fuel CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 2192 of 2438

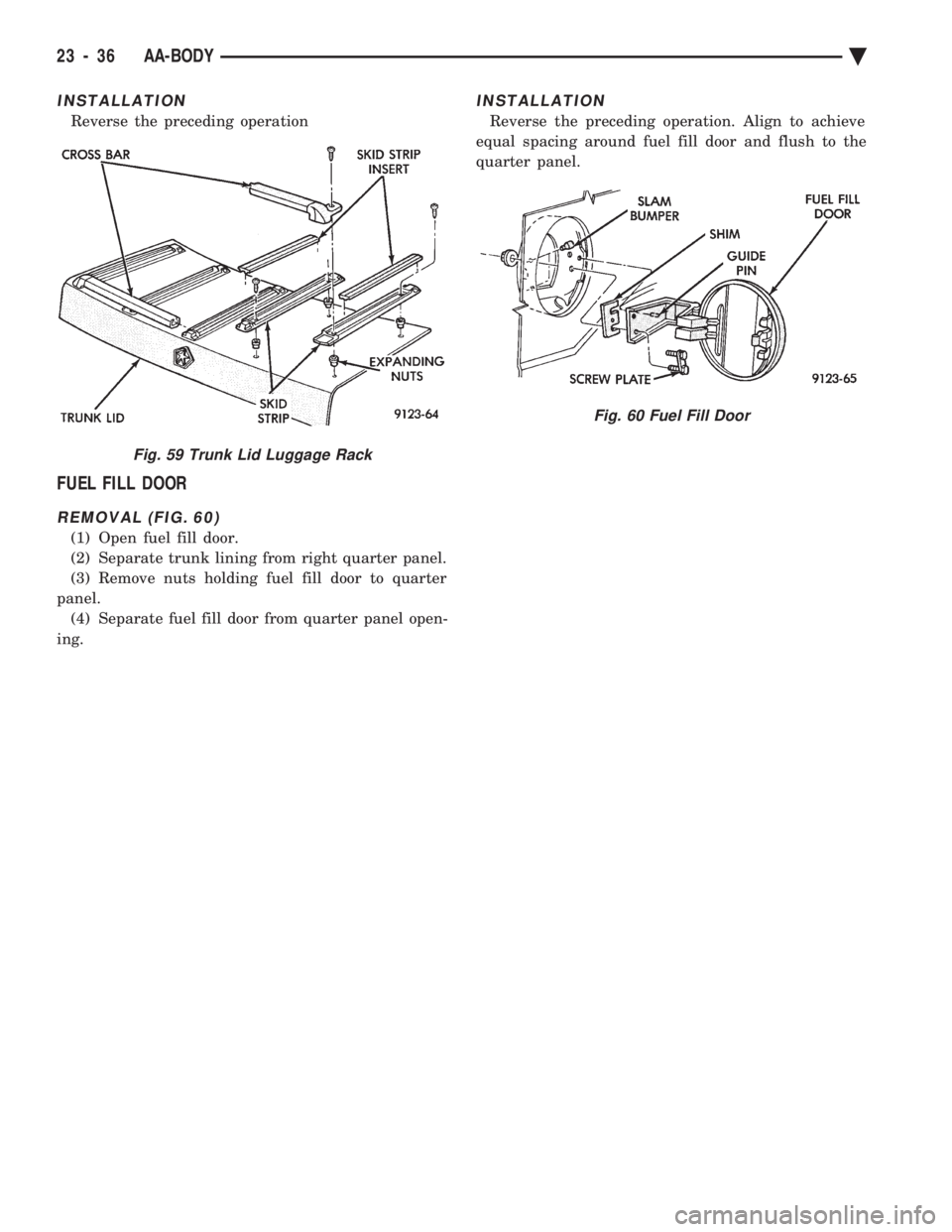

INSTALLATION

Reverse the preceding operation

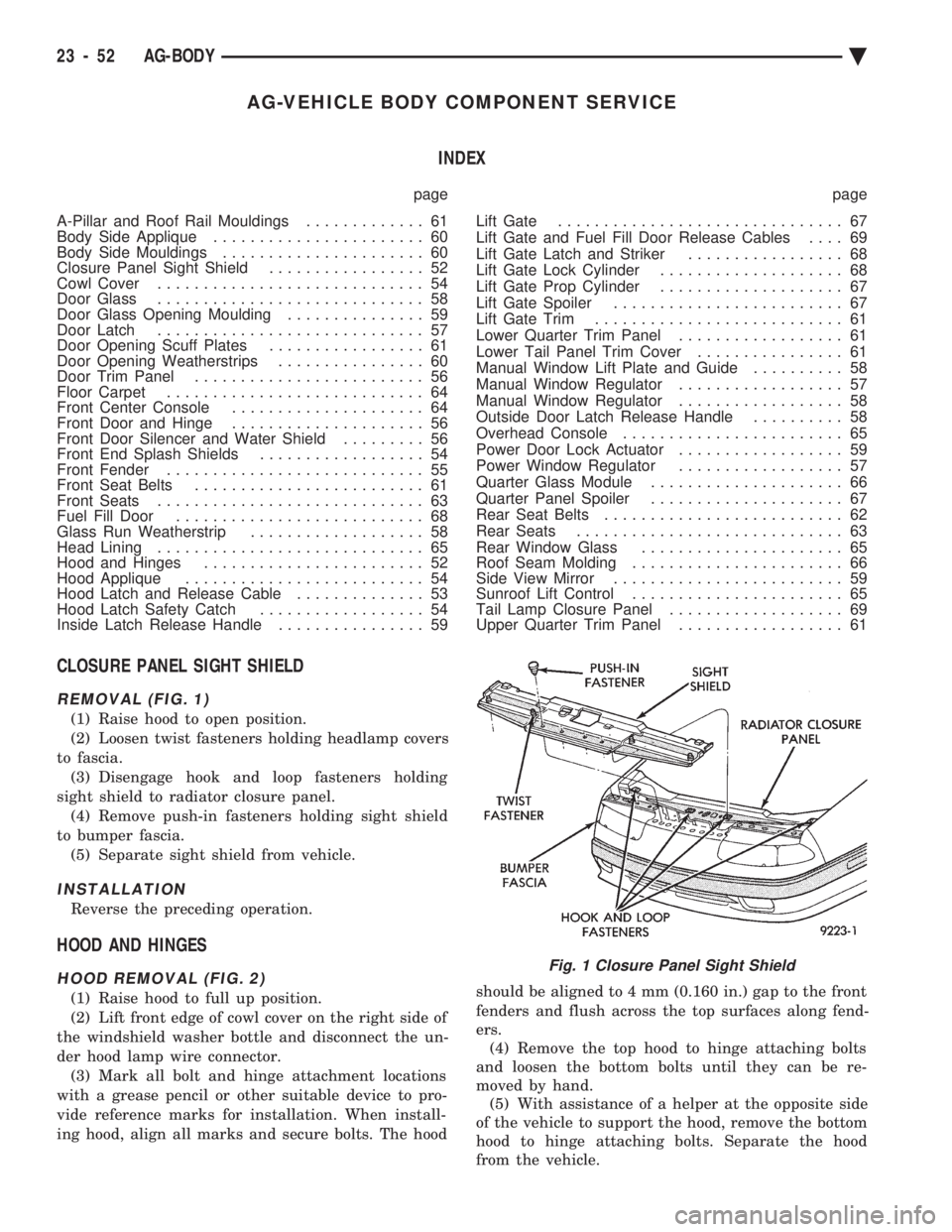

FUEL FILL DOOR

REMOVAL (FIG. 60)

(1) Open fuel fill door.

