brake CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1887 of 2438

² transaxle gear selection (park/neutral switch)

The PCM also adjusts engine idle speed through

the idle air control motor based on the following in-

puts.

² brake switch

² engine coolant temperature

² engine speed (crankshaft position sensor)

² throttle position

² transaxle gear selection (park/neutral switch)

² vehicle speed

The auto shutdown (ASD) and fuel pump relays are

mounted externally, but turned on and off by the

PCM through the same circuit. The camshaft position sensor and crankshaft posi-

tion sensor signals are sent to the PCM. If the PCM

does not receive both signals within approximately

one second of engine cranking, it deactivates the

ASD and fuel pump relays. When these relays are

deactivated, power is shut off to the fuel injector, ig-

nition coil, oxygen sensor heating element and fuel

pump. The PCM contains a voltage converter that

changes battery voltage to a regulated 8.0 volts. The

8.0 volts power the camshaft position sensor, crank-

shaft position sensor and vehicle speed sensor. The

PCM also provides a 5.0 volts supply for the coolant

temperature sensor, manifold absolute pressure sen-

sor and throttle position sensor.

AIR CONDITIONING SWITCH SENSEÐPCM INPUT

When the air conditioning or defrost switch is put

in the ON position and the low pressure, high pres-

sure and ambient temperature switches are closed,

the PCM receives an input for air conditioning. After

receiving this input, the PCM activates the A/C com-

pressor clutch by grounding the A/C clutch relay.

BATTERY VOLTAGEÐPCM INPUT

The PCM monitors the battery voltage input to de-

termine fuel injector pulse width and generator field

control. If battery voltage is low the PCM will in-

crease injector pulse width.

BRAKE SWITCHÐPCM INPUT

When the brake switch is activated, the PCM re-

ceives an input indicating that the brakes are being

applied. the brake signal cancels speed control and

unlocks the torque convertor. The brake switch is

mounted on the brake pedal support bracket.

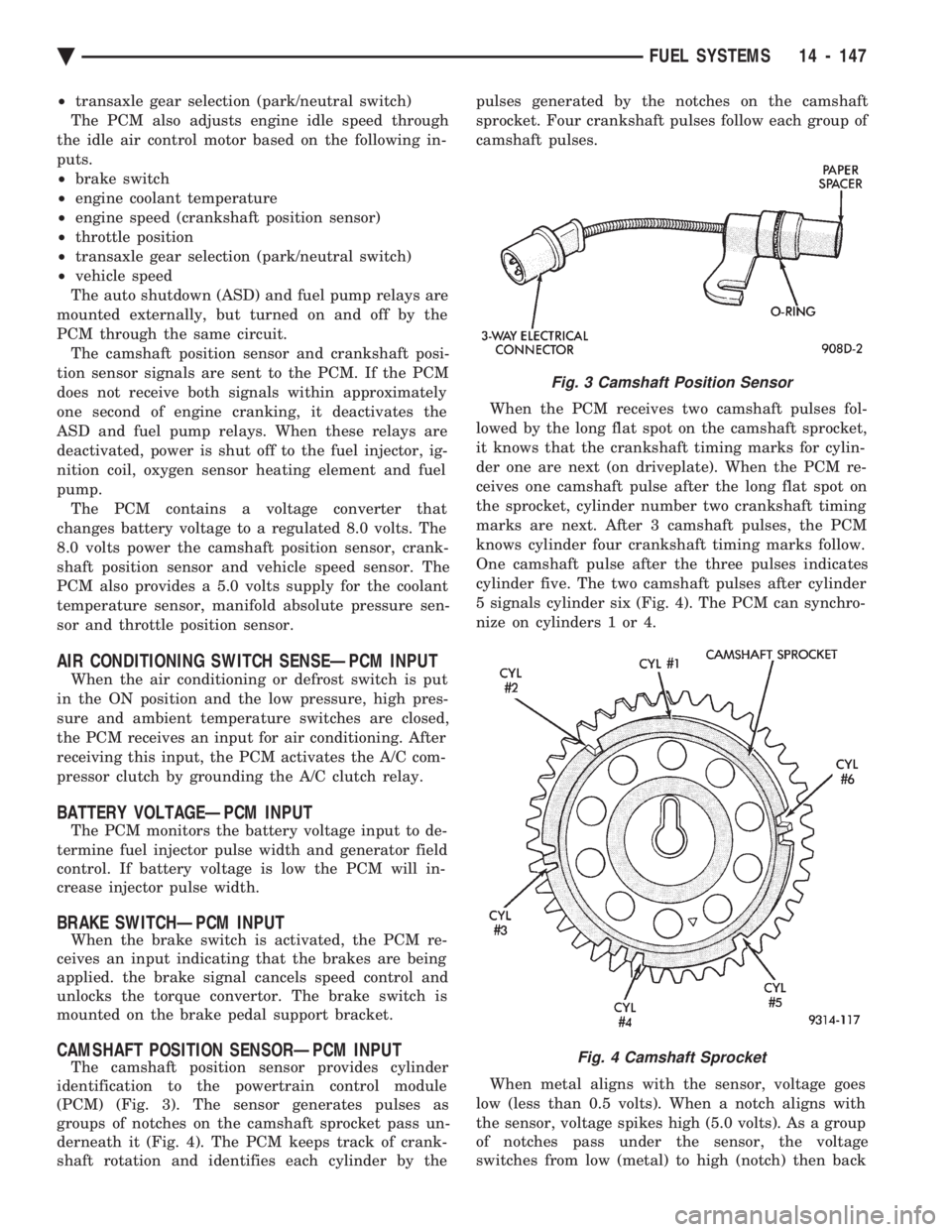

CAMSHAFT POSITION SENSORÐPCM INPUT

The camshaft position sensor provides cylinder

identification to the powertrain control module

(PCM) (Fig. 3). The sensor generates pulses as

groups of notches on the camshaft sprocket pass un-

derneath it (Fig. 4). The PCM keeps track of crank-

shaft rotation and identifies each cylinder by the pulses generated by the notches on the camshaft

sprocket. Four crankshaft pulses follow each group of

camshaft pulses.

When the PCM receives two camshaft pulses fol-

lowed by the long flat spot on the camshaft sprocket,

it knows that the crankshaft timing marks for cylin-

der one are next (on driveplate). When the PCM re-

ceives one camshaft pulse after the long flat spot on

the sprocket, cylinder number two crankshaft timing

marks are next. After 3 camshaft pulses, the PCM

knows cylinder four crankshaft timing marks follow.

One camshaft pulse after the three pulses indicates

cylinder five. The two camshaft pulses after cylinder

5 signals cylinder six (Fig. 4). The PCM can synchro-

nize on cylinders 1 or 4.

When metal aligns with the sensor, voltage goes

low (less than 0.5 volts). When a notch aligns with

the sensor, voltage spikes high (5.0 volts). As a group

of notches pass under the sensor, the voltage

switches from low (metal) to high (notch) then back

Fig. 3 Camshaft Position Sensor

Fig. 4 Camshaft Sprocket

Ä FUEL SYSTEMS 14 - 147

Page 1891 of 2438

within a range of 12.9 to 15.0 volts. Refer to Group

8A for charging system information.

