brake CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 2053 of 2438

FLUID LEVEL AND CONDITION

The transmission and differential sump have a

common oil sump with a communicating opening

between the two. The torque converter fills in both the PPark and N

Neutral positions. Place the selector lever in PPark to

check the fluid level. The engine should be running

at idle speed for at least one minute, with the

vehicle on level ground. This will assure com-

plete oil level stabilization between differential

and transmission. The fluid should be at normal

operating temperature (approximately 82 C. or 180 F.).

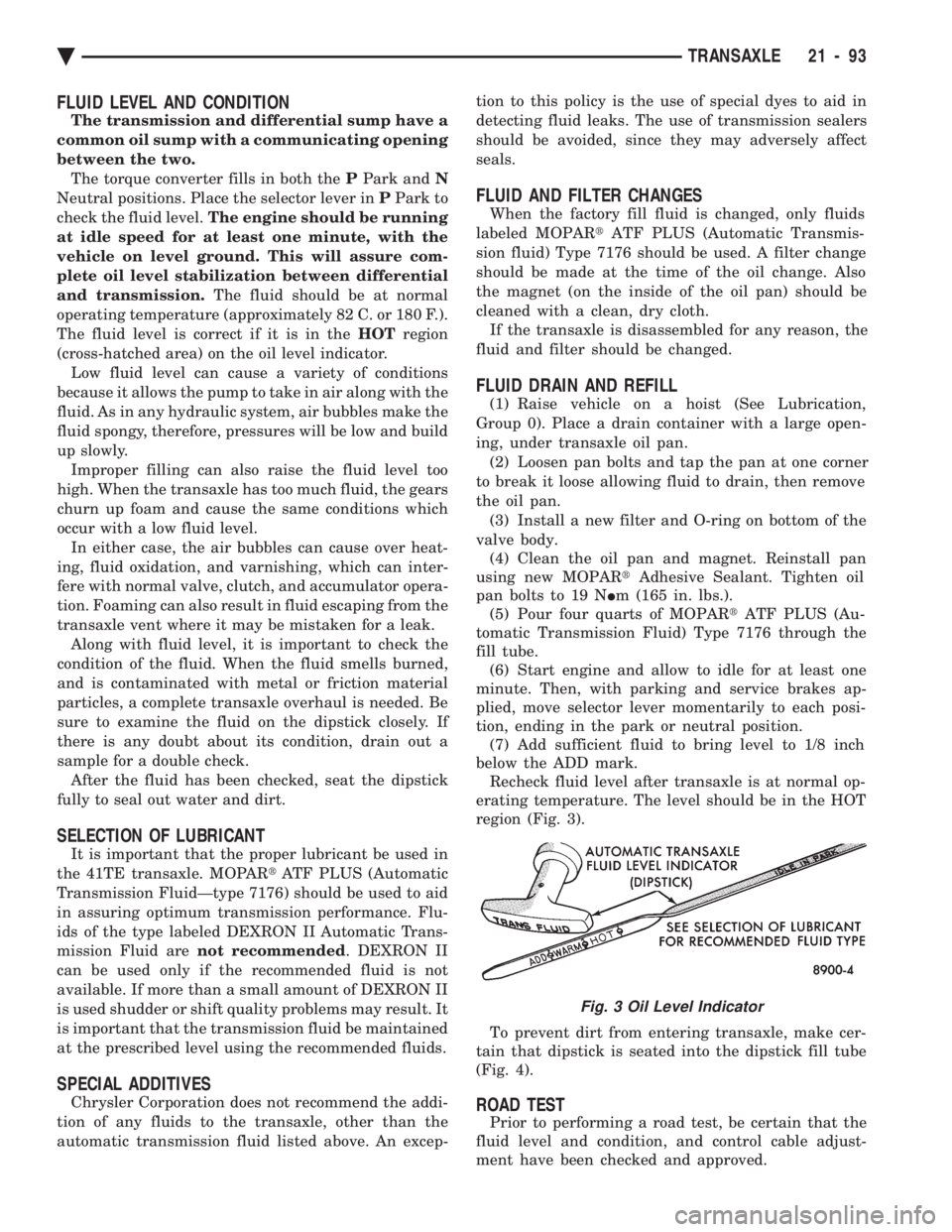

The fluid level is correct if it is in the HOTregion

(cross-hatched area) on the oil level indicator. Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with the

fluid. As in any hydraulic system, air bubbles make the

fluid spongy, therefore, pressures will be low and build

up slowly. Improper filling can also raise the fluid level too

high. When the transaxle has too much fluid, the gears

churn up foam and cause the same conditions which

occur with a low fluid level. In either case, the air bubbles can cause over heat-

ing, fluid oxidation, and varnishing, which can inter-

fere with normal valve, clutch, and accumulator opera-

tion. Foaming can also result in fluid escaping from the

transaxle vent where it may be mistaken for a leak. Along with fluid level, it is important to check the

condition of the fluid. When the fluid smells burned,

and is contaminated with metal or friction material

particles, a complete transaxle overhaul is needed. Be

sure to examine the fluid on the dipstick closely. If

there is any doubt about its condition, drain out a

sample for a double check. After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

SELECTION OF LUBRICANT

It is important that the proper lubricant be used in

the 41TE transaxle. MOPAR tATF PLUS (Automatic

Transmission FluidÐtype 7176) should be used to aid

in assuring optimum transmission performance. Flu-

ids of the type labeled DEXRON II Automatic Trans-

mission Fluid are not recommended . DEXRON II

can be used only if the recommended fluid is not

available. If more than a small amount of DEXRON II

is used shudder or shift quality problems may result. It

is important that the transmission fluid be maintained

at the prescribed level using the recommended fluids.

SPECIAL ADDITIVES

Chrysler Corporation does not recommend the addi-

tion of any fluids to the transaxle, other than the

automatic transmission fluid listed above. An excep- tion to this policy is the use of special dyes to aid in

detecting fluid leaks. The use of transmission sealers

should be avoided, since they may adversely affect

seals.

FLUID AND FILTER CHANGES

When the factory fill fluid is changed, only fluids

labeled MOPAR tATF PLUS (Automatic Transmis-

sion fluid) Type 7176 should be used. A filter change

should be made at the time of the oil change. Also

the magnet (on the inside of the oil pan) should be

cleaned with a clean, dry cloth. If the transaxle is disassembled for any reason, the

fluid and filter should be changed.

FLUID DRAIN AND REFILL

(1) Raise vehicle on a hoist (See Lubrication,

Group 0). Place a drain container with a large open-

ing, under transaxle oil pan. (2) Loosen pan bolts and tap the pan at one corner

to break it loose allowing fluid to drain, then remove

the oil pan. (3) Install a new filter and O-ring on bottom of the

valve body. (4) Clean the oil pan and magnet. Reinstall pan

using new MOPAR tAdhesive Sealant. Tighten oil

pan bolts to 19 N Im (165 in. lbs.).

(5) Pour four quarts of MOPAR tATF PLUS (Au-

tomatic Transmission Fluid) Type 7176 through the

fill tube. (6) Start engine and allow to idle for at least one

minute. Then, with parking and service brakes ap-

plied, move selector lever momentarily to each posi-

tion, ending in the park or neutral position. (7) Add sufficient fluid to bring level to 1/8 inch

below the ADD mark. Recheck fluid level after transaxle is at normal op-

erating temperature. The level should be in the HOT

region (Fig. 3).