(2) Separate trunk lining from right quarter panel.

(3) Remove nuts holding fuel fill door to quarter

panel. (4) Separate fuel fill door from quarter panel open-

ing.

INSTALLATION

Reverse the preceding operation. Align to achieve

equal spacing around fuel fill door and flush to the

quarter panel.

Fig. 59 Trunk Lid Luggage Rack

Fig. 60 Fuel Fill Door

23 - 36 AA-BODY Ä

Page 2208 of 2438

AG-VEHICLE BODY COMPONENT SERVICE INDEX

page page

A-Pillar and Roof Rail Mouldings ............. 61

Body Side Applique ....................... 60

Body Side Mouldings ...................... 60

Closure Panel Sight Shield ................. 52

Cowl Cover ............................. 54

Door Glass ............................. 58

Door Glass Opening Moulding ............... 59

Door Latch ............................. 57

Door Opening Scuff Plates ................. 61

Door Opening Weatherstrips ................ 60

Door Trim Panel ......................... 56

Floor Carpet ............................ 64

Front Center Console ..................... 64

Front Door and Hinge ..................... 56

Front Door Silencer and Water Shield ......... 56

Front End Splash Shields .................. 54

Front Fender ............................ 55

Front Seat Belts ......................... 61

Front Seats ............................. 63

Fuel Fill Door ........................... 68

Glass Run Weatherstrip ................... 58

Head Lining ............................. 65

Hood and Hinges ........................ 52

Hood Applique .......................... 54

Hood Latch and Release Cable .............. 53

Hood Latch Safety Catch .................. 54

Inside Latch Release Handle ................ 59 Lift Gate

............................... 67

Lift Gate and Fuel Fill Door Release Cables .... 69

Lift Gate Latch and Striker ................. 68

Lift Gate Lock Cylinder .................... 68

Lift Gate Prop Cylinder .................... 67

Lift Gate Spoiler ......................... 67

Lift Gate Trim ........................... 61

Lower Quarter Trim Panel .................. 61

Lower Tail Panel Trim Cover ................ 61

Manual Window Lift Plate and Guide .......... 58

Manual Window Regulator .................. 57

Manual Window Regulator .................. 58

Outside Door Latch Release Handle .......... 58

Overhead Console ........................ 65

Power Door Lock Actuator .................. 59

Power Window Regulator .................. 57

Quarter Glass Module ..................... 66

Quarter Panel Spoiler ..................... 67

Rear Seat Belts .......................... 62

Rear Seats ............................. 63

Rear Window Glass ...................... 65

Roof Seam Molding ....................... 66

Side View Mirror ......................... 59

Sunroof Lift Control ....................... 65

Tail Lamp Closure Panel ................... 69

Upper Quarter Trim Panel .................. 61

CLOSURE PANEL SIGHT SHIELD

REMOVAL (FIG. 1)

(1) Raise hood to open position.

(2) Loosen twist fasteners holding headlamp covers

to fascia. (3) Disengage hook and loop fasteners holding

sight shield to radiator closure panel. (4) Remove push-in fasteners holding sight shield

to bumper fascia. (5) Separate sight shield from vehicle.

INSTALLATION

Reverse the preceding operation.

HOOD AND HINGES

HOOD REMOVAL (FIG. 2)

(1) Raise hood to full up position.

(2) Lift front edge of cowl cover on the right side of

the windshield washer bottle and disconnect the un-

der hood lamp wire connector. (3) Mark all bolt and hinge attachment locations

with a grease pencil or other suitable device to pro-

vide reference marks for installation. When install-

ing hood, align all marks and secure bolts. The hood should be aligned to 4 mm (0.160 in.) gap to the front

fenders and flush across the top surfaces along fend-

ers. (4) Remove the top hood to hinge attaching bolts

and loosen the bottom bolts until they can be re-

moved by hand. (5) With assistance of a helper at the opposite side

of the vehicle to support the hood, remove the bottom

hood to hinge attaching bolts. Separate the hood

from the vehicle.

Fig. 1 Closure Panel Sight Shield

23 - 52 AG-BODY Ä

Page 2224 of 2438

(3) Disconnect lift gate wire connectors and rear

window washer hose, if equipped. (4) Remove upper lift gate trim molding.

(5) Support lift gate on a suitable lifting device.

(6) Disconnect top of prop cylinders from lift gate.

(7) Mark lift gate hinge locations to assist instal-

lation an alignment of lift gate. (8) With assistance of a helper, remove bolts hold-

ing lift gate to hinge. (9) Separate lift gate from vehicle.

INSTALLATION

Reverse the preceding operation.