AUTO SHUTDOWN (ASD) RELAY AND FUEL PUMP

RELAYÐPCM OUTPUT

The PCM operates the auto shutdown (ASD) relay

and fuel pump relay through one ground path. The

PCM operates the relays by switching the ground

path on and off. Both relays turn on and off at the

same time. The ASD relay connects battery voltage to the fuel

injector and ignition coil. The fuel pump relay con-

nects battery voltage to the fuel pump and oxygen

sensor heating element. The PCM turns the ground path off when the igni-

tion switch is in the Off position. Both relays are off.

When the ignition switch is in the On or Crank po-

sition, the PCM monitors the crankshaft position

sensor and camshaft position sensor signals to deter-

mine engine speed and ignition timing (coil dwell). If

the PCM does not receive the crankshaft position

sensor and camshaft position sensor signals when the

ignition switch is in the Run position, it de-energizes

both relays. When the relays are de-energized, bat-

tery voltage is not supplied to the fuel injector, igni-

tion coil, fuel pump and oxygen sensor heating

element. The ASD relay and fuel pump relay are located in

the power distribution center (Fig. 14).

IDLE AIR CONTROL MOTORÐPCM OUTPUT

The idle air control motor is mounted on the throt-

tle body. The PCM operates the idle air control motor

(Fig. 13). The PCM adjusts engine idle speed through

the idle air control motor to compensate for engine

load or ambient conditions. The throttle body has an air bypass passage that

provides air for the engine at idle (the throttle blade is closed). The idle air control motor pintle protrudes

into the air bypass passage and regulates air flow

through it. The PCM adjusts engine idle speed by moving the

idle air control motor pintle in and out of the bypass

passage. The adjustments are based on inputs the

PCM receives. The inputs are from the throttle posi-

tion sensor, crankshaft position sensor, coolant tem-

perature sensor, and various switch operations

(brake, park/neutral, air conditioning). Deceleration

die out is also prevented by increasing airflow when

the throttle is closed quickly after a driving (speed)

condition.

CANISTER PURGE SOLENOIDÐPCM OUTPUT

Vacuum for the Evaporative Canister is controlled

by the Canister Purge Solenoid (Fig. 15). The sole-

noid is controlled by the PCM.

The PCM operates the solenoid by switching the

ground circuit on and off based on engine operating

conditions. When energized, the solenoid prevents

vacuum from reaching the evaporative canister.

When not energized the solenoid allows vacuum to

flow to the canister. The PCM removes the ground to the solenoid when

the engine reaches a specified temperature and the

time delay interval has occurred. When the solenoid

is de-energized, vacuum flows to the canister purge

valve. Vapors are purged from the canister and flow

to the throttle body. The purge solenoid will also be energized during

certain idle conditions, in order to update the fuel de-

livery calibration.

MALFUNCTION INDICATOR LAMP (CHECK ENGINE

LAMP)ÐPCM OUTPUT

The malfunction indicator lamp (instrument panel

Check Engine Lamp) comes on each time the ignition

key is turned ON and stays on for 3 seconds as a

bulb test. The malfunction indicator lamp warns the

Fig. 14 Relay Identification

Fig. 15 Canister Purge Solenoid

Ä FUEL SYSTEMS 14 - 151

Page 1892 of 2438

operator that the PCM has entered a Limp-in mode.

During Limp-in Mode, the PCM attempts to keep the

system operational. The malfunction indicator signals

the need for immediate service. In limp-in mode, the

PCM compensates for the failure of certain components

that send incorrect signals. The PCM substitutes for

the incorrect signals with inputs from other sensors. Signals that can trigger the Malfunction Indi-

cator lamp (Check Engine Lamp).

² Engine Coolant Temperature Sensor

² Manifold Absolute Pressure Sensor

² Throttle Position Sensor

² Battery Voltage Input

² An Emission Related System (California vehicles)

² Charging system

The malfunction indicator (Check Engine Lamp) can

also display diagnostic trouble codes. Cycle the ignition

switch on, off, on, off, on, within five seconds and any

diagnostic trouble codes stored in the PCM will be

displayed. Refer to the 3.3L and 3.8L Multi-Port Fuel

InjectionÐOn-Board Diagnostics section of this Group

for Diagnostic Trouble Code Descriptions.

DATA LINK CONNECTORÐPCM OUTPUT

The data link connector provides the technician with

the means to connect the DRBII scan tool to diagnosis

the vehicle.

TRANSAXLE CONTROL MODULEÐPCM OUTPUT

The PCM supplies the following information to the

electronic automatic transaxle control module through

the CCD Bus:

² battery temperature

² brake switch input

² engine coolant temperature

² manifold absolute pressure (MAP)

² speed control information

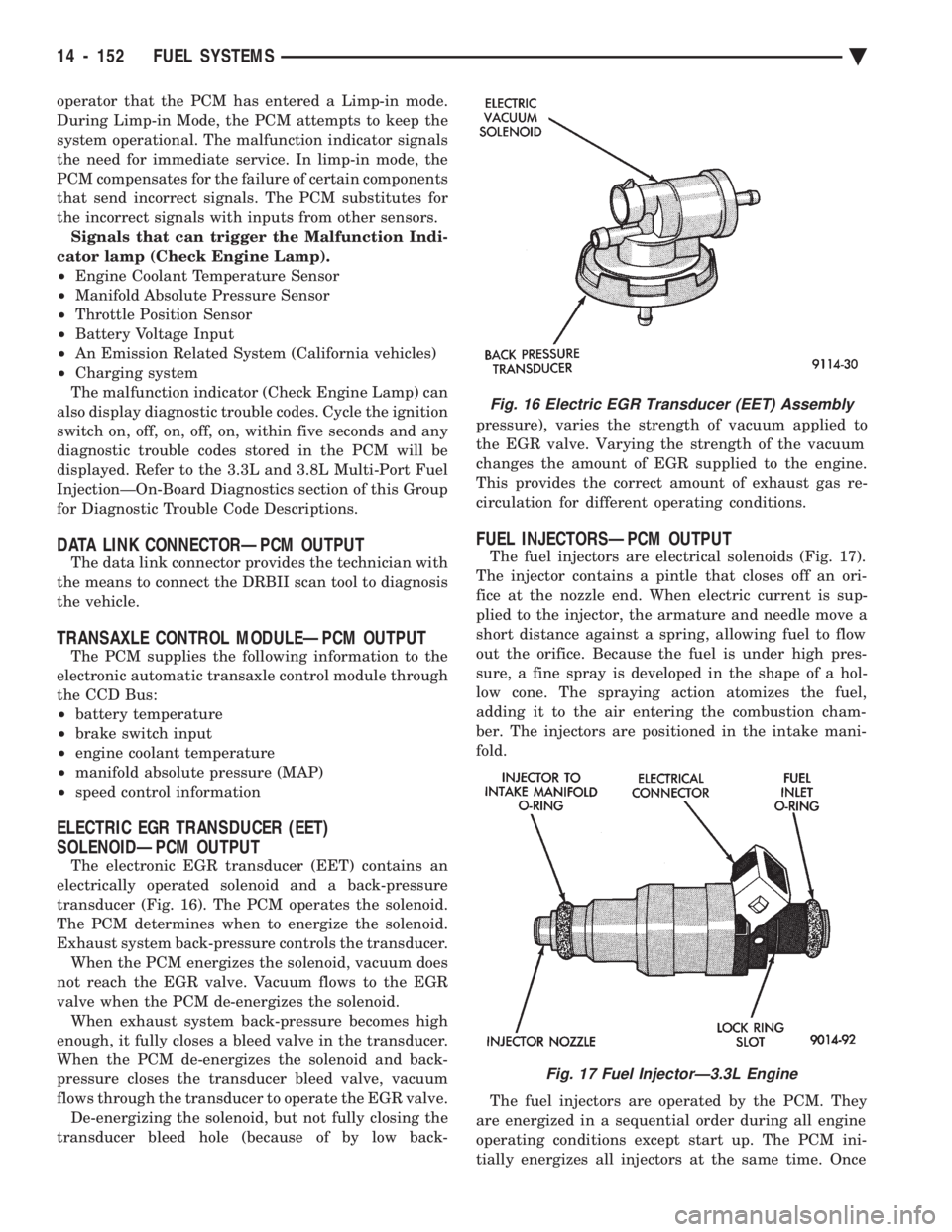

ELECTRIC EGR TRANSDUCER (EET)