To prevent dirt from entering transaxle, make cer-

tain that dipstick is seated into the dipstick fill tube

(Fig. 4).

ROAD TEST

Prior to performing a road test, be certain that the

fluid level and condition, and control cable adjust-

ment have been checked and approved.

Fig. 3 Oil Level Indicator

Ä TRANSAXLE 21 - 93

Page 2055 of 2438

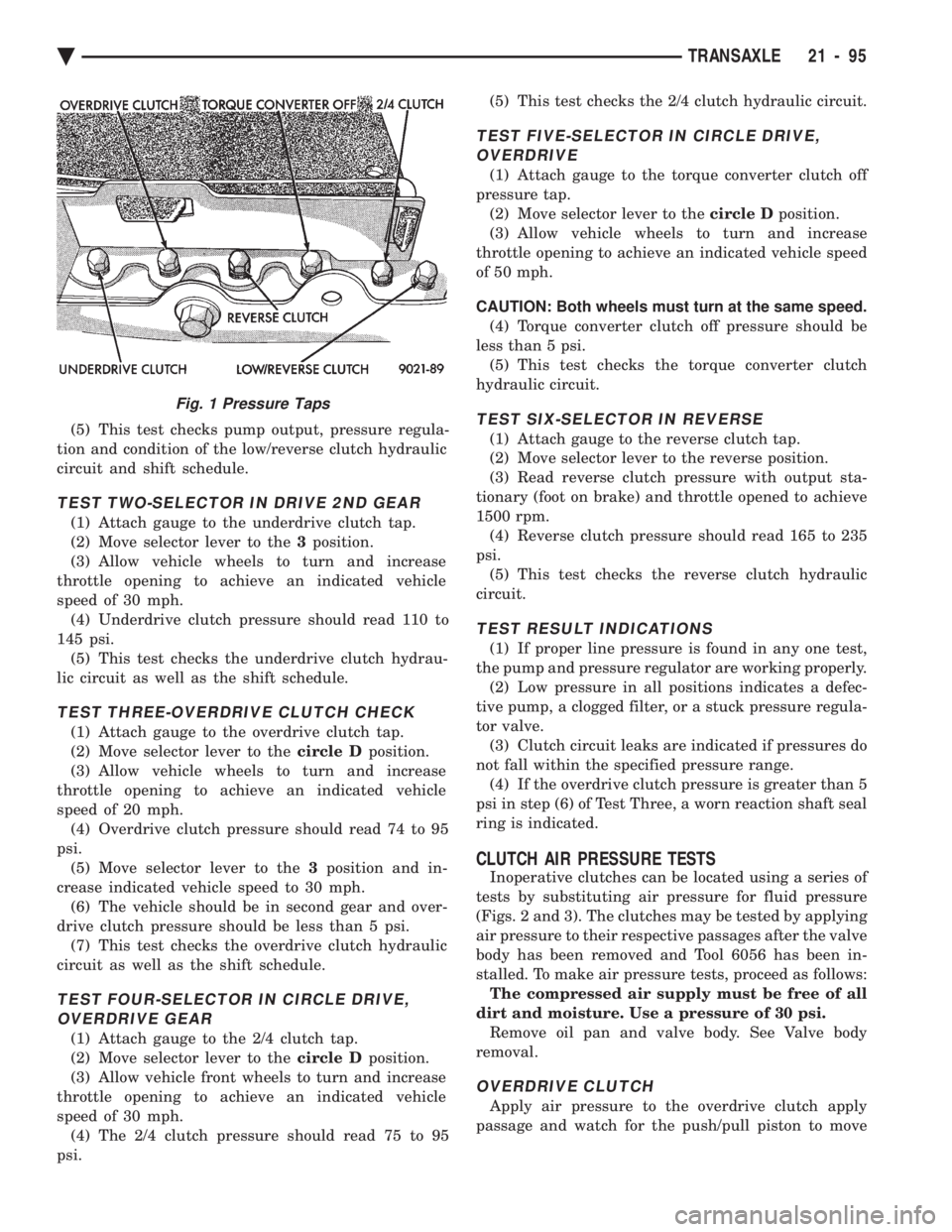

(5) This test checks pump output, pressure regula-

tion and condition of the low/reverse clutch hydraulic

circuit and shift schedule.

TEST TWO-SELECTOR IN DRIVE 2ND GEAR

(1) Attach gauge to the underdrive clutch tap.

(2) Move selector lever to the 3position.

(3) Allow vehicle wheels to turn and increase

throttle opening to achieve an indicated vehicle

speed of 30 mph. (4) Underdrive clutch pressure should read 110 to

145 psi. (5) This test checks the underdrive clutch hydrau-

lic circuit as well as the shift schedule.

TEST THREE-OVERDRIVE CLUTCH CHECK

(1) Attach gauge to the overdrive clutch tap.

(2) Move selector lever to the circle Dposition.

(3) Allow vehicle wheels to turn and increase

throttle opening to achieve an indicated vehicle

speed of 20 mph. (4) Overdrive clutch pressure should read 74 to 95

psi. (5) Move selector lever to the 3position and in-

crease indicated vehicle speed to 30 mph. (6) The vehicle should be in second gear and over-

drive clutch pressure should be less than 5 psi. (7) This test checks the overdrive clutch hydraulic

circuit as well as the shift schedule.

TEST FOUR-SELECTOR IN CIRCLE DRIVE, OVERDRIVE GEAR

(1) Attach gauge to the 2/4 clutch tap.

(2) Move selector lever to the circle Dposition.

(3) Allow vehicle front wheels to turn and increase

throttle opening to achieve an indicated vehicle

speed of 30 mph. (4) The 2/4 clutch pressure should read 75 to 95

psi. (5) This test checks the 2/4 clutch hydraulic circuit.

TEST FIVE-SELECTOR IN CIRCLE DRIVE,

OVERDRIVE

(1) Attach gauge to the torque converter clutch off

pressure tap. (2) Move selector lever to the circle Dposition.

(3) Allow vehicle wheels to turn and increase

throttle opening to achieve an indicated vehicle speed

of 50 mph.

CAUTION: Both wheels must turn at the same speed. (4) Torque converter clutch off pressure should be

less than 5 psi. (5) This test checks the torque converter clutch

hydraulic circuit.

TEST SIX-SELECTOR IN REVERSE

(1) Attach gauge to the reverse clutch tap.

(2) Move selector lever to the reverse position.

(3) Read reverse clutch pressure with output sta-

tionary (foot on brake) and throttle opened to achieve

1500 rpm. (4) Reverse clutch pressure should read 165 to 235

psi. (5) This test checks the reverse clutch hydraulic

circuit.

TEST RESULT INDICATIONS

(1) If proper line pressure is found in any one test,

the pump and pressure regulator are working properly. (2) Low pressure in all positions indicates a defec-

tive pump, a clogged filter, or a stuck pressure regula-

tor valve. (3) Clutch circuit leaks are indicated if pressures do

not fall within the specified pressure range. (4) If the overdrive clutch pressure is greater than 5

psi in step (6) of Test Three, a worn reaction shaft seal

ring is indicated.