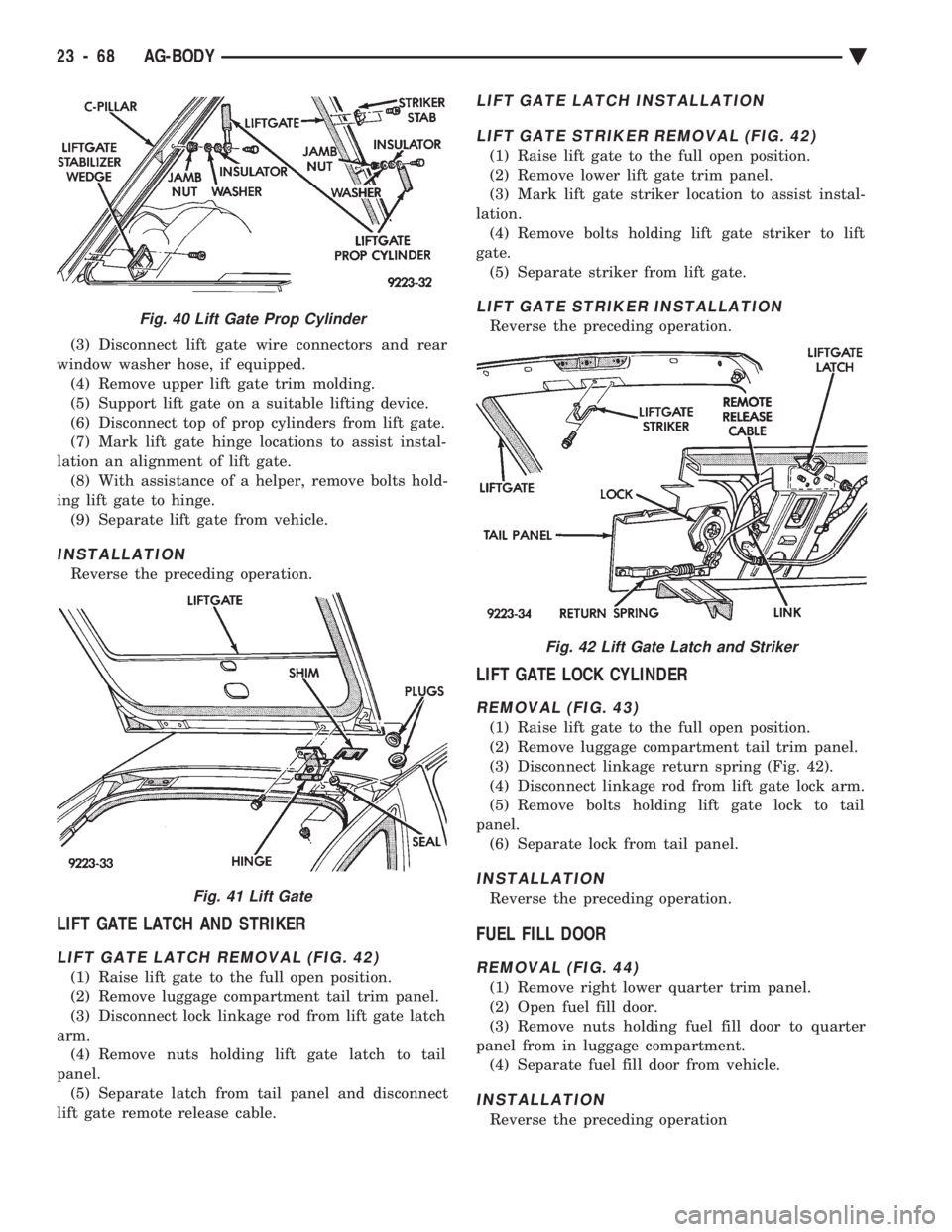

LIFT GATE LATCH AND STRIKER

LIFT GATE LATCH REMOVAL (FIG. 42)

(1) Raise lift gate to the full open position.

(2) Remove luggage compartment tail trim panel.

(3) Disconnect lock linkage rod from lift gate latch

arm. (4) Remove nuts holding lift gate latch to tail

panel. (5) Separate latch from tail panel and disconnect

lift gate remote release cable.

LIFT GATE LATCH INSTALLATION

LIFT GATE STRIKER REMOVAL (FIG. 42)

(1) Raise lift gate to the full open position.

(2) Remove lower lift gate trim panel.

(3) Mark lift gate striker location to assist instal-

lation. (4) Remove bolts holding lift gate striker to lift

gate. (5) Separate striker from lift gate.

LIFT GATE STRIKER INSTALLATION

Reverse the preceding operation.

LIFT GATE LOCK CYLINDER

REMOVAL (FIG. 43)

(1) Raise lift gate to the full open position.

(2) Remove luggage compartment tail trim panel.

(3) Disconnect linkage return spring (Fig. 42).

(4) Disconnect linkage rod from lift gate lock arm.

(5) Remove bolts holding lift gate lock to tail

panel. (6) Separate lock from tail panel.

INSTALLATION

Reverse the preceding operation.

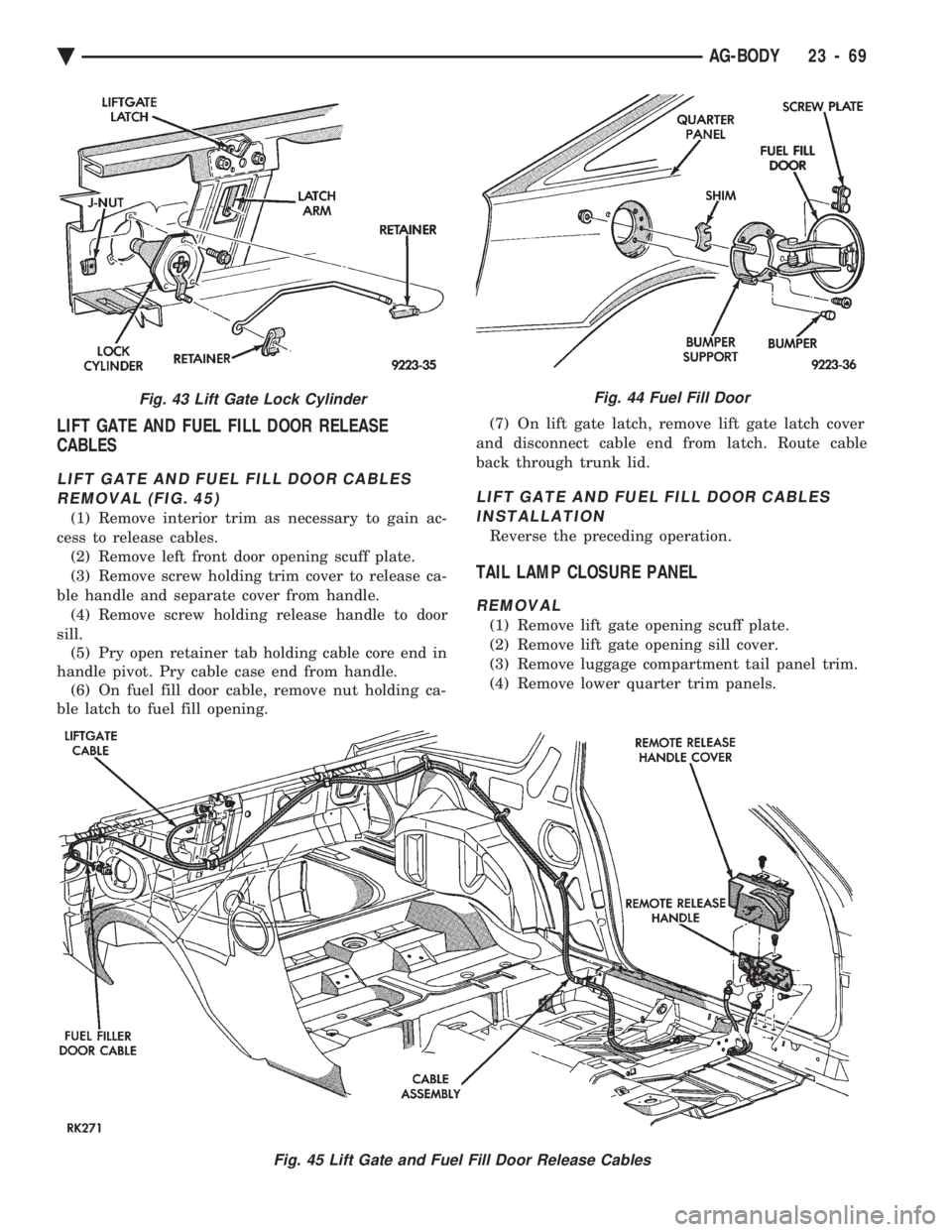

FUEL FILL DOOR

REMOVAL (FIG. 44)

(1) Remove right lower quarter trim panel.

(2) Open fuel fill door.

(3) Remove nuts holding fuel fill door to quarter

panel from in luggage compartment. (4) Separate fuel fill door from vehicle.

INSTALLATION

Reverse the preceding operation

Fig. 40 Lift Gate Prop Cylinder

Fig. 41 Lift Gate

Fig. 42 Lift Gate Latch and Striker

23 - 68 AG-BODY Ä

Page 2225 of 2438

LIFT GATE AND FUEL FILL DOOR RELEASE

CABLES

LIFT GATE AND FUEL FILL DOOR CABLES

REMOVAL (FIG. 45)

(1) Remove interior trim as necessary to gain ac-

cess to release cables. (2) Remove left front door opening scuff plate.