SOLENOIDÐPCM OUTPUT

The electronic EGR transducer (EET) contains an

electrically operated solenoid and a back-pressure

transducer (Fig. 16). The PCM operates the solenoid.

The PCM determines when to energize the solenoid.

Exhaust system back-pressure controls the transducer. When the PCM energizes the solenoid, vacuum does

not reach the EGR valve. Vacuum flows to the EGR

valve when the PCM de-energizes the solenoid. When exhaust system back-pressure becomes high

enough, it fully closes a bleed valve in the transducer.

When the PCM de-energizes the solenoid and back-

pressure closes the transducer bleed valve, vacuum

flows through the transducer to operate the EGR valve. De-energizing the solenoid, but not fully closing the

transducer bleed hole (because of by low back- pressure), varies the strength of vacuum applied to

the EGR valve. Varying the strength of the vacuum

changes the amount of EGR supplied to the engine.

This provides the correct amount of exhaust gas re-

circulation for different operating conditions.

FUEL INJECTORSÐPCM OUTPUT

The fuel injectors are electrical solenoids (Fig. 17).

The injector contains a pintle that closes off an ori-

fice at the nozzle end. When electric current is sup-

plied to the injector, the armature and needle move a

short distance against a spring, allowing fuel to flow

out the orifice. Because the fuel is under high pres-

sure, a fine spray is developed in the shape of a hol-

low cone. The spraying action atomizes the fuel,

adding it to the air entering the combustion cham-

ber. The injectors are positioned in the intake mani-

fold.

The fuel injectors are operated by the PCM. They

are energized in a sequential order during all engine

operating conditions except start up. The PCM ini-

tially energizes all injectors at the same time. Once

Fig. 16 Electric EGR Transducer (EET) Assembly

Fig. 17 Fuel InjectorÐ3.3L Engine

14 - 152 FUEL SYSTEMS Ä

Page 1900 of 2438

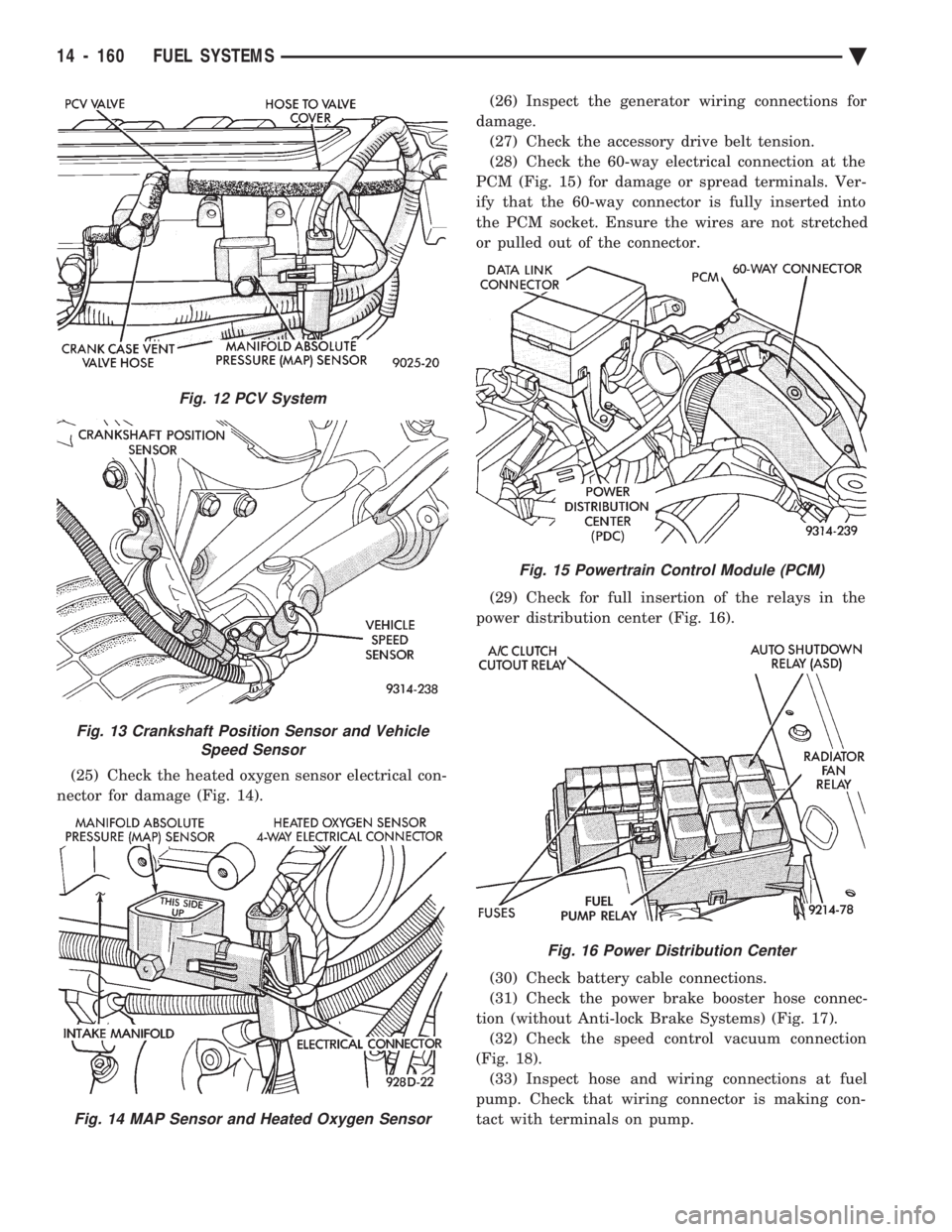

(25) Check the heated oxygen sensor electrical con-

nector for damage (Fig. 14). (26) Inspect the generator wiring connections for

damage. (27) Check the accessory drive belt tension.

(28) Check the 60-way electrical connection at the

PCM (Fig. 15) for damage or spread terminals. Ver-

ify that the 60-way connector is fully inserted into

the PCM socket. Ensure the wires are not stretched

or pulled out of the connector.

(29) Check for full insertion of the relays in the

power distribution center (Fig. 16).

(30) Check battery cable connections.