CLUTCH AIR PRESSURE TESTS

Inoperative clutches can be located using a series of

tests by substituting air pressure for fluid pressure

(Figs. 2 and 3). The clutches may be tested by applying

air pressure to their respective passages after the valve

body has been removed and Tool 6056 has been in-

stalled. To make air pressure tests, proceed as follows: The compressed air supply must be free of all

dirt and moisture. Use a pressure of 30 psi. Remove oil pan and valve body. See Valve body

removal.

OVERDRIVE CLUTCH

Apply air pressure to the overdrive clutch apply

passage and watch for the push/pull piston to move

Fig. 1 Pressure Taps

Ä TRANSAXLE 21 - 95

Page 2058 of 2438

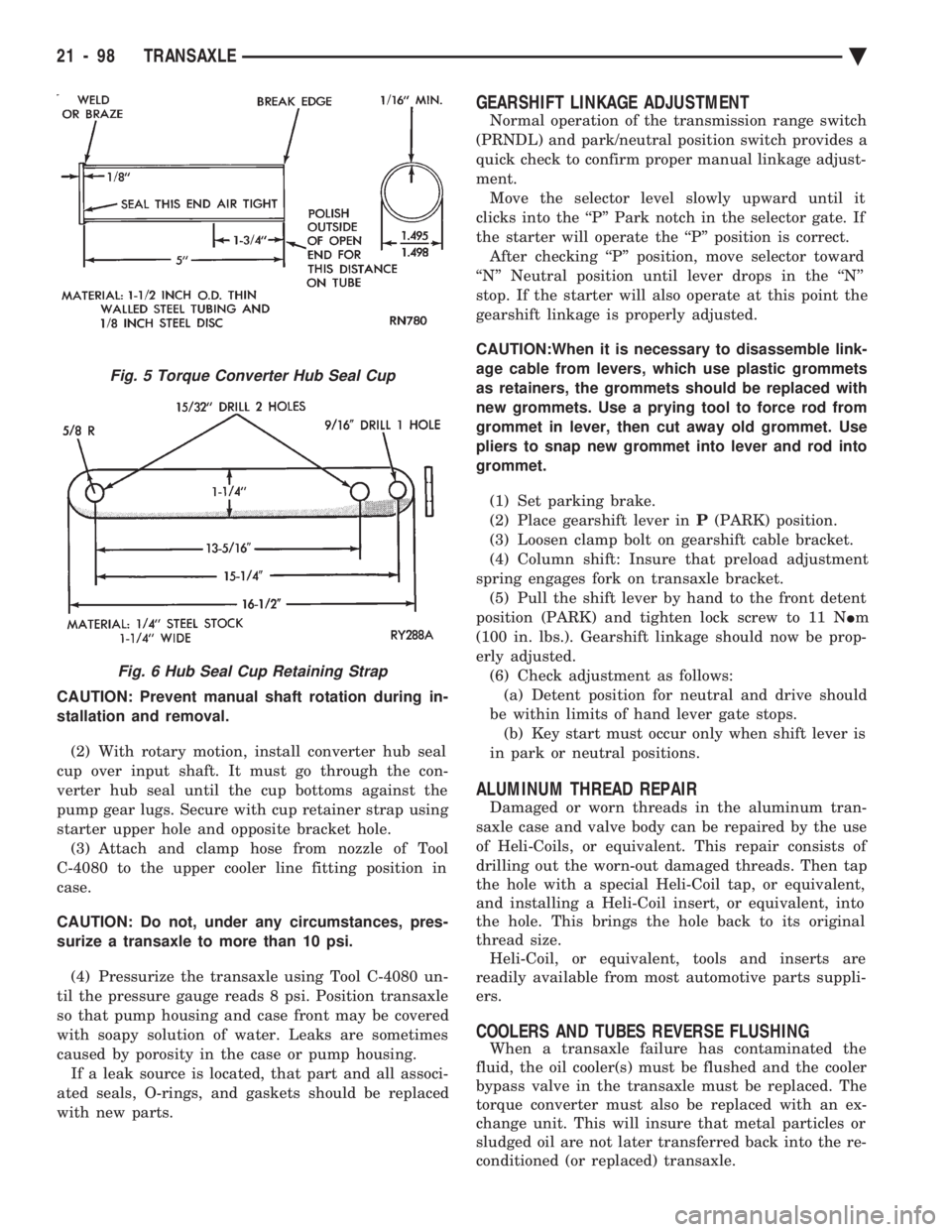

CAUTION: Prevent manual shaft rotation during in-

stallation and removal. (2) With rotary motion, install converter hub seal

cup over input shaft. It must go through the con-

verter hub seal until the cup bottoms against the

pump gear lugs. Secure with cup retainer strap using

starter upper hole and opposite bracket hole. (3) Attach and clamp hose from nozzle of Tool

C-4080 to the upper cooler line fitting position in

case.

CAUTION: Do not, under any circumstances, pres-

surize a transaxle to more than 10 psi.

(4) Pressurize the transaxle using Tool C-4080 un-

til the pressure gauge reads 8 psi. Position transaxle

so that pump housing and case front may be covered

with soapy solution of water. Leaks are sometimes

caused by porosity in the case or pump housing. If a leak source is located, that part and all associ-

ated seals, O-rings, and gaskets should be replaced

with new parts.

GEARSHIFT LINKAGE ADJUSTMENT

Normal operation of the transmission range switch

(PRNDL) and park/neutral position switch provides a

quick check to confirm proper manual linkage adjust-

ment. Move the selector level slowly upward until it

clicks into the ``P'' Park notch in the selector gate. If

the starter will operate the ``P'' position is correct. After checking ``P'' position, move selector toward

``N'' Neutral position until lever drops in the ``N''

stop. If the starter will also operate at this point the

gearshift linkage is properly adjusted.

CAUTION:When it is necessary to disassemble link-

age cable from levers, which use plastic grommets

as retainers, the grommets should be replaced with

new grommets. Use a prying tool to force rod from

grommet in lever, then cut away old grommet. Use

pliers to snap new grommet into lever and rod into

grommet.

(1) Set parking brake.

(2) Place gearshift lever in P(PARK) position.

(3) Loosen clamp bolt on gearshift cable bracket.

(4) Column shift: Insure that preload adjustment

spring engages fork on transaxle bracket. (5) Pull the shift lever by hand to the front detent

position (PARK) and tighten lock screw to 11 N Im

(100 in. lbs.). Gearshift linkage should now be prop-

erly adjusted. (6) Check adjustment as follows:(a) Detent position for neutral and drive should

be within limits of hand lever gate stops. (b) Key start must occur only when shift lever is

in park or neutral positions.

ALUMINUM THREAD REPAIR

Damaged or worn threads in the aluminum tran-

saxle case and valve body can be repaired by the use

of Heli-Coils, or equivalent. This repair consists of

drilling out the worn-out damaged threads. Then tap

the hole with a special Heli-Coil tap, or equivalent,

and installing a Heli-Coil insert, or equivalent, into

the hole. This brings the hole back to its original

thread size. Heli-Coil, or equivalent, tools and inserts are

readily available from most automotive parts suppli-

ers.

COOLERS AND TUBES REVERSE FLUSHING

When a transaxle failure has contaminated the

fluid, the oil cooler(s) must be flushed and the cooler

bypass valve in the transaxle must be replaced. The

torque converter must also be replaced with an ex-

change unit. This will insure that metal particles or

sludged oil are not later transferred back into the re-

conditioned (or replaced) transaxle.