(3) Remove screw holding trim cover to release ca-

ble handle and separate cover from handle. (4) Remove screw holding release handle to door

sill. (5) Pry open retainer tab holding cable core end in

handle pivot. Pry cable case end from handle. (6) On fuel fill door cable, remove nut holding ca-

ble latch to fuel fill opening. (7) On lift gate latch, remove lift gate latch cover

and disconnect cable end from latch. Route cable

back through trunk lid.

LIFT GATE AND FUEL FILL DOOR CABLES INSTALLATION

Reverse the preceding operation.

TAIL LAMP CLOSURE PANEL

REMOVAL

(1) Remove lift gate opening scuff plate.

(2) Remove lift gate opening sill cover.

(3) Remove luggage compartment tail panel trim.

(4) Remove lower quarter trim panels.

Fig. 45 Lift Gate and Fuel Fill Door Release Cables

Fig. 43 Lift Gate Lock CylinderFig. 44 Fuel Fill Door

Ä AG-BODY 23 - 69

Page 2227 of 2438

AJ-VEHICLE BODY COMPONENT SERVICE INDEX

page page

A-Pillar and Roof Rail Mouldings ............. 77

Cowl Cover ............................. 73

Cowl Panel Trim and Scuff Plates ............ 77

Door Glass ............................. 76

Door Glass Lift Plate and Guide Post ......... 76

Door Latch ............................. 75

Door Trim Panel ......................... 74

Floor Carpet ............................ 80

Front Center Console ..................... 79

Front Door and Hinge ..................... 75

Front Door Silencer and Water Shield ......... 74

Front End Splash Shields .................. 73

Front Seat Belts ......................... 78

Front Seats ............................. 78

Fuel Fill Door ........................... 84

Glass Run WeatherstripÐAJ-21 Body ......... 76

Grille .................................. 71

Grille Header Molding ..................... 71

Grille Opening Panel ...................... 71

Head Lining ............................. 81

Hood and Hinges ........................ 72

Hood Latch and Release Cable .............. 72

Inside Latch Release Handle ................ 76 Lower Grille

............................. 71

Outside Door Latch Release Handle .......... 76

Overhead Console ........................ 80

Power Door Lock Actuator .................. 76

Quarter Extension Trim Panel ............... 77

Quarter Glass Module ..................... 85

Quarter Trim Panel ....................... 77

Rear Seat Belts .......................... 78

Rear Seats ............................. 79

Rear Shelf Trim Panel ..................... 78

Rear Window Glass ...................... 81

Sun Roof Air Deflector .................... 81

Sun Roof Drain Tubes .................... 81

Sun Roof Weatherstrip .................... 81

Trunk Lid .............................. 82

Trunk Lid and Fuel Fill Door Release Cables . . . 83

Trunk Lid Hinge ......................... 82

Trunk Lid Latch .......................... 83

Trunk Lid Lock .......................... 83

Trunk Lid Luggage Rack ................... 83

Trunk Lid Torsion Bar ..................... 83

Trunk Opening Weatherstrip ................ 83

Window Regulator ........................ 75

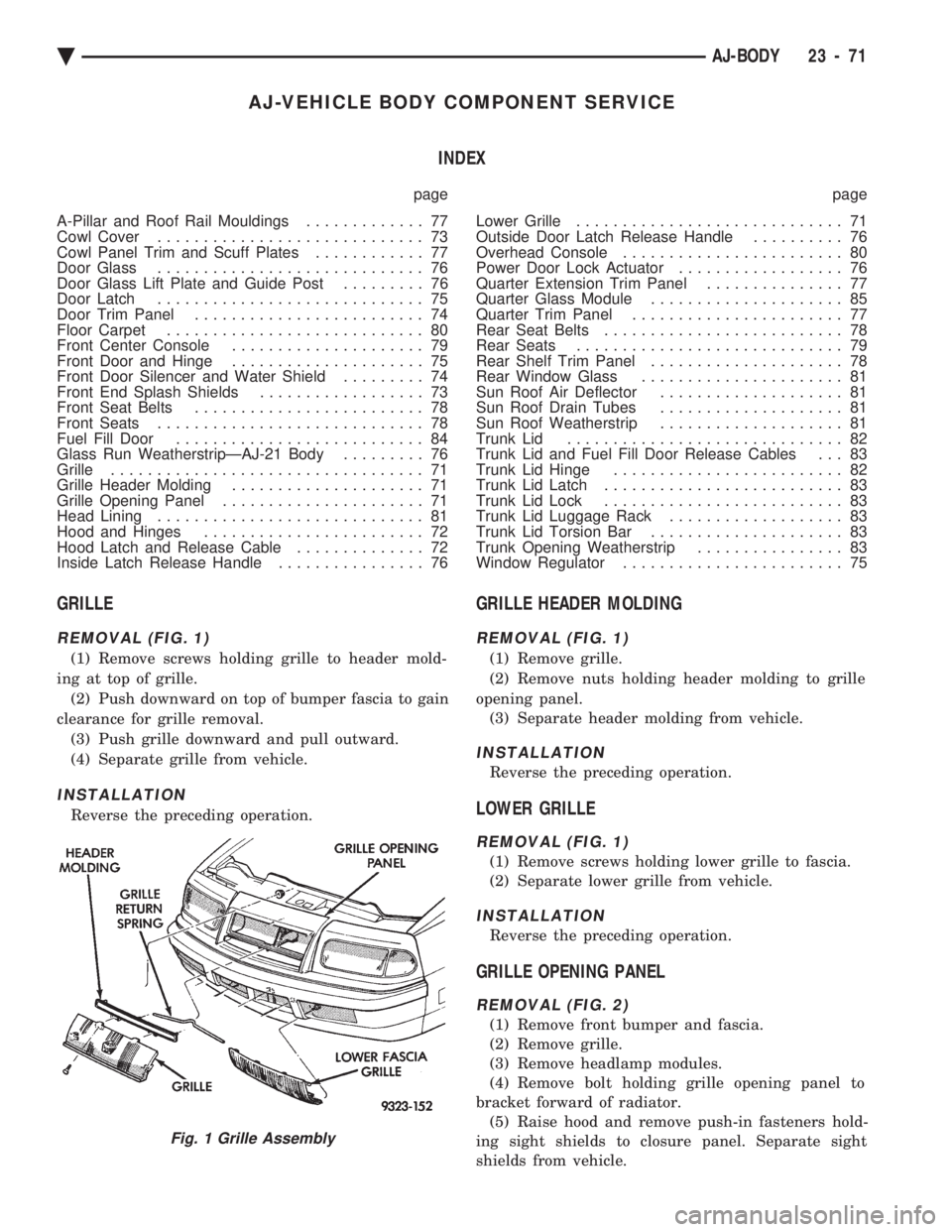

GRILLE

REMOVAL (FIG. 1)

(1) Remove screws holding grille to header mold-

ing at top of grille. (2) Push downward on top of bumper fascia to gain

clearance for grille removal. (3) Push grille downward and pull outward.

(4) Separate grille from vehicle.

INSTALLATION

Reverse the preceding operation.

GRILLE HEADER MOLDING

REMOVAL (FIG. 1)

(1) Remove grille.

(2) Remove nuts holding header molding to grille

opening panel. (3) Separate header molding from vehicle.

INSTALLATION

Reverse the preceding operation.