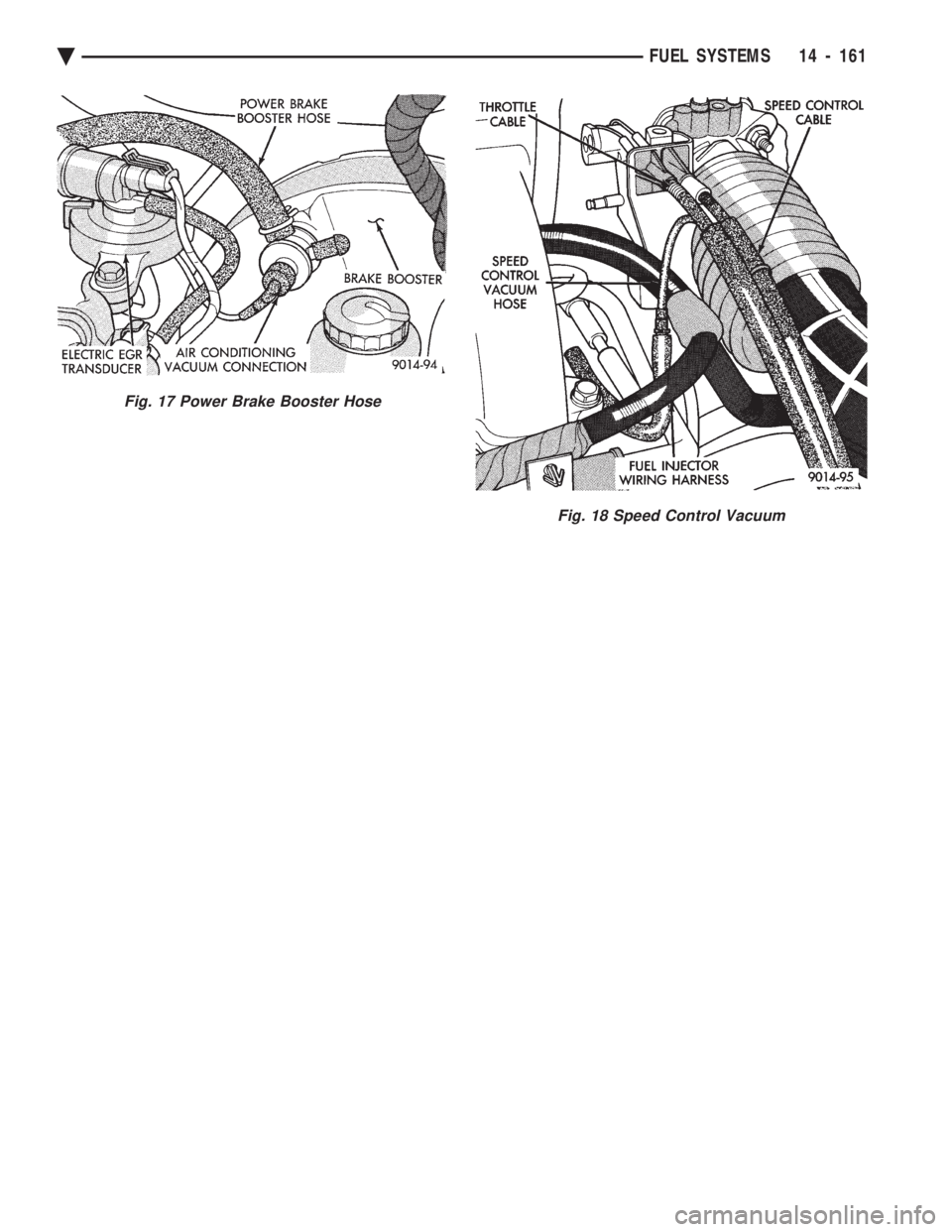

(31) Check the power brake booster hose connec-

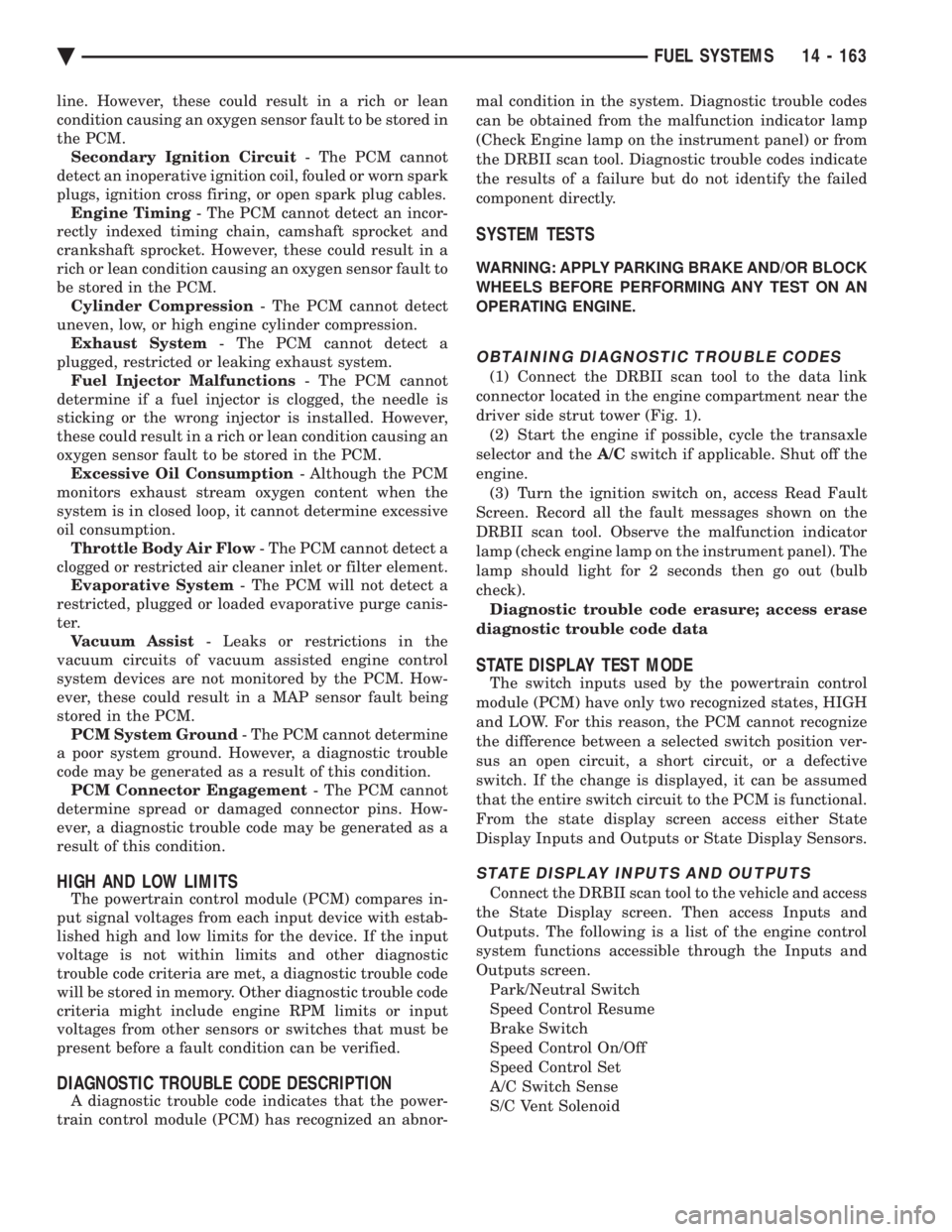

tion (without Anti-lock Brake Systems) (Fig. 17). (32) Check the speed control vacuum connection

(Fig. 18). (33) Inspect hose and wiring connections at fuel

pump. Check that wiring connector is making con-

tact with terminals on pump.