Fig. 5 Torque Converter Hub Seal Cup

Fig. 6 Hub Seal Cup Retaining Strap

21 - 98 TRANSAXLE Ä

Page 2149 of 2438

WHEELSÐTIRES

CONTENTS

page page

SPECIFICATIONS ........................ 8

TIRE SERVICE PROCEDURES .............. 1 WHEELS SERVICE PROCEDURES

........... 6

TIRE SERVICE PROCEDURES INDEX

page page

Cleaning of Tires .......................... 1

General Information ........................ 1

Pressure Gauges ......................... 2

Radial-Ply Tires ........................... 1

Repairing Leaks .......................... 3

Rotation ................................ 3 Spare TireÐCompact

...................... 1

Tire Inflation Pressures ..................... 2

Tire Noise or Vibration ..................... 3

Tire Wear Patterns ........................ 3

Tread Wear Indicators ...................... 3

GENERAL INFORMATION

Throughout this group, references may be made to a

particular vehicle by letter or number designation. A

chart showing the breakdown of these designations is

included in the Introduction Section. Tires are designed for the vehicle and provide the

best overall performance for normal operation. The

ride and handling characteristics match the vehicle's

requirements. With proper care they will give excellent

reliability traction, skid resistance and tread life. They

have load carrying capacity, when properly inflated, to

operate at loads up to the specified Maximum Vehicle

Capacity. Driving habits have more effect on tire life than any

other factor. Careful drivers will obtain, in most cases,

much greater mileage than severe or careless drivers. A

few of the driving habits which will shorten the life of

any tire are:

² Rapid acceleration and deceleration

² Severe application of brakes

² High-speed driving

² Taking turns at excessive speeds

² Striking curbs and other obstacles

Radial ply tires can be more susceptible to irregular

tread wear. It is very important to follow the tire

rotation interval shown in the section on Tire

Rotation to achieve a greater tread life potential.

RADIAL-PLY TIRES

Radial-ply tires improve handling, tread life, and

ride quality and decrease rolling resistance. Radial-ply tires must always be used in sets of four

and under no circumstances should they be used on

the front only. However, they may be mixed with temporary spare tires when necessary,

but reduced speeds are recommended. Radial-ply tires have the same load carrying capac-

ity as other types of tires of the same size. They also

use the same recommended inflation pressures.

SPARE TIREÐCOMPACT

The compact spare tire is designed for emergency

use only. The original tire should be repaired and re-

installed at the first opportunity. Refer to Owner's

Manual for complete details.

TIRE CHAINS

Tire snow chains may be used on certainmodels.

Refer to Owner's Manual for more information.

CLEANING OF TIRES

Remove protective coating on tires before delivery

of vehicle, otherwise it could cause deterioration of

tires. Remove protective coating by applying warm wa-

ter, letting it soak one minute, and then scrubbing

the coating away with a soft bristle brush. Steam cleaning may also be used for cleaning.

DO NOT use gasoline or wire brush for cleaning.

DO NOT use mineral oil or an oil-based solvent.

Ä WHEELSÐTIRES 22 - 1

Page 2155 of 2438

It is recommended that a two plane dynamic bal-

ancing machine be used when a wheel and tire as-

sembly require balancing. Static balancing should be

used only when a two plane dynamic balancing is not

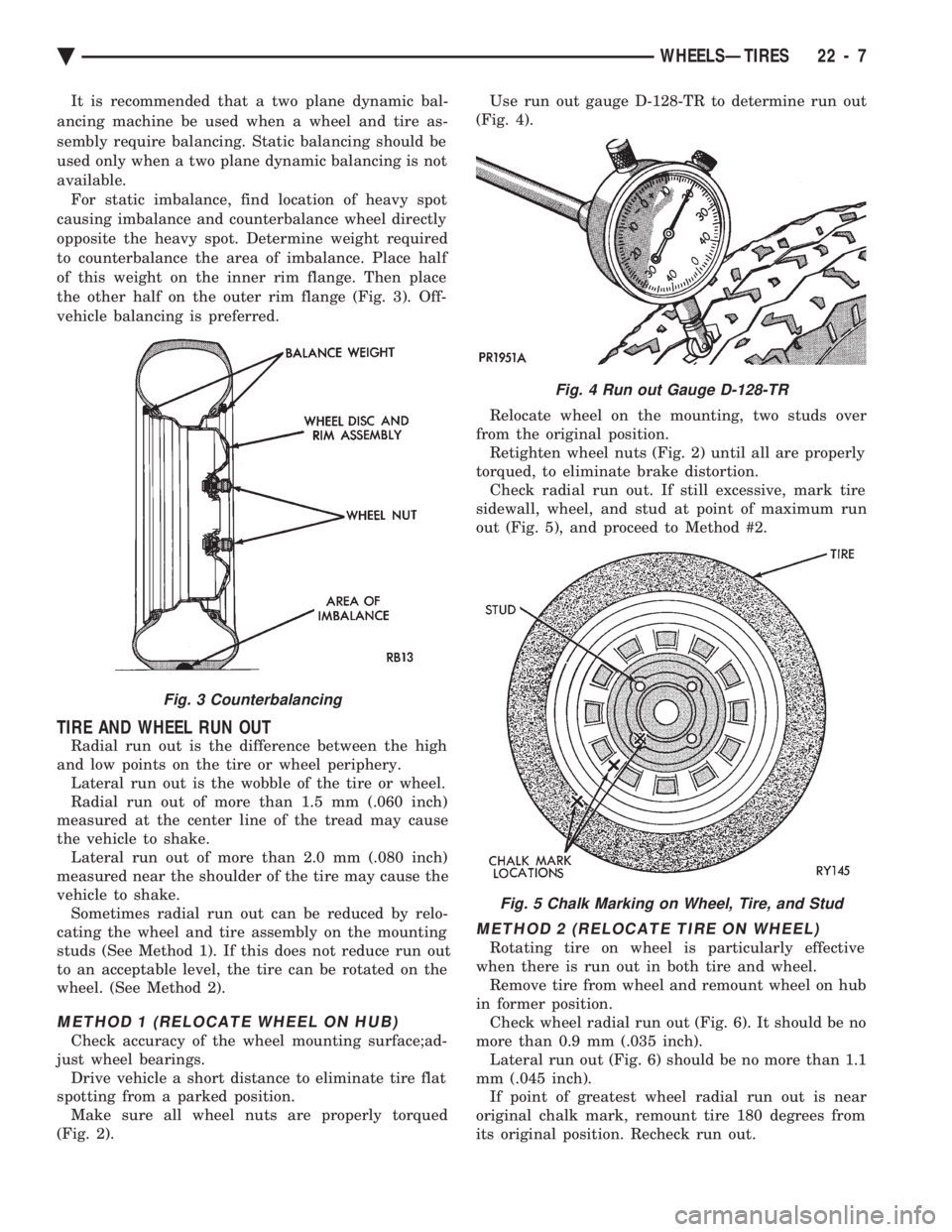

available. For static imbalance, find location of heavy spot

causing imbalance and counterbalance wheel directly

opposite the heavy spot. Determine weight required

to counterbalance the area of imbalance. Place half

of this weight on the inner rim flange. Then place

the other half on the outer rim flange (Fig. 3). Off-

vehicle balancing is preferred.

TIRE AND WHEEL RUN OUT

Radial run out is the difference between the high

and low points on the tire or wheel periphery. Lateral run out is the wobble of the tire or wheel.