LOWER GRILLE

REMOVAL (FIG. 1)

(1) Remove screws holding lower grille to fascia.

(2) Separate lower grille from vehicle.

INSTALLATION

Reverse the preceding operation.

GRILLE OPENING PANEL

REMOVAL (FIG. 2)

(1) Remove front bumper and fascia.

(2) Remove grille.

(3) Remove headlamp modules.

(4) Remove bolt holding grille opening panel to

bracket forward of radiator. (5) Raise hood and remove push-in fasteners hold-

ing sight shields to closure panel. Separate sight

shields from vehicle.

Fig. 1 Grille Assembly

Ä AJ-BODY 23 - 71

Page 2239 of 2438

TRUNK LID TORSION BAR

REMOVAL

(1) Raise and support trunk lid in the full up posi-

tion. (2) Remove trunk lining as necessary to gain ac-

cess to torsion bars. (3) Disengage adjusting end of torsion bar from the

slot in the tension adjustment bracket. (4) Pivot torsion bar out of lift arm swivel.

(5) Disconnect torsion bar from hinge.

INSTALLATION

Reverse the preceding operation.

TRUNK LID LATCH

REMOVAL

(1) Raise trunk lid to the full up position.

(2) Remove push-in fasteners holding lining to

trunk lid as necessary. (3) Disconnect remote release cable from latch.

(4) Remove bolts holding latch to trunk lid and

separate latch from vehicle.

INSTALLATION

Insert trunk lock chill into latch release driver and

reverse the preceding operation.

TRUNK LID LOCK

REMOVAL

(1) Remove trunk lid tail light assembly. Refer to

Group 8L, Lamps for proper procedures. (2) Remove trunk latch.

(3) Remove nuts holding lock cylinder and chill to

trunk lid and separate the lock from the vehicle.

INSTALLATION

Reverse the preceding operation.

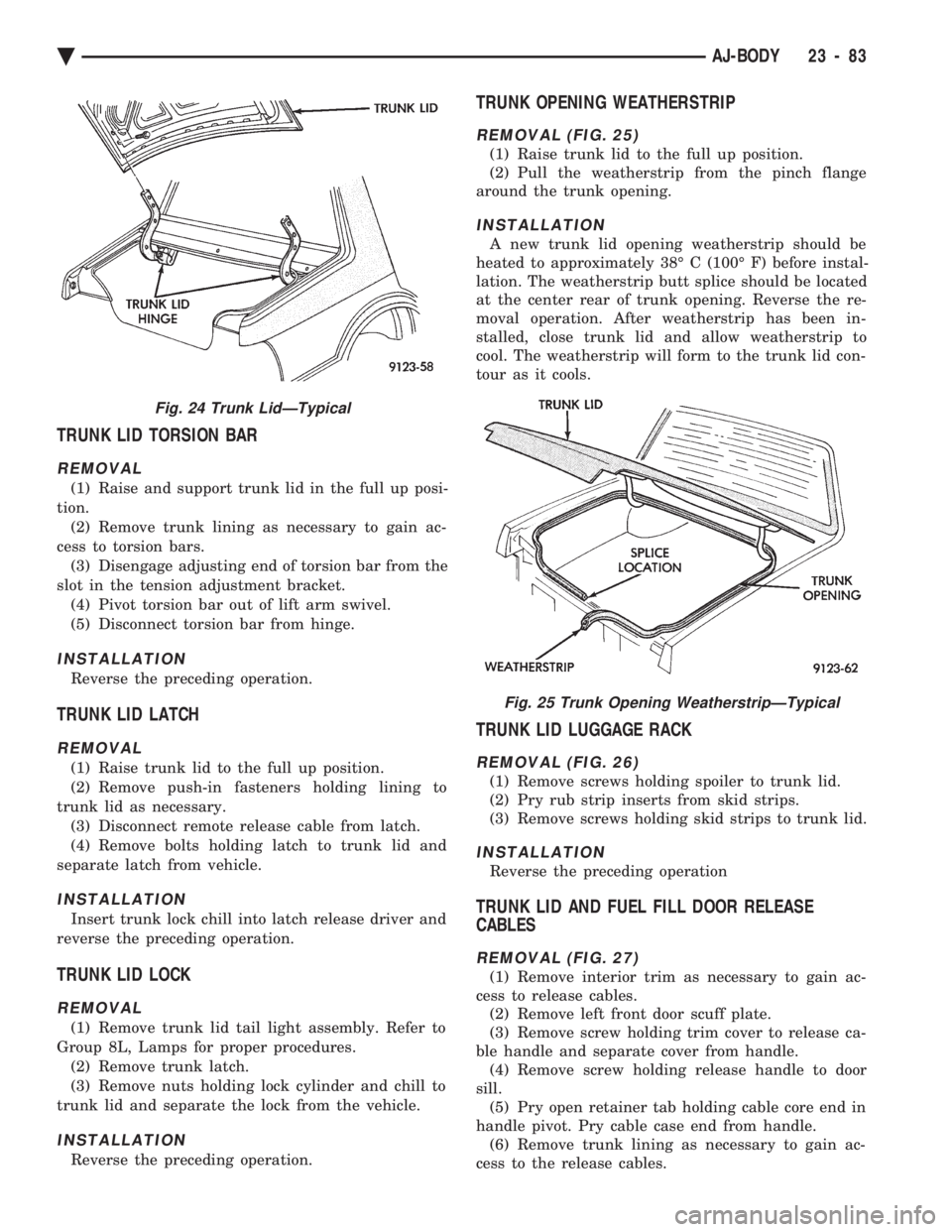

TRUNK OPENING WEATHERSTRIP

REMOVAL (FIG. 25)

(1) Raise trunk lid to the full up position.

(2) Pull the weatherstrip from the pinch flange

around the trunk opening.

INSTALLATION

A new trunk lid opening weatherstrip should be

heated to approximately 38É C (100É F) before instal-

lation. The weatherstrip butt splice should be located

at the center rear of trunk opening. Reverse the re-

moval operation. After weatherstrip has been in-

stalled, close trunk lid and allow weatherstrip to

cool. The weatherstrip will form to the trunk lid con-

tour as it cools.

TRUNK LID LUGGAGE RACK

REMOVAL (FIG. 26)

(1) Remove screws holding spoiler to trunk lid.

(2) Pry rub strip inserts from skid strips.

(3) Remove screws holding skid strips to trunk lid.