Fig. 12 PCV System

Fig. 13 Crankshaft Position Sensor and Vehicle Speed Sensor

Fig. 14 MAP Sensor and Heated Oxygen Sensor

Fig. 15 Powertrain Control Module (PCM)

Fig. 16 Power Distribution Center

14 - 160 FUEL SYSTEMS Ä

Page 1901 of 2438

Fig. 17 Power Brake Booster Hose

Fig. 18 Speed Control Vacuum

Ä FUEL SYSTEMS 14 - 161

Page 1903 of 2438

line. However, these could result in a rich or lean

condition causing an oxygen sensor fault to be stored in

the PCM. Secondary Ignition Circuit - The PCM cannot

detect an inoperative ignition coil, fouled or worn spark

plugs, ignition cross firing, or open spark plug cables. Engine Timing - The PCM cannot detect an incor-

rectly indexed timing chain, camshaft sprocket and

crankshaft sprocket. However, these could result in a

rich or lean condition causing an oxygen sensor fault to

be stored in the PCM. Cylinder Compression - The PCM cannot detect

uneven, low, or high engine cylinder compression. Exhaust System - The PCM cannot detect a

plugged, restricted or leaking exhaust system. Fuel Injector Malfunctions - The PCM cannot

determine if a fuel injector is clogged, the needle is

sticking or the wrong injector is installed. However,

these could result in a rich or lean condition causing an

oxygen sensor fault to be stored in the PCM. Excessive Oil Consumption - Although the PCM

monitors exhaust stream oxygen content when the

system is in closed loop, it cannot determine excessive

oil consumption. Throttle Body Air Flow - The PCM cannot detect a

clogged or restricted air cleaner inlet or filter element. Evaporative System - The PCM will not detect a

restricted, plugged or loaded evaporative purge canis-

ter. Vacuum Assist - Leaks or restrictions in the

vacuum circuits of vacuum assisted engine control

system devices are not monitored by the PCM. How-

ever, these could result in a MAP sensor fault being

stored in the PCM. PCM System Ground - The PCM cannot determine

a poor system ground. However, a diagnostic trouble

code may be generated as a result of this condition. PCM Connector Engagement - The PCM cannot

determine spread or damaged connector pins. How-

ever, a diagnostic trouble code may be generated as a

result of this condition.

HIGH AND LOW LIMITS

The powertrain control module (PCM) compares in-

put signal voltages from each input device with estab-

lished high and low limits for the device. If the input

voltage is not within limits and other diagnostic

trouble code criteria are met, a diagnostic trouble code

will be stored in memory. Other diagnostic trouble code

criteria might include engine RPM limits or input

voltages from other sensors or switches that must be

present before a fault condition can be verified.

DIAGNOSTIC TROUBLE CODE DESCRIPTION

A diagnostic trouble code indicates that the power-

train control module (PCM) has recognized an abnor- mal condition in the system. Diagnostic trouble codes

can be obtained from the malfunction indicator lamp

(Check Engine lamp on the instrument panel) or from

the DRBII scan tool. Diagnostic trouble codes indicate

the results of a failure but do not identify the failed

component directly.

SYSTEM TESTS

WARNING: APPLY PARKING BRAKE AND/OR BLOCK

WHEELS BEFORE PERFORMING ANY TEST ON AN

OPERATING ENGINE.

OBTAINING DIAGNOSTIC TROUBLE CODES

(1) Connect the DRBII scan tool to the data link

connector located in the engine compartment near the

driver side strut tower (Fig. 1). (2) Start the engine if possible, cycle the transaxle

selector and the A/Cswitch if applicable. Shut off the

engine. (3) Turn the ignition switch on, access Read Fault

Screen. Record all the fault messages shown on the

DRBII scan tool. Observe the malfunction indicator

lamp (check engine lamp on the instrument panel). The

lamp should light for 2 seconds then go out (bulb

check). Diagnostic trouble code erasure; access erase

diagnostic trouble code data

STATE DISPLAY TEST MODE

The switch inputs used by the powertrain control

module (PCM) have only two recognized states, HIGH

and LOW. For this reason, the PCM cannot recognize

the difference between a selected switch position ver-

sus an open circuit, a short circuit, or a defective

switch. If the change is displayed, it can be assumed

that the entire switch circuit to the PCM is functional.

From the state display screen access either State

Display Inputs and Outputs or State Display Sensors.