Radial run out of more than 1.5 mm (.060 inch)

measured at the center line of the tread may cause

the vehicle to shake. Lateral run out of more than 2.0 mm (.080 inch)

measured near the shoulder of the tire may cause the

vehicle to shake. Sometimes radial run out can be reduced by relo-

cating the wheel and tire assembly on the mounting

studs (See Method 1). If this does not reduce run out

to an acceptable level, the tire can be rotated on the

wheel. (See Method 2).

METHOD 1 (RELOCATE WHEEL ON HUB)

Check accuracy of the wheel mounting surface;ad-

just wheel bearings. Drive vehicle a short distance to eliminate tire flat

spotting from a parked position. Make sure all wheel nuts are properly torqued

(Fig. 2). Use run out gauge D-128-TR to determine run out

(Fig. 4).

Relocate wheel on the mounting, two studs over

from the original position. Retighten wheel nuts (Fig. 2) until all are properly

torqued, to eliminate brake distortion. Check radial run out. If still excessive, mark tire

sidewall, wheel, and stud at point of maximum run

out (Fig. 5), and proceed to Method #2.

METHOD 2 (RELOCATE TIRE ON WHEEL)

Rotating tire on wheel is particularly effective

when there is run out in both tire and wheel. Remove tire from wheel and remount wheel on hub

in former position. Check wheel radial run out (Fig. 6). It should be no

more than 0.9 mm (.035 inch). Lateral run out (Fig. 6) should be no more than 1.1

mm (.045 inch). If point of greatest wheel radial run out is near

original chalk mark, remount tire 180 degrees from

its original position. Recheck run out.

Fig. 3 Counterbalancing

Fig. 4 Run out Gauge D-128-TR

Fig. 5 Chalk Marking on Wheel, Tire, and Stud

Ä WHEELSÐTIRES 22 - 7

Page 2157 of 2438

BODY

CONTENTS

page page

AA-VEHICLE BODY COMPONENT SERVICE . . . 11

AC-VEHICLE BODY COMPONENT SERVICE . . . 37

AG-VEHICLE BODY COMPONENT SERVICE . . . 52

AJ-VEHICLE BODY COMPONENT SERVICE . . . 71

AJ/27-VEHICLE CONVERTIBLE BODYCOMPONENT SERVICE ................. 86

AP-VEHICLE BODY COMPONENT SERVICE . . . 97

AP/17-VEHICLE CONVERTIBLE BODY COMPONENT SERVICE ................. 117 AY-VEHICLE BODY COMPONENT SERVICE . . 133

BODY DIAGNOSTIC PROCEDURES .......... 2

GENERAL SERVICE INFORMATION .......... 1

PAINT ................................. 4

POWER SUNROOF ....................... 6

WINDSHIELD ........................... 9

GENERAL SERVICE INFORMATION

VEHICLE IDENTIFICATION

Throughout this group, references to the Chrysler

Corporation vehicle family identification code is used

when describing a procedure that is unique to that

vehicle. Refer to Introduction Group of this manual for

detailed information on vehicle identification. If a

procedure is common to all vehicles covered in this

manual, no reference will be made to a vehicle family

code.

SAFETY PRECAUTIONS AND WARNINGS

WARNING: WHEN SERVICING A VEHICLE EQUIPPED

WITH AIRBAG RESTRAINT SYSTEM, REVIEW ALL

PRECAUTIONS IN GROUP 8M, RESTRAINT SYS-

TEMS. PERSONAL INJURY CAN RESULT. EYE PROTECTION SHOULD BE USED WHEN SER-

VICING GLASS COMPONENTS. PERSONAL INJURY

CAN RESULT. USE A BREATHING FILTER WHEN SPRAYING

PAINT OR SOLVENTS IN A CONFINED AREA. PER-

SONAL INJURY CAN RESULT. AVOID PROLONGED SKIN CONTACT WITH PETRO-

LEUM OR ALCOHOL BASED CLEANING SOLVENTS.

PERSONAL INJURY CAN RESULT. DO NOT VENTURE UNDER A HOISTED VEHICLE

THAT IS NOT PROPERLY SUPPORTED ON SAFETY

STANDS. PERSONAL INJURY CAN RESULT.

CAUTION: When holes must be drilled or punched in

a inner body panel, verify depth of space to the outer

body panel, electrical wiring, or other components.

Damage to vehicle can result. Do not use abrasive chemicals or compounds on

painted surfaces. Damage to finish can result. Do not use harsh alkaline based cleaning solvents

on painted or upholstered surfaces. Damage to finish

or color can result. Do not hammer or pound on plastic trim panel

attaching fasteners when servicing interior trim. Plas-

tic panel can break.

Chrysler Corporation uses many different types of

push-in fasteners to secure the interior and exterior

trim to the body . Most of these fasteners can be reused

to assemble the trim during various repair procedures.

At times a push-in fastener cannot be removed without

damaging the fastener or the component it is holding.

If it is not possible to remove a fastener without

damaging a component or body, cut or brake the

fastener and use a new one when installing the com-

ponent. Never pry or pound on a plastic or press-board

trim component. Using a suitable fork-type prying

device, pry the fastener from the retaining hole behind

the component being removed. When installing, verify

that fastener is aligned with the retaining hole, by

hand, push directly on or over the fastener until it

seats. Apply a low force pull to the panel to verify that

it is secure. When it is necessary to remove components to service

another, it should not be necessary to apply excessive

force or bend a component to remove it. Before damag-

ing a component to be reused, verify there is no hidden

fasteners or captured edges holding the component in.

Often a fastener is hidden by carpeting nap or trim

plugs.

Ä BODY 23 - 1

Page 2169 of 2438

(2) Remove push-in fasteners holding hood latch

cover to radiator closure panel and separate cover

from vehicle. (3) Disconnect hood release cable casing and cable

end from hood latch assembly. Refer to Hood Latch

Removal procedure in this section. (4) Remove hood latch release cable handle attach-

ing bolts from under left lower edge of instrument

panel. (5) Disengage release cable rubber grommet from

engine compartment dash panel behind instrument

panel. (6) Rout cable assembly through engine compart-

ment around battery, under fender lip, under relay

bank, and under wiring harnesses, toward dash

panel. Push cable through access hole in dash panel

under the brake master cylinder, into passenger com-

partment.

HOOD LATCH RELEASE CABLE INSTALLATION

Reverse the preceding operation.