INSTALLATION

Reverse the preceding operation

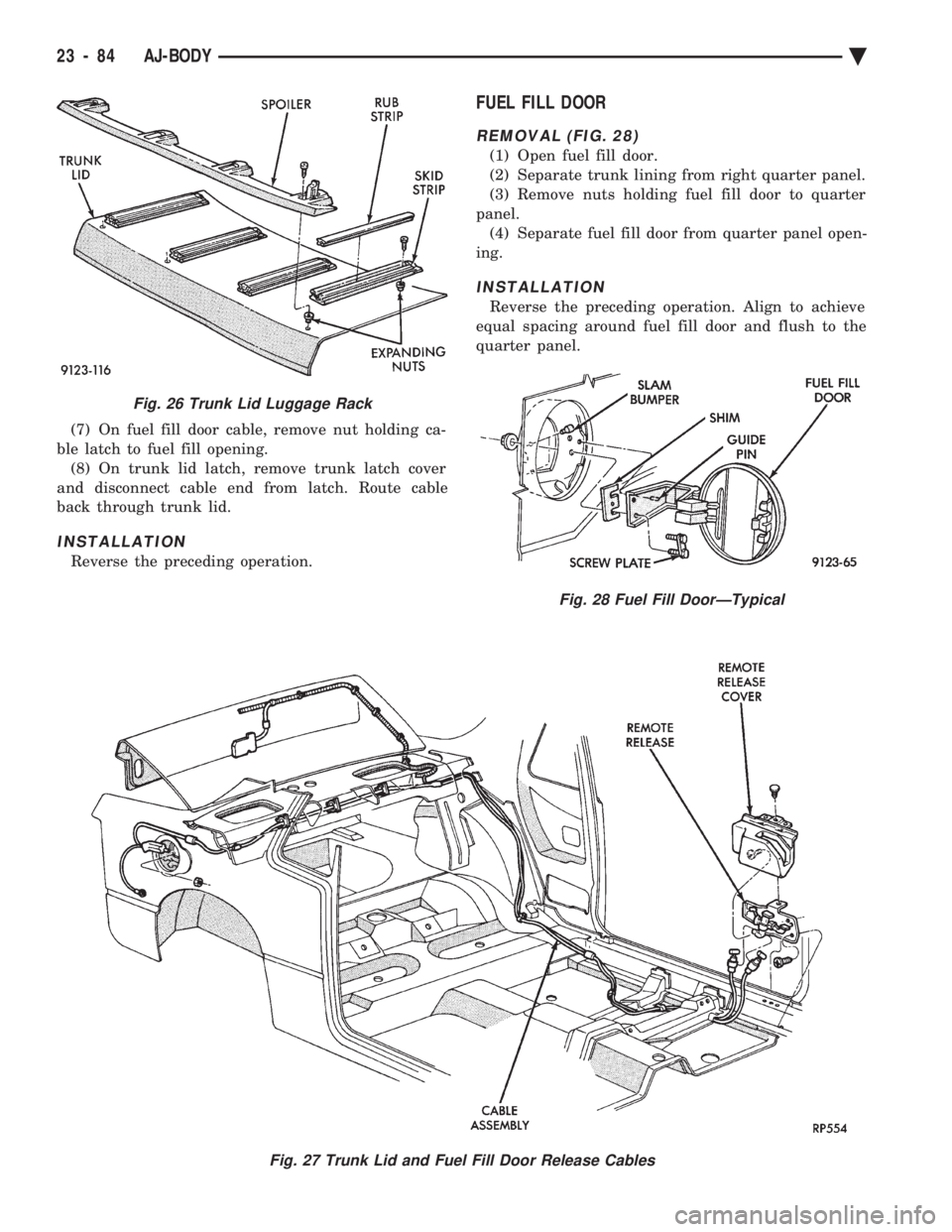

TRUNK LID AND FUEL FILL DOOR RELEASE

CABLES

REMOVAL (FIG. 27)

(1) Remove interior trim as necessary to gain ac-

cess to release cables. (2) Remove left front door scuff plate.

(3) Remove screw holding trim cover to release ca-

ble handle and separate cover from handle. (4) Remove screw holding release handle to door

sill. (5) Pry open retainer tab holding cable core end in

handle pivot. Pry cable case end from handle. (6) Remove trunk lining as necessary to gain ac-

cess to the release cables.

Fig. 24 Trunk LidÐTypical

Fig. 25 Trunk Opening WeatherstripÐTypical

Ä AJ-BODY 23 - 83

Page 2240 of 2438

(7) On fuel fill door cable, remove nut holding ca-

ble latch to fuel fill opening. (8) On trunk lid latch, remove trunk latch cover

and disconnect cable end from latch. Route cable

back through trunk lid.

INSTALLATION

Reverse the preceding operation.

FUEL FILL DOOR

REMOVAL (FIG. 28)

(1) Open fuel fill door.

(2) Separate trunk lining from right quarter panel.

(3) Remove nuts holding fuel fill door to quarter

panel. (4) Separate fuel fill door from quarter panel open-

ing.

INSTALLATION

Reverse the preceding operation. Align to achieve

equal spacing around fuel fill door and flush to the

quarter panel.