STATE DISPLAY INPUTS AND OUTPUTS

Connect the DRBII scan tool to the vehicle and access

the State Display screen. Then access Inputs and

Outputs. The following is a list of the engine control

system functions accessible through the Inputs and

Outputs screen. Park/Neutral Switch

Speed Control Resume

Brake Switch

Speed Control On/Off

Speed Control Set

A/C Switch Sense

S/C Vent Solenoid

Ä FUEL SYSTEMS 14 - 163

Page 1911 of 2438

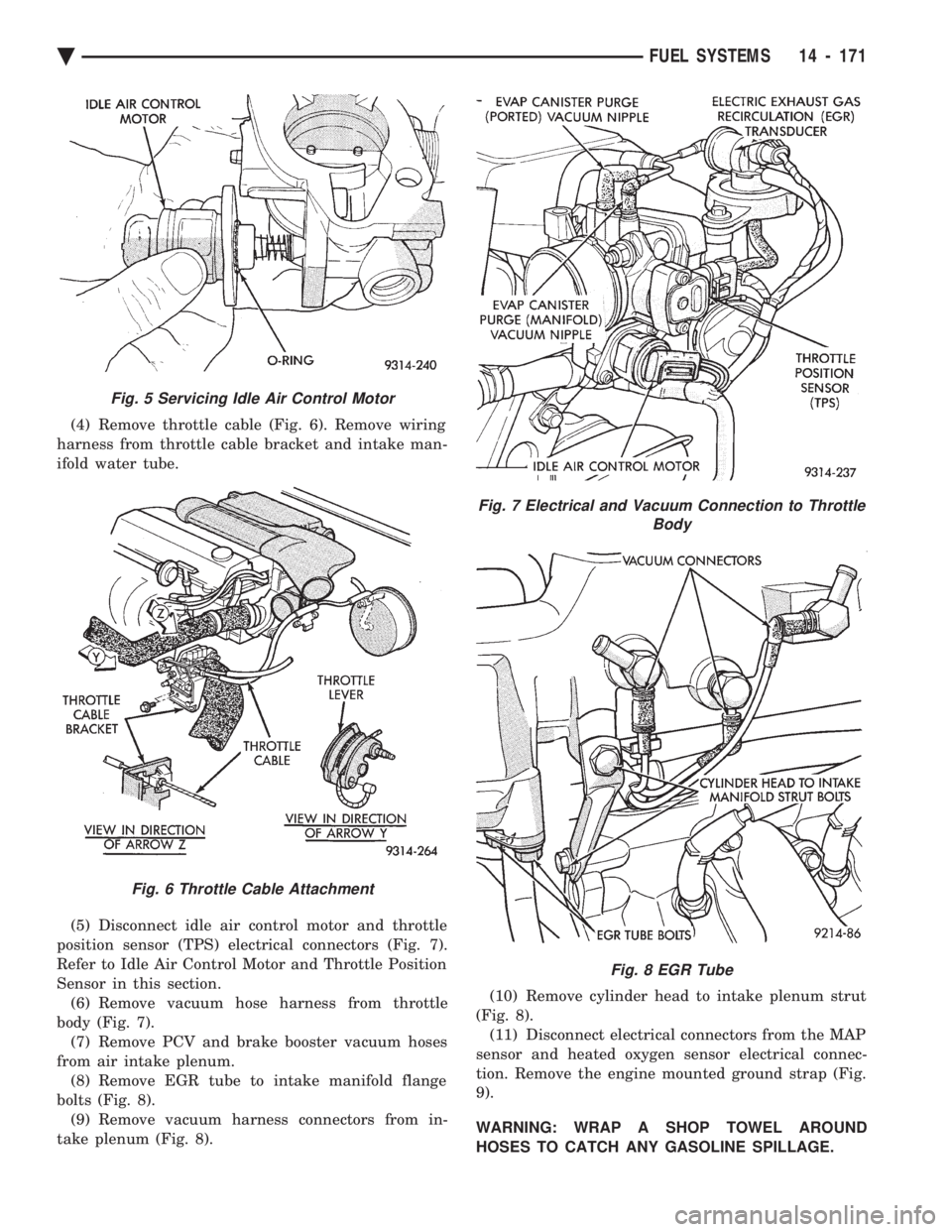

(4) Remove throttle cable (Fig. 6). Remove wiring

harness from throttle cable bracket and intake man-

ifold water tube.

(5) Disconnect idle air control motor and throttle

position sensor (TPS) electrical connectors (Fig. 7).

Refer to Idle Air Control Motor and Throttle Position

Sensor in this section. (6) Remove vacuum hose harness from throttle

body (Fig. 7). (7) Remove PCV and brake booster vacuum hoses

from air intake plenum. (8) Remove EGR tube to intake manifold flange

bolts (Fig. 8). (9) Remove vacuum harness connectors from in-

take plenum (Fig. 8). (10) Remove cylinder head to intake plenum strut

(Fig. 8). (11) Disconnect electrical connectors from the MAP

sensor and heated oxygen sensor electrical connec-

tion. Remove the engine mounted ground strap (Fig.

9).

WARNING: WRAP A SHOP TOWEL AROUND

HOSES TO CATCH ANY GASOLINE SPILLAGE.

Fig. 5 Servicing Idle Air Control Motor

Fig. 6 Throttle Cable Attachment

Fig. 7 Electrical and Vacuum Connection to Throttle Body

Fig. 8 EGR Tube

Ä FUEL SYSTEMS 14 - 171

Page 1951 of 2438

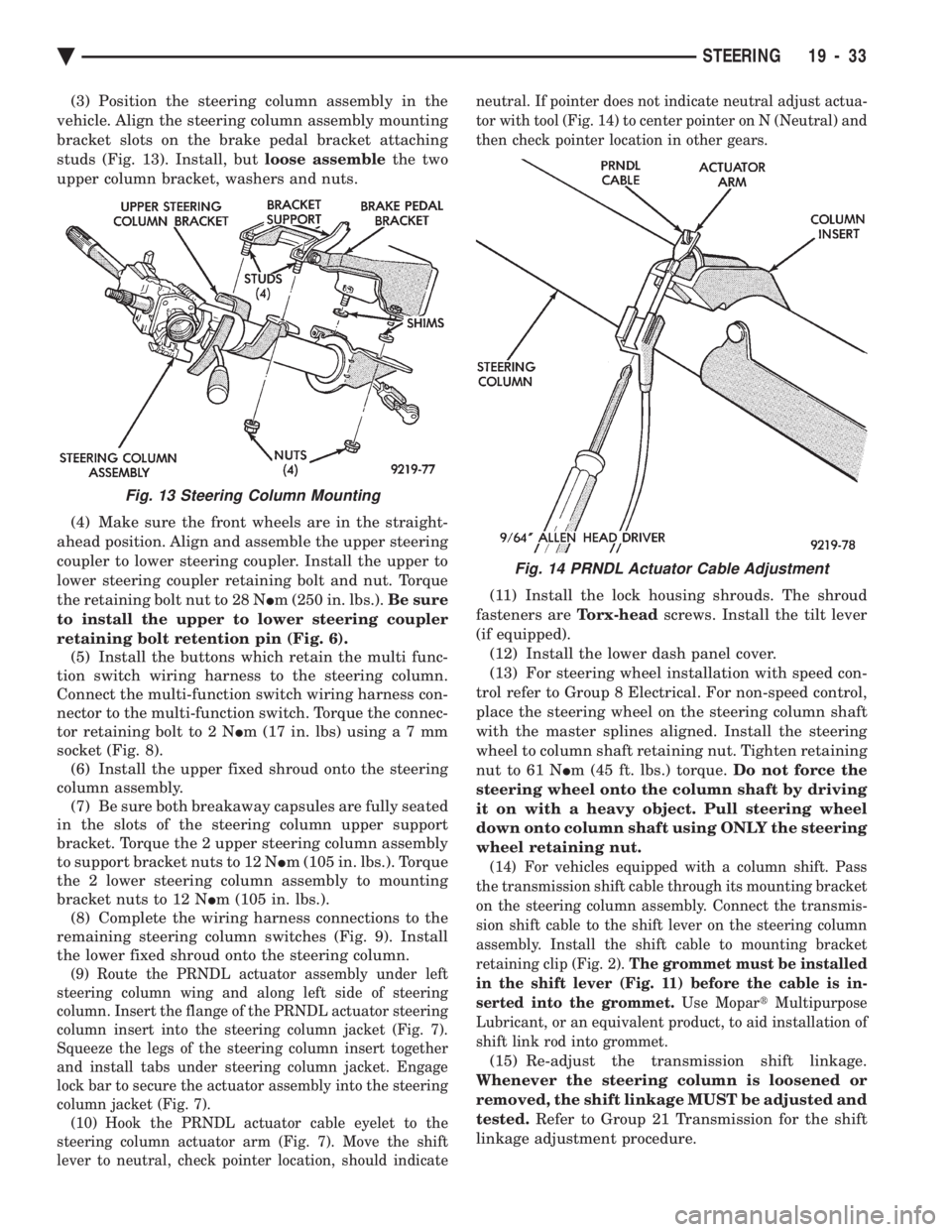

(3) Position the steering column assembly in the

vehicle. Align the steering column assembly mounting

bracket slots on the brake pedal bracket attaching

studs (Fig. 13). Install, but loose assemblethe two

upper column bracket, washers and nuts.

(4) Make sure the front wheels are in the straight-

ahead position. Align and assemble the upper steering

coupler to lower steering coupler. Install the upper to

lower steering coupler retaining bolt and nut. Torque

the retaining bolt nut to 28 N Im (250 in. lbs.). Be sure

to install the upper to lower steering coupler

retaining bolt retention pin (Fig. 6). (5) Install the buttons which retain the multi func-

tion switch wiring harness to the steering column.