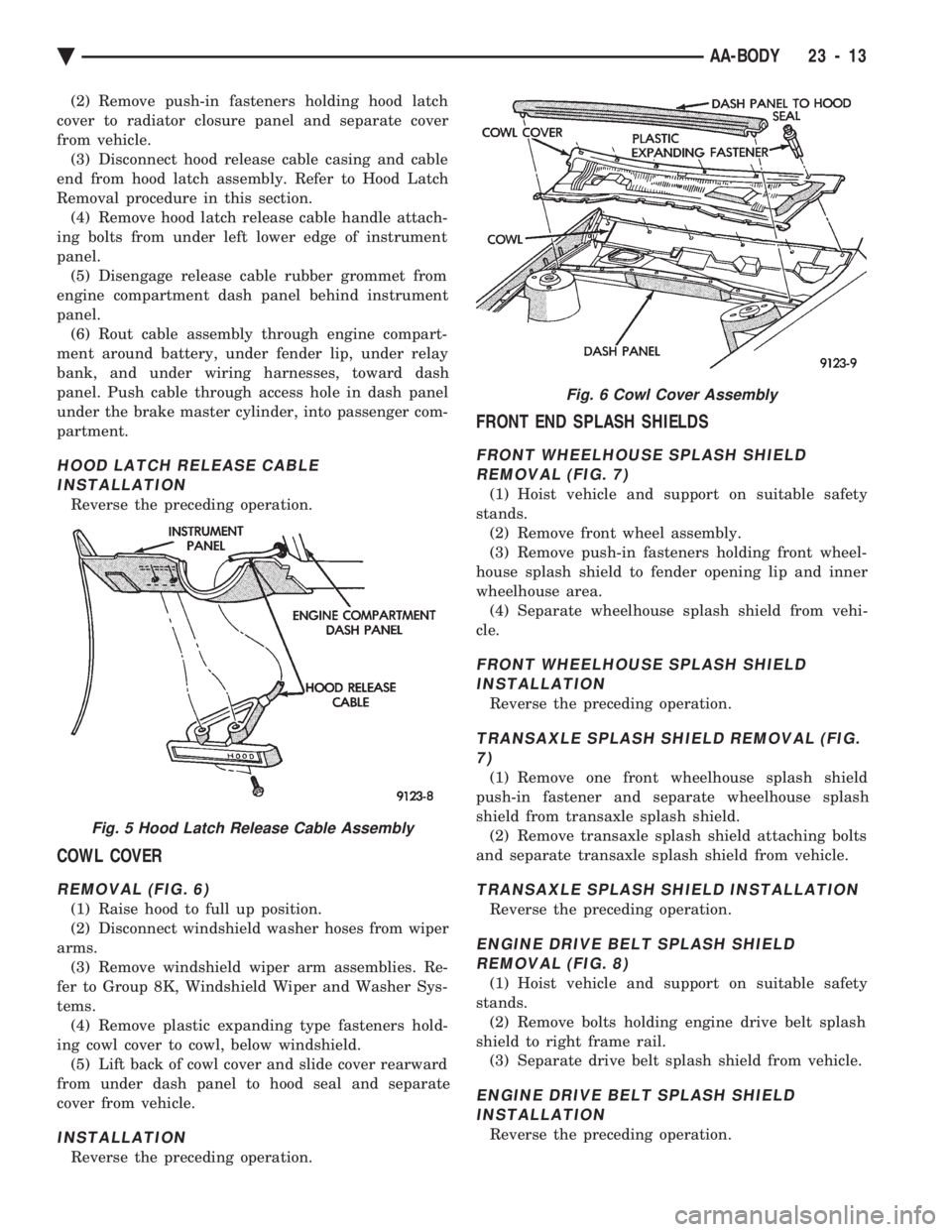

COWL COVER

REMOVAL (FIG. 6)

(1) Raise hood to full up position.

(2) Disconnect windshield washer hoses from wiper

arms. (3) Remove windshield wiper arm assemblies. Re-

fer to Group 8K, Windshield Wiper and Washer Sys-

tems. (4) Remove plastic expanding type fasteners hold-

ing cowl cover to cowl, below windshield. (5) Lift back of cowl cover and slide cover rearward

from under dash panel to hood seal and separate

cover from vehicle.

INSTALLATION

Reverse the preceding operation.

FRONT END SPLASH SHIELDS

FRONT WHEELHOUSE SPLASH SHIELD REMOVAL (FIG. 7)

(1) Hoist vehicle and support on suitable safety

stands. (2) Remove front wheel assembly.

(3) Remove push-in fasteners holding front wheel-

house splash shield to fender opening lip and inner

wheelhouse area. (4) Separate wheelhouse splash shield from vehi-

cle.

FRONT WHEELHOUSE SPLASH SHIELD INSTALLATION

Reverse the preceding operation.

TRANSAXLE SPLASH SHIELD REMOVAL (FIG.7)

(1) Remove one front wheelhouse splash shield

push-in fastener and separate wheelhouse splash

shield from transaxle splash shield. (2) Remove transaxle splash shield attaching bolts

and separate transaxle splash shield from vehicle.

TRANSAXLE SPLASH SHIELD INSTALLATION

Reverse the preceding operation.

ENGINE DRIVE BELT SPLASH SHIELD REMOVAL (FIG. 8)

(1) Hoist vehicle and support on suitable safety

stands. (2) Remove bolts holding engine drive belt splash

shield to right frame rail. (3) Separate drive belt splash shield from vehicle.

ENGINE DRIVE BELT SPLASH SHIELDINSTALLATION

Reverse the preceding operation.

Fig. 5 Hood Latch Release Cable Assembly

Fig. 6 Cowl Cover Assembly

Ä AA-BODY 23 - 13

Page 2196 of 2438

panel. Push cable through access hole in dash panel

under the brake master cylinder, into passenger com-

partment.

INSTALLATION

Reverse the preceding operation.

