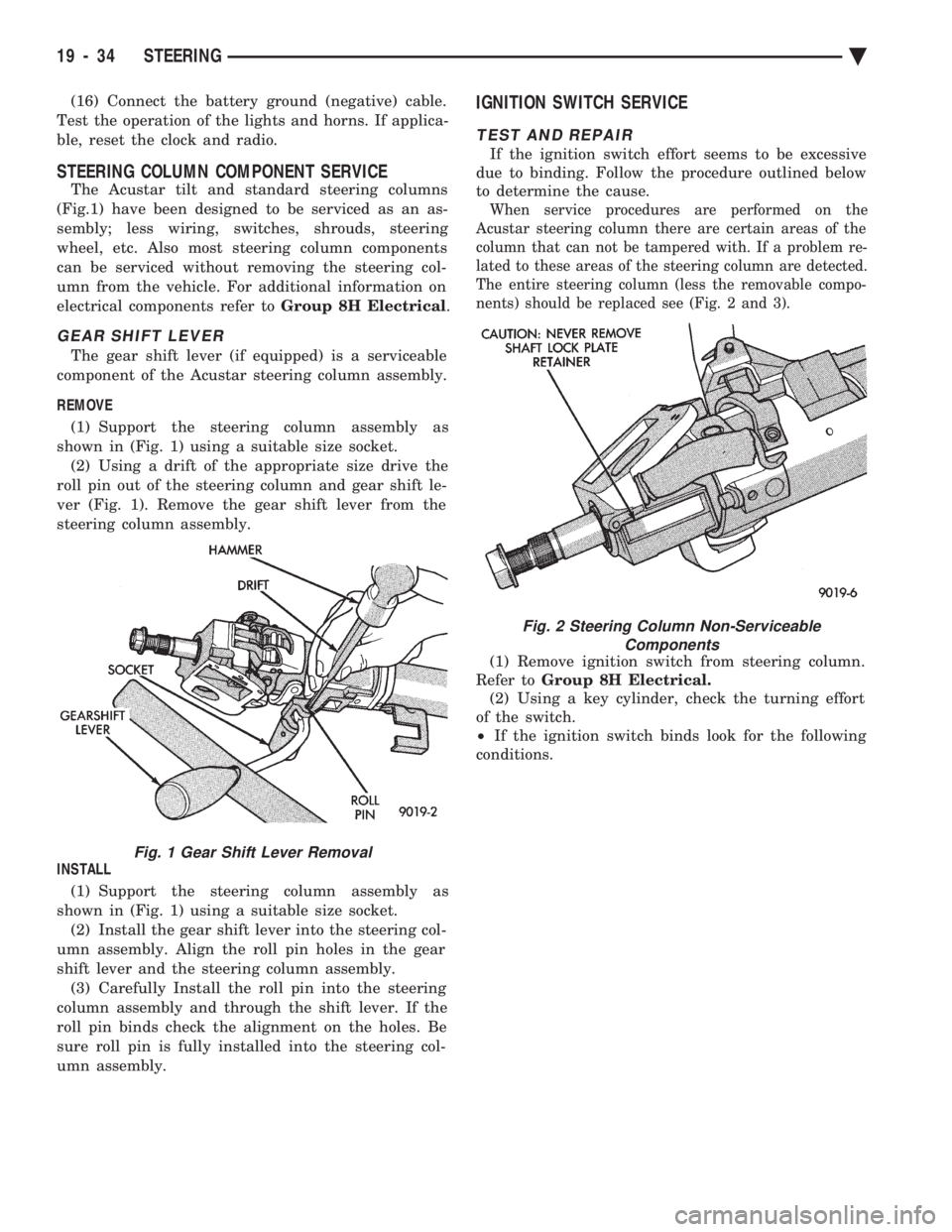

GEAR SHIFT LEVER

The gear shift lever (if equipped) is a serviceable

component of the Acustar steering column assembly.

REMOVE (1) Support the steering column assembly as

shown in (Fig. 1) using a suitable size socket. (2) Using a drift of the appropriate size drive the

roll pin out of the steering column and gear shift le-

ver (Fig. 1). Remove the gear shift lever from the

steering column assembly.

INSTALL (1) Support the steering column assembly as

shown in (Fig. 1) using a suitable size socket. (2) Install the gear shift lever into the steering col-

umn assembly. Align the roll pin holes in the gear

shift lever and the steering column assembly. (3) Carefully Install the roll pin into the steering

column assembly and through the shift lever. If the

roll pin binds check the alignment on the holes. Be

sure roll pin is fully installed into the steering col-

umn assembly.

IGNITION SWITCH SERVICE

TEST AND REPAIR

If the ignition switch effort seems to be excessive

due to binding. Follow the procedure outlined below

to determine the cause.

When service procedures are performed on the

Acustar steering column there are certain areas of the

column that can not be tampered with. If a problem re-

lated to these areas of the steering column are detected.

The entire steering column (less the removable compo-

nents) should be replaced see (Fig. 2 and 3).

(1) Remove ignition switch from steering column.

Refer to Group 8H Electrical.

(2) Using a key cylinder, check the turning effort

of the switch.

² If the ignition switch binds look for the following

conditions.

Fig. 1 Gear Shift Lever Removal

Fig. 2 Steering Column Non-Serviceable Components

19 - 34 STEERING Ä