Connect the multi-function switch wiring harness con-

nector to the multi-function switch. Torque the connec-

tor retaining bolt to 2 N Im (17 in. lbs) usin ga7mm

socket (Fig. 8). (6) Install the upper fixed shroud onto the steering

column assembly. (7) Be sure both breakaway capsules are fully seated

in the slots of the steering column upper support

bracket. Torque the 2 upper steering column assembly

to support bracket nuts to 12 N Im (105 in. lbs.). Torque

the 2 lower steering column assembly to mounting

bracket nuts to 12 N Im (105 in. lbs.).

(8) Complete the wiring harness connections to the

remaining steering column switches (Fig. 9). Install

the lower fixed shroud onto the steering column.

(9) Route the PRNDL actuator assembly under left

steering column wing and along left side of steering

column. Insert the flange of the PRNDL actuator steering

column insert into the steering column jacket (Fig. 7).

Squeeze the legs of the steering column insert together

and install tabs under steering column jacket. Engage

lock bar to secure the actuator assembly into the steering

column jacket (Fig. 7). (10) Hook the PRNDL actuator cable eyelet to the

steering column actuator arm (Fig. 7). Move the shift

lever to neutral, check pointer location, should indicate neutral. If pointer does not indicate neutral adjust actua-

tor with tool (Fig. 14) to center pointer on N (Neutral) and

then check pointer location in other gears.

(11) Install the lock housing shrouds. The shroud

fasteners are Torx-headscrews. Install the tilt lever

(if equipped). (12) Install the lower dash panel cover.

(13) For steering wheel installation with speed con-

trol refer to Group 8 Electrical. For non-speed control,

place the steering wheel on the steering column shaft

with the master splines aligned. Install the steering

wheel to column shaft retaining nut. Tighten retaining

nut to 61 N Im (45 ft. lbs.) torque. Do not force the

steering wheel onto the column shaft by driving

it on with a heavy object. Pull steering wheel

down onto column shaft using ONLY the steering

wheel retaining nut.

(14) For vehicles equipped with a column shift. Pass

the transmission shift cable through its mounting bracket

on the steering column assembly. Connect the transmis-

sion shift cable to the shift lever on the steering column

assembly. Install the shift cable to mounting bracket

retaining clip (Fig. 2). The grommet must be installed

in the shift lever (Fig. 11) before the cable is in-

serted into the grommet. Use MopartMultipurpose

Lubricant, or an equivalent product, to aid installation of

shift link rod into grommet.

(15) Re-adjust the transmission shift linkage.

Whenever the steering column is loosened or

removed, the shift linkage MUST be adjusted and

tested. Refer to Group 21 Transmission for the shift

linkage adjustment procedure.

Fig. 13 Steering Column Mounting

Fig. 14 PRNDL Actuator Cable Adjustment

Ä STEERING 19 - 33

Page 2000 of 2438

FLUID LEVEL AND CONDITION

The transmission and differential sump have a

common oil sump with a communicating opening

between the two. Before removing the dipstick, wipe all dirt off of the

protective disc and the dipstick handle. The torque converter will fill in both the PPark or N

Neutral positions. Place the selector lever in PPark to

check fluid level. Inspect fluid level on dipstick every six months.

Allow the engine to idle for at least one minute

with vehicle on level ground. This will assure

complete oil level stabilization between differen-

tial and transmission. A properly filled transaxle

will read near the addmark when fluid temperature is

21 degrees Celsius (70 degrees Fahrenheit). When the

transaxle reaches operating temperature the fluid

should be in the HOTregion.

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with the

fluid. As in any hydraulic system, air bubbles make the

fluid spongy, therefore, pressures will be low and build

up slowly. Improper filling can also raise the fluid level too

high. When the transaxle has too much fluid, the gears

churn up foam and cause the same conditions which

occur with a low fluid level. In either case, the air bubbles can cause overheating,

fluid oxidation, and varnishing, which can interfere

with normal valve, clutch, and servo operation. Foam-

ing can also result in fluid escaping from the transaxle

vent (dipstick handle) where it may be mistaken for a

leak. Along with fluid level, it is important to check the

condition of the fluid. When the fluid smells burned,

and is contaminated with metal or friction material

particles, a complete transaxle overhaul is needed. Be

sure to examine the fluid on the dipstick closely. If

there is any doubt about its condition, drain out a

sample for a double check. After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

SELECTION OF LUBRICANT

It is important that the proper lubricant be used in

these transmissions. MOPAR tATF PLUS (Automatic

Transmission Fluid-Type 7176) should be used to aid in

assuring optimum transmission performance. Fluids of

the type labeled DEXRON II Automatic Transmission

Fluid should be used only if the recommended fluid is

not available. It is important that the transmission

fluid be maintained at the prescribed level using the

recommended fluids.

SPECIAL ADDITIVES

Chrysler Corporation does not recommend the addi-

tion of any fluids to the transmission, other than the

automatic transmission fluid listed above. An ex- ception to this policy is the use of special dyes to aid in

detecting fluid leaks. The use of transmission sealers

should be avoided, since they may adversely affect

seals.

FLUID AND FILTER CHANGE

When the factory fill fluid is changed, only

fluids of the type labeled MOPAR tATF PLUS

(Automatic Transmission fluid) Type 7176 should

be used. A band adjustment and filter change

should be made at the time of the oil change. The

magnet (on the inside of the oil pan) should also

be cleaned with a clean, dry cloth. If the transaxle is disassembled for any reason,

the fluid and filter should be changed, and the

band(s) adjusted.

FLUID DRAIN AND REFILL

(1) Raise vehicle on a hoist (See Lubrication, Group

0). Place a drain container with a large opening, under

transaxle oil pan. (2) Loosen pan bolts and tap the pan at one corner to

break it loose allowing fluid to drain, then remove the

oil pan. (3) Install a new filter and gasket on bottom of the

valve body and tighten retaining screws to 5 N Im (40

in. lbs.). (4) Clean the oil pan and magnet. Reinstall pan

using new MOPAR tAdhesive sealant. Tighten oil pan

bolts to 19 N Im (165 in. lbs.).

(5) Pour four quarts of MOPAR tATF PLUS (Auto-

matic Transmission Fluid) Type 7176 through the

dipstick opening. (6) Start engine and allow to idle for at least one

minute. Then, with parking and service brakes ap-

plied, move selector lever momentarily to each posi-

tion, ending in the park or neutral position. (7) Add sufficient fluid to bring level to 1/8 inch

below the ADD mark. Recheck fluid level after transaxle is at normal

operating temperature. The level should be in the HOT

region (Fig. 1). To prevent dirt from entering transaxle, make cer-

tain that dipstick is full seated into the dipstick open-

ing.

TORQUE CONVERTER CLUTCH SOLENOID WIRING

CONNECTOR

If wiring connector is unplugged, the torque con-

verter clutch will not operate (Fig. 2).

ROAD TEST

Prior to performing a road test, be certain that the

fluid level and condition, and control cable adjustments

have been checked and approved. During the road test, the transaxle should be oper-

ated in each position to check for slipping and any

variation in shifting.

21 - 40 TRANSAXLE Ä

Page 2006 of 2438

so that pump housing and case front may be covered

with soapy solution or water. Leaks are sometimes

caused by porosity in the case or pump housing.If a leak source is located, that part and all associ-

ated seals, O-rings, and gaskets should be replaced

with new parts.