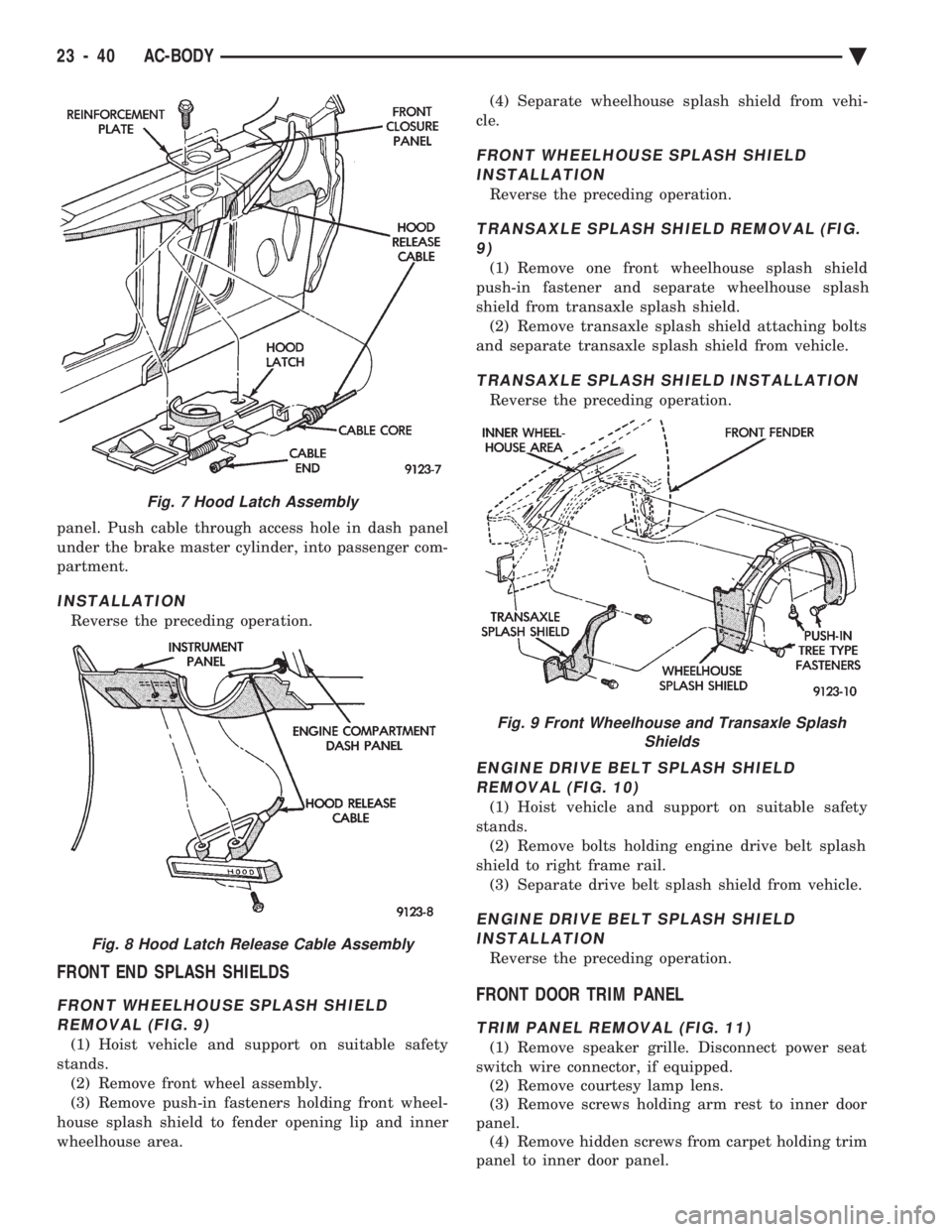

FRONT END SPLASH SHIELDS

FRONT WHEELHOUSE SPLASH SHIELD REMOVAL (FIG. 9)

(1) Hoist vehicle and support on suitable safety

stands. (2) Remove front wheel assembly.

(3) Remove push-in fasteners holding front wheel-

house splash shield to fender opening lip and inner

wheelhouse area. (4) Separate wheelhouse splash shield from vehi-

cle.

FRONT WHEELHOUSE SPLASH SHIELD INSTALLATION

Reverse the preceding operation.

TRANSAXLE SPLASH SHIELD REMOVAL (FIG.9)

(1) Remove one front wheelhouse splash shield

push-in fastener and separate wheelhouse splash

shield from transaxle splash shield. (2) Remove transaxle splash shield attaching bolts

and separate transaxle splash shield from vehicle.

TRANSAXLE SPLASH SHIELD INSTALLATION

Reverse the preceding operation.

ENGINE DRIVE BELT SPLASH SHIELD REMOVAL (FIG. 10)

(1) Hoist vehicle and support on suitable safety

stands. (2) Remove bolts holding engine drive belt splash

shield to right frame rail. (3) Separate drive belt splash shield from vehicle.

ENGINE DRIVE BELT SPLASH SHIELDINSTALLATION

Reverse the preceding operation.

FRONT DOOR TRIM PANEL

TRIM PANEL REMOVAL (FIG. 11)

(1) Remove speaker grille. Disconnect power seat

switch wire connector, if equipped. (2) Remove courtesy lamp lens.

(3) Remove screws holding arm rest to inner door

panel. (4) Remove hidden screws from carpet holding trim

panel to inner door panel.

Fig. 7 Hood Latch Assembly

Fig. 8 Hood Latch Release Cable Assembly

Fig. 9 Front Wheelhouse and Transaxle Splash Shields

23 - 40 AC-BODY Ä

Page 2210 of 2438

(4) Remove hood latch release cable handle attach-

ing bolts from under left lower edge of instrument

panel. (5) Disengage release cable rubber grommet from

engine compartment dash panel behind instrument

panel. (6) Rout cable assembly through engine compart-

ment around battery, under fender lip, under power

distribution center, and under wiring harnesses, to-

ward dash panel. Push cable through access hole in

dash panel under the brake master cylinder, into

passenger compartment.

HOOD LATCH RELEASE CABLE INSTALLATION

Reverse the preceding operation.

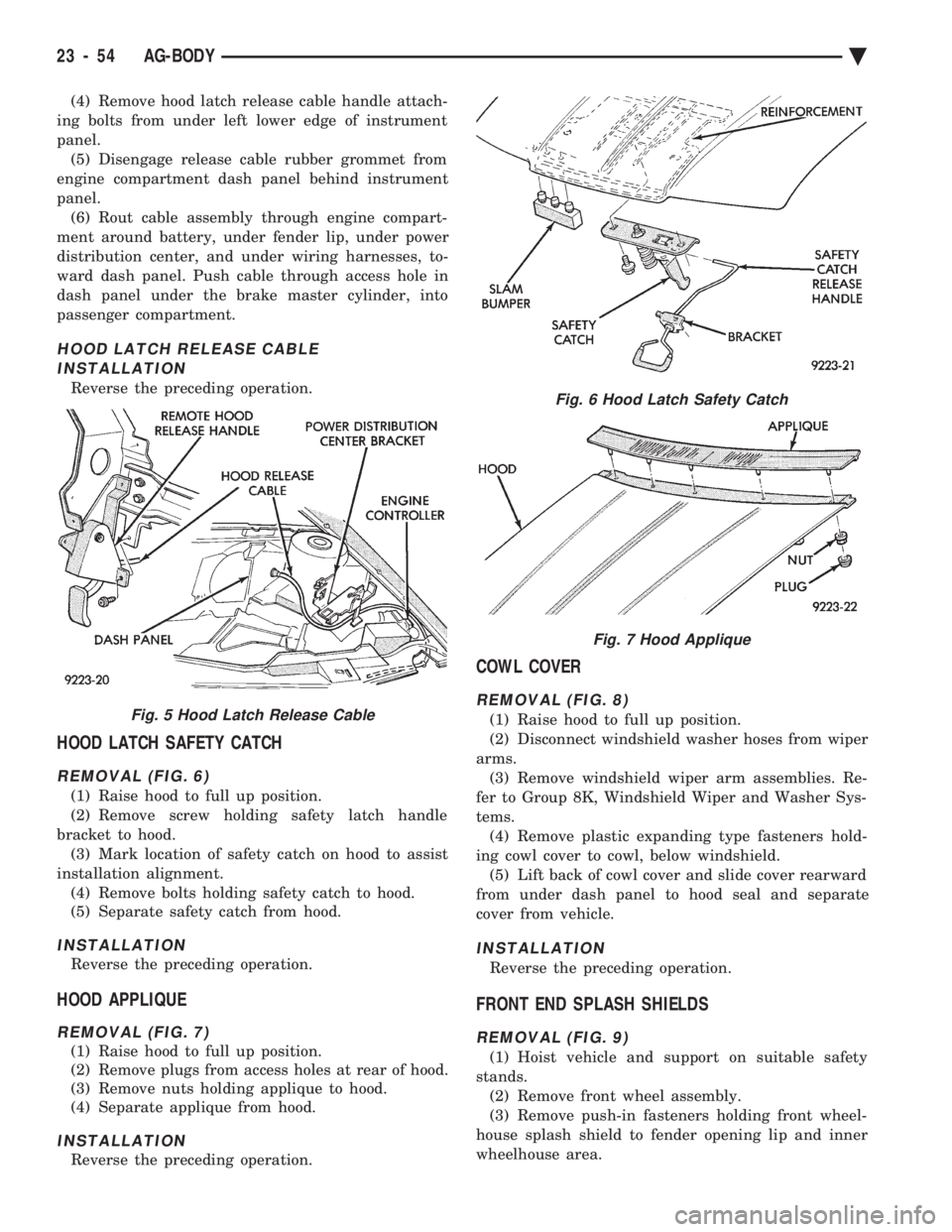

HOOD LATCH SAFETY CATCH

REMOVAL (FIG. 6)

(1) Raise hood to full up position.