Fig. 26 Trunk Lid Luggage Rack

Fig. 27 Trunk Lid and Fuel Fill Door Release Cables

Fig. 28 Fuel Fill DoorÐTypical

23 - 84 AJ-BODY Ä

Page 2395 of 2438

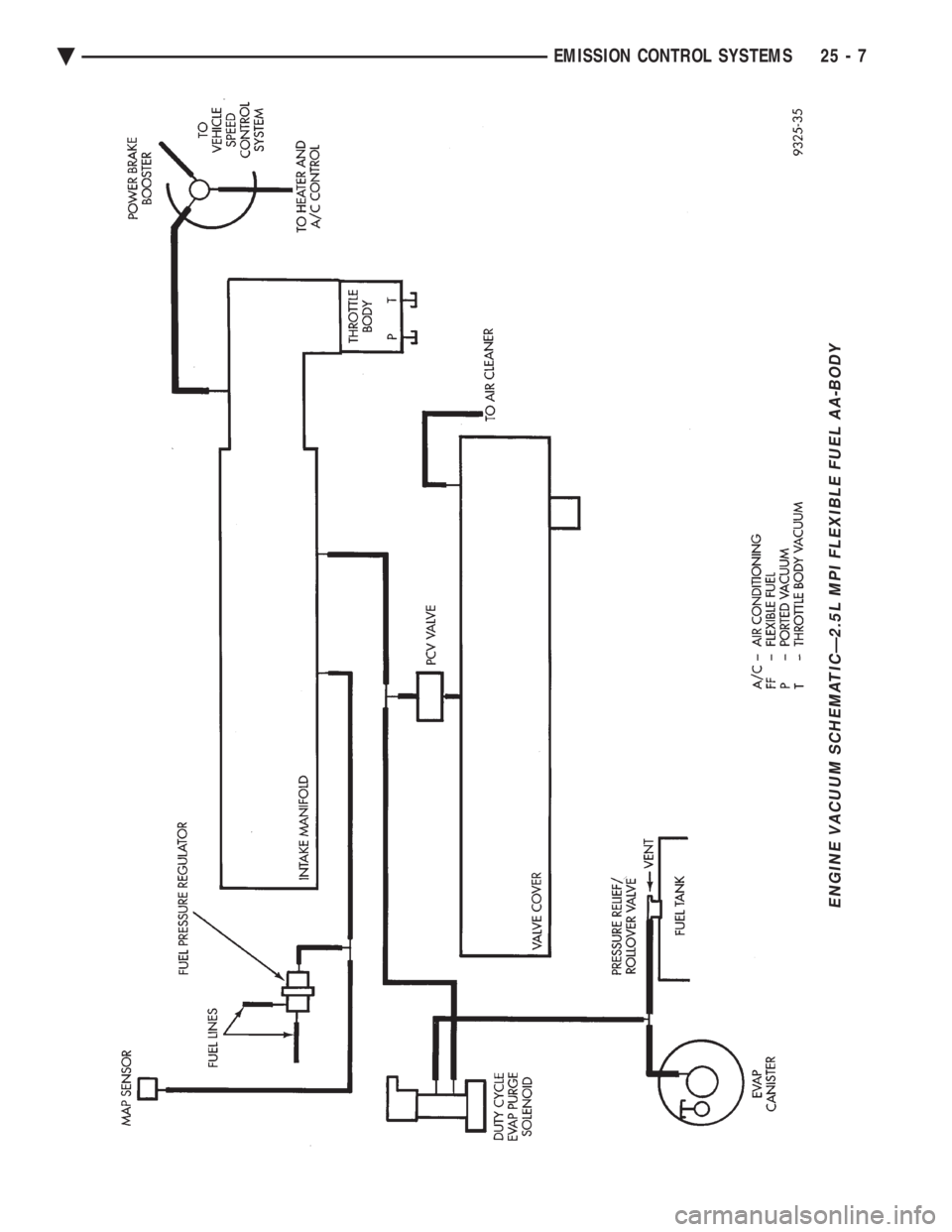

ENGINE VACUUM SCHEMATICÐ2.5L MPI FLEXIBLE FUEL AA-BODY

Ä EMISSION CONTROL SYSTEMS 25 - 7

Page 2401 of 2438

EVAPORATION CONTROL SYSTEM

The evaporation control system prevents the emis-

sion of fuel tank vapors into the atmosphere. When fuel

evaporates in the fuel tank, the vapors pass through

vent hoses or tubes to a charcoal canister. The canister

temporarily holds the vapors. The powertrain control

module (PCM) allows intake manifold vacuum to draw

vapors into the combustion chambers during certain

operating conditions. The PCM uses the canister purge

solenoid to regulate vapor flow. On 2.2L and 2.5L TBI, 3.3L, and 3.8L engines,

manifold vacuum purges the vapors at idle as well as

off idle. These engines use a bi-level purge system. The

system uses 2 sources of vacuum remove fuel vapors

from the canister. Turbo III engines use a tri-level canister purge sys-

tem. In this system, fuel vapors are drawn into the

engine through the throttle body and air cleaner. Fuel

vapors are drawn in at closed throttle, part throttle,

and wide open throttle (in boost). The 2.5L MPI (flexible fuel AA-Body) and 3.0L have

a duty cycle purge system. The powertrain control

module PCM controls vapor flow by operating the duty

cycle EVAP purge solenoid. Refer to Duty Cycle EVAP

Purge Solenoid in this section. The evaporative system uses specially manu-

factured hoses. If they need replacement, only

use fuel resistant hose.

PRESSURE RELIEF/ROLLOVER VALVE

All vehicles have a combination pressure relief and

rollover valve. The dual function valve relieves fuel

tank pressure. The valve also prevents fuel flow

through the fuel tank vent valve hoses if the vehicle

accidentally rolls over. All vehicles pass a 360É rollover. The pressure relief valve opens at a certain pressure.

When fuel tank pressure increases above the cali-

brated pressure, the valve opens to release fuel tank

vapors pressure. The evaporative (charcoal) canister

stores the vapors. For pressure relief/rollover valve

service, refer to the Fuel Tank section of Group 14.

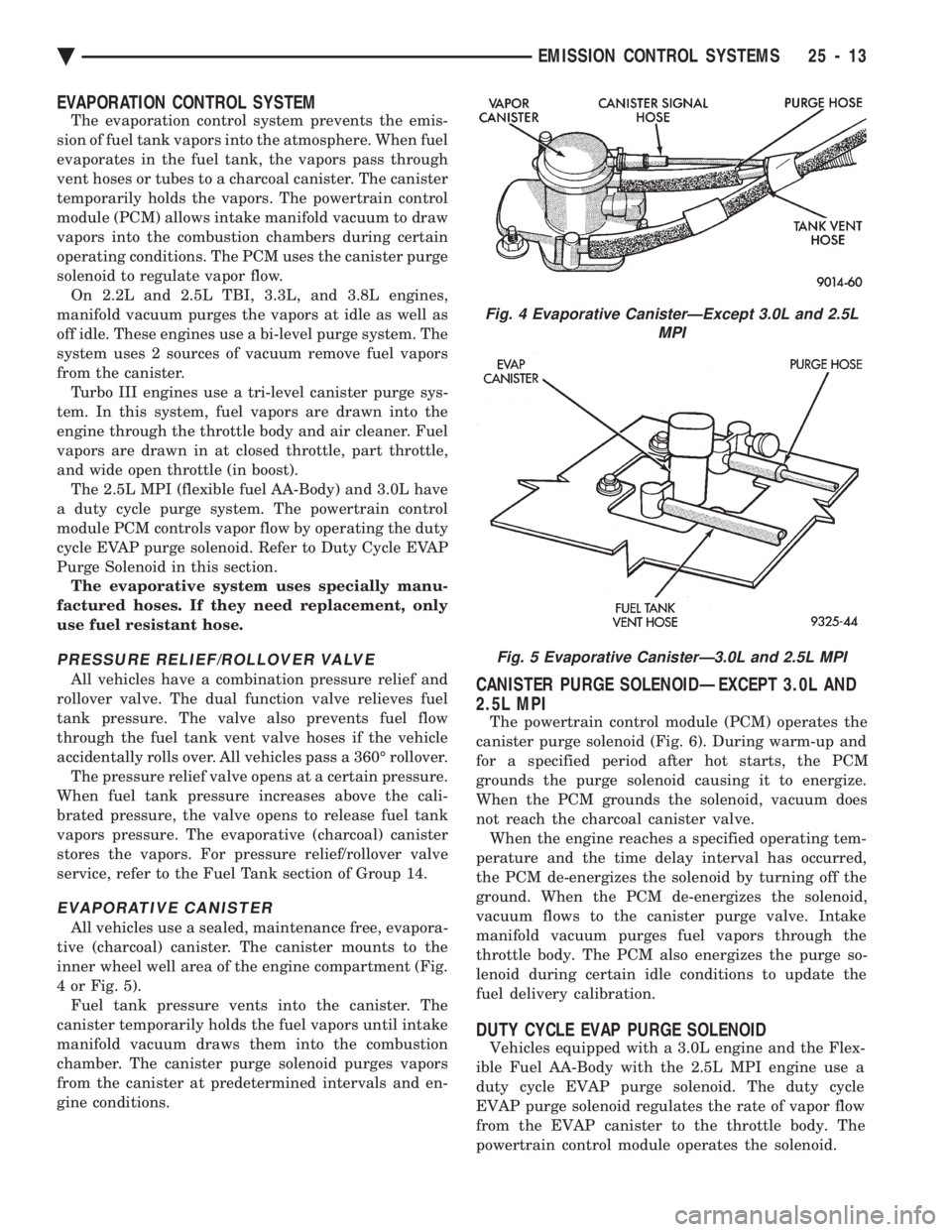

EVAPORATIVE CANISTER

All vehicles use a sealed, maintenance free, evapora-

tive (charcoal) canister. The canister mounts to the

inner wheel well area of the engine compartment (Fig.

4 or Fig. 5). Fuel tank pressure vents into the canister. The

canister temporarily holds the fuel vapors until intake

manifold vacuum draws them into the combustion

chamber. The canister purge solenoid purges vapors

from the canister at predetermined intervals and en-

gine conditions.