GEARSHIFT LINKAGE ADJUSTMENT

Normal operation of the Park/Neutral Position

Switch provides a quick check to confirm proper

manual linkage adjustment. Move the selector level slowly upward until it

clicks into the ``P'' Park notch in the selector gate. If

the starter will operate the ``P'' position is correct. After checking ``P'' position, move selector slowly

toward ``N'' Neutral position until lever drops in the

``N'' stop. If the starter will also operate at this point

the gearshift linkage is properly adjusted. If the

starter fails to operate in either position, linkage ad-

justment is required.

CAUTION: When it is necessary to disassemble

linkage cable from levers, which use plastic grom-

mets as retainers, the grommets should be replaced

with new grommets. Use a prying tool to force rod

from grommet in lever, then cut away old grommet.

Use pliers to snap new grommet into lever and rod

into grommet.

(1) Set parking brake.

(2) Place gearshift lever in P(PARK) position.

(3) Loosen clamp bolt on gearshift cable bracket.

(4) Column shift: Insure that preload adjustment

spring engages fork on transaxle bracket. (5) Pull the shift lever by hand to the front detent

position (PARK) and tighten lock. Tighten screw to

11 N Im (100 in. lbs.). Gearshift linkage should now

be properly adjusted. (6) Check adjustment as follows:(a) Detent position for neutral and drive should

be within limits of hand lever gate stops. (b) Key start must occur only when shift lever is

in park or neutral positions.

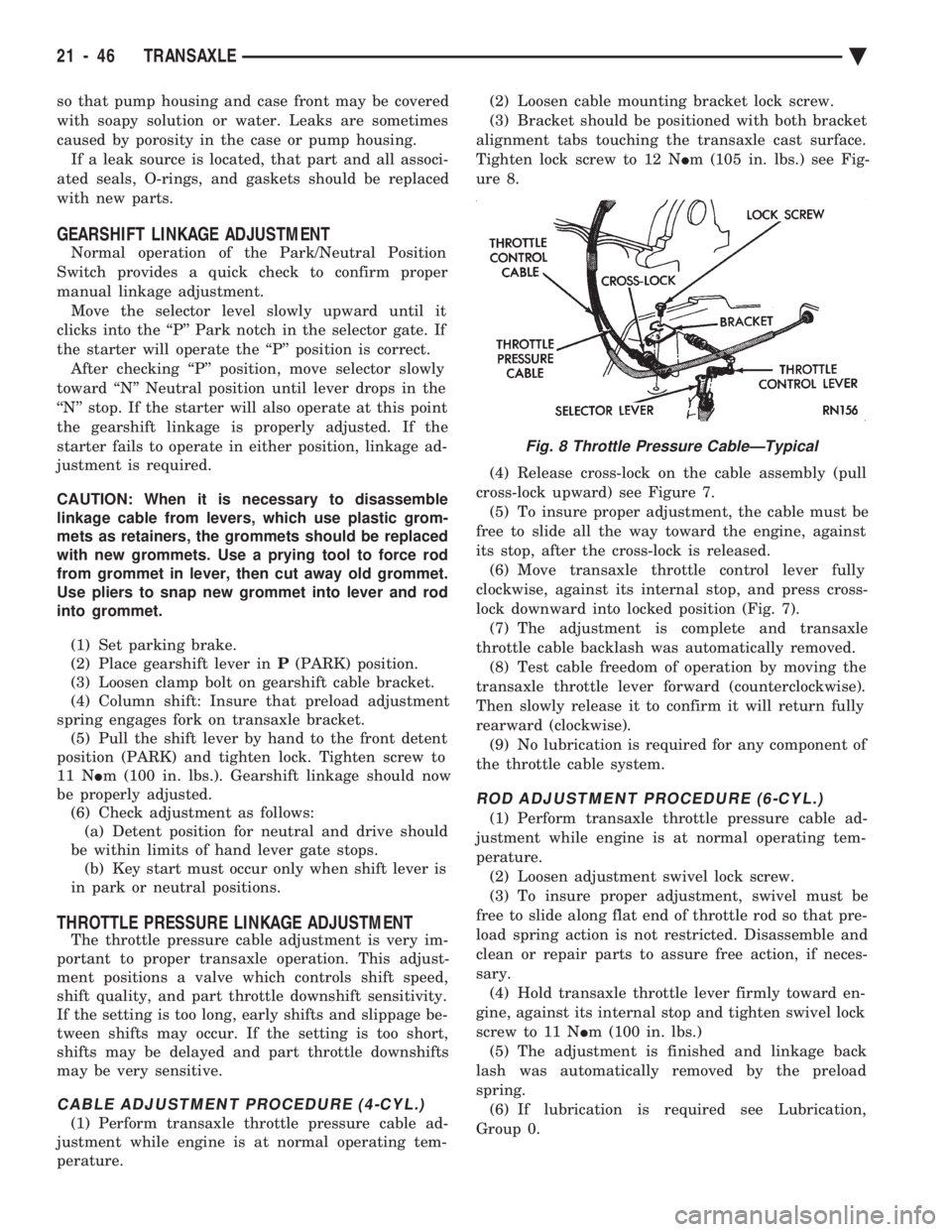

THROTTLE PRESSURE LINKAGE ADJUSTMENT

The throttle pressure cable adjustment is very im-

portant to proper transaxle operation. This adjust-

ment positions a valve which controls shift speed,

shift quality, and part throttle downshift sensitivity.

If the setting is too long, early shifts and slippage be-

tween shifts may occur. If the setting is too short,

shifts may be delayed and part throttle downshifts

may be very sensitive.

CABLE ADJUSTMENT PROCEDURE (4-CYL.)

(1) Perform transaxle throttle pressure cable ad-

justment while engine is at normal operating tem-

perature. (2) Loosen cable mounting bracket lock screw.

(3) Bracket should be positioned with both bracket

alignment tabs touching the transaxle cast surface.

Tighten lock screw to 12 N Im (105 in. lbs.) see Fig-

ure 8.

(4) Release cross-lock on the cable assembly (pull

cross-lock upward) see Figure 7. (5) To insure proper adjustment, the cable must be

free to slide all the way toward the engine, against

its stop, after the cross-lock is released. (6) Move transaxle throttle control lever fully

clockwise, against its internal stop, and press cross-

lock downward into locked position (Fig. 7). (7) The adjustment is complete and transaxle

throttle cable backlash was automatically removed. (8) Test cable freedom of operation by moving the

transaxle throttle lever forward (counterclockwise).

Then slowly release it to confirm it will return fully

rearward (clockwise). (9) No lubrication is required for any component of

the throttle cable system.

ROD ADJUSTMENT PROCEDURE (6-CYL.)

(1) Perform transaxle throttle pressure cable ad-

justment while engine is at normal operating tem-

perature. (2) Loosen adjustment swivel lock screw.

(3) To insure proper adjustment, swivel must be

free to slide along flat end of throttle rod so that pre-

load spring action is not restricted. Disassemble and

clean or repair parts to assure free action, if neces-

sary. (4) Hold transaxle throttle lever firmly toward en-

gine, against its internal stop and tighten swivel lock

screw to 11 N Im (100 in. lbs.)

(5) The adjustment is finished and linkage back

lash was automatically removed by the preload

spring. (6) If lubrication is required see Lubrication,

Group 0.

Fig. 8 Throttle Pressure CableÐTypical

21 - 46 TRANSAXLE Ä