(2) Remove screw holding safety latch handle

bracket to hood. (3) Mark location of safety catch on hood to assist

installation alignment. (4) Remove bolts holding safety catch to hood.

(5) Separate safety catch from hood.

INSTALLATION

Reverse the preceding operation.

HOOD APPLIQUE

REMOVAL (FIG. 7)

(1) Raise hood to full up position.

(2) Remove plugs from access holes at rear of hood.

(3) Remove nuts holding applique to hood.

(4) Separate applique from hood.

INSTALLATION

Reverse the preceding operation.

COWL COVER

REMOVAL (FIG. 8)

(1) Raise hood to full up position.

(2) Disconnect windshield washer hoses from wiper

arms. (3) Remove windshield wiper arm assemblies. Re-

fer to Group 8K, Windshield Wiper and Washer Sys-

tems. (4) Remove plastic expanding type fasteners hold-

ing cowl cover to cowl, below windshield. (5) Lift back of cowl cover and slide cover rearward

from under dash panel to hood seal and separate

cover from vehicle.

INSTALLATION

Reverse the preceding operation.

FRONT END SPLASH SHIELDS

REMOVAL (FIG. 9)

(1) Hoist vehicle and support on suitable safety

stands. (2) Remove front wheel assembly.

(3) Remove push-in fasteners holding front wheel-

house splash shield to fender opening lip and inner

wheelhouse area.

Fig. 5 Hood Latch Release Cable

Fig. 6 Hood Latch Safety Catch

Fig. 7 Hood Applique

23 - 54 AG-BODY Ä

Page 2220 of 2438

INSTALLATION

Reverse the preceding operation.

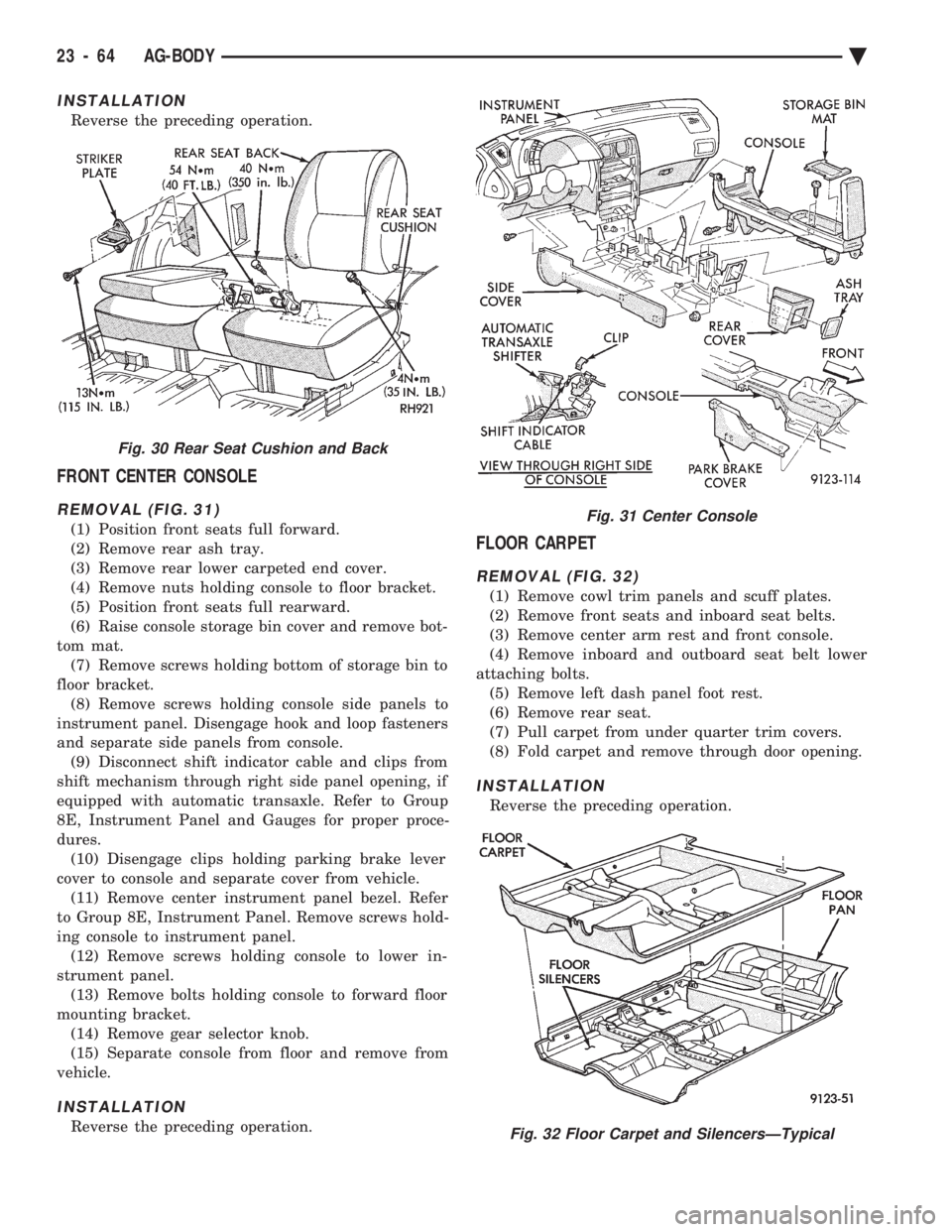

FRONT CENTER CONSOLE

REMOVAL (FIG. 31)

(1) Position front seats full forward.

(2) Remove rear ash tray.

(3) Remove rear lower carpeted end cover.

(4) Remove nuts holding console to floor bracket.

(5) Position front seats full rearward.

(6) Raise console storage bin cover and remove bot-

tom mat. (7) Remove screws holding bottom of storage bin to

floor bracket. (8) Remove screws holding console side panels to

instrument panel. Disengage hook and loop fasteners

and separate side panels from console. (9) Disconnect shift indicator cable and clips from

shift mechanism through right side panel opening, if

equipped with automatic transaxle. Refer to Group

8E, Instrument Panel and Gauges for proper proce-

dures. (10) Disengage clips holding parking brake lever

cover to console and separate cover from vehicle. (11) Remove center instrument panel bezel. Refer

to Group 8E, Instrument Panel. Remove screws hold-

ing console to instrument panel. (12) Remove screws holding console to lower in-

strument panel. (13) Remove bolts holding console to forward floor

mounting bracket. (14) Remove gear selector knob.

(15) Separate console from floor and remove from

vehicle.

INSTALLATION

Reverse the preceding operation.

FLOOR CARPET

REMOVAL (FIG. 32)

(1) Remove cowl trim panels and scuff plates.

(2) Remove front seats and inboard seat belts.

(3) Remove center arm rest and front console.

(4) Remove inboard and outboard seat belt lower

attaching bolts. (5) Remove left dash panel foot rest.

(6) Remove rear seat.

(7) Pull carpet from under quarter trim covers.

(8) Fold carpet and remove through door opening.

INSTALLATION

Reverse the preceding operation.

Fig. 30 Rear Seat Cushion and Back

Fig. 31 Center Console

Fig. 32 Floor Carpet and SilencersÐTypical

23 - 64 AG-BODY Ä