CANISTER PURGE SOLENOIDÐEXCEPT 3.0L AND

2.5L MPI

The powertrain control module (PCM) operates the

canister purge solenoid (Fig. 6). During warm-up and

for a specified period after hot starts, the PCM

grounds the purge solenoid causing it to energize.

When the PCM grounds the solenoid, vacuum does

not reach the charcoal canister valve. When the engine reaches a specified operating tem-

perature and the time delay interval has occurred,

the PCM de-energizes the solenoid by turning off the

ground. When the PCM de-energizes the solenoid,

vacuum flows to the canister purge valve. Intake

manifold vacuum purges fuel vapors through the

throttle body. The PCM also energizes the purge so-

lenoid during certain idle conditions to update the

fuel delivery calibration.

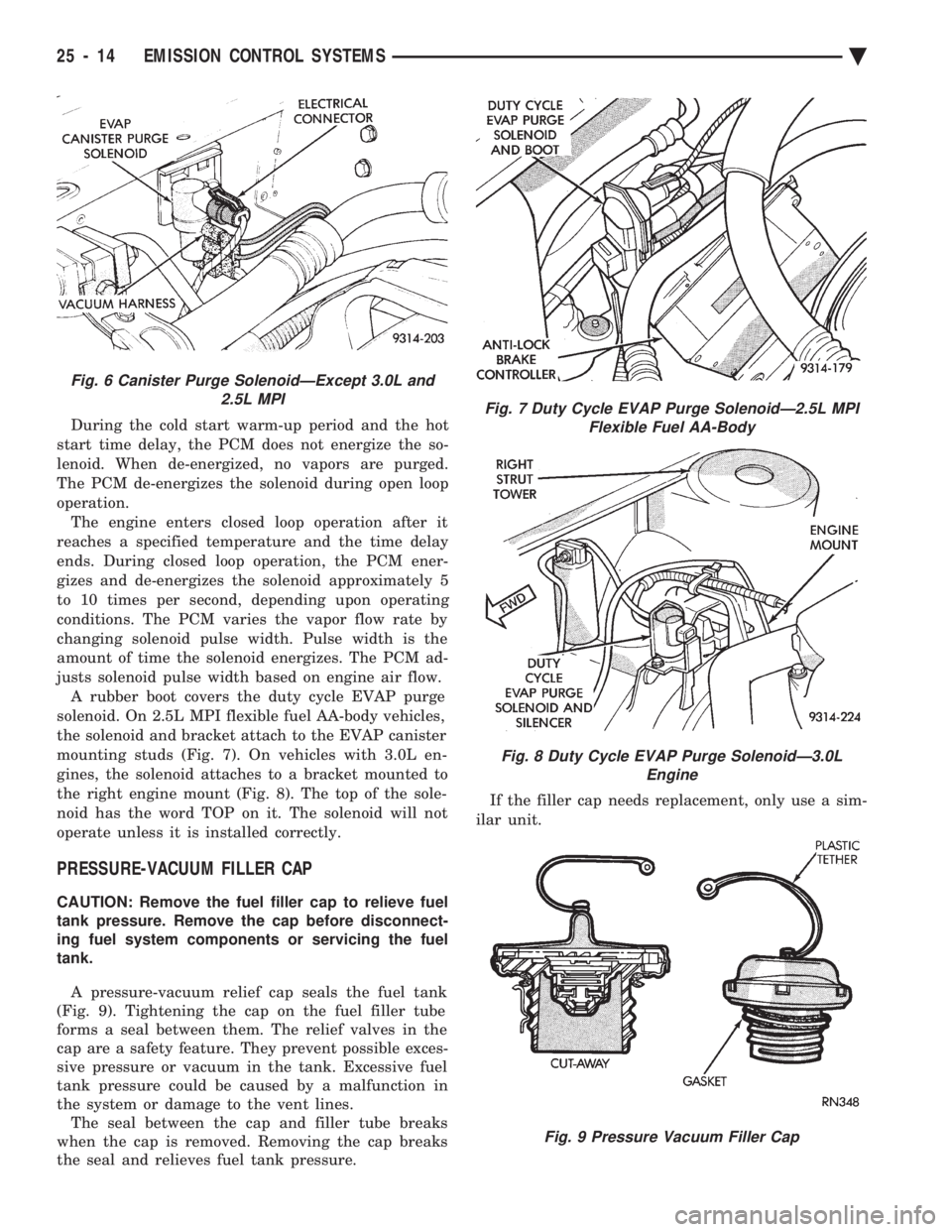

DUTY CYCLE EVAP PURGE SOLENOID

Vehicles equipped with a 3.0L engine and the Flex-

ible Fuel AA-Body with the 2.5L MPI engine use a

duty cycle EVAP purge solenoid. The duty cycle

EVAP purge solenoid regulates the rate of vapor flow

from the EVAP canister to the throttle body. The

powertrain control module operates the solenoid.

Fig. 4 Evaporative CanisterÐExcept 3.0L and 2.5L MPI

Fig. 5 Evaporative CanisterÐ3.0L and 2.5L MPI

Ä EMISSION CONTROL SYSTEMS 25 - 13

Page 2402 of 2438

During the cold start warm-up period and the hot

start time delay, the PCM does not energize the so-

lenoid. When de-energized, no vapors are purged.

The PCM de-energizes the solenoid during open loop

operation. The engine enters closed loop operation after it

reaches a specified temperature and the time delay

ends. During closed loop operation, the PCM ener-

gizes and de-energizes the solenoid approximately 5

to 10 times per second, depending upon operating

conditions. The PCM varies the vapor flow rate by

changing solenoid pulse width. Pulse width is the

amount of time the solenoid energizes. The PCM ad-

justs solenoid pulse width based on engine air flow. A rubber boot covers the duty cycle EVAP purge

solenoid. On 2.5L MPI flexible fuel AA-body vehicles,

the solenoid and bracket attach to the EVAP canister

mounting studs (Fig. 7). On vehicles with 3.0L en-

gines, the solenoid attaches to a bracket mounted to

the right engine mount (Fig. 8). The top of the sole-

noid has the word TOP on it. The solenoid will not

operate unless it is installed correctly.

PRESSURE-VACUUM FILLER CAP

CAUTION: Remove the fuel filler cap to relieve fuel

tank pressure. Remove the cap before disconnect-

ing fuel system components or servicing the fuel

tank.

A pressure-vacuum relief cap seals the fuel tank

(Fig. 9). Tightening the cap on the fuel filler tube

forms a seal between them. The relief valves in the

cap are a safety feature. They prevent possible exces-

sive pressure or vacuum in the tank. Excessive fuel

tank pressure could be caused by a malfunction in

the system or damage to the vent lines. The seal between the cap and filler tube breaks

when the cap is removed. Removing the cap breaks

the seal and relieves fuel tank pressure. If the filler cap needs replacement, only use a sim-

ilar unit.

Fig. 6 Canister Purge SolenoidÐExcept 3.0L and 2.5L MPI

Fig. 7 Duty Cycle EVAP Purge SolenoidÐ2.5L MPIFlexible Fuel AA-Body

Fig. 8 Duty Cycle EVAP Purge SolenoidÐ3.0L Engine

Fig. 9 Pressure Vacuum Filler Cap

25 - 14 EMISSION CONTROL SYSTEMS Ä